Abstract

The terbium iron garnet (TbIG) nanoparticle thin films have been prepared by a sol-gel method for potential use as a magnetic sensor. The films were deposited onto clean quartz substrate using a spin coating technique, followed by annealing at different temperature of 700, 800, 900 °C in air for 2 h. As prepare film has been also executed. Microstructural and magnetic properties of the films were measured using an X-ray diffraction (XRD), a Field Emission Scanning Electron Microscope and a Vibrating Sample Magnetometer. The XRD results revealed that the pure phase of garnet structure has been formed at 900 °C. The lattice parameter decreased initially from 11.6 to 11.4 Å when annealing temperature increased from 700 to 800 °C, and then it is increased to 12.36 Å when annealing temperature increased to 900 °C. The grain sizes increased from 12 to 18 nm with increasing of annealing temperature from 700 to 900 °C, while the thickness of the films decreased to the smallest value of 312 nm at 900 °C. The saturation magnetization increased with increasing of annealing temperature due to increasing of grain sizes. The coercivity of films exhibited a highest value of 102 kA/m at 900 °C.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Terbium iron garnets (Tb3Fe5O12) are an indispensible class in garnet ferrite group due to their potential in applications such as, storage, communications and magnetic sensors [1, 2]. The crystal structure of TbIG is a cubic and belongs to Ia 3d–(O 10h ) group; the Tb3+ ions are occupied the dodecahedral sites {24c}(222) while the two Fe3+ ions are distributed in the octahedral [16a](3) and tetrahedral (24d)(4) sites, hence the magnetic formula of TbIG can be written as {Tb +33 }[Fe +23 ](Fe +33 )O12 [3].

Terbium iron garnets have attracted more attention because it exhibited a ferrimagnetic ordering of the Tb and iron moments along the [111] direction at room temperature, whereas noncollinear magnetic structures are observed at low temperatures [4–6]. Few Authors have reported that terbium iron garnet thin films prepared by pulsed laser deposition technique showed anomalously large coercivity and in–plane easy axis of magnetization . In addition, the M-H loop measured at 20 K, exhibited about an order of magnitude enhancement in the coercivity value (H c ) than the single crystal. In addition, easy axis of the magnetization lies within film’s plane [2, 7]. No report so far for TbIG thin films prepared by simple steps for sol gel technique. This work reports the effect of annealing temperature on the structural and magnetic properties of TbIG. The sol-gel method is preferable in this work to produce thin films because it offers considerable advantages, like better homogeneity, capability to produce nanoparticles samples, simple preparation method and low preparation temperature [8, 9]. It is a wet chemical method when the solid precursor is dissolved into a solvent.

2 Method

2.1 Samples Preparation

The terbium solution was prepared by dissolving terbium (III) acetatehydrate (Tb(COOCH3)3.H2O, Alfa Aesan, 99.9 % purity) in 2 mL of acetic acid, 1 mL of distilled water and 5 μL of nitric acid and iron (III) nitrate nonahydrate (Fe(NO3)3·9H2O, 98.0 % purity) was dissolved separately in 2 mL of 2-methaoxythanol. The Tb–Fe solution refluxed at (\( 80 \pm 1 \)) °C for 3 h. The precursor solution was maintained at pH 3 by adjusting the amount of diethylamine around 0.2 mL [10, 11]. The resulting solution was refluxed again for 3 h at (\( 80 \pm 1 \)) °C followed by stirring for 48 h to obtain the homogenous gel. To prepare the film, 25 µL of the gel was dropped onto a clean quartz substrate (1.45 mm thickness). The substrate was spin coated first at 500 rpm for 15 s and then at 3500 rpm for 30 s. The film was heated at 90 °C to remove the residual solvent and at 350 °C for 15 min to burn-off the organic compounds. Then, the annealing process was carried out at 700, 800 and 900 °C in air for 2 h.

2.2 Characterization Techniques

The films nanostructures were characterized using an X-ray diffractometry (XRD, D8 Advance Bruker) with CuKα radiation (λ = 0.15406 nm) in a 2θ range of 20°–60°. The surface morphology of the films was examined using a field emission scanning microscope (FE-SEM, ZEISS Supra 55VP) operating in vacuum at 15 kV using backscatter detection. The films were coated with gold to prevent the accumulation of electrostatic charges at the surface to obtain a good image. Carbon tape was used to stick the film onto the sample holder in FE-SEM. In-plane magnetic measurements at room temperature (25 °C) were carried out using a vibrating sample magnetometer (VSM, Lake Shore 7404) with a maximum magnetic field value of 16,000 kA/m. The films were cut into small pieces of 4 × 4 mm2. The magnetization loops detected by VSM represented the magnetization of film and the substrate. No net ferrimagnetic sign was observed from the raw data, because of the diamagnetic effect from the quartz substrate. Hence, the diamagnetic contribution has been corrected for all of the hysteresis loops of the films. This correction eliminated the contribution of the substrate.

