Abstract

The tomato processing industry causes high amount of waste mainly skin and seeds that creates the environmental problem. These residues are major source of bioactive compounds and valuable pigments. Hence the purpose of this study was to extract the lycopene content from tomato pomace using conventional organic solvent extraction (COSE) and ultrasonication assisted extraction (UAE) methods. The effect of operating conditions was determined by varying extraction treatment time, solid liquid ratio and power variation in UAE. The maximum yield of lycopene was obtained in UAE (160 V for ratio 50:1 for 15 min) as compared to COSE. FTIR analysis was performed for lycopene Extract. Beta carotene was also obtained in the lycopene enriched alcoholic extract and maximum yield was found to be in UAE at 50: 1 for 20 and 30 min at 180 V. Tomato oil was isolated from dried tomato seeds obtained from tomato pomace. GC analysis was performed to study fatty acid profile.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Tomato (Solanum lycopersicon Mill.) is one of the most edible and nutritious vegetable. Lycopersicon esculentum L is a member of Solanaceae family with the production of 126 tons worldwide and it is a excellent source of primary and secondary metabolites which are necessary for human health such as vitamins, carbohydrate, fiber, and minerals with the enrichment of B-carotene, lycopene, flavonoids, phenolics and chlorophyll (Raiola et al. 2014; Bhuvaneswari and Nagini 2005; Elbadrawy and Sello 2016). Consumption of tomato is associated with the reduced risk of inflammatory processes, cancer, and chronic non communicable diseases (CNCD) including cardiovascular diseases (CVD), diabetes and obesity (Raiola et al. 2014; Rao and Agarwal 1999).

Tomatoes are principal carotenoid and red pigment in tomatoes and are industrial processed to obtain juice, ketchup, paste, dried or canned tomatoes and dried tomato powder. These products have high demand on global scale (Silva et al. 2019; Eh and Teoh 2012; Sadler et al. 1990). It is a protein food containing essential amino acids having emerging antioxidants properties (Bhuvaneswari and Nagini 2005; Vilkhu et al. 2008). Processing of tomatoes mainly has pomace as a main residue i.e. skin and seeds with a fraction of pulp. Tomato pomace has no industrial value hence it is decomposed landfill or act as animal feed. Silva et al. (2019), Zuorro et al. (2013). This decomposable feed contains nutrients and valuable phenol and several bioactive compounds such as carotenoids and particularly abundant source of lycopene (Bhuvaneswari and Nagini 2005).

Lycopene is C40 poly-isoprenoid, tetrapic hydrocarbon with 13 carbon double bonds and found to be efficient singlet oxygen quencher and responsible for bright red color in tomatoes whereas seeds are used as a source of vegetable oil (Cuccolini et al. 2013; Zuorro et al. 2013; Montesano et al. 2008). Tomato seed oil contains saturated fatty acids, mono-di-poly unsaturated fatty acid and antioxidants (Ezz et al. 2018). It is clearly stated a concern regarding safety towards environment and economy gain an interest towards green and reliable extraction techniques for byproducts from waste (Yi et al. 2009). Lycopene is extracted from tomato peels (Yi et al. 2009; Cuccolini et al. 2013; Kumcuoglu et al. 2014; Naviglio et al. 2008; MacHmudah et al. 2012; Choudhari and Ananthanarayan 2007; Rozzi et al. 2002) and health oriented tomato oil from tomato seeds (Giuffrè et al. 2017; Botineştean et al. 2014).

Montesano et al. (2008) extracts lycopene by innovative low-cost extraction method for high purity lycopene from tomato. The results shows 95% pure all trans lycopene detected by DAD HPLC with mass spectrometer. Sabio et al. (2003) also extracts the lycopene and b carotene content from tomato waste by using super critical extraction at 300 bar and 80 °C gives yield of 80 lycopene and 88% beta-carotene using 130 g of co2 per gram of matrix (Hassen et al. 2019) studied the effect of pre heating and different combinations on processing waste of tomato to study lycopene content. Hot bread, normal break and cold break method was treated to tomato paste. Naviglio et al. (2008) studied the extraction of lycopene by using high pressure extraction approach. The extract was characterized by UV-spectrophotometer, H-NMR, C-NMR and electrospray ionization mass spectroscopy.

