Abstract

In the present context of the globalized market, sustainable manufacturing has become a major concern for all organizations. The sustainable manufacturing system includes economic, environmental, and social sustainabilities. Green manufacturing enhances the environmental sustainability but, it also affects the economic and social sustainabilities. The compulsion to follow the environmental rules and regulation in any business activity has increased the awareness for the use of green products, recyclable materials for packaging, reduction of carbon emission, etc. Due to the involvement of extra costs in green manufacturing, some ignorance in the implementation of green practices may be observed. To ensure sustainable systems, selection of suppliers based on green performance measures is very important. This study evaluates the suppliers’ performances based on Green Practices as follows: environmental management and pollution control, cost, quality, and flexibility using the fuzzy-extended Elimination and Choice Expressing Reality approach. This approach helps the managers to incorporate the linguistic decision of the decision makers and convert it into quantitative scale. This method is used to eliminate and outrank the poor performers. As poor performers are outranked, this approach helps to select the most suitable green suppliers as per organization’s requirement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the recent past, climate change and its impacts on the society had been gaining momentum; and managing pollution-free environment is becoming very important in today’s business scenario (Mangla et al. 2014). Therefore, business managers/practitioners are under immense pressure to lessen the harmful ecological and social impacts in their supply chains (Ağan et al. 2016). Sancha et al. (2015) established the relationship between institutional pressures and the sustainable supplier development in various locations. Mansi (2015) discussed sustainable disclosure practices in the purchasing activities of Indian government’s public sector enterprises. Green manufacturing is concerned with the replacement of hazardous or nonrenewable inputs by less-hazardous materials or renewable materials, respectively; better control of operations at higher efficiency; equipment modification; technology change; and product modification for minimization of the waste and the emission. The compulsion of linking the green practices with corporate strategies has attracted the attention of researchers and practitioners toward sustainable manufacturing and green supply chain management (Gunasekaran and Gallear 2012; Brockhaus et al. 2013). For ensuring green manufacturing, effective management of green supply chain activities is very important.

The concepts of green supply chain management have been evolved through a number of stages—from its inception to empirical studies (Fu et al. 2012). Many terms in green supply chain are concerned with sustainable supply chain concepts (Bai and Sarkis 2010), such as supply chain environmental management (Sharfman et al. 2009); green logistics (Murphy and Poist 2000); closed-loop supply chain (Zhu and Sarkis 2006); sustainable supply network management (Cruz and Matsypura 2009); and green procurement (Gunther and Scheibe 2006). Reverse logistics consists of a collection of discarded products, inspection, sorting, and recovery activities like recycling, remanufacturing, reuse, disposal, etc. (Govindan et al. 2015).

Amindoust et al. (2012) used fuzzy inference systems for sustainable supplier selection. They divided the selection criteria into three classes: economic, environmental, and social sustainabilities. For economic sustainability, they considered profit, quality, delivery and services as the subcriteria. For environmental sustainability, they considered environmental management systems and environmental competencies as the subcriteria. Similarly, for social sustainability, they considered the rights of stakeholders, work safety, and labor health as the subcriteria.

Büyüközkan and Ciftci (2012) observed that most of the adverse effects of the product on the environment can be eliminated during the design phase of the product development. According to Eltayeb et al. (2011), eco-friendly design (known as ecodesign) process consists of design for reduction of environmentally hazardous substances, design for reuse of a product, design for recycling waste material, and design for remanufacturing. Green purchasing covers the area of waste reduction, environmental material substitution, minimization of hazardous material, etc. Hence, companies have to take care of suppliers’ environmental performance and ensure that purchased materials are environmentally friendly for cleaner production (Lin 2013).

The World Business Council for Sustainable Development (WBCSD) and the World Resources Institute in 2009 have observed that at least 80 % of carbon emissions were produced through supply chains (Hsu et al. 2013). Wittneben and Kiyar (2009) emphasized on the importance that the supplier declare the exact figure of greenhouse gas emissions and that of the objective to reduce their carbon emissions. Hsu et al. (2013) summarized the main attributes for green supplier selection in carbon management. Supplier environmental collaboration covers activities that enhance supplier’s environmental performance related to joint planning, shared knowledge, green product development, and innovations (Eltayeb et al. 2011). Environmental collaboration helps companies to assure that the purchased materials are environment-friendly and produced using green processes (Zhu and Sarkis 2007).

Environmental management systems (EMS) should include policies, procedures, and audit procedures to evaluate the environmental impact of an organization’s operations. One of the most popular EMS is the International Organization for Standardization (ISO) 14000 series (Nawrocka et al. 2009). ISO 14001 directs all supply chain partners to select more environmentally friendly practices. It develops a systematic approach to reduce the negative environmental effects of organizations, decreases resource consumption and waste, and contributes to quality improvement (Eltayeb et al. 2011; Xu and Shen 2014).

This paper consists of four sections. The first section introduces the green supply chain management; the second section outlines the literature on the attributes for evaluation of supplier’s green performance; the third section deals with the proposed methodology; the fourth section illustrates this approach with a case study, i.e., green supplier selection; and the fifth section concludes the research work.

Literature review

The green approach toward supply chain management ensures green manufacturing for sustainable performance. The operative GSCM (Green Supply Chain Management) performance leads to the decline of the solid/liquid wastes, reduction in emission levels, the use of hazardous and toxic materials, and improvement in the health-related concerns of employees and the community (Eltayeb et al. 2011). As suppliers can contribute significantly to ensuring a supply chain green, the environmental aspect of green supplier selection has gained more importance nowadays.

