Abstract

A process for the preparation of defatted, debittered and off-flavour free guar meal flour (GMF) with high protein content was standardized to improve the utility and use range of guar meal which is otherwise a low value product mainly used as poultry and cattle feed. The GMF had protein, crude fat, crude fibre and ash content of 41.51, 0.20, 6.95 and 5.50 g/100 g, respectively. The saponins and tripsin inhibitor activity of GMF were 0.67% which was significantly higher and 36.90 TIU mg/g protein that was significantly lower respectively than guar meal korma. Guar meal proteins had the amino acid makeup comparable to reported studies on soy meal proteins. Iron (41.33 mg/100 g) and zinc (6.40 mg/100 g) content in GMF was in appreciable amounts. The water absorbing capacity, swelling capacity and oil holding capacity of GMF was high hence can be used as a component in various food formulations. The incorporation of GMF at 20% level for the preparation of nutritious biscuits was found to be optimum with respect to physical and sensory characteristics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Guar (Cyamopsis tetragonoloba) is an important drought resistant annual legume which is used primarily as a fodder crop. It is a major supplementary protein source to the cattle composed of 30–33% hull, 27–30% endosperm and 43–47% germ [1]. A major commercial product from guar is its gum which has significant application in industry as a source of natural hydrocolloid. This property makes it useful in mining, petroleum drilling and textile manufacturing [2]. Guar gum, has ample applications in food industry as well. It is used as gelling, viscosifying, thickening, clouding and binding agent as well as for stabilization, emulsification, preservation, water retention and enhancement of water soluble fibre content.

The by-product of guar gum industry called guar meal consists of seed coat and germ material. Guar meal comes in two forms: Guar meal churi and Guar meal korma. Guar meal churi is a hull part of the guar seed while korma is basically the germ part and is obtained after the gum is extracted from the guar seeds. The guar meal is a potential source of protein as it contains 38–50% crude protein, which is one and a half times more the level of protein in the guar seed. The guar meal at lesser concentrations is being used as feed for livestock including poultry. It is available at approximate cost of Rs 20–30/kg. Owing to its low price and high protein, this product has ample scope to be incorporated in human foods as well when protein insufficiency is a crucial nutritional issue of Indian diets.

The lower quality and quantity of protein in traditional Indian diets results in widespread protein malnutrition among children and adults. Though the high nutritive value of guar meal has been well recognized, Guar meal has a few substances which impart bitter taste and off-flavour [3]. Due to presence of these undesirable substances, guar meal has limited use in livestock feed and almost negligible use in foods for human consumption. The pungent flavor and bitter taste might be attributed to some phospholipids or fat soluble compounds makes it unfit for human consumption. The study aims to standardize a process for the preparation of a defatted, debittered and off-flavour free guar meal flour having optimum functional and nutritional characteristics so that it can be enriched in commonly consumed food products in order to enhance the protein content of the final product and at the same time, produces texturally and organoleptically superior products thereby improving the utility and use range of guar meal.

Material and Methods

Procurement of Material

Two by-products namely guar meal korma and guar meal churi were procured from Hindustan Gum and Chemical Limited, Bhiwani, Haryana, India. The material was stored at 25 °C prior to processing and analysis. Both the products had pungent flavour and taste rendering to its non-utility for human food. The protein content of guar meal korma and churi was analysed by kjeldahl method [4]. The guar meal korma due to its higher protein content (50.81%) than churi (33.36%) was chosen for the study. The korma was ground to a fine powder in an electric grinder (S.K. Enterprise, India) with the particle size ranged between 70 and 100 mesh.

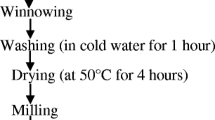

Preparation of Defatted, Debittered and Off-Flavour Free Guar Meal Flour (GMF)

Powdered guar meal of 100 g was soaked in 500 ml of undiluted ethanol (95%) in the standardized mass/volume ratio of 1:5 for 1 h at room temperature. The ethanol was drained from the mixture thus, removing the ethanol soluble materials. The residual ethanol was recovered by vacuum evaporation. The guar meal powder was then extracted with 500 ml of n-hexane for 3 h by stirring at 350 rpm. The extraction step using n-hexane was repeated twice for 3 h each so that the resultant fat in the meal became less than 0.2%. The hexane in each cycle was recovered. The two lipid components that were solubilized in ethanol and n-hexane were collected separately.

