Abstract

Cellulosimicrobium sp. CKMX1 isolated from mushroom compost, produced extracellular endo-1,4-β-xylanase (EC 3.2.1.8) at 35 °C and pH 8.0. In this study the wild strain of Cellulosimicrobium sp. CKMX1 was improved for enhanced xylanase production by using physical mutagen i.e. ultraviolet rays and chemical mutagens i.e. ethidium bromide (0.1–2.0 mg/ml) and ethyl methanesulfonate (5–70 mg/ml). Mutant (E5) with hyper xylanase production was obtained after treating wild strain with ethyl methanesulfonate on the basis of xylanase activity index and xylanase activity in liquid medium. Mutant E5 (568 U/g dry bacterial pomace) resulted in 35.89 % increase over wild strain (418 U/g dry bacterial pomace) in xylanase activity in solid state fermentation under optimized conditions. Further optimization of enzyme production by Cellulosimicrobium sp. CKMX1 mutant, E5 was carried out using central composite design following response surface methodology with four independent variables (yeast extract, ammonium nitrate, Tween 20 and carboxymethyl cellulose), which resulted in further increase of 1.63-fold in xylanase production (927.65 U/g dry bacterial pomace).The effectiveness of cellulase-free hyper xylanase producing mutant E5 to work in alkaline conditions indicates its possible applicability in paper and pulp industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbial enzymes continue to draw greater attention as alternative to chemical processes which would enable the industries to meet the increasingly stringent environment requirements to reduce the pollution load. The use of xylanolytic enzymes in pulp biobleaching process resulted in a 20–30 % decrease of chlorine requirements. The enzyme xylanase could be used in clarification of juices, wine industries, poultry diets, animal feed, production of ethanol and in biofuel in addition to its use in bio-bleaching pulp [1, 2].

Xylanases are a set of enzymes responsible for xylan biodegradation. Xylanase (1, 4-β-d-xylanxylanohydrolase EC 3.2.1.8) and β-xylosidase (1,4-β-d-xylanxylohyrolase EC 3.2.1.37) are the key enzymes for breakdown of xylan. Xylan is a polysaccharide composed of β-1,4-linked xylopyranose units [3]. Diversified generic species of microorganisms have proven to be the producer of rich source of xylanase enzyme [4], including bacteria [5], fungi [6] and actinomycetes [7].But fungal xylanases are often found contaminated with cellulases which cannot be used in paper and pulp industry. Traditional mutation and selection techniques have been exploited for the improvement of bacterial cultures and to enhance xylanase production level in microbes. Quantitative enhancement is the foremost approach which involves strain improvement mostly by physical and chemical mutations [8]. Chemical mutagens such as ethyl methanesulfonate (EMS), N-methyl-N′-nitro-N-nitrosoguanidine [3, 9] and physical mutagens such as UV have been commonly used. Solid state and submerged fermentation are most commonly used techniques for enzyme production [10–14]. Submerged fermentation (SmF) holds a tremendous potential for enzyme production particularly where crude fermented product may directly be used as a source. Xylanase production in SSF from fungi and actinomycetes have been reported, but only a few reports using bacteria showing low enzyme yields are available [15–19].

In order to improve the nutrient medium for enhancing xylanase production, conventional methods based on the “change-one-factor-at-a time” in which one independent variable is studied while fixing all others at a specific level, may lead to unreliable results and inaccurate conclusion. This experimental procedure is not only expensive but also time consuming for large number of variables. Therefore, mathematical design i.e. response surface methodology (RSM) finds wide application in nutrient media optimization for microbial enzyme production. The aim of this study is to obtain mathematical models showing the dependence of the enzyme activity on independent variables. The mathematical dependence obtained was used for prediction of the optimum values of the independent variables, ensuring the maximum enzyme activity [20, 21]. The study of xylanases has consistently increased due to its potential use in several biotechnological applications [22, 23]. Therefore, keeping in view the importance of xylanase, an attempt has been made to enhance xylanase production by carrying out mutation of Cellulosimicrobium sp. CKMX1 and further optimization of process parameters to obtain high levels of xylanase was carried out using central composite design (CCD) following RSM.

Material and Methods

Microbial Strain, its Maintenance and Media Used

The microbial culture used in study was Cellulosimicrobium sp. CKMX1 isolated from mushroom compost obtained from the Culture Collection Centre of Microbiology, Department of Basic Sciences, Dr Y S Parmar University of Horticulture and Forestry, Nauni, Solan (H.P.). 16S r RNA sequence of the strain has been deposited in the GenBank Database under accession number JN135476. The bacterial culture was maintained in Basal salt medium (BSM) containing 0.5 % xylan with the following composition (g/l): 6.0 g of Na2HPO4, 3.0 g of KH2PO4, 0.5 g of NaCl, 1.0 g of NH4Cl and separately sterilized solution of 1 M MgSO4 (2 ml) and 1 M CaCl2 (0.1 ml) were added to medium at pH 8.0 and stored at 4 °C. All the chemicals used in this study were of Analytical reagents grade purchased from BDH or E. Merck. Xylan (oat spelt) was obtained from Sigma-Aldrich, USA.

