Abstract

In this work, a novel strategy for the preparation of bio-hybrid systems based on polylactic acid (PLA) and polyhedral oligomeric silsesquioxane (POSS) was developed. Indeed, the new method consists in a preliminary functionalization of the polymer matrix and a subsequent reaction of silsesquioxane molecules, characterized by amino or hydroxyl functionalities, potentially capable of reacting with maleic anhydride groups created onto PLA by a free radical process. The method adopted to create maleic anhydride-grafted polylactic acid (PLA-g-MA) allowed to graft 0.7 wt% of MA onto the polymer backbone, avoiding a dramatic reduction of PLA molecular mass. 1H-NMR measurements demonstrated a different reactivity of the two used POSS, namely trans-cyclohexanediolisobutyl POSS (POSS-OH) and aminopropyl heptaisobutyl POSS (POSS-NH2). Indeed, the amino group of POSS-NH2 was found to react with the maleic anhydride group of PLA-g-MA allowing to obtain a hybrid system, carrying silsesquioxane molecules along the polymer backbone while the reactivity of POSS-OH turned out to be much lower. Thermal properties of the synthesized hybrid systems were assessed by means of DSC measurements. Indeed, the presence of POSS grafted onto the macromolecular chain was found to improve PLA crystallinity, by affecting the crystal nucleation density. Moreover, a decrease of surface water wettability was observed in the films made of PLA-g-MA/POSS-NH2.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polylactic acid (PLA), which is a biodegradable polyester derived from biomasses with excellent properties for various applications, has been emerging as an alternative to conventional petroleum-based polymeric materials [1, 2]. However, in order to compete with most of the commonly used polymers, the performances of PLA, such as impact strength, elongation at break, and crystallization rate, must be improved without compromising its inherent sustainability [3]. Indeed, the dispersion of proper nanofillers within PLA, yielding bio-nacomposites, can improve significantly the polymer matrix properties [4]. Among the various nanofillers applied in the preparation of PLA-based bio-nanocomposites, of particular interest is the exploitation of layered silicates, which allows the formation of bio-nacomposites that consists of PLA and organically modified clay (organoclay) [5–8]. PLA/clay bio-nanocomposites show an improvement in the mechanical and thermomechanical as well as gas barrier properties and exhibit a higher crystallization and biodegradation rates with respect to the polymer matrix. Moreover, clays are environmentally friendly material and do not significantly affect the compostability of PLA after nanocomposite formation [6].

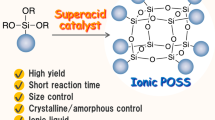

Besides clays, also carbon nanotubes (CNTs), both single- and multi-walled, received relevant attention for the preparation of PLA-based bio-nanocomposites [9–11]. The above systems, prepared by using both pure and surface oxidized/functionalized CNTs, are characterized by enhanced modulus and electrical properties. In addition to the most commonly used nanofillers, clay and carbon nanotubes, other inorganic fillers, such as silica [12], titanium dioxide [13], silver [14] and palladium [15, 16] nanoparticles, cellulose and starch nanocrystals [17], whiskers [18], and polyhedral oligomeric silsesquioxane (POSS) [19–28] were used to improve the properties of PLA. POSS, the object of the present work, are organic-inorganic hybrid molecules [29], which can be directly inserted into the macromolecular chains by using in situ polymerization [30, 31] or grafting reactions [32, 33] while melt or solution blending allows to obtain only a physical dispersion [15]. In particular, the level of POSS dispersion in PLA-based systems prepared by melt compounding was found to depend on the kind of functionalities linked to the silsesquioxane siliceous cage. Indeed, POSS characterized by particular functional groups, such as amino [19] or epoxy [20], capable of reacting and/or interacting with PLA showed an improved dispersion. The presence of POSS was found to enhance the mechanical properties of PLA, improving its modulus and elongation at break [19], the crystallization rate [21, 22], and thermal stability [20, 23]. Moreover, the specific effect of POSS on PLA combustion behavior was recently highlighted by Fox et al. [24], who exploited POSS-modified nanofibrillated cellulose as a carbon source in intumescing flame retardants for melt-blended PLA composites.