The objective of the study is to determine the recovery of essential bioactive compounds especially lycopene from tomato waste peel by different extraction methods. COSE and UAE methods are used to obtain the lycopene rich alcoholic extract. Comparing yields with antioxidant activities for lycopene rich extract associated with variation in the time of treatment, solid liquid ratio and power. In addition, the effect of b-carotene content on the extraction’s conditions have also been studied. Tomato oil was obtained from dried tomato seeds with further determination of presence of fatty acid profile were also studied.

2 Material and Methods

2.1 Material

Tomato waste (seeds and peels) were brought from NOGA industry, MIDC Hingna, Nagpur, Maharashtra, India. Pomace was collected in plastic container immediately after being processed and transported to the laboratory. Seeds were removed from the pomace by rinsing with water multiple times at different interval. Peels were dried mostly by using hot air oven and were grinded by using grinder. Peel powder was stored in zip-lock plastic bags for longer storage. Hexane, ethanol, acetone, BHT, ascorbic acid, ethanol, gallic acid (3,4,5-trihydroxybenzoic acid), folic Cialteau reagent, Na2CO3 was obtained from Himedia limited, Mumbai, India. ABTS (2,2’-azinobis ((3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt), DPPH (2,2-diphenyl-1-picrylhydrazyl), were also obtained from HIMEDI, India.

2.2 Methods

2.2.1 Extraction of Lycopene and Oil from Tomato Waste

Conventional method of Lycopene extraction was carried out as mentioned in (Kumcuoglu et al. 2014). Solid liquid ratios of 1:10 (w/v) were taken. Mixture of hexane: ethanol: acetone was taken as a liquid containing 0.004% of BHT to minimize oxidation. The suspension was mixed and homogenized by using shaker at room temperature. By adding cold distilled water two liquids i.e., polar layer and non-polar layer are seen in separating funnel. Polar layer is used for the determination of lycopene and b-carotene. Ultrasonication was also used for the extraction of lycopene from tomato pomace. High intensity probe system ultrasonicator was used. Solid- liquid mixture was taken at different variations in the UAE process. Time and Power were also varied in the experiment (Jerman et al. 2010; Wang et al. 2008; Eller et al. 2010; Arabani et al. 2014).Tomato oil was extracted by Maceration method from dried powder of tomato seeds. Petroleum ether was used as a extracting media (Fig. 1).

2.2.2 Determination by UV Visible Spectroscopy

Determination of lycopene content was done as per procedure described in (Kumcuoglu et al. 2014). Polar and non-polar layer form after adding water in the mixture of solvent (hexane: acetone: ethanol). UV Spectro photometer was available at the department of food technology in LIT, RTMNU, Nagpur. Measurement of optical density at 503 nm in a spectrophotometer was recorded. Values were finally expressed as mg/kg fresh weight (fw). Beta carotene is present in polar layer in solvent mixture. It is a provitamin A and known for a strong antioxidant. Optical density at wavelengths 663, 645, 505, and 453 nm was measured by taking polar form and blank as solvent mixture (hexane: acetone: ethanol) in ratio 2:1:1. Content of beta-carotene is determined by using formula.

β-Carotene (mg 100/mL of extract) = 0.216 × A663 −1.22×A645 – 0.304 × A505+0.452 × A453.

2.2.3 Antioxidant Activity

Antioxidant capacity of industrial tomato pomace, alcoholic lycopene rich extract and tomato seeds was evaluated. DPPH (2,2-diphenyl-1-picrylhydrazyl), total phenol compound including soluble and insoluble-bound phenol compounds were determined. The antioxidant capacity is defined by the potential to donate electrons to normalize the DPPH radical. An aliquot of ethanol (50%) of sample was added to DPPH solution and absorbance was measured at 515 nm (Periago et al. 2002). The inhibition percentage was calculated of DPPH radical by equation given (Silva et al. 2019).

