Abstract

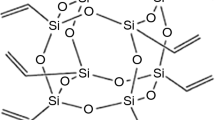

The use of polyhedral oligomeric silsesquioxanes (POSSs), as reinforcing agent for making polymer composites and nanocomposites, recorded an exponential grown in the last two decades. Differently to the other most used fillers POSSs are molecules, thus combining their nanosized cage structures that have dimensions comparable with those of most polymer segments and a particular and exclusive chemical composition. These characteristics linked with their hybrid (inorganic–organic) nature allow the researchers to obtain multifunctional materials with intermediate properties between those of organic polymers and ceramics. In this chapter, the most common POSS–polymer composites, namely epoxies, polypropylene, polystyrene, polylactide, polyimides and polyurethane, were analysed in their thermal behaviour.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Composite can be considered as the well-defined platform materials of the twenty-first century and represent today an important slice of the market in the production of modern plastics. The principle of their design is based on the adding of a second component to polymeric materials with the aim to enhance, primarily, thermal stability and/or mechanical strength. It is widely recognized in the literature that among composites, organic–inorganic hybrid materials offer advantageous performance relative to either of the non-hybrid counterparts. Many studies have shown dramatic improvement of physical properties, compared with pure materials, when inorganic particles or nanoparticles are inserted into an organic polymeric matrix. This behaviour, probably due to the interfacial interaction among nanoparticles and polymer segments, provides nanocomposites the potential to bridge the gap between ceramics and polymers [1]. In this context, the use of polyhedral oligomeric silsesquioxanes (POSSs) has grown exponentially in recent years. Differently to the other most used fillers POSSs are molecules, thus combining their nanosized cage structures that have dimensions comparable with those of most polymer segments and a particular and exclusive chemical composition. These characteristics linked with their hybrid (inorganic–organic) nature allow the researchers to incorporate POSS reagents into polymer chains and modify the local polymeric structure and chain mobility, thus obtaining multifunctional materials with intermediate properties between those of organic polymers and ceramics [2, 3]. In the last 25 years, there was an increasing interest in the use of POSSs as building blocks for inorganic–organic hybrid materials, in which the incorporated organic moiety is expected to ensure compatibility with the matrix whilst the inorganic one to contribute to the improving of properties, such as thermal stability, abrasion and oxidation resistance, reduction of polymer flammability [4,5,6,7]. The incorporation of inorganic building blocks into organic polymers, to improve its properties, continues to be a driven force for the development of new materials and one of the other reasons of choice POSS for this purpose is that are typically stable up to 300 °C, which is higher than the thermal degradation temperatures of most organic molecules [8,9,10]. Besides high-temperature stability, POSS nanoparticles, unlike other fillers such as organoclay, offer also other advantages like mono-dispersibility, low density and non-presence of trace metals [1]. The preferred method for introducing POSS cages into polymer systems is via copolymerization, which is an efficient approach to POSS-containing nanocomposites due to the formation of chemical bonds between POSS and polymer matrices [11]. Copolymerization is generally preferred to the nanocomposite preparations via physical blending, due to possibly unfavourable miscibility (or solubility) of POSS within the polymers, anyway following the functionalization of the organic vertices of the cage (e.g. alkyl, alkylene, acrylate, hydroxyl or epoxide groups), POSS molecules acquire good solubility, compatibility and reactivity with other materials compared to inorganic silica nanoparticle [12]. In fact, the typical POSS monomers are characterized by a cubic structure with eight organic corner groups, one or more of which reactive or polymerizable, thus leading to an easily functionalization of organic periphery with facile tuning of the silsesquioxane properties [13, 14]. As far as we have written above, in most cases the functionalized POSSs are covalently bound to the matrix, leading to reinforcement of the system on molecular level. Therefore, a correct balance of POSS–POSS and POSS–polymer interactions is the key factor for the resulting improved thermal performance. The increase in functionality of nanoparticles leads to steric restrictions around the forming POSS junction, thus reducing the degree of POSS aggregation. On the contrary, strong aggregation and crystallization can occur in the case of POSS pendant on the polymer chain [15]. Furthermore, it is possible to obtain copolymers, where POSS becomes part of the polymer chemical structure, by the insertion of polymerizable substituents on the cages. Reactive functional groups can also bond POSS to resin molecules, which subsequently cure into thermoset matrices. However, in both of these situations, tiny POSS domains often form as nanoparticles undergo self-aggregation in competition with both chemical bonding and molecular dispersion in the matrix [16]. The tendency to aggregation is not only determined by the POSS compatibility with the polymer matrix, which depend by the organic substituents, but also by the symmetry/asymmetry of POSSs molecules [17, 18]. In other words, the favourable combination of properties between POSS and polymers requires the optimum dispersion of POSSs in polymeric matrix, which can be set by controlling type and reactivity of organic groups in POSS cubes [11]. Thermal stability is an important characteristic of POSS compounds, which improves the thermal properties of the resultant polymer nanocomposites and hybrids, and different thermal analysis methods are used to investigate the thermal degradation of POSS-based materials. With the term thermal analysis (TA), we mean the whole of various measuring techniques that share a common feature: the measure of the material response when heated or cooled (or, in some cases, held isothermally). TA goal is to establish a connection between temperature and specific physical properties of materials [19]. The most popular techniques are reported in Table 1 where they are classified by the physical property measured.

TA, that is recognized as one of the most important research and quality control methods in the development and manufacture of polymeric materials, is used not only for measuring the actual physical properties of materials but also for clarifying their thermal and mechanical histories, for characterizing and designing processes used in their manufacture and for estimating their lifetimes. The most employed parameters to test the thermal performance of POSS–polymer composites are undoubtedly the onset decomposition temperature or initial decomposition temperature (Ti) and the temperature at 5% mass loss (T5%). Generally, this latter is considered more reliable than initial decomposition temperature, because, especially when more than one stages of degradation are detected, Ti largely depends on the slope of the descending piece of thermogravimetric (TG) curve. In order to establish the mechanism of degradation and to make prevision on the materials lifetime, kinetics studies are carried out and the obtained kinetic parameters allow to the researcher to make their hypothesis. Among these, the degradation activation energy (Ea) is the most used. The molecular level reinforcement provided by the POSS cages can significantly retard the physical aging process in the glassy state, thus another important parameters used in the material thermal characterization is the glass transition temperature (Tg), determined both with Differential Scanning Calorimetry (DSC) and Differential Thermal Analysis (DTA) and Dynamic mechanical analysis (DMA).

2 Epoxies–POSSs Composites

Among the various classes of polymers, epoxies consolidated their position as one of the most versatile ones. They are employed in different applications, such as metal coatings, automotive primer, printed circuit boards, semiconductor encapsulants, adhesives and aerospace composites. Therefore, based on their commercial applications, they can be categorized for non-structural or low-temperature applications and structural or high-temperature applications [20, 21]. Because of problems in their engineering applications like low stiffness and strength, and in processing due to the exothermic heat generated by their curing, the use of additives in their formulation has always been widely exploited [22, 23]. Silicon compounds are widely added in epoxy, resulting in high flame-retardant efficiency and good thermal stability [24, 25], among them the incorporation of POSS nanoparticles into epoxy resins has been shown to improve their thermomechanical properties.

At first, Laine and his collaborators by comparing the behaviour of nanocomposite epoxy resins based on octaglycidyl (OG) and octaethylcyclohexenyl epoxide (OC) cubic silsesquioxanes with a common organic epoxy resin—diglycidyl ether of bisphenol A (DGEBA) with diaminodiphenyl methane (DDM)—showed that small changes in organic nanoarchitecture can be important in changing or manipulating nanocomposite properties [26].

The thermomechanical properties of various formulation ratios of organic–inorganic hybrid composites (OG/DDM) have been reported by Choi et al., showing that OG/DDM composites offer better thermal stability than the standard DGEBA/DDM system [27]. Contrary to the thermal stabilities of pure DGEBA and OG, the 5% mass loss temperatures for these composites are almost identical at about 340 °C, and this was expected since that the organic tethers determine the thermal stability. However, the half decomposition temperature for OG/DDM composites is higher than that of DGEBA/DDM by ~50 °C and the char residue, in inert environment, for OG/DDM (~40%) is also higher than DGEBA/DDM (17%) as expected because of the high silica content. This difference in half decomposition temperatures was considered significant by Choi and his collaborators, because it may be construed as an effect of creating a nanocomposite. The doubt, instilled by the same authors, is that, in the nanocomposites, tether thermal motion is restricted thereby reducing the organic decomposition pathways accessible to the tether. It is likely that the inorganic component provides additional heat capacity, thereby stabilizing the bulk material against thermal decomposition except at surfaces where the decomposition would be expected to start. Moreover, they argued that the somewhat lower than expected char yield in air may be ascribed to volatilization.

