Abstract

Determining properties of rocks in rock mechanics/engineering applications such as underground tunnelling, slope stability, foundations, dam design and rock blasting is often difficult due to the requirements of high quality of core rock samples and accurate test apparatus. Prediction of the geomechanical properties of rock material has been an area of interest for rock mechanics for several years now. Nowadays, soft computing methods are used as a powerful tool to estimate the rock properties, cost and duration of the project. This has led to a lack of necessity to develop a model to predict rock properties in the field of rock mechanics. ANN (artificial neural network) models were developed to predict geomechanical properties of the sedimentary rock types using dominant frequencies of an acoustic signal during rock drilling operations. A set of experimental drilling operations test conditions around 875 were used as input parameters including drill bit spindle speeds (rpm), drill bit penetration rates (mm/min), drill bit diameters (mm) and dominant frequencies of the acoustic signal (Hz). The response (output) was uniaxial compressive strength (UCS), Brazilian tensile strength (BTS), density (\(\rho \)) and abrasivity (%). The developed models were checked using various performance indices. The results from the analysis show that the suggested ANN model approach is efficient, fits the data and accurately reflects the experimental results. The ANN models predicted physico-mechanical rock properties through the dominant frequency of acoustic signals during rock drilling operations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rock properties are very essential for the purpose of excavations, tunnelling, exploration, foundations and other allied industries in rock mechanics engineering applications. It is very difficult to test rock properties in the laboratory because of the demanding requirements, the quality of rock core samples and the need for accurate test apparatus. The estimation of the rock properties using an approximate calculation technique (soft computing) is an alternative tool; it is of interest to mining and geotechnical engineers. The literature reports a significant amount of practical equations from the predictable numerical approaches for quantifying the rock mass material. A major disadvantage of statistical relationships (for example regression study) is the estimate of the mean value only. As a result, low experimental values are overvalued and high experimental values are miscalculated. But the ANN does not force the predicted value to be a mean value, thus accurately maintaining the existing difference between the measured data.

Many investigators widely used ANN techniques such as multilayer perception (MLP), Sugeno fuzzy logic (SFL), adaptive neuro-fuzzy interface system (ANFIS), radial-based function (RBF), support vector machine (SVM), Mamdani fuzzy logic (MFL), for prediction of uniaxial compressive strength, degree of variability of rock, water quality index and probability of distribution function of dumpers. They used experimental data sets of 80% for testing and 20% for training for constructing the models. They concluded that SVM model prediction was better than MFL, RBF, ANFIS, MLP and SFL (Okon et al. 2020; Shahri et al. 2020; Kumar et al. 2019a, b, c, d; Yilma et al. 2018; Barzegar et al. 2016; Handhal 2016; Mohammadreza and Yousef 2019; Raj et al. 2020).

The ANN is able to significantly generate the suitable output from difficult or inexact information (data). It can detect the exact patterns from complex data which are predictable neither by the human brain nor by other methods of statistical analysis. It investigates the self-organised interactions between variables. Many researchers reported on the modelling of the rock mass materials and its behaviour using neural networks (Ghabousi et al. 1991; Haykin 1998; Singh et al. 2001,2003; Bhatnagar and Khandelwal 2012; Salimia et al. 2015; Momeni et al. 2015; Tripathy et al. 2015; Madhubabu et al. 2016; Abdi et al. 2018; Rastegarnia et al. 2018). They also developed correlations between geological strength index, brittleness index and temperature using various statistical approaches (Fajana 2020; Fatoba et al. 2020; Ohaegbuchu and Igboekwe 2016; Ardestani et al. 2019; Jamshidi 2018; Aka et al. 2018; Akbarpour and Abdideh 2020; Dolui et al. 2016; Ghosh et al. 2016; Salehin et al. 2020; Dehkordi et al. 2019; Kumar et al. 2018a, b, 2019a, b, c, d, 2020a, b). Rumelhart et al. (1986) proved that the ANN model was perfect for classifying complex information for the demands of a new situation (Simpson 1990). Another advantage of ANN includes self-organisation, adaptive learning based on real-time operations, self-organised redundant information coding and fault tolerance. Nevertheless, various networks can be retained even when the main network is impaired (Yilmaz and Sendir 2002; Yilmaz and Yuksek 2008; Yilmaz 2010; Yilmaz and Kaynar 2011). Meulenkamp and Grima (1999) examined the possibility of estimating unconfined compressive strength using ANN for the toughness of rocks with Equotip hardness tester based on rock toughness, dry density and sizes of the grains.