Mutation of Wild Strain of Cellulosimicrobium sp. CKMX1

Ultraviolet Mutagenesis

For ultraviolet mutagenesis (UV) 24 h old culture was exposed to short ultraviolet light (280 nm) from a distance of 15 cm for various time intervals (25, 50, 75, 100 and 125 min). Sample was withdrawn before exposure to UV irradiation for determining the initial population (cfu/ml) on BSM medium containing 0.5 % of xylan and similarly survival count after different time intervals was also determined. Survival curve was prepared and time of exposure giving 3 log kills was used for the selection of mutants.

Ethidium Bromide Mutagenesis

The sample from 24 h old culture was used to determine the initial population (cfu/ml). Ethidium Bromide (Et Br) (0.1–2.0 mg/ml) was mixed well with culture in different test tubes at room temperature. The sample from each test tube was removed after an interval of 60 min for determining survival count (cfu/ml). The concentration resulting in 1 % survival was used for carrying out mutation at 15, 30, 45, 60, 90 and 115 min interval in order to optimize the time period that would result in 3 log kill and survival curve was prepared.

Ethyl Methanesulfonate Mutagenesis

One ml of 24 h old culture was centrifuged at 1,000 rpm for 2 min. Pellet was dissolved in Tris–HCl buffer (1 ml, pH 7.0). 100 μl of sample content was withdrawn to determine initial population (cfu/ml). EMS solution (5–70 mg/ml) was added to the sample in different eppendorf tubes and a concentration resulting in 1 % survival was selected after an interval of 20 min. The selected concentration was used for carrying out mutation at 5, 25, 50 and 70 min interval in order to optimize the time period that would result in 3 log kill and survival curve was prepared.

Screening of Mutants

Survivors with difference in morphology and size of clear zone with respect to wild strain were screened on the basis of xylanase activity index [24] and were further selected based on their capacity of enzyme production in liquid medium.

Xylanase Production and Extraction

SmF was carried out by supplementing 20 ml of BSM with 0.5 % of xylan at pH 8.0. The flasks were inoculated with 0.5 ml of bacterial suspension (O.D. 1.0 at 540 nm) and incubated at 35 °C under shaken (120 rpm) conditions for 72 h. At the end of incubation period, cell density was determined by quantitative plating. The sample was centrifuged at 12,000 rpm for 15 min at 4 °C and the culture supernatant was used as crude enzyme preparation. In solid state fermentation, 20 ml BSM containing 10 g apple pomace (on dry weight basis) at pH 8.0 was autoclaved, cooled, inoculated with 10 % bacterial suspension and then incubated at 35 °C for 72 h. After incubation, contents in the flask were extracted with 50 ml sterilized buffer (0.2 M, pH 8.0, Tris–HCl). The flasks were kept in shaker for half an hour for thorough mixing of apple pomace with buffer. The sample was centrifuged and the culture supernatant was used as crude enzyme preparation.

Xylanase Assay

Xylanase activity was determined according to Dubey and Johri [25] using 0.5 ml d-xylan (1 %) in Tris–HCl buffer (0.2 M, pH 8.0) and 0.5 ml of diluted enzyme. The release of reducing sugars was determined using 3, 5-dinitrosalicylic acid (DNSA) against xylose as standard [26]. The reaction mixture contained 0.5 ml of 1 % d-xylan in Tris–HCl buffer (0.2 M, pH 8.0) and 0.5 ml 50-fold diluted enzyme. It was incubated at 50 °C for 5 min in a water bath with occasional shaking. After incubation, 3 ml DNSA reagent was added into the test tubes, which stopped the enzymatic reaction. The tubes were immersed in boiling water bath and removed after 15 min with color development. Tubes were cooled to room temperature. The contents were transferred to a 25 ml volumetric flask and final volume made up with distilled water. Optical density was measured at 540 nm in Spectronic-20. One international unit (IU) of enzyme activity was defined as the amount of enzyme required to liberate 1 μmol reducing sugar per min under given assay condition.

Filter Paperase Activity

The reaction mixture contained 50 mg strip of filter paper (Whatman No. 1) in 1 ml Tris–HCl buffer (0.2 M, pH 8.0) and 0.5 ml of diluted enzyme. The appropriate control for substrate and enzyme were also kept. The mixture was incubated at 50 °C for 1 h in water bath with occasional shaking. After incubation, 1 ml was drawn from the mixture and 3 ml of DNSA reagent was added into the test tube which stopped the enzymatic reaction. The tubes were immersed in boiling water bath for 15 min. The tubes were removed and allowed to cool at room temperature. The contents were transferred to 25 ml volumetric flask and made 25 ml with distilled water. The optical density was read at 540 nm in Spectronic-20.

