Abstract

In the present study, debittered Moringa Oleifera seed flour (DDMF) rich in protein, vitamins, minerals and balanced amino acid and fatty acid profile was used to develop functional cookies. DDMF was incorporated at 25, 50, 75 and 100% levels and studied their effect on flour rheological, physicochemical, micro-structural, sensory and nutritional properties of cookies. The results revealed that the addition of an increasing amount of DDMF from 0 to 100% increased water absorption (59.5–77%) by farinograph study; cookie dough hardness (89.2–284.7 N); decreased pasting temperature (60.2–30.1 °C) and peak viscosity (696–9 BU) by amylograph study. SEM studies of cookies indicated that, in control cookies, starch granules are completely gelatinized and enmeshed in the gluten protein matrix, whereas, in 50% DDMF incorporated cookies, partially gelatinized starch granules are seen embedded in a weak protein matrix. Sensory evaluation showed that incorporating DDMF, up to 50% of cookies had clean mouthfeel without any residue formation and were highly acceptable; however, beyond that limit, they became brittle. The addition of 50% DDMF increased cookies' in-vitro protein digestibility, mineral contents, and fatty acids content. Thus, the nutritional quality of cookies concerning quantity and quality of protein and fat could be enhanced by incorporating DDMF.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Moringa oleifera is a vital food commodity with enormous attention as the ‘natural nutrition of the tropics’ (D’souza and Kulakarni 1993). The leaves, flowers, fruit and, immature pods, seeds of this tree are highly nutritious vegetable, particularly in India, Pakistan, the Philippines, Hawaii, and many parts of Africa (Anwar and Bhanger 2003). Seeds of the Moringa oleifera plant are the most nutritious and valuable botanical and herbal remedies and nutritional supplements for industrial and agricultural purposes. Dry seeds of moringa usually contain 18–25% of protein, nearly double the contents of cereals (Abdulkarim et al. 2005) which can be increased upto 50% on defatting (Abiodun et al. 2012). The seeds offer concentrated nutrients, including proteins with balanced amino acids and a wide range of vitamins and minerals, making them an outstanding supplement for stressed and hurried individuals and a reliable source of nutrition for malnourished population worldwide. Gopalakrishnan et al. (2016) reported that the major vitamin and mineral composition of fresh Moringa oleifera seeds are calcium (45 mg/100 g), magnesium (635 mg/100 g), phosphorus (75 mg/100 g), thiamin (0.05 mg/100 g), riboflavin (0.06 mg/100 g), niacin (0.2 mg/100 g) and vitamin E (751 mg/100 g). Although slightly bitter and astringent, moringa seeds are used for food seasoning or eaten as roasted nuts (Al-Kahtani and Abou-Arab 1993).

Enrichment of food products with functional components from plant sources has been used regularly to enhance the pro-health properties. Consumer preference for functional products from plant sources are also increasing. Due to their widespread consumption in communities, bakery products are considered as the best medium for functional ingredient supplements (Kumar et al. 2015). Cookies hold an essential place among bakery products as snack items due to their taste, crisp texture, and eating convenience (Kent and Evers 1994). High protein cookies are attractive for target areas, such as low-income groups, child-feeding programs, and disaster relief operations (Claughton and Pearce 1989).

Several reports are available on the utilization of Moringa oleifera in nutritious bakery products such as moringa leaves cookies (Dachana et al. 2010; Mouminah 2015), moringa seed powder incorporated bread, cookies (Bolarinwa et al. 2017; Ogunsina et al. 2011), bread with germinated moringa seed flour along with tiger nut flour (Chinma et al. 2014) etc. No systematic study reported on the utilization of debittered Moringa oleifera seed flour (DDMF) to replace wheat flour in the processing of cookies. Therefore, the present work was planned with the main objective of improving the nutritional characteristics of cookies with particular reference to the quality of protein and fat. DDMF was used to replace wheat flour at different levels in cookie processing and determined its effect on rheological characteristics of wheat flour, dough texture, physico-sensory, nutritional quality, and fatty acid profile compared with wheat flour cookies.

