Abstract

Protection of environment and human health are two important issues to which a huge attention has been paid in recent years. These issues have been taken into account by supply chain partners, so that GSCM and HSCM issues have been raised at this area. This paper proposes a method in green supplier selection and examines suppliers of a pharmaceutical company in Iran in order to achieve a green health supply chain. In this regard, following a literature review, the domestic suppliers of effective raw materials for Tehran Chemie Pharmaceutical Co. are analyzed and prioritized by using 18 healthy and green criteria via fuzzy ELECTRE method. Then, by the results of fuzzy ELECTRE, suppliers are classified via Pareto chart and ultimately regarding position of suppliers at each category the suggestions are proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Supply chain management (SCM) deals with a variety of decisions (selection of materials, production, transportation, distribution and so on) at levels of producers, retailers and consumers. The development of global trade and increased demand for consumption of commercial products has accelerated resource depletion and further pollution in the environment. Green supply chain management has emerged as a response to the challenge of concurrent improvement in the economic and environmental performance in long-term. On the other hand, the globalization of economy affects consumers’ rights from many aspects. The fast developments in globalization have made it difficult to react properly. In the course of globalization, unprotected consumer needs the support (Hosseini 2009). Consumer health protection is perhaps the most important aspect of this protection (Hosseini 2009). Issues of health supply chain management have emerged in response to consumer health protection especially at the area of healthcare and pharmaceutical services. Since products of healthcare and pharmaceutical services play a major role in the life of any person and relate to health of body and soul of humans, inattention to production process of these products can harm the consumer’s health (Rubin 2009). Fame and reputation are the most important spiritual capitals at economic enterprises in pharmaceutical industry, as it is in other industries. This spiritual capital will be gained with compliance with professional ethics. Consumer satisfaction has a direct connection with compliance with these principles, and attention to job commitment and professional conscience in pharmaceutical and health products can raise consumer health and satisfaction (Hosseini 2009). In this study, Tehran pharmaceutical chemistry company has been selected as the industry in the area of pharmacy. Tehran pharmaceutical chemistry company, pioneered at supplying solutions based on advanced and modern technology worldwide in the area of generic and proprietary drugs and pharmaceutical raw materials, is proud of being one of the largest generic pharmaceutical companies at the Middle East; therefore, the present research aims to examine supply chain from health and green perspectives. We have put emphasis on detection and evaluation of suppliers with these features. The present research has targeted in examining green and health perspectives to evaluate suppliers for which the reason can be the linkage between these issues with each other especially in the area of health. By considering the features of the case study in pharmacy industry, the present research seeks to find green health suppliers for supply chain.

Decision-making techniques with multiple criteria enable to consider the efficient solutions by the presence of a variety of criteria for the decision. On the other hand, when a decision problem includes multiple decision makers with different tendencies arisen from ideas and views, values, goals and their organizational roles, the final decision is the result of the individuals’ tendencies and preferences, and these different ideas make changes in decision making process in a way that might have not been considered by early studies (Leyva-Lopez and Fernandez-Gonzalez 2003). Multiple criteria decision making, specifically fuzzy ELECTRE method, is used to evaluate the suppliers in this paper. The focus in ELECTRE method is on dominance relations that exist among alternatives. In other words, this method is built on the concept of concordance derived from outranking relations. These outranking relations are achieved through comparing the alternatives (de Almeida 2007).

In addition, flexibility factors such as production flexibility, responsiveness, after-sale support and engineering support could be considered. Similarly, sustainability criteria can be considered to account for people, planet and profit (Kaur et al. 2016).

The main objective of this research is the analysis of the suppliers’ performance and developing proper polices in cooperation with them in a green and health supply chain. In this regard, fuzzy ELECTRE method is used to prioritize the suppliers.

Literature Review

Green Supply Chain Management

Since the early 1990s, green supply chain management has been widely pursued in academic and business researches with the development of corporate environmental management practices, environmentally conscious manufacturing strategies and supply chain management techniques (Sheu et al. 2005; Zhu et al. 2008).

