Abstract

The experimental conditions for preparation of pomegranate peel carbon and Fe(III) modified pomegranate peel carbon were studied. The effects of main experimental parameters on carbon preparation such as carbonization time, carbonization temperature and Fe(III) impregnation ratio in pomegranate peel were investigated. The prepared carbons in various conditions were characterized by consideration of the production yield, ash content, iodine number, pH of zero point charge and their ability for adsorption of methylene blue. After preparation of carbons, their efficiency for removal of Cd2+ species from aqueous solution was investigated. The effect of experimental parameters such as Cd2+ initial concentration, pH of solution and contact time was studied by batch adsorption experiments. The fitting of experimental data in thermodynamic isotherms matched the linear results with Langmuir and Freundlich isotherms. The adsorption capacity for Cd2+ species on Fe(III) modified pomegranate peel carbon was 22.72 mg/g and the adsorption kinetic presented the pseudo-second-order kinetic model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Utilization of biomass from agricultural wastes as raw materials for production of activated carbons is an economic approach particularly in countries rich in agricultural by-products (Soleimani and Kaghazchi 2007). Numerous studies have been devoted to the preparation of low-cost high-quality activated carbons from agricultural biomasses, such as rice straw (Oh and Park 2002), rice hust (Wang et al. 2007), coconut shell (Li et al. 2008), oil palm shell (Hussein et al. 1996), corn cob (Tsai et al. 1998), bagasse (Onal et al. 2007) and pistachio nut shell (Yang and Guo 2004), which are widely used in different fields such as adsorbents, filters, catalysts or catalyst supports in water treatment, gas separation, and medicine (Babel and Kurniawan 2003). Activated carbon has extensive uses such as adsorbent for removal of wide range of contaminants from liquids and gases in industries and environment. Liquid-phase applications are treatment of potable water, treatment of wastewater, and decolorization of sugar, and the three largest gas-phase applications are air purification, automotive emission control, and solvent vapor recovery (Mohammad-Khah and Ansari 2009).

Pomegranate (Punica granatum L.) is an important commercial fruit crop that is extensively cultivated in parts of Asia, North Africa, the Mediterranean and the Middle East (Saad et al. 2012). Iran is one of the most important pomegranate producers and exporters in the world, and its total production is more than 670,000 tons. Pomegranate fruits are widely consumed fresh or processed into juice, jams, syrup and sauce. The non-edible portion (peel) of fruit is about 40–45 % of the total fruit weight and consists of several constituents, including polyphenols, ellagitannins and gallic and ellagic acids (Tehranifar et al. 2010). Therefore, the idea to change the agricultural waste of pomegranate to activated carbon is so important because it provides a low-cost material to produce a valuable product and help to clean the environment.

Based on this approach, the removal of lead(II) and copper(II) from aqueous solutions were studied using raw pomegranate peel and thermally and chemically activated carbon prepared from pomegranate peel (El-Ashtoukhy et al. 2008). Also the removal of direct blue-106 dye as an environmental pollutant from aqueous solution was studied using physically and chemically modified activated carbons prepared from pomegranate peel (Amin 2009). Phosphoric acid and zinc chloride at volumetric ratio of 1:1 and nitric acid solution followed by pyrolysis was used for preparation of activated carbon in both studies. In other work, pomegranate husk was converted into activated carbon by dehydration process using concentrated sulfuric acid and tested for its ability to remove hexavalent chromium from wastewater (El Nemr 2009).

The main objective of this study was to develop new chemical methods for preparation of modified activated carbons from pomegranate peels using Fe(II) and Fe(III) ions and evaluate the possibility of their power as adsorbents for removal of Cd2+ species from aqueous solutions. The optimization of adsorption parameters such as pH, adsorbents mass, initial cadmium concentration and time have been investigated. Also the thermodynamics and kinetics of adsorption have been evaluated. This work was carried out in December 2014 in Department of Chemical Technology, Iranian Research Organization for Science and Technology, Tehran, and the Laboratory of Analytical Chemistry, Shahid Sadoughi University of Medical Science, Yazd, I. R. Iran.