Materials and methods

Materials

Commercially available wheat flour, sugar, and Marvo brand shortening (Hindustan Lever Ltd., Mumbai, India) used for the studies were procured from the local market, Mysore, India.

Processing of debittered, moringa seed flour (DDMF)

Moringa (M. oleifera Lam.) seed was purchased in bulk from the local Mysore market, India, and processed as Ogunsina et al. (2011) described. The dried flour was coarsely pulverized in a blender, passed through a sieve size 500µ and stored in polythene bags.

Preparation of blends

Blends were prepared using a combination of wheat flour and DDMF in the ratios of 100/0, 75/25, 50/50, 25/75 and 0/100 W/W.

Chemical characteristics of flours

The characteristics such as moisture, ash, protein, dry gluten, fat, Hagberg’s falling number, and sedimentation value (Zeleny’s) were determined according to AACC (2000) methods. Total dietary fibre content was analyzed according to AOAC (2000) method, carbohydrate (Dubois et al. 1951), fatty acid, amino acid (Bidlingmeyer et al. 1984) and mineral profile (AOAC 2000) were analyzed.

Rheological characteristics

The rheological characteristics flour such as farinograph and amylograph were analyzed as per AACC (2000) methods.

Cookie-making characteristics

Cookies from blends containing 0, 25, 50, 75, and 100% DDMF were prepared using the following formulation: wheat flour and DDMF blend—100 g, sugar powder—60 g, shortening (Marvo)—50 g, and water according to the requirement. The cookie dough was sheeted to a thickness of 1.0 cm and cut using a circular cutter of 4 cm diameter. Cookies were baked at 200°C for 10 min, cooled and evaluated for physico-sensory characteristics.

Texture profile analysis of cookie dough

Texture profile analysis of cookie dough was carried out as per the methods of Kumar and Sudha (2021) at room temperature using a LR-5 K Texture Analyzer (Lloyds Instruments Ltd, Hampshire, England) with a 5 kg load cell. The cookie dough sample size of 40 mm diameter and 10 mm thickness were compressed using an aluminium disc probe (circular) of 80 mm diameter, with a compression distance of 50% of cookie dough and a 50 mm/min crosshead speed. The hardness, springiness, and cohesiveness behavior of cookie dough was analyzed using Nexygen Version 4.0 Software (LR-5 K).

Physical and sensory characteristics of cookies

The diameter (mm) and thickness (mm) of cookies were measured and the spread ratio was calculated by dividing the values of diameter by thickness. The breaking strength of cookie is one of the critical parameter in the evaluation of cookies, as it mimics the customer holding the cookies in hand and breaking by bending were measured using the texture analyzer (Model TA—HDi, Stable Micro System, Surrey, UK). The force required for breaking the cookie with a three-point bending rig was measured. The peak force (g) needed to break a single cookie was recorded, and the average value of two triplicates was reported (Kumar et al. 2016). Sensory evaluation of cookies was carried out by a panel consisting of 30 members (15 male and 15 female), including scientists, technical staff, research scholars, and project assistants who have previous experience in sensory evaluation of cookies were formed, and they were further trained in four sessions involving 2 h of training in each session. The cookies were evaluated for surface colour, surface character, texture, mouthfeel, and overall quality score on a 9-point hedonic scale as per Kumar and Sharma (2018) method. Five samples of cookies in two replicates were presented in random order.

Statistical analysis

The statistical significance of the data was analyzed using Duncan’s new multiple range test with different experimental groups appropriate to the fully randomized design with four replicates each, as Steel and Torrie (1960) explained. The significant level was established at P ≤ 0.05.

Results and discussion

Quality characteristics of wheat flour

The wheat flour used for this study contained 9.83% moisture, 0.53% fat, 9.30% protein, 45.38% carbohydrate, 0.54% ash, 2.82% dietary fiber, 9.17% dry gluten, 799 s falling number, 19.5 mL Zeleny’s sedimentation value (Table 1). The above results indicate that the flour used for the study is medium strong flour. The DDMF used for the study contained 2.77% moisture, 14.13% fat, 48.45% protein, 24.08% carbohydrate, 6.74% ash, and 35.10% dietary fiber.

