Abstract

Burning rice straw particles is a problem for generating atmospheric particulate matter (PM2.5) in Thailand. Increase in value-added rice straw such as production of rice straw particle board is an attractively promising product. The prevulcanized natural rubber-bonded rice straw particles using bis-(3-triethoxysilylpropyl)tetra sulphide (Si-69) acting as silane coupling agents were used to produce rice straw particle board. The effect of Si-69 concentrations of 2, 5, 7, and 10%w/v on the properties of rice straw particle board was investigated. The surfaces of treated rice straw particles were characterized by attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR), and X-ray photoelectron spectroscopy (XPS). In addition, modulus of rupture (MOR), modulus of elasticity (MOE), internal bonding (IB) thickness swelling (TS) and water absorption (WA) of the prepared samples were measured. The result illustrated that the rice straw particle board was successfully manufactured using prevulcanized natural rubber and Si-69 coupling agent. The rice straw surface was fully covered by Si-69 and the amount of silicon and sulphur elements were increased with increasing Si-69 concentration. Consequently, the IB, MOR and MOE of the rice straw particle tended to increase with increasing Si-69 concentration. This is possibly due to good interfacial adhesion and reasonable stress transfer between rice straw particles and prevulcanized natural rubber as well as higher crosslink density of prevulcanized natural rubber. On the other hand, TS and WA of the rice straw particle were sharply decreased with increasing Si-69 concentration because the rice straw surface may be partially covered by the hydrophobic parts of Si-69.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rice is an economic crop of Thailand and the most residue rice straw has been used for feed animal, scattered in the field and burned after harvest season. The rice straw management after harvest time is currently urgent issues. Due to burning of rice straw and agro-wastes, this is intensive one of problem for generating atmospheric particulate matter (PM), especially PM2.5 [1, 2]. The government gives rise to address this cause in numerous ways and one of solution is that biomass investigation to increase value-added rice straw is promising investigation. Rice straw particle board is an attractively promising product to rise value-added because it can be used as raw material in the replacement of wood which thanks to lignocellulosic resources containing cellulose, hemicellulose, lignin, wax and other inorganic elements, especially silica [3]. Silica was deposited on the external surface of rice straw in the form of inorganic compounds such as Si(OR)x, Si–O–Si, Si–Ox, and Si–C, respectively [3]. According to silica and wax deposited on the outer surface of rice straw, therefore, they prevent to archive good mechanical strength of the particle board. There are many reports dealing with these effects. Binderless board made from rice straw [4, 5] can be produced by grinding and hot-pressing method. However, the internal bonding (IB), modulus of rupture (MOR), and modulus of elasticity (MOE) of the final products were lower than that of diphenylmethane diisocyanate (pMDI) resin-bonded boards [6]. The crucial parameters influencing the properties of both binderless and binder board systems were mainly due to wax, ash (silica), particle sizes, and morphology of rice straw. The improvements of binder wettability and bond ability between rice straw and adhesive have been investigated in many methods such as ethanol–benzene extraction before coating by epoxide silane, applied urea formaldehyde (UF) [7] stream pretreatment, oxalic acid treatment before applying UF resin [8], and the effect of amino ethoxy and methoxy silane as coupling agent [9,10,11]. According to the advantage of using readily silane coupling agent together with conventional binders, they are still based on synthetic thermosetting resins [12], phenol formaldehyde (PF), urea formaldehyde (UF), melamine–formaldehyde (MF), and polymeric diphenylmethane diisocyanate (pMDI) resin. These binders have been classified as a carcinogenic and toxic material. Therefore, the development of environmentally friendly binders from renewable resources for rice straw particle board has been investigated to be a promising way for replacing petroleum resources such as epoxidized sucrose soyate and chemical modified soy protein [13]. The natural rubber (NR) is the alternative natural binder for producing bio-based wood adhesive due to its good mechanical properties, water resistance, and high tack [14]. However, it has poor compatibility with polar material such as silica reinforcing filler and lignocellulose material. Thus, the chemical modification of NR has been explored to improve the compatibility with those materials [15, 16]. However, this method is more difficult than using silane coupling agent. Si-69 acting as silane coupling agent has been frequently used for improving interfacial adhesion between NR and polar silica because it has ethoxy group that can bond with polar silica and sulphur atom can bond with rubber [17, 18].