% Inhibition DPPH = (A control—A sample/A control) * 100

Total phenol content was determined according to the method of Durante et al. (2017) alcoholic extract were mixed with 50 μL of Folin-Ciocalteu’s phenol reagent and 450 μL distilled water. Further addition of 500 μL of 7% (w/v) Na2CO3 and make up to 1250 μL with distilled water. Mixture was then measured at 750 nm using a spectrophotometer after keeping the mixture at room temperature for 90 min. Gallic acid was taken as standard for calibration in between 0–12 μg GA/100 μL in 80% ethanol. The final values were expressed as gallic acid equivalent per gram of seeds (Shah and Thakur 2015; Sayeed and Thakur 2019; Sayeed and Thakur 2019; Singh et al. 2022).

2.2.4 Characteristics Properties of Tomato Oil

Free fatty acids, saponification value, acid value, peroxide values and iodine values were determined in tomato oil. Free fatty acids were measure by titration of oil by 0.1 N NaOH whereas PV (peroxide value) was measure by titrating oil with 0.01 N sodium thiosulfate solution. Oil was saponified with strong reflux by alcoholic KOH solution. Saponification value is the amount of alkali required for titration with HCL as a standard solution. Physio chemical analysis including iodine value was determined according the official method of AOAC 920.18 It is expresses as g i2/100 g oil. Fatty acid profile was determined as per the method given by (Durante et al. 2017). Procedure was performed on the Agilent 5977A Series GC. Temperature of the column was 50 °C after injection for nearly 1 min. Programming at 25 °C/min to 200 °C, at 3 °C/min to 230 °C for 23 min and then maintained for a constant temperature of 250 °C. Head pressure of the column sets to 40 psi for 0.4 min with constant pressure at 20 psi. Split ratio of 5:1 with flow rate of 1.0 ml/min was set. Carrier gas of pure helium was used spectrum data was collected at interval of 0.5 s whereas solvent cut time was set to 2 min with retention time of 40 min to separate fatty acids. A single tomato oil replication was performed.

2.2.5 Statistical Analysis

All analysis was performed in triplicate and is expressed as triplicate + standard deviation. For antioxidants activity, calibration curves of linear regression were obtained by graph pad prism software. ANOVA (one way analysis) was performed to mark the difference between the batches taken when significant differences were found. Statistical tests were performed by using graph pad prism software. Tukey test was performed at confidence level at 5% through r (pearson correlation coefficient) and to establish the difference between means (p < 0.05).

3 Results and Discussion

3.1 Extraction Efficiency of Ultrasonication and Conventional Extraction Method on Alcoholic Extract

Conventional organic solvent extraction (COSE) method and ultrasonication assisted extraction (UAE) was used for the extraction of alcoholic extract. Effect of different processing methods were studied on bioactive compounds rich alcoholic extract (Jerman et al. 2010). Liquid solvent Ratios of 10:1, 35:1 and 50:1 was taken with the extraction treatment of time of 10, 20, 30 and 40 min. Power variation in the ultrasound assisted extraction was also considered. UAE consist of high intensity probe that penetrates to the inner part of cell gives effective extraction and higher efficiency Whereas Conventionally, there is no heating of liquid hence less degradation of bioactive compounds (Kumcuoglu et al. 2014).

Traditionally more amounts of solvent and high extraction time are needed for greater efficiency hence Decreasing the solvent amount and extraction time enhances extraction yield which gives high quality of extracts which can be processed by new techniques such as ultrasound assisted, microwave assisted, pulsed electric field, high pressure process and supercritical extraction (Luengo et al. 2014; Rozzi et al. 2002; Naviglio et al. 2008). Though content of lycopene and B-carotene was measured using UV spectrophotometer at 472 nm shown in below Tables 1, 2 and 3.