As far as the in situ polymerization is concerned, the direct bond of the silsesquioxane to the macromolecular chain, producing hybrid systems, might potentially enhance the specific effect of POSS on the PLA features. Indeed, hydroxyl and amino POSS were used as initiator of the ring-opening polymerization (ROP) of lactide. By using this method, Goffin et al. [24] synthesized nanohybrids by grafting the polyester chains onto POSS nanocages, using a polymerization initiated from the primary amine of the silsesquioxane, which proved to be well controlled. POSS/PLA hybrids were also successfully prepared by the ring-opening polymerization of lactide with 3-hydroxypropylheptaisobutyl POSS as an initiator in the presence of tin(II) 2-ethylhexanoate (Sn(Oct)2) as catalyst [26].

More recently, Sun et al. [27] prepared biodegradable core-shell rubber-like particles by using an octa-hydroxy POSS as initiator of the ring-opening polymerization of a mixture of ε-caprolactone and l-lactide to form poly(ε-caprolactone-co-lactide) as the rubbery core, followed by the polymerization of d-lactide to form poly(d-lactide) as the outer shell. Moreover, the efficacy of a metal-silsesquioxane (heptaisobutyl titanium-POSS) as initiator of the ring-opening polymerization of l-lactide was proved by Monticelli et al. [28], who demonstrated that this reaction leads to the direct insertion of POSS to the polymer backbone.

It is worth underlining that the exploitation of POSS or metal-POSS as initiator of the ROP of lactide allows to obtain macromolecular chains carrying the silsesquioxane only as end group. Moreover, the polymer molecular mass turns out to be affected by the concentration of POSS in the reaction mixture, decreasing it by increasing the amount of initiator. Clearly, the possibility to graft POSS along the polymer chain might further enhance the effect of the hybrid molecule on PLA final features. The above approach, widely used for the preparation of polymer/POSS system, can only be applied to polymer matrices carrying reactive side groups capable of reacting with silsesquioxane molecules. Although, PLA is not characterized by such functional groups, in this work we propose a novel approach to prepare PLA/POSS hybrids by applying a preliminary functionalization of the polymer matrix. First, in order to create reactive groups along the macromolecular chains, the grafting of maleic anhydride (MA) onto PLA was carried out by applying a reactive blending through a free radical process. The so-prepared maleic anhydride-grafted polylactic acid (PLA-g-MA) was subjected to the grafting of two different kinds of silsesquioxane: one characterized by hydroxyl groups (named POSS-OH) and another one by an amino group (named POSS-NH2). The specific effect of POSS on the features of the synthesized hybrid system was highlighted.

Experimental section

Materials

Polylactide (PLA) is a commercial product from Nature Works Co. Ltd. U.S.A. (2002D, Mn = 100.000 g/mol) with a residual monomer content less than 0.3 wt%.

Trans-cyclohexanediolisobutyl POSS (referred to as POSS-OH in the following) (Fig. 1a) and aminopropyl heptaisobutyl POSS (referred as POSS-NH2 in the following) (Fig. 1b) were purchased from Hybrid Plastics (U.S.A.) as crystalline powders and used as received.

1H NMR (ppm) (300 MHz, CDCl3) of POSS-NH2: δ 2.73 (2H, -CH2NH 2 ), 2.66 (2H, -CH2CH 2 NH2), 1.85 (7H, -CH2CH(CH3)2), 1.53 (2H, -CH2CH 2 CH2), 0.96 (42H, -CH(CH 3 )2), 0.60 (2H, -SiCH 2 CH2), and 0.60 (14H, -SiCH 2 CH).

