Summary

Following rennet-induced gelation, the coagulum is subjected to a series of treatments (e.g., cutting, cooking, stirring, acidification, whey drainage), the principal objective of which is to encourage syneresis (removal of whey from the gel) and effectively to concentrate the casein and fat to the degree characteristic of the variety. The principal treatments, which are characteristic of the variety of cheese, are described in this chapter. The cheddaring and pasta filata steps, together with moulding, pressing and packaging cheese, are also discussed.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

The rennet coagulation process is essentially similar for all cheese varieties and the structure of the coagula (gel) is also similar. The gel is subjected to a series of treatments (see Chaps. 2 and 3), the principal objective of which is to remove whey from the gel and to effectively concentrate the casein and fat to the degree characteristic of the variety. The principal treatments, which are characteristic of the type, and in some cases the variety, of cheese, are described in this chapter. Information on the manufacturing protocol for a number of cheeses is summarized in Chap. 3.

Rennet- or acid-coagulated milk gels are quite stable if left undisturbed but if cut or broken or subjected to external pressure, the para-casein matrix contracts , expressing the aqueous phase of the gel (known as whey). This process, syneresis, enables the cheesemaker to control the moisture content of the cheese and, hence, the activity of microorganisms and enzymes in the cheese and, consequently, the biochemistry of ripening and the stability and quality of the finished cheese. The higher the moisture content of cheese, the faster it will mature but the less stable it will be. High-moisture cheeses have a much greater propensity to develop off-flavours than low-moisture varieties. Although the starter and adventitious microflora of cheese have a major impact on the biochemistry of cheese ripening, they do so only in as far as the composition of the cheese curd permits. Syneresis is under the control of the cheesemaker and via syneresis, the composition and quality of the cheese.

Many of the treatments to which rennet-coagulated milk gels are subjected may be classified generically as dehydration: cheese manufacture essentially involves concentrating the fat and casein of milk approximately tenfold, with the removal of lactose, whey proteins and soluble salts in the whey. Although there are certain common features, the factors which promote and regulate syneresis (dehydration) are characteristic of the cheese variety or perhaps more correctly, family of varieties. In the case of the Cheddar- and Swiss-type cheeses, dehydration is accomplished mainly in the cheese vat by finely cutting the coagulum, extensive ‘cooking’ of the curd-whey mixture (to ~40 and ~54 °C, respectively) and vigorous agitation during cooking. For the softer (high-moisture) varieties, the gel may be scooped directly into the moulds without cutting or cooking and whey explosion occurs mainly in the moulds as the pH decreases. Curds for some varieties, e.g., Cheddar and Swiss, are subjected to considerable pressure in the cheese moulds, thus aiding whey removal while curds for the softer varieties are pressed only under their own weight.

Most of the published studies on syneresis have been concerned mainly with the factors that affect it during the early stages of dehydration in Cheddar- and Dutch-type cheeses, i.e., mainly during cooking, but it is assumed that basically the same mechanisms operate in all varieties throughout the dehydration process.

Despite its accepted importance in the control of cheese moisture, the mechanism of syneresis of rennet-induced milk gels is not well understood. There is a considerable amount of empirical information on factors that influence syneresis but the actual mechanism of syneresis has received comparatively little study. Poor methodology is mainly responsible for the lack of information; the number of principles exploited in methods used to measure syneresis attests to their unsuitability. Some authors have attempted to simulate cheese manufacture, e.g., stirring, observing a cooking profile similar to that for the cheese of interest, even adding starter but the accuracy and precision of many of the methods are poor. Many of the methods have been used only by the original investigator.

The literature on the syneresis of milk gels has been reviewed by Green and Grandison (1993), Walstra (1993) and Dejmek and Walstra (2004), and is summarized here.

8.2 Methods for Measuring Syneresis

A variety of principles have been used to quantify syneresis. These include:

-

measuring the volume of whey expressed from curd pieces under standard conditions, following cutting of the gel,

-

changes in the moisture content, volume or density of curd pieces over time,

-

use of tracers or markers to indirectly measure whey volume, or

-

changes in the electrical conductivity of the curd.