One unit of F Pase activity was defined as the amount of enzyme that produced 1 μmol of glucose/ml/min under the given assay conditions. FPase production is expressed as U/g DBP.

Carboxymethyl Cellulase Assay

The reaction mixture contained 4.5 ml of 1.1 % CMC in Tris–HCl buffer (0.2 M, pH 8.0) of diluted enzyme. The mixture was incubated at 50 °C for 1 h. After the incubation, an aliquot (volume up to one ml) was withdrawn and added to 3 ml of DNSA which stopped the enzymatic reaction. The tubes were immersed in boiling water bath for 15 min and then cooled at room temperature. The contents were transferred to 25 ml volumetric flasks and volume made up with distilled water. The optical density was read at 540 nm in Spectronic-20.

Avicelase Activity

The reaction mixture contained 2.0 ml of 1 % suspension of Avicelin, 0.2 M Tris–HCl buffer (pH 8.0), and 200 μl of enzyme solution. After incubation at 30 °C for 2 h, the mixture was filtered through Whatman No. 1 filterpaper and analyzed for reducing sugar by the method described earlier.

The unit of enzyme activity was defined as the amount of enzyme needed to liberate reducing sugar equivalent to 5 μg glucose under the assay conditions described above. Avicelase is expressed as U/g dry DBP.

β-Glucosidase Activity

The substrate for the determination of β-glucosidase activity was P-nitrophenyl β-d-glucoside. The assay mixture contained 1.0 ml of 1 mM P-nitrophenyl β-d-glucoside in 0.2 M, Tris–HCl buffer (pH 8.0) and 100 μl of enzyme solution. After incubation at 40 °C for 10 min, 2.0 ml of 1 M Na2CO3 was added to the mixture to stop the reaction. The mixture was diluted with 10 ml of distilled water and the P-nitrophenol liberated was determined from the absorbance at 400 nm. The saturated curve was made from the stock solution of P-nitrophenol (80 μg/ml).

The unit of enzyme activity was defined as the amount of enzyme which liberated 5 μg P-nitrophenol under the assay condition. β-glucosidase activity is expressed as U/g DBP.

Protein Estimation

Protein contents of the culture supernatants were assayed by the folin–ciocalteau method of Lowry et al. [27] using bovine serum albumin (BSA) as standard (10–100 μg/ml).

Response Surface Methodology–Central Composite Design

RSM and CCD was used to optimize the nutrient medium for further increase in the production of xylanase by Cellulosimicrobium sp. CKMX1 mutant E5. Based on earlier studies reported by Walia et al. [28] in authors’ laboratory, four independent variables were chosen for optimization by RSM using CCD experiments. The range and the coded values of independent variables at different levels of CCD design are given in Table 1. Each variable was studied at three levels (−1, 0, +1). The experimental design included 21 flasks with three replicates at their central coded values [29]. The mathematical relationship of response (enzyme production) and variable A, B, C and D (yeast extract, ammonium nitrate, Tween 20 and carboxymethyl cellulose) (CMC) was approximated by a quadratic model equation. The response value in each trail is the average of triplicate experiments.

Statistical Analysis

All the experiments were conducted in triplicate along with equal number of controls. The data obtained were subjected to analysis of variance technique using Completely Randomized Design (CRD). The statistical software package Design-Expert 8.0.4 (StatEase, Minneapolis, MN) was used for regression analysis of experimental data to obtain working parameters and to generate response surface graphs. Analysis of variance (ANOVA) was used to estimate statistical parameters.

Results

Screening and Selection of Mutants by Mutagenesis

UV Mutagenesis

The survival count at each interval (25, 50, 75, 100 and 125 min) was determined. Figure 1a showed that 99.25 % of the cells were killed within 125 min exposure of UV rays. 16 putative UV mutants of Cellulosimicrobium sp. CKMX1 were plated on to BSM medium containing 0.5 % xylan to determine any change in their morphology and size of clear zone [24]. Of the 16 putative mutants which showed a variable xylanase activity index as compared to wild strain (2.66) were examined for production of xylanase in liquid medium, Cellulosimicrobium sp. CKMX1 mutant M5 (Fig. 2a) was selected with xylanase activity index of 1.5 and were found to produce 9.26 ± 0.14 U/ml of xylanase activity in liquid medium as compared to wild type (Fig. 2b) which yielded 12.09 ± 0.20 U/ml, thus showing decrease in xylanase production by 23.41 %.