Materials and methods

Procedure for preparation of carbons

Pomegranate peels (PP) used in this study were prepared from the pomegranates produced in Yazd gardens in Iran at 2014. The separated peels were washed with distilled water, dried in laboratory temperature in absence of sun light for 2 weeks, ground in a ball mill and sieved between 18 and 40 mesh sizes. 10 g of residual mass was individually transferred to crucibles, obstructing with door to prevent diffusion of oxygen, and introduced into the programming furnace and heated at different temperatures (300, 400 and 500 °C), for desired times (0.5, 1, 2, 3, 4 h) given in Table 1. After cooling to laboratory temperature, the solid was washed with distilled water at 50 °C to remove excess materials. The carbon samples were dried at 105 °C for 2.5 h and ground and sieved for further tests. Another part of pomegranate peel (50 g) was divided to five equal parts (10 g), and each part was soaked in 10 ml 1, 2, 3, 4 and 5 % (w/v) FeCl3 solution, respectively, for 12 h. After dryness in oven at 80 °C for 2 h and cooling to lab temperature, the solid was washed with distilled water to remove excess materials and Cl− ions and named FePPC and used as raw material for chemically modified carbon preparation. Then, these composite biomasses carbonized in the programming oven under optimum conditions and the prepared carbon named FePPC.

Characterization of prepared carbons

For characterization of prepared carbons, FTIR spectroscopy and five specific standard procedures were performed to compare preparation parameters according to their importance in classification of the activated carbon.

Iodine number determination

The iodine number was measured using the standard test method ASTM D4607. The iodine number was determined taking 1 g of carbon sample in a clean Erlenmeyer flask, adding 10 ml of 5 % (v/v) HCl, closed and swirled until the carbon was completely wet. It was gently heated before boiling to remove any sulfur. After cooling to room temperature, 100 ml of 0.1 M iodine (Merck, Germany) solution was added. The solution was vigorously shaken and filtered. Twenty-five milliliters of the filtrate solution was titrated with 0.1 M sodium thiosulfate (Merck, Germany) solution in the presence of starch indicator.

Decolorization of methylene blue

For consideration of the decolorization potential of the prepared carbons, 100 ml of methylene blue (Sigma-Aldrich, USA) solution (200 ppm) was added in an Erlenmeyer flask containing 0.200 g activated carbon, shook for 30 min and filtered using membrane filter. The color of the filtrate was determined using a Lambda-25 UV–Vis spectrophotometer (Perkin Elmer, USA) at the wavelength of 665 nm (Kipling and Wilson 1960).

Determination of ash content

The ash content of the prepared carbons was determined using the standard test method ASTM D2866-11. A crucible was washed with 10 % (v/v) nitric acid and heated in a furnace to 500 °C, cooled in a desiccator and weighed. 0.250 g of the carbon samples was transferred into crucible and heated at 550 °C for 4 h. The percentage of ash content was determined from weight differences before and after ignition.

Determination of pH

pH was determined by ASTM D 3838-05 method. Suspension of 0.100 g carbon samples to 100 ml distilled water in an Erlenmeyer flask. The suspension was vigorously shaken for 10 min at laboratory temperature. The samples were permitted to stabilize, and the pH was measured by using a calibrated pH meter (Corning 3400, UK).

Determination of zero point charge pH

Zero point charge pH (pHzpc) is an indicator for the surface charge of carbon samples. For determination of pHzpc, 50 ml of 0.01 M NaCl solution was added in six 100-ml Erlenmeyer flasks, and its initial pH (pHi) was adjusted between 2 and 12 with dilute solution of HCl or NaOH. Then, 0.200 g of carbon samples was added to each solution, and shaken for 10 min and kept for 24 h. The final pH (pHf) of solutions was measured by using a calibrated pH meter. The pHzpc of carbon samples was extracted from plot of pHf versus pHi (Gupta and Nayak 2012).

