Abstract

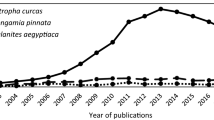

Biodiesel is produced by transesterification of edible and non-edible oils obtained from a wide range of plants. Biodiesel has developed rapidly as an eco-friendly, renewable, alternative source of energy compared to the limited resources of fossil fuels. There are wide ranging socio-economic implications of biodiesel for rural population in developing countries because biodiesel is an agriculture-based industrial product from plants. Diversion of edible oil for biodiesel, land use for biodiesel crops, and technology for biodiesel production are issues to be addressed. The use of edible and non-edible crops for biodiesel production and sustainability are discussed in this article. Biodiesel, amounting to about 300,000 barrels per day is mainly produced from edible oils and small quantities from non-edible oils from Jatropha curcas. Jatropha curcas is a multipurpose, drought-resistant, biofuel tree originating from Central and South America, though now growing pantropic. Jatropha plants produce up to 6.5 t seeds and yield about 2,000 L oil per hectare. Therefore agrotechnologies have to be developed towards mechanization and cost reduction to make an industrial product. A debate has already been started about use of edible oil for the production of biodiesel considering impact on land usage, prices of edible oil and benefits to farmers. The other potential non-edible oil crops are castor, neem and karanj (Pongamia). Therefore, a rational policy about biodiesel crops has to be evolved looking to the various needs of a particular country. Use of edible oil crops like soybeans, rapeseeds, sunflower and palm oil for non-edible purpose is a matter of debate from socio-economic aspect as population of many countries is malnourished. The Food and Agriculture Organization (FAO) of the United Nations emphasizes that the versatility of Jatropha may make it useful in poor, remote areas of the world.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The crops that are used for biofuel production are called energy crops and the utilization of energy crops as a source of renewable fuels is a concept with great relevance to current ecological and economic issues at both national and international scales. The relationship between biofuels, oil, and food markets is complex. Biofuel is liquid fuel obtained from plants through specific chemical processes. It can either be biodiesel or ethanol. In energy markets, biofuels are complementary with petroleum-based petrol and diesel. The increasing price of petroleum products and concerns about oil production are likely to have serious implications for the automobile industry in the forthcoming era. Strong global growth in demand has caused food crop based biofuels to become a significant consumer of food crops. Due to this shift in utilization of food crops for biofuels production has resulted in increasing prices of edible oils in affected markets (Collins 2008). Until now, biofuels have been produced by processing agricultural crops using available technologies.

These so called first-generation biofuels can be used to blend with conventional fuels in most vehicles and can be distributed through existing infrastructure. Advanced conversion technologies are needed for a second generation of biofuels. The second generation will use a wider range of biomass resources-agriculture, forestry and waste materials and promise to achieve higher reductions in greenhouse gas emissions and the costs of fuel production (Smeets et al. 2006; Hoogwijk et al. 2005). Agrotechnology for biodiesel crops is developing gradually to produce renewable and environmentally friendly fuel. Plant based fuels are best renewable sources, and its use can lead to a better balance of carbon dioxide and other green house gases formation responsible for global warming. The bio-energy system makes a significant contribution to the world’s growing energy needs. Brazil was the first country to start a major biofuel program in the 1970s. The basis was ethanol, produced from the country’s massive cane-sugar program. Biofuels are renewable, non-toxic, biodegradable and they contribute to energy security and reducing environment pollution. Biofuels can be produced from selected agricultural biomass of crops they offer opportunities to improve the income levels of small holder farmers. At a community level, farmers can cultivate energy crops that fetch an income while also meeting their food needs (Reddy et al. 2008). Further, due to high substitutability among major food crops and globally integrated markets, biofuels production also affects non-biofuels crops. Higher food crop prices in turn increase the feedstock cost for biofuels production. The renewable sources would only be able to compete with the fossil fuel resources if special plant crops containing energy producing hydrocarbon like material are breed and cultivated (Kalita 2010). The world-wide impetus for promoting biofuels has led to an increased focus on technology development.

Efforts are being made to develop biofuels from microbes like Escherichia coli and Saccharomyces cerevisiae (Kalscheuer et al. 2004, 2006). The first generation biofuels are obtained from edible crop plants like corn, wheat, maize, soybean, sunflower, safflower, sugarcane, rapeseed and palm oil (Pinto et al. 2005; Demirbas 2006). The second generation biofuels are obtained from non-edible crop plants like Miscanthus, Panicum virgatum or switchgrass, Hevea brasiliensis or rubber seeds, Calotropis gigantia, Euphorbia tirucalli, Jatropha curcas, Pongamia pinnata, and Calophyllum inophyllum. The third generation biofuels are likely to be obtained from microalgae like Botryococcus braunii, Chlorella sp., Dunaliella tertiolecta, Gracilaria, Pleurochrysis carterae, Sargassum (Christi 2007; Miao and Wu 2004; Qin 2005).

It is evident from available information that food crops comprise about 30–40% of the biofuel production. This has consequence in edible oil’s price (Mukherjee et al. 2011). The current enthusiasm for biofuels has resulted in private venture capital funding for startup biotechnology companies devoted to developing these species. This is coupled with government sponsored research to improve the crops and develop techniques for profitably processing the biomass into fuel (Waltz 2008). Agrotechnology for biodiesel crops are the subject of improvements in crop productivity, crop suitability and biofuels processing are all within the realm of proven biotechnological approaches. The production of ethanol from starch crops and biodiesel from oil crops is based on established technologies. In this review we consider biodiesel as alternative source of energy with the current traits that make crops more valuable for biofuel use in imminent era.

2 Biodiesel as Alternative Source of Energy

Nowadays, biodiesel fuel is an important energy resource because it is a secure, renewable, and environmentally safe alternative to fossil fuels (Sadano et al. 2010). In pursuit of better life, biofuels and bio-energy are being used as alternatives to depleting resources in particular to “petroleum products”. These renewable energy sources offer prospects of increasing energy supplies in a self reliant way in developing countries like India and also work as checkpoint for aggravating green house gases (Fairless 2007). There are numerous eco-benefits to replacing oil with biofuels like ethanol and biodiesel. For one, since such fuels are derived from agricultural crops, they are inherently renewable. Emissions from burning biodiesel in a conventional diesel engine have significantly lower levels of unburned hydrocarbons, carbon monoxide, carbon dioxide, particulate matter, sulfur oxides, odor, and noxious smoke compared to emissions from petrodiesel (Razon 2009). Carbon dioxide emissions from combustion of oxidized neat biodiesel produced 15 and 16% lower exhaust carbon monoxide and hydrocarbons, respectively when compared to petrodiesel (Abdul and Gerpen 2001), but there is a more significant carbon dioxide benefit with biodiesel made from plant oils, i.e., growing biodiesel crops (Singh and Singh 2010). During the photosynthesis process as the plants are growing and developing, carbon dioxide is drawn from the environment into the plant tissues; the plants are really carbon dioxide scrubbers. Biodiesel processed from plant oils is carbon dioxide neutral. In addition, the plants release beneficial oxygen into the environment. Accidental spills of biodiesel are far less of a problem compared to petrodiesel. Pure biodiesel is fully biodegradable; in fact, about 98% of biodiesel degrades in about 3 weeks (Leung et al. 2006). The biodegradable property of biodiesel makes it an especially attractive fuel choice for environmentally sensitive areas such as national parks, forests, and marinas (Singh and Singh 2010).

Biodiesel is defined as monoalkyl esters of long-chain fatty acid derived from triglycerides or renewable lipid resources e.g. rapeseed oil, soybean oil, palm oil with short-chain alcohols by transesterification or esterification (Fig. 1.) (Xu and Hanna 2009). Glycerol, as the principal by-product from biodiesel production units, is a low-cost renewable resource.

