Abstract

Glycoalkaloids in potato-derived products result in bitter taste and potentially toxic effects at high intakes. Generally, extraction of glycoalkaloids prior to HPLC analysis is carried out by dilute acetic acid. For most potato-derived extracts including heat-coagulated potato proteins, this extraction method is sufficient to achieve satisfying tri-glycoalkaloid (TGA) recoveries. Soluble potato proteins obtained by non-denaturing processes show different requirements for glycoalkaloid extraction. TGA extraction was optimized for two commercially available native potato protein isolates and compared to heat-coagulated potato protein. The highest TGA levels were determined in the extract when extraction was carried out at 40 °C by at least 5 % acetic or propionic acid supplemented with 20 mM Na-1-heptanesulfonate (HSA). Addition of HSA results in substantially improved TGA extraction and induces precipitation of soluble protein which enhanced sample cleanup. On the contrary, extraction of TGA from coagulated potato protein in the presence of HSA showed a reduced TGA extraction efficiency. This improved TGA extraction procedure for soluble non-denatured potato protein isolates results in reliable quantification of bitter tasting and toxic glycoalkaloid levels. This contributes to a non-bitter and safe use of the nutritional and functional benefits of this plant protein in food applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Proteins from vegetal sources are gaining more and more interest from the food industry. Today, a wide range of protein isolates from plant sources exists and includes soybean, wheat, rice, pea as well as potatoes. Among these plant proteins, proteins derived from potatoes are considered to have a superior nutritional value. Potato protein is a balanced source of essential amino acids including lysine which is generally deficient in legume and cereal proteins (Knorr 1977; Van Gelder and Vonk 1980). Besides a high nutritional quality, potato protein has also been shown to exhibit good digestibility in both rats and piglets (Nestares et al. 1993; Boisen 1999).

A good source of potato proteins available in large volumes is potato juice (PJ), a by-product from the potato starch industry. In the EU, 7 million tonnes of starch potatoes are produced on a yearly basis (Starch Europe 2014) resulting in a roughly same volume of PJ. PJ is composed of minerals, organic acids, glycoalkaloids, amino acids, and phenolic compounds and is relatively rich in soluble protein 15–20 g/l (Lisinska and Leszczynski 1989; Zwijnenberg et al. 2002). Traditionally, potato proteins are extracted from PJ by heat coagulation processes via steam injection causing denaturation and flocculation of the proteins. This results in a nutritional but largely insoluble and non-functional product which finds its way into various feed applications. Alternative methods for purification and fractionation of potato proteins have been studied and include ultra-filtration techniques (Zwijnenberg et al. 2002; Strætkvern and Schwarz 2012); the use of protein precipitation aids such as (in-)organic acids, metal salts, carboxymethyl cellulose, and organic solvents (Knorr 1982; Gonzalez et al. 1991; van Koningsveld et al. 2002; Vikelouda and Kiosseoglou 2004; Bárta et al. 2008; Bártová and Bárta 2009); foam separation technology (Liu et al. 2013); the use of clay minerals (Lindner et al. 1981; Ralla et al. 2012) as well as various (membrane-)chromatographic techniques (Strætkvern et al. 1999; Graf et al. 2009; Løkra et al. 2009; Strætkvern and Schwarz 2012). However, when applied on a larger scale, the use of the majority of these techniques is limited due to fouling, processing costs, or co-purification of the precipitation aid. Besides previous attempts, fractionated potato protein isolates have become commercially available in a food grade quality in recent years (GRAS Notice 000447: Potato Protein Isolates 2012). This allows exploitation of nutritional and functional benefits of this plant protein in food applications. Non-denatured potato protein isolates are obtained from PJ via chromatographic isolation techniques and exhibit high solubility and a wide range of techno-functionalities (Alting et al. 2011).

