Abstract

In this paper an integer linear programming model (ILP) is proposed for supplier selection by integrating the various ranks obtained from multi-criteria decision making (MCDM) techniques such as AHP, Fuzzy AHP, TOPSIS, Fuzzy TOPSIS, IRP and weighted IRP. However, the ranks obtained not necessarily are same. Such variability in ranking leads to dilemma in finalizing the suppliers’ ranks. Hence, there is a need to integrate these ranks into one consensus ranking. Therefore, this paper is an attempt to model integer linear program using various ranks (same or different) obtained from MCDM techniques to provide final suppliers’ ranks having minimum total deviation with respect to the ranks obtained from various MCDM techniques. The proposed ILP takes care of sustainability and flexibility aspects associated with supplier selection. Under flexibility factors such as production flexibility, responsiveness, after sale support and engineering support are considered. Similarly, under sustainability factors criteria are considered to account for people (social responsibility, quality certification and cultural differences), planet (environment responsibility and carbon footprint) and profit (price of the product, financial health, tariff and taxes, logistics management cost). The working methodology of the proposed framework is illustrated through an industry based survey and a case study.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The supplier selection is a very crucial problem in today’s highly dynamic business scenario involving many qualitative and quantitative criteria. Suppliers are considered as a key to a firm’s ability to provide quality products in shorter time at lower costs and with greater flexibility and reduced risk (Monczka et al. 1993). The rise in outsourcing and offshoring practices due to globalization has also added to complexity of supplier selection problem. Moreover, the need to develop sustainable supply chain practices in organizations (Carter and Rodgers 2008; Pagell and Wu 2009) have made supplier selection problem even more challenging. Hence, in order to choose best suppliers, it is important to achieve a tradeoff between these criteria which may be conflicting in nature. Hence supplier selection is a multi criteria decision making (MCDM) problem. There are a plenty of MCDM techniques used in literature by researchers across the globe to rank the suppliers. Each of these MCDM techniques is able to rank the suppliers based on selected criteria. But while choosing one particular technique, probably the information or weightages provided by other MCDM techniques to the same problem are not considered and sometimes the interactions between criteria are hence neglected. Hence, there is a need to integrate the outcomes from various MCDM techniques into one consensus ranking which must give one final ranking taking care of these MCDM techniques together. This paper proposes a mathematical model for rank aggregation for a supplier selection process with the help of a case study. “Literature review” section presents detailed literature review about supplier selection process, various criteria used in supplier selection and different decision making techniques used for selection of suitable suppliers. “Proposed framework” section provides detailed methodology used for the supplier selection and development of mathematical model. “Illustration through a case study” section illustrates the proposed methodology using a case study. “Results and discussion” section compares the proposed model with widely used Borda–Kendall (BAK) technique for comparatively larger data. “Conclusion and future scope” section concludes this paper with future scope of work.

Literature review

Supplier selection process can be classified into four stages: First is to define what should be procured from suppliers, second is defining the criteria that ensure flexibility and sustainability aspects in addition to other tangible and intangible factors for each product to be procured, third is to qualify suitable suppliers based on various qualitative and quantitative techniques, and fourth is to make final selection of suppliers (Çebi and Bayraktar 2003). The process is shown in Fig. 1.

In order to review published literature in last few decades on MCDM approaches in supplier selection problem, two aspects have been broadly looked into. The first aspect is on the consideration of supplier selection criteria over the time, and the second aspect on the methods/t techniques for supplier selection process. Existing literature have been reviewed for using descriptors like “supplier selection”, “vendor selection”, “supplier selection criteria’, “multi-criteria decision making in supplier selection” from various major databases including Scoupus, EBSCO host, Science Direct, and Google scholar. These databases primarily search for published work from leading publishing houses such as Taylor & Francis, Springer, Elsevier, Wiley, Informs, IEEE Xplore, Emerald, and Inderscience. Table 1 show various reputed journals referred for the review and Fig. 2 shows the year wise distribution of widely cited papers for this study.