Singh et al. (2001) established the necessary models to predict the geomechanical behaviour of the rock mass. Statistical analysis (ANN) was performed to estimate the rock mass properties, i.e. uniaxial compressive strength, point load strength index and Brazilian tensile strength based on the texture and composition of the rock mass. Several researchers have also established ANN predictive models to evaluate the physico-mechanical properties of rock mass such as static modulus of elasticity (E), uniaxial compressive strength, density, shore scleroscope test hardness, shear strength, slack durability and point load strength index and many other complex properties of rock mass (Sarkar et al. 2010; Dehghan et al. 2010; Zorlu et al. 2008; Sonmez et al. 2006; Tiryaki 2008a, b, 2001; Tiryaki et al. 2001; Ocak and Seker 2012). Yilmaz and Kaynar (2011) developed prediction equations for rock mass from soft computing methods. The neuro-fuzzy and ANN techniques were used to predict the swell percentage of the soil. It was concluded that these soft computing techniques are useful for reducing the uncertainties in the geotechnical applications.

However, some of the studies reported the utility of the perceptible noise and wavelet algorithm to estimate the rock bursts and presence of carbon dioxide (CO2) in the metal mines and derived the relationship between the geomechanical rock materials and acoustic emission for prediction of rock properties (Ekanem et al. 2020; Raj et al. 2016; Talkhablou et al. 2019; Obert 1941; Obert and Duvall 1942; Rafavich et al. 1984; Hardy 1972; McNally 1990; Milklusova et al. 2006; Krepelka and Futo 2007; Gradl et al. 2007; Zborovjan 2001,2002; Zborovjan et al. 2003; Flegner et al. 2014,2019; Liu et al. 2019). Vardhan and Murthy (2007) conducted a laboratory experiment to predict rock properties with equivalent noise levels generated by jackhammer percussive drilling. Many researchers have developed mathematical models for prediction of rock mass properties (Vardhan et al. 2009; Kumar et al. 2013; Narayana et al. 2019, 2020a, b; Kivade et al. 2015; Shreedharan et al. 2014; Delibalta et al. 2015; Kahraman et al. 2013; Finol et al. 2001; Gokceoglu 2002; Hassanpour et al. 2011; Teymen 2019; Krúpa et al. 2018; Omar et al. 2018; Aldeeky and Hattamleh 2018; Cao et al. 2010; Liao et al. 2018).

The literature review suggests that the ANN modelling approach is more advanced than the conventional statistical techniques (e.g. regression). The use of neural networks reduces the potential inconsistency of correlations and services in advanced computing techniques. Kumar et al. (2019a, b, 2020a) have recently attempted to correlate various rock properties using simple linear and multiple regression methods with the help of dominant frequencies produced during rock core drilling operations. They used combinations of drilling operational parameters to quantify the rock properties. Further, they suggested for work in this direction. However, it is evident that predictions of rock properties using ANN have not been used in the rock mechanics using dominant frequencies of acoustics. Therefore, this study is undertaken in this direction.

Test samples used in the research

Seven sedimentary rock types including (1) ochre, (2) bituminous coal, (3) laterite, (4) pink limestone, (5) black limestone, (6) iron stone and (7) dolomite were used to perform core drilling operations. The rock specimen’s sizes were 20 cm3. These seven rocks were collected from parts of Karnataka and Andhra Pradesh, India.

Description of equipment

BMV 45 T20 CNC drilling machine

The drilling tests were conducted with a computerised drilling machine (CNC-BMV 45 T20) operated by computer numerical control programming. The CNC drilling machine has an optimum air pressure of 6 bar. The length, width and height of the experimental room were 6, 5 and 9 m, respectively, and the room was covered with fibre panels and glass.

Data acquisition NIUSB-9234 and G.R.A.S. 40PH microphone

The DAQ (data acquisition NIUSB-9234) and G.R.A.S. 40PH microphone with programmable LabVIEW software was used to acquire the sound signals and the sound pressure levels from the rock drilling operations. The microphone receives the variations in the sound pressure levels from rock drilling operations. It converts them into electrical signals. The data acquisition is the crux of the signal processing like noise and vibration; it acquires the raw data from the source and explains meaningful content with the help of LabVIEW software algorithms. Compared to traditional measurement systems, it effectively processes signal (Forouharmajd et al. 2015). The specifications of the microphone are output impudence = < 50 Ω, power source = 2–20 m A (4 m A), sensitivity = 50 mv/pa (± 2 dB), dynamic range = 32 dB (A)—135 dB, and frequency range = 10–20 kHz, (± 3 dB). The specifications of data acquisition (DAQ) are as follows: number of channels = 4 analogue input, analogue-to-digital converter delta—sigma, and resolution = 24 bits.

Methodology

Determination of geomechanical properties of rock materials

The geomechanical properties of rock materials were determined as per the procedures recommended by ISRM suggested methods. Kumar et al. (2019a, b, 2020a) explained the methodology of UCS, BTS and dry density. Table 1 shows these rock mass properties.