Lee and Lichtenhan [28] studied the thermal behaviour of DGEBA incorporated with mono-functional epoxy-substituted POSS–Jeffamine D230 (diamine-terminated polypropylene oxide) curing agent (Fig. 1).

Reprinted from [28], © 1998 with permission from ACS Publications

Curing cycle of the POSS–epoxy system.

An increase of the glass transition temperature (Tg) as a function of the weight fraction of the mono-functional POSS–epoxy was observed. In addition, they also examined the viscoelastic response, at temperatures below Tg, correlating it to a stretched exponential relaxation function. The instantaneous modulus was not observed to be affected by incorporation of the POSS nanoparticles, on considering that time—aging time-superposition were found to be applicable to the data under all test conditions used. This finding suggested to the two authors that whilst POSS cages influence polymer chain motions, including the motion of the molecular junctions, they did not participate in the overall deformation of the chains. Finally, experiments performed under the same thermodynamic states revealed that the molecular-level reinforcement provided by the POSS cages also retarded the physical ageing process in the glassy state. Allowing the two scientists to conclude that the time required to reach a structural equilibrium was dependent to the POSS reinforcement level in epoxy and anyway was longer than for those of the neat resins.

Li et al. studied aliphatic epoxy composites with multifunctional polyhedral oligomeric silsesquioxane (POSS) (Fig. 2), (C6H5CHCHO)4(Si8O12)(CHCHC6H5)4 nanophases (epoxy/POSS 95/5 and 75/25) and epoxy blends with the pre-polymer of ladderlike polyphenylsilsesquioxane (PPSQ) (95/5, 90/10 and 85/15) by dynamic mechanical thermal analysis (DMTA) [29]. They obtained a good dispersion of POSS units in epoxy matrix, even at a nanoparticles weight per cent of 25%.

Reprinted from [29], © 2001 with permission from ACS Publications

Structures of the two POSS monomers and PPSQ pre-polymer.

This molecular dispersion is a result of:

-

the mixture of two different corner substituents which enhances the POSS derivative’s solubility;

-

the ability of epoxy groups to chemically bond to the epoxy resin’s matrix as it cures;

-

the low tendency for POSS molecules to aggregate when they are originally well dispersed [30].

Therefore confirming how important it is to determine the right balance quantity/dispersion of POSSs in the matrix. Li and co-workers found a good miscibility, among PPSQ and the aliphatic epoxy resin, only at low PPSQ content (≤10 wt%), whilst they observed phase separation starting from 15% of PPSQ. They observed an increase in the cross-linking density due to the high-temperature curing (150 °C) that enhanced cross-linking reactions among residual epoxy functions of the POSS macromer and amine groups, thereby increasing the Tg and the storage moduli (E′) values of the formulation with 75% of epoxy and 25% of POSS. In conclusion, the incorporation of the nanoparticles into the epoxy network broadens the glass transition region but had almost no influence on the Tg values that slightly increased for epoxy/PPSQ blends at ≤10 wt% of POSS. On increasing the POSS content in the epoxy matrix, the Tg value decreased in respect to that of neat epoxy probably due to hindrance of epoxy resin cross-linking caused by hard PPSQ-rich particles resulting from phase separation. Nevertheless, the inclusion of PPSQ into epoxy had no effect on the width of the glass transition region of these blends. E′ values of epoxy/POSS composites and epoxy/PPSQ blends at T > Tg were higher than those of neat epoxy. Therefore, thermal dimensional stability of epoxy was increased either by the incorporation of POSS or by the inclusion of PPSQ.

Schwab et al. demonstrated the possibility to convert POSS α-olefins into POSS α-epoxides by the means of the reaction of POSS α-olefins with m-chloroperbenzoic acid (MCPBA) [31]. They studied the reactivity of these epoxides in self-polymerization and in reaction with amines and thermally characterized the POSS epoxides. In particular, examined by differential scanning calorimetry (DSC), [(c-C6H11)7Si8O12CH2CHCH2O], [(c-C5H9)7Si8O12(CH2)6CHCH2O] and [(c-C6H11)7Si8O12(CH2)6CHCH2O] did prove to be reactive in that each of the compounds was observed to undergo an exothermic self-polymerization at a temperature (~250 °C) below the initial decomposition ones (370 °C). Furthermore, in reaction with curative aromatic amines (Shell Epolite 2330), the compounds showed irreversible exothermic transitions near 140 °C. Thermogravimetric analysis (TGA) showed, for these epoxy-POSS system, decomposition temperature ranging from 370 to 400 °C with char yield 10–30%.

Driven by the fact that the reduction of viscosity through the use of POSS-modified epoxies offers significant opportunities for low-cost processing techniques such as vacuum-assisted resin transfer moulding (RTM), the thermomechanical properties of octafunctional cubic silsesquioxane modified epoxy resins associated with dicycloaliphatic hardener were studied by He et al. using TGA, DSC and DMA [32]. Systems of octa(dimethylsiloxy butyl) (OB) epoxide at different ratios of OB/hardener were degraded, showing higher decomposition temperature than the standard Ciba epoxy resin which was ascribed, also in this case, to the POSSs dispersion and the formation of tether structure cage–epoxy matrix. The increase in thermal stability was also confirmed by a higher char yields, in fact they claimed that it is likely that the octafunctional silsesquioxane core preserves the cage structure thus contributing to improve oxidation resistance. He and co-workers observed that the Tg values at low POSS content were similar to that of the standard Ciba epoxy resin and attributed this behaviour to the reduction of overall segmental motion. Whilst at higher OB loading (20 mol% OB), they observed Tg disappearance which suggested them that the segmental motion was prohibited by the presence of the rigid silsesquioxane cage and very high cross-linking density. The papers placed under observation have so far highlighted that the presence of the POSS cages in the epoxy matrix, in the same conditions, significantly slows down the ageing process in the glassy state. However, compounds at high POSS content [29] exhibited a lower Tg which has been ascribed to the possible incomplete curing reaction of epoxy due to the inclusion of the POSS cages.

Williams et al. [33] observed a primary liquid–liquid phase separation occurred at the time of adding the diepoxide to the POSS–diamine precursor due to their incompatibility.

Choi and Laine investigated the modifications of epoxy resin by the inclusion of a series of polyfunctional silsesquioxanes with various R groups (aminophenyl and dimethylsiloxypropylglycidyl ether) [34,35,36,37]. The thermal stability of the epoxy hybrids was addressed in terms of the types of the used organic groups, tether structures between epoxy matrices and POSS cages and the defects in silsesquioxane cages. Again, in this series of studies, the authors correlated the favourable combination of properties between POSS and polymers with the dispersion of the nanoparticles. In particular, they demonstrated the possibility to increase the level of POSS dispersion in the matrix by controlling type and reactivity of R groups in silica cages, thus improving the thermal performance of the epoxy-based composites.

Zheng and collaborators continued to evaluate the effect of the type and reactivity of organic groups in POSS cages on phase behaviour and properties of the resulting epoxy hybrids [38]. With the aim to improve the miscibility of POSSs within the diglycidyl ether of bisphenol A (DGEBA), they explored the modification of the phenyl groups attached to the silicon cage by nitration and the resultant effects on the nanoparticles dispersion. It was observed that the replacement of phenyl groups with nitro-phenyl ones enhanced the miscibility, thus leading to a different morphology of the resulting epoxy/POSS hybrids. The Tg values of the obtained composites decreased with increasing POSS content as a result of the increase in total free volume, due to the inclusion of a part of bulky POSS cages at the nanoscale level. They proposed that two competitive factors determine the glass transition temperatures of resulting composites: the hindering effect of POSS cages on polymer chain motions will enhance glass transition temperature, whilst the inclusion of the bulky POSS group could give rise to the increase in free volume of the system, which will result in the decreased Tg. This effect could be comparable to plasticization effect of low-molecular-weight compounds on polymer matrix [27]. Zheng also evaluated the resistance to the thermal degradation; increased initial decomposition temperature (Ti) values and a two-step degradation mechanism were found, suggesting that the presence of POSSs did not significantly alter the degradation mechanism of the epoxy matrix. According to the literature evidence [39, 40], they proposed that mass loss from segmental decomposition via gaseous fragments could be suppressed by well-dispersed POSS cubes at the molecular level. Therefore, the improved thermal stability of epoxy/octaaminophenyl POSS (OapPOSS) vs epoxy/octanitrophenyl POSS (OnpPOSS) could be a result of the combined effects of the formation of aromatic tether structure between epoxy matrix and POSS cages and the dispersion, at nanoscale, of POSS cages in epoxy matrix. Following the peripheral groups setting pathway, they compared the thermal behaviour of OapPOSS-containing nanocomposites with the above-cited OnpPOSS–epoxy system, by founding an increased thermal stability for this latter, thus reaffirming the importance of the nanoscaled dispersion of POSS in epoxy matrices as important factor to contribute the enhanced thermal stability. In OnpPOSS-containing composites, there were no chemical bonds between the matrix and the POSS cages and the heterogeneous morphology was formed via phase separation induced by polymerization. However, in OapPOSS-containing system, the POSS cages participated in the formation of the cross-linked network, i.e. the POSS cages were tethered onto polymer matrix.