The extraction efficiencies were determined by comparing the recovery yields of lycopene and β carotene content from tomato peel extracts. Extraction was performed by at room temperature with the highest efficiency of lycopene in UAE is for 15 min at 160 V for ratio 35:1 and b-carotene at 20 min (180 V) for solid liquid ratio of 50:1. In COSE, higher yield is to be seen for the extraction time of 30 min at 10:1 ratio of solid liquid (Table 1) (Wang et al. 2008).

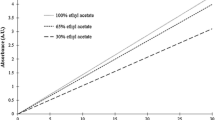

Fourier- Transform spectroscopy (FTIR) is nondestructive technique for analyzing and offers spectral bands. Spectr typical bands arise from amide and lipid groups strong and broad absorption bands of water are also shown. Intense bands of various carbohydrates and acids present in tomato enriched lycopene extract is represented (Fig. 2) (Raduly et al. 2011).

All the readings are taken in triplicate form and the values are expressed as average ± standard deviation of triplicate and the values followed by the same letter do not statically differ (P < 0.05).

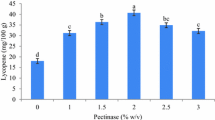

3.2 Effect of Liquid Solid Ratio on the Extraction of Alcoholic Extract

Different variations of solid liquid ratio were taken to determine the lycopene and B carotene content in the alcoholic extract obtained from COSE and UAE. In comparison, liquid–solid ratio of 35:1 yields better efficiency for lycopene content of 44.632 \(\pm\) 0.990 mg/kg and at ratio of 35:1 gives yield of 60.162 \(\pm\) 0.049 mg/kg for B carotene at 40 min. According to observations in the study as the amount of liquid increased the content of lycopene decreases. Dilution of solid into liquid gives rise to reduction of lycopene was observed (Wang et al. 2008).

In this study highest yield in UAE determines bioactive compounds including lycopene and b-carotene actively of 112.297 \(\pm\) 0.271 mg/kg at treatment of 160 V for 15 min and 0.683 \(\pm\) 0.031 mg/ml at 120 V for 35:1 duration for 15 min. Previous study undertaken by (Kunthakudee et al. 2020) extracts lycopene from tomato by using environmentally benign solvents with optimum conditions of solvent/ratio of 50:1 with extraction time of 45 min with temperature of 45 Degree C. Ethanol was used to increase the yield. Some readings are estimated as Nd that is not determined due to degradation of compounds. Factors responsible are like high temperature, low liquid for extraction or high power in UAE etc.

3.3 Effect of Variation in the Time of Treatment on the Extraction of Alcoholic Extract

COSE and UAE extractions were performed with different measuring parameters. Variations in the time of treatment of 10, 20, 30 and 40 min has been taken into considerations to study the effect of processes on the extract in terms of time (Nobre et al. 2012). Lycopene content was measured by using spectrophotometer in this ratio of COSE extraction, high amount of lycopene (68.410 \(\pm\) 0.275 mg/kg) was measured at 30 min of extraction for liquid solid ratio of 10:1. a pattern was observed in the liq-solid ratio of 35:1, in which extraction time of 40 min yields highest b carotene content of 60.162 \(\pm\) 0.049 mg/kg.

In this study In UAE, 15 min of time of treatment has been effective among all the time considered. 99.203 \(\pm\) 0.640 mg/kg 35:1 at 120 V, 112.297 \(\pm\) 0.271 mg/kg at 160 V for 50:1 yields highest amount of lycopene. More time of treatment degrades the lycopene content as it is sensitive to heat. Initially lycopene content was increased afterwards gradually decrement was observed in the lycopene content (Kumcuoglu et al. 2014). In the previous study of Eh and Teoh (2012) lycopene was extracted from tomatoes by Ultrasound extraction with enhanced efficiency of lycopene at 40 min at 40 °C and noted that enhancement of recovery is due to low temperature and extraction time.