Supplier selection criteria and methodologies

In earlier research works, cost (Awasthi et al. 2010), delivery (Kuo et al. 2010), quality (Shaik and Abdul-Kader 2011), service (Buyukozkan 2012), strategic alliance (Awasthi et al. 2010), pollution control (Lee et al. 2009), green product (Awasthi et al. 2010), and environmental management (Kuo et al. 2010) are considered as the main factors in the green supplier selection.

It has been observed that a number of criteria have been used by the researchers to evaluate the suppliers. Some of the environmental factors are considered with other factors, such as cost, quality, reliability, flexibility, etc., of the suppliers for performance measurement of suppliers or their selection. No reference has been found, which had used environmental factors in isolation for supplier selection. Thus, the review analysis shows that nowadays buyers are environmentally conscious in purchasing the goods/services, but other factors are equally important for them. In those references, no supplier is outranked, and all suppliers are considered for quota allocation as per their ranking and capacity constraints. Liu and Zhang (2011) used Elimination and Choice Expressing Reality (ELECTRE III) as an outranking method for supplier selection, but they have not considered the environmental factor at all in this process. However, they have used 19 criteria for supplier selection. Sevkli (2010) used fuzzy ELECTRE for supplier selection, but without giving any consideration to environmental factors. Tsui et al. (2015) used PROMETHEE for performance measurement of green suppliers in TFT-LCD industry and considered the environment and green management as factors with other factors for performance evaluation. Kuo et al. (2015) used DANP and VIKOR techniques to prioritize the 17 criteria and rank the suppliers. They have considered many environment-related criteria for supplier evaluation, and some criteria are related to management systems.

To incorporate all subcriteria individually in the analysis of supplier selection may be very complex; therefore, there is the need to show the overall impact of these subfactors in a broader perspective. For example, if cost is considered as one of the criteria for supplier selection, then it means that the different types of costs related to material processing, manufacturing, testing and inspection, packaging, transportation, etc. form parts of the main cost criteria. Similarly, in this paper, a total of 38 subfactors have been considered in supplier rating. These subfactors are grouped into six main clusters such as cost, quality, flexibility, service, green practices, environmental management, and pollution control, as shown in Fig. 1.

Cost

Cost components related to suppliers are purchasing, transportation, inventory, operation, maintenance, energy, inspection, delivery, security, ordering, holding, etc. (Ghodsypour and O’Brien 2001). There are some limitations of this process because all the performances should be measured in the same unit and there is complexity in developing a cost-accounting system (Petroni and Braglia 2000). Transportation cost is an important component of the logistics costs. It includes the cost of fuel or lubricants, penalties, driver salaries, maintenance costs, failure of the vehicle (Ongkunaruk and Piyakarn 2011). At the microlevel a number of cost components are there; it is very difficult to consider all the components at a time for supplier selection. Therefore, only the macrolevels of the cost components are highlighted in the decision-making problem.

Quality

It deals with quality control and assurance. Quality assurance deals with the fulfillment of customer demands with optimal utilization of resources and to coincide with the firm’s policy (Manning et al. 2006). “Business Process Reengineering (BPR)” and “Total Quality Management (TQM)” are two basic components of process organization, control, and improvement. There are many performance attributes such as certifications and awards that have been applied by the companies to benchmark the performance. ISO 9000, ISO 14000, EN 29000, and BS 5750 are some of the performance certifications and Quality improvement awards (Kardaras and Mentzas 1997).

Service

Nowadays, companies are able to provide products of a high quality, but high responsiveness, stock management, design capability, and low price, are some crucial issues in the improvement of service level to the customer. Suppliers play a crucial role in the supply chain; they provide a number of services such as assurance of fast deliveries, quick response, logistics Service, vendor managed inventory (VMI), and product design including components. Firms can improve their logistics performance through fast deliveries, quick response, low stocks, no damage, low costs, high productivity, fewer mistakes, minimum wastage, the high morale of staff, and so on. In order to meet customer’s specific and rapidly changing needs, a firm is required to be more responsive (Gunasekaran et al. 2008). The success of order-fulfillment solutions depends on the integration of order-fulfillment planning, product execution, distribution management, and cross-application integration.

Flexibility

Flexibility is an important part of the supply chain to meet the changing business requirements. Kumar et al. (2008) discussed the various types of flexibility and relationship among the variables of flexibility for global supply chain. Flexibility includes the ability to change the systems as per the requirement of the buyer. In this paper, the authors have incorporated different attributes of the flexibility for the supplier rating, which are technological change, material change, equipment upgradation, process improvement, volume flexibility, and design flexibility to reduce the use of hazardous materials, to minimize the consumption of energy, and to control the pollution and wastes during the usage of the products.