Supplier selection process has been widely addressed by researchers, practitioners and academicians all over the world since 1960s. Dickson in 1966 proposed that quality, delivery and performance are three most important criteria among 23 others based on his survey with 273 purchasing managers. There has been a considerable amount of work done in literature which reveals that criteria such as cost, quality and lead time have remained important over the time and there are many criteria such as flexibility, risk, responsiveness, environment and social have become important due to change in technology, economy, politics, and consumer orientation (Sarkis 2003). There is an urgent need to incorporate sustainability and flexibility in business operations including supplier selection (Chan 2003; Chan and Kumar 2007; Aggarwal and Singh 2015; Linton et al. 2007; Lee et al. 2008; Neto et al. 2008; Nagurney and Nagurney 2010; Ramudhin et al. 2010; Carter and Easton 2011; Dubey et al. 2015; Kaur and Singh 2016) which makes sustainability as one of the most important criteria. The distribution of various supplier selection criteria considered in the past is shown in Fig. 3. Also, Table 2 provides the details of the published work corresponding to each criterion.

The process of supplier selection is complex due to the presence of multiple inter-related criteria. There are a number of MCDM techniques applied in supplier selection process such as analytic hierarchy process (AHP), analytic network process (ANP), technique for order preference by similarity to ideal solution (TOPSIS), Fuzzy set theory, elimination and choice expressing reality (ELECTRE), Preference ranking organization method for enrichment evaluation (PROMETHEE), data envelopment analysis (DEA), mathematical programming and their hybrids to supplier selection. Also, the inter-relationship between various supplier selection criteria can be studied using techniques like ISM and DEMATEL. Table 3 provides the detailed analysis on the application of MCDM techniques on supplier selection. Application of each MCDM technique can be referred from the respective.

From Table 3, it can be observed that plethora of work on MCDM techniques on supplier selection has been carried out. However, the main drawback of individual application of the technique leads to variation in ranking of supplier even considering same input data. Figure 4 shows that a considerable amount of work is done on hybrid techniques also by combining two or more techniques together. Based on the survey conducted very limited work on integrating various supplier ranks is carried out. Therefore, this paper proposes an integrated model based on integer linear program (ILP) by considering the supplier’s rank from various MCDM techniques as input to generate one single consensus supplier’s rank. The proposed ILP minimizes the total deviation of the consensus rank with respect to individual ranks of MCDM techniques. Section 3 presents proposed framework.

Proposed Framework

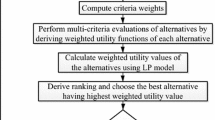

Steps involved (as shown in Fig. 5) in the proposed sustainable flexible framework for supplier selection are briefly described below:

Criteria Selection and Filtration

The initial set of supplier selection criteria is identified from literature (refer Table 2). The identified criteria are further filtered through expert opinions based on an industry based questionnaire survey.

Identifying Criteria Weights Using DEMATEL

Decision making trail and evaluation laboratory model (DEMATEL) developed by Gabus and Fontela (1972) is used to study the inter-relationship among different criteria. It has been extensively used in literature to build a structure model and analyze the direct and indirect influence among multiple criteria (Buyukozkan and Cifci 2012). In the proposed sustainable and flexible framework for supplier selection DEMATEL is used to derive weights of filtered criteria.

Using Various Multi-criteria Decision Making (MCDM) Techniques to Rank Suppliers

Different MCDM techniques have been used to rank suppliers for filtered criteria. The required input is obtained through expert interviews and is kept same for all MCDM techniques. The inputs used for Fuzzy based techniques were derived using a linguistic conversion (refer Appendix). Various MCDM techniques are used to rank suppliers namely AHP (Saaty 1980), TOPSIS (Hwang and Yoon 1981), Fuzzy AHP (Opricovic and Tzeng 2003; Khatwani et al. 2015), Fuzzy TOPSIS, IRP (Sushil 2009) and Weighted IRP (Kumar and Singh 2015).

Integer Linear Model for Rank Aggregation

Let there be n number of suppliers, which are ranked according to m different MCDM techniques. An integer linear model is developed as shown below for the aggregation of supplier’s ranks from different MCDM techniques into one consensus ranking. Following are the notations used to model ILP.

Y i is the Final aggregated ranking of supplier i, X ij is the Rank of supplier i using j th Multi-Criteria Decision Making (MCDM) technique, n is the No. of suppliers, m is the No. of MCDM techniques

Objective function

Subjected to,

The objective function of the model as shown in Eq. (1) minimizes the deviation of the final ranking from individual rankings from various MCDM techniques. Equation (2) restricts the ranking of n suppliers from 1 to n only. Equation (3) ensures that no two suppliers are given same rank; hence every supplier is given a different rank. Integer value of the rank is ensured by Eq. (4).