Et Br Mutagenesis

Culture was treated with different concentration of Et Br (0.1–2.0 mg/ml) for 60 min. 2 mg/ml of Et Br resulted in 1.25 % survival and this concentration was further evaluated at different time interval (0–115 min). After 115 min of Et Br exposure (2 mg/ml) 99.59 % kill was recorded (Fig. 1b). Survivors were observed for any change in morphology and size of clear zone [24]. Six putative mutants obtained by Et Br mutagenesis were studied for xylanase production in liquid medium, but none of them were found with hyper xylanase production.

EMS Mutagenesis

In present study, effect of different concentrations of EMS (5–70 mg/ml) on Cellulosimicrobium sp. CKMX1 for 20 min was evaluated. Perusal of Fig. 1c reveals that 70 mg/ml resulted in 0.33 % survival because increase in EMS concentration (5–70 mg/ml) declined the percentage of survivors, while the mutant frequency increased. Therefore, this concentration was further evaluated at different time intervals (0–50 min). After 50 min of EMS exposure (70 mg/ml) 99.99 % kill was recorded. The treatment of Cellulosimicrobium sp. CKMX1 with 70 mg/ml of EMS for 50 min resulted in 11 putative mutants on the basis of size of clear zone. These putative mutants were allowed to grow in liquid medium for enzyme production. Mutagenesis using EMS mutagen posed a significant increase in enzyme activity. Of all the putative mutants tested, mutant E5 (Fig. 2c) was selected with xylanase activity index of 4.12 and were accounted for 22.99 % increase in xylanase activity (14.87 ± 0.15 U/ml) in liquid medium as compared to wild strain (12.09 ± 0.18 U/ml).

Mixed Mutagenesis

In the present study, three randomly selected putative UV mutants (M3, M6, and M11) were treated with 2 mg/ml of Et Br for 115 min. Thirty-six putative mutants were selected on the basis of any change in morphology and size of clear zone. M 1511 , a putative UV and Et Br treated mutant was further treated with 2 mg/ml of Et Br for 115 min. This mutation resulted in six putative mutants. So, total 42 putative mutants were obtained by mixed mutagenesis.

Out of the 42 putative mutants which showed a variable xylanase activity index as compared to wild strain when examined for production of xylanase in liquid medium, Cellulosimicrobium sp. CKMX1 mutant M 211 (Fig. 2d) was selected with xylanase activity index of 1.0 and was found to produce 7.18 ± 0.10 U/ml of xylanase activity as compared to wild type which yielded 12.09 ± 0.14 U/ml, thus showing decrease in xylanase production by 40.61 %. UV, Et Br, EMS and mixed mutagenesis resulted into 75 putative mutants. 3 mutants were further selected on the basis of xylanase production in liquid medium i.e. E5, M5 and M 211 .

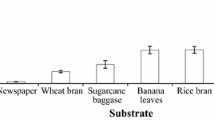

Xylanase Production by Cellulosimicrobiumsp. CKMX1 and its Mutants (E5, M 211 and M5) Under Solid-State Fermentation of Apple Pomace

Xylanase production by wild and mutant strains of Cellulosimicrobium sp. CKMX1 with apple pomace as substrate in solid state fermentation (Table 2) revealed that maximum xylanase activity was observed for mutant E5 (568.0 ± 11.0 U/g DBP) which was 35.89 % higher than that of wild strain (418.0 ± 6.0 U/g DBP) whereas the other mutant strains M5 (405.6 ± 5.0 U/g DBP)and M 211 (318.0 ± 13.0 U/g DBP) resulted in 2.97 and 23.92 % decrease in xylanase activity respectively. Maximum specific activity (6.48 ± 0.02 U/mg protein), reducing sugar (5.90 ± 0.15 mg/ml/g), extracellular protein (75.32 ± 3.0 mg/ml), with corresponding maximum viable count (180 ± 6.0 × 105 cfu/ml) and decrease in initial pH was observed for mutant E5 which was significantly higher than that of wild and other mutant strains. However, CMCase, FPase, Avicelase and β-glucosidase were not detected.

Optimization of Nutrient Medium Composition by Using CCD for Enhanced Xylanase Production by Mutant E5 in Solid-State Fermentation of Apple Pomace