Green practice

Green practice is a very broad term and covers a number of activities of green supply chain, such as green purchasing, green packaging of the product, green product, recycling of wastes and end products, remanufacturing, collection of discarded product, reuse and disposal, green design, less emission, and low use of energy. In the recent years, a “green” competency between vendors and suppliers has increased the value of the company in the market. Green packaging aims to use environmentally friendly packaging material to protect the environment. Its main characteristic is to get dissolved or degraded in nature rapidly without harming the environment. Green packaging can be explained in terms of 4R1D (reduce, reuse, reclaim, recycle, degradable) (Zhang and Zhao 2012). Another important green practice is recycling. It is a process in which the used product is reduced to its raw materials and new and different products are generated from them. Recycling can be implemented if the scrapped product could not be reused again. Recycling needs a few processes, such as extraction, separating, etc., which require energy and harm the environment (Zhang and Zhao 2012). Reuse of a product is the extension of its life at the end with little or no treatment. Reuse can also be explained utilizing the material for a second or further time. There is no addition of any new value to the product. It is the process of getting a green product (Ke et al. 2011). Remanufacturing is also considered an important green practice. It is a process of restoring a large quantity of the products to a new state. Damaged components are repaired, but it does not ensure attaining the same performance level as the original product. The manufacturers can add some values or features to the product. It can be seen similar to the recycling, but it differs from it. Recycling is concerned with the raw materials, but remanufacturing is concerned with the original function (Zhang and Zhao 2012).

Environmental management and pollution control

Recently, the environmental obligation has been added to the procurement processes. Due to the high stress on Environmental Management Systems (EMS) and the increasing awareness of the negative impacts of productions to the environment, buyers have started to evaluate the green performance of suppliers. It influences the decision-making process, and many buyers expect from their supplier for applying EMS (Handfield et al. 2002). Ozonedepleting chemicals (ODCs) such as CFC (chlorofluorocarbon) and NOxs are the human-made chemical compounds which are responsible for the depletion of the ozone layer (Ravishankara et al. 2009). International Organization for Standardization (ISO 14001) is an institution for producing guidelines to provide certification to the firm based on “environmental aspects.” All policies, regulations, goals, and targets are reassessed and reevaluated for the continuous improvement (Bansal and Bogner 2002). Supplier’s attitude toward the pollution control is very important for the buyer to work together. With the growing production rate, energy consumption grows rapidly, and the pollution is the byproduct of energy use. Therefore, pollution-control programs that imply a proper usage of energy consumption are propagated (Yanqing and Mingsheng 2012).

Shaw et al. (2012) have used fuzzy Analytic Hierarchy Process (FAHP) and multiobjective goal programming for supplier selection and quota allocation. They laid emphasis on the development of low-carbon supply chain. For supplier selection, they gave the importance to greenhouse gas emission with some of the other criteria, such as cost, quality, lead time, and demand. The quota allocation among the shortlisted suppliers is based on four objective functions: the minimization of total purchasing cost, minimization of rejection due to quality problem, minimization of late delivery, and minimization of carbon footprints.

Chaharsooghi and Ashrafi (2014) used a risk-management system, transparently, and culture and strategy in addition to economic, environmental, and social sustainabilities as the criteria for sustainable supplier evaluation and selection. They used neofuzzy TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) as the methodology for supplier selection. Deviating from simple fuzzy TOPSIS, they inserted two absolute conditions (Bad and Good) in the decision-making matrix in neofuzzy TOPSIS methodology. Neofuzzy TOPSIS compares the candidates (suppliers) with these two standards, so the distance between candidates becomes real.

It has been observed that the environmental sustainability strongly influences the economic and social sustainabilities in terms of cost- and health-related issues. Most of the researchers have talked about the environmental sustainability with economic and social sustainabilities and some other factors for supplier selection. The uniqueness of this paper is that the authors have given weights to the green practices and environmental management systems and control with some other conventional factors, such as cost, quality, flexibility, services, etc. for supplier evaluation.

Research methodology

For the ranking of suppliers for green supply chain, the Fuzzy ELECTRE approach has been applied in this paper. A number of variants of ELECTRE method have been in use for the decision-making process. In this paper, the concept of decision making with the help of fuzzy ELECTRE has been taken from the research work of Hatami-Marbini et al. (2013). Basic steps of this approach will be described in this section.

- Definition 1 :

-

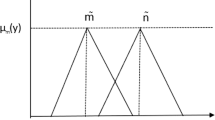

Let X be a universe set. The fuzzy set \(\tilde{A}\) is defined by a membership function, \(\mu_{{\tilde{A}}} (x) = [0,1]\), where \(\mu_{{\tilde{A}}} (x),\,\forall x \in X,\,{\text{indicates}}\,{\text{the}}\,{\text{degree}}\,{\text{of}}\,{\text{membership}}\,{\text{of}}\,\tilde{A}\,{\text{to}}\,X\)(Zadeh 1965).

- Definition 2 :

-

A triangular fuzzy number \(\tilde{A}\) is defined as (a l , a γ , a u ), a l ≤ a γ ≤ a u. The membership function \(\mu_{{\tilde{A}}} (x)\) is defined as (Zimmerman 1991; Kahraman et al. 2004)

- Definition 3 :

-

The mathematical operations of TFN (Triangular Fuzzy Number) can be done using the following equations (Chen 2014):

$$\begin{aligned} \tilde{A} + \tilde{B} = (a^{l} + b^{l} ,a^{\gamma } + b^{\gamma } ,a^{u} + b^{u} )\, \hfill \\ \tilde{A} - \tilde{B} = (a^{l} - b^{l} ,a^{\gamma } - b^{\gamma } ,a^{u} - b^{u} ) \hfill \\ \tilde{A}/\tilde{B} = (a^{l} /b^{u} ,a^{\gamma } + b^{\gamma } ,a^{u} + b^{l} ) \hfill \\ \tilde{A} \otimes \tilde{B} = (a^{l} \times b^{l} ,a^{\gamma } \times b^{\gamma } ,a^{u} \times b^{u} ) \hfill \\ {\text{Reciprocal}}\,{\text{of}}\,\tilde{A} = \,\,(1/a^{u} ,1/a^{\gamma } ,1/a^{l} ). \hfill \\ \end{aligned}$$ - Definition 4 :