Several methods for the production of biodiesel have been developed using chemical and biological catalysts, such as alkali and acidic compounds, and lipase (Kim et al. 2007). Recently, biodiesel production with enzymatic transesterification gained attention. Compared with chemical approaches, it conserves energy and easy to recover the by-product glycerol, as no acidic or alkali catalysts have to be removed from the product, and free fatty acid and water would not interfere with the reaction (Meher et al. 2006). Cost effective and eco-friendly development is required for biodiesel production. Involvement of private sector in this venture has accelerated the process of technology development. Biodiesel is gaining importance as an alternative source of energy but technology for biodiesel production from plants as well as combustion engine technology has to be refined in near future.

3 World Demand and Production of Biodiesel

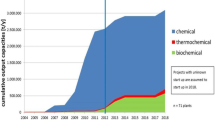

World-wide production of biofuels is rapidly growing. Apart from the European Union (EU) and the USA other countries like Canada, Brazil, Australia, India and China also implemented targets for biofuels volumes and market shares. The demand for biofuels in the USA, Europe, and other developed nations is partly driven by the need to replace fossil fuels and lessen dependence on high-priced imported oil. Biodiesel production in different countries is presented in Fig. 2. World biodiesel production has grown considerably during the last decade and likely to reach 350,000 barrel per day in 2011–12 (Fig. 3). Recently, in the EU more than 20% of edible oilseed production was processed into biodiesel. Biofuel demand depends on economic profitability and on government subsidies and mandates for biofuel use. In India, the energy demand is increasing at a rate of 6.5% per annum. The crude oil demand of the country is met by import of about 80%. Thus the energy security has become a key issue for the nation as a whole (Jain and Sharma 2010). Although an increased demand for biofuels could help farmers by raising the price of their crops; the higher prices could also hurt those same farmers, most of whom spend most of their income on food. The federal Energy Independence and Security Act of 2007 as amended in March of 2008 mandates 34.6 million tons (MT) of vehicle ethanol fuel in 2008, 49.96 MT in 2012, and 56.78 MT in 2015 (Tweeten and Thompson 2008). According to estimates published by the European Commission (2006), which are based on the same partial equilibrium model, oilseed area would be 0.75 million hectares (Mha) higher than without biofuel policies and reach 8 Mha as compared to 7.25 Mha without the expected increase in biodiesel demand. Sunflower seed area would expand by 0.2 to 1.7 Mha as compared to unchanged biofuel policies. Rapeseed area would increase by 0.55 Mha. Also cereal area could expand by 2.5–52.5 Mha as compared to the baseline.

The economic literature on the impacts of biofuels on agricultural markets is scarce, as the biofuel boom appeared only recently. The expansion of biofuel production and consumption is not limited to the United States. Increased crop-based production took place in Brazil over the last several decades, as Brazil used sugarcane as a feedstock to produce ethanol, and then use ethanol on a large scale to fuel vehicles. Canada has mandated that biofuels make up 5% of all transportation vehicle fuel by 2010. Meanwhile, Argentina has a system of differential export taxes resulting in a lower tax rates for biodiesel exports than the tax rates on feedstock exports such as corn or soybean oil. With ever increasing world demand for fuels, alternative sources have to be developed which are cost effective and eco-friendly. Still biodiesel is mainly produced from edible oils (cultivated) and small quantities from non-edible oils like Jatropha. Many issues need to be resolved before making a commercially viable fuel, such as area under cultivation for edible versus non- edible crops, production costs and issue related to subsidy by governments. If biodiesel has to blend in fossil diesel all over the world, still there would be a big gap between demand and supply.

4 Role of Food and Agriculture Organization and Governments

The encouragements to biodiesel fuel programs by the governments in many countries have expedited the efforts for the development of different production technologies, the evaluation and performance testing of different biodiesel fuels in various types of automotive vehicles, and the assessment of their impact on the environment, economy and society are current themes of interest in biodiesel production (Tyagi et al. 2010). The OECD-FAO Agricultural Outlook 2007–2016 projection states that structural changes, such as increased feedstock demand for biofuel production, and the recent reduction of surpluses due to past policy reforms, may keep prices above historic equilibrium levels during the next 10 years (OECD-FAO 2007).

In the BRIC nations (Brazil, Russia, India and China), key government initiatives are spawning hundreds of new opportunities for feedstock developments, biodiesel production and export. At present, EU accounts for 66% of the world’s total biodiesel production, followed by the United States at 1.5 MT. The world biodiesel production and capacity have increased from 7.1 MT in 2006 to 9.0 MT in 2007, and 12.2 MT in 2006 to 23.1 MT in 2007, respectively. Currently, more than 200 nations will become biodiesel producing nations and suppliers (Xu et al. 2009). The Indian draft policy, Government of India (2008) appeared to have backed off the country’s exclusive promotion of Jatropha and instead called for the use of any non-edible oilseeds grown on marginal, degraded or wastelands. The draft policy also recommended establishing 20% blending targets by 2017 for both ethanol and biodiesel. Government policies are also influencing biofuel industries in Canada, Argentina, China, countries of the Former Soviet Union, Malaysia, and Indonesia. The Government of India (GoI) has given a top priority for promotion and use of non-edible oils such as Jatropha curcas, Pongamia pinnata, etc., for production of biodiesel. Policies regarding use of crop plants for biofuel production and land use for such crops are being refined in the developing countries, which are main producers of edible and non-edible crops (FAOSTAT 2009). However, biofuels have to compete with petroleum products when subsidies are withdrawn. Governments are supporting research and developments efforts to make biodiesel a success, including subsidy on its production to reduce pollution and dependency on fossil diesel. Private industrial participation is necessary to further develop the various aspects of technology.

5 Agrotechnology Traits for Biodiesel Crops

Agrotechnological traits play an important role in the development of new biofuel crops and improve the efficiency and cost effectiveness of these crops. Agrotechnology is being used to improve the crops making them more productive or suitable to biofuels use. Jatropha curcas oil contains about 14% free fatty acid which is beyond the limit of 1% level which can be efficiently converted into biodiesel by transesterification using an alkaline catalyst (Tiwari et al. 2007). The fatty acids reported in a study of J. curcas oil are palmitic acid (11.3%), stearic acid (17%), arachidic acid (4.7%), oleic acid (12.8%), and linoleic acid (47.3%) (Adebowale and Adedire 2006). A potential major constraint in the widespread acceptance of Jatropha as a source of biodiesel is the presence of phorbol esters, which, when consumed by man and animal, are toxic and are also co-carcinogens (Makkar et al. 2009). So far sporadic efforts are made to improve J. curcas for biodiesel. Followings are the important traits required for the pertinent biodiesel crop research.

-

Improvement in the crop productivity.

-

Improvement in the efficiency of photosynthesis.

-

Development of hybridization methods for increasing the yield.

-

Improvement in abiotic stress tolerance.

-

Improvement in the efficiency to utilize nutrients.

-

Enhanced biomass production.

-

Preparing the crop for biofuel processing.

-

Economic exploitation of cake and waste

Jatropha seeds are manually collected, mainly from plants growing in wild. Therefore, above mentioned agrotechnologies have to be developed towards mechanization and cost reduction to make it an industrial product.

