Abstract

In the recent years, new techniques such as; Artificial Neural Network (ANN) were employed for developing of the predictive models to estimate the needed parameters. Soft computing techniques are now being used as alternate statistical tool. In this study, ANN models were developed to predict rock properties of sedimentary rock, by using penetration and sound level produced during percussive drilling. The data generated in the laboratory investigation was utilized for the development of ANN models for predicting rock properties like, uniaxial compressive strength, abrasivity, tensile strength, and Schmidt rebound number using air pressure, thrust, bit diameter, penetration rate and sound level. Further, ANN models were also developed for predicting penetration rate and sound level using air pressure, thrust, bit diameter and rock properties as input parameters. The constructed models were checked using various prediction performance indices. ANN models were more acceptable for predicting rock properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Neural network is a powerful technique to solve many real-world problems. Neural networks may be used as a direct substitute for auto correlation, linear regression, trigonometric, multivariable regression and other statistical analyses and techniques [1]. Neural networks, with their remarkable ability to derive meaning from complicated or imprecise data, can be used to extract patterns and detect trends that are too complex to be noticed by either humans or other computer techniques [2]. Rumelhart and McClelland [3] reported that the main characteristics of ANN include large-scale parallel distributed processing, continuous nonlinear dynamics, collective computation, high fault-tolerance, self-organization, self-learning, and real-time treatment. The particular network can be defined using three fundamental components: transfer function, network architecture and learning law [4]. It is essential to define these components to solve the problem satisfactorily.

Artificial neural networks (ANNs), or shortly, neural networks (NN) have been used for finding out the structure and functionality of biological, nature of human brain. Therefore, ANN is found to be more flexible and suitable than other modeling methods [5]. ANN is based on the neural architectures of the human brain [6], and is described as group of simple processing units, known as neurons (nodes), which are arranged in parallel layers that are connected, to each other by weighted connections. By virtue of hidden layers of neurons that lie between the input and output layers of the network and the nonlinear activation functions that are used to translate nodal input into output, ANN provides linear and nonlinear modeling without the requirement of preliminary information and assumption as to the relationship between input and output variables. This provides ANN an advantage over other statistical and conventional prediction methods such as logistic regression and numerical methods, in which nonlinear interactions among variables must be modeled in explicit functional form [7]. ANN trained with feed-forward back-propagation algorithm has been studied extensively and applied successfully in various areas, such as automotives [8], banking [9], electronics [10], finance [11], industry [12], oil and gas [13], and robotics [14]. Most of the ANNs contain three layers: input, output and hidden layer. Generally, there are various types of ANN techniques for example feed forward network, radial basis network, generalized regression network and recurrent neural network.

Multi Layer Perceptron (MLP) network models are the popular network architectures used in most of the research applications in medicine, engineering, mathematical modeling, etc. In MLP, the weighted sum of the inputs and bias term are passed to activation level through a transfer function to produce the output and the units are arranged in a layered feed-forward topology called Feed Forward Neural Network [15].

In view of the above, it is felt that investigation using percussive drilling machine which is widely used in the mining and mineral industries in production operations can help in estimating rock properties also. An attempt has been made in this investigation to determine the rock properties vis-à-vis sound level using a fabricated pneumatic drill set-up on the laboratory scale. Also, developing various models for the prediction of UCS, abrasivity, tensile strength (TS) and Schmidt rebound number (SRN) for rocks were considered using penetration rate and sound level produced during percussive drilling and prediction of penetration rate and sound level for a given air pressure, thrust and bit-rock combination. In this study, artificial neural network models were also developed to predict the rock properties of sedimentary rocks, by using penetration rate and sound level produced during drilling and prediction of penetration rate and sound level for a given air pressure, thrust and bit-rock combination. The developed models were checked using various prediction performance indices and compared with the ANN.

Laboratory Investigation

In this investigation, different types of sedimentary rocks (shale, dolomite, sandstone, limestone, and hematite), were collected from different locations of India taking care of variety of strength. During sample collection, each block was inspected for macroscopic defects so that it provides test specimens free of fractures and joints. Sound level measurement on pneumatic drill set up was carried out for five different rock samples. The size of the rock blocks was approximately 30 × 20 × 20 cm.