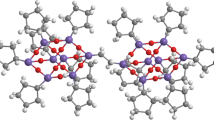

The close link between POSSs dispersion and the degree of functionalization of their organic groups has been confirmed by the studies of Matejka et al. by studying epoxy networks, based on DGEBA and poly-(oxypropylene)diamine (Jeffamine D2000) reinforced with pendant aromatic- and aliphatic-substituted POSS [15]. Improvements of nanoparticles on increasing POSS functionality were observed: in the systems with low-functional POSS cross-links or the POSS units in the backbone, the nanoparticles’ dispersion was poor and small amounts of POSS aggregates remained in the network. The aggregation resulted in a possible lower epoxy conversion, lower cross-linking density and deviations from the mean-field statistical theory of network formation [41]. They found that only a very high POSS content results in some immobilization of network chains and therefore the Tg of a majority of systems was not affected (only in a few cases a broadening of the transition was observed). POSS with flexible substituents behaved like a diluent and decreased the network Tg. The only system they possess a strong interactions between POSS and organic chains was the POSS-DGEBA,olig-D2000 network (Fig. 3).

Reprinted from [15], © 2004 with permission from ACS Publications

Structures of the POSS-DGEBA,mon and POSS-DGEBA,olig.

Matejka and co-workers observed a strong increase in Tg by 50 °C due to both POSS–chain interactions and the presence of long stiff oligomer sequences involving several POSS units. Thermal stability of these networks increases with POSS content depending on an extent of protection of organic chains by inorganic structures and also in this case the system showed highest thermal stability was the POSS-DGEBA,olig-D2000 one.

A POSS–epoxy system based on Octakis (dimethylsilyloxypropylglycidylether) silsesquioxane (OG) and meta-phenylenediamine (mPDA) was synthesized and characterized by Chang et al. [42]. The activation energy, based on both Kissinger [43] and Flynn–Wall–Ozawa [44, 45] methods, in curing OG/mPDA system was higher than that of the classic DGEBA/mPDA system as well as the Tg. This increase was explained with the POSS cages capability in hindering the motion of the network junctions. High values of the temperature at the maximum rate of mass loss (Tm) and high char yield were measured for the cured OG/mPDA system, despite a large fraction of unreacted amine groups give raise to low Ti due to their tendency to decompose or volatilize on heating at relatively low temperature.

After their first study on the use of POSS in epoxy matrices, Zheng and his collaborators synthesized an octaammonium chloride salt of octaaminopropyl polyhedral oligomeric silsesquioxane (OapPOSS) to be used as intercalating agent for sodium montmorillonite (MMT) modifying [46]. POSS-intercalated MMT system is shown in Fig. 4. The presence of POSS nanoparticles leads to an expansion of the MMT galleries from 1.3 to 1.7 nm and exploited to prepare epoxy–MMT nanocomposites. No modification in Tg value was observed in respect to the neat epoxy when the POSS–MMT content was less than 10 wt%, whilst a slightly decrease of Tg value was recorded by increasing the POSS–MMT content up to 15 wt%, which was attributed to the incomplete curing reaction resulting from the POSS–MMT loading. Furthermore, an improvement in the thermal stability was evaluated by performing thermogravimetric analysis, which showing an increase of the char residue as a function of the POSS–MMT concentration.

Reprinted from [46], © 2005 with permission from Elsevier

Formation of epoxy–MMT nanocomposites mediated by ammonium of OapPOSS.

The structure and properties of organic–inorganic hybrid nanocomposites prepared from a resole phenolic resin and a POSS-mixture-containing trisilanolphenyl POSS were investigated by Pittman et al. [16]. Nanocomposites with POSS, ranging from 1.0 to 10 wt%, heterogeneously dispersed in both cured matrix and dispersed phase domains were thermal characterized by the means of DSC and TGA. The hydrogen bonding between the phenolic resin and POSS Si–OH groups increased their mutual compatibility, but did not prevent POSS aggregation and phase separation during curing, thus resulting in a slightly increase in the temperature at 5% mass loss (T5%), whilst Tg remained practically constant [16].

Jones and collaborators prepared an epoxy/POSS system based on commercial products (SC-15 epoxy from Applied Poleramic Inc.; Epoxy Cyclohexyl POSS from Hybrid Plastics.). A low-viscosity, two-phased, toughened epoxy resin system consisting of part A (resin mixture of diglycidylether of bisphenol A, aliphatic diglycidlether epoxy toughener) and part B (hardener mixture of cycloaliphatic amine and polyoxylalkylamine) was prepared, showing that the addition of 5 wt% of POSS yielded a considerable increase of 16 °C in Tg but a modest enhancement of 10 °C in Tm. They found that the thermal performance of epoxy is increased with the POSS content, attributing this behaviour to the rigidity of the nanoparticles that would increase the rigidity of the whole epoxy system [47].

Higher Tg than neat epoxy resin was found also by Hu et al. that studied a series of epoxy resin/POSS prepared based on octavinyl polyhedral oligomeric silsesquioxane (OVPOSS) and phosphorus-containing epoxy resin (PCEP synthesized via the reaction between bisphenol A epoxy resin, DGEBA, and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, DOPO) [48]. Their thermogravimetric study evidenced a one-stage degradation process for both OVPOSS–PCEP and PECP and an increase in the temperature at 50% mass loss (T50%) for the hybrid material prepared. Hu and co-workers hypothesized the formation, in inert environment, of a ceramic-like layer that can prevent the inner part of the hybrid from further degradation, and, in air atmosphere, the oxidation of OVPOSS to a silicon dioxide layer that can improve the thermo-oxidation resistance of the EP matrix. Furthermore, they attributed the increase of char yield with the OVPOSS content to the synergistic effect of phosphorus and silicon, where phosphorus-enriched char formation and silicon protected the char from thermal degradation.

Epoxy resin nanocomposites, based on DGEBA and tetraglycidyl diamino diphenyl methane (TGDDM), were prepared by Alagar and his collaborator via in situ copolymerization with 4,40-diaminodiphenylsulphone (DDS) in the presence of octaaminophenyl silsesquioxane (OAPS) up to 20 wt% [49]. Their DSC and DMA results showed an increase in Tg, compared with control epoxy systems, only for the composites at 3 wt% due to the increase of free volume in the hybrid systems by the effect of bulky POSS cage. Differently, TGA experiments indicated an improved resistance to the thermal degradation, explained with both the higher epoxy functionality present in TGDDM and the level of nanoscale POSS dispersion, resulting in the formation of aromatic tether structure among epoxy and nanoparticles cores (Fig. 5).

Reprinted from [49], © 2006 with permission from Elsevier

Schematic representation of POSS-reinforced epoxy nanocomposites.

The kinetics of the degradation of epoxy nanocomposites containing different fractions of n-phenylaminopropyl-POSS were studied by Pistor et al. [50] using the Avrami model [51,52,53]. They observed that the incorporation of POSS monomer reduced the Avrami constant (k′) and consequently increased the half-life (t1/2) of the degradation reaction. The observed reduction of the k’ means that the degradation rate tends to decrease due to the presence of POSS that may be hindering the degradation of the epoxy resin, thereby increasing its resistance to the thermal degradation. In addition, an increase of the POSS content resulted in an increase in the Avrami exponent (n). At 2 < n < 3, the degradation process propagates in two and three dimensions, respectively, thus suggesting that the incorporation of POSS facilitated heat diffusion in three dimensions. Pistor and co-workers observed a decrease in thermal conductivity, due to the increased space among the polymeric chains for the inclusion of POSS. They associated these lower values of thermal conductivity with the Avrami exponent, and thus, the three-dimensional diffusion suggested that there was greater free volume between the chains, which facilitated the dispersion of heat and increased the degradation activation energy (Ea). Consequently, they justified the different thermal performance of the various POSS monomers, used to reinforce epoxy system, with the hybrid characteristic and the ability to change the degradation mechanism by changing the volume of the cage [54]. Finally, they attributed the increase in Tg to the reinforcement effect of POSS-containing amine groups [55]. In their opinion, the change of Tg is not associated with the increased free volume, but with the type of reactive groups present in the POSSs. In the case of a decrease in Tg, a POSS with epoxy reactive groups was used [56], whereas an increase in Tg is related to the influence of the amine-reactive groups present in the nanocages.