Based on earlier studies conducted in authors’ laboratory by Walia et al. [28], yeast extract, ammonium nitrate, Tween 20 and CMC were identified as the major factors affecting xylanase production by Cellulosimicrobium sp. CKMX1. In the present work, the interaction of these four independent variables, i.e. yeast extract, ammonium nitrate, Tween 20 and CMC concentrations was studied for optimization of enzyme production by mutant E5 using CCD experiment. Regression analysis was performed to fit the response function to the experimental data. The results of RSM experiments for studying the effect of the four variables along the mean actual and predicted response are presented in Table 3. The highest xylanase activity (927.65 U/g DBP) was observed at run number 6, whereas the factors like yeast extract (1.00 %) and CMC (5.00 %) were used at their high levels and ammonium nitrate (0.20 %), Tween 20 (0.20 %) were used at their low levels respectively. Design expert predicted the maximum xylanase yield to be 926.81 U/g DBP which was very close to the actual level of xylanase produced in the optimized medium i.e. 927.65 U/g DBP. This activity was 1.63-fold higher than that obtained by mutant E5 of Cellulosimicrobium sp. CKMX1 with basic BSM medium containing apple pomace and 2.22-fold higher than activity obtained by Cellulosimicrobium sp. CKMX1, wild strain with basic BSM medium containing apple pomace. Minimum xylanase activity (465.75 U/g DBP) was observed at run number 12, where all the factors were used at their low levels i.e. yeast extract (0.20 %), ammonium nitrate (0.20 %), Tween 20 (0.20 %) and CMC (1.00 %). Table 4 shows the regression analysis for this experiment, presenting the estimates and hypothesis tests to the coefficients of regression. At the 5 % probability level, the linear and quadratic coefficients of A (yeast extract), B (ammonium nitrate), C (Tween 20), D (CMC) and the coefficients of interaction between them were found to be significant. This shows that all the four independent variables had significant effect on the xylanase activity.

The regression equation obtained showed that the xylanase production may be best predicted by the model.

After eliminating the non-significant terms, the final response equation for xylanase production is given as follows:

where A is the level of yeast extract, B is ammonium nitrate, C is Tween 20 and D is CMC concentration. The statistical significance of a second-order model equation was evaluated by the F test analysis of variance which showed that the coefficient of determination (R2) for xylanase production as a function of the independent variables was found to be 99 %, which showed that the model correlated well with measured data and was statistically significant at P ≤ 0.05. The corresponding ANOVA of the empirical model obtained along with the values of the coefficient of determination (R2) and the adjusted determination coefficient (adj R2) are presented in Table 4. The lack-of-fit analysis gave non-significant Pvalues (>0.05) and F values lower than corresponding tabulated F values, thus proving that the model obtained was highly significant. In addition, the high value of R2 (0.99 %) indicated that the fitted models could explain at least 99 % of the total variation in the responses. These facts indicate that the quadratic models were appropriate to fit and describe satisfactorily the experimental data regarding xylanase production.

The contour plot and three dimensional response surfaces were plotted on the basis of the model equation so as to investigate the interaction among the variables and to determine the optimum concentration of each factor for maximum xylanase production by mutant E5 of Cellulosimicrobium sp. CKMX1. Also, significant interaction (P ≤ 0.05) was observed between ammonium nitrate (X2) and CMC (X4); yeast extract (X1) and CMC (X4) of three independent variables and this synergy was indicated by isoresponse contour plot and three dimensional response surfaces (Figs. 3, 4). The production of xylanase mostly reaches a peak in the region of levels ‘0’ and ‘+1’ for the factor yeast extract and CMC; the levels ‘0’ and ‘−1’for Tween 20 and level ‘−1’ for ammonium nitrate.

Based on the model obtained, the optimal working conditions were defined to attain high xylanase activity minimizing the ammonium nitrate and Tween 20 concentration. Thus, the point assigned as optimum corresponded to 1.00 % of yeast extract, 0.20 % of ammonium nitrate, 0.20 % of Tween 20 and 5.00 % of CMC. Under these conditions, the model predicted a xylanase activity of 926.81 U/g DBP.