Nutritional Analysis of Korma and GMF

Guar meal korma and GMF were analyzed for moisture, crude protein, crude fat, ash, and crude fibre according to the methods described by AOAC [4]. Carbohydrates were determined by difference from the total moisture, crude protein, crude fat, ash, and crude fibre. Amino acid content was determined by Amino Acid Analyzer (Hitachi, L-8900). The minerals in the samples were assessed by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES). The saponin content was determined by double extraction gravimetric method described by Harborne [5]. Trypsin inhibitor activity (TIA) was analyzed by the method of Roy and Rao [6].

Functional Properties of GMF

Water holding capacity (WHC) and oil holding capacity (OHC) were determined by the methods described by Sosulski et al. [7] and swelling capacity (SWC) were measured according to the method reported by Okaka and Potter [8]. Emulsifying activity and emulsion stability were determined by the method of Yasumatsu et al. [9]. Foaming capacity and stability after 30 min were determined in 1% protein solutions as reported by Wang and Kinsella [10].

Biscuit Formulations and Preparation

To test the suitability of GMF for enrichment in high protein biscuits, the biscuits were standardized by blending refined wheat flour (72% extraction rate) with guar meal flour in varying ratios i.e. T0—100:0 (control); T1—90:10; T2—80:20; T3—70:30. Control formulation (T0) comprised of 100 g wheat flour, 50 g sugar, 50 g butter, 1 g salt, 0.5 g sodium bicarbonate, 0.25 g ammonium bicarbonate, 0.5 g baking powder and 10 ml milk. Butter and sugar were mixed until creamy using hand blender (Philips HR 1469, 300-W). The dried ingredients were shifted twice and were put into the mixture of butter and sugar. They were uniformly mixed to obtain consistent dough. The dough was rolled out to a height of 5 mm and cut into spherical shape with diameter of 6 cm using a biscuit cutter. The biscuits were baked at 180 °C for 20–25 min, cooled at room temperature and sealed in plastic bags for further measurements and analysis.

Physical Characteristics of Biscuits

Diameter (D) and thickness (T) of the biscuits were studied. Five pieces of biscuits from each formulation were weighed and the average weight (W) of each biscuit was noted down. They were then placed edge to edge and stacked one above the other to measure the diameter (D) and thickness (T), respectively. The average values of diameter (D) and thickness (T) were expressed in mm [11]. The spread ratio is calculated as D/T. The hardness (in terms of maximum force used to break the biscuits) was measured by stable Micro-System Texture Analyzer (TA-XT2i texture analyzer Stable Micro Systems, UK). The texture analyzer settings were fixed (pre-test speed 2.0 mm/s, test speed 0.5 mm/s, post-test speed 10 mm/s, distance 4 mm/s, load cell 50 and 200 points.

Sensory Evaluation

The sensory evaluation of biscuits was carried out in the Department of Food and Nutrition, Punjab Agricultural University, Ludhiana by a panel of ten semi-trained panellists. A 9-point Hedonic scale was applied to evaluate the biscuits for colour, appearance, texture, taste, flavour and overall acceptability.

Statistical Analysis

All the experiments were conducted thrice. Mean and standard deviations for the various parameters were computed. Analysis of variance (ANOVA) and student’s t test were employed to assess the difference in parameters using Microsoft Excel (2003) Statistical Analysis Tool Pack. Least Significant Difference (LSD) at 5% was calculated for the comparison among the parameters.