3 Results

3.1 Structural Analysis

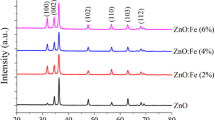

Figure 1 shows the XRD patterns of Tb3Fe5O12 films as prepared and annealed at 700, 800 and 900 °C. The results were compared with the Joint Committee on Powder Diffraction Standard (JCPDS-ICDD; number 01-071-0697) for pure TbIG . The films before annealing demonstrate an amorphous structural behavior. At 700 and 800 °C, the films show some of garnet peaks mixed with the minute quantity of Fe2O3 and Fe3O4, because of those annealing temperature were inadequate to complete the crystallization [12]. At 900 °C, the film shows a pure phase of garnet structure resulted a shifting of diffraction angle to the lower 2θ angle.

The lattice parameter a of the films at different annealing temperatures values of 700, 800 and 900 °C was calculated from the XRD patterns by using Bragg’s law. Bradley and Jay’s extrapolation against cos2θ [13] was used to calculate the lattice parameter of phase present at different content. The lattice parameters values of films at annealing temperatures between 700 and 900 °C are illustrated in Fig. 2. It can be seen that the lattice parameter of the films is responded to increment of annealing temperature. The films show a highest lattice parameter value of 12.36 Å at 900 °C which is close to 12.4 Å for TbIG bulk [3], but it is lower than 12.59 Å for the film which was prepared by pulsed laser deposition technique [7]. Increasing of the lattice parameter initiated the shifting of the diffraction peaks to the lower 2θ angle [14].

3.2 Morphological Characteristic

The FE-SEM images the TbIG films are shown in Fig. 3. The films exhibited agglomerate grains form with voids. The grains size of films has observed to be increased as annealing temperature is increased. The bigger grain size value for film was recorded to be 18 nm at 900 °C due to increase of surface energy [15]. However, increasing the grains size of films with annealing temperature could affect the magnetic properties. The thickness of films was measured from the film’s cross section backscattered FE-SEM micrograph. Figure 4 shows the thickness images of TbIG films. The average thickness values of TbIG films are found to be decreased as 456, 344 and 312 nm at annealing temperature of 700, 800 and 900 °C, respectively. It can be observed that the film with bigger grain size exhibited reduction in the thickness due to the agglomeration.

3.3 Magnetic Properties

In plan hysteresis loops of TbIG films at different annealing temperatures of 700, 800 and 900 °C are shown in Fig. 5. It can be observed that all films were saturated and the hysteresis loops shapes indicate the soft ferrimagnetic nature of films. The M s and H c at room temperature (25 °C) were obtained from the hysteresis loop of each film. Figure 6 shows variations of M s and H c of TbIG films with annealing temperature. From the Figure it can be seen that at 700 and 800 °C the films have same M s value (3 kA/m); low M s could be related to existence of Fe2O3 and Fe3O4 in the films. Increasing of annealing temperature up to 900 °C led to increase M s to 13 kA/m which is smaller than 23 kA/m for TbIG powder prepared by sol-gel method [16]. Additionally, evolution of the grain size with annealing temperature causes to increase the M s [17]. The H c of films has observed initially decreases from 135 to 67 kA/m as annealing temperature increases from 700 to 800 °C, but it is increased markedly at 900 °C with value of 102 kA/m, the increasing of H c can be stated to the coercivity of nanoparticles that is governed by permanent domain rotation [18]. Although the H c of films shows a highest value at 900 °C, but still has a soft magnetic feature because of it is less than 1000 kA/m.

4 Conclusions

Effect of annealing temperature on the structural and magnetic properties of TbIG sol-gel films has been studied. The results indicated that best annealing temperature to crystalline the films is 900 °C. The M s and H c of films are also responded to increment of annealing temperature. The films have potential in magnetic sensor and microwave applications due to low H c . However, the films showed an interesting result at different annealing temperature values which is need more study in further work.

References

R.J. Joseyphus, A. Arayanasamy, A.K. Nigam, R. Krishnan, Effect of mechanical milling on the magnetic properties of garnets. Magn. Magn. Mater 296, 57–64 (2006). doi:10.1016/j.jmmm.2005.04.018

N. Kumar, R. Bhargava, S. Kumar, A.K. Chawla, R. Chandra, M. Bohra, In-plane magnetization with high coercivity in terbium iron garnet thin films deposited on Pt/Si substrate by PLD. Magn. Magn. Mater 322, 1727–1730 (2010). doi:10.1016/j.jmmm.2009.12.015

M. Lahoubi, M. Guillot, A. Marchand, F. Tcheou, E. Roudault, M. Lahoubi, M. Guillot, A. Marchand, F. Tcheou, E. Roudault, Double umbrella structure in terbium iron garnet. IEEE Trans. Magn. 20(5), 1518–1520 (1984). doi:10.1109/TMAG.1984.1063259