More recently, Raimondo et al. studied the degradation mechanism of a multifunctional fire-retardant graphene/polyhedral oligomeric silsesquioxane epoxy resin [57]. In both oxidative and inert environment, a two-step thermal degradation process was observed suggesting that the inclusion of glycidyl polyhedral oligomeric silsesquioxane (GPOSS) and carboxylated partially exfoliated graphite (CpEG) nanoparticles in the matrix did not significantly modify the degradation mechanism of the prepared formulation. TGA experiments in air highlighted that, compared with the unfilled T20BD epoxy resin, the multifunctional epoxy resin T20BD + 5%GPOSS + 1.8%CpEG showed a slight increase in the thermal stability related to the first stage of the degradation process and a substantial increase in the second stage which is even more significant in nitrogen. The higher thermal stability detected for the multifunctional T20BD + 5%GPOSS + 1.8%CpEG, with respect to all the analysed formulations, was attributed by the authors to a synergistic action of GPOSS and CpEG, even considering that the high thermal conductivity of graphene sheets might facilitate heat dissipation within nanocomposites and consequently improve the thermal stability of the entire composite material [58]. They concluded that the different trend of the degradation in both oxidative and inert atmosphere was a clear evidence that the beginning of the first stage is due to degradation processes which do not involve oxygen (dehydration, random scission, etc.), whereas the second step is strongly dependent on the oxygen availability. The different behaviour observed in inert environment was ascribed to decomposition and release of various fragments over a wider temperature range with respect to the second stage in air. Finally, they observed that the neat T20BD system exhibited a continual crispy char relevant of quite a good thermostability of the neat system. Nevertheless, no intumescence was observed for the system without GPOSS particles, differently than that containing them, for which intumescent char was obtained highlighting that the incorporation of POSS significantly enhances the thermostability.

3 Polypropylene–POSSs Composites

Polypropylene (PP) is probably the most important material among polyolefins because it can couple interesting properties, such as low density and high melting temperature, with low cost of manufacturing and highly versatility thus allowing different structural designs and improving thermomechanical properties. Another aspect not to be underestimated is the possibility of blending PP with other polymers or with reinforcing agents for obtaining materials having superior characteristics [59].

As for almost all the studies concerning the POSS molecules also those on the addition to PP see involved the operative unit at the Edwards Air Force Base Research Laboratory by Phillips, Blanski and their collaborators. They focused their studies on the crystallization, at quiescent and shear states, in isotactic polypropylene (iPP)-containing nanostructured POSSs by the means of DSC [60]. The addition of POSS up to 30 wt% significantly increased the crystallization rate during shear, compared with the rate observed for the neat polymer. Although it is well known that POSS crystals had a limited role in shear-induced crystallization, dispersed POSS molecules behaved as weak cross-linkers in polymer melts and increased the relaxation time of iPP chains after shear. Therefore, a faster crystallization rate was obtained, due to the improvement of the overall orientation of the polymer chains with the addition of nanoparticles, which was faster with higher POSS concentrations. The addition of POSS decreased the average long-period value of crystallized iPP after shear, which indicates that iPP nucleation probably started considerably near molecularly dispersed POSS molecules.

Novel organic/inorganic hybrid copolymers, up to 73 wt% PP–POSS, have been prepared by Coughlin and co-workers, using single-site catalysis, via direct copolymerization of a POSS macromonomer having a polymerizable norbornene linkage and propylene [1]. The obtained copolymers had a slightly decreased melting temperature compared to homo-polypropylene prepared with the same metallocene catalyst, despite the thermal decomposition proceeded, apparently, in a different way. T5% in air did not increase until high POSS concentration even though the PP–POSS copolymers have a much slower decomposition rate compared with homo-polypropylene, whilst the onset of decomposition temperature in nitrogen increased moderately. They proposed for the PP–POSS decomposition, a mechanism of random chain scission, in which the tertiary carbons were indicated like the more susceptible to degradation site, and attributing to the presence of POSS nanoparticles the slowdown of the degradation process [1].

A fundamental contribution to the study of the thermal properties of PP functionalized POSS nanocomposites was given by the group of Professor Camino in Turin. Camino and his collaborators studied the thermal and thermo-oxidative degradation of PP reinforced, by melt blending, with dimeric [(i-C4H9)7Si7O12Al]2 and oligomeric [{(i-C4H9)7Si7O12}2Zn3]n POSSs (Al-POSS and Zn-POSS, respectively) (Figs. 6 and 7) [61]. Their initial purpose was to exploit the ability of metal POSS, under oxidative conditions, to produce a ceramic thermally stable phase. TGA curves in nitrogen atmosphere did not show significant changes in thermal properties with respect to neat PP, whilst thermo-oxidative tests performed in air showed a strong effect of metal POSS compounds on degradation pathways.

Reprinted from [61], © 2006 with permission from Elsevier

Molecular structures of Al-POSS.

Reprinted from [61], © 2006 with permission from Elsevier

Molecular structures of Zn-POSS.

In particular when they increased the POSSs content up to 10 wt%, they observed an overall retarded degradation, testified by the shifting of TGA curves with respect to neat PP and a residue at the end of the analysis which was consistent with the amount of POSS inorganic fraction filled in the composites. In the case of both Al-POSS and Zn-POSS, the TGA plots clearly showed two degradation steps, thus indicating two overlapping degradation processes. They supposed that the first one corresponded to the degradation of neat PP on the sample surface since during the first-stage PP macromolecules are degraded into volatile oligomers by the fragmentation process. The second weight loss step was explained with the degradation of the residue formed during the first step. They proposed an interesting three steps mechanism by assuming that the oxidation of the sample surface determines the accumulation of POSS, with formation of a thermally stable phase, similar to the one observed on neat POSS heating. This ceramic superficial layer probably acts as a physical barrier, limiting the gas transport at the interface, thus influencing the kinetics of the degradation reactions. Camino and co-workers continued their studies evaluating the influence of POSS functionalization on PP-based composites, in particular by focusing their research on the effects of the different alkyl substituents (Fig. 8) on the thermal and morphological characteristics of the prepared composites.

Reprinted from [62], © 2005 with permission from Elsevier

a ome-, b oib-, c oic-POSS cage structures.

They found marked differences in the morphology of the composites by increasing alkyl chain length from octamethyl-POSS (OM-POSS) to octaisobutyl-POSS (oib-POSS): specifically, a higher extent of dispersion for this latter filler. Further increase in the substituent chain length to octaisooctyl-POSS (OIO-POSS) did not bring improvement on POSS dispersion. As regard the thermo-oxidative degradation, they recorded an increase in Tm at high POSS loadings, which was more evident at higher dispersion extents (oib-POSS-based composites). They attributed this behaviour to oxygen scavenging by the inorganic phases cumulating on the surface of the material by polymer ablation and concluding that the composite characteristics are not simply driven by the length of the organic substituents, as one could predict on the basis of an expected increase in compatibility between the two phases [62]. The results of the group of Turin indicated that the length of alkyl substituents on POSS cages plays a fundamental role in determining the dispersion degree and the interactions with the PP matrix during the cooling process from the melt. Camino and co-workers supported their finding with microscopic analyses, which showed that OM-POSS gave mainly rise to crystalline aggregates on micron-size scale, whereas OIO-POSS and, partially, oib-POSS were well dispersed in the matrix encouraging interactions of the long alkyl groups with the polymer chains, as compared to POSS–POSS auto-aggregation. At all investigated compositions, the authors found a different behaviour of OM-POSS and OIO-POSS, with this latter that retarded the crystallization kinetics due to its high dispersion as liquid phase component whilst the first one resulted to be a nucleating agent for PP. Finally, they pointed out their attention to the inorganic reinforcement amount by highlighting that oib-POSS showed a different behaviour depending on its content in PP. They observed that at low content (3 wt%), the nanodispersion of oib likely hinders the PP crystal growth, thus resulting in a retarded crystallization; at higher content (10 wt%), this effect is counterbalanced by the presence of oib crystal aggregates which behave as nucleants for PP [63].

