Abstract

Balancing cost and time present a critical yet conflicting challenge in scheduling of construction projects. In today;s highly competitive construction market, achieving a subtle balance in optimizing objectives (time and cost) is vital for success of projects, requiring project participants to make essential trade-offs. With multi-objective particle swarm optimization (MOPSO), this study presents a time–cost trade-off (TCT) optimization model to overcome the challenges and constraints associated with existing TCT models. The focus is on multi-mode construction project activities, where each mode represents a different option for a construction activity requiring varying amounts of resources, time, and cost. The paper aims to select the best alternatives for project activities. For demonstrating the effectiveness of the developed MOPSO method in generating a set of Pareto-optimal solutions, it is applied to a real case study project. The working of proposed method in simultaneously optimizing two objectives is evaluated against existing trade-off optimization methods. The project team is provided with trade-off plots and an a priori approach to select one of the generated Pareto-optimal solutions. Additionally, this research will benefit the project;s stakeholders by maximizing profits, and the findings of this study can assist organizations and project teams in improving their scheduling choices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

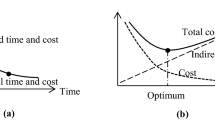

Construction projects are the oldest infrastructure projects. Construction projects are very important projects for the all-round development of any nation (Trivedi & Sharma, 2023). The continuous evolution of project management arises from the necessity to monitor and optimize construction project objectives (Shi et al., 2010). Construction project management consists of planning, scheduling and controlling stages (Kaveh & Ilchi Ghazaan, 2020; Kaveh & Laknejadi, 2013a). During the planning phase, certain projects; objectives must be established from the project stakeholders; viewpoint (Kaveh, 2016; Rastegar Moghaddam et al., 2021). The fundamental approach for project planning and management depends largely on these stated objectives. When it comes to planning and completion of construction projects, the two most important considerations are time (or duration) and cost (Toğan & Eirgash, 2019). However, project time and costs fluctuate with the different consumption amount of resources (Luong et al., 2018). The use of cost-effective resources using advanced technology reduces project time, but increases cost of the project (Kaveh & Laknejadi, 2011; Kaveh et al., 2013). Furthermore, low-cost resources reduce cost, while project time might be delayed by available low-cost resources and conventional methods (Kaveh, 2014; Kaveh et al., 2013, 2020). Thus, time and cost are contradictory and conflicting objectives, and establishing an equilibrium between time and cost is more essential to effectively execute the project.

In recent decades it has been increasingly common for practitioners to resolve trade-off issues. In this context, Feng et al. (1997), Zhang and Li (2010), Eirgash et al. (2019) and others put effort to address the TCT issues. TCT is also expanded to time–cost-resources trade-off due in course of increasing association and need of project stakeholders (Habibi et al., 2017; Zahraie & Tavakolan, 2009). This article also proposes a novel model for optimising TCT issues in order to relieve the complexity and constraints of current models.

A construction project comprises a sequence of interlinked activities (Eirgash & Toğan, 2023). Each activity may be completed by using one of the different alternatives (Kaveh & Laknejadi, 2013a, 2013b). Various time frames, costs, and resources are connected with each activity;s; alternative type (Afshar et al., 2009; Kaveh & Massoudi, 2014). Therefore, this paper provides the optimal technique or way to successfully deliver a project, as a project can be executed in different ways depending on the possible combinations of execution modes available.

Following introductory overview, the paper thoroughly examines the existing literature and identifies research gaps following the formulation of the TCT problem. Subsequently, the developed MOPSO model is detailed with implementation using MATLAB software. The efficacy and practicality of proposed model is demonstrated through comparative analysis of the results as well as its application in a case study project. The final section of this article showcases the findings, draws conclusions, and outlines avenues for future research.

Past researches

As per the literature review, there are three types of project scheduling methods: deterministic, heuristic, and meta-heuristic methods (Panwar et al., 2019). Initially, Kelley and Walker (1959) suggested CPM method for planning of project tasks. Following that, CPM was used to create various deterministic methods-based scheduling models.

Heuristic techniques, rooted in past problem-solving practices, are integral in various domains such as planning and scheduling (Zhou et al., 2013). Notable heuristic planning approaches like Fondhahl (Fondahl, 1962), approximation Siemens (Siemens, 1971), and structural stiffness (Moselhi, 1993). In addition, Zhang et al. (2006), Elazouni (2009) and Di et al. (2013) have strived to build heuristic scheduling techniques.