Adsorption experiments

Batch adsorption experiments were carried out in laboratory scale and temperature. All working solutions were freshly prepared from 1000 ppm Cd2+ stock solution (Sigma-Aldrich, USA). A desired mass of adsorbent was added to a series of Erlenmeyer flask containing 100 ml of 50 ppm Cd2+ at primary pH. Samples were agitated for 5, 10, 20, 30, 60, 90 and 120 min on laboratory shaker, and then centrifuged at 3500 rpm for Cd2+ analysis. Adsorption isotherms were recorded by varying the initial Cd2+ concentration from 10 to 200 mg/l with 0.25 g/100 ml of adsorbent at pH = 6.36 and the optimum contact time of 60 min. Residual cadmium in samples was measured by atomic absorption spectrometry (Varian AA240, Australia) at wavelength 228.8 nm, slit of 0.5 nm for low concentration (<20 ppm), wavelength of 352.5 nm, slit of 0.2 nm for high concentration (>20 ppm), and air–C2H2 flow rate of 4:1.7 ml/min.

Data analysis

pH of zero point charge

The point of zero charge is an important interfacial parameter which is extensively used in characterizing the ionization of a surface. When particles such as oxides, sulfides, and activated carbons are dispersed in aqueous solution, they get surface charge corresponding to dissociation of surface functional groups that react in aqueous solution. When carbon surfaces are exposed to water, adsorption of ions (H+, OH−) produce hydroxylated surface according to Eqs. 1 and 2:

The net charge can be positive or negative, corresponding to the carbon structure, the ionic strength of solution and the pH. At relatively low pH’s, the particles have positive charge, and at relatively high pH’s, the particles have a negative charge. The point at which the total net charge on adsorbent surface reaches zero is named the point of zero charge (Gupta and Nayak 2012).

Adsorption isotherm models

In order to successfully represent the equilibrium adsorptive behavior, it is important to have a satisfactory description of the equation state between the two phases composing the adsorption system. An adsorption isotherm describes the fraction of adsorbate molecules that are partitioned between liquid and solid phases at equilibrium. Several important two variable isotherms are available to design the adsorption systems (Vijayaraghavan et al. 2006).

Freundlich isotherm

The Freundlich isotherm is applicable to both monolayer (chemisorption) and multilayer adsorption (physisorption) and is based on the assumption that the adsorbate adsorbs onto the heterogeneous surface of adsorbent. The linear from of Freundlich equation is expressed as:

where K F and n are Freundlich isotherm constants related to adsorption capacity and adsorption intensity, respectively, and C e is the equilibrium concentration (mg/l).

Langmuir isotherm

The Langmuir isotherm assumes monolayer adsorption on a uniform surface with a finite number of adsorption sites. Once a site is filled, no further sorption can take place on that site. As such the surface will eventually reach a saturation point where the maximum adsorption of the surface will be achieved. The linear form of the Langmuir isotherm model is described as:

where K L is the Langmuir constant related to the energy of adsorption and q m is the maximum adsorption capacity (mg/g).

Adsorption kinetics

Pseudo-first-order, pseudo-second-order, Elovich and intra-particle diffusion models were used to test the experimental data and thus explain the adsorption kinetic process. The procedure of adsorption kinetic was identified to adsorption equilibrium, samples were withdrawn at time intervals and the concentrations of Cd2+ ions similarly measured (Almasi et al. 2012).

Adsorption capacity

Adsorption capacity q (mg metal ion per g) was determined by mass balance, as follows:

where C 0 and C t are ion concentrations (mg/l) at initial and time of t, respectively, V is the volume of the solution (ml) and m is the mass of adsorbent (g).

Pseudo-first-order kinetic

The pseudo-first-order equation (Lagergren’s equation) describes adsorption in solid–liquid system based on the adsorption capacity onto one adsorption site on the surface of adsorbent (Salam 2013):

where S represents an unoccupied adsorption site on the surface of adsorbent and k 1 is the pseudo-first-order rate constant (h−1).

The linear from pseudo-first-order model can be expressed as:

where q e and q t (mg/g) are the adsorption capacity at equilibrium and time t (h), respectively.