Farinograph characteristics

The effect of incorporation of DDMF on the farinograph characteristics of wheat flour is reported in Table 2. The increasing amount of DDMF in the blend from 0 to 100% increased the farinograph water absorption from 59.5 to 77.0%. This increase in the water absorption capacity of the flour is mainly due to the increase in protein concentration with the addition of DDMF, which is known to have more affinity for water. The dough development time, i.e. time necessary to reach 500 BU consistencies, was 3.1 min for control, 8.5 min (25% DDMF), 9.6 min (50% DDMF), 11.4 min. (75% DDMF), and 12.7 min (100% DDMF), respectively. The dough stability value representing the strength of the dough increased up to 50% DDMF level, and at higher levels of 75 and 100%, the stability decreased significantly. Similar observations of increased water absorption and dough development time and a decrease in dough stability with the addition of dried moringa leaf powder were reported by Dachana et al. (2010). An increase in the dough development time values were due to delayed development of gluten or slower hydration property of moringa seed protein. The mixing tolerance index values, which are inversely proportional to the strength of the dough, increased from 46 to 77 BU from control flour to 100% DDMF, thus indicating a decrease in the strength of the dough. Similar results of decreasing dough strength have been reported by McWatters (1978) with the addition of protein-rich flours from defatted peanut, soybean and field pea.

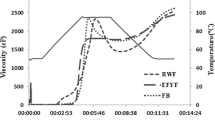

Amylograph characteristics

With an increase in the level of DDMF addition, the pasting temperature increased upto 75%, i.e. 60.2 (for control) to 89.1 (for 75%) and then decreased to 30.1 °C (Table 2). Peak viscosity indicating starch’s granule’s ability to swell freely before their physical breakdown significantly reduced from 696 to 9 BU with an increase in DDMF from 0 to 100%. Hot paste viscosity representing the stability of the already broken starch granules at the cooking temperature decreased with DDMF. The cold paste viscosity, when compared with control (470 BU), decreased with 25% DDMF (316 BU), 50% DDMF (269 BU), 75% DDMF (25BU) and 100% DDMF (7 BU). From the above results, it can be attributed that the mixture of starch, protein, fat and dietary fiber present in moringa seed flour increased the pasting temperature of starch, and decreased the viscosity during heating, cooking, and cooling. A decrease in peak viscosity, break down and setback, when chickpea flour was added to wheat flour, was reported by Gomez et al. (2008) and attributed to decreased carbohydrate content and difference in protein contents which affects the viscosity parameters. The breakdown and setback values indicating the ease of cooking, and the tendency to retrograde decreased from 313 to 0 BU and 226 to 0 BU with the addition of DDMF for 0 to 100% DDMF respectively. The reduced value for setback and break down shows less resistance of starch for thermal treatment, having a reduced tendency to retrograde. The effect of incorporation of germinated tiger nut flour and Moringa flour to wheat flour was studied by Chinma et al. (2014) and reported that the rapid viscoanalyzer (RVA) properties of flour samples showed low peak viscosity, trough, breakdown, setback, final viscosity, and pasting temperature value than 100% wheat flour. This can be attributed to amylase activity in germinated flour, the difference in the amylose—amylopectin ratio of the starches, and the reduction in the gluten content due to the use of gluten-free flours.

Texture profile analysis

The effect of DDMF on the cookie dough texture profile analysis is presented in Table 2. Results indicated a significant increase in the hardness of dough and a decrease in springiness and cohesiveness. The hardness of the control cookie dough was 89.2 N, and it was increased to 96.6 N with an addition of 50% DDMF. An increase in dough hardness could be seen due to an increase in DDMF. The springiness value indicates elastic recovery of dough after first deformation decreased from 0.29 mm for control to 0.26, 0.19, 0.02 and 0.01 mm for 25%, 50%, 75% and 100% respectively. The cohesiveness of the dough decreased from 0.06 for control to 0.05, 0.050, 0.04 and 0.02 for 25%, 50%, 75% and 100% respectively. Kumar et al. (2016) studied the protein and dietary fibre-rich four different multigrain mixes incorporated wheat flour dough texture profile properties. They reported that incorporating multigrain mixes increased the hardness and decreased the springiness and gumminess property of short biscuit dough. The decrease in springiness and cohesiveness values might be due to the dilution of gluten protein (Dachana et al. 2010). These results show that an increased content of DDMF produced higher gumminess and less springy dough.

