Abstract

Lycopene is a highly-prized antioxidant with associated health benefits and is abundant in natural sources. A green valorization approach was used to extract lycopene from tomato processing waste. Ultrasound-assisted extraction was applied to the tomato waste using an eco-friendly solvent mixture containing ethyl lactate and ethyl acetate for the extraction of lycopene. Extraction parameters were: X1 = extraction temperature (°C), X2 = proportion of ethyl acetate in solvent mixture (% v/v), X3 = solvent:sample ratio (mL/g), and X4 = extraction time (min). A Box–Behnken design was used to define experimental conditions, and response surface methodology was then conducted to determine the optimized conditions: X1 = 63.4 °C, X2 = 30% (v/v), X3 = 100 mL/g, and X4 = 20 min. The experimental optimized extraction yield of lycopene was 1334.8 µg/g (d.w.), in agreement with the predicted yield. At the same conditions without ultrasound, a yield of 1209.5 µg/g (d.w.) was obtained (9.4% lower). Ultrasound increases extraction yield, and tomato processing by-products are a viable alternative source of extractable lycopene. This represents a greener strategy for the extraction of lycopene in comparison to conventional methods using organic solvents, and shows a promising alternative use for a food processing waste.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of agricultural by-products as source material for the extraction of high value-added compounds has been heavily investigated in recent years [1, 2]. Due to their organic composition, these wastes represent alternative raw materials that could be exploited for the recovery of bioactive compounds that have positive effects on human health and also widespread technological applications, as coloring agents and antioxidants. Lycopene is an example of a high-value biomolecule that could be potentially recovered from food processing wastes, as a valorization approach to minimize the environmental impact of waste disposal and increase the sustainability of the overall process. Lycopene is a carotenoid and a valuable dietary antioxidant, with activity against diseases such as cancer and cardiovascular diseases [3,4,5]. It is widely used by various industries, as a dietary supplement for human nutrition, and as a natural colorant and antioxidant in products with high lipid content [6].

Lycopene is usually extracted from natural sources, especially red-coloured vegetables such as tomatoes [6], red pepper [7] and watermelon [8]. Synthetic routes for lycopene synthesis have been developed [9], but given the abundance of the compound in natural materials and the market preference for natural products, the extraction of the carotenoid from these sources is preferred. The major source of lycopene is tomato, due to its high lycopene content [3] and low cost compared to other lycopene-rich fruits and vegetables [6]. Many companies extract lycopene from tomatoes worldwide, and a high-lycopene tomato variety, containing around 150–250 mg/kg (fresh weight, f.w.), has been developed specifically to be used as source for lycopene extraction [10]. Commercial extraction of lycopene involves crushing the raw tomatoes to separate fibrous materials (such as skin and seeds) from the juice, then extracting the compound from the juice using an organic solvent. However, most of the lycopene in tomatoes (72–92%) is found in the skin fraction [11]. Therefore, tomato pomace, the by-product from industrial processing, can be considered a potential source of lycopene as it is mostly composed of skin and seeds.

The extraction of lycopene from vegetables requires the use of organic solvents, such as hexane, due to the hydrophobic nature of the compound. Hexane has advantages of low cost, good capacity for solubilizing lipophilic compounds, and low boiling point [12], and is considered as a food grade solvent by the FDA in residual concentrations of up to 25 ppm [13]. However, this solvent has a high environmental impact as it is obtained from petroleum [14], thus requiring safe handling and storage procedures. Alternative strategies can be developed using the principles of green chemistry to overcome the disadvantages associated with the use of organic solvents for extraction, where green chemistry promotes the reduction or elimination of hazardous materials and processes. Green solvents are alternatives to conventional organic solvents due to their low toxicity, high biodegradability, and sustainable production from non-petroleum sources. One example is ethyl acetate (ethyl ethanoate) (EA), an environmentally friendly organic solvent commonly used for extraction of lipophilic compounds [15]. Although overexposure to EA may cause health hazards such as skin irritation and unconsciousness, it is considered a low-toxicity solvent due to its rapid hydrolysis to ethanol and acetic acid during metabolism [16]. Its presence in food products is accepted in concentrations of up to 25 mg/kg, and it is even used as a flavouring agent due to its fruity aroma [17]. EA is considered a green alternative to hexane because it can be produced from bio-based ethanol, and is biodegradable in air and water [18]. The solvent has been used for extraction of lycopene from tomato, resulting in yields that are comparable to hexane extraction [19,20,21]. Another promising green solvent is ethyl lactate (ethyl 2-hydroxypropanoate) (EL), a non-corrosive, non-toxic (non-carcinogenic and non-teratogenic), non-ozone depleting, biodegradable, considered as generally recognized as safe (GRAS) solvent [22]. EL can be commercially obtained from lactic acid and ethanol, both of which can be obtained from fermentation processes [23]. Recently, EL has shown good potential for the extraction of carotenoids from tomato and other plant materials [24,25,26,27]. Therefore, both EA and EL represent promising green alternatives to hexane for carotenoid extraction.