Equipment/Instrumentation

Drilling Machine

A jackhammer drill is a compressed air operated machine. The drill weighs 10–30 kg and is hand held. It can drill holes with diameter varying from 25 to 40 mm. It can be used to drill both vertical and horizontal holes up to 3 m depth. Drilling with the pneumatic drill consists essentially in the drill delivering blows against the bottom of the holes and lifting the rock cuttings. In the laboratory, all the sound level measurements were conducted on a commercially used jackhammer drill machine (Atlas Copco, RH658L) operated by compressed air with suitable arrangement made to measure applied thrust and air pressure. The important specifications of the jackhammer drill used were:

-

Weight of the jackhammer drill machine (28 kgs).

-

Number of blows per minute—2200.

-

Type of drill rod—Integral drill steel and Threaded (R22) type with tungsten carbide drill bit.

-

Recommended maximum air pressure—589.96 kPa.

-

Bit geometry—Chisel and Cross.

.

Equivalent Sound Level Measuring Instrument

Sound pressure levels were measured with a CENTER make Model 320, IEC 651 Type II sound level meter. The instrument was equipped with a CENTER make windscreen for minimizing the sound effect produced from wind, ½ inch electret condenser microphone, digital display, time weighting and level ranges. The microphone and the pre-amplifier assembly were mounted directly on the sound level meter. The sound level meter was calibrated before taking up any measurement using an acoustic calibrator available in the institute. For all measurements, the sound level meter was kept hand-held. The instrument was set to measure A- weighted sound levels in the range of 30 dB (A) to 130 dB (A).

Methodology

Determination of Rock Properties

Compressive strength is one of the most important mechanical properties of rock material, used in blast hole design. To determine the UCS of the rock samples, 54 mm diameter NX size core specimens, having a length-to-diameter ratio of 2.5:1 were prepared as suggested by ISRM standards [16]. Each block was represented by at least three core specimens. The oven dried and NX size core specimens were tested by using a microcontroller compression testing machine. The average results of uniaxial compressive strength (UCS) values of different rocks were arrived from the set of three measurements.

The abrasivity of rock samples was also determined in accordance with the International Society of Rock Mechanics (ISRM) suggested methods. For this purpose, Los Angeles abrasion apparatus was used.

Tensile strength (TS) of rock was obtained from Brazilian test. To determine the TS of the rock samples, 54 mm diameter NX-size core specimens, having a length less than 27 mm were prepared as suggested by ISRM standards (Brown, 1981). The cylindrical surfaces were made free of any irregularities across the thickness. End faces were made flat to within 0.25 mm and parallel to within 0.25°. The specimen was wrapped around its periphery with one layer of masking tape and loaded into the Brazilian tensile test apparatus across its diameter. Load was applied continuously at a constant rate so that failure occurred within 15–30 s. Three specimens of the same sample were tested and the average results of Brazilian TS of different rocks were obtained.

Collected different rock block samples of sedimentary rocks from different locations of India were used to determine the Schmidt hardness. The rock samples having an approximate dimension of 30 × 20 × 20 cm were prepared, and the test surfaces of all specimens were smoothened and polished. Schmidt hammer hardness test were carried out in the laboratory according to the ISRM suggested method. Schmidt hammer was held vertically and five impacts were carried out at each point, and peak rebound value was recorded. The test was repeated at least two times on any rock type and average value was recorded as rebound number. The hammer orientation was chosen in the same direction of stress application in UCS tests.

Determination of A-weighted Equivalent Sound Level

The rock samples were kept on the base plate and clamped properly with bolt and nut so that rock block does not move while drilling. The drill rod attached to the chuck of the drill machine and the bit tip is made to touch the rock block (Fig. 1). Initially collaring was done before starting drilling a hole in the rock. Air pressure was varied from 392, 441, 490, 539 and 588 kPa and for each air pressure, thrust is varied from 100 to 1000 N with an increment of 100 N on each rock sample. Noise measurements were carried out in open space (outdoor location) to reduce the effect of reflecting noise. In this laboratory investigation, three integral steel chisel bits with 30, 34, and 40 mm diameter and 42, 43, and 62 cm length were used. These bits were selected from among the available sizes.

For each air pressure and thrust combination holes were drilled in each rock and sound level measurements were carried out. For each air pressure and thrust mentioned above, the A-weighted equivalent continuous sound level was measured (30 s each at all the measurement locations and for a particular bit-rock combination) by holding the sound level meter at a distance of 15 cm from the drill rod, drill bit, exhaust, and operator’s position. Similarly, the A-weighted equivalent continuous sound level was measured at the operator’s position refers to the position of the operator’s ear, which was at a height of 1.7 m from the ground level and 0.75 m from the center of the experimental set up. Depth of the hole drilled was measured after the drilling operation in each rock block using vernier scale. The duration of drilling was recorded using a stop-watch and thereafter the penetration rate was determined from the depth of the hole drilled (mm) and the duration of drilling (s).