Meta-heuristic techniques have shown worth in the discovery of relatively good answers instead of precise solutions in large multi objective optimization problems, but certainly they do not guarantee the global optimum solutions (Sharma & Trivedi, 2022, 2023a). Feng et al. (1997) has devised a genetic algorithm and a Pareto-front method for solving the issue of TCT problems. MOPSO based TCT models were presented in the study of Yang et al. (2001) and Zhang and Li (2010), taking into account both direct and indirect operations costs. The simulated annealing method in the solution of TCT issues was assessed by the experiments of Anagnostopoulos and Kotsikas (2010). The multiple-objective ant colony optimization method to the TCT issues was also given by Xiong and Kuang (2008). For the determination of the Pareto-optimal front in TCT optimisation, Fallah-Mehdipour et al. (2012) found the NSGA II as efficient algorithm. Activity duration and costs are different owing to changes in resource use (Senouci & Eldin, 2004). Limited time, money and available resources encourage the creation of TCT models for resources. The resource constrained scheduling problems (RCSPs) were classified by Habibi et al. (2018) in four types depending on resource type, trade-off factors, goal function type, and the information available.

In the present research, the concept of the mode of activities execution is used. Sharma and Trivedi (2020) used this concept at first and demonstrated that there are many methods of execution for carrying out an activity. The time and resource usage of each mode vary in performances (Hartmann & Briskorn, 2010). There are also two kinds of resources, non-renewable and renewable. Human and machinery resources should be divided into renewable resources since they are fully accessible for companies (Carlier & Moukrim, 2015). Raw material is classified as non-renewable resources since it is accessible in definite and determined quantities (Kyriakidis et al., 2012).

The multi-skilled personnel algorithms were developed by Santos and Tereso (2011) to demonstrate that each implementation method is distinct in time and cost, according to the human resources skill level. However, changes in the scheduling scheme are required if the primary scheduling schedule is made impossible by disruptions in length or resources. Deblaere et al. (2011) have proposed a variety of planning methods to fix disruptions in the schedule for the primary scheduling. Beşikci et al. (2015), without sharing resources across projects, have addressed a multi-mode planning issue in a multi-project context. A technique was developed by Delgoshaei et al. (2016) for modifying the allocation of excessive resources by discontinuing the activities. There may be many methodologies for performing an activity, but activity must be carried out using the same way once one method is started. Recent research (Elbeltagi et al., 2016) presented a PSO model scheduling with time, costs, resources and cash flow concurrently optimisation. However, for assured convergence to an optimal local level the original PSO still needs significant modification (Van Den Bergh & Engelbrecht, 2010). Therefore, there are few studies in the literature for optimising more than one objective in construction project scheduling, this paper prompts practitioners to make an effort to research more than one objective optimization in construction project scheduling.

Problem formulation

At first, it is required to formulate the TCT problems in effective manner. This section of paper clearly formulates the TCT problem before presenting the developed research methodology. To complete a building project, a lot of activities must be completed. One of the execution modes for an activity (A) should be used. Due to variations in resource utilization impacting completion time and cost, it is essential to allocate the suitable alternative to each activity within a construction project.

In this study, the input parameters include Activity Time (AT) and Activity Cost (AC). Consider a building project comprising activities A-1, A-2,…,A-n, each with corresponding alternatives Alt-1, Alt-2,… Alt-m. The completion of these activities is influenced by different execution modes (LR, MR, ER), each associated with specific quantities of labor, material, and equipment resources. Consequently, numerical values for AT and AC are computed based on activities and their alternatives. The primary objective of this article is to simultaneously minimize Project Time (PT) and Project Cost (PC), which are functions of AT and AC, respectively. The study operates under the assumptions that (i) all activities must be executed promptly (Sharma & Trivedi, 2023b) and (ii) there exist priority connections between activities, which can be visually represented as a network (Sharma & Trivedi, 2021).

As a result, this simultaneous optimization problem with two objectives can be formulated as follows;

Objective 1: Minimize PT

In the current research, the calculation of Project Time (PT) employs the Precedence Diagramming (PD) method. The foundation of the PD method is the Critical Path (CP) of an AON method. Equation (1) illustrates that the duration of all activities along the critical path serves as the basis for deriving the Project Time (PT) for a building project.

Here, ATA represents the overall duration of the critical path (A).

Objective 2: Minimize PC

The cost of completing a project is the sum of individual project activities costs (AC). The AC is, however, the total of direct costs and indirect activity costs, direct costs (D.C) primarily comprise of costs for work, materials and equipment, while Indirect costs (I.C) includes extra expenses during project.

where, \(\sum_{A}D.C\) is the sum of direct costs of project activities, whereas indirect costs can be calculated by simply multiplying PT and daily indirect costs.