Results and Discussion

The lipid components recovered from ethanol and n-hexane extraction were 1.7 and 3.73%, respectively. Srivastava et al. [3] reported that the fat in guar meal contains some solvent soluble fractions which impart pungency and off-flavour. The extracted lipid components may have use in non-food industrial products. The proximate composition of defatted GMF is given in Table 1. The protein content of GMF was significantly (p ≤ 0.01) lower than the korma. The ethanol and n-hexane extraction process resulted in a loss of protein in GMF by 18.3%. Though there was a protein loss during extraction process, but it was at the expense of loss of bitter and off-flavour compounds. The reduction in protein could be attributed to solubility of some protein fractions in alcohol during extraction process. GMF had negligible amounts of fat as compared to korma. The moisture, crude fibre and ash contents were statistically similar in korma and GMF. GMF has high protein (41.51%) low carbohydrates (37.82%) and negligible fat (0.20%), hence may prove suitable for enrichment of cereal flours for enhanced protein and lesser calorific value. Proximate composition of guar meal has not been reported in literature because it is inedible for humans due to its unpleasant taste and flavour. The composition of GMF was closer to the nutritive value of soybean meal which is being commercially used as a protein source for human consumption in the form of defatted soy flour [12,13,14].

The saponins in korma and GMF were 0.58 and 0.67%, respectively. Peisker [15] and Hanssen [16] found 0.5 to 0.6% saponins in soybean meal. Saponins in GMF was comparable to various commercial soybean flours (0.43–0.67%) but lesser than soy protein isolate i.e. 0.76% [17]. Trypsin inhibitor activity of korma and GMF was 39.46 and 36.90 TIU mg/g protein. Trypsin inhibitor activity was lesser in GMF as compared to soybean flour (43–84 TIU/mg protein) [18]. A higher activity of trypsin inhibitor in soybean ranging between 100 and 184 TUI/mg of protein has been observed [19]. Thacker and Kirkwood [20] reported that the trypsin inhibitors ranged between 21.1 and 31.1 mg/g of soybean protein. The activity of these inhibitors in soybean products was decreased by heating processes. Nidhina and Muthukumar [21] revealed a negligible amount of tripsin inhibitors in industrial guar meal as compared to soybean meal. Guar seed may contain more trypsin inhibitors and it might have been deactivated during the gum extraction procedure, where it has undergone heat treatment up to 100 °C. The results revealed that the GMF had closer values for saponins and trypsin inhibitors in comparison to soybean meal. Moreover, the GMF would be used in the product development where heat treatment is necessary, thus may result in further reduction in these two anti-nutrients in the final products.

Amino acid composition of Guar meal korma and GMF is shown in Table 2. They are close to each other in amino acid makeup. Sulphur amino acids are low but other amino acids are present in substantial amounts in GMF. The protein of soybean contains the considerable quantity of lysine, but value of protein is limited by methionine and cysteine content [13, 14]. Guar meal proteins had the amino acid makeup comparable to the reported values of soymeal proteins, hence GMF can be supplemented in cereal flours to mutually balance their limiting amino acids. The mineral content of guar meal korma and GMF has been shown in Table 3. The results showed that the mineral content of both the products was almost similar indicating that there was no loss of minerals during the standardized extraction process. Though all the minerals were present in good amounts, however iron (41.33 mg/100 g) and zinc (6.40 mg/100 g) content was present in appreciable amounts. Therefore, GMF can be used to supplement the traditional food products in order to enhance total iron and zinc content.

The functional properties of GMF have been given in Table 4. The water absorbing capacity (WAC) and swelling capacity (SC) of GMF was 3.47 g of water/g and 19.7% respectively which were higher than other legume flours such as green gram flour [22], soybean flour [23], and lupin flour [24]. The higher WAC and SC is a critical function of its protein, thereby makes it suitable for viscous foods like soups, gravies, doughs and baked products. The oil holding capacity (OHC) was also higher (1.62 g of oil/g) than cereal flours but comparable with other legume flours [22, 23]. The ability of guar proteins to bind with oil makes it useful in food systems where optimum oil absorption is desired. This may give some advantage for bakery products such as biscuits and improve mouth feel and flavour retention which require a good oil absorbing capacity [24].

The emulsifying activity (EA) and emulsifying stability (ES) of GMF was 56.33 and 73.08% while foaming capacity and activity was 145.4 and 91.4%, respectively. The values for emulsifying and foaming properties were higher in comparison to other legume flours due to its higher protein content [22,23,24,25]. The capacity of guar protein to enhance the formation and stabilization of emulsions is important for its applications in food products. Khalil [26] also reported higher emulsifying activity (51.78%) and stability (69.54%) of guar protein isolate.