ANN Modeling

Artificial neural network model is developed by using the experimental data based on MLP. In order to develop a best possible MLP architecture based on good generalization ability and a compact structure, different training algorithms were compared. Detailed procedure used for developing the optimized MLP model for sedimentary rock type is given. Similar procedure is employed and results were obtained also for other types of rock.

Steady state experimental data were used for ANN modeling. Out of 750 data, approximately 70 % (525 data) were used in the training and remaining 225 data were employed for testing the models. Air pressure, bit diameter, thrust, penetration rate and A-weighted equivalent sound level were used as the input parameters. These input parameters cover the entire problem domain under study and are effective in their prediction. Rock properties such as UCS, Abrasivity, SRN, and TS, were the output parameters for the model. A schematic representation of the ANN model is shown in Fig. 2. Similarly, air pressure, thrust, bit diameter, and rock properties were used as the input parameters. Sound level and penetration rate, were the output parameters for the model. The architecture of the neural network model is shown in Fig. 3.

To ensure that each input provides an equal contribution in the ANN, the inputs to the model were pre-processed and scaled into a common numeric range (0, 1). A network with three hidden layer was used with a sigmoid activation function in the hidden layer and output layer.

The number of empirical equations obtained from the conventional statistical techniques for assessing the rock properties. The major demerit of statistical relations (e.g. regression analysis) is the prediction of mean values only. Consequently, low experimental values are overestimated, while high experimental values are underestimated. A neural network does not force the predicted value to be a mean value, thus preserving and using the existing variance of the measured data. Because of ANN’s ability to learn and generalize interactions among many variables, ANN's technology has been reported to be very useful in modeling the rock material behaviour. Study indicated that ANN technology is more powerful than conventional statistical techniques in predicting penetration rate, sound level and rock properties.

One of the most important aspects of NN is the learning process. Learning cycle in ANN model is as shown in Fig. 4. In this study, feed forward networks namely MLP have been used to develop the prediction model of rock properties and penetration rate and sound level.

The multilayer feed-forward network is the most commonly used network architecture with the back propagation algorithm. Back propagation networks, and multilayered perceptrons, in general, are feed forward networks with distinct input, output, and hidden layers. The units function basically like perceptrons, except that the transition (output) rule and the weight update (learning) mechanism are more complex.

Back Propagation

Back-propagation Neural Network (BPNN) algorithm is widely used in solving many practical problems. The BPNN learns by calculating the errors of the output layer to find the errors in the hidden layers. Due to this ability of back-propagation, it is highly suitable for problems in which no relationship is found between the output and inputs. Due to its flexibility and learning capabilities, it has been successfully implemented in wide range of applications. A Back-propagation Network consists of at least three layers of units: an input layer, at least one intermediate hidden layer, and an output layer. Typically, units are connected in a feed-forward fashion with input units fully connected to units in the hidden layer and hidden units fully connected to units in the output layer.

The input pattern is presented to the input layer of the network. These inputs are propagated through the network until they reach the output units. This forward pass produces the actual or predicted output pattern. Because Back propagation is a supervised learning algorithm, the desired outputs are given as part of the training vector. The actual network outputs are subtracted from the desired outputs and an error signal is produced. This error signal then serves as the basis for the back propagation step, whereby the errors are passed back through the neural network by computing the contribution of each hidden processing unit and deriving the corresponding adjustment needed to produce the correct output. The connection weights are then adjusted and the neural network has just “learned” from an experience. Once the network is trained, it will provide the desired output for any of the input patterns.

Steps of the Back Propagation Algorithm

The MLP network was implemented using MATLAB Neural Network Toolbox. The network was trained using four different back-propagation training algorithms namely, Resilient Back-propagation algorithm (trainrp), Scaled Conjugate Gradient algorithm (trainscg), Gradient descent with adaptive learning back-propagation algorithm (traingda) and Levenberg–Marquardt algorithm (trainlm). The output of the network was compared with the desired output at each presentation and the error was computed. This error was then back-propagated to the network and used for adjusting the weights in such a way that the error decreased with iteration. Mean square errors (MSE) of 1.0e−5, a minimum gradient of 1.0e−5 and maximum number of epochs of 2000 were used. The training process would stop if any of these conditions is met. For each of the training algorithms, a number of trials were conducted initially to fix the number of neurons in the hidden layer. The number of neurons for which MSE is minimum, was selected as the optimum number of neurons in the hidden layer.