An illustration has been carried out using an industry based survey for criteria filtration shown in “Criteria identification and filtration through industry based survey” section and a case study for ranking of suppliers at BOBST Lausanne in “Ranking of suppliers using different MCDM techniques for BOBST” section.

Illustration Through a Case Study

Criteria Identification and Filtration Through Industry Based Survey

Based on an elaborate literature review, 24 criteria for supplier selection are selected for industry based survey. Survey is carried out among purchasing managers for various industries in India, Germany, and Switzerland. There were a total of 41 responses from various industries. Respondents were asked to rank the criteria on a 5-point scale, where 1 stands for not at all important and 5 stand for extremely important. The average rating of each criteria can be seen from the bar chart shown in Fig. 6. The table showing mean ratings, standard deviations and Z-scores is shown in Appendix Table 12.

According to survey carried out, the reliability of the suppliers in terms of product quality and delivery are identified as most important criteria for supplier selection followed by lead time, responsiveness and production flexibility. But the parameters like the shareholders, size of the firm and cultural differences are identified as least important for supplier selection process. The criteria having their average rating below three (which are ERP compatibility, carbon footprint, shareholders, size of the firm and cultural differences) are not considered for further analysis.

Identifying Criteria Weights Using DEMATEL

The Average matrix was generated for DEMATEL with the help of purchasing managers (Appendix) for the 19 criteria. Pair-wise comparison was carried out among criteria on a scale comprising of five levels- 0,1,2,3,4 representing “No influence”, “Low influence”, “Middle influence”, “High influence”, and “Very High influence” respectively. Detailed steps for DEMATEL can be referred from Tzeng et al. (2007). The causal influence of criteria is tabulated below. The causality diagram is shown in Fig. 7 by plotting Prominence (D + R) on x- axis and Relation (D − R) on y-axis. Prominence is the total strength of the influence of criteria, the greater the value of D + R, the greater is the influence of the criteria on other criteria. Relation gives an idea how a criteria is affecting or being affected by other criteria. If D − R is positive, it means that a criterion is affecting other criteria, and when it is negative, it means that a criterion is influenced by other criteria. Results can be seen from Table 4, Which shows that criteria like technological and technical capability, market reputation. Responsiveness, cost and delivery reliability are among highly influential criteria. Figure 7 shows the causality diagram of criteria.

Ranking of Suppliers Using Different MCDM Techniques for BOBST

A case study was performed for BOBST, Lausanne. BOBST is the world’s largest provider of machinery and services to packaging companies. The company founded by Joseph Bobst in 1890, today has 11 production facilities in 8 countries, and has its presence in more than 50 countries. The employee strength of the company is over 4800. They have a huge pool of suppliers for different products that they acquire from various countries. The importance of criteria in supplier selection is very much a function of the particular product to be procured. Hence, the case study was focused on selection of suppliers for procurement of square tube, which is an essential part in the machinery. They have mainly six suppliers for acquiring this part, which they identify by their geographical location, mainly India, Switzerland and Central Eastern Europe. All MCDM techniques mentioned in proposed framework were applied based on the inputs by the purchasing managers. Tables 5 and 6 show the priority vectors for suppliers for each criteria obtained from AHP and fuzzy AHP. The pairwise comparison for all criteria for AHP and fuzzy AHP can be seen in Appendix Tables 15 and 16. Fuzzy AHP makes use of triangular fuzzy numbers as linguistic variables to represent expert’s opinions and to achieve final priority vectors of various criteria and alternatives (shown in Appendix Table 13).

Tables 7 and 8 show separations from ideal and negative ideal solution and relative closeness index using TOPSIS and Fuzzy-TOPSIS. The net dominance of suppliers calculated using IRP and weighted IRP is shown in Table 9. The final ranks obtained by using above mentioned techniques are shown in Table 10. From the table it can be clearly observed that each of these MCDM techniques is able to rank the suppliers based on selected criteria, however, there can be some variations in the final rankings of the suppliers even when started with same inputs. But when one is choosing one particular technique, probably the information or weightages provided by other MCDM techniques is neglected. Hence, there must be one consensus ranking which minimizes these deviations among the ranks provided these MCDM techniques. Therefore, the mathematical model developed for rank aggregation was used to obtain an integrated ranking. The model was solved using LINGO 10 solver and the integrated ranks can also be seen from Table 10. The mathematical model minimizes the deviation of the one consensus ranking from the ranks given by different ranking techniques.