The use of assisting technologies, such as the application of ultrasound, to improve the efficiency of solvent extraction from biological materials is another strategy for reducing the environmental impact of extraction, and has been widely studied in recent years [28, 29]. The increase of extraction yield observed in ultrasound-assisted processes has been associated with the acoustic cavitation phenomenon, in which ultrasound waves cause a violent collapse of gas bubbles present in the solvent [30]. Ultrasonication has been applied as assisting technology for the extraction of several bioactive compounds from food processing wastes, such as phenolic compounds from sunflower seed cake [31] and from apple peels [32], flavonoids from citrus peels [33], among many others. Also, it has been previously studied for the extraction of lycopene from tomato [21, 34] and tomato processing by-products [35,36,37]. However, to the best of our knowledge, no study has yet been published evaluating the ultrasound-assisted extraction of lycopene from tomato pomace using EL, nor its use combined with EA.

In this study, a three-fold strategy was applied to develop a greener alternative for lycopene extraction using (1) food by-products (i.e. tomato processing waste) as source material, (2) green solvents to replace conventional organic solvents, and (3) ultrasound to improve extraction yield. Although EL has shown good potential for the extraction of carotenoids from plant materials, this is the first report that combines these three approaches for extraction of lycopene from tomato-based material. Thus, the objective of this study was to establish optimal conditions for the ultrasound-assisted extraction (UAE) of lycopene from tomato pomace with a green solvent mixture of ethyl lactate and ethyl acetate. Extraction parameters investigated were temperature, proportion of ethyl acetate in solvent mixture, solvent:sample ratio and time. A Box–Behnken experimental design and response surface methodology (RSM) were used to optimize extraction conditions, which were experimentally verified, and compared to extraction without ultrasound.

Materials and Methods

Chemicals

Ethyl lactate (CAS 687-47-8) and ethyl acetate (CAS 141-78-6) were purchased from Sigma-Aldrich (Oakville, ON, Canada), and were of analytical grade. The lycopene standard (CAS 502-65-8) was purchased from Fisher Scientific (Ottawa, ON, Canada).

Plant Material

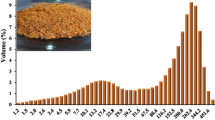

Tomato pomace was collected from a tomato processing plant located in the state of Goiás (Brazil), immediately after being produced. The moisture content of the fresh pomace was ~ 62.8%, and it was composed of 61.5% skin and 38.5% seeds. The sample was freeze-dried in a benchtop freeze dryer (Liotop L108, Liotop, São Carlos, Brazil) for ~ 16 h to a final moisture content of ~ 5.6%. The moisture content of samples was determined in vacuum oven (Lindberg Blue M, Thermo Scientific, Asheville, NC, USA) at 72 °C and 14 psi until constant weight (AOAC method 934.06) [38]. Freeze-dried samples were vacuum packed, transported to Halifax (NS, Canada), and kept at − 20 °C until further analysis. Immediately before extraction, samples were ground using a manual grinder (Smartgrind, Black and Decker, Mississauga, ON, Canada) and sieved through a 0.5-mm (32 mesh) sieve.

Box–Behnken Experimental Design

Optimization of UAE was performed using a Box–Behnken design (BBD) to determine the experimental points. The extraction parameters used in the experimental design were chosen based on results from other lycopene extraction studies [15, 21, 34, 39]. The parameters were X1 = extraction temperature (°C), X2 = proportion of ethyl acetate in the ethyl lactate–ethyl acetate solvent mixture (%, v/v), X3 = solvent:sample ratio (mL/g) and X4 = extraction time (min). The experimental design was established according to a BBD for four factors [40]. In this design, each variable (Xi) assumes three levels (ki), coded as − 1, 0, and + 1. Extreme high (ki = + 1) and low (ki = − 1) natural values of each parameter were defined based on preliminary studies, and the centre level (ki = 0) was then calculated as the median of the extremes. The natural (Xi) and coded (ki) levels used in the design for each variable are shown in Table 1.

The BBD matrix is presented in Table 2, with six centre points. To reduce possible effects of external variations, the experiments were conducted in randomized order as shown in Table 2. The six centre point runs (runs 25–30) were not randomized, but evenly interspersed among the other experimental points, since they provide a measure of process stability and allow estimating inherent variability of the process [41] and therefore must be regularly verified throughout the experiment.