Methods based on the volume of expressed whey are simple and straightforward to execute but complete recovery of whey is difficult and syneresis continues during any separation process. Similar constraints apply to methods that depend on the volume or composition of the curd and, in addition, the actual analytical step may be difficult while avoiding continuing syneresis. Methods based on the use of a tracer or marker involve adding a small volume of a solution of some tracer (e.g., a dye) to the system at the start of syneresis; as the volume of free whey increases, the concentration of tracer in the solution decreases. The principal problems to be avoided are diffusion of the tracer into, or its adsorption, onto the curd particles. The opposite principle has also been used: a small amount of clarified whey is placed on top of the cut gel; whey expressed from the curd is turbid owing to the presence of fat globules and therefore the turbidity of the free whey increases as syneresis progresses. As the moisture content of curd decreases, its electrical conductivity decreases; as with many other methods, clean separation of curd particles from the whey without concomitant changes is a problem.

However, using these methods, and data from actual cheesemaking experiments, the influence of several factors on syneresis is now well established, at least in general terms.

8.3 Influence of Compositional Factors on Syneresis

The syneresis of rennet-induced milk gels is influenced by milk composition which, in turn, is affected by the feed, stage of lactation and health of the animals from which the milk is obtained. Fat tends to reduce syneresis and increase the water-holding capacity of cheese curd; increasing the fat content of cheese milk increases cheese yield by ~1.2 times the weight of additional fat. However, syneresis tends to be directly related to casein concentration, i.e., good syneresis occurs at high casein levels. Since the fat and casein levels in milk tend to change in parallel, they have off-setting effects on syneresis. Concentration of milk suppresses syneresis, possibly because of its effect on gel strength, although the rigidity modulus (see Chap. 14) at the time of cutting appears to have little effect on syneresis.

The rate of syneresis is directly related to the acidity, and, therefore, is inversely related to pH; it is optimal at the isoelectric point of casein (i.e., pH 4.6–4.7). The addition of CaCl2 to milk promotes syneresis but the effect appears to be less than might be expected and may be negative at certain pH values and at high calcium concentrations, especially if the gel is held for a long period before cutting. The adverse effect of a high concentration of calcium has been attributed to interaction of Ca2+ with the aspartate and glutamate groups of proteins, leading to an increased net positive charge, swelling of the protein and suppression of syneresis. It is likely that a firmer gel, such as would be obtained on longer holding, would also be more resistant to syneresis. The influence of colloidal calcium phosphate on syneresis does not appear to have been investigated. Addition of a low level of NaCl increases the rate of syneresis but higher levels retard it.

8.4 Influence of Processing Variables on Syneresis

The extent of syneresis, and hence the moisture content of cheese, is influenced by various cheesemaking procedures; many of these factors are exploited by cheesemakers to control cheese composition, and hence its flavour and texture. The principal factors are:

8.4.1 Size of the Curd Particles

Everything else being equal, the smaller the curd pieces, the faster the rate and the greater the extent of syneresis, reflecting the greater surface area available for loss of whey. For some high-moisture cheeses, the coagulum may not be cut but scooped, unbroken, into cheese moulds. For Cheddar- and Dutch-type cheeses the coagulum is cut into cubes of about 1 cm side using knives with vertical or horizontal wires or bars (Fig. 8.1a, b). Traditionally, the coagulum for many Swiss or hard Italian varieties was cut with a harp (Fig. 8.1c) or a basket-like implement known as a spino (Figs. 8.1d and 8.2) which is used in a swirling action around the hemi-spherical or conically shaped vats used traditionally for these varieties. In the large modern vats used for Cheddar, Dutch and other varieties, the rectangular cutting knives are fixed in a staggered fashion to an axle running through the vat and serve to cut the coagulum and later to agitate the curd-whey mixture during cooking when the direction of rotation of the axle is reversed (Fig. 8.3); one side of the bars of the knives is sharpened and it is important to maintain a sharp edge to make a clean cut and minimize the loss of fat and casein into the whey.

Illustrations of cheese vats showing the curd knives/stirrer blades : (a) arranged vertically in a Double-O Multicurd vat, (b) arranged horizontally, in a staggered mode, along central horizontal shaft, in a cylindrical OST vat; (c) toward the end of the cutting cycle in a horizontal cheese vat. The blades are tapered and move in the direction of the sharp edge (knife) when cutting and in the reverse direction (blunt edge, stirrer) when stirring [from technical brochures by: Gadan A/S, Them, Denmark (Multicurd vat), and Tebel-MKT B.V. Leeuwarden, Holland (Ost vat)]