Physico-sensory characteristics of cookies

The results presented in Table 2 show that with an increase in the level of DDMF from 0 to 100%, the spread ratio reduced from 5.5 to 4.1. The decrease in spread ratio could be due to dilution and disruption of gluten strands by adding DDMF, thereby losing its elastic recovery properties (Kumar et al. 2015). The colour analysis of the cookies crust revealed that an increasing addition of DDMF flour decreased the lightness and increased the redness value. The lightness of cookies decreased from 79.0 for control cookies to 42.8for 100% DDMF cookies. The redness value increased from 1.8 for control cookies to 4.4, 5.4, 5.9, and 5.9 for 25%, 50%, 75% and 100% DDMF. The yellowness value of the cookie represented by b value decreased with an increase in the percentage of DDMF for 100% DDMF cookie. These results indicate that the use of DDMF decreased the lightness and yellowness and increased the redness of cookies due to the presence of brown coloured DDMF apart from the Maillard reaction and caramelization process during baking, as explained by Kumar and Sudha (2021). The breaking strength of cookies indicates the force required to break increased from 1989 to 4169 g force for 0 to 50% DDMF, indicating an increase in the hardness.However, at a higher percentage of DDMF incorporation, the hardness value decreased to 2202 g force could be due to an increase in brittleness.

The sensory studies indicated that (Fig. 1a, b), the surface colour of cookies became darker as the level of DDMF increased, and the sensory score for surface colour decreased from 8 to 5.5 for control and 100% DDMF added cookies, respectively. The surface character of the control cookie was smooth, and it became rough with the increasing addition of DDMF due to the coarser particle of DDMF. The texture scores decreased from 8.3 for control to 5.7 for 100% DDMF cookies. The cookies became harder up to 50% incorporation; however, beyond that limit, it became brittle. These results support the physical characteristics of cookies evaluated by instrumental methods, viz. hunter colour values and texture analyzer. Up to 50% level of addition, cookies had a clean mouthfeel without any residue formation and were highly acceptable. It could be concluded that a maximum of 50% level of incorporation of DDMF was optimum concerning physical and sensory quality. Earlier, Kumar and Sudha (2021) also reported similarly that incorporating multigrain mix at 25, 50, 75, and 100% levels, cookies became dark coloured, with a rough surface. Breaking strength increased up to 50% incorporation of the multigrain mix, and beyond that, hardness decreased due to a reduction in gluten content.

Nutritional characteristics of cookies

The cookies' protein content and fat content increased with DDMF and increased from 28.08 to 36.81% and 5.58 to 27.35%, respectively for control to 50% DDMF cookies. Since there is a decrease in carbohydrate content of DDMF as compared to wheat flour, the carbohydrate content for the 50% moringa cookie also decreased to 37.24% compared to control, having 40.70%. An increase in dietary fibre content from 4.88% to 11.13% for control and 50% DDMF cookie was also observed, which might be due to the higher dietary fiber content of DDMF. Earlier, Kulthe et al. (2014) have also reported increased protein and decreased carbohydrate content with an increasing amount of defatted soy flour in the cookies. The increase in protein, lipid, and dietary fiber content might be due to their appreciably higher content in DDMF.