Determination of Los Angeles abrasion

Los Angeles abrasion (LA) is defined as the resistance to wearing and abrasion of rock aggregates. Initially, several types of rock aggregates were prepared as per ISRM standards (i.e. sieve passing at 25.4 mm, retained on 19.0 mm). The rock aggregates with 1250 ± 25 g were placed in the LA testing apparatus and tightly locked. The cylindrical drum revolved 500 times at a constant speed of 30–33 rpm. The discharged material was sieved on a 1.7 mm sieve. The rock aggregates coarser than 1.7 mm were washed substantially and weighted to the nearest gram for their LA percentage wear to be determined. Equation (1) is used to determine the LA percentage wear.

Experimental arrangement

The core drilling operations were conducted using a computer numerical controlled drilling machine (BMVK 45 T20) as shown in Fig. 1. During the drilling operations, this study used five types of diamond core drill bits with diameters of 6, 10, 16, 18 and 20 mm, penetration rates of 2, 3, 4 5 and 6 mm/min, and drill bit speeds of 150, 200, 250, 300 and 350 rpm. The rock samples were kept tightly between a vice with the help of two long nuts and bolts. The DAQ microphone was kept at 1.5 cm from the periphery of the drill bit to measure the sound level. The microphone was attached to a DAQ NIUSB-9234 with a channel cable which was connected to a personal computer with a USB cable. The sound pressure level (frequency of the sound) could be seen over the DAQ personal computer (DAQ-PC). However, Fig. 1 also shows spark 705 + noise dosimeter, dosimeter microphone, noise dosimeter PC, dynamometer and dynamometer digital indicator. The dynamometer was used to determine the specific level of energy which encompasses the further scope of this study.

Geomechanical properties of rock materials sound signal measurement

The geomechanical properties of rock materials with sound signal measurement were conducted using DAQ NIUSB-9234 with various bit–rock combinations as shown in Fig. 1. The microphone was placed 1.5 cm from the drill bit diameter for all geomechanical properties of rock materials sound signal measurements. The DAQ NIUSB-9234 can record around 51,200 samples of sound signals within 1 s. The highest amplitude of FFT was chosen to analyse the time-domain plots. The LabVIEW software code was used to record accurate sound pressure levels during drilling operations for this investigation. The LabVIEW block diagram code is shown in Fig. 2a, b.

The sound pressure levels were recorded for 60 s for selected combinations of drill bit diameters, penetration rates and drill bit speeds. The selected drilling test condition combinations correspond to the sound pressure level at dominant frequencies as shown in Table 2. A total of 125 test conditions were arrived at for selected rock blocks (seven types of rocks × 125 test conditions = 875). The sound pressure levels were recorded 60 s for all 875 test conditions. These 60-s sound pressure data were utilised to determine the dominant frequencies using frequency analysis. Drill bit diameters in mm, spindle speed in RPM, penetration rate in mm/min and dominant frequencies (Hz) were used as input parameters for ANN modelling of rock mass properties. The response was considered for UCS, BTS, density and abrasivity.

Determining dominant frequencies

The dominant frequencies were selected based on the fast Fourier transform (FFT). The FFT is the process of a time-varying signal altered to its frequency domain. The sound pressure levels were recorded for duration of 60 s after drill bit penetration into selected rock samples corresponding drilling operational parameters such as drill bit diameters, penetration rates and spindle speeds. The operational drilling parameters and dominant frequencies are shown in Table 2. These 60-s duration data were used to determine dominant frequencies using FFT analysis. Initially, the signals were analysed using time domain, and then the time-domain peak amplitude time (sec) was treated as peak amplitude. These peak amplitude FFTs were considered in the selection of a dominant frequency. The dominant frequencies were chosen to be between 5000 and 8000 Hz from the selected FFTs. This range reports rock porting acoustic signals defined by Zborovjan (2001, 2002), Zborovjan et al. (2003). These frequencies were used for a feedforward-type ANN (MLP) as training and testing data to predict the rock properties during rock drilling. The time and frequency domains shown in Figs.3a–g and 4a–g correspond to the test conditions, i.e. drill bit diameter 10 mm, penetration rate 2 mm/min and spindle speed 350 rpm (10, 2 and 350). The time-domain plots in Fig. 3a–g show that the peak amplitude corresponds to 21, 22, 37, 30, 48, 23 and 9 s for ochre, bituminous coal, laterite, pink limestone, black limestone, iron stone and dolomite, respectively. The peak amplitude FFT in this time domain was used to select dominant frequencies of 5240, 7629, 5525, 7789, 7943, 6735 and 6975 Hz for ochre, bituminous coal, laterite, pink limestone, black limestone, iron stone and dolomite, respectively.

Results and analysis

The geomechanical properties of rock materials of the results from the laboratory investigations based on the statistical assessments such as standard deviation, maximum, minimum and mean values. The dominant frequencies between 5000 and 8000 Hz were selected for all the rock types, as pointed out by the Zborovjan (2001, 2002) and Zborovjan et al. (2003). The variations of the dominant frequencies during drilling operations with geomechanical rock properties (UCS, BTS, density and abrasivity) at the speed of 350 rpm, the penetration rate of 6 mm/min and the drill bit diameter of 18 mm for selected rock types are shown in Fig. 5.