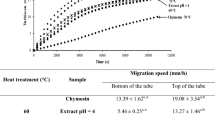

8.4.2 Cook Temperature

Heating the curd/whey mixture (a process referred to as cooking or scalding) promotes syneresis (Fig. 8.4a). The cook temperature is characteristic of the variety, e.g., 31 °C for high-moisture varieties such as Camembert (in effect, no cooking), 36 °C for Gouda and Edam, 38–40 °C for Cheddar, 52–55 °C for Emmental and Parmesan. The cook temperature must match the thermal stability of the starter: acid production by some Lactococcus strains is stopped > ~ 35 °C but others withstand cooking at 40–42 °C; cooking cheese curds to a temperature that inhibits the culture may have a negative effect on syneresis owing to the reduced rate of acidification. A cook temperature up to 55 °C may be used when a thermophilic starter is used; these starters survive but do not grow at 55 °C and hence syneresis depends on temperature rather than on pH. In fact, temperature and pH are complementary: syneresis of low-acid curds, e.g., Emmental, depends mainly on temperature while in high-acid curds, e.g., Camembert, temperature is of little consequence.

Effect of temperature (a) and pH (b) on the rate and extent of syneresis in cut/broken renneted-milk gels (from Fox and McSweeney 1998)

For most varieties, cooking is performed by circulating hot water, or preferably steam, through the jacket of the cheese vat (steam is preferable because it can be shut off more readily than hot water, facilitating better control of temperature). Before the availability of hot water or steam for cooking curds and whey, cooking was performed over an open fire and would have been difficult to control precisely. Cooking over or near an open fire is still used in artisanal farmhouse cheesemaking. Illustrations of old cheese factories suggest that jacketed vats (i.e., hot water or steam) were used from the start of industrialized cheesemaking. For Dutch-type cheeses and a number of other varieties, cooking is performed by removing part (30–40 %) of the whey and replacing it by warm water to give a blend of the desired temperature. This method was probably used initially in farm-scale cheese production which lacked steam or facilities to circulate hot water or steam through a jacketed vat. It was probably used for many other varieties but its use has been discontinued for most of them except Dutch-type cheeses for which its main function now is to reduce the lactose content of the cheese curd and thereby control the pH of the cheese.

The rate of cooking is characteristic of the variety (see Chap. 3). If the rate of cooking is too fast, especially during the early stages, excessive dehydration will occur at the curd surface, leading to the formation of a skin (case hardening) which will retard syneresis and the removal of whey from the interior of the curd pieces, and hence give a high-moisture cheese.

8.4.3 Rate of Acid Development

The lower the pH, the faster is the rate and the greater the extent of syneresis (Fig. 8.4b). Presumably, this reflects the reduced inter-protein repulsion by the negative charge on the casein molecules as the isoelectric point is approached.

8.4.4 Stirring of the Curd-Whey Mixture

During cooking, the curd/whey mixture is stirred, which serves a number of functions:

-

it facilitates cooking,

-

it prevents the curd pieces from matting (which would have a strong negative effect on syneresis), and

-

it promotes syneresis via collisions between curd pieces and between curd pieces and the vat wall.

Everything else being equal, syneresis is directly proportional to the intensity of stirring. Initially, the curd is very soft and gentle stirring should be used—a period of 5–10 min is allowed for the cut surfaces of the curd pieces to “heal”; vigorous agitation of the curd during this period will cause extensive losses of fat and protein into the whey and a decrease in cheese yield (see Chap. 10).

For some varieties, the curd is held in the whey until a certain pH is reached, e.g., 6.2 for Cheddar, after which the curds and whey are separated, usually using metal screens. For other varieties, e.g., Gouda, the curds and whey are separated after holding at the desired cook temperature for a defined period. For yet other varieties, e.g., Parmesan, the curds and some whey are scooped from the vat using a cheesecloth and transferred to perforated moulds where much of the whey drainage occurs. If whey separation occurs in the cheese vat, stirring of the curds during draining (referred to as dry stirring) is a useful way of promoting syneresis but is not applicable for most varieties.

8.4.5 Pressing

After removal of the whey, the curds mat to form a continuous mass. Treatment of this mass of curd is characteristic of the variety and may involve inverting the mass of curd in the moulds, turning and piling blocks of curd in the vat (traditional “cheddaring” during which period acid develops), and in many cases, pressing (see Chap. 3). Syneresis occurs during these operations but is not easily controlled. With the exception of Cheddar-type cheese, acidification occurs mainly after moulding and this promotes considerable syneresis of the curds. For Cheddar and similar varieties, acidification occurs mainly during “cheddaring” in the vats, and relatively little syneresis occurs after moulding.