Results and Discussion

In this paper, the integer linear model is proposed to aggregate the ranks obtained by various MCDM techniques for supplier selection process by minimizing the deviation in the ranks. The proposed model is compared with widely used Borda–Kendall (BAK) technique. BAK technique is quite popular in literature because of its computational simplicity (Cook and Seiford 1982; Jensen 1986). In Borda–Kendall method, the mean values of the ranks given by various ranking techniques are calculated for each supplier. Ranks obtained by BAK technique are then compared with the developed mathematical model.

Using BAK approach (Table 11), a tie can be observed among two suppliers, however, when this tie is broken arbitrarily and deviation was calculated for all combinations, it was found same as 38, which is same as the deviation calculated for mathematical model. However when the comparison between ILP model and BAK approach is carried out for a relatively bigger data set (10 suppliers, 6 MCDM techniues), it is observed that that proposed model minimizes the total deviation of the ranks for suppliers than BAK approach (shown in Appendix Table 14).

Conclusion and Future Scope

This paper attempts to aggregate the results given by various MCDM techniques into one consensus ranking by proposing a mathematical model which minimizes the deviation in ranks given by different ranking techniques. The model is compared with widely used BAK approach of obtaining consensus ranks and it was found that model effectively minimizes the deviation for a larger data set. However, in this model all techniques are considered equal i.e. having same weight, but different MCDM techniques can be given priorities based on their sensitivity analysis. The model can be extended by considering more criteria related to modes of shipment, supply chain network structure, carbon market and uncertainty to make the existing model more sustainable and robust.

References

Aggarwal, R., & Singh, S. P. (2014). An integrated stochastic supplier selection problem incorporating incremental volume discounts. International Journal of Mechanical and Production Engineering, 2(2), 7–12.

Aggarwal R. & Singh S. P. (2015). Chance constraint based multi-objective stochastic model for supplier selection, International Journal of Advanced Manufacturing Technology (Available online).

Babic, Z., & Plazibat, N. (1998). Ranking of enterprises based on multicriterial analysis. International Journal of Production Economics, 56, 29–35.

Barbarosoglu, G., & Yazgac, T. (2000). A decision support model for customer value assessment and supply quota allocation. Production Planning & Control, 11(6), 608–616.

Bevilacqua, M., Ciarapica, F. E., & Giacchetta, G. (2006). A fuzzy-QFD approach to supplier selection. Journal of Purchasing & Supply Management, 12, 14–27.

Bhutia, P. W., & Phipon, R. (2012). Appication of ahp and topsis method for supplier selection problem. IOSR Journal of Engineering (IOSRJEN), 2, 43–50.

Bhutta, K. S., & Huq, F. (2002). Supplier selection problem: a comparison of total cost of ownership and analytical hierarchy process approach. Supply Chain Management: An International Journal, 7, 126–135.

Boer, L., Wegen, L., & Telgen, J. (1998). Outranking method in support of supplier selection. European Journal of Operational Research, 4, 109–118.

Buyukozkan, G., & Cifci, G. (2012). A novel hybrid MCDM approach based on fuzzy DEMATEL, fuzzy ANP and fuzzy TOPSIS to evaluate green suppliers. Expert Systems with Applications, 39(3), 3000–3011.

Caniels, M. C. J., Gehrsitz, M. H., & Semeijn, J. (2013). Participation of suppliers in greening supply chains: An empirical analysis of German automotive suppliers. Journal of Purchasing & Supply Management, 19, 134–143.

Cao, Y., Luo, X., Kwong, C. K., & Tang, J. (2014). Supplier pre-selection for platform based products: a multi-objective approach. International Journal of Production Research, 52(1), 1–19.

Carter, C. R., & Easton, P. L. (2011). Sustainable supply chain management: evolution and future directions. International Journal of Physical Distribution & Logistics Management, 41(1), 46–62.

Carter, C. R., & Rogers, D. S. (2008). A framework of sustainable supply chain management: moving toward new theory. International Journal of Physical Distribution & Logistics Management, 38(5), 360–387.

Çebi, F., & Bayraktar, D. (2003). An integrated approach for supplier selection. Logistics Information Management, 16(6), 395–400.

Chamodrakas, I., Batis, D., & Martakos, D. (2009). Supplier selection in electronic marketplaces using satisficing and fuzzy AHP. Experts Systems with Applications, 37(1), 490–498.

Chan, F. T. S. (2003). Interactive selection model for supplier selection process: an analytical hierarchy process approach. International Journal of Production Research, 41(15), 3549–3579.