Pseudo-second-order kinetic

The pseudo-second-order rate assumes that one ion is adsorbed onto two sorption sites on the adsorbent surface:

It has been applied for analyzing chemisorption kinetic from liquid solutions and linearly expressed as:

where k 2 is the rate constant for pseudo-second-order adsorption (g/mg h) and k 2 q 2e (mg/g h) is the initial adsorption rate.

Elovich kinetic

The Elovich equation is one of the rate equations widely used to the adsorption of solute from liquid solution. The linear form by assuming A E B E ≫ t and applying a boundary conditions q t = 0 at t = 0 and q t = t at t = t is presented as:

where q represents the amount of adsorbed at time t, α is the adsorption constant and a is the initial adsorption rate.

Intra-particle diffusion equation

The intra-particle diffusion equation is expressed as (Sukpreabprom et al. 2014):

where ki is the intra-particle diffusion rate constant (mg/g min0.5) and I is the intercept.

Gibbs free energy

The standard Gibbs free energy ΔG° (kJ/mol) was calculated using the equilibrium constant:

The expression of K 0 can be simplified by assuming that the concentration in the solution approaches zero resulting in C s → 0, and the activity coefficients approach unity at these very low concentrations (Huang et al. 2007). And it can be written as:

where C s and C e are metal ion concentration adsorbed (m mol/g) and metal ion concentration in equilibrium solution (mol/l).

Results and discussion

Optimization of carbonization conditions

The adsorption capacity of activated carbon is highly influenced by preparation conditions such as temperature, activation time and chemical impregnation ratio. These parameters influence the pore development and surface characterization. In this work, we separately optimized the effect of these parameters on carbonization of pomegranate peels and Fe(III) modified pomegranate peels by one factor at a tome optimization procedure.

Effect of temperature and time on activated carbon preparation

In order to produce the high product yield and adsorption capacity of activated carbon for economical validity, the temperature and time of carbonization must be well controlled. The samples were pyrolyzed at desired temperatures and activation times and then the ash content, pH, iodine number, removal efficiency of MB, and yield of preparing activated carbon under these conditions were analyzed. The temperature and time conditions and their results are presented in Table 1.

Product yield is an important measure of the feasibility for preparing activated carbon from a given precursor. According to Guo and Rockstraw (Guo and Rockstraw 2006), significant product yield differences can be observed depending on the origin of carbon material and activation process. The activated carbon yields decreased with increasing of time in a constant temperature and for all states were in a range of 37.0–57.8 % (Table 1). These results are in agreement with the findings of other researchers who reported carbon yield of 39.99–55.44 % for most activated carbon raw materials (Ioannidou and Zabaniotou 2007). It can be seen that the local agriculture by-product studied in present work has suitable carbonization yield.

According to Puri and Bansal (Puri and Bansal 1965), the iodine number value is an indication to the surface area of the activated carbon. Iodine adsorption is a simple and fast adsorption method to determine the adsorptive capacity of activated carbon. The amount of iodine adsorbed increased with increasing of time for all temperatures and reached to maximum of 983 mg/g at 400 °C and 3 h (Table 1).

Another method for evaluation of the surface area and the pore size distribution of prepared activated carbons is removal of methylene blue. The methylene blue removal value represent the adsorption capacity of activated carbon for molecules with dimension similar to methylene blue and the surface area which results from the presence of pore sizes greater than 1.5 nm (Kannan and Sundaram 2001). The removal of methylene blue increased slowly with increasing time in constant temperature and gave a maximum value of 92.2 % for carbon prepared at 400 °C for 3 h (Table 1).

The Brunauer–Emmett–Teller (BET) graphs of nitrogen adsorption–desorption isotherm and pore size distribution for FePPC is shown in Fig. 1a, b. As shown in Fig. 1a, the BET adsorption–desorption isotherms of FePPC can be described as type-IV hysteresis loops, which are indicative of the mesoporous nature of carbon porosity. Also Fig. 1b exhibited a narrow pore distribution with a peak value of around 2.5 nm, which is in good agreement with the methylene blue adsorption.