8.4.6 Salting

As discussed in Chap. 9, all cheeses are salted at the end of manufacture. Salting causes the loss of moisture from the curd (~2 kg H2O are lost per kg of salt absorbed). However, salting should not be used as a means of controlling cheese moisture.

8.4.7 Milk Quality and Pre-Treatment

Heating milk under conditions that cause whey protein denaturation and interaction with casein micelles reduces the tendency of rennet-induced milk gels to synerese. Homogenization of whole milk has a similar effect. It has been reported that the growth of psychrotrophs in milk reduces its syneretic properties, i.e., leads to a high-moisture cheese; an increased level of rennet slightly increase the rate of syneresis, while plasmin activity in milk is reported to reduce syneresis.

8.5 Kinetics and Mechanism of Syneresis

Data from various investigations indicate that syneresis is initially a first order reaction, i.e., the rate of syneresis depends on the amount of whey remaining within the curd. It is generally assumed that syneresis is due to protein-protein interactions and may be regarded as a continuation of the gel assembly process during rennet coagulation. The inhibitory effects of high concentrations of salts (CaCl2, NaCl, KCl) on syneresis imply that ionic attractions are involved. Urea promotes syneresis, suggesting that hydrogen bonds are not involved. The effectiveness of pH in promoting syneresis is probably due to a reduction of overall charge as the isoelectric point is approached. Studies on artificial milk systems implicate the ε-NH2 group of the lysine residues in casein in syneresis; the apparent importance of ε-NH2 groups in the second phase of rennet coagulation was discussed in Chap. 7. Lysozyme, which reacts with casein micelles, reducing their charge and rennet coagulation time, also accelerates syneresis when added to milk. Some authors have concluded that curd-firming and syneresis are different aspects of the same phenomenon but opinions are not unanimous. As discussed in Chap. 7, electron microscopic studies have shown that the aggregation of casein micelles to form a gel is followed by increasingly closer contact between the micelles, leading to fusion. The syneretic pressure in an uncut gel is very small (~1 Pa) but when the coagulum is cut, the whey leaks out. Syneresis is initially a first order reaction because the pressure depends on the amount of whey in the curd; holding curd in whey retards syneresis owing to back pressure of the surrounding whey, while removing whey promotes syneresis. When the curd is reduced to ~70 % of its initial volume, syneresis becomes dependent on factors other than the volume of residual whey in the curd. It has been proposed that hydrophobic and ionic interactions within the casein network are probably responsible for the advanced stages of syneresis. This is in accord with the promotion of syneresis by reduced pH and low levels of CaCl2, which reduce micellar charge and increase hydrophobicity, and by increased temperature which increases hydrophobic interactions.

The foregoing discussion on syneresis pertains especially to the syneresis occurring in the cheese vat, i.e., mainly to hard and semi-hard varieties. Syneresis continues after hooping (moulding) and represents the major part of syneresis in soft varieties. Presumably, the mechanism of syneresis in the moulds is the same as in the cheese vat although the range of treatments that can be applied at this stage is rather restricted. External pressure is applied to the curds for many cheese varieties after moulding and makes a significant contribution to whey removal; in general, the drier the cheese curd at hooping, the higher the pressure applied, which is probably a reflection of the greater difficulty in ensuring fusion of low-moisture curds.

8.6 Textured Cheese

The development of a recognizably fibrous texture is part of the manufacturing procedure for a small number of cheese varieties and these textural properties were traditionally regarded as an essential feature of their organoleptic properties. Texturized cheeses belong to two classes: Cheddar and some closely related varieties, in which a fibrous texture is developed prior to pressing, and pasta filata types , e.g., Mozzarella, Kashkaval and Provalone, in which texturization is accomplished by heating, stretching and kneading the curd.