Chan, F. T. S., & Kumar, N. (2007). Global supplier development considering risk factors using fuzzy extended AHP-based approach. Omega, 35, 417–431.

Chan, F. T. S., Kumar, N., Tiwari, M. K., Lau, H. C. W., & Choy, K. L. (2008). Global supplier selection: a fuzzy-AHP approach. International Journal of Production Research, 46(14), 3825–3857.

Chen, C. T., Lin, C. T., & Huang, S. F. (2006). A fuzzy approach for supplier evaluation and selection in supply chain management. International Journal of Production Economics, 102, 289–301.

Choi, T. Y., & Hartley, J. L. (1996). An exploration of supplier selection practices across the supply chain. Journal of Operations Management, 14, 333–343.

Cook, W. D., & Seiford, L. M. (1982). On the Borda–Kendall consensus method for priority ranking problems. Management Science, 28(6), 621–637.

Deng, Y., & Chan, F. T. S. (2011). A new fuzzy dempster MCDM method and its application in supplier selection. Expert Systems with Applications, 38, 9854–9861.

Dickson, G. W. (1966). An analysis of vendor selection systems and decisions. Journal of Purchasing, 2(1), 5–17.

Dulmin, R., & Mininno, V. (2003). Supplier selection using a multi-criteria decision aid method. Journal of Purchasing & Supply Management, 9, 177–187.

Dyer, J. H., & Hatch, N. W. (2004). Using supplier networks to learn faster. Sloan Management Review, 45(3), 57–63.

Gabus, A., & Fontela, E. (1972). World problems, an invitation to further thought within the framework of DEMATEL.”. Geneva: Battelle Geneva Research Center.

Gencer, C., & Gurpinar, D. (2007). Analytic network process in supplier selection: A case study in an electronic firm. Applied Mathematical Modelling, 31, 2475–2486.

Genovese, A., Koh, S. C. L., Bruno, G., & Esposito, E. (2013). Greener supplier selection: state of the art and some empirical evidence. International Journal of Production Research, 51(10), 2868–2886.

Ghodsypour, S. H., & O’Brien, C. (1998). A decision support system for supplier selection using an integrated analytic hierarchy process and linear programming. International Journal of Production Economics, 56–57, 199–212.

Dubey R., Gunasekaran, A. & Childe S. J. (2015). The design of a responsive sustainable supply chain network under uncertainty. The International Journal of Advanced Manufacturing Technology, 1-19.

Ha, S. H., & Krishnan, R. (2008). A hybrid approach to supplier selection for the maintenance of a competitive supply chain. Expert Systems with Applications, 34(2), 1303–1311.

Haleem, A., Sushil, Qadri M. A., & Kumar, S. (2012). Analysis of critical success factors of world class manufacturing practices: An application of interpretive structural modelling and interpretive ranking process. Production Planning and Control, 23(10–11), 722–734.

Handfield, R. B. (1994). US global sourcing: Patterns of development. International Journal of Operations & Production Management, 14(6), 40–51.

Handfield, R., Walton, S. V., Sroufe, R., & Melnyk, S. A. (2002). Applying environmental criteria to supplier assessment: A Study in the application of the analytical hierarchy process. European Journal of Operational Research, 141(1), 70–87.

Haq, A. N., & Kannan, G. (2006). Fuzzy analytical hierarchy process for evaluating and selecting a vendor in a supply chain model. International Journal of Advanced Manufacturing Technology, 29, 826–835.

Helper, S. R., & Sake, M. (2012). Supplier relations in Japan and the United States: are they converging? Sloan Management Review, 36(3), 77–85.

Hong, Z., & Lee, C. K. M. (2013). A decision support system for procurement risk management in the presence of spot market. Decision Support Systems, 55, 67–78.

Houshyar, A., & Lyth, D. (1992). A systematic supplier selection procedure. Computers & Industrial Engineering, 23(1–4), 173–176.

Hsu, C. W., & Hu, A. H. (2009). Applying hazardous substance management to supplier selection using analytic network process. Journal of Cleaner Production, 17(2), 255–264.

Humphreys, P. K., Shiu, W. K., & Chan, F. T. S. (2001). Collaborative buyer-supplier relationships in Hong Kong manufacturing firms. Supply Chain Management: An International Journal, 6(4), 152–162.