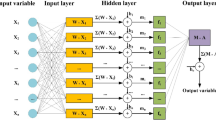

The modelling of the dominant frequencies generated through a drilling operation is influenced by various factors. ANN resolves various complex problems with its vast data. It can replicate the functioning of human brain cells and the processing of the data through neurons like interrelated elementary processing device (Haykin 1998; Meireles et al. 2003; Yilmaz 2009). ANN architecture contains an input layer, an output layer and a hidden layer known as a feedforward network. It can support an input (multiple) variable to predict the output (multiple) variables.

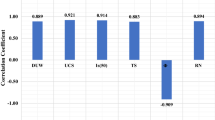

Artificial neural network modelling

A total of 875 test conditions experimental data were used to predict geomechanical rock properties during drilling operations to model rock properties through ANN. Out of these, 70% data (612 test conditions) were used for the training set and the remaining 30% data (263 test conditions) were used to test the models. Figure 6 shows the multi-layer perceptron (MLP) generalised structure of the ANN model. The spindle speed, penetration rate, dominant frequencies and drill bit diameter were employed as input parameters, while the output responses were UCS, BTS, dry density and abrasivity in these models. These input parameters are effective for constructing the ANN prediction model and cover the problem of the domain being investigated.

It was ensured that every input variable delivers an equal contribution in the neural network architecture. The network architecture panel details the particular network used to solve the problems with sigmoid activation function in the hidden and output layer. One hidden layer was used to predict geomechanical properties of rock materials in this investigation. The hidden layer computes the weighted inputs and produces the net input which is then applied with sigmoid activation functions to produce the actual output. The multi-layer perceptron network was employed by MATLAB 2015 ANN toolbox. Seven types of back-propagation training algorithms were used to train the data sets. These algorithms show the network accuracy and the performance (mean square error—MSE) of the plots. The seven algorithms are trainscg (scaled conjugate gradient algorithm), traingda (gradient descent with adaptive learning back-propagation algorithm), trainrp (resilient back-propagation algorithm), traingdx (gradient descent with momentum and adaptive learning back-propagation algorithm, trainlm (Levenberg–Marquardt algorithm), trainbfg (BFGS quasi-Newton back-propagation algorithm) and traincgf (conjugate gradient back-propagation with Fletcher–Reeves updates algorithm).

While training the algorithms, the number of neurons in the hidden layer was estimated using the trial-and-error method. It revealed that 6–35 neurons were used in a hidden layer with the tansig transfer function corresponding to seven types of back-propagation training algorithms. Primarily, several trails were conducted to fix the number of neurons in the hidden layer for every type of algorithms. The minimum RMSE value and the maximum VAF value were selected for the optimal number of neurons in the hidden layer. The seven types of back-propagation training algorithms performance and network architecture are shown in Tables 3 and 4. Table 3 clarifies that “resilient back-propagation algorithm (trainrp)” was the most significant (fewer epochs and the time take convergence is lesser) of the seven back-propagation training algorithms with 35 neurons and minimum number of epochs—9—for the prediction of geomechanical properties of rock material. This is the optimal number because of the low RMSE value with the highest value of regression (R), respectively.

The errors in geomechanical rock properties as shown in Figs. 7 and 8 are calculated based on a comparison of the data about the measured geomechanical rock properties and the ANN predictions. Figure 8 shows that the resilient back-propagation algorithm (trainrp) predicted geomechanical rock properties (UCS, BTS, density and abrasivity) with less than 10% error.

Performance prediction of training and testing algorithms model

The ANN models were checked by various performance indices to find the correlation coefficients of the models. The performance indices were computed using Eqs. (2)–(4):

Table 3 shows the performance of the neural network training algorithms. It is apparent that values accounting for (VAF), root-mean-square error (RMSE) and mean absolute percentage error (MAPE) are minimum for the network using trainrp (resilient back-propagation algorithm) corresponding to the other types of the algorithms for both testing and training data. The values accounting for (VAF) for training data were 99.88889755, 97.68637706, 99.81301744 and 99.87040879% for UCS, BTS, density and abrasivity, respectively. Conversely, the values for testing data were 96.86481391, 99.99156503, 96.57112216 and 99.81102796%, respectively. Additionally, the root-mean-square error (RMSE) values for training data were 0.028310352, 1.000170242, 0.00013771 and 1.000840687 for UCS, BTS, density and abrasivity, respectively, whereas the values for testing data were 0.008283036, 0.000813739, 1.000000901 and 0.000483. The mean absolute percentage error (MAPE) values for training data were 3.00774799, 0.000674671, 1.003452443 and 1.001654485, respectively. However, the values for testing data were 1.00063162, 1.001236596, 0.00181521 and 2.000732, respectively. Hence, the trainrp (resilient back-propagation algorithm) algorithm could be efficiently used as a predictor to estimate the geomechanical properties of rock material based on the dominant frequency of acoustic signals during diamond core drilling operations.