Green supply chain management is not a concept on which all researchers agree (Ahi and Searcy 2013). However, the majority of authors state that it emerges from the idea that companies must become greener (Alfred and Adam 2009), must try to reach a win–win perspective (Hart and Dowell 2011) and must connect the supply chain decisions with sustainable development (Seuring 2013).

From the literature, several definitions of GSCM deserve attention:

-

GSCM encompasses a set of environmental practices that encourage improvements to the environmental practices of two or more organizations within the same supply chain (Vachon and Klassen 2006).

-

GSCM is the process of incorporating environmental concerns into supply chain management including product design, material sourcing and selection, manufacturing, delivery of final products and management of product’s end-of-life (Srivastava 2007).

-

GSCM can be achieved by considering environmental issues at the purchasing, product design and development, production, transportation, packaging, storage, disposal and end of product life cycle management stages (Min and Kim 2012).

-

GSCM aims to improve environmental management through environmental collaboration or through the resolution of mutual problems that reduce the environmental risks in supply chains (Vachon and Klassen 2006).

GSCM, as a subsystem of a sustainable supply chain (Seuring 2013; Beske and Seuring 2014), can be defined as the integration of environmental issues into the interorganizational practices of SCM, including reverse logistics (Sarkis et al. 2011). Hervani et al. (2005) agree with this definition of GSCM when emphasizing the adoption of green purchases, green manufacturing, greener distribution of products and reverse logistics.

Zhu et al. (2008) empirically investigated GSCM practices in manufacturing companies. Companies can apply GSCM as a group of practices, as shown in Table 1.

Their results point to the importance of the following practices: internal environmental management, green purchases, cooperation with consumers, ecodesign and recovering investments. Reverse logistics has also been noted as a GSCM practice (Srivastava 2007).

Health Supply Chain Management

A health supply chain is the network of entities that plan, source, fund and distribute health products and manage associated information and finances from manufacturers through intermediate warehouses and resellers to distributors and health service delivery.

Healthcare supply chain management (HSCM) is a set of approaches to link medicines, equipment, laundry, food, suppliers, vendors, hospital and transport for efficient and effective use of resources to achieve total quality management (Kazemzadeh et al. 2012).

There are few studies which have been conducted at the area of detection of the criteria for health supply chain. In Table 2, two studies which are conducted at this area are mentioned. In these studies, some criteria are examined to evaluate green and health perspectives of supply chain.

Mentioned studies in the hospital services fields, put more emphasis on health perspective of supply chain.

Evaluation of Green Health Suppliers

Numerous studies are conducted to evaluate and select suppliers, but most of them mentioned general criteria to evaluate suppliers some of which are presented in Table 3.

There are few studies concentrating on a specific issue of the problems related to green health supply chain. In the context of green perspective of supplier evaluation, Kannan et al. (2014) evaluated 17 criteria among 21 via Fuzzy TOPSIS. Some studies that are conducted in the context of health supply chain are as follow:

Kumar et al. (2017) evaluated the suppliers’ performances based on green practices including: environmental and pollution management, cost, quality and flexibility using the fuzzy-extended Elimination and Choice Expressing Reality concept. In another research, Wang et al. (2017) proposed an integrated MCDM model with QUALIFLEX (qualitative flexible multiple criteria method) approach based on the cloud model, in order to assess the green performance of companies under economic and environmental criteria.

Bag and Gupta (2017) considered the influence of both external factors and internal factors on sustainable innovation in supplier networks with a case in South African experience. In addition, in some researches we find perception of risk and mitigation strategies regarding GSCM with intuitive and interpretive decision technique (Mangla et al. 2014).

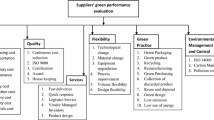

With regard to the criteria mentioned in Tables 1, 2 and 3 for the present research, 18 criteria, which are mentioned in Table 4, were selected to examine green health suppliers. The reason for why all the criteria were not used is that some of the criteria could be integrated with each other. On the other hand, some criteria have not been among health and green criteria; thus, they were removed. In addition, some criteria enabled to have green and health criteria which were mentioned once.