Mineral analysis

The mineral composition of wheat flour, DDMF, control cookie, and 50% DDMF cookie is presented in Table 3. DDMF is a rich source of minerals, including calcium (Ca), magnesium (Mg), iron (Fe), and zinc (Zn). The Ca in DDMF, wheat flour, control and 50% DDMF cookie is 904.5, 32.6, 28.02 and 191.7 mg/100 g, respectively. The Mg level was highest in DDMF, followed by 50% DDMF cookie, wheat flour, and control cookie. The Fe content of DDMF, wheat flour, control, and 50%DDMF cookie is 67.50, 7.55, 3.03 and 13.65 mg/100 g, respectively. The Zn content was found highest in DDMF (16.74 mg/100 g), followed by 50% DDMF cookie (3.95), wheat flour (1.70), and control cookie (1.16), respectively. The 50% DDMF incorporated cookie had higher contents of Ca (191.7 mg/100 g), Mg (87 mg/100 g), Fe (13.65 mg/100 g) and Zn (3.95 mg/100 g) compared to the control cookie. Earlier, Kumar et al. (2019), in their study on the influence of whole multigrain premix on the nutritional quality of biscuits, also concluded that the biscuits supplemented with whole multigrain premix had an increase in the content of minerals in comparison to control biscuits.

Fatty acid profile

The percentage of fatty acids in the wheat flour, DDMF, control, and 50% DDMF cookie was represented in Fig. 2. Wheat flour was rich in linoleic acid followed by oleic acid, whereas DDMF flour was found to have oleic followed by gonodoic and palmitoleic acid content. The results of the fatty acid profile of the control cookie and cookie with 50% DDMF showed an increase in the unsaturated fatty acids. The control cookies had 28.58 and 4.28%, whereas 50% of DDMF cookies had 51.69 and 2.38% oleic and linoleic acid. It can be concluded that the incorporation of DDMF significantly decreased the saturated fatty acids and increased the mono and polyunsaturated fatty acids in 50% DDMF cookies. Similarly, Abdulkarim et al. (2005) also determined that the major saturated fatty acids in M. oleifera seed oil were palmitic, stearic, arachidic, and behenic acids, and the essential unsaturated fatty acid is oleic acid (67.9–70.0%), with small amounts of palmitoleic, linolenic, linoleic, and eicosenoic acids.

Amount of Fatty Acids present in Wheat flour (WF); Moringa Oleifera seed. Flour (DDMF); Control cookie (C) and Cookie with 50%DDMF (50%). C10:0- Capric acid, C12:0- Lauric acid, C14:0- Myristic acid, C16:0- Palmitic acid, C18:2- Linoleic acid, C18:1- Oleic acid, C18:0- Stearic acid, C16:1- Palmitoleic acid, C20:1- Gonodoic acid, C19:0- Nonadecanoic acid

In-vitro protein digestibility

According to Table 3, the highest IVPD was found for DDMF (92.35%), followed by 88.96% for a cookie with 50% DDMF, 67% for wheat flour and 61.35% for a control cookie. This result indicates that incorporating DDMF at a 50% level improved the protein quantity and digestibility. Earlier, Kumar et al. (2019) also reported the highest IVPD of 71.73% for multigrain biscuits containing 40% of the multigrain mix compared to 38.13% for control biscuits and attributed to an increase in protein content in multigrain biscuits.

Amino acid profile

The amino acid composition of DDMF and wheat flour is presented in Table 4. DDMF was rich in many of the essential amino acids (EAA). The most abundant EAA of DDMF is leucine (7.58 g/100 g protein). DDMF was also found to be rich in a valine (5.63 g/100 g protein) and methionine (2.72 g/100 g protein) compared to their content of 4.50 and 1.31 g/100 g protein, respectively, in wheat flour. The total EAA content of DDMF is higher by 6.68 g/100 g protein than wheat flour. This observation indicates that the cookies supplemented with 50% DDMF will have higher amino acid content than the control cookie. However, lysine and cysteine in DDMF and cysteine and methionine in wheat flourare the first and second limiting amino acids, respectively. The content of non-essential amino acids (NEAA) was higher in wheat flour.