6 Crops for Biodiesel

Biodiesel can be produced from edible oilseed crops such as soybean (Glycine max L.), rapeseed (Brassica spp.) or sunflower (Helianthus annuus L.). Other vegetable oils that have been used in biodiesel production include corn, cotton seed and peanuts. However, given the large gap between the demand and supply of edible oils, many countries cannot afford to use vegetable oils for biodiesel production. In addition, the use of vegetable oil as fuel is less polluting than petroleum fuels (Jain and Sharma 2010). Fortunately, bio-diesel can also be produced from non-edible oil seeds from shrubs such as Ratanjot (J. curcas), karanj (Pongamia pinnata) and neem (Azadirachta indica) (Reddy et al. 2008; Vasudevan and Briggs 2008). The production of biodiesel from different crops and testing its efficacy was carried out using internal combustion engine. The results are presented in Table 1.

The Jatropha seed is considered to be toxic to animals, one of the reasons it is used as a natural hedge in developing nations. Recognition, that Jatropha oil can yield an exceptional biodiesel has led to a surge of interest in Jatropha across the globe, more so in view of the potential for avoiding the dilemma of “food vs. fuel” (Reddy and Pamidimarri 2010; Mandpe et al. 2005). In the United States, biodiesel is made from soybean oil, while in Europe; rapeseed (or canola) oil is a common feedstock. In developing countries like India, Jatropha is a viable source of non-edible oil. Crops currently using for biodiesel production and agrotechnology efforts to improve the production and reduce the cost of biofuel in these species are discussed. A debate has already been started about use of edible oil for the production of biodiesel considering impact on land usage, prices of edible oil and benefits to farmers. Therefore, a rational policy about biodiesel crops has to be evolved looking to the various needs of a particular country.

6.1 Non–edible Oil Crops

6.1.1 Jatropha curcas

6.1.1.1 Biology

Jatropha curcas is a small tree belongs to the Euphorbiaceae family (Figs. 4, 5, 6, 7, 8 and 9). The leaves are cordate, 3–5 lobed and 10–15 cm long; stomata are hypostomatic and paracytic (Rubiaceous) type. It flowers twice in a year in India, during May–June and September–November. Seeds usually mature within a month. The inflorescence is axillary paniculate polychasial cyme (Fig. 5). The flowers are unisexual, monoecious yellowish green in glabrous or pubescent cymes at the end of the branches. Female flower produce higher amount of nectar than male flower. Fifty percent of female flowers set fruit with 53% fertilization rate, 32% apomixes rate and 2:3 seed-ovule ratio. Fruits are trilocular capsules (Fig. 6), 1.5–3.0 cm long. Jatropha trees produce many seeds that are very rich with oils, the seed contain 30–40% of oil with 21% saturated fatty acids and 79% unsaturated fatty acids. Oil extracted from the seeds has traditionally been used as lamp oil and also in soap manufacture (Reddy and Pamidimarri 2010; Gübitz et al. 1999).

6.1.1.2 Habitat

Jatropha is a vigorous, drought- and pest-resistant plant, and can grow under a wide range of rainfall regimes ranging from 200 to over 1,500 mm per annum. Jatropha trees will grow under a variety of conditions, withstanding high temperatures, drought, slope, and varied pH levels. Most data comes from Jatropha production in regions where water is either too scarce or too expensive with which to irrigate. The rooting system is composed of three or four primary lateral roots spreading near the soil surface and one vertical root that can reach down more than 5 m, allowing it to survive in very dry climates. Jatropha has shown high demands for nitrogen and phosphorous, the demands for nitrogen and phosphorous can be easily met, as Jatropha is highly efficient at adsorbing nutrients from marginal soils.

6.1.1.3 Occurrence

Jatropha curcas is a multipurpose, drought-resistant, biofuel tree originating from Central and South America, but now growing pantropic. It is indigenous to the Caribbean, but it is used around the world in Central and South America, India, Africa, and Southeast Asia to provide natural hedges and fence-rows, as it is not browsed by most livestock.

6.1.1.4 Plantation

Propagation of Jatropha can be done by seed or by cuttings, with trees grown from seeds (Fig. 7) producing harvestable seed crops within 2 years and trees grown from cuttings producing harvestable seed in the first year of growth. The estimated potential area of Jatropha plantation is 59–1,486 Mha worldwide, and the potential production is 56–3,613 MT dry seed per year (Li et al. 2009). It has been estimated that 1 ha plantations (Fig. 8) of Jatropha trees could produce up to 6.5 t of seed per year and about 2,000 l of oil, which can be used for soap-making, various medical treatments, and production of diesel fuel. This kind of information can be used for policy makers and prospective countries should identify their land areas suitable for Jatropha plantations using geographic information system and other land suitability modeling. Although Jatropha is expected to ease fuel shortage and global warming potential, the large-scale cultivation has become more controversial, with growing awareness of loss of biodiversity and food security (Abhilash et al. 2011). To contribute to the fuel supply, renewable energies such as Jatropha appear to be an attractive resource for biodiesel production in India and other countries as it can be grown on waste land and does not need intensive water supply (Leduc et al. 2009).

6.1.1.5 Agrotechnology

J. curcas is still an undomesticated plant in which many basic agronomic properties are not yet thoroughly understood (Achten et al. 2008). J. curcas bears bunch of fruits at the apex of the branches. Therefore, limited branching is considered one of the major factors limiting yield in this species. Manual pruning is one of the major management practices in commercial plantations of this crop (Fig. 9), resulting in production of more branches and thus increased potential for more inflorescences leading to a higher seed yield. However, this method is time-consuming, labor-intensive and expensive, e.g., plant growth regulators caused an increase in the seed hydrocarbon content in response to hormonal application to J. curcas (Augustus et al. 2002). Nitrogen supply can improve the plant growth, though plant can grow in low nitrogen and adapt to drought stress (Wang et al. 2011).

A single foliar application of N6-benzyladenine at 12 millimolar (mM) significantly increased branches in both the pot (4.0) and field (13.2) trials compared to manual pruning (1.8 and 5.7, respectively) and control (no new branches) plants. In the field, a single foliar application of 1.0 mM 2,3,5-triiodobenzoic acid (TIBA) resulted in a significant increment in the number of branches (15.9) after 7 months. Of all the plant growth regulators examined, 2,3:4,6-di-O-isopropylidene-2-keto-L-gluconic acid (a pesticide, common chemical name, dikegulac) at 2.0 mM produced the maximum number of branches (18.0) in the field 7 months after application (Abdelgadir et al. 2009). The same authors reported that a single foliar application of N6-benzyladenine produced more flowers per plant, more fruits per bunch, heavier and bigger fruits and seeds with more oil compared to manual pruning. Treatment with TIBA yielded more flowers per plant and heavier fruits with a higher oil content than the control and manually pruned plants. Treatment with dikegulac yielded similar results. More fruits per bunch and more seeds per fruit were also produced. Maleic hydrazide treatment yielded more flowers per plant, heavier and bigger fruits with more, heavier, oil rich seeds compared to the control and manual pruning. This study indicated that foliar application of plant growth regulators (PGR) as chemical branching agent in J. curcas may have a sequential effect in boosting seed production, seed oil content and improves fruit quality (Abdelgadir et al. 2010).

