Abstract

The nanocrystalline Ni-Zn ferrite thin film with the chemical formula Ni0.3Zn0.7Fe2O4 were deposited on glass substrate using sol-gel synthesis of metal nitrate aqueous solutions and spin-coating technique. Thin films of nickel-zinc ferrite have been prepared using spin-coating technique onto the ITO glass substrates. As-deposited films are annealed at 400, 500, 600 and 700 °C for 1 h. The Ni-Zn ferrite thin film with crystallite size of 20 nm has been successfully synthesized. The thickness of deposited films was below 300 nm and crystallite size was below 20 nm. The X-ray diffraction (XRD) analysis found the Ni-Zn thin films nanoferrite has a spinel cubic structure and lattice parameter of Fd3m. The crystallinity of the prepared Ni-Zn ferrite films increases as increase substrate temperature of a film deposition. Microstructures and chemical analysis by scanning electron microscopy and energy-dispersive spectroscopy showed that nanosized nickel-zinc ferrite particles with a diameter of 18.6 to 41.3 nm exist in the thin film. Magnetic properties of the Ni-Zn films have been characterised at room temperature, whereas the saturation magnetization M s. of the Ni-Zn films increase with increasing grain sizes. Maximum saturation magnetization M s. and coercivity H c are 3.42 emu/g and 16.54 Oe for thin films annealed at 500 and 700 °C, respectively. The M s. of the films shows a trend increasing and the H c value decreasing as increase the annealed temperature and the grain size of the Ni-Zn ferrite thin films. The conductivity decreases with increasing annealed temperature. It has been shown that the DC resistivity, saturation magnetization and coercivity of deposited films are influenced by annealing temperatures. The magnetic properties of Ni-Zn thin film with grain size of 18.6–41.3 nm shown a superparamagnetic behaviour were observed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The demand for advanced technology in electronics has attracted research interest on the structural, magnetic and electrical properties of ferrites. The trend for downsizing electronic devices and the potential applications of soft ferrite materials have leads to the fabrication of ferrite thin films. Recent years, an impressive research work on the growth and characterization of ferrite thin film has been developed in the literature due to their wide range of technological application in numerous fields.

Ferrite thin films are very important for the fabrication of sensors [1], memory [2] and microwave devices [3]. There are several physical methods ion sputtering [2, 4, 5], pulsed laser deposition [6], sol-gel [7, 8] and spray pyrolysis [9,10,11,12], and chemical methods (solvothermal, photochemical, electrochemical, thermolytic, sol-gel, etc.) to synthesize nanocrystalline thin film and to control its crystal size [11]. Nickel ferrite is the most suitable material for device application. It has a technological importance in electrical and magnetic industries gas sensor material [12]. Sol-gel is a chemical method that fabricates material through the process of phase change from liquid phase (sol) to solid phase (gel). Fabrication that employs this method will usually be entailed by either spin-coating or dip-coating process followed by heat treatment process. Walker et al. [13] found that annealing treatment is required to reduce material defects. Annealing treatment is a common procedure in fabrication of nanomaterial to either improve the quality of crystal or stabilize the structure at a temperature [14]. Wang et al. [15] studied the effects of annealing temperature on the structural and magnetic properties of Ni0.8Zn0.2Fe2O4 thin films at room temperature. The coercivity were decrease as average grain size increased by varying the annealing temperature from 600 to 900 °C, while their saturation magnetization increased and the crystallinity improved as increase the annealing temperature. These results also agreed with Mathe and Bhosale [16].

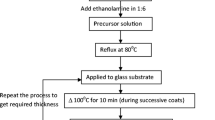

A spin coating with a simple apparatus is a versatile technique for producing various thin film materials of a wide range of the composition in air at a relatively low temperature and a high deposition rate. The spin coating of Co ferrite films [17], Zn ferrite thin film [18] and Ni-Zn ferrite thin films [19] have been reported. In this work, nanostructured Ni0.3Zn0.7Fe2O4 ferrite thin films have been prepared by using sol-gel spin-coating method annealed at low temperatures (400–700 °C). As a result, the size of grains was obtained below 50 nm with annealing temperature at lower temperatures (400–700 °C) for crystallization. Using sol-gel synthesis route is useful to achieve the nanosize grains fabrication of magnetic ferrite thin films at relatively low annealing temperature. This sol-gel synthesis route is an efficient method to fabricate an integrated thin film device. The phase structure, magnetic hysteresis at room temperature, microstructure and conductivity of the nanostructure Ni-Zn nanoferrite thin films has been studied.