Ultrasound-Assisted Extraction (UAE) of Lycopene

Preliminary analyses indicated that the proposed solvent mixture EL–EA could obtain 73% higher lycopene yield than a mixture of hexane and acetone, both at 1:1 (v/v) [42]; therefore, its use as solvent for the UAE was further evaluated. The UAE of lycopene from tomato pomace was conducted in an ultrasound water bath (Branson 2510R-DTH, Branson Ultrasonics Corp., Danbury, CT, USA), with fixed frequency (40 kHz) and power (100 W), with internal dimensions of 24 × 14 × 10 cm (L × W × D) and 2.8 L capacity, where a constant water level was used as well as the placement of samples in the bath. The solvent mixture was prepared immediately before use, and placed in water bath to achieve extraction temperature before being added to the sample. According to the experimental condition (Table 2), the appropriate amount of sample was added to 10 mL screw-capped glass tubes. Then, 5 mL of the solvent mixture were added, the tubes were vortexed for 10 s, and placed in the ultrasound bath. The extraction temperature was controlled within ± 1 °C of the set temperature with a calibrated thermometer and adjusted using hot and cold water as needed. At the end of the extraction time, the tubes were removed from the bath and centrifuged (Sorvall RT1, Thermo Scientific, Madison, WI, USA) at 2916×g for 10 min at 20 °C for separation of the pellet from the lycopene extract. The supernatant (extract) was then transferred to another tube for spectrophotometric analysis. Extraction was performed under reduced light to reduce carotenoid degradation.

Determination of the UAE Lycopene Yield

Lycopene Calibration Curves

A lycopene standard curve was determined for each solvent mixture with different EL:EA ratio, where spectrophotometric analyses were performed under dimmed light to reduce carotenoid degradation. A 500 µg/mL lycopene stock solution was prepared by dissolving pure lycopene standard in EA, which was kept at − 20 °C for up to 1 week for determination of the standard curve. The stock solution was diluted with the appropriate solvent mixture as needed to give concentrations varying from 5 to 30 µg/mL. Absorbance readings were performed immediately after dilution using a UV–Vis spectrophotometer (Genesys 10S UV–Vis, Thermo Scientific, Madison, WI, USA) in duplicate for each dilution. Wavelength scans from 350 to 550 nm were used to confirm the lycopene three-peak absorbance spectrum, which consisted of peaks at approximately 450, 470 (maximum), and 505 nm, with the specific wavelength varying according to the solvent used [4, 43]. The maximum absorbances (at approximately 470 nm, Table 3, Online Resource 1) for the lycopene solutions were used to construct standard curves for each solvent mixture, and linear regression equations were subsequently obtained by plotting absorbance against lycopene concentration (µg/mL), going through the origin. The regression equations obtained for each calibration curve are shown in Table 3, where L is lycopene concentration in µg/mL and Apeak is the absorbance value at wavelength of the absorption peak (λpeak). The standard equations (R2 > 0.99) were used to calculate lycopene concentration for each extract obtained from the BBD experimental conditions.

UAE Lycopene Yield

The lycopene extraction yield obtained from each treatment was determined according to Strati and Oreopoulou [25]. Since lycopene is the major carotenoid in tomatoes and tomato products [44, 45], lycopene standard curves have been used by other researchers for estimating the total carotenoid content in tomato products [39, 46]. The concentration of lycopene (µg/mL) in each extract was therefore determined using the peak absorbance in the UV–Vis spectra in relation to the appropriate standard curve (Table 3). Then, the lycopene extraction yield was calculated according to Eq. 1, where L is the concentration of lycopene in the extract calculated using the regression equations (µg/mL), V is the final volume of extract obtained (mL), w is the sample weight used for extraction (g), and m is the moisture of the sample. Results are expressed as µg of lycopene per g dry weight (d.w.).

Response Surface Analysis

RSM was used to optimize lycopene yield under the studied conditions, using Minitab® version 17.3.1 software (Minitab Inc., PA, USA). Responses were fitted to a second-degree polynomial equation, as shown in Eq. 2, where Y is the response variable (lycopene yield, µg/g), β0 is the constant (or model intercept); βi is the linear coefficient of each variable Xi; βii is the quadratic coefficient; βij is the cross-product coefficient of interaction between variables Xi and Xj; and Xi and Xj are the independent variables. Models were obtained for coded and natural factors, and analysis of variance (ANOVA) was performed on the full model to determine the significant variables affecting extraction yield (p < 0.05). The initial full quadratic model was refined by stepwise backward elimination of non-significant terms [47], using a significance level of 5%. ANOVA was used to evaluate the significance and goodness-of-fit of the final reduced model, which was used to predict lycopene yield (Ypred). Three-dimensional surface plots of lycopene yield versus each combination of 2 factors (with remaining two factors held at centre level, ki = 0) were used to illustrate the influence of the variables in the response.

Optimization, Model Validation and Comparison Without Ultrasound

The optimal extraction conditions for maximizing lycopene yield with UAE were determined from the final model using the response optimizer function in Minitab® (v. 17.3.1). Experiments were then performed in triplicate at the optimal extraction conditions to validate the model. In addition, results were compared with solvent extraction without ultrasound (SE) at the same optimal extraction conditions, to evaluate the effect of ultrasound on extraction yield.

Results and Discussion

Lycopene Standard Curves in Different Solvent Mixtures

The absorbance spectrum of a carotenoid is highly dependent on the solvent in which the compound is dissolved [43]. To allow the correct estimation of the carotenoid content of the extracts, standard curves of pure lycopene were obtained for each solvent mixture used in the extraction (Fig. 1). The increase in the amount of EA in the solvent mixture from 30 to 100% caused a hyperchromic effect in all concentrations used [48].