6.1.1.6 Biodiesel Production

The common oilseeds as soybean, cottonseed, sunflower and rapeseed are rich sources of phospholipids (Nieuwenhuyzen and Tomas 2008). Phospholipids pose many problems for the storage and processing of the crude oil and are removed from oil during refining by a process known as degumming. The oil obtained by mechanical crushing (machines known as expeller) or solvent extraction is termed “crude” oil, as it contains a number of impurities. Some of the impurities, such as seed fragments and meal fines, are oil insoluble and thus can be readily removed by filtration. Others, including free fatty acids, hydrocarbons, ketones, tocopherols, glycolipids, phytosterols, phospholipids, proteins, pigments, and resins, are soluble or form stable colloidal suspensions in the oil. Most of these have unfavorable effects on the flavor, odor, appearance, and shelf life of the oil, and therefore have to be removed from the vegetable oils by chemical or physical refining processes (Zufarov et al. 2008). Currently, industrial-scale biodiesel synthesis relies on the chemically-catalyzed transesterification of vegetable oils with short-chain alcohols, usually methanol. Chemically-catalyzed transesterification of triglycerides to their corresponding alkyl esters provides high conversion yields with short reaction times. When acid catalysts are used, careful removal of catalyst residues from the final product, entailing large volumes of wash-effluent, is required to avoid damage to engine parts (Jachmanian et al. 2010). There are various technologies explored for the development of biodiesel process at pilot plant scale using Jatropha oil as the raw material with methanol and sodium hydroxide as the catalyst and evaluate the produced biodiesel as a fuel. Studies of biodiesel production from Jatropha oil by transesterification on both bench and pilot scales have been developed and evaluated (Diwani et al. 2009). The optimization of biodiesel production was reported in J. curcas oil via alkali-catalyzed methanolysis. The reaction was in the presence of NaOH as catalyst was carried out to investigate the optimum conditions and to study the effects of variables on the reaction. These variables included methanol-to-oil molar ratios of 4:1–10:1, catalyst concentrations of 0.25–2.0% w/w of oil, reaction temperatures of 32–60°C, and reaction times of 5–40 min. Due to the low price of sodium hydroxide, the short reaction time, and high methyl ester content obtained, these optimum conditions can be used in large-scale production to reduce the cost of production (Nakpong and Wootthikanokkhan 2010). From the ongoing account it is clear that technology development is in its preliminary phase and refinement for industrial process is required.

6.1.2 Pongamia pinnata

Pongamia pinnata (L.) Pierre tree belongs to the family Fabaceae, popularly known as ‘Karanj’ (in Hindi). It is known for its multipurpose benefits and as a potential source of biodiesel (Sharma and Singh 2008; Kesari et al. 2009). Its added benefits to grow on marginal lands make it a suitable candidate in agro-forestry. These properties support the suitability of this plant for large-scale production required by a sustainable biodiesel industry (Scott et al. 2008; Kesari and Rangan 2010). The seeds contain about 28–34% oil with a high percentage of polyunsaturated fatty acids. The tree can grow on unproductive land and is adaptable to wide agro-climatic conditions (Kesari and Rangan 2010). The Ministry of Agriculture through National oil seeds and vegetable oils development board (NOVOD) is promoting Pongamia under the scheme of Integrated Development of tree-borne oil seeds. The NOVOD board has undertaken the plantation model of Pongamia in an area of approximately 1,400 ha for producing parent material for large-scale plantation (NOVOD Report 2009). Biodiesel production from the non-edible oil of P. pinnata by transesterification of the crude oil with methanol and KOH as catalyst has been established. A maximum conversion of 92% (oil to ester) was achieved using a 1:10 M ratio of oil to methanol at 60°C. When tetrahydrofuran was used as co-solvent, the conversion increased to 95% (Karmee and Chadha 2005). Agrotechnology for systematic cultivation and oil production are still required for the plant.

6.1.3 Ricinus communis

Ricinus communis belongs to the family Euphorbiaceae and it is commonly known as castor oil plant. Castor oil is extracted from the seeds, which contain about 46% oil. This oil is highly viscous. Castor oil dissolves easily in alcohol, ether, glacial acetic acid, chloroform, carbon sulfide, and benzene. It’s made up of triglycerides: 91–95% ricinoleic acid, 4–5% linoleic acid, and 1–2% palmitic and stearic acids. Besides being used as a laxative, castor oil is widely used in the industrial field because of its many properties. In the textile industry, castor oil is used for moisturizing and removal of grease in fabrics, and for the manufacturing of waterproof fabrics. The leftover seedcake (protein-meal) has a highly-toxic component known as ricin, a blood coagulant that can be lethal in very small doses. There are expensive means of detoxifying the seedcake after oil extraction, if the high-protein meal needed to be used as animal feed. The oil can be used in medicinal applications as well, but only in small doses. Under irrigation, yields from castor bean can exceed 1,000 kg/ha of seed regularly, and experimental tests in the U.S.A. and Brazil have given yields up to 5,000 kg/ha. Although there is potential for very high oil yield from castor bean, the fact it is considered a weed by many agricultural producers certainly limits its viability as an option to produce significant amounts of biodiesel (Poteet 2006). Castor oil is already used as automobile lubricant (industrial process) and its diversion in to biodiesel may affect market cost.

6.1.4 Azadirachta indica

The neem tree (Azadirachta indica) is an evergreen tree of the family Meliaceae and is native to India and Burma. Neem trees are fast-growing and can grow up to 35 m tall, and although evergreen, they will lose their leaves in times of severe drought. One tree can produce millions of flowers, and in one flowering cycle, a mature tree may produce many thousands of seeds. Seeds are small and round to oval in shape, with oil content ranging from 20 to 33%, depending on the variety. It is estimated that a mature neem tree may produce 30–50 kg of fruit each year. Neem trees are considered to be a sacred tree in India because of their multitudinous uses. Products derived from the neem tree include neem oils, bark, leaves, and seed cake, each of which can serve a different purpose. In India, neem oil extracted from seeds is used for soap primarily, but it is also used in medicine and as a natural pesticide, capable of repelling various harmful insects from food and fiber crops (Pal 2007). There are many uses of leaves, bark and seed oil neem plant. It is mainly used as avenue tree. How much seeds are available for biodiesel production has to be surveyed properly.

6.1.5 Algae

Algae, mainly microalgae, have recently gained attention as a new biomass/biolipid source for the production of biodiesel. It has unique benefits as an aquatic species and do not require arable land for cultivation (Wawrik and Harriman 2010). This means that algae cultivation does not need to compete with agricultural commodities for growing space (Haag 2007). Microalgae are photosynthetic microorganisms which convert sunlight, water and CO2 to sugars, from which macromolecules, such as lipids and triacylglycerols can be obtained. These triacylglycerols are the promising and sustainable feedstock for biodiesel production (Khan et al. 2009). The algae that are used in biodiesel production are usually aquatic unicellular green algae. Under good conditions, green algae can double its biomass in less than 24 h (Christi 2007). Additionally, green algae can have huge lipid contents, frequently over 50%. This high yield, high density the use algae as a source of biomass for fuel production is investigated, in terms of its productivity, practicality, and innovative potential to create a cost competitive, environmentally friendly, and renewable source of liquid fuel. The annual productivity and oil content of algae is far greater than seed crops, e.g., soybean produces about 450 L oil per hectare, canola produces 1,200 L/ha, and palm produces 6,000 L/ha; compare that to algae can yield 90,000 L/ha (Christi 2007). Oil content was found in different green algae on the basis of dry weight, Chlorella spp. 28–32%, Nitzschia spp. 45–47%, Nannochloropsis spp. 31–68% and Schizochytrium spp. 50–77% (Campbell 2008).

In order to efficiently produce biodiesel from algae, high productivity of fatty acid-containing lipid components is essential when the algae are grown in open culture systems (Bisen et al. 2010).

The pilot plant designs are used for microalgae culture of high oil content species. There are two methods of large-scale production of microalgae: raceway pond and tubular photobioreactor (Janssen et al. 2003). On the one hand, closed photobioreactors have had more significance, because they allow a better control of the cultivation conditions than open systems. Therefore, closed photobioreactors have some advantage: higher biomass productivities are obtained and contamination troubles are controlled (Pegallapati and Nirmalakhandan 2011). On the other hand, open ponds have easier operation and construction, although they are limited in the control of culture conditions. It is the best system for mass cultivation of microalgae, moreover, raceway ponds are the most profitable (Ugwu et al. 2008). Algal oil can be an economic source for biofuel in the future is still highly dependent on the petroleum oil price.