1H NMR (ppm) (300 MHz, CDCl3) of POSS-OH: 0.96 (42 H, -CH(CH 3 )2), 0.60 (14H, -SiCH 2 CH), 0.60 (2H, -SiCH 2 CH2), 0.60 (4H, -CH2 CH 2 CH), 1.46 (4H, -CH2 CH 2 CHOH), 1.85 (7H, -CH2CH(CH3)2), 1.85 (1H, -CH(CH2)3), 3.57 (2H, -CH2 CHOH), and 3.44 (2H, -CH2 CHOH).

Dimethyl-2,5-di-(tert-butylperoxy)hexane organic peroxide (Lupersol 101), maleic anhydride (MA), and tetrahydrofuran (THF) were purchased from Sigma–Aldrich and used as received.

PLA-g-MA/POSS hybrid preparation

The maleation of polylactide was carried out by applying the procedure previously reported [34], which is briefly outlined in the following. Indeed, the maleation was carried out by adding PLA, MA, and Lupersol 101 to a glass reactor, namely a laboratory internal mixer provided with a mechanical stirrer (Heidolph, type RZR1), which was connected to a vacuum line and evacuated for 30 min at room temperature. Then, the reactor was purged with helium for 30 min. The above operations were repeated at least three times, to be sure to avoid humidity coming in contact with the reagents. The percentages of Lupersol and MA were 0.5 wt% and 6 wt%, respectively. The reactor was placed in an aluminum block oven at 180 °C and mixed for 10 min. The mixture was dissolved in chloroform and precipitated in methanol in order to eliminate the fraction of MA not linked to the polymer.

For the hybrid system preparation, 5 g of PLA-g-MA and 1 g of POSS (POSS-NH2 or POSS-OH), the molar amount of which was more than the grafted maleic anhydride, were dissolved in 75 and 25 mL of THF, respectively. The solution of POSS was dropped into the PLA-g-MA solution and stirred at 50 °C for 2 h under inert atmosphere. The product was precipitated in hexane, a solvent of the used POSS, filtered, and repeatedly washed with hexane. The product was dried under vacuum at 30 °C.

Characterization

Both the neat PLA, PLA-g-MA, and the hybrids containing POSS were characterized by means of 1H NMR spectroscopy: 1H NMR spectra were recorded with a Varian NMR Mercury Plus apparatus at a frequency of 300 MHz in CDCl3 solutions containing TMS as internal standard.

The reduced viscosity of the samples, dissolved in chloroform at a concentration of 0.5 g/dL, was determined with an Ubbelohde viscometer thermostated at 25 ± 0.5 °C in a water bath.

Differential scanning calorimetry was performed under a continuous nitrogen purge on a Mettler calorimetric apparatus, model DSC1 STARe System. Both calibrations of heat flow and temperature were based on a run in which one standard sample (indium) was heated through its melting point. The samples, having a mass between 2.5 and 6 mg, were heated from room temperature to 200 °C, then cooled down to room temperature and finally heated to 200 °C again. A scanning rate of 10 °C/min was used both on heating and cooling.

Fourier transform infrared absorption spectra were recorded by a Bruker IFS66 spectrometer. All the samples were scanned in the range 400-4000 cm−1 with nitrogen purge.

Wide-angle X-ray diffraction (WAXD) was carried out on a Philips PW 1830 powder diffractometer (Ni-filtered Cu Kα radiation). Films for WAXD measurements were cast from solutions prepared by dissolving PLA-g-MA or PLA-g-MA/POSS systems in chloroform (2 wt%) at room temperature. Dense films, characterized by a thickness of ca. 200 μm, were obtained by evaporating the solvent from the cast solution along an overnight exposure in an oven at 110 °C.

The development of morphology during melt-crystallization was followed by means of a Leika DMLP polarized optical microscope equipped with a ×20 objective lens. The microscope was coupled with a Linkam CSS450 stage to enable a careful control of the thermal history while acquiring optical micrographs with a dedicated digital video-camera. The sample was initially loaded in the cell as a powder, melted, and compressed in a film of approximately 20 μm thickness by moving the stage plates gently towards each other. In order to compare POM with DSC experiments, an analogous temperature protocol was adopted. In particular, the sample was annealed for 2 min at 200 °C and then cooled to room temperature at 10 °C/min. Optical micrographs were taken at 125 °C, with a frequency of approximately 30 s.