The position of the absorption peak (λmax) of carotenoids depends on several factors, such as the molecular environment in which the carotenoid molecule is inserted [4, 48]. For this reason, the same compound shows different absorption peaks for different solvents. Considering the three solvent mixtures evaluated, the increase in the amount of ethyl acetate in the solvent mixture caused a hypsochromic shift, that is, a displacement in the λmax to a shorter wavelength [48]. The λmax observed for lycopene in 100% EA (473 nm, as shown in Table 3) was the same [25] or within a ± 1 nm variation [49] from the values reported in other studies.

Lycopene Extraction Yield and Modeling

The lycopene yield at each experimental treatment is shown in Table 2. Experimental lycopene yield varied between 760.9 and 1264.5 µg/g. The centre point replicates ranged from 991.5 to 1189.0 µg/g. Besides providing a measure of process stability and variability, the centre points also provide an estimation of quadratic terms [41]. In this study, the centre points average was 1078.3 ± 77.7 µg/g, representing a coefficient of variation of 7.2%.

ANOVA testing was performed on the full quadratic polynomial model to determine the variables with significant effect on extraction yield (p < 0.05). The ANOVA results for the final reduced quadratic model are shown in Table 4. Although the linear terms X1 (p = 0.075) and X3 (p = 0.158) did not have a significant effect on extraction, both were included in the model for hierarchical purposes. The final reduced model was significant (p < 0.0001), indicating that the quadratic model fitted the observed experimental results well. Also, the lack-of-fit was not significant (p = 0.652), further suggesting that model goodness-of-fit is satisfactory [50].

The reduced models containing only significant terms are shown in Eqs. 3 and 4, using coded (ki, Eq. 3) and natural factors (Xi, Eq. 4). The regression model was also used to calculate the predicted yields for each treatment, thus allowing the comparison of the experimental yield with the corresponding predicted values (Table 2), which shows that the prediction error was below 10% for most of the treatments, indicating good adequacy of the predicted model. Equation 3 shows that the strongest effect on lycopene yield (largest coefficient) is due to the negative first-order effect of factor X2. Here, the proportion of EA in the solvent mixture is the factor influencing the extraction yield the most, and an increase in the proportion of EA causes a decrease in lycopene yield.

Factors X1 (temperature) and X2 (proportion of EA in solvent mixture) showed negative quadratic effects on lycopene yield. For temperature, while an initial increase will increase mass transfer rates and extraction yield, a further increase in temperature decreases lycopene yield. This is likely due to thermal degradation of lycopene at high temperatures [51, 52]. High extraction yields can be observed at higher temperatures due to several effects, including the decrease in surface tension and solvent viscosity, leading to improved sample wetting and matrix penetration; the increase in molecular motion of the solvent, leading to higher solubility; and the destruction of the plant matrix, increasing the availability of the target compound to the solvent [53, 54]. However, an upper temperature limit must be defined to avoid thermal degradation. In the present study, the higher temperature likely caused carotenoid degradation, since the optimal temperature was below the maximum of 70 °C.

The negative quadratic effect of EA proportion in the solvent mixture (X2) indicates that increasing the amount of EA beyond an optimal value causes a decrease in the lycopene yield, suggesting that EL is more efficient for extraction than EA. The extraction of carotenoids from tomatoes has been previously investigated using EA [19,20,21] or EL [24,25,26,27] individually, with yields comparable to or higher than hexane. Our results show that the mixture of EL with EA was effective for obtaining high lycopene extraction yield (between 760.9 and 1264.5 µg/g), and the highest yield was achieved with the lowest proportion of EA, indicating that EL is the major component responsible for the extraction efficiency.

The positive linear effect of solvent:sample ratio (X3) shows that an increase of this ratio (more solvent for a fixed amount of sample) could further increase the extraction yield. However, the maximum ratio would be limited by cost and environmental considerations for the amount of solvent used. Thus, the maximum amount of solvent recommended was fixed at 100 mL/g of sample, which is a reasonable level close to the maximum amount tested in other studies [34, 39].

Extraction time (X4) showed a negative linear effect, where higher lycopene yields were observed at lower extraction times. The decreased yield observed at higher extraction time could have been caused by the longer exposure of the bioactive compound to agents that cause carotenoid degradation, such as light and oxygen [49, 52]. Although the exposure to these agents was minimized during the experimental procedure, their presence could not have been completely excluded, similarly to the conditions that would be observed in a large-scale process. Therefore, it is possible that some level of thermal- and photo-degradation could have taken place when the extraction procedure was carried out for a longer period of time.

RSM Analysis and Optimization of UAE

RSM is a powerful tool for achieving high performance from processes at reduced costs. In this study, RSM was used to optimize the ultrasound-assisted extraction (UAE) of lycopene from tomato pomace. From the quadratic models obtained (Eqs. 3, 4), three-dimensional surface plots were constructed to illustrate the influence of the interaction of two factors at a time over the lycopene extraction yield. Figures 2 and 3 show the effect of the two significant interactions (interaction X1 × X4 and X3 × X4, respectively) over lycopene yield. For each set of two parameters shown in the plots, the other two were held at the centre value (ki = 0).