Morgan et al. investigated the bulk and surface properties of POSS–PP composites prepared via high shear melt mixing. They observed POSS aggregates ranging in size from 10 to 100 nm within the matrix, that giving rise to dramatic modification of surface properties. In particular, with the incorporation of 10% oib-POSS, they recorded a 60% reduction in relative COF (from 0.17 to 0.07), a doubling of hardness (109–225 MPa) and a reduction in modulus (1.9–3.9 GPa). Bulk property evaluations by DMA, on the other hand, showed only minimal changes when POSSs were incorporated, thus demonstrated preferential segregation of the POSS aggregates to the surface in comparison to the bulk region [64].

Also Fina et al. observed micron-sized POSS aggregates (Fig. 9) and reinforced the hypothesis of the protective layer formation thanks to the action of the inorganic part of the POSSs, by reporting the study on a maleic anhydride-grafted polypropylene (PPgMA)/POSS. They obtained this system with a one-step reactive blending process by POSS grafting. The thermal performance was evaluated and compared with a non-reactive PPgMA/POSS nanocomposite as a reference, showing advantages in terms of higher thermal stability in the case of the grafting process with respect to simple melt blending [65]. POSS has accumulated on the sample surface during the earlier stage of PPgMA/am-POSS, thus gave rise to higher thermal stability in oxidative environment. Indeed, volatilization of grafted POSS was hindered as compared to unbound oib-POSS, allowing POSS oxidation with the production of a ceramic phase [3], which acts as a protective barrier, limiting the polymer volatilization rate. They put in foreground the role of am-POSS on thermo-oxidative degradation of PP by monitoring the mass loss in air in isothermal conditions at 250 °C, which was approximately the pure matrix Ti. They observed a fast degradation (50% mass loss after 20 min and a stable 6% residue after 300 min) for pristine PP and a similar behaviour for PPgMA/oib-POSS (50% mass loss after 23 min and a stable 9% residue after 300 min), attributing the slightly modification for this latter to the partial formation of a ceramic phase through POSS oxidation in isothermal condition. Indeed, at 250 °C oib-POSS suffered evaporation in competition with oxidation, leading to an insoluble glassy phase [66]. Increasing the degradation time to 45 min, a decrease in mass loss rate was observed for PPgMA/am-POSS (50% mass loss and a 15% residue after 300 min). In this case, POSS was retained in the condensed phase thanks to grafting, resulting in accumulation of a ceramic physical barrier by POSS thermo-oxidation. This accounted for the slower weight loss kinetics and the higher residue compared to PPgMA/oib-POSS. On continuing their studies, Fina and his collaborators investigated polysilsesquioxane (PSS) with different organic groups (methyl, vinyl or phenyl) (Fig. 10) with the aim to correlate dispersion in PP matrix and thermal properties with the silsesquioxane organic fraction type. They prepared polysilsesquioxane-based polymer blends, obtaining a submicronic PSS domain dispersion with vi- and ph-PSS, whereas residual aggregates were found with me-PSS [67].

Reprinted from [65], © 2009 with permission from Elsevier

SEM micrographs of PPgMA/oib-POSS with EDS elemental analysis inset (a) and SEM micrograph of PPgMA/am-POSS (b).

Reprinted from [67], © 2010 with permission from Elsevier

Polysilsesquioxane approximate structure.

They generally observed improved performances for the PP/silsesquioxane in terms of higher thermal stability, due to the formation of the above-cited ceramic superficial layer that acted as a protection towards degradation of the underlying material. PP/me-PSS showed a rapid increase of the weight loss rate above 280 °C, which they attributed to the rupture of the protective layer, with consequent limited delay of Tm (~10 °C). By contrast, PP/vi-PSS showed a lower weight loss rate, reaching a plateau in the range between 320 and 350 °C, thus suggesting that the protective layer from vi-PSS is more thermally stable than the one from me-PSS. They supported this hypothesis by recording an increase in Tm of about 35 °C with respect to neat PP. Finally, PP/ph-PSS showed a higher thermo-oxidative stability, evidenced by the lowest weight loss rate for temperatures below 330 °C and the highest Tm (379 °C).

Successively, the influence of POSS chemical structure and grafting degree on the morphological characteristics and thermal properties of isotactic PP maleic anhydride functionalized PP (PP-g-MA) was investigated by Bartczak et al. [68]. They found that grafting of POSS cages on PP chains leads to the POSS dispersion on the molecular level, unlike when POSS was mixed with plain iPP, which resulted in phase-separated blend with crystallites of POSS dispersed in iPP matrix. They observed a faster degradation of PP in an oxidative atmosphere (air) than in inert conditions due to peroxidation, thus resulting in a decrease of PP-g-MA degradation temperature of about 90 °C comparing to degradation in N2 atmosphere. Samples of PP grafted with POSS demonstrate highly improved thermo-oxidative stability comparing to PP-g-MA, giving raise a shift of Tm from 379 to 415 °C for composites. They explained the greatly improved thermo-oxidative stability of PP-g-POSS by the accumulation of POSS on the sample surface during the earlier stage of PP-g-POSS degradation, thus limiting the polymer volatilization rate.

4 Polystyrene–POSSs Composites

Polystyrene (PS) is one of the more produced thermoplastic polymers due to its versatile application in different fields. Because of its low-cost, good processability, transparency and good electrical property, PS products are present almost everywhere [7]. PS can be found in applications where abrasion, chemical resistance, as well as thermal stability are required [69] and therefore lend it to act as a matrix for polymer composites. When considering the development of composites based on thermoplastic polymers, and more specifically PS, it is particularly difficult to ensure good interfacial adhesion between the matrix and the reinforcing agents. This shortage of compatibility between many reinforcing agents and PS is due to its inert nature and the lack of reactive groups (as compared with thermosetting systems or other engineering thermoplastics), which limits the level of interaction [70]. In the last two decades, hybrid materials, with superior structural and functional properties, have been developed by incorporating nanofillers into polymer matrices. Carbon nanotubes, layered silicates, and others [71,72,73] were firstly used to prepare organic–inorganic hybrid systems, but, in recent years, polyhedral oligomeric silsesquioxanes have attracted the attention for the use as molecular fillers in the production of PS-based nanocomposites.

Haddad et al. synthesized, by free radical bulk polymerization of cyclohexyl-, cyclopentyl- and isobutyl-substituted POSS-styrenes (Fig. 11), obtaining a series polymers in a high yield and purity [74], that showed a variation in modulus above the Tg. They observed a much more prominent variation for the cycloalkyl POSS copolymer than the isobutyl POSS one, thus speculating on a cage’s groups’ effect on bulk polymer properties leading to differences in polymer microstructure. They concluded that the packing of the POSS cages in the glassy matrix is strongly affected by the type of group on the POSS moiety.

Reprinted from [76], © 1996 with permission from ACS Publications

POSS macromer converted to a hybrid polymer with a pendent architecture.

Random copolymers of syndiotactic polystyrene (sPS) and POSS have been synthesized by Coughlin and co-workers [75] through copolymerizations of styrene and (POSS)–styryl macromonomer. Their thermal investigation revealed, not surprisingly, that the copolymers at low POSS content (0–3.2 mol%) had a minor increase in Tg (from 98 to 102 °C), according to Haddad and Lichtenhan [76] that reported a dramatic increase in Tg only at POSS content above 7.8 mol% in atactic poly(4-methyl styrene)–POSS copolymers (Fig. 12).

Reprinted from [76], © 1996 with permission from ACS Publications

POSS styryl macromer synthesis and polymerization.

Coughlin and his collaborators also observed a decrease in melting and crystallinity with increasing the POSS content. Furthermore, they noted that PS–POSS copolymer at 3.2 mol% POSS did not show a melting peak on the second DSC scan, attributing this finding to the disruption of the crystallization process of sPS due to random incorporation of POSS. They completed the investigation with TGA, demonstrating that the inclusion of the inorganic nanoparticles makes the organic polymer matrix more thermally stable. In particular, they recorded T5% values slightly higher than those obtained from Haddad and Lichtenhan, speculating that this improvement in the resistance to the thermal degradation could arise from the semicrystalline nature of the polymer matrix influencing the aggregation of the inorganic POSS component of the copolymers. Finally, considering the higher values of the residue found at the end of TGA scans, they attributed, in agreement with the literature [77] and with what has already been seen for PP, the thermal oxidative stability to the formation of a silica layer on the surface of the polymer (in the molten state), which acted as a barrier preventing further degradation of the underlying polymer. On continuing their research in this specific field, Coughlin and collaborators wanted to prove that control over the placement of the POSS within an organic polymer is possible using living/controlled polymerization methodologies. The tethering of POSS to an anionically synthesized polymer will extend the range of materials as well as the morphologies that can be achieved. By studying the physical behaviour of the synthesized PS–POSS composites, they observed that the presence of POSS tethered at the end of the polystyrene chain did not alter the Tg, suggesting that the POSS moieties and PS chains are isolated from each others, for the higher-molecular-weight samples [78].