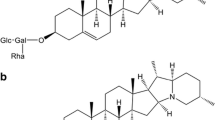

One of the prerequisites for a food-grade potato protein isolate is a final product with sufficiently reduced levels of bitter taste and toxic glycoalkaloids. These secondary plant metabolites are naturally present in Solanaceae species like potato, tomato, and eggplant. In potato tubers, two tri-glycosilated forms of the steroidal alkaloid solanidine exist, α-solanine and α-chaconine. Both tri-glycoalkaloids (TGA) contribute approximately 95 % to the total glycoalkaloid level in potato (Friedman et al. 1997). The total glycoalkaloid level is therefore generally considered as the sum of both tri-glycosilated forms. The levels of TGA in consumption potatoes generally range 10–100 mg/kg fresh weight and are limited to 200 mg/kg by the US Food and Drug Administration (FDA) (Knuthsen et al. 2009). In contrast, some industrial starch potato varieties can exceed this TGA limit. Large majority of glycoalkaloids in those potatoes remains present in the PJ during starch extraction and tends to partition with proteins in a number of protein extraction methods (Driedger and Sporns 1999; Friedman 2006; Bártová and Bárta 2009). As a result, TGA levels in potato protein isolates can reach levels well over 1000 mg/kg. Ingesting potato protein isolates or potato products with high levels of glycoalkaloids results in a bitter taste and can cause gastrointestinal disturbances, neurological disorders, and, in some cases, death. The bitter taste becomes apparent at levels of 140 mg/kg TGA or more (Friedman 2006). Morris and Lee (1984) calculated a range of 2 to 5 mg/kg body weight TGA to be the toxic dose for humans while ingestion of 3 to 6 mg/kg could be fatal. To be able to use the benefits of potato protein for human nutrition, it is essential that potato protein isolates are accurately monitored for TGA content.

Quantification of potato glycoalkaloids is generally carried out by HPLC for routine determination as recommended (AOAC: Official Methods of Analysis 997.13 2000), although various other techniques have been proven suitable as well (Friedman et al. 1997; Friedman 2004). HPLC analysis of glycoalkaloids is preceded by extraction and sample cleanup. Extraction of TGA has been performed on many if not all parts of the potato plant in either fresh or dried form. Acidic mixtures of water and other polar protic solvents have successfully been used for TGA extraction while non-aqueous solvents were shown to be less suitable for dried samples (Friedman et al. 1997). In a few cases, extraction of TGA was assisted by the addition of an ion-pairing agent (Houben and Brunt 1994). An optimized solid-phase extraction procedure and subsequent HPLC analysis of TGA extracted from coagulated potato protein was reported by Alt et al. (2005). The insoluble nature of coagulated potato proteins allows multiple exhaustive extractions to be performed on a sample with little or no carryover of protein in the solvent. In contrast to coagulated potato proteins, native potato proteins exhibit high solubility in TGA extraction solvents such as dilute organic acid. Consequently, all sample material will be subjected to SPE cartridge with risk of cartridge overloading and poor TGA recoveries as a result. In this study, the extraction of TGA from commercially available denatured and non-denatured (native) potato proteins was optimized for routine quality control analysis. The use of non-aqueous TGA extraction solvents was omitted to avoid necessity of solvent evaporation step before SPE sample cleanup. All three potato protein products show different requirements for an efficient extraction and analysis of TGA content.

Materials and Methods

Materials and Chemicals

The standards of α-solanine and α-chaconine were purchased from Carl Roth GmbH + Co. KG (Karlsruhe, Germany). Chemicals were purchased from Merck (Darmstadt, Germany) in p.a. quality or LC grade (acetonitrile). Na-1-heptanesulfonate (HPLC grade) and 100 % acetic acid were obtained from VWR BDH Prolabo (Leuven, Belgium). Ultrapure water was obtained from a MilliQ Academic (Merck-Millipore, Billerica, USA). Potato protein samples were obtained from AVEBE (Veendam, The Netherlands). As a reference for coagulated potato protein, a sample Protamyl PF was used. For the analysis of TGA extraction from non-denatured potato protein, a sample Solanic 206P was taken as a reference for HMW native potato protein and Solanic 306P as a reference for LMW native potato protein. HMW and LMW potato protein samples were selected with relatively high TGA levels and the presence of both α-solanine and α-chaconine.