Hwang, C. L., & Yoon, K. (1981). Lecture notes in economics and mathematical systems. Multiple objective decision making, methods and applications: A State-of-the-Art Survey (p. 164). Berlin: Springer.

Igoulalene, I., Benyoucef, L., & Tiwari, M. K. (2015). Novel fuzzy hybrid multi-criteria group decision making approaches for the strategic supplier selection problem. Expert Systems with Applications, 42, 3342–3356.

Jensen, R. E. (1986). Comparison of consensus methods for priority ranking problems. Decision Sciences, 17(2), 195–211.

Kabir, G., & Hasin, M. A. A. (2011). Comparative analysis of AHP and Fuzzy AHP models for multicriteria inventory classification. International Journal of Fuzzy Logic Systems, 1(1), 1–16.

Kahraman, C., Cebeci, U., & Ulukan, Z. (2003). Multi-criteria supplier selection using fuzzy AHP. Logistics Information Management, 16(6), 382–394.

Kannan, G., & Haq, A. N. (2007). Analysis of interactions of criteria and sub-criteria for the selection of supplier in the built-in-order supply chain environment. International Journal of Production Research, 45(17), 3831–3852.

Kannan, G., Haq, A. N., Sasikumar, P., & Arunachalam, S. (2008). Analysis and selection of green suppliers using interpretative structural modelling and analytic hierarchy process. International Journal of Management and Decision Making, 9(2), 163–182.

Karsak, E. E., & Dursun, M. (2015). An integrated fuzzy MCDM approach for supplier evaluation and selection. Computers & Industrial Engineering, 82, 82–93.

Kaufmann, L., Kreft, S., Ehrgott, M., & Reimann, F. (2012). Rationality in supplier selection decisions: The effect of the buyer’s national task environment. Journal of Purchasing & Supply Management, 18, 76–91.

Kaur, H., & Singh, S. P. (2014). Modeling low carbon procurement problem. California Business Review, 2(2), 7–11.

Kaur, H., & Singh, S. P. (2016). Modelling Flexible Procurement Problem, In Sushil, K. T. Bhal, S. P. Singh (Eds.), Managing Flexibility: People, Process, Technology and Business (pp. 147–170). New Delhi: Springer.

Khatwani, G., Singh, S. P., Trivedi, A., & Chauhan, A. (2015). Fuzzy-TISM: A fuzzy extension of TISM for group decision making. Global Journal of Flexible Systems Management, 16(1), 97–112.

Kilincci, O., & Onal, S. A. (2011). Fuzzy AHP approach for supplier selection in a washing machine company. Expert Systems with Applications, 38(8), 9656–9664.

Kumar, P., Shankar, R., & Yadav, S. S. (2011). Global supplier selection and order allocation using FQFD and MOLP. International Journal of Logistics Systems and Management, 9(1), 43–68.

Kumar R., & Singh S. P., (2015). AHP-IRP: An integrated approach for decision making; International conference on evidence based management 2015 (ICEBM), 605-612, ISBN: 978-93984935-18-4

Kuo, Y., Yang, T., & Huang, G. W. (2008). The use of grey relational analysis in solving multiple attribute decision-making problems. Computers & Industrial Engineering, 55(1), 80–93.

Lamming, R., & Hampson, J. (1996). The environment as a supply chain management issue. British Journal of Management, 7(1), 45–62.

Lee, A. H., Chen, W. C., & Chang, C. J. (2008). A fuzzy AHP and BSC approach for evaluating performance of IT department in the manufacturing industry in Taiwan. Expert Systems with Applications, 34(1), 96–107.

Lee, A. H., Kang, H. Y., Hsu, C. F., & Hung, H. C. (2009). A green supplier selection model for high-tech industry. Expert System with Applications, 36(4), 7917–7927.

Lee, C. C., & Ou-Yang, C. (2008). Development and evaluation of the interactive bidding strategies for a demander and its suppliers in supplier selection auction market. International Journal of Production Research, 46(17), 4827–4848.

Linton, J. D., Klassen, R., & Jayaraman, V. (2007). Sustainable supply chains: An introduction. Journal of Operations Management, 25, 1075–1082.

Locke, R. M. & Romis, M. (2012). Improving work conditions in global supply chains. Sloan Management Review, 48.

Lu, L. Y., Wu, C. H., & Kuo, T. C. (2007). Environmental principles applicable to green supplier evaluation by using multi-objective decision analysis. International Journal of Production Research, 45(18–19), 4317–4331.