An important contribution to the study of the structure–property relationships between the POSS fillers and the thermomechanical properties of the PS composites was given by the work group of Professor Tanaka at the Kioto University [79], by using eight kinds of octa-substituted aliphatic and aromatic POSS, at different concentrations, as a filler (Fig. 13).

Reprinted from [80], © 2012 with permission from Royal Society of Chemistry

Chemical structures of octa-substituted POSS fillers.

They found homogeneous dispersion and high compatibility for the POSS in the polymer matrices that were valuable for the hybridization with organic and inorganic segments on a nanoscale. The result was a shift to higher values of Tg and decomposition temperature with increase the POSS content up to 5%. Two tendencies for thermal reinforcement by loading POSS nanoparticles were observed. First, longer alkyl chains in the POSS fillers had a positive effect to enhance thermal stability of the polymer composites (an enhancement ranging from 25 to 30 °C was recorded in the temperature at 20% mass loss, T20%, of composites containing octyl- and octadecyl-POSS), second, the existence of unsaturated bonds in the POSSs. Compared with the T20% values of the composites containing 5 wt% vinyl- and ethyl-POSS, which have same number of carbon atoms, the former showed significant enhancement to thermal stability of polymer matrices. They speculated that it was likely that longer alkyl chains and unsaturated groups were favourable for enhancing stability due to the strong hydrophobic interaction between POSS and polymers.

Monticelli et al. synthesized, by one-step reactive blending, a copolymer of styrene-maleic anhydride copolymers (PSMA) and a POSS characterized by an amino group as reactive side, obtaining a cyclic imide linkage binding POSS to the polymer backbone due to the occurrence of imidization reaction between the MA group of PSMA and the amino group of POSS molecule. With this typology of synthesis, they obtained a good POSS dispersion, at nanometric level, in the polymer matrix. It is worth to note that when they used a mixing temperature lower than POSS melting one, a surface reaction at the POSS crystal/polymer boundary occurred, leading to the formation of a very peculiar two-phase structure evolving with time at different POSS concentrations. Monticelli and co-workers studied the physical properties of these biphasic systems by the means of DSC and DMTA and found two Tg, depending on the presence of unbound POSS acting as a plasticizer [81].

Wang et al. chemically bonded a mono-functional POSS to a PS chain, modified by the introduction of an active agent [82], observing an increase in Tg of 16 °C that attributed to the rigid nature and diameter (~25–30 Å) of POSS moiety which lead to dominate the movement of the local chain of the polymer [83]. They then confirmed that the incorporation of POSS enhanced the thermal stability of PS by measuring for POSS–PS composites an initial decomposition temperature of about 65 °C and a Tm of 53 °C higher than those of pure PS.

In this context, namely that of the dispersion at nanoscale level of POSSs aiming the enhancement in physical and mechanical properties as compared to virgin PS, fit the studies on POSS of my research group at the University of Catania. Taking advantage of the above-reported literature on the specific topic, we started by the assumption that the different behaviour of each specific POSS in various polymer matrices is attributable to the size of cage, nature of organic periphery, concentration and solubility in the polymer. Thus, the ability of POSS to be dispersed at molecular level is the key to realize physical properties’ enhancement like the increase of thermal stability. On considering that symmetric POSSs, with the same height corner organic groups, have been extensively studied in literature and since it is known that aliphatic bonded groups improve solubility and compatibility with polymer matrices but worsen thermal properties [79], whilst aromatic groups act in the opposite way [3], we used, to reinforce PS, some asymmetric substituted POSSs, where a phenyl group was introduced at one of the height cage’s slot. POSSs were prepared by corner-capping reaction of trisilanol with trichlorosilane and/or triethoxysilane [84, 85]. Nanocomposites were obtained by in situ polymerization of styrene in the presence of different quantities of POSS, namely 3, 5 and 10 wt% [86]. Synthesis of mono-substituted silsesquioxanes by a method of corner-capping reactions has been developed by Feher and starts from his pioneering discovery of the synthesis of an incompletely condensed silsesquioxane that contains three reactive hydroxyl groups [87]. The three silanol groups of the incompletely condensed silsesquioxane are very reactive, readily reacting with virtually any organotrichlorosilane (R′SiCl3) to yield the fully condensed cage. A variety of mono-functional silsesquioxanes (as the sole reaction products) can then be easily synthesized by simply varying the R′ group of the organotrichlorosilane. Furthermore, subsequent modifications of this R′ group have since led to the synthesis of various mono-functional monomers that could be polymerized to make organic-inorganic hybrid materials. The first step of our research was to investigate whether and how much the POSS content improves the thermal properties of nanocomposites in respect to neat PS, and on the basis of the obtained thermal parameters, the best filler content was 5 wt% of POSS. Then in the comparison between octaisobutyl-POSS (oib-POSS) and phenyl heptaisobutyl-POSS (ph,hip-POSS), the greatest increases in thermal parameters were recorded for this latter molecular filler as testified from the considerable increase in initial decomposition temperatures (+45 °C about in both oxidative and inert atmosphere) and in degradation activation energy (+40 kJ/mol about) [88, 89]. The better thermal performance showed by nanocomposites filled with the ph,hib-POSS in respect to the octaisobutyl one was attributed to the different structure of the POSSs used as reinforcement. The lower glass transition temperature found for the oib-POSS–PS nanocomposite strengthened this hypothesis. Even though apparently similar, the POSSs we used for nanocomposite design were significantly different: at this stage of the research, we thought that the use of a symmetric POSS, in which stronger POSS–POSS interactions occur, gave rise to auto-aggregation phenomena and thus lower dispersion of filler into polymeric matrix. We got the final confirmation from SEM analysis that showed us this nanometric aggregate (Fig. 14).

On continuing our study in this field, we synthesized nanocomposites based on PS with, this time, seven phenyl and one alkyl groups (Fig. 15). We observed a great increase in both T5% (+116 °C with respect PS) and Ea of degradation (+105 kJ/mol with respect PS) values. Increase was confirmed, also for the Tg (+28 °C with respect the oib-POSS–PS nanocomposite).

Because of the experience acquired in the reinforcement of polymeric matrices tells us that the compatibility between the matrix and filler in these systems is of great importance, we do not want to limit the introduction of a simple T8 cage. Always through a corner-capping reaction (Fig. 16), we then synthesized dumb-bell-shaped POSSs with an aromatic thioether bridge [90].

We have already determined that, compared to an unbridged system, dumb-bell-shaped POSS had a better thermal stability and a better viscosity [91]. By checking their compatibility with the polymer matrix, high-magnification Scanning Electron Microscopy revealed that the beads found in the composites with a POSS content of 5 and 10 wt% had a porous structure with squared POSS nanocrystallites that increase in dimension with the increase of POSS content [92]. The above-observed behaviour could be due to the symmetric structure of the bridged filler that facilitates POSS auto-aggregation phenomena, clearly observed by scanning electron microscopy (Fig. 17).

Consequently, with the aim to enhance the compatibility and miscibility of filler thus leading to the improvement of nanocomposites thermal properties, the idea was to synthesize a series of dumbbell shaped POSSs with aliphatic bridge so that the presence in the filler of jointed chains allows to silicon cages a sufficiently free movement which should increases as a function of carbon atoms in the bridge (and so chain length) [93, 94]. Indeed, we obtained an increase in the resistance to the thermal degradation, measured with the initial decomposition temperature, with respect to the PS reinforcing with the POSS bearing the aromatic bridge, which increased as a function of the alkyl bridge length [95]. Therefore, in the designing of these materials we must ask whether the priority should be the dispersion in the matrix, and then the possibility to opt for the asymmetric unbridged POSSs, or a higher compatibility with the polymer and then the possibility to opt for the symmetric, but with a bridge that can be functionalized, dumb-bell-shaped POSSs. An alternative way could be to consider an aliphatic bridge, which allows the freedom of movement of silicon cages, possibility that is not permitted to the spatially blocked aromatic bridge.