Conclusion

Rock properties in this study were predicted using train and test data employed in the ANN with the help of the recorded sound levels at dominant frequencies during core drilling operations in the laboratory. The operational parameters such as drill bit diameters, penetration rates and spindle speeds including dominant frequencies were used as input parameters to the feedforward back-propagation ANN type. Around seven types of training algorithms were tested to generalise the performance of the network. The comparison of the performance reports shows that resilient back-propagation algorithm (trainrp) is the best with an accuracy of 96–97% (values accounted for), 0.00013771–1.000840687 (root-mean-square error) and 0.000674671–3.00774799 (mean absolute percentage error) on the training and testing data associated with minimum epochs. It can be said that the ANN predicts the geomechanical properties of rock materials using the dominant frequency of acoustic signals produced during core drilling operations. In this investigation, the ANN technique was used to predict rock properties using dominant frequencies during drilling. Further investigation in this area can be conducted using the “Fuzzy logic” technique for the sound levels generated during rock drilling operations.

References

Abdi Y, Garavand AT, Sahamieh RZ (2018) Prediction of strength parameters of sedimentary rocks using artificial neural networks and regression analysis. Arab J Geosci 11:587

Aka MU, Okeke FN, Ibuot JC, Obiora DN (2018) Geotechnical investigation of near-surface structures using seismic refraction techniques in parts of akwa ibom state, southern nigeria. Model Earth Syst Environ 4(2):451–459

Akbarpour M, Abdideh M (2020) Wellbore stability analysis based on geomechanical modeling using finite element method. Model Earth Syst Environ 6:617–626

Aldeeky H, AlHattamleh O (2018) Prediction of engineering properties of basalt rock in jordan using ultrasonic pulse velocity test. Geotech Geol Eng 36(6):3511–3525

Ardestani EA, Davarpanah A, Zargar G, Mirshekari B (2019) Mathematical modeling of formation damage effect during underbalanced drilling operations. Model Earth Syst Environ 5(4):1651–1661

Barzegar R, Sattarpour M, Nikudel MR, Moghaddam AA (2016) Comparative evaluation of artificial intelligence models for prediction of uniaxial compressive strength of travertine rocks, case study: Azarshahr area, NW Iran. Model Earth Syst Environ 2(2):76

Bhatnagar A, Khandelwal M (2012) An intelligent approach to evaluate drilling performance. Neural Comput Appl 21(4):763–770

Cao QJ, Wiercigroch M, Pavlovskaia E, Yang SP (2010) Bifurcations and the penetrating rate analysis of a model for percussive drilling. Acta Mech Sin 26(3):467–475

Dehghan S, Sattari GH, Chelgani SC, Aliabadi MA (2010) Prediction of uniaxial compressive strength and modulus of elasticity for travertine samples using regression and artificial neural networks. Min Sci Technol 20(1):41–46

Dehkordi MS, Lazemi HA, SaeedModaghegh HR (2019) Estimation of the drop modulus using the brittleness index of intact rock and geological strength index of rock mass, case studies: Nosoud and Zagros tunnels in Iran. Model Earth Syst Environ 5(2):479–492

Delibalta MS, Kahraman S, Comakli R (2015) The usability of noise level from rock cutting for the prediction of physic–mechanical properties of rocks. Fluct Noise Lett 14(1):1550006

Dolui G, Chatterjee S, Chatterjee ND (2016) Geophysical and geochemical alteration of rocks in granitic profiles during intense weathering in southern Purulia district, West Bengal. India Model Earth Syst Environ 2(3):132

Ekanem AM, George NJ, Thomas JE, Ekpenyong NE (2020) Seismic modelling study of CO 2 effects on P-wave amplitude. Modeling Earth Systems and Environment 00904–9

Fajana AO (2020) Geohazard characterization of subsurface materials using integrated geophysical methods for post foundation studies: a case study. Modeling Earth Systems and Environment 1–13

Fatoba JO, Eluwole AB, Sanuade OA, Hammed OS, Igboama WN, Amosun JO (2020) Geophysical and geochemical assessments of the environmental impact of Abule-Egba landfill, southwestern Nigeria. Modeling Earth Systems and Environment, pp 1–7

Finol J, Guo YK, Jing XD (2001) A rule based fuzzy model for the prediction of petro physical rock parameters. J Pet Sci Eng 29:97–113

Flegner P, Kačur J, Durdán M, Leššo I, Laciak M (2014) Measurement and processing of vibro-acoustic signal from the process of rock disintegration by rotary drilling. Measurement 56:178–193