Discussion

To reduce bio-processing cost and enhance xylanase production level in microbes, different strategies have been developed [3]. The traditional mutagenesis approach which would increase the xylanase activity is being successfully employed in fungal [24, 30, 31] and bacterial [32] strains. Mutagens lead to mutation by inducing lesion or modification in base sequence of DNA that remained unrepaired. Thus, an attempt was made to develop Cellulosimicrobium sp. CKMX1 by mutagenesis and selection into efficient strain for production of xylanase. The parent strain was treated with UV irradiations, Et Br and EMS. The UV mutant, M5 of Cellulosimicrobium sp. CKMX1 illustrated 23.41 % decrease in enzyme activity. UV irradiation might have caused error at replication of DNA and so resulted in mutation. Decreased xylanase activity for mutant M5 could be because of the reason that the gene responsible for production of xylanase might have decreased in DNA due to mutation (this is due to decrease in gene copy number or deteoration in expression of genes or both) which resulted in decrease in enzyme activity [33]. Similar method for screening of UV mutants of Fusarium oxysporium was reported by Singh et al. [24]. Putative mutants developed were chosen on the basis of their ability to hydrolyze xylan source which resulted in mutant UV-11 with two to three fold increase in xylanase activity as compared to that of parent strain. Likewise, the chemical mutagens are stronger mutagenic agents and cause permanent changes in DNA sequence. They bring about transitions from G: C → A:T and have preferential effect on DNA replication. Chemical mutagen used in the present study i.e. EMS resulted in a mutant which exhibited 22.99 % improvement in enzyme activity. This is in agreement with the work showing screening of 28 putative mutants of parental strain Bacillus licheniformis GUB30UCM [9]. After xylanase production by screened mutants in liquid medium, Haq et al. [34] reported development of mutant Bacillus licheniformis EMS-20040 for high α-amylase production using EMS as chemical mutagen. Many other reports regarding developing mutants of Bacillus sp. with EMS treatment are available [35–37]. However, mixed mutagenesis strategy i.e. UV and Et Br resulted mutant M 211 with 40.61 % decrease in xylanase activity as compared to that of wild strain. Similar strategy was also used in order to achieve higher level of xylanase production using either combination of UV and Et Br or UV and NTG [38–40]. Steiner et al. [38]. mutated Penicillium purpurogenum with UV light and N-methyl-N′-nitrosoguanidine and reported two mutants NG-188 and NG-737 with enhanced xylanase activity. The best selected UV mutant (UV-64) was treated with N-methyl-N′-nitrosoguanidine and a second generation of mutant was obtained. Similarly mutant At-ch-5.6 was also developed by mixed mutagenesis strategy of UV and EMS [37] with hyper α-amylase activity. The selection of mutant strains (M 211 and M5) with decreased xylanase activity for comparison purposes, in present study, is of considerable significance because these strains could serve appropriate control for future molecular characterization of gene responsible for xylanase production in the wild and hyper xylanase producer strains of Cellulosimicrobium sp. CKMX1.

Physical and chemical mutagenesis of parent strain i.e. Cellulosimicrobium sp. CKMX1 resulted in three mutants viz. E5, M5 and M 211 which were further evaluated in solid state fermentation with apple pomace as substrate. Xylanase production by wild and mutant strains of Cellulosimicrobium sp. CKMX1 revealed that maximum xylanase activity was observed for mutant E5 (568.00 U/g DBP) which was 35.89 % higher than wild strain whereas other mutant strains, M5 (405.60 U/g DBP) and M 211 (318.00 U/g DBP) resulted in 2.97 % and 23.92 % decrease in xylanase activity respectively. Specific activity (6.48 U/mg Protein), reducing sugar (5.90 mg/ml/g), extracellular protein (75.32 mg/ml) and viable count (180 × 105 cfu/ml) were also found maximum for mutant E5 with decrease in initial pH. Blakeman et al. [41] and Walia et al. [42] reported that when the proportion of carbohydrate in fermentation medium is high, a pronounced drop in final pH occurs. The substantial decrease in final pH may be attributed to the production and accumulation of organic acids in the production medium. The present study clearly indicates that the variation in final pH of fermentation medium influenced the xylanolytic activity of both wild and mutant strains. However, CMCase, FPase, avicelase and β-glucosidase were not detected in the culture supernatant of wild strain, as well as in the mutant strain. Cellulosimicrobium sp. CKMX1 is an unusual bacterial strain in that it produces cellulase-free, alkali stable xylanase. This xylanase has been shown to solubilise pulp actively under alkaline conditions, which is one of the desirable criteria for industrial applications.

For further increase in the production of xylanase by Cellulosimicrobium sp. CKMX1 mutant E5, nutrient medium was optimized by using RSM. According to Design Expert the maximum xylanase yield was 926.81 U/g DBP in optimized medium which composed of (g/l): 1 % (w/w) yeast extract, 0.20 % (w/w) ammonium nitrate,0.20 % (v/w) Tween 20 and 5 % (w/w) CMC, which is very close to the actual level of xylanase produced in the optimized medium i.e. 927.65 U/g DBP by mutant E5. Xylanase production is 1.63-fold higher in comparison to the activity obtained by mutant E5 of Cellulosimicrobium sp. CKMX1with basic BSM medium containing apple pomace. However, CMCase, FPase, avicelase and β-glucosidase were not detected in the culture supernatant of mutant strain in RSM and clearly suggest its application in pulp and paper industry. Many reports are available for optimization of xylanase production from microbial sources using a statistical approach [43, 44]. Walia et al. [28] also employed RSM and CCD to optimize a fermentation medium for the production of xylanase by Cellulosimicrobium sp. CKMX1 at pH 8.0. The optimized medium resulted in a 1.6-fold increase in xylanase production. The RSM applied to the optimization of xylanase production in that investigation allowed quick identification of the important factors and interaction between them and also suggested the importance of a variety of factors at different levels.

Conclusion

In conclusion, the mutant strain E5 of Cellulosimicrobium sp. CKMX1 was 2.22-fold more effective in producing cellulase free alkaline xylanase as compared to that of wild strain. The enzyme produced by this strain can work at high pH optimally and cellulase free state that is primary requirement for the treatment of alkaline pulp. So, it is concluded that Cellulosimicrobium sp. CKMX1 and its hyper xylanase producing mutant strain E5 can be very useful for paper and pulp industry.