Contact angle measurements were performed at room temperature with an Erma G-1 contact angle meter by using pure water as probe liquid.

Results and discussions

The preparation of the hybrid systems based on POSS has been preliminary focused on the functionalization of the polymer matrix by grafting MA onto PLA, carried out by applying a reactive blending through a free radical process. By using the above method, it was found that the addition of 0.5 wt% of L101 and 6 wt% of MA leads to the grafting of 0.7 wt% of MA [34]. Moreover, viscosity measurements indicated a slight negative effect on the molecular mass of PLA, the reduced viscosity of PLA-g-MA decreasing of ca. 10 % with respect to the starting PLA. In order to evaluate the hybrid system chemical structure, 1H-NMR measurements were performed. Figure 2 compares the spectra of the pristine PLA-g-MA with that of the hybrid based on POSS-NH2. The 1H-NMR spectrum of PLA-g-MA reveals two major set of signals with chemical shifts of about 1.5 ppm, assigned to methyl protons and 5.2 ppm, assigned to methine protons of PLA. The resonance at 7.2 ppm is attributed to the solvent deuterated chloroform. The resonances at 2.2–2.5 and 3.5–4.0 ppm are assigned to the methine and methylene protons of the succinic anhydride ring, respectively, which suggests, as reported in the case of maleation of syndiotactic polystyrene [35], that the grafting reaction consists of single succinic anhydride rings. In 1H-NMR spectra of the samples based on POSS, PLA-g-MA/POSS-NH2, and PLA-g-MA/POSS-OH, together with the above strong signals coming from the PLA chain, other peaks are observed in the region between 0.5 and 1.0 ppm. In particular, in the case of the hybrid based on POSS-NH2, PLA-g-MA/POSS-NH2, the signals at 0.94 ppm and 0.63 ppm were assigned to the methyl protons (-Si-CH2CH(CH 3)2) and methylene protons (-Si-CH 2CH(CH3)2), respectively, and the small signals at 1.88 ppm (region not shown) can be ascribed to the methine protons (-Si-CH2CH(CH3)2). Indeed, this finding reveals that POSS is chemically bound to PLA chains, un-reacted silsesquioxane being removed by the purification process. Moreover, the resonance at 2.2–2.5 and 3.5–4.0 ppm disappears in the sample treated with POSS-NH2, thus indicating the reaction of the succinic anhydride rings.

By comparing the integration area of the peak at 5.2 ppm to those of the peaks belonging to the POSS-NH2, it is possible to calculate the amount of the silsesquioxane grafted onto the polymer backbone. The results obtained from 1H-NMR highlight that ca. 70 % of the maleic anhydride groups of PLA react with the amino functionalities of POSS and that the percentage of silsesquioxane moiety grafted onto the polymer is ca. 4 %. A similar 1H-NMR spectrum (results not shown) was obtained in the case of POSS-OH, but the areas of the peaks related to POSS moiety were much lower than those in the spectrum of PLA-g-MA/POSS-NH2. This different behavior might be ascribed to the steric hindrance of the hydroxyl functionalities of POSS-OH, which, being on two vicinal carbon atoms in the same cyclohexane ring, likely retain a limit reactivity. This result highlights also the importance of properly choosing the functionalities of the silsesquioxane. In the light of these results, the hybrids based on POSS-NH2 were considered in detail for a further characterization.

In order to better assess the structure of the hybrid systems, FT-IR measurements also were carried out. Figure 3 compares IR spectra of the pristine PLA-g-MA with that of PLA-g-MA/POSS-NH2.

Although the two spectra are similar, some modifications are visible in the part of the spectrum between 1,850 and 1,650 cm−1. Indeed, a shoulder is clearly visible at 1,710 cm−1, which can be assigned to the carbonyl group stretching vibration of an amide. Thus, as illustrated in Fig. 2, these results prove the occurrence of the reaction between the MA group of PLA-g-MA and the amino group of POSS molecules.