Results and Analysis

Results obtained from the laboratory tests and their basic statistical evaluations such as minimum, maximum, average values and standard deviations of different parameters and range (minimum and maximum) of A-weighted equivalent sound level and penetration rate (mm/sec) recorded during drilling of different rocks are given in Table 1. For collected rock types, the variation of penetration rate (0.64–2.15 mm/s) and equivalent sound level (Leq) with mechanical properties of rocks using integral drill bit diameter of 30, 34 and 40 mm for sedimentary rocks are shown in Fig. 5a–c. Experimental mean values and ANN predicted mean values using trainlm algorithm for sedimentary rocks using integral drill bit diameters of 30, 34 and 40 mm are shown in Fig. 6a–d.

The modeling of penetration rate and sound level produced during drilling is influenced by many factors. Artificial neural networks are widely used as one of the ways to tackle complex and ill defined problems. They are nonlinear information processing systems, which are built from interconnected elementary processing device called neurons [6]. ANNs can accommodate input variables to predict multiple output variables. A commonly used ANN model is a feed forward network with supervised learning which contains an input layer, some hidden layers and an output layer.

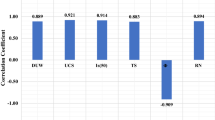

The architecture and performances of the network using different training algorithms are given in Table 2. It is clear from Table 2; that, trainlm converges faster than all other training algorithms as the number of epochs as well as the time taken for convergence is less. The variation of MSE with the number of neurons in the hidden layer for trainlm algorithm is shown in Fig. 7. From the Fig. 7, it can be observed that for the performance model, when the number of neurons in the hidden layer was increased (13,10,7) the error was 0.0001 and it decreased as the number of neurons in the hidden layer (7, 4, 2) was decreased and reached maximum of 0.000132 and on increasing the number of neurons further, MSE gradually increased. Training results based on the 5–3–4 configuration, training and testing data error of sedimentary rock is shown in Figs. 8–11. Performance of the developed model of ANN for sedimentary rocks using integral drill bit is as shown in Figs. 5–6, 12–13.

Performance Prediction of the Model

Trained networks were tested for performance. The performances of the networks were evaluated using Values Account For (VAF) and Root Mean Square Error (RMSE) indices [2, 17–20]. VAF, RMSE and MAPE can be computed using Eqs. (2, 3 and 4) respectively.

where y and y′ are the experimental value and ANN predicted value respectively. The calculated indices are given in Tables 3 and 4. If the VAF is 100 and RMSE is 0, then the model will be excellent. Mean absolute percentage error (MAPE) which is a measure of accuracy in a fitted series value in statistics was also used to check the prediction performances of the models. MAPE usually expresses accuracy as a percentage (Eq. 3).

where Ai is the experimental value and Pi is the ANN predicted value. Lower value of MAPE shows that there is a better correlation between predicted values and experimental results. The obtained values of RMSE, VAF and MAPE, are given in Tables 3 and 4.

The network performance for different training algorithms is shown in Table 5. It is clear from the table, VAF values are maximum; RMSE and MAPE values are minimum for the network using train algorithm when compared to the other models for both training and testing data. VAF values were 95.576, 94.284, 96.215 and 93.317 % for UCS, Abrasivity, TS and SRN respectively, whereas for the test data these values were 90.567, 91.324, 92.253 and 89.137 % respectively. Further, the RMSE values were 0.1530, 0.0316, 0.0172 and 1.689 for UCS, Abrasivity, TS and SRN respectively for the training data, whereas for the test data these values were 0.1813, 0.0349, 0.0199 and 5.043 respectively for the test data. MAPE values for the training data were 4.424, 5.216, 3.785 and 6.683 % for UCS, Abrasivity, TS and SRN respectively, whereas, the corresponding values for the testing data were 9.433, 8.676, 7.468 and 10.629 %. Hence, the MLP model with trainlm algorithm can be effectively used as a predictor of rock properties based on sound level produced during drilling. Also, performance prediction indices of different training algorithm for mechanical properties of sedimentary rocks using integral drill bit is given in Tables 6 and 7, and performance of different training algorithm for sound level and penetration rate of sedimentary rocks using integral drill bit is given in Tables 6 and 7.