Proposed research methodology

PSO is widely recognized as a popular meta-heuristic technique for solving optimization problems. In this study, a Multi-Objective PSO (MOPSO) model was developed by integrating the non-dominant sorting (NDS) process into the PSO framework. The NDS process is employed to identify solutions by creating non-dominated fronts (NDF), each of which offers solutions without domination by others (Sharma & Trivedi, 2023c; Tiwari et al., 2020). In the MOPSO model, each particle represents a solution to the optimization problem, similar to the chromosomes in the project schedule. The fixed number of cells (genes) on each chromosome corresponds to all activities in construction (Tiwari et al., 2022). Thus, each gene on the chromosome holds a value (allele) for a different decision, representing the approach to accomplishing that task. Every possible chromosome in a Time–Cost Trade-off (TCT) problem offers its unique solution. To illustrate the chromosomal solution in the TCTP problem, consider a project with nine activities, each having five modes of completion. Figure 1 depicts a conceivable chromosomal solution for this TCTP. The activities range from 1 to 9, and the associated execution modes are 4, 4, 5, 3, 5, 4, 5, 4, 3. This results in 59 different methods to complete this project following permutation guidelines.

Step-by-step process for utilizing the MOPSO to address the TCTPs is given below:

Step-1: Initial population (P t ) Generation of size N

In the first step, an initial population (Pt) of size N is generated, comprising N swarm particles. Each particle is represented by a chromosome, and their fitness values, which represent the estimated PT and PC values, are computed using Eqs. (1) and (2).

Step-2: Evaluation of local best (Lbest) and global best (Gbest) of P particles

Lbest (\({X}_{iL}\)) represents the value of alternative assigned to each activity. To determine their global best positions (\({X}_{G}\)), the non-leaders are categorized into groups F1, F2, F3, and so forth. Given the objective of minimizing objectives, F1 is identified as the leading group. In the current iteration, Gbest (\({X}_{G}\)) emerges from solutions outside of F1. The top solution within F1, exhibiting the greatest average Euclidean distance, is designated as the G-best position (\({X}_{G}\)). The density or sparsity of non-dominated solutions is assessed similarly to the boundary of a rectangle formed by adjacent non-dominated solutions, known as the average Euclidean distance. For instance, the average Euclidean distance (\({E.D}_{k}\)) for a non-dominated solution \({X}_{k}\) is calculated as follows:

here, \({f}_{1}\left({X}_{k}\right)\) and \({f}_{2}\left({X}_{k}\right)\) represent the values of objectives 1 and 2 for the solution \({X}_{k}\). The non-dominated solution with the largest average Euclidean distance is given priority as Gbest (\({X}_{G}\)).

Step-3: Update particle position

The location of P particles is restored using the following formulas:

when t varies from 1 to maximum number of iterations (T), i = 1,…,P, and P stands for the total number of particles as previously explained, V stands for the particle velocity, X stands for the particle position, c1 and c2 for the learning factors, r1 and r2 for random numbers between 0 and 1, and w(t) for the inertia weight that regulates the influence of previous velocities on current velocities. In process of updating particle positions within the MOPSO algorithm, the particle; s current location undergoes two stages of refinement during subsequent rounds. Initially, the modified position is assessed to determine whether it surpasses the existing one. This evaluation involves comparing the fitness or objective function values associated with the modified position against those of the current position. If the modified position yields superior performance in terms of the optimization objectives, it is adopted as new position for particle.

Following this evaluation, if the updated position and the current position are not dominated by each other, the decision of accepting the updated position is made at random from the current position. In other words, if neither position dominates the other in terms of objective function values, randomness is introduced to decide whether to retain the current position or adopt the updated position. This random selection mechanism helps in maintaining diversity within the population and prevents premature convergence towards a single solution.

These two stages of updating particle positions contribute to the exploration–exploitation trade-off inherent in MOPSO, enabling the algorithm to efficiently navigate the search space and discover diverse sets of high-quality solutions to complex multi-objective optimization problems.

Step-4: Generation of new position of particles

In the process of generating new positions for particles within the MOPSO algorithm, potential revisions that could lead to extended project durations or increased costs are addressed by selecting a random updated location to ensure alignment with intended project constraints. After this selection, further evaluation is conducted: if the duration and cost of the chosen location are below the desired thresholds, it may be adopted as the new position. This iterative process is applied to each particle, ensuring consistency in constraint adherence and solution evaluation. By integrating these considerations into position updates, MOPSO effectively balances exploration of the solution space with the necessity of meeting project constraints, facilitating the discovery of optimal solutions that fulfil both optimization objectives and practical project requirements.