TGA Extraction

Extraction of TGA was carried out by weighing 100 mg of protein sample in a 50-ml plastic centrifuge tube to which 30 ml TGA extraction buffer was added. Standard TGA extraction buffer was 5 % acetic acid supplemented with 20 mM Na-1-heptanesulfonate unless otherwise stated. Samples were incubated in 40 °C water bath while shaking at 150 strokes/min for 2 h followed by centrifugation at 9000×g for a duration of 10 min using a Heraeus Multifuge 1 SR. Supernatant of the extract was filtered using a Pall Acrodisc GHP 0.45-μm syringe filter. The soluble protein content in these TGA extracts was determined by the use of a Kjeldahl calibrated (Nx6.25) Sprint Protein Analyzer (CEM Corporation, Matthews, USA) using the supernatant of the sample. The molecular weight distribution of the proteins in HMW and LMW potato protein fractions is determined by an Experion method according to the manufacturer’s recommendations (Bio-Rad Laboratories, Hercules, USA).

Online SPE-HPLC Method

Analysis was carried out on an isocratic online SPE-HPLC system equipped with a Robothlon online SPE system (Separations Analytical Instruments B.V., Hendrik-Ido-Ambacht, The Netherlands) coupled to a Smartline HPLC pump 1000 (Knauer, Berlin, Germany), Smartline variable single wavelength UV/VIS detector 2520 (Knauer, Berlin, Germany), a Jetstream 2 plus column thermostat (Industrial Electronics, Langenzersdorf, Austria), a Model 2003 vacuum degasser (Biotech, Onsala, Sweden), and a Chromgate v.3.3.2 data system (Knauer, Berlin, Germany). The online SPE system contains an Oasis HLB Prospect-2/Symbiosis 10 × 2mm cartridge (Waters, Milford, MA, USA). Cartridges are replaced preventively every 96 cycles. The cartridge is washed at a flow rate of 1 ml/min for 4 min with 100 % acetonitrile followed by a 3-min wash with ultrapure water after which an 850 μl quantity of a TGA extract was loaded onto the cartridge. The cartridge was subsequently washed for 30 s with water, 2 min with wash buffer 1 (25 % acetonitrile/1.5 % NH4OH), and 30 s with ultrapure water followed by 4 min with wash buffer 2 (15 % acetonitrile/10 mM phosphate buffer pH .6). TGA was retrieved from the cartridge by the mobile phase of the HPLC system. Separation of α-solanine and α-chaconine was carried out on a Hypersil ODS 250 mm × 4.6 mm 5 μm C18 column with a Hypersil ODS C18 5.0 × 4.6 mm guard column (Thermo scientific, Waltham, USA) at a temperature of 34 °C and a flow rate of 1.6 ml/min. The mobile phase consisted of a 60/40 mixture of 100 % acetonitrile and 10 mM phosphate buffer pH 7.6 degassed using the degas function of a ultrasonic cleaner (VWR International, Leuven, Belgium) and filtered over a 0.45-μm PVDF filter (Waters, Milford, MA, USA). Chromatograms were recorded at a wavelength of 202 nm.

Recovery

The effect of protein concentration during TGA extraction was determined by preparing a 16.6 mg/ml solution of HMW and LMW potato protein separately in TGA extraction buffer. This was diluted in eight steps with TGA extraction buffer to cover a range of protein concentration down to 1.7 mg/ml followed by TGA extraction and online SPE-HPLC analysis. TGA content in gram per kilogram was plotted against the protein concentration during TGA extraction to show equal recoveries at 3.3 mg/ml protein or less. Recovery of the calibration curve in sample matrix was carried out by extracting 0.1 g of HMW and LMW potato protein separately in 30 ml TGA extraction buffer. To cover the same concentration range as the calibration curve, α-solanine and α-chaconine standards were added. TGA extraction and online SPE-HPLC analysis was carried out as described above. Recovery of the calibration line in LMW and HMW matrices is represented by the coefficient of the curve.