Flegner P, Kačur J, Durdán M, Laciak M (2019) Processing a measured vibroacoustic signal for rock type recognition in rotary drilling technology. Measurement 134:451–467

Forouharmajd F, Mohammadi Z, Ahmadvand M, Forouharmajd F (2015) Sound pressure level tools design used in occupational health by means of labview software. Int J Environ Health Eng 4(1):1–6

Ghaboussi J, Garrett JH Jr, Wu X (1991) Knowledge-based modeling of material behavior with neural networks. J Eng Mech 117(1):132–153

Ghosh PK, Bandyopadhyay S, Jana NC (2016) Mapping of groundwater potential zones in hard rock terrain using geoinformatics: a case of kumari watershed in western part of West Bengal. Model Earth Syst Environ 2(1):1

Gokceoglu C (2002) A fuzzy triangular chart to predict the uniaxial compressive strength of the Ankara agglomerates from their petrographic composition. Eng Geol 66:39–51

Gradl C, Eusteslll AW, Thonhauser G (2007) An analysis of noise characteristics of drill bits. J Energy Resour Technol 134(013103):1–6

Handhal AM (2016) Prediction of reservoir permeability from porosity measurements for the upper sandstone member of Zubair Formation in Super-Giant South Rumila oil field, southern Iraq, using M5P decision tress and adaptive neuro-fuzzy inference system (ANFIS): a comparative study. Model Earth Syst Environ 2(3):111

Hardy HR (1972) Application of acoustic emission techniques to rock mechanics research acoustic emission ASTM STP 505. American Society for Testing and Materials, pp 41–83

Hassanpour J, Rostami J, Zhao J (2011) A new hard rock TBM performance prediction model for project planning. Tunn Undergr Space Technol 26(5):595–603

Haykin S (1998) Neural networks: a comprehensive foundation. Prentice Hall PTR, Upper Saddle River, NJ, USA

Jamshidi A (2018) Prediction of TBM penetration rate from brittleness indexes using multiple regression analysis. Model Earth Syst Environ 4(1):383–394

Kahraman S, Delibalta MS, Comakli R (2013) Noise level measurement test to predict the abrasion resistance of rock aggregates. Fluct Noise Lett 12(4):1350021

Kivade SB, Murthy ChSN, Vardhan H (2015) ANN models for prediction of sound and penetration rate in percussive drilling. J Inst Eng 96(2):93–103

Krepelka F, Futo J (2007) Acoustics aspects of technological process in the rock identification. Acta montanistica slovaca 12(1):25–28

Krúpa V, Kruľáková M, Lazarová E, Labaš M, Feriančiková K, Ivaničová L (2018) Measurement, modeling and prediction of penetration depth in rotary drilling of rocks. Measurement 117:165–175

Kumar BR, Vardhan H, Govindaraj M, Vijay GS (2013) Regression analysis and ANN models to predict rock properties from sound levels produced during drilling. Int J Rock Mech Min Sci 58:61–72

Kumar SV, Kunar BM, Murthy ChSN (2018a) Experimental investigation and statistical analysis of operational parameters on temperature rise in rock drilling. Int J Heat Technol 36(4):1174–1180

Kumar SV, Murthy ChSN, Kunar BM (2018b) Effect of thermal response on physical properties during drilling operations a case study. Mater Today 5(2):7404–7409

Kumar NH, Choudhary RP, Murthy CS (2019a) Evolution of the probability distribution function of shovel–dumper combination in open cast limestone mine using RWB and ANN: a case study. Model Earth Syst Environ 5(4):1607–1613

Kumar CHV, Vardhan H, Murthy CS (2019b) Quantification of rock properties using frequency analysis during diamond core drilling operations. J Inst Eng 100(1):67–81

Kumar CHV, Vardhan H, Murthy CS, Karmakar NC (2019c) Estimating rock properties using sound signal dominant frequencies during diamond core drilling operations. J Rock Mech Geotech Eng 11(4):850–859

Kumar SV, Kunar BM, Murthy ChSN (2019d) Temperature measurement during rotary drilling of rocks a statistical approach learning and analytics in intelligent systems. Springer Book Series 2:303–309

Kumar CHV, Vardhan H, Murthy CS (2020a) Multiple regression model for prediction of rock properties using acoustic frequency during core drilling operations. Geomech Geoeng 15(4):297–312

Kumar CHV, Murthy CS, Vardhan H (2020b) Prediction of specific energy using dominant frequency of acoustics produced during diamond core drilling operations. AIP Conf Proc 2204(1):040003 (AIP Publishing LLC)

Kumar SV, Kunar BM, Murthy ChSN, Ramesh MR (2020c) Measurement of bit-rock interface temperature and wear rate of the tungsten carbide drill bit during rotary drilling. Friction 8(6):1073–1082