References

Kohli U, Nigam P, Singh D, Chaudhary K (2001) Thermostable, alkalophilic and cellulase free xylanase production by Thermoactinomycesthalophilus subgroup C. Enzyme Microb Technol 28:606–610

Shah AR, Madamwar D (2005) Xylanase production by a newly isolated Aspergillus foetidus strain and its characterization. Proc Biochem 40:1763–1771

Xu ZH, Bai YL, Xu X, Shi JS, Tao WY (2005) Production of alkali-tolerant cellulase-free xylanase by Pseudomonas sp. WLUN024 with wheat bran as the main substrate. World J Microbiol Biotechnol 21:575–581

Mullai P, Fathima NSA, Rene ER (2010) Statistical analysis of main and interaction effects to optimize xylanase production under submerged cultivation conditions. J Agric Sci 2:144–153

Sanghi A, Garg N, Kuhar K, Kuhad RC, Gupta VK (2009) Enhanced production of cellulase-free xylanase by alkalophilic Bacillus subtilis ASH and its application in biobleaching of kraft pulp. Bioresour Technol 4(3):1109–1129

Dhiman SS, Garg G, Mahajan R, Garg N, Sharma J (2009) Single lay out and mixed lay out enzymatic processes for bio-bleaching of kraft pulp. Bioresour Technol 100:4736–4741

Ninawe S, Kapoor M, Kuhad RC (2007) Purification and characterization of extracellular xylanase from Streptomyces cyaneus SN32. Bioresour Technol 99(5):1252–1258

Ellaiah P, Prabhakar T, Ramakrishna B, Taleb AT, Adinarayana K (2002) Strain improvement of Aspergillus niger for the production of lipase. Indian J Microbiol 42:151–153

Haq I, Tasneem M, Raana K, Khan A, Mukhtar H, Javed M (2004) Optimization of cultural conditions for the production of xylanase by chemically mutated strain of Aspergillus niger GCBCX-20. Intern J Agric Biol 6(6):1115–1118

Babu KP, Satyanarayana T (1995) Αlpha amylase production by thermophilic Bacillus coagulans in solid state fermentation. Proc Biochem 30:305–309

Ashraf H, Haq I, Qadeer MA, Iqbal J (2001) Screening of Bacillus licheniformis mutants for improved production of alpha amylase. Pak J Bot 33:517–525

Gupta U, Kar R (2009) Xylanase production by a thermo-tolerant Bacillus sp. under solid state and submerged fermentation. Braz Arch Biol Technol 52(6):1363–1371

Annamalai N, Thavasi R, Jayalakshmi S, Balasubramanian T (2009) Thermostable and alkaline tolerant xylanase production by Bacillus subtilis isolated from marine environment. Indian J Biotechnol 8:291–297

Nagar SK, Gupta VK, Kumar D, Kumar L, Kuhad RC (2010) Production and optimization of cellulase-free, alkali-stable xylanase by Bacillus pumilus SV-85S in submerged fermentation. J Indian Microbiol Biotechnol 37:71–83

Archana A, Satyanarayana T (1997) Xylanase production by thermophilic Bacillus licheniformis A99 in solid state fermentation. Enzyme Microb Technol 21(1):12–17

Gessesse A, Mamo G (1999) High level xylanase production by an alkalophilic Bacillus sp. by using solid state fermentation. Enzyme Microb Technol 25:68–72

Heck J, Flores S, Hertzm P, Ayub M (2005) Optimization of cellulase-free xylanase activity by Bacillus coagulans BL69 in solid state cultivation. Proc Biochem 40:107–112

Battan B, Sharma J, Kuhad RC (2006) High level of xylanase production by alkalophilic Bacillus pumilus ASH under solid state fermentation. World J Microbiol Biotechnol 22:1281–1287

Sindhu I, Chhibber S, Capalash N, Sharma P (2006) Production of cellulase free xylanase from Bacillus megateriumby solid state fermentation for biobleaching of pulp. Curr Microbiol 853:167–172

Ghanem NB, Yusef HH, Mahrouse HK (2000) Production of Aspergillus terreus xylanase in solid state cultures: application of the Plackett–Burman experimental design to evaluate nutritional requirements. Bioresour Technol 73:113–121

Bocchini DA, Alves-Prado HF, Baida LC, Roberto IC, Gomes E, Da Silva R (2002) Optimization of xylanase production by Bacillus circulans D1 in submerged fermentation using response surface methodology. Process Biochem 38:727–731

Lo YC, Saratale GD, Cheu WM, Bai MD, Chang JS (2009) Isolation of cellulose hydrolytic bacteria and applications of the cellulolytic enzymes for cellulosic biohydrogen production. Enzyme Microb Technol 44:417–425