-

Hamming distance between two fuzzy numbers (\(\tilde{A}\),\(\tilde{B}\)) is defined as (Hamming 1950)

$$\int\limits_{R} {\left| {\mu_{{\tilde{A}}} (x) - \mu_{{\tilde{B}}} (x)} \right|} {\text{where }}R{\text{ is the set of real numbers}}.$$(2)However, for simplicity in calculation, the distance between two fuzzy numbers (Chen 2000; Li and Yang 2004), especially in ELECTRE method can be represented by

$$d\left( {\tilde{A},\tilde{B}} \right) = \sqrt {\sum\limits_{k = 1}^{3} {(A_{k} - B_{k} )^{2} } }.$$(3) - Definition 5 :

-

Standard intersection, \(A \cap B\) and standard union, \(A \cup B\) of two fuzzy sets, \(\tilde{A}\;\,{\text{and}}\,\;\tilde{B}\) are defined as \((\tilde{A} \cap \tilde{B})(x) = \hbox{min} [\tilde{A}(x),\tilde{B}(x)]\) and \((\tilde{A} \cup \tilde{B})(x) = \hbox{max} [\tilde{A}(x),\tilde{B}(x)]\) respectively.

- Definition 6 :

-

Comparison of fuzzy numbers on the basis of outranking

The outranking relations in ELECTRE are shown as S,which means ‘‘at least as good as.’’ Considering two alternatives Af and Ag, four situations may arise (Hatami-Marbini and Tavana 2011):

-

Af S Ag and not Ag S Af (Af is strictly preferred to Ag),

-

AgS Af and not AfS Ag (Ag is strictly preferred to Af),

-

Af S Ag and Ag S Af (Af is indifferent to Ag)

-

Not Af S Ag and not Ag S Af (Af is incomparable to Ag).

Fuzzy ELECTRE

Fuzzy ELECTRE is a process of multicriteria decision making. In this process, poor performers are outranked, and only comparable performers are ranked. This outranking is based on the concordance and discordance values. Fuzzy sets are used to incorporate the linguistic variables or vague state of mind of the decision-makers. The major steps of the fuzzy TOPSIS are discussed as follows (Pl refer Appendix 1 for framework):

Step 1: Preparation of fuzzy decision matrix

To prepare a fuzzy decision matrix of ‘m’ alternatives and ‘n’ attributes, first, the fuzzy importance of the attributes is determined. The decision makers are given different weightages on the basis of their respective experiences and levels in organization hierarchy, e.g., the first, second, and third decision makers among the three levels are assigned with the weights of 40, 35, and 25 % respectively.

After deciding the weights for the decision makers, the fuzzy importance(s) of attributes is(are) decided by a weighted average of the ratings of attributes by the decision makers using the following formula:

where k = 1,2,…,K is the number of decision makers; j = 1,2,…,n is the number of attributes; and \(\tilde{W}_{jk}\) is the importance of jth attributes assigned by kth decision makers.

After deciding the importance(s) of the various attributes, various alternatives are rated against each attribute by all the K decision makers, and the final fuzzy rating of alternatives is determined by weighted average using the following formula:

where k = 1,2,…,K is the number of decision makers; i = 1,2,…,m is the number of alternatives; j = 1,2,…,n is the number of attributes; and \(\tilde{x}_{ijk}\) is the rating of ith alternative against the jth attributes by the kth decision maker.

The decision matrix can be represented as

Step 2: Preparation of normalized decision matrix

Linear-scale normalization is applied to ensure that all values of the elements in the decision matrix have homogeneous and comparable units. Moreover, this transformation guarantees that every triangular fuzzy number belongs to [0,1] which reduces the complexity in the mathematical operations. The normalized fuzzy decision matrix is shown below:

where B is the set of benefit attributes; i = 1,2…,m; and j = 1,2,…,n.

where C is the set of cost attributes; i = 1,2…,m; and j = 1,2,…,n.

Step 3: Computing the weighted normalized matrix

Multiply the standard rating of the alternatives with the importance of corresponding attributes to compute the weighted normalized matrix using the following formula:

Step 4: Calculating the distance between any two alternatives

The concordance and discordance matrices are prepared using the weighted normalized fuzzy decision matrix and pairwise comparison of the alternatives. Considering two alternatives A x and A y , the concordance set is formed as \(J^{C} = \{ J|\tilde{v}_{xj} \ge \tilde{v}_{yj} \}\) where \(J^{C}\) is the concordance coalition of the attributes and the assertion is A x SA y . The discordance set is defined as \(J^{D} = \{ J|\tilde{v}_{xj} \le \tilde{v}_{yj} \}\) where \(J^{D}\) is the discordance coalition, and it is against the assertion, A x SA y . Note that S is the outranking relation, and A x SA y means that ‘‘A x is at least as good as A y .’’

In order to compare any two alternatives A x and A y , with respect to each attribute, and to define the concordance and discordance sets, we specify the least upper bound of the alternatives, max \(\left( {\tilde{v}_{xj} ,\tilde{v}_{yj} } \right)\)), and then, the distance is used with the following assumptions:

Step 5: Constructing the concordance and discordance sets, and concordance and discordance matrices

The concordance set is the set of attributes for which \(\tilde{v}_{xj} \ge \tilde{v}_{yj}\) and the discordance set is the set of the attributes for which \(\tilde{v}_{xj} \le \tilde{v}_{yj}\). The following concordance matrix is formed in which the elements are the fuzzy summation of the fuzzy importance weights for all the attributes in the concordance set.