Other important parameters for characterization of carbon are pH and ash content. pH of activated carbon can be defined as the pH of a suspension of carbon in distilled water. The presence of acid functional group such as carboxylic, phenolic and others on the surface of carbon may cause the acidic property of activated carbon. The pyrolysis step increases charge surface of the sample and activation process increases the surface area and porosity of activated carbon (Chong Lua et al. 2009). The activated carbon prepared at 400 °C and for 3 h had the maximum pH value (pH = 6.11), which indicates higher functional groups. Ash content represents the non-carbon or mineral materials, which is not chemically combined with the carbon surface. It consists of various useless mineral substances, which become more concentrate during the activation process. It comprises of 1–20 % and primarily depends on the type of raw materials and activation process. High ash content is undesirable for activated carbon since it reduces the mechanical strength of carbon and affects adsorption capacity. The ash content of prepared carbons at different conditions was varied in range of 9.2–12.0 % which showed pomegranate peel has suitable ash content.

The temperature for preparation of carbon should be high enough to dry and volatilize all non-carbonaceous substances during carbonization. If the temperature of carbonization is too high, it sorely affects the activity of produced carbon. This parameter influences the molecular architecture of the carbonized materials and leads to variety of the surface sites and pores (Li et al. 2008; Zhao et al. 2015). Primary works showed that by heating a material at 500–700 °C for 3 h lead to the formation of activated carbon with large surface area (Li et al. 2008). Changing the prepared carbon structure by the imperfect burn off material layers changes the arrangement of active sites in carbon skeleton. Adsorption capacity of prepared carbons especially for metal ion depends on a number of acidic polar oxygen functional groups present on its surface. Therefore, the optimum temperature and time of carbonization was selected with regard to these parameters based on the experimental data from Table 1 as 3 h for time of carbonization, and 400 °C for temperature of carbonization. This is due to the fact that at relatively moderate temperature (300–500 °C), the oxygen is highly reactive and flows though the formed porous structure toward the inner of the particles (Laine and Yunes 1992). Under optimum conditions, the ash content, pH value, iodine number, efficiency of MB removal and carbon yield for prepared carbon were 9.9 %, 6.11, 983 mg/g, 92.2 % and 38.2 % respectively.

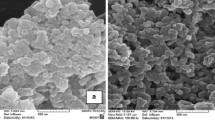

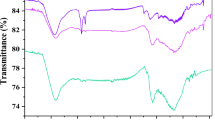

Infrared technique was used for identification of functional groups on the carbon samples. The FTIR spectra of prepared activated carbon were obtained in KBr pills (Philips PU 9624 FTIR spectrometer, UK) and indicated that there were various functional groups detected on the surface of prepared carbons. Infrared spectra of PPC and FePPC (Fig. 2) showed the characteristic peaks of PPC at 1623.06 cm−1 (C=O stretching) faced to significant shift in FePPC to 1615.49 cm−1 (C=O) which indicated the interaction of the functional groups of active constituents in pomegranate peel and complex formation after addition of Fe ions. Comparison of PPC and FePPC spectra on the other hand revealed the shifting of certain peaks. Significant band shifting from 3430.52, 1623.06, 1319.58, and 575.76 cm−1 on PPC to 3428.75, 1615.49, 1317.92, and 567.01 cm−1 on FePPC, respectively, corresponding to the bonded OH stretching, C=O stretching in carboxyl and C–O–C stretching and Fe–O has revealed the successful binding of Fe(III) ions onto pomegranate peel to form modified carbon. A similar observation has been reported for interaction of orange peel and magnetic nanoparticle in the Gupta study (Gupta and Nayak 2012).

Effect of impregnation ratio of Fe(III) to pomegranate peel on activated carbon preparation

In order to optimize the effect of Fe(III) impregnation ratio, five concentrations of 1–5 % (w/v) of FeCl3 corresponding to ratios of 0.1–0.5 were impregnated to pomegranate peel (PP) and allowed to react with natural functional groups in PP, and then the biomass was heated at optimum conditions for carbonization. The activated carbons prepared with 0.1–0.5 impregnation ratios were used for removing of Cd2+ species. Figure 3 illustrates the dependence of the removal efficiency of the activated carbon against the impregnation concentration of 1–5 % (w/v) FeCl3 solutions.