The physical and sensory characteristics of the control and GMF supplemented biscuits have been given in Table 5. A significantly (p ≤ 0.05) higher thickness and spread ratio was observed in cardamom flavoured biscuits supplemented with 20 and 30% of GMF in comparison to control and 10% GMF supplemented biscuits. In a study, the height and diameter remained constant up to 15% level of incorporation of Bengal gram flour in biscuits but the spread ratio and spread factor decreased with the increase in Bengal gram flour level [27]. Similarly, an increase in the level of defatted soya flour incorporation in biscuits resulted in a linear decrease of diameter and spread ratio while, thickness of biscuits increased with increase in concentration [28]. A reduction in spread ratio of biscuits incorporated with pea flour has also been reported [29]. Reduction of spread ratio of biscuits may be attributed to better binding strength of guar protein as similar to other legume flours has also been reported. The hardness of the biscuits was significantly (p ≤ 0.05) increased with 20 and 30% replacement of refined wheat flour with GMF when compared to control biscuits.

Though all the products were acceptable but the score for colour and appearance of biscuits showed no significant change up to 20% GMF supplementation, however, 30% GMF supplementation decreased the score significantly (p ≤ 0.05) for both colour and appearance. There was no significant change in texture up to 20% supplementation, a significantly (p ≤ 0.05) lower score for texture was observed when refined wheat flour was replaced by 30% of GMF. The taste and flavour score of the biscuits supplemented with 20 and 30% of GMF was significantly (p ≤ 0.05) lower than the control and 10% supplemented GMF biscuits. The overall acceptability was significantly (p ≤ 0.05) different in control and GMF supplemented biscuits. Shakuntala et al. [27] observed that the supplementation of Bengal gram flour at 15–20% level not only improved protein quality but also improved the dough texture and sensory parameters in biscuits.

Conclusion

The study concluded that GMF can be recommended as a balanced cheap source of protein with acceptable functional properties, which may be used as a component in various food formulations. It can be supplemented in various baked and extruded products as a protein source, thereby improving their nutritive value. Moreover, the process of defatted, debittered and off-flavour free guar flour with high protein content may improve the utility and use range of guar meal which is otherwise a low value product mainly used as poultry and cattle feed.

References

Lee JT, Connor-Appleton S, Haq AU, Bailey CA, Cartwright AL (2004) Quantitative measurement of negligible trypsin inhibitor activity and nutrient analysis of guar meal fractions. J Agric Food Chem 52:6492–6495

Wong LJ, Parmar C (1997) Cyamopsis tetragonoloba (L.) Taubert. In: Faridah Hanum I, van der Maesen LJG (eds) Record from Proseabase. PROSEA (Plant Resources of South-East Asia) Foundation, Bogor

Srivastava S, Anees K, Ramani R (2011) Promise of guar meal. Sci Rep 48:38–39

AOAC (2000) Official methods of analysis, 16th edn. Association of official Analytical Chemists, Washington

Harborne JB (1973) Phytochemical methods, 1st edn. Chapman and Hall, London, p 273

Roy DN, Rao PS (1971) Trypsin inhibitors assay from soybean. J Agric Food Chem 19:257–259

Sosulski FW, Garatt MO, Slinkard AE (1976) Functional properties of ten legume flours. Int J Food Sci Technol 9:66–69

Okaka JC, Potter NN (1977) Functional and storage properties of cowpea-wheat flour blends in bread making. J Food Sci 42:828–833

Yasumatsu K, Sawada K, Maritaka S, Toda J, Wada T, Ishi K (1972) Whipping and emulsifying properties of soy bean products. Agric Biol Chem 36:719–727

Wang JC, Kinsella JE (1976) Functional properties of novel proteins: alfalfa leaf protein. J Food Sci 41:286–292

AACC (2000) Approved methods of the American association of cereal chemists, 10th edn. The Association, St. Paul