Application of ELECTRE in Supplier Evaluation

De Boer et al. (1998) studied the application of outranking methods in supplier selection and concluded that outranking techniques may be a useful additional tool for the problem of supplier selection. They stated that considering the increasing importance as well as the increasing complexity of many contemporary supplier selection decisions, it is somewhat surprising that the following properties have gained very little attention: non-compensatory decision rules aimed at selecting acceptable alternatives, uncertainty, indetermination and imprecision resulting from incomplete data, vaguely and/or arbitrarily defined criteria and imprecise appraisal of criteria. They conclude outranking techniques may provide the basis for developing supplier selection models that can effectively deal with these properties.

Outranking methods apply the pairwise comparison of alternatives to build an outranking relation. One advantage of using outranking methods is that there is no need for converting the original scales into abstract using an arbitrary dictated range; instead, you can use purely ordinal scales in these methods (Martel and Roy 2006), and thus, these methods are able to maintain the original concrete verbal meaning simultaneously for another methodology considering purely ordinal scales.

In contrast to other methods, outranking methods allow incomparability between alternatives that can occur because of lack of information or inability of the decision maker to compare alternatives (Siskos 1982). The first outranking method called ELECTRE I was developed in 1968. After that, several other outranking methods were developed mainly during 1970s and 1980s. ELECTRE and its derivatives have been widely used for different real-world applications such as energy planning (Beccali et al. 2003), vendor selection (Montazer et al. 2009), electric project selection (Buchanan and Vanderpooten 2007), and civil and environmental engineering (Hobbs and Meier 2012).

ELECTRE is a MCDM method which is based on the study of outranking relations, and it uses concordance and discordance indexes to analyze the outranking relations among the alternatives. Concordance and discordance indexes could be interpreted as measurements of satisfaction and dissatisfaction that a decision maker prefers one alternative over the other (Daneshvar Rouyendegh and Erol 2012).

Problem Statement

Protection of human and environment against chemical substances and polluted equipment has been regarded as one of the important issues in organizations. Advancement in technology, technical equipment and use of various chemical materials in the production process of countries has raised risks for the man and environment. In the beginning, attention to environment and human health has been just the concern for the developed countries, but today it is also considered as a major concern for developing and the Third World countries. In international communities, proliferated trend has started in protection of human health and environment, so that we are obliged to join the international treaties. This process has appeared in form of legal requirements, treaties, agreements and conventions which keep increasing each year. It can perhaps say that not just the manufacturing organization but also the business partners in this organization should be committed to the principles of protection of man and environment, especially in the organizations which their products have a direct connection with the man’s health. This also goes true in Tehran Chemie Pharmaceutical Co; thus, this company has constantly made attempts to measure output from the factory emissions, constant use of refinery and elimination of filters and chemical wastes. This company is aiming to improve the quality of life through innovative solutions in the health area with 50 years constant presence in pharmaceutical industry and productions of over 100 drugs. To achieve quality goals, Tehran Chemie Pharmaceutical Company has made attempt to detailed design and implementation of quality assurance system in compliance with WHO standards in drug control and has supplied the best pharmaceutical products with favorable clinical effectiveness. To produce products, this company is in connection with many companies such as suppliers, distributors and so forth through the supply chain. However, supposing that the company applies all its activities to produce a healthy and green production, if one of the trade partners does not comply with the principles and rules pertaining to healthy, green and high-quality perspectives, it will affect output of Tehran Chemie Pharmaceutical Company. In its supply chain, if Tehran Chemie Pharmaceutical Company is considered as manufacturer, this organization will be in contact with numerous suppliers to produce its products, so that this research aims to examine the relationship between suppliers and manufacturer shown in Fig. 1.

Even though Tehran Chemie Pharmaceutical Company is in connection with the international and domestic suppliers, this research only considers domestic suppliers. Domestic suppliers collaborate with each other at three areas of effective early materials, lateral early materials and packaging. In this research, just the suppliers of effective early materials have been examined that on the whole there were 19 suppliers. Due to non-homogeneity of the products of these suppliers, the present research will not aim to select suppliers but examine and classify the suppliers in a way that the suppliers who comply less with principles of company are identified and obliged to accept these principles by taking some policies. The expected principles of manufacturer are in collaboration with the green health suppliers in supply chain, protection from health and security of the end consumer and protection of environment. Therefore, there are some major goals in conducting this research which are:

-

Proposing a method for analyzing the suppliers based on green and health issues

-

Taking into account the vagueness of data

-

Classification of suppliers into different groups in order to take proper polices for each class of suppliers

-

Implementing the method in the case study and analyze the results

Development of Methodology

The present research aims to examine and evaluate the green health suppliers, for which Tehran Chemie Pharmaceutical Company has been selected as the case study. This study serves in the context of pharmaceutical products producing over 100 types of products which is in connection with numerous suppliers for its products. Thus, domestic suppliers and suppliers of effective early materials have been selected as the sample group providing various products for the company. The present research intends to evaluate these 19 companies based on 18 criteria which are mentioned in Table 4. Fuzzy ELECTRE method has been mentioned as the analysis and evaluation method for this issue. Thus, the 6-point questionnaire (very high, high, relatively high, relatively low, low and very low) has been designed in which the respondents have been asked to evaluate these 19 companies based on the mentioned criteria. In this study, the respondents were three decision makers working in Tehran Chemie Pharmaceutical Company having general recognition from 19 suppliers. In next section, fuzzy description of responses, ELECTRE technique and data analysis are described. In next sections, reliability and validity of questionnaire, fuzzy description of responses, Fuzzy ELECTRE method and data analysis are explained.

Reliability and Validity of Questionnaire

Two components are applied to measure the extent to which measurement instruments (questionnaire) are suitable: validity and reliability. Validity determines to which extent the prepared instrument measures the specific considered concepts. Validity tests have been classified in three groups: content validity, criterion validity and construct validity. Apparent validity and extensive questionnaire scale are considered a preliminary index for content validity. Criterion validity refers to efficiency of a measurement instrument in predicting behavior of a person at specific situations. Construct validity indicates to which extent measurement instruments measure a characteristic with theoretical background. In this research, content validity confirmed by experts’ and professors’ views has been used. Cronbach’s alpha has been used to measure the reliability of instruments, found as the most suitable technique in terms of reliability and time saving, and it equals to 0.893. Thus, it can conclude that reliability of questionnaire is at acceptable level.

Fuzzy Set Theory

In most of conditions, the certain data and information are not sufficient to develop the model of problem because people’s judgment is made ambiguous for which it cannot consider certain values (Tsaur et al 2002); fuzzy set theory was proposed by Professor Lotfi Zadeh in 1985 in response to such conditions. Indeed, this theory has been developed to resolve the problems in which the evaluations are ambiguous and uncertain. Fuzzy set theory provides a suitable framework to describe behavior of uncertain states. Certain types of fuzzy numbers which are called triangular and trapezoidal are the traditional instruments of expressing vague states. Figure 2a displays triangular fuzzy number which is displayed in [t 1, t m, t u], and Fig. 2b displays trapezoidal fuzzy number which \(\left[ {t_{1} ,t_{1}^{{\prime }} ,t_{\text{u}}^{{\prime }} ,t_{\text{u}} } \right]\) is used to display it. In this research, triangular fuzzy numbers have been used to evaluate each company regarding various criteria.

Fuzzy ELECTRE Method

To quantify criteria, verbal variables have been used, scored via triangular fuzzy numbers in the ranges. For instance, fuzzy number (4, 6, 8) is used to display status “almost high” (Fig. 3).

To develop decision matrix to evaluate suppliers based on each criteria, a special evaluation and scoring questionnaire has been designed and on the whole three fuzzy questionnaires have been obtained, which it requires transforming matrices to a fuzzy performance matrix before applying ELECTRE method. In this regard, with regard to nature of triangular fuzzy number, three points of triangular number at final matrix were obtained through making an average among experts’ judgments.

where m = 3, i = {1, 2,…19} and j = {1, 2,…18}.

Center of area represented in Eq. 2 is used to defuzzify decision making matrix.

Crisp decision making matrix is shown in Table 5.

Up to now, the score for evaluation of each item has been obtained based on each criterion. With regard to rest of inputs, it requires specifying importance or weight of each of criteria. Shannon entropy method has been used to determine weights of criteria. With regard to the results from distributed questionnaire and their analysis based on mentioned method, scores and nature of criteria are represented in Table 6. The main idea has been grounded on this basis that the more dispersion in values of a criterion, that criterion will be of greater importance. Using the formula below, weight for each criterion has been calculated.