The interaction between time and temperature (X1 × X4) (Fig. 2) shows that high lycopene yields can be achieved with a combination of either high temperature for short time or low temperature for longer time. This could be related to the ability of the solvent to penetrate the plant cell to extract the target compound, as discussed previously. At higher temperatures, mass transfer processes are enhanced, thus less time is required to achieve a high yield, while at lower temperatures more time is required for the solvent to reach the cell interior. The sharp decrease in lycopene yield at low temperature and short extraction time observed in Fig. 2 indicates this insufficient access of the solvent to the plant matrix. Interestingly, a sharp decrease was also observed at the combination of high temperature and high extraction time levels. This could indicate degradation of lycopene due to prolonged exposure of the sample to the high temperatures, since exposure to heat is one of the main factors that can cause lycopene degradation [52].

Figure 3 illustrates the influence of the interaction between solvent:sample ratio and time (X3 × X4) on lycopene yield, with the highest yield obtained at high solvent:sample ratio and short extraction time. The relationship between solvent:sample ratio and time can be explained by the saturation of the solvent with the extracted compound. At higher ratios, more solvent is available to dilute the target compound, thus the mass transfer rates are maintained at high levels for longer [53]. As the highest yield is achieved with short extraction times, this suggests that the solvent penetrates the sample easily, quickly reaching the cell matrix and solubilizing the target compound.

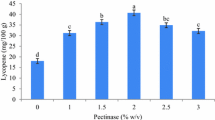

The optimal extraction conditions obtained from RSM analysis were X1 = 63.4 °C, X2 = 30% (v/v) EA, X3 = 100 mL/g solvent:sample, and X4 = 20 min (Table 5), with a predicted lycopene yield of 1343.9 µg/g. Validation studies were performed in triplicate under the optimal conditions to verify the predicted yield. The average experimental yield at the optimal extraction conditions was then 1334.8 µg/g, showing good agreement with predicted values (only 0.7% error). These results further validate the model, indicating good prediction capacity.

RSM has been used to optimize the UAE of lycopene from tomatoes and its by-products using different extraction conditions (Table 6). Lycopene extraction yield can vary considerably among different studies, depending on the raw material and the extraction conditions applied, as shown by a recent review [54]. When using UAE, extraction yields also depends on the ultrasound equipment characteristics, such as power, frequency, shape, and size [28, 36]. For example, Kumcuoglu et al. [37] optimized UAE of dried tomato processing waste and obtained an extraction yield of 90.1 mg/kg (0.09 mg/g), much lower than the yield from the present work (1.3 mg/g), using a solvent mixture of hexane/acetone/ethanol (2:1:1) containing 0.05% (w/v) BHT, at a lower solvent:sample ratio. In comparison, Eh and Teoh [34] obtained a lycopene yield of 5.11 mg/g from dried tomato pulp by UAE using hexane/acetane/ethanol (2:1:1), at a lower temperature and amount of solvent, for a longer extraction time (Table 6).

The optimized lycopene yield of 1.33 g/kg (d.w.) achieved in this study shows the effectiveness of a greener extraction process for obtaining a high value-added product from a widely available agro-industrial waste. The use of tomato pomace as raw material for lycopene extraction represents an efficient and environment-friendly use of a food waste, helping to reduce the environmental impact of food production [55]. In addition, the use of green solvents and ultrasound to improve the extraction yield also reduces environmental impact of extraction processes, which generally involve hazardous organic solvents and large energy inputs to achieve desirable yields [28]. Furthermore, with the use of GRAS solvents there is potential for creating further value from the solids remaining after lycopene extraction, and further work should be conducted to investigate the extraction of macronutrients (dietary fiber, proteins, or oils), which would provide greater use of the waste.

Comparison of UAE with Solvent Extraction Without Ultrasound

To evaluate the effect of ultrasound on lycopene yield of the optimized process, solvent extraction (SE) was performed under the same optimal extraction conditions, without ultrasound. A yield of 1209.5 µg/g (d.w.) was obtained, which was 9.4% lower than with UAE, showing that the applied ultrasound treatment promoted an increase in extraction yield, when the other extraction parameters were kept constant, contributing towards a greener method for lycopene extraction. Ultrasonication has been reported to promote an increase in extraction yield due to acoustic cavitation occurring in the solvent [30]. The corresponding collapse of the gas bubbles in the liquid results in several physical effects on the plant matrix, such as fragmentation, erosion, capillarity, detexturation, and sonoporation [56], facilitating the release of the target compound from the plant matrix to the solvent media. This increase in the mass transfer rates contributes towards a greener process by the reduction of the amount of solvent and energy required to achieve a desired extraction yield. In comparison to this study, Eh and Teoh [34] reported a higher increase of 27% on lycopene extraction yield with the use of ultrasound compared to SE without ultrasound. The difference in the degree of improved extraction observed in the present study could be due to ultrasound equipment characteristics and could also indicate a higher efficiency of the green solvent mixture for penetrating plant cells and reaching the target lycopene compound.