Results and Discussion

TGA Extraction of Heat-Coagulated Potato Protein

TGA extraction of three potato protein isolates was tested using a series of extraction solvents. The potato protein isolates include an insoluble protein obtained by heat coagulation of potato juice (CPP) and two non-denatured protein isolates obtained by chromatographic separation and isolation of potato proteins from potato juice. Fractionation of soluble potato proteins results in a fraction which is composed of proteins with a low molecular weight of less than 35 kDa (LMW) and another fraction of proteins with a high(er) molecular weight above 35 kDa (HMW). Heat-coagulated potato proteins naturally contain levels of TGA well over 1000 mg/kg due to partitioning of the alkaloids with the protein in the coagulation process. TGA extraction efficiency was evaluated by acidic aqueous TGA extraction solvents containing organic and inorganic acids. Good solubility of the alkaloids requires an acidic environment (Wolf and Duggar 1946) while the use of organic acids provides a reduced polar environment with high TGA extraction efficiency (Friedman et al. 1997). Organic acid solvents were supplemented by the addition of the ion-pair agent sodium-1-heptanesulfonate (Houben and Brunt 1994). Variation in the extraction of TGA between the three different potato protein products was observed (Fig. 1). TGA levels in the extracts obtained by 5 % acetic acid supplemented with 20 mM Na-1-heptanesulfonate (HSA) were normalized to 100 % for all three potato protein isolates. Extraction of TGA from heat-coagulated potato proteins was equally efficient with all three solvents independent of the concentration. The presence of 20 mM HSA resulted in a reduced level of TGA of this protein sample. The ratio α-solanine/α-chaconine was 1:1 for all extracts showing no preferred extraction of either solanine or chaconine in any of those extracts (Table 1).

TGA Extraction of Native Potato Protein Isolates

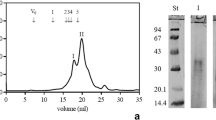

Extraction of TGA from HMW potato protein was equally efficient in the presence of 10–50 mM hydrochloric acid as extraction with 5 or 8 % of either acetic acid or propionic acid. Reduced TGA levels observed in extracts of 2 % organic acid could be attributed to a reduced extraction of α-solanine as indicated by a low α-solanine/α-chaconine ratio (Table 1). Addition of 20 mM HSA to acetic acid or propionic acid did not result in the detection of elevated TGA levels in the extract. In contrast to HMW potato protein, extraction of TGA from non-denatured LMW potato protein by various extraction buffers resulted large differences. Higher TGA levels were determined in the extract at increasing acid concentration. Propionic acid was more efficient in extracting TGA compared to acetic acid or dilute levels of hydrochloric acid. Extraction of α-chaconine is marginally dependent of the acid concentration while the proportion α-solanine in the extract increased at increasing acid concentration. The reduced polarity of propionic acid over acetic acid or hydrochloric acid extraction solvents enhances the partitioning of TGA in the aqueous phase. This resulted in the quantification of higher TGA levels in the LMW protein product (Table 1 and Fig. 2a). High retention of specifically α-solanine on the LMW potato protein fraction suggests the presence of a solatriose-specific binding protein in the LMW potato protein fraction. Two sugar moieties that differ solatriose from chacotriose are β-d-glucopyranosyl and β-d-galactopyranosyl residues. TGA extraction of LMW potato protein in the presence of 2 % acetic acid supplemented with either 50 mM d-glucose or d-galactose did not improve extraction of α-solanine (data not shown). These observations suggest high affinity of α-solanine for native LMW potato protein is not based on a direct sugar-specific interaction with proteins such as lectins. Ion-pair extraction using 20 mM HSA supplemented to both organic acids at either 5 or 8 % concentration resulted further enhanced extraction of α-solanine for the LMW potato protein fraction. Formation of an ion-pair of HSA with the amine group in the solanidine aglycon is likely to facilitate extraction of α-solanine in this potato protein fraction. The exact nature of this solatriose-specific interaction between α-solanine and native LMW potato protein fraction remains however unclear. Enhanced extraction of α-solanine in the presence of HSA might also be a result of the observed protein precipitation induced by the ion-pairing agent. Changes in the folded state of the LMW protein can alter the binding kinetics of α-solanine to a specific domain resulting in an improved extraction efficiency. HSA-induced protein precipitation of both HMW and LMW proteins in the extract was enhanced at temperatures up to 40 °C. TGA extraction carried out at temperatures above 40 °C does not result in a further increase protein precipitation nor TGA extraction (data not shown). Residual protein levels in the TGA extract after centrifugation and filtration are less than 10 % of the original quantity introduced in the extraction. Protein precipitation in LMW as well as HMW samples by HSA at 40 °C reduced the interference of the matrix in the chromatogram (Fig. 2a, b). Heat-coagulated potato proteins do not benefit from the addition of HSA as protein precipitation aid as a result of the insoluble nature of the product.