In traditional Cheddar manufacture, the drained curds are piled along the sides of the vat during which matting (fusion) of individual curd particles occurs. To enable faster turnover of the cheese vats, it became common practice in the 1960s to transfer the curds/whey after cooking to cheaper cheddaring “sinks” where whey drainage and cheddaring occurred. The piles of curd are cut into blocks (30 × 10 cm) which are inverted frequently and piled over a period of ~2 h. This operation, known as cheddaring, was considered by many researchers and cheesemakers as the essential, characteristic part of the Cheddar cheese manufacturing process. During cheddaring, the curd flows under its own weight, leading to fusion and deformation of curd particles which was believed to be responsible for the ‘chicken breast meat’ structure of fresh Cheddar curd, and for the characteristic texture of mature Cheddar cheese. Cheddaring promotes a number of physico-chemical conditions which are conducive to curd flow and texturization:

-

solubilization of micellar calcium which is bound to the casein and acts as a cementing agent between the casein micelles/sub-micelles,

-

a decrease in the concentration of micellar Ca, resulting in an increase in the ratio of soluble to casein-bound Ca; soluble Ca as a % of total Ca in the curd increases from ~5 to 40 as the pH decreases from 6.15 to 5.2.

-

an increase in para-casein hydration which increases with decreasing pH in the range 6.6 to 5.15 (see Fig. 8.5), and

-

an increase in the viscous character of the curd.

The increase in casein hydration with decreasing pH is probably a consequence of the increase the ratio of soluble to micellar Ca; it has been found in model casein systems that casein hydration is inversely related to the concentration of casein-bound Ca (Sood et al. 1980).

As a consequence of the decrease in casein-bound Ca and the increase in casein hydration , the viscoelastic casein matrix, with occluded liquid fat and moisture phases, flows if unrestricted, especially when piled and pressed under its own weight. The flow of curd gives the desired planar orientation of the strands of the para-casein network. The physico-chemical changes in curd during cheddaring are summarised in Fig. 8.5. However, there is little scientific support for the necessity of cheddaring; on the contrary, there is strong evidence that cheddaring is of no consequence to Cheddar cheese quality and serves only to allow the desired degree of acid development and syneresis to occur.

Various forms of restricted flow under different degrees of external pressure result in Cheddar cheese with a lower moisture content than curd cheddared in the traditional manner. Differences in the extent of curd deformation caused by modified “cheddaring” processes diminish during milling, salting and pressing and have little effect on the flavour and textural characteristics of the final cheese. The development of a fibrous texture results in loss of the micelle structure but this is not essential as the amount of deformation is very small and is probably altered by the subsequent and more extensive deformation during pressing.

In modern practice, most Cheddar cheese curd is manufactured in continuous, mechanical cheddaring systems in which little flow occurs in comparison with traditional methods (Fig. 8.6); indeed, matting is prevented in the manufacture of some Cheddar-type cheeses, e.g., stirred-curd Cheddar. The textural qualities of Cheddar cheese produced by these systems is acceptable, indicating that ‘flow’ during manufacture is not essential.

(a) Schematic representation of a Tetra-Pak Alfomatic continuous system for dewheying, cheddaring, milling and salting curd for Cheddar cheese. 1. Whey strainer (screen), 2. Whey pump, 3. Agitator, 4. Conveyors with variable speed drive, 5. Agitators (optional) for production of stirred-curd Cheddar, 6. Chip mill, 7. Dry salting system (from Bylund 1997). (b) Photograph of the exterior of an Alfomatic continuous cheddaring system in industry. Note the walkway to the left which indicates the scale of the apparatus

Presumably, the various interactions, ionic and/or hydrophobic, which are considered to be responsible for syneresis, continue during the cheddaring process but there appears to have been no studies on this aspect of cheesemaking.

In the manufacture of Mozzarella and other pasta filata (stretched-curd) cheeses, the acidified curd is heated to ~58–60 °C by kneading in hot water (~78 °C) and stretched in equipment designed to cause extension of the hot molten curd (Fig. 8.7a). This process, whereby the curd is converted into a plastic molten mass (Fig. 8.7b–d), is referred to as plasticization and was developed originally in hot climates as a means of heat-treating and hence extending the shelf-life of curd of poor microbiological status. Successful texturization of the curd requires that the viscoelastic para-casein matrix undergoes limited flow and stretches into hot molten sheets, without breaking, when extended. Plasticization is accompanied by microstructural changes in the cheddared curd, including further linearization of the para-casein matrix into fibres and coalescence of fat into elongated pools which are trapped between, and show the same orientation as, the protein fibres (Fig. 8.8).