Conclusions

A green valorization approach was used for lycopene extraction from tomato processing waste, and optimized using RSM. Tomato pomace was used as the raw material, a novel and efficient green solvent mixture (EL and EA) provided an alternative to conventional organic solvents, and ultrasound was applied to improve extraction yield. The optimized extraction conditions (63.4 °C, 30% (v/v) EA in solvent mixture, 100 mL/g solvent:sample ratio, and 20 min), achieved a high lycopene yield of 1334.8 ± 83.9 µg/g in a relatively short time with a mild temperature. The yield without ultrasound at optimum conditions was 1209.5 µg/g which was 9.4% lower than with UAE, showing that the applied ultrasound treatment promoted an increase in extraction yield. This is the first study evaluating the ultrasound-assisted extraction of lycopene from tomato pomace using EL in combination with EA. These results indicate the effectiveness of the novel green solvent mixture proposed for lycopene extraction, and represent a more environmentally sustainable approach for lycopene extraction from tomato pomace and the valorization of industrial tomato processing waste.

References

Galanakis, C.M.: Recovery of high added-value components from food wastes: conventional, emerging technologies and commercialized applications. Trends Food Sci. Technol. 26, 68–87 (2012)

Mirabella, N., Castellani, V., Sala, S.: Current options for the valorization of food manufacturing waste: a review. J. Clean Prod. 65, 28–41 (2014)

Rao, A.V., Agarwal, S.: Role of lycopene as antioxidant carotenoid in the prevention of chronic diseases: a review. Nutr. Res. 19(2), 305–323 (1999)

Rodriguez-Amaya, D.B., Kimura, M.: Harvestplus Handbook for Carotenoid Analysis. HarvestPlus Technical Monograph 2. International Food Policy Research Institute (IFPRI) and International Center for Tropical Agriculture (CIAT), Washington, DC (2004)

Singh, P., Goyal, G.K.: Dietary lycopene: its properties and anticarcinogenic effects. Compr. Rev. Food Sci. Food Saf. 7, 255–270 (2008)

Ciriminna, R., Fidalgo, A., Meneguzzo, F., Ilharco, L.M., Pagliaro, M.: Lycopene: emerging production methods and applications of a valued carotenoid. ACS Sustain. Chem. Eng. 4(3), 643–650 (2016)

Arimboor, R., Natarajan, R.B., Menon, K.R., Chandrasekhar, L.P., Moorkoth, V.: Red pepper (Capsicum annuum) carotenoids as a source of natural food colors: analysis and stability—a review. J. Food Sci. Technol. 52(3), 1258–1271 (2015)

Celli, G.B., Teixeira, A.G., Duke, T.G., Brooks, M.S.: Encapsulation of lycopene from watermelon in calcium-alginate microparticles using an optimized inverse-gelation method. Int. J. Food Sci. Technol. 51, 1523–1529 (2016)

Shen, R., Jiang, X., Ye, W., Song, X., Liu, L., Lao, X., Wu, C.: A novel and practical synthetic route for the total synthesis of lycopene. Tetrahedron 67, 5610–5614 (2011)

Rath, S., Olempska-Beer, Z., Kuznesof, P.M.: Lycopene extract from tomato. Chemical and Technical Assessment (CTA). http://www.fao.org/fileadmin/templates/agns/pdf/jecfa/cta/71/lycopene_extract_from_tomato.pdf (2009). Accessed 28 Aug 2017

Sharma, S.K., Le Maguer, M.: Lycopene in tomatoes and tomato pulp fractions. Ital. J. Food Sci. 8(2), 107–113 (1996)

Wang, L., Weller, C.L.: Recent advances in extraction of nutraceuticals from plants. Trends Food Sci. Technol. 17, 300–312 (2006)

FDA (U.S. Food and Drug Administration): Food Additive Status List. U.S. Department of Health and Human Service, Silver Spring, MD. https://www.fda.gov/Food/IngredientsPackagingLabeling/FoodAdditivesIngredients/ucm091048.htm#ftnH (2018). Accessed 07 Apr 2018

ATSDR (Agency for Toxic Substances and Disease Registry): Toxicological profile for n-Hexane. U.S. Department of Health and Human Services, Public Health Service, Atlanta, GA. https://www.atsdr.cdc.gov/toxprofiles/tp113.pdf (1999). Accessed 21 June 2017

Strati, I.F., Oreopoulou, V.: Process optimisation for recovery of carotenoids from tomato waste. Food Chem. 129, 747–752 (2011)

Hartwig, A.: Ethyl acetate. In: The MAK-Collection for Occupational Health and Safety. Part I: MAK Value Documentations. pp. 167–176. Wiley, Hoboken (2012)

WHO (World Health Organization): Evaluations of the Joint FAO/WHO Expert Committee on Food Additives (JECFA). http://apps.who.int/food-additives-contaminants-jecfa-database/chemical.aspx?chemID=2357 (1996). Accessed 07 Apr 2018