Experimental

The starting materials used were nickel nitrate hexahydrate, iron nitrate nanohydrate and zinc nitrate hexahydrate were used as a precursor for the starting sol preparation. The precursors were dissolved in a beaker using deionised water and stirred for 15 mins with a molar ratio of Ni:Zn:Fe = 1:1:2 using a hot plate. A sol-gel formed after left 24 h for aged. The aged sol 1.0 ml was dropped on ITO glass substrate and spin coated for 25 s at 3500 rpm (revolutions per mins). The deposition was repeated several times to obtain the require thickness (300 nm). The films were drying in room temperature and annealed in air at temperatures of 400, 500, 600 and 700 °C. The structure and phase deposited films were examined by XRD using Philips X’pert diffractometer model 7602 EA Almelo operating at 40 kV/30 mA obtained in the theta range 20° to 80° using low scan with 0.012o step size, 0.44 s scan step size, CuKα radiation (λ = 1.5417 Å). Magnetic properties of the samples; saturation magnetization (M s), remnance magnetization (M r) and coercivity (H c) were recorded at room temperature using a vibrating sample magnetometer (VSM) model 7404 Lake Shore. The maximum value of the applied magnetic field is 5000 G (G), using an interval of 134 G. The microstructure and composition of the sample was carried out by a NovaNano 230 field emission electron microscopy (FESEM), voltage 5.0 kV with attached energy-dispersive (EDX) spectroscopy. The electrical resistance measurements were made by using standard two-probe method Keithley digital multimetres.

Results and discussion

Structural analysis

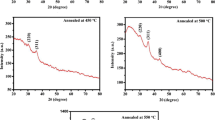

Figure 1 shows the XRD pattern of spin coating and air annealed ferrite thin films on the ITO glass substrate. The XRD patterns show single cubic spinel phase of the Ni0.3Zn0.7Fe2O4 ferrite thin films according to JCPDS reference code 74–2081 and 82–1049, respectively. As the increase in grain size as increasing annealing temperature, as indicate the narrowing the XRD spectrum lines. As (220), (311), (400), (511), (440) which are allowed peaks of the single cubic spinel structures. Plane (311) most intense in each annealing temperature whereas other at relatively low intense. These planes formed nickel–zinc ferrite phases. The small peak intensities in XRD pattern revealed the existence of fine grain nanocrystalline with the most part as amorphous. The crystallite sizes of all ferrite thin films are found to be between 16 and 18 nm calculated using Scherrer equation. Annealing temperature has pronounced the effect on grain size. The lattice parameter calculated for pure nickel ferrite thin film is 8.338 Ǻ claimed by Gupta et al. [20]. This is in accordance with the variation in lattice parameter with Zn content reported for the bulk ferrites.

Magnetic properties

The hysteresis loop of Ni-Zn ferrite thin films as in Fig. 2. The magnetic parameters of saturation magnetization M s. and coercivity H c are listed in Table 1. The M s. and H c could be attributed to the varied grain size and crystallinity. The lower value of M s. Ni0.3Zn0.7Fe2O4 films could be caused by the several reasons. Kumar et al. [21] stated that a large grain boundary volume presented in thin films would result in increase of the M s. Other reasons the increase M s. are due to complex spinel structure, it was difficult to gain Ni0.3Zn0.7Fe2O nanoferrite films with perfect crystallization. The metal cations can occupy either A sites (tetrahedral) or B sites (octahedral), which will result in a partially disordered cation distribution in the crystal lattice [22]. The saturation magnetization (M s) increases with the grain size, and the observations on larger decrease are interpreted mostly by oxygen absorption, characteristic to the preparation technique.