Plasticization of low-moisture Mozzarella: (A) kneading-plasticizing equipment (from Costruzioni Meccaniche e Tecnologia S.p.a., Perveragno, Cuneo, Italy) consisting of hot water heating unit, cheese shredding unit, plasticization chamber where the curd is kneaded and stretched in hot water by toothed arms which oscillate backwards and forwards in opposite directions, and an auger, which conveys the plasticized cheese to the moulding unit. (C) mid-stage of plasticization; shredded curds have begun to fuse but plasticization is not yet complete, as shown by the presence of lumps in the curd mass; (B) fully plasticized molten curd mass which exhibits a long consistency and an oily surface sheen; and (D) moulding of the plasticized curd

Confocal laser scanning micrographs of Mozzarella cheese curd at various stages of manufacture: after cutting (a), at whey drainage (b), after cheddaring (c) and after plasticization (d). The white-grey areas represent the para-casein matrix, while the black areas represent the occluded fat and moisture phases. Bar = 25 μm (From Auty and Guinee, unpublished results)

The physico-chemical changes responsible for plasticization of the curd have not been elucidated unequivocally. However, based on information derived from studies on the behaviour of curds of different composition and pH when subjected to texturization (Guinee, unpublished results) and microstructural changes that accompany placticization (e.g., Fig. 8.8), and the viscoelastic changes in curd when heated to a temperature similar to that during the plasticization process (Guinee et al. 1998), it may be speculated that successful texturization is a consequence of:

-

an adequate degree of casein hydration of the cheddared curd, which is controlled by its pH, total calcium content and ratio of soluble to casein-bound Ca

-

heat-induced coalescence of free fat (formed as a consequence of shearing of the fat globule membrane) which lubricates the flow of the para-casein matrix, and

-

extension and shear stresses applied to the curd which assist in the displacement of contiguous planes of the para-casein matrix.

The relationship between para-casein hydration and pH may be explained by the dominance of two opposing forces over the pH range 6.0 to 5.0, i.e.:

-

those that promote neutralization of negative charges which lead to contraction of the para-casein thereby limiting hydration and impeding flow of the para-casein matrix, and

-

those that promote solubilization of micellar calcium which is conducive to casein hydration and promotes flow of the para-casein matrix.

At pH values in the range 6.0 to 5.2, solubilization of micellar calcium appears to be dominant as decreasing pH results in an increase in hydration of para-casein. In contrast, the reduction in pH is the dominant factor at pH 5.2–4.6, as decreasing pH results in a marked decrease in para-casein hydration. The total calcium content of the curd, which is controlled mainly by the pH of the milk at setting and that of the curd at whey drainage, determine the curd pH at which plasticization is possible. In the normal manufacture of Mozzarella, the milk is typically set at pH 6.55, the whey is drained at pH 6.15 and the ideal pH for plasticizing acidified curd is ~5.15. At this pH, the concentration of calcium in the curd (~27 mg/g protein) and the proportion of soluble calcium (~40 % of total) ensure that the para-casein is sufficiently hydrated to enable successful plasticization. At increasingly higher curd pH, the curd becomes progressively less smooth after plasticization, reflecting the decrease in para-casein hydration because of the reduced ratio of soluble to casein-bound calcium. Similarly, in processed cheese manufacture, heating of cheese is accompanied by aggregation of the protein and exudation of moisture and free fat unless emulsifying salts (e.g., sodium orthophosphates) are added to bind casein-bound Ca (see Chap. 17). At a curd pH > 5.4, the curd fails to plasticize adequately; instead a non-plastic mass, with a rough, dull, short, lumpy consistency is obtained. However, successful plasticization may be achieved at a higher curd pH, e.g. 5.6–5.8, if the Ca level in the curd is sufficiently low (e.g. <18 mg/g protein), as in the case of directly-acidified Mozzarella.

In the manufacture of directly-acidified Mozzarella , acidification is performed by the addition of a food-grade acid, rather than the conversion of lactose to lactic acid by the starter culture. The milk pH is typically adjusted to ~5.6 prior to rennet addition and no further change in pH occurs during curd manufacture, which is otherwise similar to that for conventional Mozzarella made using a starter culture. Following whey drainage, the curd, typically with a pH ~ 5.6, plasticizes readily on heating and stretching. The ability of curd made by direct acidification to plasticize at a higher-than-normal pH can be explained on the basis of the interactive effects of total curd calcium and the ratio of soluble to casein-bound Ca (which changes with pH) on para-casein hydration. While soluble Ca as a % of total Ca decreases from ~40 to 20 as the pH is increased from 5.15 to 5.6, the total concentration of calcium is lower and hence the level of casein-bound Ca is probably similar to that obtained at pH 5.15 in conventional cheese manufacture. Hence, as there is an inverse relationship between casein-bound Ca and casein-bound moisture, the degree of para-casein hydration obtained in directly-acidified Mozzarella curd at pH 5.6 is similar to, or somewhat greater than, that in conventionally-produced Mozzarella curd at pH 5.3. Indeed, comparative studies have shown that the water-binding capacity of directly-acidified Mozzarella cheese curd (pH 5.6) is higher than that of conventionally-produced Mozzarella curd (pH 5.2) during the first three weeks of ageing (Kindstedt and Guo 1977).