5 Polylactide–POSSs Composites

Polylactide (PLA) is a bio-based, biocompatible and biodegradable thermoplastic polyester produced by condensation polymerization of lactic acid (LA; 2-hydroxy propionic acid), which is extracted from fully renewable resources such as corn, sugar beet or rice. PLA has been widely studied and used in medical applications because of its bioresorbable and biocompatible properties in the human body. Furthermore, economic studies showed that PLA can be considered an economically feasible material for use as a packaging polymer, and medical studies have shown that the level of molecules that migrates from packaging containers to food is much lower than the amount of the same molecules used in common food ingredients [96]. However, PLA exhibits some disadvantages, such as low thermo-oxidative stability and slow crystallization rate, which up today greatly limited its application. Several methods, including blending with other polymers and copolymerization, have commonly been used to control PLA properties [97, 98]. The addition of nanoparticles such as nanoclay and carbon nanotubes into PLA has proven to be an attractive way to improve its performance [99, 100]. As for nanoparticles, more and more attention has been paid to POSS.

Poly(l-lactide)s (PLLA) tethered with 0.02–1.00 mol% octaglycidylether polyhedral oligomeric silsesquioxane (OPOSS) were prepared by Huang et al. through solution ring-opening polymerization of l-lactide in the presence of Sn(Oct)2 catalyst [101]. They then prepared a series of PLLA/PLLA-OPOSS 1–30 wt% nanocomposites, by solution blending, that showing similar degradation profiles, indicating that the presence of OPOSS does not significantly altered the degradation mechanism of PLLA matrix. T5% values of the PLLA/PLLA-OPOSS were higher than those of neat PLLA and increased up to 20 wt% of PLLA-OPOSS content. Huang and co-workers ascribed this improvement in the thermo-oxidative stability to a good dispersion of the POSS cubes in nanocomposites, resulting in a silica layer during the decomposition, which prevents PLLA from further degradation. By the means of DSC measurements, they also observed a shift of the cold-crystallization temperatures of PLLA/PLLA-OPOSS nanocomposites to higher values, compared to that of the neat PLLA. In parallel, the area of the crystallization peak became higher than that of the neat PLLA, thus suggesting an increase in the crystallization rate because of the heterogeneous nucleation effect of the OPOSS molecules dispersed uniformly in the PLLA matrix. On the other side, the glass transition temperature of the PLLA/PLLA-OPOSS nanocomposites remained consistent with that of neat PLLA, regardless their content.

Biodegradable poly(l-lactide) (PLLA)/octamethyl-POSS (ome-POSS) nanocomposites were prepared, by Qiu and Yu via simple melt compounding at various ome-POSS loadings [102]. They obtained a homogeneous dispersion in the matrix and a similar degradation profile for both neat PLLA and its nanocomposites, suggesting that the presence of ome-POSS did not alter the degradation mechanism of the matrix. They found a T5% value of about 347 °C for neat PLLA, and a growth from 294, 305 and 321 °C for the PLLA/ome-POSS nanocomposites, with increasing the ome-POSS loading from 2 to 8 wt%, respectively, indicating that the incorporation of ome-POSS reduced the thermal stability of the PLLA matrix. The effect of ome-POSS on the non-isothermal cold and melt crystallization behaviours and isothermal melt crystallization kinetics was further investigated by them. Qiu and Yu found that non-isothermal melt crystallization of PLLA was induced by the presence of ome-POSS in the nanocomposites at a relatively high cooling rate of 15 °C/min, whilst neat PLLA hardly crystallized at the same cooling rate (Fig. 18). Moreover, the overall crystallization rates were faster in the nanocomposites than in neat PLLA and increased with increasing the ome-POSS loading; however, the crystallization mechanism of PLLA remains unchanged despite the presence of ome-POSS. They hypothesized that ome-POSS may act as an effective nucleating agent during the crystallization process of PLLA.

Reprinted from [102], © 2011 with permission from ACS Publications

Polarized optical microscopy (POM) images of neat PLLA and its nanocomposites crystallized at 125 °C; a neat PLLA for 90 min, b POSS-2 for 35 min, c POSS-5 for 18 min and d POSS-8 for 12 min.

Hu et al., during the attempts to develop a bio-derived polylactide composite with improved flame retardancy and anti-dripping properties, utilized intumescent flame retardant (IFR) together with trisilanolisobutyl polyhedral oligomeric silsesquioxane (TPOSS) nanoparticles and observed a delay in the thermo-oxidation process of the PLA [103]. They recorded a synergistic effect among microencapsulated ammonium polyphosphate (MCAPP), melamine (MA) and TPOSS that imparted excellent flame retardancy to PLA. The incorporation of TPOSS into PLA obviously decreased the peak heat release rate (PHRR) and total heat released (THR) values of the composites in the microscale combustion calorimeter MCC tests, and effectively delayed the thermo-oxidation process of the PLA. The decomposition of TPOSS gave rise to many active radicals, which interacted with H and OH radicals in the gaseous phase of the fire and retarded polymer degradation and combustion. The additives’ actions were explained in the following way: MCAPP catalysed the formation of a protective char whilst TPOSS prevented the char from further thermal degradation, thus shielding the underlying polymeric substrate from further burning.

The effect of screw speed on the thermal and morphological properties of melt compounded plasticized PLA–POSS composites was investigated by Kodal et al. They found that incorporation of POSS particles to the PLA decreased the melt viscosity of the composites due to the slip-agent behaviour of POSS molecules, by improving the yield strength and modulus values. Moreover, they observed a homogeneous POSS particles’ dispersion in the matrix at all loadings, regardless of screw speed. It was revealed from DSC that POSS particles acted as a nucleating agent for PLA independently from mixing conditions, thus resulting in an increase of crystallinity as a function of POSS and a slightly decrease of both Tg and cold-crystallization temperature [104].

Monticelli and her collaborators introduced functionalized POSS (one by hydroxyl groups −OH and another with an amino bearing molecule −NH2) into some electrospinning solutions for the preparation of electrospun stereocomplex polylactide (sc-PLA)-based fibres [105]. The thermal decomposition of all the analysed fibres was found to occur in one step, and the presence of POSS in the fibres significantly affected the Ti values, by enhancing those of the fibres containing POSS–OH and POSS–NH2 at 340 and 338 °C in respect to the 319 °C of sc-PLA fibres. This behaviour, already found for other polymer matrices described elsewhere in this chapter, was ascribed to the formation of a silica layer on the surface of the polymer hence serving as a barrier and limiting the degradation of the polymer. Indeed, as at the Ti, the evaporation of both POSS–OH and POSS–NH2 is not completed, and the silsesquioxanes can play a protection action towards the polymer. The results found by Monticelli and co-workers point out that not only the formation of stereocomplex can affect PLA degradation, but also the presence of POSS, which in the case of electrospun nanofibres is homogeneously dispersed in the polymer matrix (Fig. 19), can contribute to the increase of the PLA thermal stability. Professor Monticelli group continued their studies by setting a novel strategy for the preparation of bio-hybrid systems based on PLA and POSS, adopting a preliminary functionalization of the matrix and a subsequent reaction of amino or hydroxyl functionalities POSS, potentially capable of reacting with maleic anhydride groups created onto PLA by a free radical process [106].

Reprinted from [105], © 2014 with permission from ACS Publications

SEM micrographs of PLLA/PDLA fibres prepared by applying the optimal electrospinning conditions and containing: a POSS–NH2 and b POSS–OH.

The main advantage of their preparation method is that it was not accompanied by a change of the polymer molecular mass. By means of DSC, they observed that the incorporation of POSS had little effects on the Tg value of PLA-g-MA, which is around 62.5 °C. Although cold crystallization (Tcc) and melting peak (Tm) were found not to change in the hybrid systems, they recorded an increase in the degree of crystallinity related to the amount of POSS grafted onto the polymer, being the degree of crystallinity much higher in the sample based on POSS–NH2. Finally, they highlighted that in the case of the nanocomposites prepared by melt blending, the addition of POSS was found to enhance the crystallinity of PLA just up to 17% [107], whilst in the synthesized hybrid based on POSS–NH2 the increment was almost 200%.

Pramoda et al. reported the effects of using graphene oxide (GO) nanosheets and POSS nanocages as filler for in situ ring-opening polymerized PLA [108]. Thermal investigations showed that the nanocomposites reinforced with GO and POSS as nanofillers, either as physical mixture of GO-functionalized and POSS-functionalized or as GO-graft-POSS, were far more superior as compared with the nanocomposites having individually dispersed nanofillers in the PLA matrix. In particular, the nanocomposites produced by incorporating GO-functionalized or POSS-functionalized showed only a slight improvement (i.e. ~10 °C) in thermal properties, whereas the T5% increased to about 19 °C for PLA/physical mixture of GO and POSS and of about 31 °C for PLA/GO-graft-POSS. The two fillers, when used in combination, worked synergistically to improve the thermal stability of the PLA. The best results, however, were achieved with the GO-graft-POSS for which they hypothesized a more effective improving in thermal property deriving by POSS, with its three-dimensional structure and eight arms, than by the two-dimensional GO. Furthermore, they observed an increase in Tg at 59.5 °C for the PLA/GO-POSS physical mixture and 58 °C for PLA/GO-graft-POSS.