6.2 Edible Oil Crops

There is heated debate about whether to use edible oil crops for biofuel production or not as well as cultivation of non-edible crops like Jatropha on land already under agriculture use. Currently, more than 95% of the world biodiesel is produced from edible oil which is easily available on large scale from the agricultural industry. However, continuous and large-scale production of biodiesel from edible oil without proper planning may cause negative impact to the world, such as depletion of food supply leading to economic imbalance. A possible solution to overcome this problem is to use non-edible oil or waste edible oil (Gui et al. 2008). The natural issue arising from the diversion of arable land from food production to bio-energy crops is that how will this affect food production and food security? Biofuel proponents, and there is already a vocal ‘biofuel lobby’, argue that bioenergy crops would only be grown on degraded or wasteland, not fertile land. But, if the wasteland is capable of supporting Jatropha cultivation, should it not be used for the cultivation of selected cereal or oil crops, or if not that, then fodder grasses? India and all of South Asia have large livestock populations, which serve as additional support for local food security. The region is deficient in fodder and all kinds of non-arable land should be diverted to fodder grasses, not crops to produce agrofuels (Sahai 2010). Use of edible oil crops for non-edible purpose is a matter of debate from socio-economic aspect as population of many countries is malnourished.

6.2.1 Glycine max

Soybean is an annual crop grown in temperate, subtropical and tropical climates around the world, and its primary producers are the United States, Brazil, Argentina, China, and India. Soybean oil is the major edible oil in the world. Uses for soybean include as an edible vegetable, as a source for cooking oil, as a crop for pasture, fodder, or silage, and as a source for oils used in the manufacture of paints, linoleum, oil cloth, printing inks, soap, insecticides, and disinfectants. The average oil content for soybeans is 18–20%, with protein content of 40%. In favorable conditions, a high yield of soybeans seeds around the world is approximately 1,700 kg/ha. Soybean oil deodorizer distillate (SODD) is a valuable by-product in the refining of soybean oil and amounts to 0.2–0.5% of the feedstock. It is rich in triglycerides, free fatty acid, natural tocopherols (vitamin E) and sterols, which are widely used in the biofuel, food and pharmaceutical industries (Yun et al. 2010). An efficient method to recover acid oil from soybean soapstock has been investigated. This soap splitting (SS) process can be successfully operated at ambient temperature only with water and sulfuric acid. Maximum yield (97%) of acid oil was achieved based on the total fatty acids of soybean soapstock. The advantages of this process revealed a prospect option to utilize SS for biodiesel production. (Balan et al. 2009: Wang et al. 2007). Soybeans are edible and protein rich crops. Surplus oil may be diverted at present for biodiesel technology development but ultimately alternative non-edible crops have to be developed.

6.2.2 Helianthus annuus

Sunflower is an annual, upright, broadleaf plant with a growing cycle of approximately 4 months from planting to maturity. It is native to the western United States, and it was spread throughout North America by Native Americans. The seeds are harvested for edible oil production, commercial birdseed, and as a snack-food for human consumption.

Production of sunflower takes place all over the world, including western Russia, Ukraine, and Argentina. Average yields of approximately 1,500 kg/ha are lower than soybean yields, and the necessary inputs are greater (Pimentel and Patzek 2005). A continuous process was developed for production of biodiesel from sunflower oil in basic medium. The conditions of conducting the process were found with consideration of the kinetics of the interesterification reaction. The modeling method is widely used for obtaining reliable information on the process due to its expanded thermodynamic packages, extensive data on components, and improved methods of calculation, although it also gives some anticipated differences from the real data from conducting the process (Maceiras et al. 2010; Balan et al. 2009). Similar to soybean, it is primarily edible oil and diversion to non-edible purposes is not likely to be encouraged in near future.

6.2.3 Elaeis guineensis

Palm oil is derived from the fruit (both the flesh and the seed) of a tall palm species that can grow up to 20 m (over 65 ft) tall. The fruits are produced in large clusters numbering from 200 to 300 per cluster, weighing up to 10 kg. Each fruit is about the size of a plum, and the oil content of the fleshy endosperm can be anywhere from 40 to 70% in some varieties, and palm kernel oil contents are typically about 50%. The oil palm originated along the western coast of Africa, and has since spread to most tropical areas in the world. Palm oil is used as an ingredient in margarines, vegetable oils, candles, lubricants, soaps, and more recently, biodiesel production. According to the U.S. Department of Agriculture, 28 MT of palm oil were produced worldwide in 2004, and it is on pace to surpass soybean oil as the most widely produced vegetable oil in the world. Demand for palm oil is rising particularly for use as a biodiesel fuel. The demand for palm oil usage is forecast to double by 2020 (Yusof and Arif 2005). To achieve that production increase, 1,160 new square miles will have to be planted every year for 20 years. Palm oil is good candidate as its oil is not preferred over soybean and sunflower but production cost and area under cultivation are important.

6.2.4 Brassica napus

Rape is a cruciferous crop that produces storage root below ground and vegetation similar to kale above ground. The rapeseed is harvested for oil production, with an increasing demand for use as a biodiesel source worldwide. Rapeseed oil is also used in lubricants, illuminants, and soap manufacturing. It is primarily produced in Canada (known as canola oil) and Western Europe, but significant production also takes place in China. Oil contents for rapeseed average between 37 and 50%, making it a high-yielding oil crop. Seed yields can vary from 900 to 3,000 kg/ha and yields of 1,500 kg/ha would yield approximately 500 kg of oil and 1,000 kg of a high protein meal remaining after oil extraction. Biodiesel production from rapeseed is used in a major way using different biodiesel production technologies (Long et al. 2011). How much edible oil can be diverted in the production of biodiesel without affecting the food security has to be seen in near future.

7 Economic and Environmental Benefits

Advantages and disadvantages of using biodiesel as an alternative source of energy are summarized in Table 2. Encouragement of biodiesel is mainly because of reducing dependency on limited resources of fossil fuel, developing alternative fuels from renewable sources, benefits to farmers and less pollution in the environment or higher carbon credits. Agriculture based industrial process development is always beneficial to masses as agriculture is the prime profession in many developing countries. These processes can provide cost benefits to farmers. Since the plant like Jatropha can be grown on marginal lands, use of such land will provide additional benefits to farmers as these crops will not compete with irrigated crop land. Major impact will be on environment because of large acres cultivation of plants on land otherwise lying barren (Anonymous 2010; Achten et al. 2007). When crop like soybean is used, soybean biodiesel produces 41% less greenhouse gas emissions than diesel fuel. Soybeans have another environmental advantage over crop like corn because they require much less nitrogen fertilizer and pesticides, which get into groundwater, streams, rivers and oceans. These agricultural chemicals pollute drinking water, and nitrogen decreases biodiversity in global ecosystems. Nitrogen fertilizer, mainly from corn, causes the ‘dead zone’ in the Gulf of Mexico (http://www.sciencedaily.com/releases/2006/07/060710180310.htm). It is evident from available data, usage and economic benefits that J. curcas is attaining significant importance in the rural economy of developing countries and will have an impact on socio-economic status of community being a labor intensive crop. The major benefits are summarized in Fig. 10.