It is observed that at selected experimental conditions the use of impregnation concentration of 1 % (w/v) FeCl3 corresponding to ratio of 0.1 results in the highest removal efficiency. Higher percentage of FeCl3 increases the ash content of activated carbon and reduces the removal efficiency. The presence of iron in iron modified pomegranate peel carbon was confirmed by energy-dispersive X-ray spectroscopy (EDX) analysis. The results showed the peaks of Fe with abundance of 9.55 wt% in FePPC.

Optimization of adsorption parameters

Physiochemical factors such as temperature, rate of agitation, contact time, pH of solution, adsorbate initial concentration and adsorbent mass affect the mechanism, capacity and rate of adsorption. Optimized parameters of contact time, adsorbate initial concentration and adsorbent mass have a large economic impact on the adsorption process. It is clear that the less contact time and high adsorption capacity cause the process industrially applicable. Therefore, the effects of effective parameters were initially optimized in the constant agitation and temperature.

Effect of contact time

The time required for reaching the adsorption process to equilibrium was determined. The initial concentration of Cd2+ 50 mg/l was impacted with 0.25 g of each adsorbent at initial solution pH of 6.36. Figure 4 shows the efficiency of Cd2+ adsorption on prepared carbons at different adsorption times. Graphs indicate rapid initial uptake rate of Cd2+ adsorption at beginning until 30 min, and after that the adsorption rate became constant. It was found that the equilibrium was attained after 60 min with final adsorption of 52.1 % for PPC and 71.5 % for FePPC. It is obvious that by increasing time, adsorption of Cd2+ ions on both adsorbents increased. The adsorption rate at first depends on unoccupied sites on the surface of carbons; therefore, the Cd2+ ions adsorption was relatively high. Thereupon, the extent of Cd2+ species adsorption was constant with rising contact time until the process reached to equilibrium. Such an adsorption rate could be attributed to the external surface diffusion. Since nearly all the active sites of PPC and FePPC exist on their exterior, thus they are easily available to Cd2+ species for adsorption and rapidly approach to equilibrium.

In addition, the contact time is one of the parameters affecting on development of surface charges adsorbent/solution interface. A medium uptake of the Cd2+ species and establishment at period of 60 min indicates the chemical process is dominant for adsorption of ions.

Effect of pH

The pH of solution has a remarkable impact on the adsorption process, whereas it governs the dissociation of active sites on the adsorbent, the degree of ionization and speciation of metals. In order to characterize the effect of pH on Cd2+ species adsorption, the batch equilibrium adsorption experiments were conducted at the pH value in the range of 3–8 for both adsorbents. The selected pHs correspond to Ramos study for Cd2+ speciation (Ramos and Rangl 1997), and they showed the predominant species at pH > 8.0 was Cd(OH)2, pH = 7–8 was Cd(OH)+and pH < 7 was Cd2+. The extent of Cd2+ adsorption onto PPC and FePPC as a function of pH also is reported in Fig. 5. The maximum percent of Cd2+ removal on PPC and FePPC (29 and 89 %, respectively) were observed at pH = 7–8. It significantly drops at pH value less than 7, so the variation of pH leads to positive charge of surface and a highly decreasing of Cd2+ ions adsorption on the FePPC.

According to the acid-base Pearson theory (Pearson 1968), hard acids prefer to interact with hard bases and soft acids with soft bases. At pH lower than 7, Cd2+ ions exist in free ionic form with soft acid characteristics and have tendency for interaction with carboxyl groups as soft bases; the result caused increase in adsorption process. On the other hand the carboxyl or hydroxyl groups of adsorbents change to –COOH and –OH with H+ due to higher concentration and mobility of H+ ions in the solution which compete with Cd2+ for adsorption onto the sites of carbon, so adsorbent not able to adsorb the metal ion. It seems that the adsorption process occurs by physical adsorption or ion exchange in low pH. The maximum adsorption in the pH range of 7–8 may be due to the interaction of Cd(OH)+ with negative sites of oxygen in carboxyl and hydroxyl groups present in surface of carbon samples. In this pH range, there are lower concentrations of H+ ions and active sites on the carbon surface are more negative, therefore caused greater adsorption of Cd2+ species.