Nasser NH, Ali AM, Keera AA (2010) Xylanase production by Streptomyces lividans and its application on waste paper. Aust J Basic Appl Sci 4(6):1358–1368

Singh A, Kuhad RC, Kumar M (1995) Xylanase production by a hyperxylanolytic mutant of Fusarium oxysporum. Enzyme Microb Technol 17:551–553

Dubey K, Johri BN (1987) Xylanolytic activity of thermophile Sporotrichum sp. and Mycelipthora thermophilum. Indian Acad Sci 97(3):247–255

Miller GL (1959) Use of dinitrosalicyclic acid reagent for determination of reducing sugars. Annu Chem 31:426–428

Lowry DH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin-phenol reagent. J Biol Chem 193:265–275

Walia A, Mehta P, Chauhan A, Shirkot CK (2012) Optimization of cellulose-free xylanase production by alkalophilic Cellulosimicrobium sp. CKMX1 in solid state fermentation of apple pomace using central composite design and response surface methodology. Ann Microbiol 63:187–198

Chadha BS, Gulati H, Minhas M, Saini HS, Singh N (2004) Phytase production by the thermophilic fungus Rhizomucor pusillus. World J Microbiol Biotechnol 20:105–109

Kuhad RC, Manchanda M, Singh A (1998) Optimization of xylanase production by a hyperxylanolytic mutant strain of Fusarium oxysporum. Proc Biochem 33:641–647

Bakri Y, JawharM Arabi MIE (2008) Improvement of xylanase production by Cochliobolus sativus in submerged culture. Food Technol Biotechnol 46(1):116–118

Subramaniyan S, Sandhia GS, Prema P (2001) Biotech control of xylanase production without protease activity in Bacillus sp. by selection of nitrogen source. Biotechnol Lett 23:369–371

Gaedner JE, Simmons JE, Snustad DP (1991) Principal of genetics, 8th edn. Wiley, New York, pp 303–304

Haq I, Ali S, Saleem A, Javed MM (2009) Mutagenesis of Bacillus licheniformis through ethyl methanesufonate for alpha amylase production. Pak J Bot 41(3):1489–1498

Hamad A, Haq I, Qadeer MA, Javed I (2001) Screening of Bacillus licheniformis mutants for improved production of alpha-amylase. Pak J Bot 33:23–36

Kotchoni SO, Shonukan OO, Gachomo WE (2003) Bacillus pumilusBpCRI 6, a promising candidate for cellulase production under conditions of catabolite repression. Afr J Biotechnol 2(6):140–146

Shafique S, BajwaR Shafique S (2009) Mutation of Alternaria tenuissima FCBP-252 for hyper active α-amylase. Indian J Exp Biol 47:591–596

Steiner J, Carmona P, Ponce C, Berti M, Eyzaguirre J (1995) Short communication: isolation of mutants of Penicillium purpurogenum with enhanced xylanase and β-xylosidase production. World J Microbiol Biotechnol 14:589–590

Mayorga RL, Ponce NT (1998) Isolation of a hyperxylanolytic Cellulomonas flavigena mutant growing on continuous culture on sugar cane bagasse. Biotechnol Lett 20:443–446

Chand P, Aruna A, Maqsood AM, Rao LV (2005) Novel mutation method for increased cellulase production. J Appl Microbiol 28:606–610

Blakeman JP, McCracken AR, Seaby DA (1988) Changes brought about in solid substrate after fermentation of mixtures of cereals and pulses with Rhizopusoryzae. J Food Sci Agric 45:109–118

Walia A, Mehta P, Chauhan A, Shirkot CK (2012) Production of alkalophilic xylanases by Paenibacillus polymyxa CKWX1 isolated from decomposing wood. Proc Natl Acad Sci India. doi:10.1007/s40011-012-0122-1

Yu X, Hallett SG, Sheppard J, Watson AK (1997) Application of the Plackett–Burman experimental design to evaluate nutritional requirements for the production of Colletrichum coccodes spores. Appl Microbiol Biotechnol 47:301–305

Wang Q, Hou Y, Xu Z, Miao J, Li G (2008) Optimization of cold-active protease production by the psychrophilic bacterium Colwellia sp. NJ341 with response surface methodology. Bioresour Technol 99:1926–1930

Acknowledgments

The authors thank the Department of Science and Technology, under the Ministry of Science and Technology, Government of India, for providing a contingency Grant through an Inspire fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guleria, S., Walia, A., Chauhan, A. et al. Mutagenesis of Alkalophilic Cellulosimicrobium sp. CKMX1 for Hyper-Production of Cellulase-Free Xylanase in Solid State Fermentation of Apple Pomace. Proc. Natl. Acad. Sci., India, Sect. B Biol. Sci. 85, 241–252 (2015). https://doi.org/10.1007/s40011-013-0273-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40011-013-0273-8