Kumar SV, Kunar BM, Murthy ChSN (2020d) ANN model for prediction of bit-rock interface temperature during rotary drilling of limestone using embedded thermocouple technique. J Therm Anal Calorim 139(3):2273–2282

Liao M, Liu Y, Chávez JP, ChongWiercigroch ASM (2018) Dynamics of vibro-impact drilling with linear and nonlinear rock models. Int J Mech Sci 146:200–210

Liu S, Li X, Li Z, Chen P, Yang X, Liu Y (2019) Energy distribution and fractal characterization of acoustic emission (AE) during coal deformation and fracturing. Measurement 136:122–131

Madhubabu N, Singh PK, Kainthola A, Mahanta B, Tripathy A, Singh TN (2016) Prediction of compressive strength and elastic modulus of carbonate rocks. Measurement 88:202–213

McNally GH (1990) The prediction of geotechnical rock properties from sonic and neutron logs. Aus Soc Explor Geophys 21(1/2):65–71

Meireles MR, Almeida PE, Simões MG (2003) A comprehensive review for industrial applicability of artificial neural networks. IEEE Trans Industr Electron 50(3):585–601

Meulenkamp F, Grima MA (1999) Application of neural networks for the prediction of the unconfined compressive strength (UCS) from Equotip hardness. Int J Rock Mech Min Sci 36(1):29–39

Miklusova V, Usalova L, Ivanicova L, Krepelka F (2006) Acoustic signal - new feature in monitoring of rock disintegration process. Contrib Geophys Geod 36:125–133

Mohammadreza AG, Yousef AG (2019) Modelling soil compaction of agricultural soils using fuzzy logic approach and adaptive neuro-fuzzy inference system (ANFIS) approaches. Model Earth Syst Environ 5(1):13–20

Momeni E, Armaghani DJ, Hajihassani M, Amin MFM (2015) Prediction of uniaxial compressive strength of rock samples using hybrid particle swarm optimization-based artificial neural networks. Measurement 60:50–63

Narayana CRL, Tripathi AK, Pal SK (2019) Estimation of rock strength properties using selected mechanical parameters obtained during the rotary drilling. J Inst Eng 100(2):177–186

Narayana CRL, Tripathi AK, Pal SK (2020a) Rock strength characterization using measurement while drilling technique. Indian Geotech J 50:994–1005

Narayana CRL, Tripathi AK, Pal SK (2020b) Prediction of mechanical properties of sedimentary type rocks using rotary drilling parameters. Geotech Geol Eng 38:4863–4876

Obert L. (1941) Use of sub audible noises for prediction of rock bursts—Part I. U.S. Bureau of Mines R.I.3555.

Obert L, Duvall W (1942) Use of sub audible noises for prediction of rock bursts—Part II.U.S. Bureau of Mines R.I.3654

Ocak I, Seker SE (2012) Estimation of elastic modulus of intact rocks by artificial neural network. Rock Mech Rock Eng 45(6):1047–1054

Ohaegbuchu HE, Igboekwe MU (2016) Determination of subsurface rock properties from AVO analysis in konga oil field of the niger delta, southeastern nigeria. Model Earth Syst Environ 2(3):124

Okon AN, Adewole SE, Uguma EM (2020) Artificial neural network model for reservoir petrophysical properties: porosity, permeability and water saturation prediction. Modeling Earth Systems and Environment, pp 1–18

Omar H, Ahmad J, Nahazanan H, Mohammed TA, Yusoff ZM (2018) Measurement and simulation of diametrical and axial indirect tensile tests for weak rocks. Measurement 127:299–307

Rafavich F, Kendall CH, Todd TP (1984) The relationship between acoustic properties and the petrographic character of carbonate rocks. Geophysics 49(10):1622–1636

Raj AS, Oliver DH, Srinivas Y, Viswanath J (2016) Wavelet denoising algorithm to refine noisy geoelectrical data for versatile inversion. Model Earth Syst Environ 2(1):36

Raj AS, Srinivas Y, Damodharan R, Oliver DH, Viswanath J (2020) Presentation of neurofuzzy optimally weighted sampling model for geoelectrical data inversion. Modeling Earth Systems and Environment, pp. 1–12

Rastegarnia A, Teshnizi ES, Hosseini S, Shamsi H, Etemadifar M (2018) Estimation of punch strength index and static properties of sedimentary rocks using neural networks in south west of Iran. Measurement 128:464–478

Rumelhart DE, McClelland JL (1986) PDP Research Group. Parallel distributed processing: Exploration in the microstructure of cognition 1

Salehin S, Hadavandi E, Chelgani SC (2020) Exploring relationships between mechanical properties of marl core samples by a coupling of mutual information and predictive ensemble model. Model Earth Syst Environ 6(1):575–583

Salimia A, Moormanna C, Singhb TN, Jainc P (2015) TBM performance prediction in rock tunneling using various artificial intelligence algorithms. In Proceeding 11th Iranian and 2nd Regional Conference Tunnels and the Future”, Stuttgart, Germany