The aim of this research was to investigate the mechanical strength of prevulcanized natural rubber-bonded rice straw particle board using bis-(3-triethoxysilylpropyl)tetra sulphide (Si-69) acting as silane coupling agent. The effect of silane concentration to mechanical strength of rice straw particle board was evaluated and discussed in more detail.

Materials and methods

Materials

Prevulcanized natural rubber latex was purchased from Chemical and Material Co. Ltd. Bis-(3-triethoxysilylpropyl)tetra sulphide (TESPT or Si-69 was supplied by JJ-Degussa (Thailand) Co., Ltd., and its chemical structure was shown in Fig. 1. Rice straw was obtained from Faculty of Agriculture, Ubon Ratchathani University, Ubon Ratchathani, Thailand.

Chemical structure of bis(3-triethoxysilylpropyl)tetrasulfide (Si-69) [17]

Manufacture of rice straw particle boards

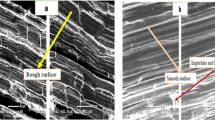

The whole rice straw was cut using scissor and was then dried in oven at 50 °C for 24 h. The small pieces of rice straw were grinded by a blender machine until they passed through 3-mm screen to make whole powder. These raw materials were mixed into the Si-69 solutions, prepared by dissolution in ethanol solvent, at different concentrations of 2, 5, 7 and 10%w/v for 10 min and were then dried in an oven at 50 °C for 24 h. The dried samples were subsequently sprayed with prevulcanized NR latex in a rotating drum equipped with paddle mixers at a weight ratio of rice straw ratio to prevulcanized NR latex, 70:30 (wt%). The rice particles were then dried in a hot air oven for 2 h at 50 °C and finally compressed with a hot-press machine at 150 °C for 10 min. The samples size was 150 mm × 150 mm × 5 mm.

Determination of rice straw particle board properties

The mechanical properties of rice straw particle board were measured following the Kurokochi and Sato [5] Modulus of rupture (MOR), modulus of elasticity (MOE) and internal bonding (IB) of rice straw particle board were also investigated. In addition, thickness swelling (TS) and water absorption (WA) were performed following ASTM D 570. Before testing, the weight and dimensions, i.e., length, width and thickness, of each specimen were measured. Conditioned samples of each type of samples were soaked in distilled water at room temperature for 40 days. Samples were then removed from the water, patted dry and measured again. Each obtained value represents the average of six samples. Water absorption was calculated according to the following equation:

where WA is the water absorption in percentage, and M1 and M2 are the sample weights before and after immersion (g). The values of the thickness swelling (TS) in percentage were calculated following Eq. (2):

where T1 and T2 is thickness (mm) of the dried and wetted sample, respectively.

Investigation by attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectroscopy

The chemical compositions of modified rice straw particle were determined by FTIR 2000 Perkin Elmer with ATR-FTIR mode. The spectra were recorded with the resolution of 4 cm−1 in the range of 4000–400 cm−1 and a diamond crystal was used.

Investigation by synchrotron X-ray photoelectron spectroscopy (XPS)

The amount of chemical element was determined using synchrotron XPS. The experiment was investigated at the beamline BL3.2Ua, photoemission spectroscopy (PES) of the Siam Photon Laboratory. X-ray photoelectron spectrum was obtained from an X-ray photoelectron spectrometer (PHI5000 Versa Probe II, ULVAC-PHI, Japan). The monochromatic Al Kα X-ray (1486.6 eV) was used as an excitation source.

Results and discussion

Effect of surface treatment

ATR-FTIR was used to determine the chemical compositions of modified rice straw surface. Figure 2 shows ATR-FTIR spectra of rice straw surface treated by Si-69 at various concentrations. The broad absorption band of rice straw was observed around 1000 cm−1, assigned to C–OH stretching of cellulose and C–O–C of lignin [19]. In addition, the board absorption band detected at 3320 cm−1 was attributed to OH stretching due to hydrogen bonding [19]. The two peaks at 2920 and 2844 cm−1 were assigned to -CH2 asymmetric and symmetric stretching comprising of the majority of the aliphatic fractions of waxes [19]. After treatment with various Si-69 concentrations, the absorption band of rice straw was decreased whereas the absorption bands of Si-69 coupling agent were clearly observed at 1075 and 1102 cm−1, attributing to the Si–O–C stretching [9].