The coercivity H c was decreases as increase the annealing temperature and average grain size (Fig. 3). The maximum value of H c was 16.54 Oe for the grain size 26.25 nm. The H c observed were closed to Nie et al. [23] as reported that the value of H c within the range 20–210 Oe. The decreases of H c contributed from the transition of the single domain to the multidomain [24]. The coercivity (H c) has a maximum at grain size of about 26 nm and a steep decrease at larger grain sizes (41.3 nm). The smaller grain sizes, the decrease of H c due to the randomizing effects of thermal energy. Thermal energy is important role in magnetic instability of single domain magnetic particles. Due to the smaller grain sizes, the thermal agitation becomes small and will not be able to cause fluctuations in the magnetic spin orientations of the nanoparticles where they freeze in random orientations. The latter is probably due to the decreased anisotropy constant, which leads to a sharp decrease in coercivity according to the random anisotropy model. Relation of the decrease H c as increase grain size as stated by Fernando et al. 2011 [25] that show the linear inverse proportionality between coercivity (H c) and grain size (D) by H c α 1/D.

Microstructure analysis

The FESEM images show the Ni0.3Zn0.7Fe2O4 films have dense and homogenous grains with an average grain size is tabulated in Table 2. The average grain size of the Ni0.3Zn0.7Fe2O4 nanoferrite thin films are 18.61 nm (400 °C), 26.25 nm (500 °C), 28.12 nm (600 °C) and 41.32 nm (700 °C). The grains of the films are spherical and uniform, and cohesion of grains is due to the magnetic attraction. The average grain size of the films is presented in Fig. 4. The histogram of grain size distribution shifted to the larger grain size as the annealing temperature increased. The grain size of the films also increases as temperature increases (Figs. 4 and 5).

Electrical properties

Figure 6 shows the linear curve of the I-V measurement of the Ni0.3Zn0.7Fe2O4 nanoferrite films in ambient light with voltage supply ranging from −10 to 10 V. Linear curves indicate that the gold metal contact show ohmic behaviour with the thin films. From the graph, it showed that the most conductive sample is 700 °C followed by 600, 500 °C and the least conductive is for sample sintered at 400 °C. From the I-V measurement, resistivity ρ were calculated and plotted as in Fig. 7. The resistivity ρ were found to increase with increase annealing temperatures, 2.4–6.4 × 10−3 Ωcm. The films perform a larger grain size with increase annealing temperature. The high resistivity 6.4 × 10−3 Ωcm can be due to the high band gap of the material and is within the range of the reported values [26]. The resistivity decreases at 700 °C due to the grain size increases (42.3 nm) as compared to 600 °C grain size of (28 nm). Increase annealing temperature leads to a decrease in grain boundaries and hence resistivity [26]. Smaller grains also imply smaller grain to grain surface contact area and therefore reduced the current flow, thus decrease the resistivity [27]. The conductivity σ graph plotted as a reciprocal of electrical resistivity. Conductivity σ of the Ni0.3Zn0.7Fe2O4 nanoferrite thin films showed a decreased in conductivity as the increasing annealing temperatures, 1.55–4.14 × 102 S-cm. The conduction mechanism in ferrites is due to electron hopping of Fe2+ between Fe3+ ions and hole hopping between Ni2+ and Ni3+ at two adjacent B sites [28]. Zn is substituted with Ni in Ni x Zn1-x Fe2O4, and enters the octahedral sites, whereas zinc has a strong affinity for tetrahedral sites. Therefore, a partial substitution of Ni for zinc dilutes the conduction mechanism occurring through octahedral sites [29].