S. Thongmee, P. Winotai, I.M. Tang, Local field fluctuations in the substituted aluminum iron garnets Y3Fe5-xAlxO12. Solid State Commun. 109, 471–476 (1999). doi:S0038-1098(98)00583-3

R. Hock, H. Fuess, T. Vogt, M. Bonnet, Crystallographic distortion and magnetic structure of terbium iron garnet at low temperatures. Solid State Chem. 84(1), 39–51 (1990). doi:10.1016/0022-4596(90)90182-W

S. Geller, J. Remeika, R. Sherwood, H. Williams, G. Espinosa, Magnetic study of the heavier rare-earth iron garnets. Phys. Rev. 137, 1034–1038 (1965). 103. http://dx.doi.org/10.1103/PhysRev.137.A1034

N. Kumar, N.G. Kim, Y.A. Park, N. Hur, J.H. Jung, K.J. Han, K.J. Yee, Epitaxial growth of terbium iron garnet thin films with out-of-plane axis of magnetization. Thin Solid Films 516(21), 7753–7757 (2008). doi:10.1016/j.tsf.2008.05.032

X. Haitao, H. Yang, W. Xu, L. Yu, Magnetic properties of Bi-doped Y3Fe5O12. Current App. Phys. 8, 1–5 (2008). doi:10.1016/j.cap.2007.04.002

S. Hossini, H.R. Madaah, Z.A. Nemati, Synthesis of nanocrystalline yttrium iron garnet by sol-gel combustion process: the influence of pH of precursor solution. Mater. Sci. Eng. B. 129, 211–215 (2006). doi:10.1016/j.mseb.2006.01.014

F.W. Aldbea, N.I. Ahmad, N.B. Ibrahim, M. Yahya, Effect of increasing pH value on the structural, optical and magnetic properties of yttrium iron garnet films prepared by a sol-gel method. Sol-Gel Sci. Technol. 71(1), 31–33 (2014). doi:10.1007/s10971-014-3326-4

F.W. Aldbea, N.B. Ibrahim, M.H. Abdullah, R.E. Shaiboub, Structural and magnetic properties of TbxY3−xFe5O12 (x = 0 to 0.8) thin film prepared via sol-gel method. Sol-Gel Sci. Technol. 62, 483–489 (2012). doi:10.1007/s10971-012-2752-4

A.C. Rastogi, V.N. Moorthy, Magnetic properties of yttrium iron garnet thin films changed through surface modification by CoO overlayer growth for magneto-optic recording applications. Magn. Magne. Mater 214, 228–239 (2002). doi:10.1016/S0304-8853(01)01360-9

V.K. Pecharsky, P.Y. Zavalij, Fundamentals of Powder Diffraction and Structural Characterization of Metals (Springer, New York, 2009. doi:10.1007/978-0-387-09579-0

N.B. Ibrahim, C. Edwards, S.B. Palmer, Pulsed laser ablation deposition of yttrium iron garnet and cerium-sbstituted Y films. Magn. Magn. Mater 220, 183–194 (2000). doi:10.1016/S0304-8853(00)00331-0

F.W. Aldbea, N.B. Ibrahim, M.H. Abdullah, R.E. Shaiboub, Effect of Annealing Temperature on the Structural and Magnetic Properties of TbxY3-xFe5O12(x = 0.0, 1.0, 2.0) Thin Films Prepared by Sol-Gel Process (RCSSST, Malaysia, Trans Tech Publications, Switzerland, 2002). doI:10.4028/www.scientific.net/AMR.501.236

H. Young Jun, K. Jun Sig, S. In-Bo, K. Chul Sung, Spin rotation at compensation point studies of Tb3Fe5O12 by Mössbauer spectroscopy. Magn. IEEE Trans. Magn. 40(4), 2808–2810 (2004). doi:10.1109/TMAG.2004.832105

T.-C. Mao, J.-C. Chen, Influence of the addition of CeO2 on the microstructure and the magnetic properties of yttrium iron garnet ceramic. Magn. Magn. Mater. 302, 74–81 (2006). doi:10.1016/j.jmmm.2005.08.018

X. Haitao, H. Yang, L. Lu, Effect of erbium oxide on synthesis and magnetic properties of yttrium iron garnet nanoparticles in organic medium. Mater. Sci. Mater. Electron. 19, 509–513 (2008). doi:10.1007/s10854-007-9372-8

Acknowledgments

The authors would like to thank Malaysian Ministry of Science and Technology for supporting this work under Grant No. 03-01-02-SF0538.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Aldbea, F.W., Ibrahim, N.B. (2015). Effect of Annealing Temperature on the Structural and Magnetic Properties of Terbium Iron Garnet Thin Films Prepared by Sol-Gel Method. In: Polychroniadis, E., Oral, A., Ozer, M. (eds) 2nd International Multidisciplinary Microscopy and Microanalysis Congress. Springer Proceedings in Physics, vol 164. Springer, Cham. https://doi.org/10.1007/978-3-319-16919-4_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-16919-4_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-16918-7

Online ISBN: 978-3-319-16919-4

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)