Step-5: Evaluating the updated position

After population members; positions have been updated, each population member is assessed using PT and PC; s objective functions.

Step-6: NDS of updated population

After generation of updated positions for particles, the revised population undergoes non-dominated sorting to organize and distribute particles into distinct fronts based on their dominance relationships. This sorting process, illustrated in Fig. 2, classifies particles into non-dominated fronts, where each front consists of particles that are not dominated by any other particle in terms of all optimization objectives. By categorizing particles in this manner, non-dominated sorting provides insights into the trade-offs between different objectives and helps identify the Pareto-optimal solutions. These fronts represent different levels of solutions, with the first front containing the most optimal solutions and subsequent fronts representing progressively less optimal solutions. This organization aids in identifying diverse sets of high-quality solutions that offer different trade-offs between conflicting objectives, enabling decision-makers to make informed choices during the optimization process.

Step-7: Pareto-optimal front

The first non-dominant front is closest to the objective axis, as shown in Fig. 2. As a result, the Pareto-Optimal front can be identified as the first non-dominated front in minimization problems.

Step-8) Selection of one solution from Pareto-optimal solutions

To start the real construction work required to finish the project, the project team must select one ideal option. Ferreira et al. (2007) discussed a number of strategies for selecting one solution from the resulting Pareto-optimal set. The weighted sum technique, which uses Eqs. (6) and (7) as inputs, is one of its techniques:

where \({w}_{i}\) denotes the weight of the \({i}_{th}\) objective and \({x}_{ij}\) denotes the \({j}_{th}\) solution to the \({i}_{th}\) objective. For example, the project team might believe that addressing the TCTPs requires equal amounts of time and money.

Case study and results

This research demonstrates the adaptability, efficiency, and effectiveness of established MOPSO model through resolution of a real case study project, despite numerous completed case studies supporting the proposed concept. The case study involves construction of a three-story structure in Delhi, India, as outlined in Table 1. The project comprises 19 activities, and each task can be executed in three different ways, each associated with a distinct set of resources, estimating unique durations and costs. Table 1 presents the values of AT and AC for each option and activity before the commencement of actual construction. AON network diagram for project is shown as Fig. 3. With 319 different ways to complete tasks based on various combinations of alternate options, a robust optimization algorithm becomes imperative for selecting the optimal approach. After assigning the best alternative for each project activity, a singular approach is chosen to achieve project completion while optimizing both time and cost.

The MOPSO-based scheduling model is applied to identify Pareto-optimal solutions for scheduling phase of the previously mentioned case study project. The programming of developed MOPSO-based TCT model was executed on a computer equipped with an i7 CPU, a 64-bit operating system, and configured with 8 GB RAM. To ensure optimal performance, a thorough consideration of iterations was undertaken. The current instance involved running between 10 and 200 trials and iterations, with the most favorable outcomes observed after 120 iterations.

At the 120th iteration, the analysis yielded ten distinct Pareto-optimal solutions, as detailed in Table 2. The TCT curve for this scheduling period is illustrated in Fig. 4. The PT values span from 124 to 148 days, while the PC values range from 12,286,155 to 13,653,118 INR. It is evident that the solution with the highest PC value corresponds to the lowest PT value.

Figure 4 clearly shows that obtained Pareto-optimal solutions are diverge and converge, which shows the efficiency of proposed model in determining the optimal solutions for TCT optimization. The solutions are widely distributed over Pareto-optimal front and highly converged towards origin point.

The proposed MOPSO-based TCT model should be compared with the results obtained from existing TCT models based on MOGA, MOTLBO, and MOACO. According to the findings presented in Table 3, the suggested MOPSO approach yielded the lowest PT and PC values for the case study project.

Then, one of the Pareto optimal solutions is selected to complete the project, employing Eqs. (6) and (7). In this selection process, the best options for the 19 projects are determined by assigning equal weight (0.5) to both time and cost considerations. The selected alternatives for each activity are presented in Table 4, where the project duration (PT) and project cost (PC) values are provided.

Thus, time and cost are contradictory and conflicting objectives, and establishing an equilibrium between time and cost is more essential to effectively execute the project. For this purpose, this paper has been successfully provided a suitable procedure to solve the TCT type problems.