3.4 Effect of UAE on the Extraction of Lycopene Enriched Alcoholic Extract

In ultrasound assisted extraction, three different powers were used for different extraction time and ratio (Jerman et al. 2010). At power of 120 V, for the liq-solid ratio of 35:1 for 10 min of treatment lycopene compound was not observed due to less extraction time. In the whole extraction of 120 V, in liquid-solvent ratio [35:1] extraction time of 40 min and in ratio of 50:1 at time of 30 min gives highest lycopene content. Turbidity was also observed which increasing with the extraction time whereas amount of polar layer decreases with extraction time and increase with the liquid solvent ratio. Power was increased to 160 V on the ultrasonicator to check the difference between the lycopene extracted by increasing the power. Same liq-solid ratio (35:1 & 50:1) was maintained with the same extraction time. At 35:1 ratio decreasing content of lycopene pattern was followed with increasing the extraction time. After 15 min of extraction 104.527 \(\pm\) 0.031 mg/kg of lycopene was determined. Here lycopene gets suddenly decreased due to the more dilution of solid with solvent; Kumcuoglu et al. (2014).

By increasing the extraction time for 30 min 102.320 \(\pm\) 0.302 mg/kg lycopene was obtained hence 30 min gives the highest yield. (Lianfu and Zelong 2008) compares ultrasound and microwave assisted extraction from tomatoes for lycopene extraction. Temperature of 56.4 °C and for 29.1 min at ratio of 8:1 was optimized to get highest lycopene of 89.4%. (Li et al. 2014) optimized the processing papaya waste for extraction of lycopene by using ultrasound extraction process with optimal conditions of 42.28% ethanol for time 26.09 min at 50.12 °C with maximum extraction of 189.8 ug/g fresh weight which was marked higher as compared to traditional process (153.9 ug/g).

3.5 Effect of DPPH Free Scavenging Radical Activity and Phenol Compounds in Bioactive Enriched Alcoholic Extract

Scavenging activity was studied to evaluate the stability of DPPH radical to determine antioxidant activity. The colorimetric technique is used to determine antioxidant activity using free radical. The absorbance is measured at 515 nm. The degree of discoloration specifies the activity of scavenging potential of antioxidant in the extract. DPPH radical activity of raw peel and lycopene has shown in the graph represented. Raw peel showed the antioxidant activity of 93.53 ± 3.6% where as in lycopene extract 98.70 ± 2.3%. All the extracts were prepared in ethanol. This indicates that peel has the lowest scavenging free radical activity than lycopene. It is associated that scavenging activity is related to alteration of hydroxyl groups in the aromatic ring of phenolics, thus emerging their denoting ability of hydrogen (Elbadrawy and Sello 2016; Periago et al. 2002). Insoluble and soluble phenolics compounds are determined by considering gallic acid as a standard. Phenolic compounds are majorly found in fruits and vegetables. It is one of the phytochemicals play a major role in physiological and morphological activities and contributes the sensory characteristics of plants. They have the vital role of antioxidants along with carotenoids and vitamins. Soluble and insoluble phenols have studied had represented graphically as shown Fig. 3.

Silva et al. (2019) characterized tomato processing byproduct for determination of antioxidant activity of DPPH, TEAC, FRAP and TPC. The phenol content was varied between 0.08 ± 0.18 and 22.75 ± 2.36 mg Gallic acid equivalent (GAE)0.100g1 of dry weight. (Periago et al. 2002) studied the phenol and antioxidant, lycopene content in different tomato species. (Nour et al. 2015) studied the incorporation of lycopene in bread and its antioxidant activity of phenolic content of 865.77 mg GAE/kg.

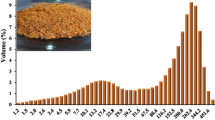

3.6 Effect of Extraction of Tomato Oil on the Fatty Acid Profile

Fatty acid profile was studied of tomato oil extracted by maceration method by using hexane represented in Fig. 4 and tabulated in Table 4. It is clearly stated that linoleic acid represents the major fatty acid with the percentage of 54.2% of all fatty acids followed by oleic acid (19.6), palmitic acid (14.6) and stearic acid (5.3). Elbadrawy and Sello, 2016) estimates the similar value extracted of lycopene peel oil. Saturated fatty acids were found in tomato seeds oil was 24.8% with maximum amount of polyunsaturated (54.59) fatty acids was observed. High level of omega 6 fatty acids were obtained in oil 54.59 which is essential fatty acids and protect from cardio vascular disease (Table 4) (Elbadrawy and Sello 2016; Botineştean et al. 2014). Zuorro et al. (2013) produced tomato seed oil by using enzymes with the production of 25 kg/ton oleoresin with lycopene of 6.8%. Arabani et al. (2014) studied the tomato extraction hot water using pre-treatments of using ultrasound and microwave extraction process from tomato seeds. GC analysis of fatty acids are determined with saponification and iodine value.