Reduced TGA content after extraction in the presence of 50 mM HSA was observed for all three potato protein samples (Fig. 1). Extraction of TGA from LMW protein is enhanced by the presence of HSA. The optimal HSA concentration for TGA extraction was determined. LMW potato protein incubated with 5 % HAc in the presence of 0 up to 100 mM HSA at 40 °C revealed that the highest TGA levels were determined when extraction solvent was supplemented with 10 or 20 mM HSA (Fig. 3). Higher HSA levels during extraction result in rapid formation of a protein precipitate which limits the extraction of TGA.

Recovery of TGA

High solubility of non-denatured potato protein in TGA extraction buffer affects its recovery on the SPE cartridge. TGA recovery of both α-solanine and α-chaconine was determined in a HMW as well as a LMW potato protein matrix. Protein fractions were extracted with 5 % acetic acid and 20 mM HSA supplemented with α-solanine and α-chaconine. A serial dilution of the extract in the acetic acid-HSA extraction buffer covers a range of protein concentration of 0.05–0.5 g/30 ml followed by a 2-h extraction at 40 °C. Quantification of the samples after SPE and HPLC analysis revealed that over 97 % of both α-solanine and α-chaconine could be recovered up to a concentration of 0.1 g protein per 30 ml extraction buffer. Higher levels of protein in the extraction buffer resulted in a diminished recovery of TGA. Recoveries of 89 % (HMW) and 91 % (LMW) were obtained in case extraction was carried out at a protein concentration of 0.5 g/30 ml TGA extraction buffer.

Recovery of the calibration curve in a sample matrix at 0.1 g HMW or LMW potato protein was 95.6 % for α-solanine and 95.5 % for α-chaconine in case of HMW potato protein and 97.8 % for α-solanine and 96.3 % for α-chaconine in case of LMW potato protein. Analysis of 0.5 μg/ml (N = 43) and 4 μg/ml (N = 45) solanine and chaconine standards as well as a LMW protein TGA extract (N = 55) over a period of 5 months resulted in relative standard deviation of 2.22/4.29 %, 2.12/1.97 %, and 2.94/3.54 % for α-solanine and α-chaconine, respectively.

Limit of Quantification

TGA levels in commercially available native potato protein isolates HMW and LMW are less than 300 mg/kg, and for a number of applications, an upper limit of 150 mg/kg is preferred. Reducing the sample quantity to 100 mg in 30 ml TGA extraction buffer in order to maintain a recovery of at least 95 % affects the quantification limit of the system. Reliable quantification of both α-solanine and α-chaconine could be achieved down to 0.125 μg/ml concentrations referring to a limit of quantification of 37.5 mg/kg α-solanine or α-chaconine.

Increased TGA extraction volumes from coagulated potato proteins can be applied to SPE sample cleanup due to the insoluble nature of the proteins. This results in an increased signal and lower detection limit (Alt et al. 2005). Similar to TGA extracts from insoluble coagulated potato proteins, precipitation of soluble potato proteins induced by HSA during TGA extraction allows the application of larger volumes to the SPE cartridge. Applying 1, 2, and up to 5 volumes of TGA standards to the SPE cartridge results in a linear increase in peak area for both α-solanine and α-chaconine. Increasing the volume of the TGA extract applied to the SPE cartridge by a factor 5 allows reliable quantification of TGA levels which remain below detection limit at 1 volume (Table 2). This results in an improved detection of the actual TGA level in the sample down to levels of 7.5 mg/kg.