With regard to Table 6, the highest weight relates to the criterion of sale of used materials and old used equipment and the least weight relates to the criterion of advantages of timely delivery.

Proposed Fuzzy ELECTRE

By performing the previous stages, prioritization of decision problem is provided though fuzzy ELECTRE. After developing the crisp decision matrix, it requires calculating the concordance and discordance parameters of items.

The first and second stages: normalization and weighted decision matrix

The criteria may have specific dimensions; thus, normalizing should be used to be able to compare various measurements. In this research, vector descaling method using Eq. 4 has been used under which values of various criteria become dimensionless.

Then, the obtained matrix should be weighted via Eq. 5. The normalized weighted matrix is obtained through multiplying descaled matrix (N) by diagonal matrix of weights (\(W_{n \times n}\)), i.e.,

To avoid prolongation of Contents, normalized weighed matrix as shown in Table 7 has been sufficed.

The Third Stage: Calculate Concordance

At this stage, firstly concordance set of each pair of alternatives must be calculated based on Eq. 6. In this regards, there will be concordance matrix of 18 criteria in which pairwise comparison of items regarding the considered criterion has been considered.

Then, with regard to Eq. 7, the elements of the total concordance matrix (c) are calculated. In Table 8, the total concordance matrix is shown.

The Fourth Stage: Discordance Calculation

At this step, firstly paired discordance of parameters for each pair of alternatives is calculated regarding Eq. 8:

Then, elements of total discordance matrix are calculated via Eq. 9 after calculating discordance index for each pair of alternatives. In Table 9, total discordance matrix has been shown.

The Fifth Stage: Develop Concordance and Discordance Boolean Matrix

With regard to Eq. 10 , concordance Boolean matrix (C) and discordance Boolean matrix (d) are calculated for paired comparisons of items through combining indices of concordance and discordance values.

The Sixth Stage: Develop the Final Dominance Matrix (Table 10)

By completing the stages above, the general matrix is calculated via equation below:

Ranking suppliers via the equations deduced from general matrix is as follows, respectively: S6, S8, S1 and S16, S2 and S17, S12, S13, S14 and S15, S4 and S11, S5 and S18 and S19, S3 and S7 and S10 and at the lowest rank S9.

As observed, supplier 6 with 18 superiorities has the highest score and supplier 9 without any superiority has the lowest rank.

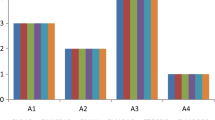

Classification of Suppliers via Pareto Chart

Pareto chart is used to discover the causes which are responsible for most effects. Using this chart, we can detect the changes made in the factors and their interactions to make suitable and optimal actions before increasing consequences (Wilkinson 2006). Since the present research aimed to evaluate suppliers rather than to select them, the suppliers are classified to determine the appropriate policies to face with suppliers via Pareto chart. For this, dominance of each supplier has been considered as frequency based on which Pareto chart has been depicted. Pareto chart relating to classification of suppliers is displayed in Fig. 4.

As shown in Fig. 4, suppliers 6, 8, 1, 16, 17, 12, 13 with the highest dominance outperform about 75% to others; thus, they have been considered in category A. Suppliers 14, 15, 11, 4 and 5 are classified in category B, and others with 5% contribution are classified in category C.