Now, we determine the concordance level as

The discordance matrix is prepared as

where

Now, we determine the disconcordance level as

Step 6: Preparing the Boolean matrices E and F for the concordance and discordance matrices

where

where

Step 7: Preparing the final matrix

A final matrix G is prepared by peer-to-peer multiplication of the elements of the matrices, E and F, which can be represented as

Step 8: Constructing a decision graph and ranking the alternatives

A decision graph is drawn using the final matrix G in order to determine the ranking order of the alternatives. Let A x and A y be two alternatives. There is an arc between the two alternatives from A x to A y if alternative A x outranks A y ; there is no arc between the two alternatives if alternatives A x and A y are incomparable; and there are two arcs between the two alternatives in both directions if these alternatives are not different.

Case illustration

In an automotive supply chain, supplier plays an important role, and the success of the supply chain depends on the performance of the supplier. Only a few parts of the automobile are of strategic importance and produced in-house. Most of the components are outsourced, and the buyer depends on his supplier for those components. Therefore, the buyer develops a strategic relationship with the supplier. Some of the autocomponents are supplied in the integrated form to the OEM or assembler. These components may be supplied by the tier-1 or tier-2 suppliers. A detailed structure of a typical automotive supply chain is shown in Fig. 2. It has been observed that many components, such as tires, tubes, and electric, and electronic parts are directly supplied or supplied from the regional distributors to the assembler.

In this research, about twenty autocomponent suppliers were considered for green performance evaluation at the initial stage, but finally, eight suppliers were shortlisted on the basis of their market shares. These suppliers are supplying the autocomponents to the world’s leading car manufacturers in India and abroad. All the suppliers are certified by the ISO certification and awarded with different quality awards. Some suppliers are more concerned with the environment and pollution. However, most of the suppliers in developing countries have a lack of awareness and show ignorant behavior toward the green product, carbon footprint, and the emission control. This ignorance may be due to lack of infrastructure, intention to provide the products at low cost to meet the competition, no strict control of the government over the implementation of environmental management systems, etc. In the developed nation, implementation of the environmental rules and regulation is more strict in comparison with developing nation due to the availabilities of infrastructure and technology, awareness among the buyers and suppliers related to environmental rules and regulations, strict control of the government over the implementation of the green practices in manufacturing, mandatory nature of ISO 14000 certification, social health awareness, etc.

Therefore, to know the suppliers’ efforts toward the green supply chain management, a framework has been proposed to evaluate the suppliers’ green performance. To gather the exact information about the suppliers, all the three levels of management of a buyer company were consulted for their opinion. The decision maker from the top-level management is given the highest weightage (40 %), from middle-level management is given the moderate weightage (35 %), and from lower-level management is given less weightage (25 %). On the basis of these decision makers, total six groups of attributes were shortlisted to rate the suppliers. These attributes are cost, quality, services, flexibility, green practice, environmental management, and pollution control. The importance of these attributes is based on the weighted average of the ratings of the decision makers. Table 1 shows the linguistic and the fuzzy quantitative scales that are used in this paper. In this table, the first column shows the linguistic scale for the importance ratings of the criteria; the second column shows the linguistic scale for the performance ratings of the alternatives with respect to the various criteria, and the last column shows the fuzzy quantitative scale for the corresponding linguistic scale. Since the linguistic scale cannot be directly used in mathematical operations, it is converted to fuzzy quantitative scale.

The final weights of the attributes for supplier evaluation are calculated using a weighted average of the opinion given by the decision makers: for example, the first decision maker, second decision maker, and the third decision maker rate the importance of the attributes ‘cost’ as very high, high, and very high, respectively. The weighted average of the importance of cost can be calculated using Eq. (4). The importance ratings of the attributes by these three decision makers and their weighted averages are shown in Table 2.

After finding the weighted average of the importance of all the attributes, suppliers are evaluated by these decision makers against all the attributes on a linguistic scale as shown in Table 1. The ratings of suppliers by all the three decision makers against the various attributes are shown in Table 3.

Then the weighted average of the ratings of the suppliers for all the decision makers is calculated using Eq. (5). The fuzzy decision matrix is prepared using the weighted average of ratings of suppliers against the various attributes. The elements of the fuzzy decision matrix are normalized using Eqs. (8) and (9) to represent the elements on a uniform scale, i.e., on the scale between 0 and 1. Equation (8) is used for the benefit attributes, and Eq. (9) is used for the cost Attributes.

After the preparation of fuzzy normalized matrix, the elements of the fuzzy normalized matrix are multiplied by the weights of corresponding attributes using the Eq. (10). Thus, the weighted normalized matrix is prepared.

From the weighted normalized matrix, the distance between two alternatives such as \(\tilde{v}_{A1C1}\) and \(\tilde{v}_{A2C1}\) for an attribute C 1, is calculated using Eq. (3). Similarly, distance matrices of all the alternatives for each attribute are prepared using Eqs. (11) and (12).

Now concordance sets of the attributes are prepared for all the attributes based on the distance matrix. The jth attributes will be the elements of the respective concordance sets of attributes, x and y, if \(\tilde{v}_{xj} \ge \tilde{v}_{yj}\). A concordance matrix is prepared based on the weights of the attributes of the concordance set. For example, the concordance set between the alternatives A1 and A3 is represented as {2, 5, 6}. The elements for A1 and A3 in the concordance matrix will be the fuzzy sum of the importance weights of attributes 2, 5, and 6.