Sarkar K, Tiwary A, Singh TN (2010) Estimation of strength parameters of rock using artificial neural networks. Bull Eng Geol Env 69(4):599–606

Shahri AA, Larsson S, Renkel C (2020) Artificial intelligence models to generate visualized bedrock level: a case study in Sweden. Model Earth Syst Environ 6:1509–1528

Shreedharan S, Hegde C, Sharma S, Vardhan H (2014) Acoustic fingerprinting for rock identification during drilling. Int J Min Miner Eng 5(2):89–105

Simpson PK (1990) Artificial neural systems: foundations, paradigms, applications, and implementations. Pergamon.

Singh VK, Singh D, Singh TN (2001) Prediction of strength properties of some schistose rocks from petrographic properties using artificial neural networks. Int J Rock Mech Min Sci 38(2):269–284

Singh TN, Kanchan R, Verma AK, Singh S (2003) An intelligent approach for prediction of triaxial properties using unconfined uniaxial strength. Min Eng J 5(4):12–16

Sonmez H, Gokceoglu C, Nefeslioglu HA, Kayabasi A (2006) Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. Int J Rock Mech Min Sci 43(2):224–235

Talkhablou M, Kianpour M, Aghda SF (2019) ArcGIS fuzzy modeling to assess the relationship between seismic wave velocity and electrical resistivity with limestone mass quality (case study: Asmari Formation, southwest Iran). Model Earth Syst Environ 5(3):1025–1035

Teymen A (2019) Estimation of Los Angeles abrasion resistance of igneous rocks from mechanical aggregate properties. Bull Eng Geol Env 78(2):837–846

Tiryaki B (2008a) Application of artificial neural networks for predicting the cuttability of rocks by drag tools. Tunn Undergr Space Technol 23(3):273–280

Tiryaki B (2008b) Predicting intact rock strength for mechanical excavation using multivariate statistics, artificial neural networks, and regression trees. Eng Geol 99(1–2):51–60

Tiryaki B, Ayhan M, Hekimoglu OZ (2001) A new computer program for cutting head design of roadheaders and drum shearers. In 17th International Mining Congress and Exhibition of Turkey–IMCET 655–662

Tripathy A, Singh TN, Kundu J (2015) Prediction of abrasiveness index of some Indian rocks using soft computing methods. Measurement 68:302–309

Vardhan H, Murthy ChSN (2007) An experimental investigation of jack hammer drill noise with special emphasis on drilling in rocks of different compressive strengths. Noise Control Eng J 55(3):282–293

Vardhan H, Adhikari CR, Govindaraj M (2009) Estimating rock properties using sound levels produced during drilling. Int J Rock Mech Min Sci 46:604–612

Yilma M, Kiflie Z, Windsperger A, Gessese N (2018) Application of artificial neural network in water quality index prediction: a case study in little akaki river, addis ababa, ethiopia. Model Earth Syst Environ 4(1):175–187

Yilmaz I (2009) Prediction of the strength and elasticity modulus of gypsum using multiple regression, ANN, and ANFIS models. Int J Rock Mech Min Sci 46:803–810

Yilmaz I (2010) Comparison of landslide susceptibility mapping methodologies for Koyulhisar, Turkey: conditional probability, logistic regression, artificial neural networks, and support vector machine. Environ Earth Sci 61(4):821–836

Yilmaz I, Kaynar O (2011) Multiple regression, ANN (RBF, MLP) and ANFIS models for prediction of swell potential of clayey soils. Expert Syst Appl 38(5):5958–5966

Yılmaz I, Sendır H (2002) Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng Geol 66(3–4):211–219

Yılmaz I, Yuksek AG (2008) An example of artificial neural network (ANN) application for indirect estimation of rock parameters. Rock Mech Rock Eng 41(5):781–795

Zborovjan M (2001) Identification of minerals during drilling process via acoustic signal. Metallurgy and Foundry Krakow Poland 26 (4)

Zborovjan M (2002) Identification of Minerals from Sound during Drilling. Semestral Project TU-Kosice, Poland

Zborovjan M, Lesso I, Dorcak L (2003) Acoustic identification of rocks during drilling process. Acta Montanistica Slovaca 8(4):191–193

Zorlu K, Gokceoglu C, Ocakoglu F, Nefeslioglu HA, Acikalin S (2008) Prediction of uniaxial compressive strength of sandstones using petrography-based models. Eng Geol 96(3–4):141–158

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, C.V., Vardhan, H. & Murthy, C.S.N. Artificial neural network for prediction of rock properties using acoustic frequencies recorded during rock drilling operations. Model. Earth Syst. Environ. 8, 141–161 (2022). https://doi.org/10.1007/s40808-021-01103-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40808-021-01103-w