Discussion on Findings

HSCM and GSCM are considered as two issues emerged for protection from environment and consumer health in the process of supply chain management (i.e., these two can protect environment and human health). There are a variety of techniques through which protection from environment and human health can be achieved. In the present research, an attempt has been made to explain one of these methods. For this, two supply chain levels have been examined, considering the fact that suppliers provide healthy and green raw materials for the producer. The study under discussion is supply of effective early materials for a pharmaceutical company by its 19 domestic suppliers so that evaluation and examination of these suppliers have been targeted to have healthy and green supply chain. These suppliers were evaluated based on the criteria extracted from previous investigations via fuzzy ELECTRE method, so that the results from investigation indicate that some of the suppliers outperform others (i.e., their adherence to healthy and green principles is greater). For instance, supplier S6 outperforms other 19 suppliers. Then, supplier S8 outperforms other 17 suppliers. Further, some of the suppliers do outperform others such as suppliers S1 and S16 who outperform supplier 10. Further, supplier S9 has been ranked the lowest, among suppliers, as it did not outperform others. Yet, since the present research has not aimed to select and remove suppliers among them, in this stage the results from evaluation of fuzzy ELECTRE were grouped using Pareto chart. Classification of suppliers aimed to propose optimal policy for them well suited to position each of them. Results from classification via Pareto chart indicate that 75% of superiorities are classified in group A. 20 and 5% are classified in group B and C, respectively. Existing companies in group A outperform others followed by other groups.

Conclusion

Suppliers play an important role in the performance of the supply chain. In recent years, there are more concerns with the health and environment issues. Therefore, the analysis of the suppliers performance and developing proper polices in cooperation with them is an important issue. In this paper, fuzzy ELECTRE method is used to prioritize the suppliers and then put them in different classes of A, B and C. The researchers have suggested that the companies in group A require the policies such as protection and improvement; thus, the policies such as reward, subside and so forth can be effective for their protection. The companies in groups B and C can be persuaded via the policies such as sharing the company’s benefit to increase their adherence to principles of HSCM and GSCM. On the other hand, providing competitive conditions between suppliers can be an important factor to achieve goal of organization. Lack of sufficient information resources at the area of HSCM especially at the area of HSCM criteria due to novelty of issue has been one of the restrictions faced by the researchers in this research; thus, the future researchers are suggested to detect the criteria at area of HSCM. Further, the researchers are suggested to use other multicriteria decision making methods for similar studies. Conducting research at other SCM areas can be also beneficial or using hybrid supplier selection models may be concentrated on the application of different methods for evaluating multiple attributes in supplier selection.

References

Ahi, P., & Searcy, C. (2013). A comparative literature analysis of definitions for green and sustainable supply chain management. Journal of Cleaner Production, 52, 329–341.

Alfred, A. M., & Adam, R. F. (2009). Green management matters regardless. The Academy of Management Perspectives, 23(3), 17–26.

Bag, S., & Gupta, S. (2017). Antecedents of sustainable innovation in supplier networks: A South African experience. Global Journal of Flexible Systems Management, 18(3), 231–250.

Beccali, M., Cellura, M., & Mistretta, M. (2003). Decision-making in energy planning. Application of the ELECTRE method at regional level for the diffusion of renewable energy technology. Renewable Energy, 28(13), 2063–2087.

Beske, P., & Seuring, S. (2014). Putting sustainability into supply chain management. Supply Chain Management: An International Journal, 19(3), 322–331.

Buchanan, J., & Vanderpooten, D. (2007). Ranking projects for an electricity utility using ELECTRE III. International Transactions in Operational Research, 14(4), 309–323.

Daneshvar Rouyendegh, B., & Erol, S. (2012). Selecting the best project using the fuzzy ELECTRE method. Mathematical Problems in Engineering, 2012(2012), 790142-1–790142-12.

de Almeida, A. T. (2007). Multicriteria decision model for outsourcing contracts selection based on utility function and ELECTRE method. Computers and Operations Research, 34(12), 3569–3574.

De Boer, L., van der Wegen, L., & Telgen, J. (1998). Outranking methods in support of supplier selection. European Journal of Purchasing and Supply Management, 4(2–3), 109–118.

Gupta, K., & Ramesh, A. (2015). Analyzing drivers and barriers of coordination in humanitarian supply chain management under fuzzy environment. Benchmarking: An International Journal, 22(4), 559–587.

Hart, S. L., & Dowell, G. (2011). Invited editorial: A natural-resource-based view of the firm: Fifteen years after. Journal of Management, 37(5), 1464–1479.

Hervani, A. A., Helms, M. M., & Sarkis, J. (2005). Performance measurement for green supply chain management. Benchmarking: An International Journal, 12(4), 330–353.

Hobbs, B. F., & Meier, P. (2012). Energy decisions and the environment: A guide to the use of multicriteria methods (Vol. 28). Berlin: Springer.