It is worth underlining that the above grafting reaction, carried out by applying mild conditions, is not accompanied by a change of the polymer molecular mass, as confirmed by viscosity measurements (results not shown). This aspect represents one of the main advantage of this novel preparation method, as the classical approaches applied for POSS-hybrid synthesis, being based on the use of silsesquioxane molecules as initiators of the ring-opening polymerization of lactide, give a relevant decrease of the polymer molecular mass by increasing the amount of POSS in the reaction mixture and produce macromolecular chains carrying the silsesquioxane only as end group. Conversely, our approach allows from one part to maintain the pristine PLA molecular mass and from the other to tune the level of POSS grafting, which depends on the concentration of the polymer functional groups.

The thermal properties of the hybrid systems based on POSS were studied by means of DSC. Figure 4 shows the DSC traces (as recorded during the second heating scan) for the neat PLA-g-MA, PLA-g-MA/POSS-NH2, and PLA-g-MA/POSS-OH.

DSC results clearly show that the incorporation of POSS has little effect on the glass transition temperature (T g) of PLA-g-MA, which is around 62.5 °C. Neat PLA-g-MA exhibits a cold crystallization (T cc) and a melting peak (T m) at 128 and 151 °C, respectively. Although, T cc and T m were found not to change in the hybrid systems, the melting heat (ΔH m) turned out to be much higher in the samples grafted with POSS.

Indeed, on the basis of the melting heat of 100 % crystalline (ΔH o) PLA (93 J/g), the degree of crystallinity (W c) of the neat PLA and of the hybrids based on POSS were determined. W c is ca. 5 % for PLA-g-MA, increasing to 7 and 15 % for PLA-g-MA/POSS-OH and PLA-g-MA/POSS-NH2, respectively. It is worth underlining that the increase of W c seems to be related to the amount of POSS grafted onto the polymer, being the degree of crystallinity much higher in the sample based on POSS-NH2. It is worth underlining that in the case of the nanocomposites prepared by melt blending, the addition of POSS was found to enhance the crystallinity of PLA only to the a maximum of 17 % [20], while, as previously underlined, in the synthesized hybrid based on POSS-NH2 the increment was almost 200 %.

In order to further elucidate the role of POSS on the PLA crystallization, WAXD measurements were carried out. Figure 5 shows the WAXD pattern of the neat PLA-g-MA film and that of the hybrid film based on POSS-NH2, namely the sample whose crystallinity was more affected by the grafting of POSS. Both films exhibit a diffraction pattern typical of crystalline PLA [21], consisting of two major crystalline diffraction peaks at 2θ values of 16.6 and 19.0° and two additional small peaks at 15.0 and 22.5°. Moreover, in the spectrum of the hybrid film, a very small and broad peak at ca. 8° is visible, which indicates some degree of short-range aggregation of the silsesquioxane molecules, being typical of POSS crystal [36].

Although, the spectra of the two films are similar, the intensity of the diffraction peaks of PLA-g-MA/POSS-NH2 appears to be considerably more intense, thus highlighting a higher crystallinity of the hybrid film when compared to the pristine one. Indeed, the above finding supports DSC measurements results.

In order to elucidate the peculiar behavior of the POSS-based hybrid, measurements by means of a hot stage coupled to a polarized optical microscope were carried out. By comparing the micrographs, taken at 125 °C during isothermal crystallization of pristine PLA-g-MA with that of PLA-g-MA/POSS-NH2, it is clearly visible that the hybrid sample shows a higher nucleation density, i.e. a greater number of spherulites per unit volume, thus highlighting a nucleation effect of the silsesquioxane (Fig. 6).

It was reported that there was a nucleating effect of POSS for several polymers [29], including PLA [21] when it is dispersed in the matrix by melt or solution blending. However, due to the adopted synthesis and purification procedure, un-reacted crystalline POSS, able to provide nucleation sites, is not expected to be present in the hybrid samples.