Conclusions

This paper discusses the use of ANN for the prediction of rock properties such as UCS, abrasivity, TS, and SRN. Penetration rate and A-weighted equivalent sound level were measured during the drilling of rock. The experiments were carried out using parameters like air pressure, thrust, bit diameter, penetration rate and sound level. These were used as input features for a feed forward type ANN, namely, MLP. Different training algorithms were tested in order to study the generalization performance of the network. The performance comparison showed that trainlm algorithm gave the best generalization performance, with an accuracy of around 89–95 % (VAF) on the test (unseen) data, with minimum training epochs. Hence, this work establishes the effectiveness of ANN for prediction of rock properties using penetration rate and sound level produced during drilling.

References

T.N. Singh, R. Kanchan, A.K. Verma, S. Singh, An intelligent approach for prediction of triaxial properties using unconfined uniaxial strength. Min. Eng. J. 5, 12–16 (2003)

I. Yilmaz, A.G. Yuksek, An example of artificial neural network application for indirect estimation of rock parameters. Rock Mech. Rock Eng. 41(5), 781–795 (2008)

D. Rumelhart, J. McClelland, Parallel Distributed Processing: Explorations in the Microstructure of Cognition (Bradford Books, MIT Press, Cambridge, 1986)

P.K. Simpson, Artificial Neural System Foundation, Paradigm, Application and Implementation (Pergamon Press, New York, 1990)

L. Zhang, J.H. Jiang, P. Liu, Y.Z. Liang, R.Q. Yu, Multivariate nonlinear modeling of fluorescence data by neural network with hidden mode pruning algorithm. Anal. Chim. Acta 344, 29–39 (1997)

S. Haykin, Neural Networks: A Comprehensive Foundation (MacMillan, New York, 1994)

J.V. Tu, Advantages and disadvantages of using artificial neural networks versus logistic regression in predicting medical outcomes. J. Clin. Epidemiol. 49, 1225–1231 (1996)

M. Majors, J. Stori, C. Dongil, Neural network control of automotive fel-injection systems. Control Syst. Mag. IEEE 14, 31–36 (2002)

C.E. Arzum, K. Yalcin, Evaluating and forecasting banking crises through neural network models: an application for Turkish banking sector. Expert Syst. Appl. 33, 809–815 (2007)

L. Bor-Ren, R.G. Hof, Neural networks and fuzzy logic in power electronics. Control Eng. Pract. 2, 113–121 (2003)

Z. Xiaotian, X. Hong Wang, L. Li, H. Li, Predicting stock index increments by neural networks: the role of trading volume under different horizons. Expert Syst. Appl. 34, 3043–3054 (2008)

G.R. Cheginia, J. Khazaeia, B. Ghobadianb, A.M. Goudarzic, Prediction of process and product parameters in an orange juice spray dryer using artificial neural networks. J. Food Eng. 84, 534–543 (2008)

N.S. Peranbur, A. Preechayasomboon, Development of a neuroinference engine for ADSL modem applications in telecommunications using an ANN with fast computational ability. Neurocomputing 48, 423–441 (2002)

N. Huang, K.K. Tan, T.H. Lee, Adaptive neural network algorithm for control design of rigid-link electrically driven robots. Neurocomputing 71, 885–894 (2008)

P. Venkatesan, S. Anitha, Application of a radial basis function neural network for diagnosis of diabetes mellitus. Curr. Sci. 91(9), 1195–1199 (2006)

E.T. Brown, Rock characterization testing and monitoring. In International Society of Rock Mechanics (ISRM) Suggested Methods (Pergamon, Oxford, 1981)

M. Alvarez Grima, R. Babuska, Fuzzy model for the prediction of unconfined compressive strength of rock samples. Int. J. Rock Mech. Min. Sci. 36, 339–349 (1999)

J. Finol, Y.K. Guo, X.D. Jing, A rule based fuzzy model for the prediction of petrophysical rock parameters. J. Petrol. Sci. Eng. 29, 97–113 (2001)

C. Gokceoglu, A fuzzy triangular chart to predict the uniaxial compressive strength of the Ankara Agglomerates from their petrographic composition. Eng. Geol. 66, 39–51 (2002)

I. Yilmaz, A.G. Yuksek, Prediction of the strength and elasticity modulus of gypsum using multiple regression, ANN, ANFIS models and their comparison. Int. J. Rock Mech. Min. Sci. 46(4), 803–810 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kivade, S.B., Murthy, C.S.N. & Vardhan, H. ANN Models for Prediction of Sound and Penetration Rate in Percussive Drilling. J. Inst. Eng. India Ser. D 96, 93–103 (2015). https://doi.org/10.1007/s40033-015-0067-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-015-0067-7