3.7 Effect of Antioxidant Activity on Isolated Tomato Oil

Tomato seeds recovered from industrial tomato waste after extraction of juice from fresh fruits for extraction of tomato seeds oil. Total phenols, soluble and insoluble phenols was studied as phenol compounds are present in both soluble and insoluble form exits in vacuoles and plant matrix respectively. In all assayed sample of tomato oil was measured spectrophotometrically for DPPH radical scavenging activity and total phenolic content is graphically represented (Figs. 5 and 6). Measurement was taken in three replicates (Durante et al. 2017). Giuffrè et al. (2017) worked on tomato seed to obtain edible oil. fatty acid methyl ester profile, free acidity, peroxide value, spectrophotometric characteristics, phenol content, and radical scavenging activity (DPPH) values were determined for edible tomato oil. Botineştean et al. (2014) determines the physiochemical properties of The FA composition of tomato seed edible oil, by gas chromatography results in linoleic acid (20.8–39.9 mg/mL), arachidic acid (0.08–0.4 mg/mL), palmitic acid (6.3–19.3 mg/mL), stearic acid (0.1–0.8 mg/mL), linolenic acid (0.7–4.9 mg/mL), palmitoleic acid (0.03–0.5 mg/mL), myristic acid (0.05–0.2 mg/mL) and oleic acid (2.5–14.2 mg/mL), margaric acid (0.02–0.11 mg/mL). The oil content of tomato seeds was registered in the range of 13.3–19.3%.

4 Conclusion

Lycopene was extracted from two different methods of COSE and UAE from tomato pomace by using solvent. From these two methods highest amount of lycopene was extracted in UAE at 160 V for ratio 50:1 for 15 min. High content of Beta carotene was found in UAE at 50: 1 for 20 and 30 min at 180 V. These readings showed the wise efficiency of UAE as compared to COSE. FTIR examines the purity of lycopene and quantifies its compounds. Antioxidant activity such as DPPH (2,2-diphenyl-1picrylhydrazyl) and total phenolic compound was performed. Lycopene shows the highest antiradical activity in comparable to tomato dried peel. Extracted lycopene can be incorporated at various food products for human consumption. Due to red dark bright colour and appearance of tomato oil was of great influence to eyes. Its antiradical activity determines its antioxidants potential. Peroxide value, acid value, iodine value, free fatty acids allows its edibility so can be further used for human consumption for the beneficial of human society.

References

Arabani AA, Hosseini F, Anarjan N (2014) Pre-processing and oil extraction from the seeds of tomato wastes using microwave and ultrasound treatments. J Appl Environ Biol Sci 4:125–130

Bhuvaneswari V, Nagini S (2005) Lycopene : a review of its potential as an anticancer agent 627–635

Botineştean C, Gruia AT, Jianu I (2014) Utilization of seeds from tomato processing wastes as raw material for oil production. J Mater CyclesWaste Manag 17:118–124. https://doi.org/10.1007/s10163-014-0231-4

Choudhari SM, Ananthanarayan L (2007) Enzyme aided extraction of lycopene from tomato tissues. Food Chem 102:77–81. https://doi.org/10.1016/j.Foodchem.2006.04.031

Cuccolini S, Aldini A, Visai L et al (2013) Environmentally friendly lycopene purification from tomato peel waste: Enzymatic assisted aqueous extraction. J Agric Food Chem 61:1646–1651. https://doi.org/10.1021/jf3027815