When POSS is covalently bound to the polymer chain, the resulting effect on crystallization is highly dependent on the specific molecular architecture. Indeed, the presence of POSS as a pendant group of the backbone chain greatly hinders the crystallization process in poly(ethylene) (PE)-POSS copolymers, leading to smaller and defective PE crystallites [36]. On the other end, the presence of silsesquioxane molecules, attached to one end of PLA chains, was found to appreciably increase the crystal nucleation density [28]. On the basis of the literature findings, it is possible to hypothesize that the polymer structuring depends also on the amount of silsesquioxane molecules attached to the macromolecular chains. In the case of our hybrid sample, characterized by a low grafting density, the partial POSS aggregation, evidenced by WAXD measurements, is likely to promote the structuring of the long chain segments lying between two silsesquioxane molecules, similar as in the case of the attachment of POSS at one end of the macromolecular chain [28]. Conversely, when the amount of POSS inserted into the polymer is high, it can hinder the macromolecule organization.

The wettability of neat and hybrid films was evaluated by contact angle measurements. The contact angle of PLA films is ca. 73°, while that of hybrid film based on POSS-NH2 was found to be higher, being ca. 95°. The influence of POSS on surface properties was previously evidenced on other POSS/polymer systems. An increase of surface hydrophobicity with respect to the neat polymer matrix was found in the case of the styrene-maleic anhydride copolymers (PSMA)/POSS systems [36]. This finding was explained by taking into account the cumulative effect of the eight hydrophobic isobutyl groups, attached to the POSS cage, as well as the increase of surface roughness of the nanocomposite films. Also in our case, the increment of contact angle can be ascribed to the hydrophobic nature of silsesquioxane molecules grafted to the polymer chains.

Conclusions

In this paper, a new bio-hybrid system based on polylactic acid (PLA) and polyhedral oligomeric silsesquioxane (POSS), characterized by the presence of POSS directly attached to the polymer backbone, has been prepared by applying a simple approach. The new method consists in a preliminary functionalization of the polymer matrix and a subsequent reaction of silsesquioxane molecules characterized by functionalities, potentially capable of reacting with maleic anhydride groups created onto PLA by a free radical process. Indeed, with respect to the classical approaches applied for POSS-hybrid synthesis, which being based on the use of silsesquioxane molecules as initiators of the ring-opening polymerization of lactide give a relevant decrease of the polymer molecular mass by increasing the amount of POSS in the reaction mixture and produce macromolecular chains carrying the silsesquioxane only as end group, our method allows to maintain the pristine PLA molecular mass and to tune the level of POSS grafting.

It is of utmost relevance that the presence of silsesquioxane molecules, attached to the polymer chains, improves PLA crystallinity, by affecting the crystal nucleation density, as well as the film hydrophobicity.

References

Lim L-T, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci 33:820–852. doi:10.1016/j.progpolymsci.2008.05.004

Södergård A, Stolt M (2002) Properties of lactic acid based polymers and their correlation with composition. Prog Polym Sci 27:1123–1163. doi:10.1016/S0079-6700(02)00012-6

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9:63–84

Sinha Ray S (2012) Polylactide-based bionanocomposites: a promising class of hybrid materials. Acc Chem Res 45:1710–1720. doi:10.1021/ar3000376

Sinha Ray S, Yamada K, Okamoto M, Fujimoto A, Ogami A, Ueda K (2003) New polylactide/layered silicate nanocomposites. 5. Designing of materials with desired properties. Polymer 44:6633–6646. doi:10.1016/j.polymer.2003.08.021

Sinha Ray S, Yamada K, Okamoto M, Ogami A, Ueda K (2003) New polylactide/layered silicate nanocomposites. 3. High-performance biodegradable materials. Chem Mater 15:1456–1465. doi:10.1021/cm020953r

Monticelli O, Bocchini S, Gardella L, Cavallo D, Cebe P, Germelli G (2013) Impact of synthetic talc on PLLA electrospun fibers. Eur Polym J 49:2572–2583. doi:10.1016/j.eurpolymj.2013.05.017