Cascant, M.M., Breil, C., Garrigues, S., de la Guardia, M., Fabiano-Tixier, A.S., Chemat, F.: A green analytical chemistry approach for lipid extraction: computation methods in the selection of green solvents as alternative to hexane. Anal. Bioanal. Chem. 409, 3527–3539 (2017)

Calvo, M.M., Dado, D., Santa-Maria, G.: Influence of extraction with ethanol or ethyl acetate on the yield of lycopene, β-carotene, phytoene and phytofluene from tomato peel powder. Eur. Food Res. Technol. 224, 567–571 (2007)

Lavecchia, R., Zuorro, A.: Improved lycopene extraction from tomato peels using cell-wall degrading enzymes. Eur. Food Res. Technol. 228, 153–158 (2008)

Lianfu, Z., Zelong, L.: Optimization and comparison of ultrasound/microwave assisted extraction (UMAE) and ultrasonic assisted extraction (UAE) of lycopene from tomatoes. Ultrason. Sonochem. 15, 731–737 (2008)

Villanueva-Bermejo, D., Reglero, G., Fornari, T.: Recent advances in the processing of green tea biomolecules using ethyl lactate. A review. Trends Food Sci. Technol. 62, 1–12 (2017)

Pereira, C.S.M., Silva, V.M.T.M., Rodrigues, A.E.: Ethyl lactate as a solvent: properties, applications, and production processes—a review. Green Chem. 13, 2658–2671 (2011)

Ishida, B.K., Chapman, M.H.: Carotenoid extraction from plants using a novel, environmentally friendly solvent. J. Agric. Food Chem. 57, 1051–1059 (2009)

Strati, I.F., Oreopoulou, V.: Effect of extraction parameters on the carotenoid recovery from tomato waste. Int. J. Food Sci. Technol. 46, 23–29 (2011)

Strati, I.F., Gogou, E., Oreopoulou, V.: Enzyme and high pressure assisted extraction of carotenoids from tomato waste. Food Bioprod. Process. 94, 668–674 (2015)

Strati, I.F., Oreopoulou, V.: Recovery and isomerization of carotenoids from tomato processing by-products. Waste Biomass Valoriz. 7(4), 843–850 (2016)

Chemat, F., Rombaut, N., Sicaire, A., Meullemiestre, A., Fabiano-Tixier, A., Abert-Vian, M.: Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 34, 540–560 (2017)

Vilkhu, K., Mawson, R., Simons, L., Bates, D.: Applications and opportunities for ultrasound assisted extraction in the food industry—a review. Innov. Food Sci. Emerg. 9, 161–169 (2008)

Suslick, K.S.: Sonochemistry. Science 247(4949), 1439–1445 (1990)

Zardo, I., Sobczyk, A.E., Marczak, L.D.F., Sarkis, J.: Optimization of ultrasound assisted extraction of phenolic compounds from sunflower seed cake using response surface methodology. Waste Biomass Valoriz. (2017). https://doi.org/10.1007/s12649-017-0038-3

Deng, G., Xu, D., Li, S., Li, H.: Optimization of ultrasound-assisted extraction of natural antioxidants from sugar apple (Annona squamosa L.) peel using response surface methodology. Molecules 20, 448–459 (2015)

Londoño-Londoño, J., Lima, V.R., Lara, O., Gil, A., Pasa, T.B.C., Arango, G.J., Pineda, J.R.R.: Clean recovery of antioxidant flavonoids from citrus peel: optimizing an aqueous ultrasound-assisted extraction method. Food Chem. 119, 81–87 (2010)

Eh, A.L., Teoh, S.: Novel modified ultrasonication technique for the extraction of lycopene from tomatoes. Ultrason. Sonochem. 19, 151–159 (2012)

Ahmadi, M., Heidari, O., Nafchi, A.R.M.: Optimization of lycopene extraction from tomato waste with the integration of ultrasonic—enzymatic processes by response surface methodology. J. Ind. Eng. Res. 1(2), 29–34 (2015)

Konwarh, R., Pramanik, S., Kalita, D., Mahanta, C.L., Karak, N.: Ultrasonication—a complementary ‘green chemistry’ tool to biocatalysis: a laboratory-scale study of lycopene extraction. Ultrason. Sonochem. 19, 292–299 (2012)

Kumcuoglu, S., Yilmaz, T., Tavman, S.: Ultrasound assisted extraction of lycopene from tomato processing wastes. J. Food Sci. Technol. 51(12), 4102–4107 (2014)

AOAC (Association of Official Analytical Chemists): Method 934.06: Moisture in Dried Fruits. Official Methods of Analysis of the AOAC International, 18 edn. AOAC International, Gaithersburg (2005)

Kaur, D., Wani, A.A., Oberoi, D.P.S., Sogi, D.S.: Effect of extraction conditions on lycopene extractions from tomato processing waste skin using response surface methodology. Food Chem. 108, 711–718 (2008)

Box, G.E., Hunter, J.S., Hunter, W.G.: Statistics for Experimenters: Design, Innovation, and Discovery, 2 edn. Wiley, Hoboken (2005)