Scanning electron microscopic (SEM) studies

SEM showed the heterogeneous structure from where we can distinguish undamaged and damaged starch granular encrust in smaller shape structure. The protein and protein aggregates jellified during heating to form flat and aggregate with starch. Figure 3 represents the SEM of crumb (cross-section) of control and 50% DDMF cookies. Figure 3a is the SEM of control cookies wherein gelatinized large and small wheat starch granules (LSG and SSG) enmeshed in gluten protein can be observed. The structure is more heterogeneous than that of the 50% DDMF cookie structure. The protein component of the dough has been described as a network covering starch granules by Rao et al. (2022). In Fig. 3b, the SEM of cookies with 50% DDMF, partially gelatinized small wheat starch granules can be seen entrapped into protein fibrils. The cookie with 50% DDMF has partially gelatinized, and lesser amount of starch granules embedded into the protein matrix as compared to the control cookie, which could be due to the replacement of gluten with Moringa proteins or because of the granular starch structure has been dominated by flat structure due to protein aggregation. Earlier, Indrani et al. (2010), in their study on the ultrastructure of bread dough using a mixture of multigrain like soya bean, fenugreek seeds, flaxseeds, oats and sesame seeds, reported that at a 20% level of multigrain addition, the protein matrix was disrupted. The microstructure of 50% DDMF incorporated cookies also showed disruption in the gluten protein matrix due to the replacement of wheat flour with high fiber DDMF. This was also indicated in the biscuit texture, as the hardness of biscuits increased due to a reduction in the spread ratio (McWatters 1978).

Conclusion

Cookies with Moringa seed flour had improved the nutritional, physical, and sensory qualities. They were rich in protein, ash and dietary fiber; unsaturated fatty acids, essential amino acids, and minerals (Ca, Mg and Fe). They had protein quantity and higher digestibility than the control cookie. They had increased farinograph water absorption and dough stability, decreased amylograph pasting temperature, and peak viscosity. Increased hardness and decreased cohesiveness were noticed. The brown colour of the flour adversely affected colour quality. Moringa cookies had partially gelatinized and lesser amount of starch granules embedded into the protein matrix.

Availability of data and material

All data generated or analysed during the current study are included in this published article.

Code availability

Not applicable.

Abbreviations

- DDMF:

-

Debittered moringaseed flour

- SEM:

-

Scanning electron microscope

- IVPD:

-

In vitro protein digestibility

- EAA:

-

Essential amino acids

- NEAA:

-

Non-essential amino acids

References

AACC (2000) Approved methods of analysis, 10th edn. Cereals & Grains Association, St Paul, MN, USA

Abdulkarim SM, Long K, Lai OM, Muhammad SKS, Ghazali HM (2005) Some physico-chemical properties of moringa oleifera seed oil extracted using solvent and aqueous enzymatic methods. Food Chem 93:253–263

Abiodun OA, Adegbite JA, Omolola AO (2012) Chemical and physicochemical properties of moringa flours and oil. Global J Sci Frontier Res Bio Sci 12(5):12–17

Al-Kahtani HA, Abou-Arab AA (1993) Comparison of physical, chemical, and functional properties of moringa peregrina (Al-Yassar or Ao¨-Ban) and soybean proteins. Cereal Chem 70:619–626

Anwar F, Bhanger MI (2003) Analytical characterization of Moringa oleifera seed oil grown in temperate regions of Pakistan. J Agri Food Chem 51:6558–6563

AOAC (2000) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Washington, DC

Aranyi C, Hawrylewicz EJ (1968) A note on scanning electron microscopy of flours and doughs. Cereal Chem 45:500–502

Bidlingmeyer BA, Cohen SA, Tarvin TL (1984) Rapid analysis of amino acids using pre-column derivatization. J Chromatogr 336:93–104

Bolarinwa IF, Aruna TE, Raji AO (2017) Nutritive value and acceptability of bread fortified with moringa seed powder. J Saudi Soc Agri Sci 18:195–200

Chinma CE, Abu JO, Akoma SN (2014) Effect of germinated tigernut and moringa flour blends on the quality of wheat-based bread. J Food Proce Preser 38:721–727

Claughton SM, Pearce RJ (1989) Protein enrichment of sugar snap cookies with sunflower protein isolate. J Food Sci 54:354–356

D’souza J, Kulkarni AR (1993) Comparative studies on nutritive values of tender foliage of seedlings and mature plants of Moringa oleifera Lam. J Econ Taxonomic Bot 17:479–485