Bugatti V, Livi S, Hayrapetyan S, Wang Y, Estevez L, Vittoria V, Giannelis EP (2013) Deposition of LDH on plasma treated polylactic acid to reduce water permeability. J Colloid Interface Sci 396:47–52. doi:10.1016/j.jcis.2013.01.006

Bourbigot S, Fontaine G, Gallos A, Bellayer S (2011) Reactive extrusion of PLA and of PLA/carbon nanotubes nanocomposite: processing, characterization and flame retardancy. Polym Adv Technol 22:30–37. doi:10.1002/pat.1715

Barrau S, Vanmansart C, Moreau M, Addad A, Stoclet G, Lefebvre J-M, Seguela R (2011) Crystallization behavior of carbon nanotube − polylactide nanocomposites. Macromolecules 44:6496–6502. doi:10.1021/ma200842n

Yoon JT, Lee SC, Jeong YG (2011) Effects of grafted chain length on mechanical and electrical properties of nanocomposites containing polylactide-grafted carbon nanotubes. Compos Sci Technol 70:776–782. doi:10.1016/j.compscitech.2010.01.011

Bae GY, Jang J, Jeong YG, Lyoo WS, Min BG (2010) Superhydrophobic PLA fabrics prepared by UV photo-grafting of hydrophobic silica particles possessing vinyl groups. J Colloid Interface Sci 344:584–587. doi:10.1016/j.jcis.2010.01.024

Zhuang W, Liu J, Zhang JH, Hu BX, Shen J (2009) Preparation, characterization, and properties of TiO2/PLA nanocomposites by in situ polymerization. Polym Compos 30:1074–1080. doi:10.1002/pc.20658

Xu X, Yang Q, Wang Y, Yu H, Chen X, Jing X (2006) Biodegradable electrospun poly(l-lactide) fibers containing antibacterial silver nanoparticles. Eur Polym J 42:2081–2087. doi:10.1016/j.eurpolymj.2006.03.032

Gardella L, Basso A, Prato M, Monticelli O (2013) PLA/POSS nanofibers: a novel system for the immobilization of metal nanoparticles. ACS Appl Mater Interfaces 5:7688–7692. doi:10.1021/am402280j

Monticelli O, Putti M, Gardella L, Cavallo D, Prato M, Nitti S (2014) New stereocomplex PLA-based fibers: effect of POSS on polymer functionalization and properties. Macromolecules 47:4718–4727. doi:10.1021/ma500528a

Lee K-Y, Blaker JJ, Bismarck A (2009) Surface functionalisation of bacterial cellulose as the route to produce green polylactide nanocomposites with improved properties. Compos Sci Technol 69:2724–2733. doi:10.1016/j.compscitech.2009.08.016

Goffin A-L, Raquez J-M, Duquesne E, Siqueira G, Habibi Y, Dufresne A, Dubois P (2011) From interfacial ring-opening polymerization to melt processing of cellulose nanowhisker-filled polylactide-based nanocomposites. Biomacromolecules 12:2456–2465. doi:10.1021/bm200581h

Turan D, Sirin H, Ozkoc G (2011) Effects of POSS particles on the mechanical, thermal, and morphological properties of PLA and plasticised PLA. J Appl Polym Sci 121:1067–1075. doi:10.1002/app.33802

Wang R, Wang S, Zhang Y (2009) Morphology, rheological behavior, and thermal stability of PLA/PBSA/POSS composites. J Appl Polym Sci 113:3095–3102. doi:10.1002/app.30333

Yu J, Qiu Z (2011) Preparation and properties of biodegradable poly(l-lactide)/octamethyl-polyhedral oligomeric silsesquioxanes nanocomposites with enhanced crystallization rate via simple melt compounding. ACS Appl Mater Interfaces 3:890–897. doi:10.1021/am1012485

Pan H, Qiu Z (2010) Biodegradable poly(l-lactide)/polyhedral oligomeric silsesquioxanes nanocomposites: enhanced crystallization, mechanical properties, and hydrolytic degradation. Macromolecules 43:1499–1506. doi:10.1021/ma9023685