8.7 Moulding and Pressing of Cheese Curd

At some stage in the manufacturing process (e.g., just after coagulation for Camembert, after cooking for Emmental or after acidification for Cheddar), the curds are transferred to moulds of characteristic shape and size. The principal purpose of moulding is to allow the curd to form a continuous mass; matting of high-moisture curds occurs readily under their own weight but pressing is required for low-moisture cheese. It is important that the curds are warm during pressing, especially for low-moisture curds.

Various pressing systems have been developed, ranging from very simple to continuous presses. In modern Cheddar cheese factories, the salted curds are formed and pressed under their own weight and under a slight vacuum in towers (Wincanton towers; Fig. 8.9) for about 30 min. On exiting the tower, 20 kg blocks are cut from the base of the column of curd by a guillotine and placed in plastic bags which are sealed under vacuum. The reader is referred to Kosikowski and Mistry (1997), Robinson and Wilbey (1998), Bennett and Johnson (2004) or other texts on cheese technology for examples of cheese pressing systems.

(a) Schematic representation of a block former (Wincanton tower, or Block former) system for Cheddar-type cheese. 1. Column, 2. Curd feed, 3. Cyclone, 4. Level sensor, 5. Vacuum unit, 6. Combined bottom plate and guillotine, 7. Elevator platform, 8. Ejector, 9. Barrier bag, 10. Conveyor to vacuum sealing, 11. Whey drainage (from Bylund 1997). (b) Block formers in a commercial Cheddar cheese factory

Cheeses are made up in characteristic shapes and sizes (see Chap. 3). At first glance, it might appear that the shape and size of a cheese are cosmetic. While this may be so in many cases, size and shape are very significant in certain varieties, e.g., surface-ripened cheese (mould or smear) are formed into small, low cylinders—these features are important since these cheeses ripen from the surface toward the centre—if large cheeses were made, the surface would become over-ripe while the centre remained unripe. For cheeses with large eyes, e.g., Emmental, a large cheese is required, as otherwise the leakage of CO2 through the surface would be excessive and the pressure of gas within the cheese would not build-up to the partial pressure required to form eyes.

8.8 Packaging

Like other sectors of the food industry, indeed industry in general, packaging has become a major feature of cheese production, distribution and retailing. Kosikowski and Mistry (1997) include a useful chapter on various aspects of packaging of cheese and fermented milks. Kadoya (1990) provides a more general discussion on food packaging, including a chapter on cheese and fermented milks. The science and technology of packaging are specialized subjects which will not be discussed here.

The objectives of packaging of cheese, as for any food item, are:

-

To protect it against physical, chemical or microbial contamination. Mould growth is of particular concern; since moulds are aerobic, their growth can be prevented by covering the cheese with wax or plasticote or vacuum-packed in plastic film which should have low permeability to oxygen and be free of pin holes. By preventing contamination, packaging serves a public health function as well as reducing losses due to spoilage.

-

To reduce the loss of moisture from the surface and therefore increase economic return; to achieve this, packaging material should have low permeability to moisture.

-

To prevent physical deformation of the cheese, especially soft cheeses, and thus facilitate stacking during ripening, transport and retailing.

-

Packaging provides an opportunity for product labelling and brand identification. This creates the opportunity for advertising and to provide nutritional information.

After salting (see Chap. 9), those cheeses on which the growth of moulds (surface or internal) or of a surface smear is encouraged are transferred to a room at a controlled temperature (~15 °C) and humidity (90–95 % equilibrium relative humidity). Even at this high humidity, some loss of moisture from the surface occurs but the loss is insufficient to create a rind (low-moisture surface layer). After sufficient growth of mould or smear has occurred, such cheeses may be wrapped in foil or grease-proof paper to avoid further loss of moisture.