Now discordance matrix is also prepared from the distance matrix. Considering two alternatives, i.e., suppliers A x and A y , the jth attribute is placed in the discordance set assuming that A x SA y , where S is the outranking relation, if and only if A x is preferred to A y . In the fuzzy environment, the discordance set is formed as \({\text{J}}^{\text{D}} = \, \{ {\text{J}}|\tilde{v}_{xj} \le \tilde{v}_{yj} \,\}\) where J D is the discordance coalition of the attributes. The discordance matrix is constructed using Eq. (16).

For example, let us consider Suppliers, A1 and A2. In the evaluations of A1 and A2, the distances in terms of each attribute are (0.21, 0), (1.09, 0), (0, 0), (1.39, 0), (0.24, 0), and (0.92, 0), respectively, in the distance matrix, and the all the pair values satisfy the definition of the discordance set. Therefore, the discordance set includes all the pairs and the corresponding discordance levels by means of Eq. (16) as follows:

After preparing the concordance and discordance matrices, we prepare the Boolean matrices E and F for the both concordance and discordance matrices, respectively. The values of \(\tilde{\bar{C}}\) are calculated as (5.62, 7.68, 8.98) from concordance matrix using Eq. (14). If the individual element of concordance matrix is greater than or equal to \(\tilde{\bar{C}}\), then the value of that element in Boolean matrix will be 1, and if the individual element of concordance matrix is less than \(\tilde{\bar{C}}\), then the value of that element in Boolean matrix will be 0.

The value of \(\bar{D}\) is calculated as (0.7) from discordance matrix using Eq. (17). If the individual element of disconcordance matrix is greater than or equal to \(\bar{D}\), then the value of that element in Boolean matrix will be 0, and if the individual element of concordance matrix is less than \(\bar{D}\), then the value of that element in Boolean matrix will be 1. Detailed analysis of above-mentioned steps in tabular forms is given in Appendix 2.

Both the Boolean matrices derived from concordance and discordance matrices are aggregated by peer-to-peer multiplication of their elements to capture their simultaneous effects, and the constructed general matrix G thus is presented in Table 4.

Finally, the decision graph is constructed based on the final matrix G as shown in Fig. 3. The decision graph enabled us to identify the ranking order of the Suppliers. The outgoing arc shows the domination of one supplier over another, and the incoming arc shows the domination of other suppliers over the arrow-headed supplier.

A’s are shown in this decision graph (Fig. 3):

-

Supplier A1 is dominated by Suppliers A2, A3, A4, A5, A6, A7, and A8.

-

Supplier A2 dominates A1 and A8, while it is dominated by Suppliers A5 and A7.

-

Supplier A3 dominates Supplier A1, while it is dominated by A6.

-

Supplier A4 dominates Suppliers A1, A7, and A8, while it is dominated by Suppliers A5.

-

Supplier A5 dominates Suppliers A1, A2, A4, and A8.

-

Supplier A6 dominates Supplier A3, while it is dominated by A5.

-

Supplier A7 dominates Suppliers A1, A2, and A8, while it is dominated by Supplier A4.

-

Supplier A8 is dominated by A2, A4, A5, and A7.

From Fig. 3, It can be observed that A5 is the first-ranked supplier as it dominates the suppliers A1, A2, A4, A6, and A8. Supplier A4 dominates Suppliers, A1, A7, and A8 and Supplier A6 dominates A3. Thus, indirectly, Supplier A5 dominates all the other suppliers and has the first rank. Similarly, Supplier A4 gets the second rank; Supplier A7 gets the third rank. Suppliers A6 and A2 have the fourth and fifth ranks, respectively. Suppliers A1 and A8 are outranked as they do not show domination over any supplier.

This method leads us to the other multicriteria decision-making methods such as AHP, TOPSIS, ANP (Analytic Network Process), etc. where outranking of the poor performers is not possible. These methods provide ranks to all the alternatives or DMUs (Decision-making Units); even poor performers get some ranks. In the ELECTRE method, the decision maker uses concordance and discordance indices to analyze outranking relations among different alternatives and to choose the best alternative. The poor performers are outranked by all the good performers and do not get any rank. Thus, it may help the manager to eliminate and shortlist only comparable performers or suppliers.

There are some limitations of the ELECTRE method. The lowest performances under certain criteria are not displayed due to the way preferences are incorporated. The outranking method prevents the strengths and weaknesses of the alternatives from being directly identified, nor results and impacts to be verified (Konidari and Mavrakis 2007). ELECTRE has been used in energy, economics, environmental, water management, transportation problems, etc. Like other methods, it also takes the uncertainty and vagueness factors into account.

Conclusions

Nowadays, sustainability has become a major concern for all organizations to survive in global markets. Organizations have become very particular in the procurement of raw materials and selection of suppliers accordingly. Supplier selection is usually done in terms of traditional measures without considering sustainability perspective. This paper has tried to illustrate an approach for supplier selection to ensure environmental sustainability with other factors in the whole value chain. This study considers thirty-eight factors which are grouped into six clusters such as cost, quality, flexibility, service, green practice, environmental management, and pollution control. Suppliers are evaluated and ranked using fuzzy outranking approach.