Song L, Xuan S, Wang X, Hu Y (2012) Flame retardancy and thermal degradation behaviors of phosphate in combination with POSS in polylactide composites. Thermochim Acta 527:1–7. doi:10.1016/j.tca.2011.07.012

Fox DM, Lee J, Citro CJ, Novy M (2013) Flame retarded poly(lactic acid) using POSS-modified cellulose. 1. Thermal and combustion properties of intumescing composites. Polym Degrad Stab 98:590–596. doi:10.1016/j.polymdegradstab.2012.11.016

Goffin A-L, Duquesne E, Moins S, Alexandre M, Dubois P (2007) New organic–inorganic nanohybrids via ring opening polymerization of (di)lactones initiated by functionalized polyhedral oligomeric silsesquioxane. Eur Polym J 43:4103–4113. doi:10.1016/j.eurpolymj.2007.07.041

Lee JH, Jeong YG (2010) Preparation and characterization of nanocomposites based on polylactides tethered with polyhedral oligomeric silsesquioxane. J Appl Polym Sci 115:1039–1046. doi:10.1002/app.31076

Sun Y, He C (2013) Biodegradable “core–shell” rubber nanoparticles and their toughening of poly(lactides). Macromolecules 46:9625–9633. doi:10.1021/ma4020615

Monticelli O, Cavallo D, Bocchini S, Frache A, Carniato F, Tonelotto A (2011) A novel use of Ti-POSS as initiator of L-lactide ring-opening polymerization. J Polym Sci Part A Polym Chem 49:4794–4799. doi:10.1002/pola.24926

Cordes DB, Lickiss PD, Rataboul F (2010) Recent developments in the chemistry of cubic polyhedral oligosilsesquioxanes. Chem Rev 110:2081–2173. doi:10.1021/cr900201r

Carniato F, Bisio C, Gatti G, Boccaleri E, Bertinetti E, Coluccia S, Monticelli O, Marchese L (2009) Titanosilsesquioxanes embedded in synthetic clay as a hybrid material for polymer science. Angew Chem Int Ed 48:6059–6061. doi:10.1002/anie.200901927

Monticelli O, Fina A, Cozza ES, Prato M, Bruzzo V (2011) POSS vapor phase grafting: a novel method to modify polymer films. J Mater Chem 21:18049–18054. doi:10.1039/C1JM13553H

Monticelli O, Fina A, Cavallo D, Gioffredi E, Delprato G (2013) On a novel method to synthesize POSS-based hybrids: an example of the preparation of TPU based system. Express Polym Lett 7:966–973. doi:10.3144/expresspolymlett.2013.95

Fina A, Monticelli O, Camino G (2010) POSS-based hybrids by melt/reactive blending. J Mater Chem 20:9297–9305. doi:10.1039/C0JM00480D

Gardella L, Calabrese M, Monticelli O (2014) PLA maleation: an easy and effective method to modify the properties of PLA/PCL immiscible blends. Colloid Polym Sci. doi:10.1007/s00396-014-3328-3

Lia H-M, Chena H, Shenb Z-G, Linb S (2002) Preparation and characterization of maleic anhydride-functionalized syndiotactic polystyrene. Polymer 43:5455–5461. doi:10.1016/S0032-3861(02)00369-5

Monticelli O, Fina A, Ullah A, Waghmare P (2009) Preparation, characterization, and properties of novel PSMA-POSS systems by reactive blending. Macromolecules 42:6614–6623. doi:10.1021/ma900969b

Acknowledgements

We are grateful to the Italian Ministry of Education and University through the 2010-2011 PRIN project (Grant No. 2010XLLNM3_005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gardella, L., Colonna, S., Fina, A. et al. On novel bio-hybrid system based on PLA and POSS. Colloid Polym Sci 292, 3271–3278 (2014). https://doi.org/10.1007/s00396-014-3369-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-014-3369-7