Recently, Ozkoc et al. reported the effects on the thermal properties after the inclusion, at different loading level, of reactive and non-reactive POSSs in PLA matrix [109]. The incorporation of POSS particles into the matrix reduced slightly the Tg value of pure PLA, about 58 °C, independently of POSS used. The decline in Tg showed that both non-reactive and reactive POSSs acted as a plasticizer and affected the free volume of polymer–POSS system by interacting with each other [110, 111]. Ozkoc and collaborators attributed this effect to the dispersion of POSS particles at the nanoscale level in the matrix, which was already observed. In addition, they evaluated the thermal stability of PLA and PLA–POSS composites showing that T5% of pure PLA (341.4 °C) increased with the addition of POSS particles due to the physical barrier by POSS molecules, which limited the heat flux to the matrix.

6 Polyimides–POSSs Composites

Over the past 20 years, the development of the industrial chemistry leads to improved technologies in producing polymers which are becoming more widely used to improve the quality of human life: from aerospace to high-tech household appliances, textiles, insulation materials in industry and construction, medical and biological field and much more over. An important polymeric materials family, responded to certain technical requirements, are polyimides (PI). Since their first synthesis by Bogert in 1908 [112] and high-molecular-weight aromatic polyimides synthesis in 1955 [113], interest in this class of polymers has been growing steadily because of their thermo-oxidative stability, unique electrical properties, high radiation and solvent resistance, and high mechanical strength [114]. Their characteristics are due to the functional group CO–NR2 called imide that gives the name to this family of polymers. Specifically, the presence of n − π conjugation between non-pair electron of nitrogen atom and π electrons of the carbonyl group makes them resistant to chemical agents and moisture, whilst the type of hydrocarbon residues (arenes, aliphatic) and the presence of other functional groups (Cl, F, NO2, OCH3, etc.) determine their physical properties and thus their application [115]. Thanks to its outstanding properties such as high strength and good thermal stability and to the development of the additive manufacturing, PI today has been widely used also as technology material for structural applications [116, 117]. However, the particularity of the applications that see it constantly subjected to solicitations can lead to a premature degradation. Another extensively used of polyimide is as spacecraft material in low Earth orbit (LEO), where hazards such as atomic oxygen (AO) or electrostatic discharge (ESD) act for the material degradation. Thus, the need to develop new high-efficiency techniques to increase the lifetime and enhance its thermal stability. The various methods applied to enhance its resistance to the degradation are generally classified into two categories, namely the application of protective coatings on its surface and the introduction of functional compounds into polyimide by physical blend or chemical bond [118,119,120,121].

Mu and collaborators synthesized a series of structural phosphorus-containing POSS–PI nanocomposites at various percentage of phosphorus [122], obtaining nanocomposites displayed outstanding thermal properties. With a phosphorus content of 1.61 wt%, they observed an enhancement of the resistance to the degradation and shift towards higher value of Tg (295 °C). Moreover, the nanocomposites presented much higher atomic oxygen (AO) durability compared with pure PI because of the incorporation of special functional groups of phosphorus oxide and POSS.

With the same phosphorus content (1.61 wt%), the atomic oxygen (AO) erosion yields already decreased to 51.9% of pure POSS–PI nanocomposites. Mu and co-workers continued their studies by synthesizing a series of structural phosphorus-containing POSS–PI hybrid materials, which incorporated phenyl phosphine oxide (PPO) structure into the main chains of POSS–PI. Using the DSC technique, they observed a raising of Tg for the POSS–PI hybrid materials by the incorporation of PPO structure into polymer matrix [123]. With the introduction of PPO structure in PI chains, the C electron cloud density and intermolecular forces increased because of the P=O bond, which provided the electronic properties that resulted in the difficulty of segmental motion and increased Tg. The thermal stability of the prepared composites was evaluated, by Mu and co-workers, using TGA and resulting in an evident increase in T5% (and thus resistance to thermal degradation) due to the P=O with high bond energy. The phosphorus-containing POSS–PI hybrid materials displayed higher residuals of degradation than reference POSS–PI, that increased as a function of PPO content, which was ascribed to the ceramic formation from POSS moiety during thermal decomposition and to phosphorus oxide.

Atar et al. prepared PI-based nanocomposite films by incorporating POSS and carbon nanotube (CNT) additives (Fig. 20). They investigated the influence of the POSS content on the thermo-optical properties of the CNT–POSS–PI films in comparison to those of control PI and CNT–PI films [124].

Reprinted from [124], © 2015 with permission from ACS Publications

Schematic illustration of CNT–POSS–PI film fabrication process. a A ~9-μm-thick CNT sheet is first grown by CVD on a pre-patterned Si substrate. b A POSS–PAA blend, composed of (i) PMDA–ODA monomer and (ii) trisilanolphenyl POSS, is then infiltrated into the CNT sheet. c The free-standing CNT–POSS–PI film is mechanically peeled from the substrate after curing.

CNT–POSS–PI films, with POSS content ranging from 5 to 15 wt%, exhibited sheet resistivities that remained essentially unchanged after exposure to AO with a fluence of ~2.3 × 1020 O atoms cm−2. Atar and co-workers evaluated the possible applications of the prepared composites under simulated space environmental conditions, including thermal cycling, ionizing radiation and AO. The performance of the CNT–POSS–PI films was investigated under extreme thermal cycling, a common hazard of the space environment. The composite films (5 mm × 5 mm) were subjected to 29 thermal cycles from −100 to 140 °C using a temperature-controlled stage in a nitrogen atmosphere. The sheet resistivities of the CNT–POSS–PI films (5 and 15 wt% POSS content) were measured at the conductive bottom surfaces (containing CNTs) using the four-point van der Pauw method [125] at the minimum and maximum temperatures after every second cycle. These properties make the prepared CNT–POSS–PI films with 15 wt% POSS content excellent candidates for applications where AO durability and electrical conductivity are required for flexible and thermally stable materials. Hence, they are suggested here for LEO applications such as the outer layers of spacecraft thermal blankets.

He et al. prepared a series of functional POSS–PI nanocomposites by using a two-step approach (Fig. 21)—first, the octa(aminophenyl)silsesquioxane (OAPS)/NMP solution was mixed with polyamic acid (PAA) solution prepared by reacting 4,4′-diaminodiphenylmethane and 3,3′,4,4′-benzophenonetetracarboxylic dianhydride in NMP, and second, the polycondensation solution was treated by thermal imidization [126].

Reprinted from [126], © 2003 with permission from Elsevier

(i) H2O, benzene, benzyltrimethylammonium hydroxide, stir at RT/N2; (ii) fuming nitric acid, stir at RT; (iii) Pd/C, THF, NEt3, HCO2H, reflux, 60 °C; (iv) phthalic anhydride, NMP, 270 °C.

The resulting PI–POSS nanocomposites exhibited excellent thermomechanical properties, such as high Tg and low coefficient of thermal expansion (CTE). The glass transition temperature increased from 301.4 °C for pure PI to 421.0 °C for PI–POSS nanocomposite at an amine group ratio 0.4, due to the significant increase of the cross-linking density in the nanocomposites. The well-defined ‘hard particles’ (POSS) and the strong covalent bonds between the PI and the ‘hard particles’ lead to a significant improvement in the thermal stability testified by an increase in T5% from 513 °C for PI to 551 °C for the nanocomposites.

Another series of functional POSS–PI nanocomposites were prepared, by Sarojadevi et al., using the same two-step approach of He and co-workers. The well-defined ‘hard particles’ (POSS) and the strong covalent bonds in the amide linkage, between the carbon atom of the carboxyl side group in PAA and the nitrogen atom of the amino group in POSS, led to a significant improvement in the thermal properties. Tg increased from 160.4 to 210.0 °C, and T5% increased from 321.5 to 496.9 °C by passing from pure PI to PI–POSS nanocomposite. This behaviour was probably due to the homogeneous dispersion of POSS cages in the PI observed by Sarojadevi and co-workers, together with the increase in storage modulus of PI on incorporating POSS within the matrix [127].