Luthra, S., Garg, D., & Haleem, A. (2014). Critical success factors of green supply chain management for achieving sustainability in Indian automobile industry. Production Planning & Control, 1–24.

Mangla, S., Kumar, P., & Barua, M. K. (2014). A flexible decision framework for building risk mitigation strategies in green supply chain using SAP-LAP and IRP approaches. Global Journal of Flexible Systems Management, 15(3), 203–218.

Mathiyazhagan, K., Govindan, K., NoorulHaq, A., & Geng, Y. (2013). An ISM approach for the barrier analysis in implementing green supply chain management. Journal of Cleaner Production, 47, 283–297.

Min, H. (1994). International supplier selection: a multi attribute utility approach. International Journal of Physical Distribution & Logistics Management, 24(5), 24–33.

Moghaddam, K. S. (2015). Fuzzy multi-objective model for supplier selection and order allocation in reverse logistics systems under supply and demand uncertainty. Expert Systems with Applications, 42(15), 6237–6254.

Mohanty, R. P., & Deshmukh, S. G. (1993). Use of analytic hierarchic process for evaluating sources of supply. International Journal of Physical Distribution & Logistics Management, 23(3), 22–28.

Monczka, R. M., Trent, R. J., & Callahan, T. J. (1993). Supply base strategies to maximize supplier performance. International Journal of Physical Distribution & Logistics Management, 23(4), 42–54.

Muralidharan, C., Anantharaman, N., & Deshmukh, S. G. (2002). A multi-criteria group decision making model for supplier rating. Journal of Supply Chain Management, 38(4), 22–33.

Nagurney, A., & Nagurney, L. S. (2010). Sustainable supply chain network design: a multicriteria perspective. International Journal of Sustainable Engineering, 3(3), 189–197.

Narasimhan, R. (1983). An analytical approach to supplier selection. Journal of Purchasing and Materials Management, 19, 27–32.

Narasimhan, R., Talluri, S., & Mahapatra, S. K. (2006). Multiproduct, multicriteria model for supplier selection with product life-cycle considerations. Decision Sciences, 37, 577–603.

Neto, J. Q. F., Bloemhof-Ruwaard, J. M., Van Nunen, J. A. E. E., & van Heck, E. (2008). Designing and evaluating sustainable logistics networks. International Journal of Production Economics, 111(2), 195–208.

Nydick R.L., & Hill R. P., (1992). Using analytic heirarchical process to structure supplier selection procedure. International Journal of Purchasing and Materials Management 28(2): 31–36.

Opricovic, S., & Tzeng, G. H. (2003). Defuzzification within a fuzzy multicriteria decision model. International Journal of Uncertainty, Fuzziness and Knowledge-Based Systems, 11(5), 635–652.

Pagell, M., & Wu, Z. (2009). Building a more complete theory of sustainable supply chain management using case studies of 10 exemplars. Journal of Supply Chain Management, 45(2), 37–56.

Pishvaee, M. S., Razmi, J., & Torabi, S. A. (2012). Robust possibilistic programming for socially responsible supply chain network design: A new approach. Fuzzy Sets and Systems, 206, 1–20.

Punniyamoorthy, M., Mathiyalagan, P., & Parthiban, P. (2011). A strategic model using structural equation modeling and fuzzy logic in supplier selection. Expert System with Applications, 38(1), 458–474.

Rajesh, R., & Ravi, V. (2015). Supplier selection in resilient supply chains: a grey relational analysis Approach. Journal of Cleaner Production, 86, 343–359.

Ramudhin, A., Chaabane, A., & Paquet, M. (2010). Carbon market sensitive sustainable supply chain network design. International Journal of Management Science and Engineering Management, 5(1), 30–38.

Saaty, T. L. (1980). The analytic hierarchy process. New York: McGraw-Hill.

Sarkis, J. (2003). A strategic decision framework for green supply chain management. Journal of Cleaner Production, 11, 397–409.

Sarkis, J., & Dhavale, D. G. (2014). Supplier selection for sustainable operations: A triple-bottom-line approach using a Bayesian framework. International Journal of Production Economics. doi:10.1016/j.ijpe.2014.11.007i.

Sarkis, J., & Talluri, S. (2002). A model for strategic supplier selection. Journal of supply chain management, 38(1), 18.

Shen, J., Liu, Y., & Tzeng, Y. (2012). The cluster-weighted DEMATEL with ANP method for supplier selection in food industry. Journal of Advanced Computational Intelligence and Intelligent Informatics, 16(5), 567.