In addition, the amount of Si-69 on rice straw surface was determined using synchrotron XPS and the results are listed in Table 1. The surface of treated and untreated rice straw surface possessed carbon, oxygen, and silicon. The proportion of Si and S of the treated rice straw surface was increased by varying Si-69 concentrations. It could be claimed that rice straw surface was successfully covered by Si-69 and its amount was varied with its concentration.

Effect of surface treatment to mechanical properties

The effect of Si-69 concentration to internal bonding is shown in Fig. 3. It was found that internal bonding (IB) sharply increased with increasing Si-69 concentration. This is due to good adhesion between rice straw particles and natural rubber which was contributed by Si-69. According to ATR-IR and XPS results, the outer surface of rice straw particles was mainly consisted of carbon oxygen and silicon. These compositions were in the form of Si-(OR)x, Si-Ox [3] and C–OH, C–O–C of cellulose and lignin [19]. Therefore, both cellulose and silica compounds in the external surface of rice straw could be hydrolyzed and then condensed to create chemical bonding with Si-69 coupling agent. After that, the chemical bonding between Si-69 and natural rubber was further created by a chemical reaction as shown in Fig. 4 [17]. In addition, the chemical bonding points were possibly increased with increasing the Si-69 concentration. The influences of Si-69 on the MOR and MOE of the treated rice straw particle board to are also presented in Figs. 5 and 6. It is seen that both MOR and MOE increase with increasing Si-69 concentration. These effects are possible due to the increase in crosslink density of vulcanized natural rubber. Actually, rice straw was bonded together using the prevulcanized natural rubber and the Si-69 coupling agent. The Si-69 coupling agent plays a key role in the good interfacial adhesion as described in previous section. Under applied loading, stresses could transfer from the rice straw particles to the rubber phases due to the good interfacial adhesion. Therefore, high crosslink density rubber is more resistant deformation than low crosslink density one. The Si-69 consists of 4 sulfur atoms on its molecule and these sulfur atoms can be attributed to the rubber phase during vulcanization. This phenomenon is widely known as “sulfur contribution effect” [20], as displayed in Fig. 4b.

Bonding of rice straw particles to Si-69 (a), to rubber (b) at 150 C [17]

Effect of surface treatment to water absorption and thickness swelling

The effects of surface treatment on the water absorption (WA) and thickness swelling (TS) are shown in Fig. 7. The capacity of water absorption and thickness swelling is directly related to the density, the presence of voids and the bonds between the rice straw and the matrix [21]. It was found that the thickness swelling and water absorption were sharply decreased after treatment and slightly decreased with increasing Si-69 concentration. This resulted from the good adhesion between rice straw particle and rubber, which was supported by Si-69 coupling agent. The chemical structure of Si-69 consists of both ethoxy groups and methyl as well as sulphur group which is a hydrophobic part. Therefore, some parts of the rice straw particle surface might be covered by the hydrophobic fraction. This leads to the decrease in the polar fraction of hydroxyl groups of silica compound and cellulose, resulting in a decrease in water absorption. In addition, the increase in crosslinking density obtained by vulcanization of natural rubber with sulphur moiety in the Si-69 can also improve dimension stability and water absorption of these particle boards by reduction of thickness swelling [18].

Conclusions

The rice straw particle was successfully manufactured using natural rubber latex and Si-69, which acted as bio-adhesive and coupling agent. The mechanical properties (IR, MOR, and MOE) and water absorption as well as thickness swelling of particle board were improved. These properties increased with increasing Si-69 concentration up to 10 wt%. The Si-69 gave strong interfacial adhesion between rice straw particle and natural rubber during compression into particle boards. can improve crosslinked density of natural rubber adhesive. Therefore, the Si-69 coupling agent can be used for replacing synthetic binder adhesive such as urea formaldehyde melamine and formaldehyde.