Traditionally, the development of a rind was encouraged on internal bacterially-ripened cheese by controlled drying of the surface. If properly formed, the rind effectively seals off the interior of the cheese, preventing excessive loss of moisture and the growth of microorganisms on the surface. To stabilize further the surface of such cheeses, they were rubbed with oil (e.g., butter oil or olive oil) or coated with paraffin wax. Sometimes, wax of a particular colour is used, e.g., red for Edam, black for extra-mature Manchego, Cheddar and probably other cheeses. The colour of the wax is characteristic of the variety or of its maturity and is recognised by the consumer as an index of variety or quality.

Today, many internal bacterially-ripened cheeses are packaged in plastic bags of low gas permeability or coated with film-forming plastic material. A variety of plastic packaging materials are used for cheese, e.g., cellophane, cellophane-polyethylene, polyvinyl chloride, polyvinylidene chloride, polystyrene, polypropylene, ethylene vinyl acetate, co-extruded polyolafin, metal foils or paper.

Gasses, e.g., CO2 and H2S, are produced in many cheeses during ripening; CO2 will cause bulging of the package while H2S has an obnoxious aroma which will render the cheese unacceptable. To avoid such problems, the package should be permeable to these gasses.

Packaging is particularly important for soft cheeses, e.g., Cottage, Quarg and Cream and processed cheeses. Metal foils are widely used for consumer or catering packages of processed cheese. Much processed cheese is commercialized as individual slices wrapped in plastic material. High-moisture fresh cheeses are commercialized in plastic tubs, plastic-, wax- or foil-lined cardboard containers or in plastic packages.

Metal cans or glass jars may be used to package natural and processed cheese to offer a novelty presentation feature or, in the case of cans, to provide extra physical protection during distribution and storage.

As for other foods, the packaging of cheese has led to the development of specialized packaging equipment, much of which is highly automated and computerized.

References

Bennett RJ, Johnson KA (2004) General aspects of cheese technology. In: Fox PF, McSweeney PLH, Cogan TM et al (eds) Cheese: Chemistry, Physics and Microbiology. Major Cheese Groups, vol 2, 3rd edn. Elsevier, Amsterdam, pp 23–50

Bylund G (1997) Dairy Processing Handbook. Tetra Pak, Lund

Dejmek P, Walstra P (2004) The syneresis of rennet-coagulated curd. In: Fox PF, McSweeney PLH, Cogan TM et al (eds) Cheese: Chemistry, Physics and Microbiology. General Aspects, vol 1, 3rd edn. Elsevier, Amsterdam, pp 71–103

Fox PF, McSweeney PLH (1998) Dairy Chemistry and Biochemistry. Blackie Academic and Professional Publishers, London

Green ML, Grandison AS (1993) Secondary (non-enzymatic) phase of rennet coagulation and post-coagulation phenomena. In: Fox PF (ed) Cheese: Chemistry, Physics and Microbiology, vol 1, 2nd edn. Chapman & Hall, London, pp 101–140

Guinee TP, Auty MAE, Harrington D et al (1998) Characteristics of different cheeses used in pizza pie. Aust J Dairy Technol 53:109 (Abstract)

Kadoya T (1990) Food Packaging. Academic, San Diego

Kindstedt PS, Guo MR (1977) Chemically-acidified pizza cheese production and functionality. In: Cogan TM, Fox PF, Ross RP (eds) Proceedings 5th Cheese Symposium. Teagasc, Dublin, pp 24–30

Kosikowski FV, Mistry VV (1997) Cheese and Fermented Milk Foods, 3rd edn. F.V. Kosiskowski LLC, Westport

Robinson RK, Wilbey RA (1998) Cheesemaking Practice, R. Scott, 3rd edn. Aspen Publishers Inc., Gaithersburg

Sood SM, Sidhu KS, Dewan RK (1980) Voluminosity and hydration of casein micelles from abnormal milks. NZ J Dairy Sci Technol 15:29–35

Walstra P (1993) The syneresis of curd. In: Fox PF (ed) Cheese: Chemistry, Physics and Microbiology, vol 1, 2nd edn. Chapman & Hall, London, pp 141–191

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer New York

About this chapter

Cite this chapter

Fox, P.F., Guinee, T.P., Cogan, T.M., McSweeney, P.L.H. (2017). Post-Coagulation Treatment of the Renneted-Milk Gel. In: Fundamentals of Cheese Science. Springer, Boston, MA. https://doi.org/10.1007/978-1-4899-7681-9_8

Download citation

DOI: https://doi.org/10.1007/978-1-4899-7681-9_8

Published:

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4899-7679-6

Online ISBN: 978-1-4899-7681-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)