Hosseini, M. (2009). Respecting the rights of consumers in the advertising and marketing of pharmaceutical products and cosmetics. Iranian Journal of Medical Ethics and History of Medicine, 3(1), 33–42.

Kannan, D., de Sousa Jabbour, A. B. L., & Jabbour, C. J. C. (2014). Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. European Journal of Operational Research, 233(2), 432–447.

Kaur, H., Singh, S. P., & Glardon, R. (2016). An integer linear program for integrated supplier selection: A sustainable flexible framework. Global Journal of Flexible Systems Management, 17(2), 113–134.

Kazemzadeh, R. B., Sepheri, M. M., & Firouzi Jahantigh, F. (2012). Design and analysis of a health care supply chain management. Advanced Materials Research, 433–440, 2128–2134.

Kumar, P., Singh, R. K., & Vaish, A. (2017). Suppliers’ green performance evaluation using fuzzy extended ELECTRE approach. Clean Technologies and Environmental Policy, 19(3), 809–821.

Leyva-Lopez, J., & Fernandez-Gonzalez, E. (2003). A new method for group decision support based on ELECTRE III methodology. European Journal of Operational Research, 148(1), 14–27.

Mangla, S. K., Kumar, P., & Barua, M. K. (2014). A flexible decision framework for building risk mitigation strategies in green supply chain using SAP–LAP and IRP approaches. Global Journal of Flexible Systems Management, 15(3), 203–218.

Martel, J. M., & Roy, B. (2006). Analyse de la signifiance de diverses procédures d’agrégation multicritère. INFOR: Information Systems and Operational Research, 44(3), 191–215.

Min, H., & Kim, I. (2012). Green supply chain research: Past, present, and future. Logistics Research, 4(1–2), 39–47.

Montazer, G. A., Saremi, H. Q., & Ramezani, M. (2009). Design a new mixed expert decision aiding system using fuzzy ELECTRE III method for vendor selection. Expert Systems with Applications, 36(8), 10837–10847.

Rubin, P. H. (2009). Markets, tort law, and regulation. Cato Journal, 31(2), 217–236.

Sarkis, J., Zhu, Q., & Lai, K. H. (2011). An organizational theoretic review of green supply chain management literature. International Journal of Production Economics, 130(1), 1–15.

Seuring, S. (2013). A review of modeling approaches for sustainable supply chain management. Decision Support Systems, 54(4), 1513–1520.

Sheu, J. B., Chou, Y. H., & Hu, C. C. (2005). An integrated logistics operational model for green-supply chain management. Transportation Research Part E: Logistics and Transportation Review, 41(4), 287–313.

Siskos, J. (1982). A way to deal with fuzzy preferences in multi-criteria decision problems. European Journal of Operational Research, 10(3), 314–324.

Srivastava, S. K. (2007). Green supply-chain management: A state-of-the-art literature review. International Journal of Management Reviews, 9(1), 53–80.

Tsaur, S. H., Chang, T. Y., & Yen, C. H. (2002). The evaluation of airline service quality by fuzzy MCDM. Tourism Management, 23(2), 107–115.

Vachon, S., & Klassen, R. D. (2006). Extending green practices across the supply chain: The impact of upstream and downstream integration. International Journal of Operations and Production Management, 26(7), 795–821.

Wang, K. Q., Liu, H. C., Liu, L., & Huang, J. (2017). Green supplier evaluation and selection using cloud model theory and the QUALIFLEX method. Sustainability, 9(5), 688.

Wilkinson, L. (2006). Revising the Pareto chart. The American Statistician, 60(4), 332–334.

Zhu, Q., Sarkis, J., & Lai, K. H. (2008). Confirmation of a measurement model for green supply chain management practices implementation. International Journal of Production Economics, 111(2), 261–273.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shojaie, A.A., Babaie, S., Sayah, E. et al. Analysis and Prioritization of Green Health Suppliers Using Fuzzy ELECTRE Method with a Case Study. Glob J Flex Syst Manag 19, 39–52 (2018). https://doi.org/10.1007/s40171-017-0168-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40171-017-0168-2