Discussion over findings

The findings from the proposed research methodology provide valuable insights into the optimization of TCT problems in construction projects. Firstly, the utilization of MOPSO demonstrates its effectiveness in generating Pareto-optimal solutions, which are crucial for balancing conflicting objectives such as project time and cost. By integrating non-dominant sorting (NDS) into the PSO process, the model efficiently identifies solutions that are not dominated by others, offering a diverse set of trade-off options for project stakeholders.

The case study conducted on a construction project in Delhi, India, illustrates the practical application of the MOPSO-based optimization model. With 19 activities and multiple alternatives for each, the project presents a complex scheduling problem. However, the MOPSO model efficiently evaluates various combinations of activity alternatives, considering their respective durations and costs. This results in the identification of Pareto-optimal solutions that represent the trade-offs between project time and cost, providing decision-makers with a range of feasible options to choose from.

Furthermore, the comparison of the proposed MOPSO approach with existing TCT models based on different meta-heuristic techniques highlights its superiority in terms of minimizing both project time and cost. The MOPSO approach consistently outperforms other algorithms such as MOGA, MOTLBO, and MOACO, yielding lower project time and cost values. This indicates the robustness and efficiency of the MOPSO-based optimization model in tackling complex TCT problems in construction project scheduling.

The selection of a final solution from the Pareto-optimal set involves considering various factors such as project priorities, resource constraints, and stakeholder preferences. Strategies like the weighted sum technique offer a systematic approach to selecting the most suitable solution based on predefined criteria. This ensures that the chosen solution aligns with the project objectives while optimizing both time and cost aspects.

In conclusion, the findings of the research highlight the importance of adopting advanced optimization techniques like MOPSO for addressing TCT problems in construction projects. By simultaneously optimizing project time and cost objectives, the proposed model facilitates informed decision-making, enhances project efficiency, and ultimately contributes to the successful execution of construction projects. Moreover, the comparative analysis underscores the effectiveness of the MOPSO approach, emphasizing its potential for improving scheduling choices and maximizing project outcomes in the construction industry.

Conclusion

In conclusion, the research provides a comprehensive examination of the efficacy of MOPSO in addressing TCT problems within construction projects. Through a detailed case study conducted in Delhi, India, the study effectively demonstrates the applicability and efficiency of the MOPSO model in real-world project scheduling scenarios. By considering multiple project activities and their respective alternatives, the MOPSO model efficiently navigates the complexities of scheduling, ultimately yielding Pareto-optimal solutions that strike a balance between project time and cost objectives.

Moreover, the practical application of the MOPSO model underscores its relevance in the construction industry, where project timelines and budget constraints are critical considerations. The ability of the model to handle diverse activity combinations and resource allocations exemplifies its utility in optimizing project scheduling decisions. This not only enhances project efficiency but also empowers decision-makers with a range of feasible options to achieve project completion while minimizing costs and adhering to deadlines.

The comparative analysis conducted against other TCT optimization techniques further solidifies the superiority of the MOPSO approach. Consistently outperforming alternative methods such as MOGA, MOTLBO, and MOACO, the MOPSO model demonstrates its robustness and effectiveness in minimizing project time and cost values. This comparative advantage positions the MOPSO model as a preferred choice for addressing TCT challenges in construction project scheduling.

Furthermore, the study emphasizes the importance of advanced optimization techniques in tackling complex scheduling problems inherent in construction projects. By simultaneously optimizing project time and cost objectives, the MOPSO model facilitates informed decision-making, enhances project efficiency, and contributes to the successful execution of construction projects. Strategies such as the weighted sum technique provide a structured approach to selecting the most suitable solution based on predefined criteria, ensuring alignment with project goals and priorities.

In conclusion, the research findings underscore the potential of MOPSO-based optimization models to improve scheduling choices, maximize project outcomes, and enhance decision-making processes in the construction industry. As construction projects continue to grow in complexity, the adoption of advanced optimization techniques like MOPSO becomes increasingly vital for optimizing project performance and delivering successful outcomes.

Data availability

Data can be obtained from the corresponding author upon reasonable request.