Dachana KB, Rajiv J, Indrani D, Prakash J (2010) Effect of dried moringa (Moringa oleifera lam) leaves on rheological, microstructural, nutritional, textural and organoleptic characteristics of cookies. J Food Qual 33:660–677

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1951) A colorimetric method for the determination of sugars. Nature 168:167

Gomez M, Oliete B, Caballero PA, Ronda F, Blanco CA (2008) Effect of nut paste enrichment on wheat dough rheology and bread volume. Food Sci Technol Int 14:57–65

Gopalkrishnan L, Doriya K, Kumar DS (2016) Moringa oleifera: a review on nutritive importance and its medicinal application. Food Sci Hum Wellness 5:49–56

Indrani D, Soumya C, Rajiv J, Rao GV (2010) Multigrain bread–its dough rheology, microstructure, quality and nutritional characteristics. J Tex Stud 41:302–319

Kent NL, Evers AD (1994) Technology of cereals: an introduction for students of food science and agriculture, 4th edn. Woodhead Publishing, Sawston

Kulthe AA, Pawar VD, Kotecha PM, Chavan UD, Bansode VV (2014) Development of high protein and low calorie cookies. J Food Sci Technol 51:153–157

Kumar KA, Sharma GK (2018) The effect of surfactants on multigrain incorporated short biscuit dough and its baking quality. J Food Measand Charact 12:1360–1368

Kumar KA, Sharma GK, Anilakumar KR (2019) Influence of multigrain premix on nutritional, in-vitro and in-vivo protein digestibility of multigrain biscuit. J Food Sci Technol 56:746–753

Kumar KA, Sharma GK, Khan MA, Govindraj T, Semwal AD (2015) Development of multigrain premixes - its effect on rheological, textural and micro-structural characteristics of dough and quality of biscuits. J Food Sci Technol 52:7759–7770

Kumar KA, Sharma GK, Khan MA, Semwal AD (2016) A study on functional, pasting and micro-structural characteristics of multigrain mixes for biscuits. J Food Measand Charact 10:274–282

Kumar KA, Sudha ML (2021) Effect of fat and sugar replacement on rheological, textural and nutritional characteristics of multigrain cookies. J Food Sci Technol 58:2630–2640

McWatters KH (1978) Cookie baking properties of defatted peanut, soyabean and field pea flours. Cereal Chem 55:853–863

Mouminah HHS (2015) Effect of dried Moringa oleifera leaves on the nutritional and organoleptic characteristics of cookies. Alexand Sci Exchange J 36:297–302

Ogunsina B, Radha C, Indrani D (2011) Quality characteristics of bread and cookies enriched with debittered Moringa oleifera seed flour. Int J Food Sci Nutri 62:185–194

Rao S, Ashwath Kumar K, Indrani D (2022) Low carbohydrate high fat flour: its rheology, bread making, physico-sensory and staling characteristics. J Food Sci Technol 59:2220–2230

Steel RGD, Torrie JH (1960) Principles and procedures of statistics. Principles and Procedures of Statistics

Acknowledgements

The authors are thankful to the Director, CSIR-CFTRI, Mysore for extending facilities for this research work.

Funding

Department of Biotechnology, Government of India, New Delhi has extended financial support for this research in the form of Grant-in-Aid Project to Dr. C. Radha, Sanction No.BT/Bio-CARe/05/400/2010–2011 dated 16–02-2012.

Author information

Authors and Affiliations

Contributions

JA Conductedexperiments and contributed to writing this manuscript. AKK Designed the experiments, Data analysis and manuscript writing. ID Design of experiments. RC Conceived the idea, supervised the work and finalized the manuscript. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared no conflicts of interest for this article.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agrawal, J., Kumar, K.A., Indrani, D. et al. Effect of Moringa oleifera seed flour on the rheological, physico-sensory, protein digestibility and fatty acid profile of cookies. J Food Sci Technol 59, 4731–4739 (2022). https://doi.org/10.1007/s13197-022-05555-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05555-5