Durante M, Montefusco A, Marrese PP et al (2017) Seeds of pomegranate, tomato and grapes: an underestimated source of natural bioactive molecules and antioxidants from agri-food by-products. J Food Compos Anal 63:65–72. https://doi.org/10.1016/j.jfca.2017.07.026

Eh AL, Teoh S (2012) Ultrasonics Sonochemistry Novel modified ultrasonication technique for the extraction of lycopene from tomatoes. Ultrason Sonochemistry 19:151–159. https://doi.org/10.1016/j.ultsonch.2011.05.019

Elbadrawy E, Sello A (2016) Evaluation of nutritional value and antioxidant activity of tomato peel extracts. Arab J Chem 9:S1010–S1018. https://doi.org/10.1016/j.arabjc.2011.11.011

Eller FJ, Moser JK, Kenar JA et al (2010) Extraction and analysis of tomato seed oil. JAOCS J Am Oil Chem Soc 87:755–762. https://doi.org/10.1007/s11746-010-1563-4

Ezz MK, Ibrahim NK, Said MM et al (2018) The beneficial radioprotective effect of tomato seed oil against gamma radiation-induced damage in male rats. J Diet Suppl 15:923–938. https://doi.org/10.1080/19390211.2017.1406427

Giuffrè AM, Capocasale M, Zappia C (2017) Tomato seed oil for edible use: cold break, hot break, and harvest year effects. J Food Process Preserv 41:1–11. https://doi.org/10.1111/jfpp.13309

Hassen Y, Gebre H, Haile A (2019) Effects of pre-heating and concentration temperatures on physico-chemical quality of semi concentrated tomato (Solanum lycopersicum) Paste 10. https://doi.org/10.4172/2157-7110.1000795

Jerman T, Trebše P, Mozetič Vodopivec B (2010) Ultrasound-assisted solid liquid extraction (USLE) of olive fruit (Olea europaea) phenolic compounds. Food Chem 123:175–182. https://doi.org/10.1016/j.foodchem.2010.04.006

Kumcuoglu S, Yilmaz T, Tavman S (2014) Ultrasound assisted extraction of lycopene from tomato processing wastes. J Food Sci Technol 51:4102–4107. https://doi.org/10.1007/s13197-013-0926-x

Kunthakudee N, Sunsandee N, Chutvirasakul B et al (2020) Extraction of lycopene from tomato with environmentally benign solvents: box-Behnken design and optimization. Chem Eng Commun 207:574–583. https://doi.org/10.1080/00986445.2019.1610882

Li A, Li S, Xu D et al (2014) Optimization of ultrasound-assisted extraction of lycopene from papaya processing waste by response surface methodology. https://doi.org/10.1007/s12161-014-9955-y

Lianfu Z, Zelong L (2008) Optimization and comparison of ultrasound / microwave assisted extraction (UMAE) and ultrasonic assisted extraction (UAE) of lycopene from tomatoes 15:731–737. https://doi.org/10.1016/j.ultsonch.2007.12.001

Luengo E, Álvarez I, Raso J (2014) Improving carotenoid extraction from tomato waste by pulsed electric fields. Front Nutr 1:1–10. https://doi.org/10.3389/fnut.2014.00012

MacHmudah S, Zakaria WS et al (2012) Lycopene extraction from tomato peel by-product containing tomato seed using supercritical carbon dioxide. J Food Eng 108:290–296. https://doi.org/10.1016/j.jfoodeng.2011.08.012

Montesano D, Fallarino F, Cossignani L et al (2008) Innovative extraction procedure for obtaining high pure lycopene from tomato. Eur Food Res Technol 226:327–335. https://doi.org/10.1007/s00217-006-0541-4

Naviglio D, Caruso T, Iannece P et al (2008) Characterization of high purity lycopene from tomato wastes using a new pressurized extraction approach. J Agric Food Chem 56:6227–6231. https://doi.org/10.1021/jf703788c

Nobre BP, Gouveia L, Matos PGS et al (2012) Supercritical extraction of lycopene from tomato industrial wastes with ethane. Molecules 17:8397–8407. https://doi.org/10.3390/molecules17078397