8 Impact on Agriculture Sustainability

Biofuels have become a major issue on global commodities markets over the last years as they are increasingly put forward as politically, environmentally and economically friendly alternatives to fossil fuels. Currently biodiesel is obtained from both edible and non-edible crops. In fact, no project can be considered sustainable if it is not both economically and socially sustainable. Sustainability can be framed by three inseparable dimensions: environmental, economic and social (Achten et al. 2007). If the plant like J. curcas is produced on lands which are not suitable for edible crop production, this will have no problem. Although even some basic agronomic characteristics of J. curcas are not yet fully understood, the agrotechnology is being developed rapidly. Preliminary lifecycle energy and greenhouse gas balances are positive for J. curcas, but the green house gas balance is expected to be much dependent on the type of land use. The other factors important for the sustainability are: cultivation intensity, the distance to markets, soil, water, vegetation structure and biodiversity. Next to biodiesel production and wasteland reclamation, J. curcas also hosts socio-economic development potential. The multipurpose character of the plant (Fig. 10) and the labor-intensive production chain are thought to be the main drivers for rural development in most of the developing countries.

Economic and environmental benefits of cultivation of Jatropha curcas on large waste lands for sustainable agriculture. Besides control of soil erosion and clean environment (soil, water and air), it provides seed cake and glycerol as by-products which have many uses in agriculture, cosmetic and medicinal industries

Soybean biodiesel produce more energy than is needed to grow the crops and convert them into biodiesel. However, biodiesel cannot come close to meeting the growing demand for alternatives to petroleum products. Dedicating all current U.S. corn and soybean production to biofuels would meet only 12% of gasoline demand and 6% of diesel demand. Therefore, It may be concluded that agriculture sustainability will depend upon future technology development in coming years to make biodiesel an alternative source of energy.

9 Conclusion

Biofuels have the potential to substitute for some of that “fossil” oil. The need for substitution is driven by rapidly increasing carbon dioxide concentrations in the atmosphere, caused by burning fossil fuels, with associated global warming which is suggested to cause a 0.5 m rise in the sea level by the end of the century. Biodiesel demand is constantly increasing as the reservoir of fossil fuel are depleting. Unfortunately biodiesel produced from oil crop, waste cooking oil and animal fats are not able to replace fossil fuel. The viability of the first generation biofuels production is however questionable because of the conflict with food supply. Jatropha plant is projected as major player in biodisel production using marginal soils. Microalgae is other alternative for oil production in place of land crops. Microalgal biorefinery approach can be used to reduce the cost of making microalgal biodiesel. Microalgal-based carbon sequestration technologies cover the cost of carbon capture and sequestration. On the same time, quality standards for biodiesel are developing and quality certification systems have started to emerge, prompting engine manufacturers to extend their warranties. However, the economics of today’s diesel prices and the prices of potential feedstock sources do not seem promising without continued government support and technological improvements. Projected increases in vegetable oil prices, especially soybean oil, will continue to squeeze margins for biodiesel producers. Even with supportive policies and infrastructure, time will be needed before second generation biofuels will be able to make an impact in any developing country, because of the research, development and demonstration requirements needed to reach the commercial implementation stage. Given the still-early point in commercial development of second-generation biofuel technologies, it is difficult to project what role developing countries are likely to take in a global biofuel economy in the long term. One possibility is that they simply become exporters of second generation feed stocks, taking advantage of their favorable natural climates and low labor costs for growing biomass. A more attractive evolution would be their becoming producers, users and exporters of finished biofuels, thereby retaining domestically more of the considerable added value involved in the conversion of the feed stocks to finished fuels.

Abbreviations

- EU:

-

European Union

- FAO:

-

Food and Agriculture Organization

- UN:

-

United Nations

- USA:

-

United States of America

References

Abdelgadir HA, Johnson SD, Van Staden J (2009) Promoting branching of a biofuel crop Jatropha curcas L. by foliar application of plant growth regulators. Plant Growth Regul 58:287–295

Abdelgadir HA, Jager AK, Johnson SD, Van Staden J (2010) Influence of plant growth regulators on flowering, fruiting, seed oil content, and oil quality of Jatropha curcas. Suth Afr J Bot 76:440–446

Abdul M, Gerpen JHV (2001) The effect of biodiesel oxidation on engine performance and emissions. Biomass Bioenergy 20:317–325

Abhilash PC, Srivastava P, Jamil S, Singh N (2011) Revisited Jatropha curcas as an oil plant of multiple benefits: critical research needs and prospects for the future. Environ Sci Pollut Res 18:127–131

Achten WMJ, Mathijs E, Verchot L, Singh VP, Aerts R et al (2007) Jatropha biodiesel fueling sustainability? Biofuels Bioprod Biorefin 1:283–291

Achten WMJ, Verchot L, Franken YJ, Mathijs E, Singh VP, Aerts R et al (2008) Jatropha bio-diesel production and use. Biomass Bioenergy 32:1063–1084

Adebowale KO, Adedire CO (2006) Chemical composition and insecticidal properties of the underutilized Jatropha curcas seed oil. Afr J Biotechnol 5:901–906

Agarwal D, Kumar L, Agarwal AK (2008) Performance evaluation of a vegetable oil fuelled compression ignition engine. Renew Energy 33:1147–1156

Anonymous (2010) Impacts of the EU biofuel target on agricultural markets and land use: a Comparative modelling assessment. http://ec.europa.eu/energy/renewables/studies/doc/landuse_change/study_jrc_biofuel_target_iluc.pdf

Augustus GDPS, Jayubalan M, Seiler GJ (2002) Evaluation and bioinduction of energy components of Jatropha curcas. Biomass Bioenergy 23:161–164

Azam MM, Waris A, Nahar NM (2005) Prospects and potential of fatty acid methyl esters of some non-traditional seed oils for use as biodiesel in India. Biomass Bioenergy 29:293–302

Balan V, Rogers CA, Chundawat SPS, Sousa LDC, Slininger PJ, Gupta R, Dale BE (2009) Conversion of extracted oil cake fibers into bioethanol including DDGS, canola, sunflower, sesame, soy, and peanut for integrated biodiesel processing. J Am Oil Chem Soc 86:157–165

Balusamy T, Marappan R (2007) Performance evaluation of direct injection diesel engine with blends of Thevetia peruviana seed oil and diesel. J Sci Ind Res 66:1035–1040

Banapurmath NR, Tewari PG, Hosmath RS (2008) Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters. Renew Energy 33:1982–1988

Bisen PS, Sanodiya BS, Thakur GS, Baghel RK, Prasad GBKS (2010) Biodiesel production with special emphasis on lipase-catalyzed transesterification. Biotechnol Lett 32:1019–1030

Bouaid A, Diaz Y, Martinez M, Aracil J (2005) Pilot plant studies of biodiesel production using Brassica carinata as raw material. Catal Today 106:193–196

Bouaid A, Martinez M, Aracil J (2009) Production of biodiesel from bioethanol and Brassica carinata oil: oxidation stability study. Bioresour Technol 100:2234–2239

Campbell MN (2008) Biodiesel: algae as a renewable source for liquid fuel. Guelph Eng J 1:2–7

Chapagain BP, Yehoshua Y, Wiesman Z (2009) Desert date (Balanites aegyptiaca) as an arid lands sustainable bioresource for biodiesel. Bioresour Technol 100:1221–1226

Christi Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Collins K (2008) The role of biofuels and other factors in increasing farm and food prices: a review of recent developments with a focus on feed grain markets and market prospects. Kraft Foods Global, Inc., Chicago

Das LM, Bora DK, Pradhan S, Naik MK, Naik SN (2009) Long-term storage stability of biodiesel produced from Karanja oil. Fuel 88:2315–2318