Conclusions

Efficient extraction of TGA from a native potato protein isolate is determined by the type of extraction solvent, concentration, presence of Na-1-heptanesulfonate (HSA), and the amount of protein in the extraction buffer. High recoveries of TGA from native HMW and LMW potato protein fractions were obtained using a TGA extraction solvent composed of at least a 5 % concentration of either acetic acid or propionic acid in water. Ion-pair extraction using 20 mM HSA improves the recovery of α-solanine from the LMW potato protein fraction resulting in an enhanced accuracy of the actual TGA level in this product. Furthermore, HSA serves as a protein precipitation aid for both HMW and LMW potato proteins. HSA-induced protein precipitation is enhanced at extraction temperatures up to 40 °C resulting in chromatograms with fewer impurities and improved baseline. Overloading of the cartridge by an excess of soluble protein in the TGA extract is prevented and larger volumes can be applied to the SPE cartridge. This contributes to a detection limit of the system of less than 10 mg/kg and recoveries over 97 % were obtained. Addition of HSA to the extraction buffer diminished the recovery of TGA from coagulated potato protein samples. The use of this improved TGA extraction procedure for denatured and non-denatured potato protein isolates allows accurate detection of low TGA levels through routine quality control analysis.

Abbreviations

- TGA:

-

Tri-glycoalkaloid

- HSA:

-

Na-1-heptanesulfonate

- PJ:

-

Potato juice

- HMW:

-

High molecular weight potato protein isolate

- LMW:

-

Low molecular weight potato protein isolate

- kDa:

-

Kilodalton

- SPE:

-

Solid-phase extraction

- HCl:

-

Hydrochloric acid

- HAc:

-

Acetic acid

- PPA:

-

Propionic acid

- mM:

-

Millimolar

References

Alt V, Steinhof R, Lotz M, et al. (2005) Optimization of glycoalkaloid analysis for use in industrial potato fruit juice downstreaming. Eng Life Sci 5:562–567

Alting AC, Pouvreau L, Giuseppin MLF, van Nieuwenhuijzen NH (2011) Potato proteins. In: Phillips GO, Williams PA (eds) Handbook of food proteins, first. Woodhead Publishing Ltd., Cambridge, pp. 316–334

AOAC official method 997.13 (2000) Glycoalkaloids (α-Solanine and α-Chaconine) in potato tubers. In: AOAC official methods of analysis. Chapter 49 Natural Toxins, pp 62–64

Bárta J, Heřmanová V, Diviš J (2008) Effect of low-molecular additives on precipitation of potato fruit juice proteins under different temperature regimes. J Food Process Eng 31:533–547

Bártová V, Bárta J (2009) Chemical composition and nutritional value of protein concentrates isolated from potato (Solanum tuberosum L.) fruit juice by precipitation with ethanol or ferric chloride. J Agric Food Chem 57:9028–9034

Boisen S (1999) Determination of the digestibility and biological value of two potato protein concentrates. Tjele, Denmark

Driedger DR, Sporns P (1999) Glycoalkaloid concentration in by-products of potato starch extraction as measured by matrix-assisted laser desorptionionization mass spectrometry. J Food Process Preserv 23:377–390

Friedman M (2004) Analysis of biologically active compounds in potatoes (Solanum tuberosum), tomatoes (Lycopersicon esculentum), and jimson weed (Datura stramonium) seeds. J Chromatogr A 1054:143–155

Friedman M (2006) Potato glycoalkaloids and metabolites: roles in the plant and in the diet. J Agric Food Chem 54:8655–8681

Friedman M, McDonald GM, Filadelfi-Keszi PM (1997) Potato glycoalkaloids: chemistry, analysis, safety, and plant physiology. CRC Crit Rev Plant Sci 16:55–132

Gonzalez JM, Lindamood JB, Desai N (1991) Recovery of protein from potato plant waste effluents by complexation with carboxymethylcellulose. Food Hydrocoll 4:355–363

Graf A-M, Steinhof R, Lotz M, et al. (2009) Downstream-processing mit Membranadsorbern zur isolierung nativer proteinfraktionen aus kartoffelfruchtwasser. Chemie Ing Tech 81:267–274