References

Afshar, A., Ziaraty, A. K., Kaveh, A., & Sharifi, F. (2009). Nondominated archiving multicolony ant algorithm in time-cost trade-off optimization. Journal of Construction Engineering and Management, 135(7), 668–674. https://doi.org/10.1061/(asce)0733-9364(2009)135:7(668)

Anagnostopoulos, K. P., & Kotsikas, L. (2010). Experimental evaluation of simulated annealing algorithms for the time-cost trade-off problem. Applied Mathematics and Computation. https://doi.org/10.1016/j.amc.2010.05.056

Beşikci, U., Bilge, Ü., & Ulusoy, G. (2015). Multi-mode resource constrained multi-project scheduling and resource portfolio problem. European Journal of Operational Research. https://doi.org/10.1016/j.ejor.2014.06.025

Carlier, J., & Moukrim, A. (2015). Storage resources. In: Handbook on Project Management and Scheduling Vol. 1. https://doi.org/10.1007/978-3-319-05443-8_9

Deblaere, F., Demeulemeester, E., & Herroelen, W. (2011). Reactive scheduling in the multi-mode RCPSP. Computers and Operations Research. https://doi.org/10.1016/j.cor.2010.01.001

Delgoshaei, A., Al-Mudhafar, A., & Ariffin, M. K. A. (2016). Developing a new method for modifying over-allocated multi-mode resource constraint schedules in the presence of preemptive resources. Decision Science Letters. https://doi.org/10.5267/j.dsl.2016.5.002

Di, C., Sun, F. Q., Liu, S. X., & Wang, Y. F. (2013). Priority rule based heuristics for project scheduling problems with multi-skilled workforce constraints. In: 2013 25th Chinese Control and Decision Conference, CCDC 2013. https://doi.org/10.1109/CCDC.2013.6561233

Eirgash, M. A., & Toğan, V. (2023). A novel oppositional teaching learning strategy based on the golden ratio to solve the time-cost-environmental impact trade-off optimization problems. Expert Systems with Applications. https://doi.org/10.1016/j.eswa.2023.119995

Eirgash, M. A., Toğan, V., & Dede, T. (2019). A multi-objective decision making model based on TLBO for the time—cost trade-off problems. Structural Engineering and Mechanics, 71(2), 139–151. https://doi.org/10.12989/sem.2019.71.2.139

Elazouni, A. (2009). Heuristic method for multi-project finance-based scheduling. Construction Management and Economics. https://doi.org/10.1080/01446190802673110

Elbeltagi, E., Ammar, M., Sanad, H., & Kassab, M. (2016). Overall multiobjective optimization of construction projects scheduling using particle swarm. Engineering, Construction and Architectural Management. https://doi.org/10.1108/ECAM-11-2014-0135

Fallah-Mehdipour, E., Bozorg Haddad, O., Rezapour Tabari, M. M., & Mariño, M. A. (2012). Extraction of decision alternatives in construction management projects: Application and adaptation of NSGA-II and MOPSO. Expert Systems with Applications. https://doi.org/10.1016/j.eswa.2011.08.139

Feng, C. W., Liu, L., & Burns, S. A. (1997). Using genetic algorithms to solve construction time-cost trade-off problems. Journal of Computing in Civil Engineering. https://doi.org/10.1061/(ASCE)0887-3801(1997)11:3(184)

Ferreira, J. C., Fonseca, C. M., Gaspar-Cunha, A. (2007). Methodology to select solutions from the pareto-optimal set: a comparative study. In: Proceedings of GECCO 2007: Genetic and Evolutionary Computation Conference. https://doi.org/10.1145/1276958.1277117

Fondahl, J. W. (1962). A non-computer approach to the critical path meghod for the construction industry. Technical Report No. 9, Stanford University, pp 1–163.

Habibi, F., Barzinpour, F., & Sadjadi, S. J. (2017). A multi-objective optimization model for project scheduling with time-varying resource requirements and capacities. Journal of Industrial and Systems Engineering, 10(November), 92–118.

Habibi, F., Barzinpour, F., & Sadjadi, S. J. (2018). Resource-constrained project scheduling problem: Review of past and recent developments. Journal of Project Management, 3, 55–88. https://doi.org/10.5267/j.jpm.2018.1.005

Hartmann, S., & Briskorn, D. (2010). A survey of variants and extensions of the resource-constrained project scheduling problem. European Journal of Operational Research. https://doi.org/10.1016/j.ejor.2009.11.005

Kaveh, A. (2014). Advances in metaheuristic algorithms for optimal design of structures. Advances in Metaheuristic Algorithms for Optimal Design of Structures. (Vol. 9783319055). Springer. https://doi.org/10.1007/978-3-319-05549-7

Kaveh, A. (2016). Applications of metaheuristic optimization algorithms in civil engineering. Applications of Metaheuristic Optimization Algorithms in Civil Engineering. Springer. https://doi.org/10.1007/978-3-319-48012-1