Dash AK, Pradhan RC, Das LM, Naik SN (2008) Some physical properties of simarouba fruit and kernel. Int Agrophys 22:111–116

Demirbas A (2006) Energy priorities and new energy strategies. Energy Educ Sci Technol 16:53–109

Deshmukh SJ, Bhuyar LB (2009) Transesterified hingan (Balanites) oil as a fuel for compression ignition engines. Biomass Bioenergy 33:108–112

Devan PK, Mahalakshmi NV (2009a) A study of the performance, emission and combustion characteristics of a compression ignition engine using methyl ester of paradise oil-eucalyptus oil blends. Appl Energy 86:675–680

Devan PK, Mahalakshmi NV (2009b) Utilization of unattended methyl ester of paradise oil as fuel in diesel engine. Fuel 88:1828–1833

Diwani GE, Attia NK, Hawash SI (2009) Development and evaluation of biodiesel fuel and by-products from Jatropha oil. Int J Environ Sci Technol 6:219–224

European Commission (2006) Communication from the Commission to the Council and the European Parliament. Renewable Energy Road Map. Renewable energies in the 21st century: building a more sustainable future. COM 848 final, Brussels

Fairless D (2007) Biofuel: the little shrub that could – maybe. Nature 449:652–655

FAOSTAT (2009) Land use classifications. Food and Agricultural Organization of the United Nations, Rome

Frohlich A, Rice B (2005) Evaluation of Camelina sativa oil as a feedstock for biodiesel production. Ind Crop Prod 21:25–31

Government of India (2008) The national policy on bio-fuel. Ministry of New and Renewable Energy, New Delhi

Gübitz GM, Mittelbach M, Trabi M (1999) Exploitation of the tropical oil seed plant Jatropha curcas L. Bioresour Technol 67:73–82

Gui MM, Lee KT, Bhatia S (2008) Feasibility of edible oil vs nonedible oil vs waste edible oil as biodiesel feedstock. Energy 33:1646–1653

Gumus M (2008) Evaluation of hazelnut kernel oil of Turkish origin as alternative fuel in diesel engines. Renew Energy 33:2448–2457

Haag AL (2007) Algae bloom again. Nature 447:520–521

Hoogwijk MA, Faaij B, de Vries EB, Turkenburg W (2005) Potential biomass energy out to 2100 for four IPCC SRES land-use scenarios. Biomass Bioenergy 29:225–257

Jachmanian I, Dobroyan M, Moltini M, Segura N, Irigaray B, Veira JP, Vieitez I, Grompone MA (2010) Continuous lipase-catalyzed alcoholysis of sunflower oil: effect of phase-equilibrium on process efficiency. J Am Oil Chem Soc 87:45–53

Jain S, Sharma MP (2010) Prospects of biodiesel from Jatropha in India: a review. Renew Sustain Energy Rev 14:763–771

Janssen M, Tramper J, Mur L, Wijffels R (2003) Enclosed outdoor photobioreactors: light regime, photosynthetic efficiency, scale-up, and future prospects. Biotechnol Bioeng 81:193–210

Kalita D (2010) Potentiality of hydrocarbon yielding plants for future energy and chemicals. In: Ramawat KG (ed) Desert plants: biology and biotechnology. Springer, Berlin/Heidelberg, pp 37–56

Kalscheuer R, Luftmann H, Steinbüchel A (2004) Synthesis of novel lipids in Saccharomyces cerevisiae by heterologous expression of an unspecific bacterial acyltransferase. Appl Environ Microbiol 70:7119–7125

Kalscheuer R, Stölting T, Steinbüchel A (2006) Microdiesel: Escherichia coli engineered for fuel production. Microbiology 152:2529–2536

Karmee SK, Chadha A (2005) Preparation of biodiesel from crude oil of Pongamia pinnata. Bioresour Technol 96:1425–1429

Kesari V, Rangan L (2010) Development of Pongamia pinnata as an alternative biofuel. Crop – current status and scope of plantations in India. J Crop Sci Biotechnol 13:127–137

Kesari V, Krishnamachari A, Rangan L (2009) Effect of auxins on adventitious rooting from stem cuttings of candidate plus tree Pongamia pinnata (L.), a potential biodiesel plant. Trees Struct Funct 23:597–604

Khan SA, Rashmi HMZ, Prasad S, Banerjee UC (2009) Prospects of biodiesel production from microalgae in India. Renew Sustain Energy Rev 13:2361–2372

Khemkladngoen N, Cartagena JA, Fukui K (2011) Physical wounding-assisted agrobacterium mediated transformation of juvenile cotyledons of a biodiesel-producing plant, Jatropha curcas L. Plant Biotechnol Rep 5:235–243

Kim SJ, Jung SM, Park YC, Park K (2007) Lipase catalyzed transesterification of soybean oil using ethyl acetate, an alternative acyl acceptor. Biotechnol Bioprocess Eng 12:441–445

Leduc S, Natarajan K, Dotzauer E, McCallum I, Obersteiner M (2009) Optimizing biodiesel production in India. Appl Energy 86:125–131

Leung DYC, Koo BCP, Guo Y (2006) Degradation of biodiesel under different storage conditions. Bioresour Technol 97:250–256

Li S, Wang Y, Dong S, Chen Y, Cao F, Chai F et al (2009) Biodiesel production from Eruca sativa Gars vegetable oil and motor, emissions properties. Renew Energy 34:1871–1876

Long YD, Guo F, Fang Z, Tian XF, Jiang LQ, Zhang F (2011) Production of biodiesel and lactic acid from oil using sodium silicate as catalyst. Bioresour technol 102:6884–6886

Maceiras R, Rivero JJ, Cancela MA, Urrejola S, Sanchez A (2010) Development and modeling of production of biodiesel from sunflower oil. Chem Technol Fuels Oils 46:154–159

Makkar H, Maes J, Greyt WD, Becker K (2009) Removal and degradation of phorbol esters during pre-treatment and transesterification of Jatropha curcas oil. J Am Oil Chem Soc 86:173–181

Mandpe S, Kadlaskar S, Degen W, Keppeler S (2005) On road testing of advanced common rail diesel vehicles with biodiesel from the Jatropha curcas plant. Soc Automot Eng Inc 26:356–364

Meher LC, Vidya Sagar D, Naik SN (2006) Technical aspects of biodiesel production by transesterification—a review. Renew Sustain Energy Rev 10:248–268

Miao X, Wu Q (2004) High yield bio-oil production from fast pyrolysis by metabolic controlling of Chlorella protothecoides. J Biotechnol 110:85–93

Mukherjee P, Varshney A, Johnson S, Jha TB (2011) Jatropha curcas: a review on biotechnological status and challenges. Plant Biotechnol Rep. doi:10.1007/s11816-011-0175-2

Nabi MN, Akhter MS, Shahadat MMZ (2006) Improvement of engine emissions with conventional diesel fuel and diesel–biodiesel blends. Bioresour Technol 97:372–378

Nakpong P, Wootthikanokkhan S (2010) Optimization of biodiesel production from Jatropha curcas L. oil via alkali-catalyzed methanolysis. J Sustain Energy Environ 1:105–109

Nieuwenhuyzen WV, Tomas MC (2008) Update on vegetable lecithin and phospholipid technologies. Eur J Lipid Sci Technol 110:472–476

NOVOD (2009) 4th R&D report on tree borne oilseeds, NOVOD Board India. http://www.novodboard.com/4th%20R&D-Report.pdf

OECD-FAO (2007) OECD-FAO Agricultural outlook 2007–2016. Organization for Economic Development and Co-operation, Paris, and the U. N. Food and Agricultural Organization of the United Nations, Rome