The fuzzy ELECTRE, a fuzzy outranking approach of supplier evaluation/selection is a very effective multiattribute decision-making tool which is used to outrank the suppliers having poor performance. The uniqueness of this approach is that it eliminates the suppliers performing very poorly, whereas, in other multiattribute decision-making tools, each alternative has some rank. Thus, using the fuzzy ELECTRE method, the decision makers can discard many suppliers who are not performing up to a certain minimum level. By following this approach, decision makers can concentrate only on selected top ranked suppliers for further development as per their business requirement. Moreover, suppliers also know their relative performance with respect to other suppliers. Therefore outranked suppliers can also work on their performance improvement to meet emerging requirements of the market. The findings of the paper will also motivate suppliers to adopt green initiatives in their processes. However, findings may further be validated with some cases and empirically based studies.

Future scope of the research

The future work related to supplier selection may be more focused on green production and green practices such as solid waste, chemical waste, air emission, water waste, energy, environmental friendly materials, redesign of product, staff training, recycling, reuse, remanufacturing, disposal, environmental policy, training, ISO 14001, top management commitment, etc. to improve the environmental sustainability and its relationship with economic and social sustainability. This approach can be applied for selection of sustainable supplier in other sectors also, where the number of suppliers is more and difficult to choose. As it outranks poor performers, therefore buyers would be able to focus on performing suppliers only.

References

Ağan Y, Kuzey C, Acar MF, Açıkgöz A (2016) The relationships between corporate social responsibility, environmental supplier development, and firm performance. J Clean Prod 112:1872–1881

Amindoust A, Ahmed S, Saghafinia A, Bahreininejad A (2012) Sustainable supplier selection: a ranking model based on fuzzy inference system. Appl Soft Comput 12(6):1668–1677

Awasthi A, Chauhan SS, Goyal SK (2010) A fuzzy multicriteria approach for evaluating environmental performance of suppliers. Int J Prod Econ 126(2):370–378

Bai C, Sarkis J (2010) Integrating sustainability into supplier selection with gray system and rough set methodologies. Int J Prod Econ 124(1):252–264

Bansal P, Bogner WC (2002) Deciding on ISO 14001: economics, institutions, and context. Long Range Plan 35(3):269–290

Brockhaus S, Kersten W, Knemeyer AM (2013) Where do we go from here? Progressing sustainability implementation efforts across supply chains. J Bus Logist 34:167–182

Buyukozkan G (2012) An integrated fuzzy multi-criteria group decision-making approach for green supplier evaluation. Int J Prod Res 50(11):2892–2909

Büyüközkan G, Ciftci G (2012) A combined fuzzy AHP and fuzzy TOPSIS based strategic analysis of electronic service quality in healthcare industry. Expert Syst Appl 39(3):2341–2354

Chaharsooghi SK, Ashrafi M (2014) Sustainable supplier performance evaluation and selection with neofuzzy TOPSIS method. Int Sch Res Not. doi:10.1155/2014/434168

Chen C-T (2000) Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst 114:1–9

Chen T-Y (2014) An ELECTRE-based outranking method for multiple criteria group decision making using interval type-2 fuzzy sets. Inf Sci 263:1–21

Cruz JM, Matsypura D (2009) Supply chain networks with corporate social responsibility through integrated environmental decision-making. Int J Prod Res 47(3):621–648

Eltayeb TK, Zailani S, Ramayah T (2011) Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: investigating the outcomes. Resour Conserv Recycl 55(5):495–506

Fu X, Zhu Q, Sarkis J (2012) Evaluating green supplier development programs at a telecommunications systems provider. Int J Prod Econ 140(1):357–367

Ghodsypour SH, O’Brien C (2001) The total cost of logistics in supplier selection, under conditions of multiple sourcing, multiple criteria and capacity constraint. Int J Prod Econ 73(1):15–27

Govindan K, Azevedo SG, Carvalho H, Machado VC (2015) Lean, green and resilient practices influence on supply chain performance: interpretive structural modeling approach. Int J Environ Sci Technol 12(1):15–34

Gunasekaran A, Gallear D (2012) Special issue on sustainable development of manufacturing and services. Int J Prod Econ 140(1):1–6

Gunasekaran A, Lai KH, Cheng TCE (2008) Responsive supply chain: a competitive strategy in a networked economy. Omega Int J Manag Sci 36(4):549–564

Gunther E, Scheibe L (2006) The hurdle analysis. A self-evaluation tool for municipalities to identify, analyze and overcome hurdles to green procurement. Corp Soc Responsib Environ Manag 13(2):61–77

Hamming RW (1950) Error detecting and error correcting codes. Bell Syst Tech J 26:147–160

Handfield R, Walton SV, Sroufe R, Melnyk SA (2002) Applying environmental criteria to supplier assessment: a study in the application of the Analytical Hierarchy Process. Eur J Oper Res 141(1):70–87

Hatami-Marbini A, Tavana M (2011) An extension of the ELECTRE I method for group decision-making under a fuzzy environment. Omega Int J Manag Sci 39:373–386

Hatami-Marbini A, Tavana M, Moradi M, Kangi F (2013) A fuzzy group Electre method for safety and health assessment in hazardous waste recycling facilities. Saf Sci 51:414–426

Hsu CW, Kuo TC, Chen SH, Hu AH (2013) Using DEMATEL to develop a carbon management model of supplier selection in green supply chain management. J Clean Prod 56(1):164–172

Kahraman C, Cebeci U, Ruan D (2004) Multi-attribute comparison of catering service companies using fuzzy AHP: the case of Turkey. Int J Prod Econ 87:171–184