Conclusion

Spherical Ni0.3Zn0.7Fe2O nanoferrite thin films with grain size of 18.6–42.3 nm have been fabricated via sol-gel synthesis and spin-coating method. XRD spectra confirm the films crystallinity increases with increase the annealing temperatures. Films annealed at 700 °C shows good crystallinity. EDX shows stoichiometric formation of Ni0.3Zn0.7Fe2O nanoferrite thin films. The Ni-Zn thin film was observed the presence of the superparamagnetic behaviour, as the smaller grain size range. Magnetic parameters M s. and H c were observed as the M s. decreases and H c increases with the increase annealing temperatures. The electrical resistivity of films was found to increase with increasing annealing temperature. This conventional process is a simple and very useful method to synthesize high-quality sphere-like Ni-Zn nanoferrite thin films. It will be promising low-cost alternative methods that produce high-quality thin films nanoferrite in the future.

References

Kiyomura, T., Maruo, Y., Gomi, M.: Electrical properties of MgO insulating layers in spin-dependent tunneling junctions using Fe3O4. J Appl Phys. 88(8), 4768 (2000)

Wang, L.S., Nie, S.J., Wang, J.B., Xu, L., Yuan, B.B., Liu, X.L., Luo, Q., Chen, Y., Yue, G.H., Peng, D.L.: Effect of experiment parameters on the structure and magnetic properties of NiZn-ferrite films. Mater Chem Phys. 160, 321–328 (2015)

Chavan, S.M., Babrekar, M.K., More, S.S., Jadhav, K.M.: Structural and optical properties of nanocrystalline Ni–Zn ferrite thin films. J Alloys Compd. 507(1), 21–25 (2010)

Guo, D., Zhang, Z., Lin, M., Fan, X., and Chai, G.: Ni–Zn ferrite films with high resonance frequency in the gigahertz range deposited by magnetron sputtering at room temperature. J Appl Phys. 42(12), 125006 (2009)

Prado, J., Gómez, M.E., Prieto, P., Mendoza, A.: Growth temperature dependence of the hysteretic behavior of Ni0.5Zn0.5Fe2O4 thin films. J Magn Magn Mater. 321(18), 2792–2794 (2009)

Sorescu, M., Diamandescu, L., Swaminathan, R., Mchenry, M.E., Feder, M.: Structural and magnetic properties of NiZn and Zn ferrite thin films obtained by laser ablation deposition. J Appl Phys. 105, 3–5 (2005)

Gao, P., Hua, X., Degirmenci, V., Rooney, D., Khraisheh, M., Pollard, R., Bowman, R.M., Rebrov, E.V.: Structural and magnetic properties of Ni1-x Znx Fe2O4 nanopowders prepared by sol–gel method. J Magn Magn Mater. 348, 44–50 (2013)

Bae, S.Y., Kim, C.S., Oh, Y.J.: Magnetic properties of sol-gel derived Ni–Zn ferrite thin films on yttria stabilized zirconia buffered Si(100). J Appl Phys. 85(8), 5226–5228 (1999)

Shimada, Y., Matsushita, N., Abe, M., Kondo, K., Chiba, T., Yoshida, S.: Study on initial permeability of Ni–Zn ferrite films prepared by the spin spray method. J Magn Magn Mater. 278, 256–262 (2004)

Beji, Z., Ammar, S., Smiri, L.S., Vaulay, M.-J., Herbst, F., Gallas, B., Fiévet, F.: Spray deposition of nanocrystalline Ni1−x Znx Fe2O4 (x ≤ 0.6) films from polyol-mediated sol: microstructure and magnetic properties. J Appl Phys. 103(7), 07E744 (2008)

Owens, G.J., Singh, R.K., Foroutan, F., Alqaysi, M., Han, C., Mahapatra, C., Kim, H.: Progress in materials science sol–gel based materials for biomedical applications. Prog Mater Sci. 77, 1–79 (2016)

Reddy, C.V.G., Manorama, S.V., Rao, V.J.: Semiconducting gas sensor for chlorine based on inverse spinel nickel ferrite. Sensors Actuators B Chem. 55, 90–95 (1999)

Walker, P.M.B.: The Wordsworth Dictionary of Science & Technology. Wordsworth, Hertfordshire (1995)

N. Shanmugam, S. Cholan, N. Kannadasan, K. Sathishkumar, G. Viruthagiri (2013) Effect of annealing on the ZnS nanocrystals prepared by chemical precipitation method. 2013