Oluwaniyi OO, Ibeyimi SA (2007) Efficacy of catalysts in the batch esterification of the fatty acids of Thevetia peruviana seed oil. J Appl Sci Environ Manage 66:1035–1040

Pal A (2007) Production of insecticides. In: Ramawat KG, Merillon JM (eds) Biotechnology secondary metabolites plants and microbes, vol 2. Science Publishers, Enfield, pp 131–149

Pegallapati AK, Nirmalakhandan N (2011) Energetic evaluation of an internally illuminated photobioreactor for algal cultivation. Biotechnol Lett 33:2161–2167

Pimentel D, Patzek TW (2005) Ethanol production using corn, switchgrass, and wood; biodiesel production using soybean and sunflower. Nat Resour Res 14:65–76

Pinto AC, Guarieiro LLN, Rezende MJC, Ribeiro NM, Torres EA, Lopes WA, Pereira PAP, Andrade JB (2005) Biodiesel: an overview. J Braz Chem Soc 16:1313–1330

Poteet MD (2006) Biodiesel crop implementation in Hawaii. Department of Agriculture, Hawaii Agriculture Research Center Aiea, HI 96701

Qin J (2005) Bio-hydrocarbons from algae. Report for the Rural Industries Research and Development Corporation, RIRDC Publication No. 05/025

Ramadhas AS, Jayaraj S, Muraleedharan C (2005) Biodiesel production from high FFA rubber seed oil. Fuel 84:335–340

Rashid U, Anwar F (2008) Production of biodiesel through base-catalyzed transesterification of safflower oil using an optimized protocol. Energy Fuel 22:1306–1312

Razon LF (2009) Alternative crops for biodiesel feedstock. CAB Rev. doi:10.1079/PAVSNNR20094056

Reddy MP, Pamidimarri DVNS (2010) Biology and biotechnology advances in Jatropha curcas -a biodiesel plant. In: Ramawat KG (ed) Desert plants: biology and biotechnology. Springer, Berlin/Heidelberg, pp 58–72

Reddy BVS, Ramesh S, Kumar AA, Wani SP, Ortiz R, Ceballos H, Sreedevi TK (2008) Bio-fuel crops research for energy security and rural development in developing countries. Bioenergy Res 1:248–258

Sadano Y, Toshimitsu R, Nakano JKY, Yano T (2010) Optimization of compost fermentation of glycerol by-product discharged from biodiesel fuel production process. J Mater Cycles Waste Manage 12:308–313

Sahai S (2010) http://www.genecampaign.org/Publication/Article/AG-Food-Security/Biofuel%20vs%20food%20security.pdf Accessed 15 Feb 2010

Sahoo PK, Das LM (2009) Combustion analysis of jatropha, karanja and polanga based biodiesel as fuel in a diesel engine. Fuel 88:994–999

Sahoo PK, Das LM, Babu MKG, Naik SN (2007) Biodiesel development from high acid value polanga seed oil and performance evaluation in a CI engine. Fuel 86:448–454

Sarma AK, Konwer D, Bordoloi PK (2005) A comprehensive analysis of fuel properties of biodiesel from koroch seed oil. Energy Fuel 19:656–657

Saydut A, Duz MZ, Kaya C, Kafadar AB, Hamamci C (2008) Transesterified sesame (Sesamum indicum L.) seed oil as a biodiesel fuel. Bioresour Technol 99:6656–6660

Scholz V, da Silva JN (2008) Prospects and risks of the use of castor oil as a fuel. Biomass Bioenergyy 32:95–100

Scott PT, Pregelj L, Chen N, Hadler JS, Djordjevic MA, Gresshoff PM (2008) Pongamia pinnata: an untapped resource for the biofuels industry of the future. Bioenergy Res 1:2–11

Sendzikiene E, Makareviciene V, Janulis P (2005) Oxidation stability of biodiesel fuel produced from fatty wastes. Pol J Environ Stud 14:335–339

Sharma YC, Singh B (2008) Development of biodiesel from karanja, a tree found in rural India. Fuel 87:1740–1742

Singh SP, Singh D (2010) Biodiesel production through the use of different sources and characterization of oils and their esters as the substitute of diesel: a review. Renew Sustain Energy Rev 14:200–216

Smeets EMW, Faaij APC, Lewandowski IM, Turkenburg WC (2006) A bottom-up assessment and review of global bioenergy potentials to 2050. Progress in Energy and Combustion Science 33:56–106

Tiwari AK, Kumar A, Raheman H (2007) Biodiesel production from Jatropha oil (Jatropha curcas) with high free fatty acids: an optimized process. Biomass Bioener 31:569–577

Tweeten L, Thompson SR (2008) Long-term global agricultural output supply–demand balance and real farm and food prices. Department of Agricultural, Environmental and Development Economics the Ohio State University

Tyagi OS, Atray N, Kumar B, Datta A (2010) Production, characterization and development of standards for biodiesel – a review. J metrol soc of India 25:197–218

Ugwu CU, Ogbonna JC, Tanaka H (2008) Photobioreactors for mass cultivation of algae. Bioresour Technol 99:4021–4028

Vasudevan PT, Briggs M (2008) Biodiesel production—current state of the art and challenges. J Ind Microbiol Biotechnol 35:421–430

Waltz E (2008) Cellulosic ethanol booms despite unproven business models. Nat Biotechnol 26:8–9

Wang ZM, Lee JS, Park JY, Wu CZ, Yuan ZH (2007) Novel biodiesel production technology from soybean soapstock. Korean J Chem Eng 24:1027–1030

Wang WG, Li R, Liu B, Li L, Wang SH, Chen F (2011) Effects of low nitrogen and drought stresses on proline synthesis of Jatropha curcas seedling. Acta Physiol Plant 33:1591–1595

Wawrik B, Harriman BH (2010) Rapid, colorimetric quantification of lipid from algal cultures. J Microbiol Methods 80:262–266

Xin J, Imahara H, Saka S (2009) Kinetics on the oxidation of biodiesel stabilized with antioxidant. Fuel 88:282–286

Xu YX, Hanna MA (2009) Synthesis and characterization of hazelnut oil-based biodiesel. Ind Crop Prod 29:473–479

Xu Y, Liu H, Du W, Sun Y, Ou X, Liu D (2009) Integrated production for biodiesel and 1,3-propanediol with lipase-catalyzed transesterification and fermentation. Biotechnol Lett 31:1335–1341

Yun L, Ling W, Yunjun Y (2010) Cogeneration of biodiesel and tocopherols by combining pretreatment with supercritical carbon dioxide extraction from soybean oil deodorizer distillate. Chem Technol Fuels Oils 46:79–86

Yusof B, Arif SM (2005) Vision 2020—the palm oil phenomenon. Oil Palm Ind Econ J 5:2

Zufarov O, Schmidt Š, Sekretár S (2008) Degumming of rapeseed and sunflower oils. Acta Chimica Slovaca 1:321–328

Acknowledgements

This work was supported by financial assistance from University Grants Commission-Departmental Research Program (UGC-DRS) under special assistance program for medicinal plant research to K.G. Ramawat. V. Sharma thanks to UGC, New Delhi for financial assistance in the form of SRF.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Sharma, V., Ramawat, K.G., Choudhary, B.L. (2012). Biodiesel Production for Sustainable Agriculture. In: Lichtfouse, E. (eds) Sustainable Agriculture Reviews. Sustainable Agriculture Reviews, vol 11. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-5449-2_6

Download citation

DOI: https://doi.org/10.1007/978-94-007-5449-2_6

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-5448-5

Online ISBN: 978-94-007-5449-2

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)