References

Maneepitaka S, Ullahb H, Dattab A (2019) Effect of water and rice straw management practices on yield and water productivity of irrigated lowland rice in the Central Plain of Thailand. Agriculture 211:89–97

Phairuang W, Suwattiga P (2019) The influence of the open burning of agricultural biomass and forest fires in Thailand on the carbonaceous components in size-fractionated particles. Environ Pollut 247:238–247

Pan M, Yu L, Gan X (2017) Structural analysis and transformation of biosilica during lignocellulose fractionation of rice straw. J Mol 1127:575–582

Kurokochi Y, Sato M (2015) Effect of surface structure, wax and silica on the properties of binderless board made from rice straw. Ind Crops Prod 77:949–953

Kurokochi Y, Sato M (2015) Properties of binderless board made from rice straw: the morphological effect of particles. Ind Crops Prod 69:55–59

Li X, Cai Z, Winandy Jerrold E, Basta Altaf H (2010) Selected properties of particleboard panels manufactured from rice straws of different geometries. Bioresour Technol 101:4662–4666

Han G, Umemura K, Kawai S, Kajita H (1999) Improvement mechanism of bondability in UF-bonded reed and wheat straw boards by silane coupling agent and extraction treatments. J Wood Sci 45:299–305

Li X, Cai Z, Winandy Jerrold E, Basta Altaf H (2011) Effect of oxalic acid and steam pretreatment on the primary properties of UF-bonded rice straw particleboards. Ind Crops Prod 33:665–669

Zhao Y, Qiu J, Feng H, Zhang M (2012) The interfacial modification of rice straw fiber reinforced poly(butylene succinate) composites: effect of aminosilane with different alkoxy groups. J Appl Polym 125:3211–3220

Ismail MR, Yassene AAM (2012) Effect of silane coupling agents on rice straw fiber/polymer composites. Appl Compos Mater 19:409–425

Tayfun U, Dogan M, Bayramli E (2016) Effect of surface modification of rice straw on mechanical and flow properties of TPU-based green composites. Polym Compos. https://doi.org/10.1002/pc.23331

Ferdosian F, Pan Z, Gao G, Zhao B (2020) Bio-based adhesives and evaluation for wood composites application. Polymers. https://doi.org/10.3390/polym9020070

Sitza Evan D, Bajwaa Dilpreet S, Websterb Dean C (2017) Epoxidized sucrose soyate—a novel green resin for crop straw based low density fiberboards. Ind Crops Prod 107:400–408

Radabutra S, Khemthong P, Saengsuwan S, Sangya S (2020) Preparation and characterization of natural rubber bio-based wood adhesive: effect of total solid content, viscosity, and storage time. Polym Bull 77:2737–2747

Nimpaiboon A, Sakdapipanich J (2020) Compatibility enhancement of silica and natural rubber compound using UVA-induced silane-grafted saponified skim natural rubber. J Polym Res. https://doi.org/10.1007/s10965-017-1420-3

Onchoy N, Phinyocheep P (2016) Preparation and characterization of brominated natural rubber applied in siica-filled natural rubber vulcanizates. Rubber Chem Technol 89:406–418

Brinke JW, Debnath SC, Reuvekamp LAEM, Noordermeer JWM (2003) Mechanistic aspects of the role of coupling agents in silica–rubber composites. Compos Sci Technol 63:1165–1174

Sae-ouia P, Sirisinha C (2005) Comparison of reinforcing efficiency between Si-69 and Si-264 in an efficient vulcanization system. Polym Test 24:439–446

Li F-h, Hu H-j (2012) Structure and saccharification of rice straw pretreated with microwave-assisted dilute lye. Ind Eng Chem Res 51:6270–6274

Sae-ouia P, Sirisinha C (2006) Roles of silane coupling agents on properties of silica-filled polychloroprene. Eur Polym J 42:479–486

Nunna S, Chandra PR, Shrivastava S, Jalan A (2012) A review on mechanical behavior of natural fiber based hybrid composites. J Reinf Plast Compos 31(11):759–769

Acknowledgements

Financial support from the Center of Excellence for Innovation in Chemistry (PERCH-CIC), Ministry of Higher Education, Science, Research and Innovation, and Thailand and National Science and Technology Development Agency (NSTDA) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Radabutra, S., Khemthong, P. & Saengsuwan, S. Effect of silane coupling agent pretreatment on the properties of rice straw particleboard bonded with prevulcanized natural rubber latex. J Rubber Res 24, 157–163 (2021). https://doi.org/10.1007/s42464-021-00081-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-021-00081-z