GRAS notice 447 (2012) GRAS Exemption claim for potato protein isolates. U.S. Food and Drug Administration

Houben RJ, Brunt K (1994) Determination of glycoalkaloids in potato tubers by reversed-phase high-performance liquid chromatography. J Chromatogr A 661:169–174

Knorr D (1977) Protein recovery from waste effluents of potato processing plants. Int J Food Sci Technol 12:563–580

Knorr D (1982) Effects of recovery methods on the functionality of protein concentrates from food processing wastes. J Food Process Eng 5:215–230

Knuthsen P, Jensen U, Schmidt B, Larsen IK (2009) Glycoalkaloids in potatoes: content of glycoalkaloids in potatoes for consumption. J Food Compos Anal 22:577–581

Lindner P, Ben-Gera I, Keren R (1981) Precipitation of proteins from potato juice with bentonite. J Sci Food Agric 32:1177–1182

Lisinska G, Leszczynski W (1989) Potato science and technology. In: Lisinska G, Leszczynski W (eds) Potato science and technology. Elsevier applied science publishers Ltd., London, New York, pp. 11–43

Liu Z, Wu Z, Li R, Fan X (2013) Two-stage foam separation technology for recovering potato protein from potato processing wastewater using the column with the spiral internal component. J Food Eng 114:192–198

Løkra S, Schüller RB, Egelandsdal B, et al. (2009) Comparison of composition, enzyme activity and selected functional properties of potato proteins isolated from potato juice with two different expanded bed resins. LWT - Food Sci Technol 42:906–913

Morris SC, Lee TH (1984) The toxicity and teratogenicity of Solanaceae glycoalkaloids, particularly those of the potato (Solanum tuberosum): a review. Food Technol Aust 36:118–124

Nestares T, Lopez-Jurado M, Sanz A, Lopez-Frias M (1993) Nutritional assessment of two vegetable protein concentrates in growing rats. J Agric Food Chem 41:1282–1286

Ralla K, Sohling U, Suck K, et al. (2012) Separation of patatins and protease inhibitors from potato fruit juice with clay minerals as cation exchangers. J Sep Sci 35:1596–1602

Starch Europe (2014) EU starch market figures. The European Starch Industry Association. http://www.starch.eu/european-starch-industry/. Accessed 13 Oct 2015

Strætkvern KO, Schwarz JG (2012) Recovery of native potato protein comparing expanded bed adsorption and ultrafiltration. Food Bioprocess Technol 5:1939–1949

Strætkvern KO, Schwarz JG, Wiesenborn DP, et al. (1999) Expanded bed adsorption for recovery of patatin from crude potato juice. Bioseparation 7:333–345

Van Gelder WMJ, Vonk CR (1980) Amino acid composition of coagulable protein from tubers of 34 potato varieties and its relationship with protein content. Potato Res 23:427–434

van Koningsveld GA, Gruppen H, de Jongh HH, et al. (2002) The solubility of potato proteins from industrial potato fruit juice as influenced by pH and various additives. J Sci Food Agric 82:134–142

Vikelouda M, Kiosseoglou V (2004) The use of carboxymethylcellulose to recover potato proteins and control their functional properties. Food Hydrocoll 18:21–27

Wolf MJ, Duggar BM (1946) Estimation and physiological role of solanine in the potato. J Agric Res 73:1–32

Zwijnenberg HJ, Kemperman AJB, Boerrigter ME, et al. (2002) Native protein recovery from potato fruit juice by ultrafiltration. Desalination 144:331–334

Acknowledgments

The authors wish to thank Paul Mijland for carrying out the one-way ANOVA analysis and Joan Schipper for assistance with the TGA analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Marc C. Laus declares that he has no conflict of interest. Gert Klip declares that he has no conflict of interest. Marco L. F. Giuseppin declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Laus, M.C., Klip, G. & Giuseppin, M.L.F. Improved Extraction and Sample Cleanup of Tri-glycoalkaloids α-Solanine and α-Chaconine in Non-denatured Potato Protein Isolates. Food Anal. Methods 10, 845–853 (2017). https://doi.org/10.1007/s12161-016-0631-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-016-0631-2