Van Eys JE, Offner A, Bach A (2004) Chemical analysis. Manual of Quality Analysis for Soybean Products in the Feed Industry. American Soybean Association. http://www.asa-europe.org/Library/library_e.htm

ENV/JM/MONO (2001) 15 Unclassified 2001 Series on the Safety of Novel Foods and Feeds No. 2, consensus Document on Compositional Considerations for New Varieties of Soybean: Key Food and Feed Nutrients and Anti-nutrients, 30-November-2001 for Soybean Products in the Feed Industry. American Soybean Association. http://www.asa-europe.org/Library/library_e.htm

Banaszkiewicz T (2011) Nutritional value of soybean meal, soybean and nutrition. Prof. Hany El-Shemy (Ed.), InTech. http://www.intechopen.com/books/soybean-andnutrition/nutritional-value-of-soybean-meal, ISBN: 978-953-307-536-5

Peisker M (2001) Manufacturing of soy protein concentrate for animal nutrition. Cah Options Mediterr 54:103–107

Hanssen OK (2003) Soya is no soya: (soya proteins for feed products). Feed Int 23:14–18

Philip A, Dziedzic SZ, Kearsley MW (1986) Saponin content of soya and some commercial soya products by means of high-performance liquid chromatography of the sapogenins. J Sci Food Agric 37:694–698

Guillamón E, Pedrosa MM, Burbano C, Cuadrado C, Sánchez MC, Muzquiz M (2007) The trypsin inhibitors present in seed of different grain legume species and cultivar. Food Chem 107:68–74

Kakade M, Siomons N, Liener I, Lambert J (1972) Biochemical and nutritional assessment of different varieties of soybeans. J Agric Food Chem 20:87–90

Thacker PA, Kirkwood RN (1990) Non-traditional feed sources for use in swine production. Butterworth Publishers, Stoneham, pp 175–184

Nidhina N, Muthukumar SP (2015) Antinutritional factors and functionality of protein-rich fractions of industrial guar meal as affected by heat processing. Food Chem 173:920–926

Chandra S, Samsher (2013) Assessment of functional properties of different flours. Afr J Agric Res 8:4849–4852

Ali MAM, El Tinay AHE, Elkhalifa AEO, Mallasy LO (2012) Effect of different supplementation levels of soybean flour on pearl millet functional properties. Food Nutr Sci 3:1–6

Salem EM, Ahmed HF (2012) Partial substitution of eggs by lupin flour and its protein isolates to cake manufacturing. J Appl Sci Res 8:3717–3723

Hutton CW, Campbell AM (1981) Protein functionality in foods, water and fat absorption. ACS Sym Ser 147:177–200

Khalil MM (2001) Biochemical and technological studies on the production of isolated guar protein. Nahrung/Food 45:21–24

Shakuntala B, Masur K, Tarachand C, Kulkarni UN (2009) Development of high protein biscuits from bengal gram flour. Karnataka J Agric Sci 22:862–864

Aleem Zaker MD, Genitha TR, Syed IH (2012) Effects of defatted soy flour incorporation on physical, sensorial and nutritional properties of biscuits. J Food Process Technol 3:149

Kaur K, Singh B, Kaur A (2010) Preparation of bakery products by incorporating pea flour as a functional ingredient. Am J Food Technol 5:130–135

Acknowledgements

The authors are thankful to the Center of Innovative and Applied Bioprocessing, Mohali, Punjab, India for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Additional information

Significance Statement

A novel process of removing unpleasant flavour and taste causing factors from guar meal using GRAS solvents has been explained. The resultant nearly defatted, debittered and off-flavour free flour can be a potential nutrient rich supplement of plant origin with higher economic value.

Rights and permissions

About this article

Cite this article

Sandhu, P.P., Bains, K., Singla, G. et al. Nutritional and Functional Properties of Defatted, Debittered and Off-Flavour Free High Protein Guar (Cyamopsis tetragonoloba) Meal Flour. Proc. Natl. Acad. Sci., India, Sect. B Biol. Sci. 89, 695–701 (2019). https://doi.org/10.1007/s40011-018-0988-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40011-018-0988-7