NIST/SEMATECH: NIST/SEMATECH e-Handbook of Statistical Methods. 5. Process Improvement. http://www.itl.nist.gov/div898/handbook/pri/pri.htm (2012). Accessed 05 Apr 2017

Silva, Y.P.A., Pereira, V.A., Brooks, M.S., Ferreira, T.A.P.C.: Effect of solvent on lycopene extraction yield from tomato pomace. Paper presented at the CSBE/SCGAB Annual General Meeting and Technical Conference joint with CIGR VI Technical Symposium, Winnipeg, Canada. http://www.csbe-scgab.ca/publications/meeting-papers/csbe-technical-conferences/8072 (2017). Accessed 25 Aug 2017

Zang, L., Sommerburg, O., Van Kuijk, F.J.G.M.: Absorbance changes of carotenoids in different solvents. Free Radic. Biol. Med. 23(7), 1086–1089 (1997)

Tonucci, L.H., Holden, J.M., Beecher, G.R., Khachik, F., Davis, C.S., Mulokozi, G.: Carotenoid content of thermally processed tomato-based food products. J. Agric. Food Chem. 43(3), 579–586 (1995)

Gama, J.T., Tadiotti, A.C., Sylos, C.M.: Comparison of carotenoid content in tomato, tomato pulp and ketchup by liquid chromatography. Aliment. Nutr. 17(4), 353–358 (2006)

Periago, M.J.S., Rincón, F., Agüera, M.D., Ros, G.: Mixture approach for optimizing lycopene extraction from tomato and tomato products. J. Agric. Food Chem. 52, 5796–5802 (2004)

Lundstedt, T., Seifert, E., Abramo, L., Thelin, B., Nyström, Å, Pettersen, J., Bergman, R.: Experimental design and optimization. Chemom. Intell. Lab. 42(1), 3–40 (1998)

Brittton, G.: UV/visible spectroscopy. In: Britton, G., Liaaen-Jensen, S., Pfander, H. (eds.) Carotenoids. Volume 1B: Spectroscopy, pp. 13–62. Birhäuser Verlag, Basel (1995)

Takehara, M., Nishimura, M., Kuwa, T., Inoue, Y., Kitamura, C., Kumagai, T., Honda, M.: Characterization and thermal isomerization of (all-E)lycopene. J. Agric. Food Chem. 62, 264–269 (2014)

Berger, P.D., Maurer, R.E., Celli, G.B.: Experimental Design with Applications in Management, Engineering, and the Sciences, 2 edn. Springer, Cham (2018)

Henry, L.K., Catignani, G.L., Schwartz, S.J.: Oxidative degradation kinetics of lycopene, lutein, and 9-cis and all-trans β-carotene. J. Am. Oil Chem. Soc. 75(7), 823–829 (1998)

Lee, M.T., Chen, B.H.: Stability of lycopene during heating and illumination in a model system. Food Chem. 78, 425–432 (2002)

Palma, M., Barbero, G.F., Piñero, Z., Liazid, A., Barroso, C.G., Rostagno, M.A., Prado, J.M., Meireles, M.A.A.: Extraction of natural products: principles and fundamental aspects. In: Rostagno, M. A., Prado, J. M. (eds.) Natural Product Extraction: Principles and Applications, pp. 58–88. The Royal Society of Chemistry, Cambridge (2013)

Strati, I.F., Oreopoulou, V.I.: Recovery of carotenoids from tomato processing by-products—a review. Food Res. Int. 65, 311–321 (2014)

Sala, S., Anton, A., McLaren, S.J., Notarnicola, B., Saouter, E., Sonesson, U.: In quest of reducing the environmental impacts of food production and consumption. J. Clean Prod. 140, 387–398 (2017)

Toma, M., Vinatoru, M., Paniwnyk, L., Mason, T.J.: Investigation of the effects of ultrasound on vegetal tissues during solvent extraction. Ultrason. Sonochem. 8(2), 137–142 (2001)

Acknowledgements

The authors would like to thank the processing company who provided the tomato pomace for this study and are grateful to Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Coordination for the Improvement of Higher Education Personnel) (CAPES—Brazil), the Department of Foreign Affairs, Trade and Development (DFATD—Canada), and the Natural Sciences and Engineering Research Council (NSERC—Canada) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Silva, Y.P.A., Ferreira, T.A.P.C., Celli, G.B. et al. Optimization of Lycopene Extraction from Tomato Processing Waste Using an Eco-Friendly Ethyl Lactate–Ethyl Acetate Solvent: A Green Valorization Approach. Waste Biomass Valor 10, 2851–2861 (2019). https://doi.org/10.1007/s12649-018-0317-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0317-7

) 100% ethyl acetate, (

) 100% ethyl acetate, ( ) 65% ethyl acetate–35% ethyl lactate, and (

) 65% ethyl acetate–35% ethyl lactate, and ( ) 30% ethyl acetate–70% ethyl lactate

) 30% ethyl acetate–70% ethyl lactate