Shi, P., Yan, B., Shi, S., & Ke, C. (2015). A decision support system to select suppliers for a sustainable supply chain based on a systematic DEA approach. Information Technology and Management, 16(1), 39–49.

Shyur, H., & Shih, H. (2006). A hybrid MCDM model for strategic vendor selection. Mathematical and Computer Modelling, 44, 749–761.

Simić, D., Svirčević, V., & Simić, S. (2015). A hybrid evolutionary model for supplier assessment and selection in inbound logistics. Journal of Applied Logic, 13, 138–147.

Smytka, D. L., & Clemens, M. W. (1993). Total cost supplier selection model: A case study. International Journal of Purchasing and Materials Management, 29, 42–49.

Sushil, (2009 a). Interpretive ranking process. Global Journal of Flexible Systems Management, 10(4), 1–10.

Sushil, (2009b). SAP-LAP linkages—a generic interpretive framework for analyzing managerial contexts. Global Journal of Flexible Systems Management, 10(2), 11–20.

Talib, F., Rahman, Z., & Qureshi, M. N. (2011). Analysis of interaction among the barriers to total quality management implementation using interpretive structural modeling approach. Benchmarking: An International Journal, 18(4), 563–587.

Tate, W. L., Dooley, K. J., & Ellram, L. M. (2011). Transaction cost and institutional drivers of supplier adoption of environmental practices. Journal of Business Logistics, 32(1), 6–16.

Tzeng, G. H., Chiang, C. H., & Li, C. W. (2007). Evaluating intertwined effects in e-learning programs: A novel hybrid MCDM model based on factor analysis and DEMATEL. Expert Systems with Applications, 32(4), 1028–1044.

Viswanadham, N., & Samvedi, A. (2013). Supplier selection based on supply chain ecosystem, performance and risk criteria. International Journal of Production Research, 51(21), 6484–6498.

Wang, G., Samuel, H. H., & Dismukes, J. P. (2004). Product-driven supply chain selection using integrated multi-criteria decision-making methodology. International Journal of Production Economics, 91, 1–15.

Ware, N. R., Singh, S. P., & Banwet, D. K. (2012). Supplier selection problem: A state-of-the-art review. Management Science Letters, 2(5), 1465–1490.

Ware, N. R., Singh, S. P., & Banwet, D. K. (2014a). A mixed-integer non-linear program to model dynamic supplier selection problem. Expert System with Applications, 41, 671–678.

Ware, N. R., Singh, S. P., & Banwet, D. K. (2014b). Analysing the effect of demand variation on multi-product, multi-source, multi-period model for supplier selection problem. Industrial Engineering Journal, 7(2), 13–18.

Ware, N. R., Singh, S. P., & Banwet, D. K. (2014c). Modeling flexible supplier selection framework. Global Journal of Flexible Systems Management, 15(3), 261–274.

Weber, C. A., Current, J. R., & Benton, W. C. (1991). Vendor selection criteria and methods. European Journal of Operations Research, 50(1), 2–18.

Weber, C. A., & Desai, A. (1996). Determination of paths to vendor market efficiency using parallel coordinates representation: A negotiation tool for buyers. European Journal of Operational Research, 90, 142–155.

Wittstruck, D., & Teuteberg, F. (2011). Towards a holistic approach for sustainable partner selection in the electrics and electronics industry, governance and sustainability in information systems. Managing the Transfer and Diffusion of IT, IFIP Advances in Information and Communication Technology, 366, 45–69.

Wu, D., & Olson, D. L. (2008). A comparison of stochastic dominance and stochastic DEA for vendor evaluation. International Journal of Production Research, 46(8), 2313–2327.

Xia, W., & Wu, Z. (2007). Supplier selection with multiple criteria in volume discount environments. Omega, 35, 494–504.

Zadeh, L. A. (1965). Fuzzy sets. Information Control, 8, 338–353.

Zhu, Q., Sarkis, J., & Geng, Y. (2005). Green supply chain management in China: pressures, practices and performance. International Journal of Operations & Production Management, 25(5), 449–468.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaur, H., Singh, S.P. & Glardon, R. An Integer Linear Program for Integrated Supplier Selection: A Sustainable Flexible Framework. Glob J Flex Syst Manag 17, 113–134 (2016). https://doi.org/10.1007/s40171-015-0105-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40171-015-0105-1