Kaveh, A., & Ilchi Ghazaan, M. (2020). A new VPS-based algorithm for multi-objective optimization problems. Engineering with Computers, 36(3), 1029–1040. https://doi.org/10.1007/s00366-019-00747-8

Kaveh, A., Izadifard, R. A., & Mottaghi, L. (2020). Optimal design of planar RC frames considering CO2 emissions using ECBO, EVPS and PSO metaheuristic algorithms. Journal of Building Engineering, 28, 101014. https://doi.org/10.1016/j.jobe.2019.101014

Kaveh, A., Kalateh-Ahani, M., & Fahimi-Farzam, M. (2013). Constructability optimal design of reinforced concrete retaining walls using a multi-objective genetic algorithm. Structural Engineering and Mechanics, 47(2), 227–245. https://doi.org/10.12989/sem.2013.47.2.227

Kaveh, A., & Laknejadi, K. (2011). A novel hybrid charge system search and particle swarm optimization method for multi-objective optimization. Expert Systems with Applications, 38(12), 15475–15488. https://doi.org/10.1016/j.eswa.2011.06.012

Kaveh, A., & Laknejadi, K. (2013a). A hybrid evolutionary graph-based multi-objective algorithm for layout optimization of truss structures. Acta Mechanica, 224(2), 343–364. https://doi.org/10.1007/s00707-012-0754-5

Kaveh, A., & Laknejadi, K. (2013b). A new multi-swarm multi-objective optimization method for structural design. Advances in Engineering Software, 58, 54–69. https://doi.org/10.1016/j.advengsoft.2013.01.004

Kaveh, A., & Massoudi, M. S. (2014). Multi-objective optimization of structures using Charged System Search. Scientia Iranica, 21(6), 1845–1860.

Kelley, J. E., & Walker, M. R. (1959). Critical-path planning and scheduling. In: Proceedings of the Eastern Joint Computer Conference, IRE-AIEE-ACM 1959, pp 160–173. https://doi.org/10.1145/1460299.1460318

Kyriakidis, T. S., Kopanos, G. M., & Georgiadis, M. C. (2012). MILP formulations for single- and multi-mode resource-constrained project scheduling problems. Computers and Chemical Engineering. https://doi.org/10.1016/j.compchemeng.2011.06.007

Luong, D. L., Tran, D. H., & Nguyen, P. T. (2018). Optimizing multi-mode time-cost-quality trade-off of construction project using opposition multiple objective difference evolution. International Journal of Construction Management. https://doi.org/10.1080/15623599.2018.1526630

Moselhi, O. (1993). Schedule compression using the direct stiffness method. Canadian Journal of Civil Engineering, 20(1), 65–72. https://doi.org/10.1139/l93-007

Panwar, A., Tripathi, K. K., & Jha, K. N. (2019). A qualitative framework for selection of optimization algorithm for multi-objective trade-off problem in construction projects. Engineering, Construction and Architectural Management. https://doi.org/10.1108/ECAM-06-2018-0246

Rastegar Moghaddam, M., Khanzadi, M., & Kaveh, A. (2021). Multi-objective billiards-inspired optimization algorithm for construction management problems. Iranian Journal of Science and Technology - Transactions of Civil Engineering, 45(4), 2177–2200. https://doi.org/10.1007/s40996-020-00467-w

Santos, M. A., & Tereso, A. P. (2011). On the multi-mode, multi-skill resource constrained project scheduling problem—a software application. Advances in Intelligent and Soft Computing. https://doi.org/10.1007/978-3-642-20505-7_21

Senouci, A. B., & Eldin, N. N. (2004). Use of genetic algorithms in resource scheduling of construction projects. Journal of Construction Engineering and Management. https://doi.org/10.1061/(ASCE)0733-9364(2004)130:6(869)

Sharma, K., & Trivedi, M. K. (2020). Latin hypercube sampling-based NSGA-III optimization model for multimode resource constrained time–cost–quality–safety trade-off in construction projects. International Journal of Construction Management. https://doi.org/10.1080/15623599.2020.1843769

Sharma, K., & Trivedi, M. K. (2021). Development of multi-objective scheduling model for construction projects using opposition-based NSGA III. Journal of the Institution of Engineers (india): Series A. https://doi.org/10.1007/s40030-021-00529-w

Sharma, K., & Trivedi, M. K. (2022). AHP and NSGA-II-Based Time–Cost–Quality Trade-Off Optimization Model for Construction Projects (pp. 45–63). Springer. https://doi.org/10.1007/978-981-16-1220-6_5