Nour V, Ionica ME, Trandafir I (2015) Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste. J Food Sci Technol 52:8260–8267. https://doi.org/10.1007/s13197-015-1934-9

PA Silva Y, Borba BC, Pereira VA et al (2019) Characterization of tomato processing by-product for use as a potential functional food ingredient: nutritional composition, antioxidant activity and bioactive compounds. Int J Food Sci Nutr 70:150–160. https://doi.org/10.1080/09637486.2018.1489530

Periago MJ, Martínez-Valverde I, Chesson A (2002) Phenolic compounds, lycopene and antioxidant activity in commercial varieties of tomato (Lycopersicum esculentum). J Sci Food Agric 82:323–330. https://doi.org/10.1002/jsfa.1035

Raduly MF, Doncea SM, Ion R (2011) Lycopene determination in tomatoes by different spectral techniques (UV-.VIS, FTIR and HPLC). Dig J Nanomat Biostr 6(3):1349–1356

Raiola A, Rigano MM, Calafiore R et al (2014) Review article enhancing the health-promoting effects of tomato fruit for biofortified food

Rao AV, Agarwal S (1999) In the prevention of chronic diseases : a review. Science 80(19):305–323

Rozzi NL, Singh RK, Vierling RA et al (2002) Supercritical fluid extraction of lycopene from tomato processing by products. J Agric Food Chem 50:2638–2643. https://doi.org/10.1021/jf011001t

Sabio E, Lozano M, Montero De Espinosa V et al (2003) Lycopene and β-carotene extraction from tomato processing waste using supercritical CO2. Ind Eng Chem Res 42:6641–6646. https://doi.org/10.1021/ie0301233

Sadler G, Davis J, Dezman D (1990) Rapid extraction of lycopene and P-carotene from reconstituted tomato paste and pink grapefruit homogenates 55:1460–1461

Sayeed R, Thakur M (2019) Comparative studies on extraction methods of betalain content and anti-oxidant activity of biocolorant obtained from Celosia cristata L. flowers. Medicinal Plants: Intern J Phytomed Rel Indus 11(4):367–371

Shah R, Thakur M (2015) Qualitative phytochemical screening, total phenolic content, in-vitro antioxidant and antimicrobial activity in methanolic extracts of Cantharellus cibarius Fr. Plant Arc: Intern J 15(1):555–560

Singh V, Thakur M, Rai MK, Prakash (2022) Evaluation of in-vitro functional potential of developed synergistic Fe-Vit C rich powder for anemic adolescent girls. Indian J Agri Biochem 35(2):213–219. https://doi.org/10.5958/0974-4479.2022.00032.6

Vilkhu K, Mawson R, Simons L et al (2008) Applications and opportunities for ultrasound assisted extraction in the food industry-a review 9:161–169. https://doi.org/10.1016/j.ifset.2007.04.014

Wang J, Sun B, Cao Y et al (2008) Optimisation of ultrasound-assisted extraction of phenolic compounds from wheat bran. Food Chem 106:804–810. https://doi.org/10.1016/j.foodchem.2007.06.062

Yi C, Shi J, Xue SJ et al (2009) Effects of supercritical fluid extraction parameters on lycopene yield and antioxidant activity. Food Chem 113:1088–1094. https://doi.org/10.1016/j.foodchem.2008.08.083

Zuorro A, Lavecchia R, Medici F et al (2013) Enzyme-assisted production of tomato seed oil enriched with lycopene from tomato pomace. Food Bioprocess Technol 6:3499–3509. https://doi.org/10.1007/s11947-012-1003-6

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Admane, D. (2024). Effect of Ultrasonication on the Recovery of Essential Bioactive Compounds from Tomato Waste. In: Thakur, M. (eds) Sustainable Food Systems (Volume II). World Sustainability Series. Springer, Cham. https://doi.org/10.1007/978-3-031-46046-3_5

Download citation

DOI: https://doi.org/10.1007/978-3-031-46046-3_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46045-6

Online ISBN: 978-3-031-46046-3

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)