Ke Q, Zhang H, Liu G, Li B (2011) Remanufacturing engineering literature overview and future research needs. In: glocalized solutions for sustainability in manufacturing, pp. 437–442

Konidari P, Mavrakis D (2007) A multi-criteria evaluation method for climate change mitigation policy instruments. Energy Policy 35(12):6235–6257

Kumar P, Shankar R, Yadav SS (2008) Flexibility in global supply chain: modeling the enablers. J Model Manag 3(3):277–297

Kuo RJ, Wang YC, Tien FC (2010) Integration of artificial neural network and MADA methods for green supplier selection. J Clean Prod 18(12):1161–1170

Kuo TC, Hsu C-W, Li J-Y (2015) Developing a green supplier selection model by using the DANP with VIKOR. Sustainability 7:1661–1689

Lee AHI, Kang H-Y, Hsu C-F, Hung H-C (2009) A green supplier selection model for high-tech industry. Expert Syst Appl 36(4):7917–7927

Li D-F, Yang J-B (2004) Fuzzy linear programming technique for multiattribute group decision making in fuzzy environments. Inf Sci 158:263–275

Lin RJ (2013) Using fuzzy DEMATEL to evaluate the green supply chain management practices. J Clean Prod 40:32–39

Liu P, Zhang X (2011) Research on the supplier selection of a supply chain based on entropy weight and improved ELECTRE-III method. Int J Prod Res 49(3):637–646

Mangla SK, Kumar P, Barua MK (2014) Flexible decision approach foranalysing performance of sustainable supply chains under risks/uncertainty. Glob J Flex Syst Manag 15(2):113–130

Manning L, Baines R, Chadd S (2006) Quality assurance models in the food supply chain. Br Food J 108(2):91–104

Mansi M (2015) Sustainable procurement disclosure practices in central public sector enterprises: evidence from India. J Purch Supply Manag 21(2):125–137

Kardaras D, Mentzas, G (1997) Using fuzzy cognitive maps to model and analyze business performance assessment. Published in Chen J, Mital A (eds). Advances in Industrial Engineering Applications and Practice II, pp. 63–68

Murphy PR, Poist RF (2000) Green logistics strategies: an analysis of usage patterns. Transp J 40(2):5–16

Nawrocka D, Brorson T, Lindhqvist T (2009) ISO 14001 in environmental supply chain practices. J Clean Prod 17(16):1435–1443

Ongkunaruk P, Piyakarn C (2011) Logistics cost structure for mangosteen farmers in Thailand. Systems Engineering Procedia 2:40–48

Petroni A, Braglia M (2000) Vendor selection using principal component analysis, vendor selection using principal component analysis. J Supply Chain Manag 36(2):63–69

Ravishankara AR, Daniel JS, Portmann RW (2009) Nitrous Oxide (N2O): the dominant ozone-depleting substance emitted in the 21st century. Science 326(5949):123–125

Sancha C, Longoni A, Giménez C (2015) Sustainable supplier development practices: drivers and enablers in a global context. J Purch Supply Manag 21(2):95–102

Sevkli M (2010) An application of the fuzzy ELECTRE method for supplier selection. Int J Prod Res 48(12):3393–3405

Shaik M, Abdul-Kader W (2011) Green supplier selection generic framework: a multi-attribute utility theory approach. Int J Sustain Eng 4(1):37–56

Sharfman M, Shaft T, Anex R (2009) The road to cooperative supply-chain environmental management: trust and uncertainty among proactive firms. Bus Strategy Environ 18(1):1–13

Shaw K, Shankar R, Yadav SS, Thakur LS (2012) Supplier selection using fuzzy AHP and fuzzy multi-objective linear programming for developing low carbon supply chain. Expert Syst Appl 39(9):8182–8192

Tsui C-W, Tzeng G-H, Wen U-P (2015) A hybrid MCD M approach for improving the performance of green suppliers in the TFT-LCD industry. Int J Prod Res 53(21):6436–6454

Wittneben Bettina BF, Kiyar D (2009) Climate change basics for managers. Manag Decis 47(7):1122–1132

Xu J, Shen F (2014) A new outranking choice method for group decision making under Atanassov’s interval-valued intuitionistic fuzzy environment. Knowl Based Syst 70:177–188

Yanqing X, Mingsheng X (2012) A 3E model on energy consumption, environment pollution and economic growth an empirical research based on panel data. Energy Proced 16:2011–2018

Zadeh LA (1965) Fuzzy sets. Inform Control 8:338–353

Zhang G, Zhao Z (2012) Green packaging management of logistics enterprises. Physics Proced 24:900–905

Zhu Q, Sarkis J (2006) An inter-sectoral comparison of green supply chain management in China: drivers and practices. J Clean Prod 14(5):472–486

Zhu Q, Sarkis J (2007) The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int J Prod Res 45(18–19):4333–4355

Zimmerman HJ (1991) Fuzzy set theory and its applications, 2nd ed. Kluwer Academic Publishers, Boston, MA

Acknowledgments

Authors express sincere thanks to Chief editor of the journal and reviewers for their constructive and valuable suggestions to improve the quality and content of the paper.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kumar, P., Singh, R.K. & Vaish, A. Suppliers’ green performance evaluation using fuzzy extended ELECTRE approach. Clean Techn Environ Policy 19, 809–821 (2017). https://doi.org/10.1007/s10098-016-1268-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1268-y