Sharma, K., & Trivedi, M. K. (2023a). Discrete OBNSGA III method-based robust multi-objective scheduling model for civil construction projects. Asian Journal of Civil Engineering, 24(7), 2247–2264. https://doi.org/10.1007/s42107-023-00638-w

Sharma, K., & Trivedi, M. K. (2023b). Modelling the resource constrained time-cost-quality-safety risk-environmental impact trade-off using opposition-based NSGA III. Asian Journal of Civil Engineering, 24(8), 3083–3098. https://doi.org/10.1007/s42107-023-00696-0

Sharma, K., & Trivedi, M. K. (2023c). Statistical analysis of delay-causing factors in indian highway construction projects under hybrid annuity model. Transportation Research Record Journal of the Transportation Research Board. https://doi.org/10.1177/03611981231161594

Shi, Y. J., Qu, F. Z., Chen, W., & Li, B. (2010). An artificial bee colony with random key for resource-constrained project scheduling. Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics). https://doi.org/10.1007/978-3-642-15597-0_17

Siemens, N. (1971). Simple CPM time- cost tradeoff algorithm. Management Science, 17(6), 354–363.

Tiwari, A., Sharma, K., & Trivedi, M. K. (2020). NSGA III based Time-Cost-Environmental Impact Trade-Off Optimization Time—Cost—Environmental Impact Trade-Off Optimization Model, December, pp 10–25. https://doi.org/10.1007/978-981-16-1220-6

Tiwari, A., Sharma, K., & Trivedi, M. K. (2022). NSGA-III-Based Time–Cost–Environmental Impact Trade-Off Optimization Model for Construction Projects, pp 11–25. https://doi.org/10.1007/978-981-16-1220-6_2

Toğan, V., & Eirgash, M. A. (2019). Time-cost trade-off optimization of construction projects using teaching learning based optimization. KSCE Journal of Civil Engineering, 23(1), 10–20. https://doi.org/10.1007/s12205-018-1670-6

Trivedi, M. K., & Sharma, K. (2023). Construction time–cost–resources–quality trade-off optimization using NSGA-III. Asian Journal of Civil Engineering, 24(8), 3543–3555. https://doi.org/10.1007/s42107-023-00731-0

Van Den Bergh, F., & Engelbrecht, A. P. (2010). A convergence proof for the particle swarm optimiser. Fundamenta Informaticae. https://doi.org/10.3233/FI-2010-370

Xiong, Y., & Kuang, Y. (2008). Applying an ant colony optimization algorithm-based multiobjective approach for time-cost trade-off. Journal of Construction Engineering and Management. https://doi.org/10.1061/(ASCE)0733-9364(2008)134:2(153)

Yang, Z., Shen, C., Zhang, L., Crow, M. L., & Atcitty, S. (2001). Integration of a StatCom and battery energy storage. IEEE Transactions on Power Systems. Doi, 10(1109/59), 918295.

Zahraie, B., & Tavakolan, M. (2009). Stochastic time-cost-resource utilization optimization using nondominated sorting genetic algorithm and discrete fuzzy sets. Journal of Construction Engineering and Management. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000092

Zhang, H., & Li, H. (2010). Multi-objective particle swarm optimization for construction time-cost tradeoff problems. Construction Management and Economics, 28(1), 75–88. https://doi.org/10.1080/01446190903406170

Zhang, H., Li, H., & Tam, C. M. (2006). Heuristic scheduling of resource-constrained, multiple-mode and repetitive projects. Construction Management and Economics. https://doi.org/10.1080/01446190500184311

Zhou, J., Love, P. E. D., Wang, X., Teo, K. L., & Irani, Z. (2013). A review of methods and algorithms for optimizing construction scheduling. Journal of the Operational Research Society, 64(8), 1091–1105. https://doi.org/10.1057/jors.2012.174

Funding

No funding was received.

Author information

Authors and Affiliations

Contributions

Krushna Chandra Sethi collected the data, Kamal Sharma analyzed the data, Shyamveer Singh Chauhan wrote the manuscript, and Aditya Kumar Agarwal reviewd and finalized manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts with any involved parties.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agarwal, A.K., Chauhan, S.S., Sharma, K. et al. Development of time–cost trade-off optimization model for construction projects with MOPSO technique. Asian J Civ Eng 25, 4529–4539 (2024). https://doi.org/10.1007/s42107-024-01063-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-024-01063-3