Fe, Z., Wang, L., Dong, H., Li, J., Hua, J., Xu, S., Feng, M., Li, H.: Effects of annealing temperature on structural and magnetic properties. Ceram Int. 40, 10323–10327 (2014)

Bhosale, V.I., Mathe, C.H.: Effect of annealing on spray deposited Ni-Zn ferrite thin films. Indian J Eng Mater Sci. 10, 166–168 (2003)

Wu, Z., Okuya, M., Kaneko, S.: Spray pyrolysis deposition of zinc ferrite films from metal nitrates solutions. Thin Solid Films. 385, 109–114 (2001)

Bellad, S.S., Bhosale, C.H.: Substrate temperature dependent properties of sprayed CoFe2O4 ferrite thin films. Thin Solid Films. 322, 93–97 (1998)

Takayama, A., Okuya, M., Kaneko, S.: Spray pyrolysis deposition of NiZn ferrite thin films. Solid State Ionics. 172(1–4 SPEC. ISS), 257–260 (2004)

Gupta, N., Verma, A., Kashyap, S.C., Dube, D.C.: Microstructural, dielectric and magnetic behavior of spin-deposited nanocrystalline nickel-zinc ferrite thin films for microwave applications. J Magn Magn Mater. 308(1), 137–142 (2007)

Kumar, N., Prasad, S., Misra, D.S., Venkataramani, N., Bohra, M., Krishnan, R.: The influence of substrate temperature and annealing on the properties of pulsed laser-deposited YIG films on fused quartz substrate. J Magn Magn Mater. 320(18), 2233–2236 (2008)

Nakashima, S., Fujita, K., Tanaka, K., Hirao, K., Yamamoto, T., Tanaka, I.: First-principles XANES simulations of spinel zinc ferrite with a disordered cation distribution. Phys Rev B Condens Matter Mater Phys. 75(17), (2007)

Nie, S.J., Geng, H., Wang, J.B., Sen Wang, L., Wang, Z.W., Xu, R., Yue, G.H., Chen, Y.Z., Peng, D.L.: The structure and magnetic properties of NiZn-ferrite films deposited by magnetron sputtering at room temperature. Adv Mater Res. 690–693, 1702–1706 (2013)

Desai, M., Prasad, S., Venkataramani, N., Samajdar, I., Nigam, A.K., Keller, N., Krishnan, R., Baggio-Saitovitch, E.M., Pujada, B.R., Rossi, A.: Anomalous variation of coercivity with annealing in nanocrystalline NiZn ferrite films. J Appl Phys. 91(10 I), 7592–7594 (2002)

Rodrigues-jr, D., Landgraf, G., Jose, F.: Determining the effect of grain size and maximum induction upon coercive field of electrical steels. J Magn Magn Mater. 323, 2335–2339 (2011)

Mathews, N.R., Morales, E.R., Cortés-Jacome, M.A., Toledo Antonio, J.A.: Influence of annealing temperature on structural, optical and photocatalytic properties. Sol Energy. 83(9), 1499–1508 (2009)

Kingery, W.D., Bowen, H.K., Uhlmann, D.R.: Introduction to Ceramics, 2nd edn. Wiley, New York (1976)

Batoo, K., Ansari, M.: Low temperature-fired Ni-Cu-Zn ferrite nanoparticles through auto-combustion method for multilayer chip inductor applications. Nanoscale Res Lett. 7(1), 112 (2012)

El-Sayed, A.M.: Electrical conductivity of nickel-zinc and Cr substituted nickel-zinc ferrites. Mater Chem Phys. 82(3), 583–587 (2003)

Acknowledgements

The authors are grateful to Ministry of Higher Education Malaysia (MOHE) and University Putra Malaysia for Research University Grant (vote number 5526200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yusuf, Y., Azis, R.S., Kanagesan, S. et al. Microstructure and magnetic properties of Ni-Zn ferrite thin film synthesized using sol-gel and spin-coating technique. J Aust Ceram Soc 53, 767–774 (2017). https://doi.org/10.1007/s41779-017-0090-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-017-0090-2