The pHzpc of an adsorbent is an important characteristic parameter, which determines the pH that the adsorbent surface is electrically neutral. The pHzpc of carbon samples was extracted from plot of pHf versus pHi and showed pHzpc of PPC and FePPC were 9.34 and 6.03, respectively. This was mostly ascribed to the fact that the pHzpc of FePPC was shifted from 9.34 to 6.03 after modification with Fe+3 ions. This further revealed that FePPC had more amounts of acidic functional groups on the surface compared to the PPC. Similar observation was made for modification of orange peels with iron oxide nanoparticles (Gupta and Nayak 2012).

At pH less than 6, the surface charge of PPC and FePPC are positive, that is unfavorable for adsorption of Cd2+. When 6 < pH < 8, the surface charge of PPC is positive and for FePPC is negative, thus it is only favorable for the adsorption of Cd2+ species on FePPC. At the same time, because of the increasing fraction of Cd(OH)+, the electrostatic attraction between PPC surface and Cd2+ species weakened. At pH > 8, the Cd2+ species appear in the form of Cd(OH)2 particles and physically adsorb on carbon surface, whereas the experiments of the Cd2+ adsorption on prepared carbons were carried out in the range of 3–8, thus it resulted in medium rate for adsorption. The variation of pH from 2 to 6 did not cause any increase in Cd2+ species removal (15–20 % for PPC and 51–67 % for FePPC), but at pH greater than 7, a moderate increase in the adsorption rate of Cd2+ species on the FePPC was observed, and it reached to 90 %.

Adsorption kinetic

The kinetic values of adsorption were analyzed using pseudo-first-order, pseudo-second-order, Elovich kinetic and intra-particle diffusion models. These models correlate solute adsorption to predict the required reactor volume. The linear forms of these models have been introduced by Eqs. 7–11. Figure 6 shows the linear relationship of the graphs, in which qe and k is determined from the slope and intercept of lines, respectively. Among the plots, the linear regression correlation coefficient (R2 value) of the pseudo-second-order line is higher than the others (Table 2).

These results confirm that the Cd2+ species adsorption onto FePPC is well represented by the pseudo-second-order kinetic model. This means that the adsorption rate is proportional to Eq. 9 and to the squared of Cd2+ species concentration. As seen in Fig. 6, in the beginning, there is high concentration of cadmium ions so the adsorption rate is fast and after 60 min, the adsorption rate becomes slow to 120 min. Adsorption does not significantly change with further increase in the contact time after reaching to equilibrium time of 120 min.

Adsorption isotherm

Adsorption capacity is an important parameter in consideration of adsorption process. According to mass balance Eq. 5, the initial adsorbate concentration, solution volume and adsorbent dosage affect adsorption capacity. In this work, isotherm studies were recorded by varying the initial concentrations of Cd2+ ions and the adsorption capacity q e (mg/g) was calculated at constant volume and adsorbent dosage. The experimental data were fitted to two kinds of popular isotherm equations (Langmuir, Freundlich). The linearized Langmuir and Freundlich isotherm plots are showed in Fig. 7. The estimated parameters with correlation coefficient (R 2) for the different models have been listed in Table 3. The value of R 2 is considered as a measure of the goodness-of-fit of experimental data on the isotherm’s model. The R 2 values confirmed that adsorption of Cd2+ species onto the FePPC obeyed to the both Langmuir and Freundlich isotherms.

Langmuir adsorption isotherm

The Langmuir isotherm is based on the assumption that maximum adsorption corresponds to formation of a saturated monolayer of solute particles on the adsorbent surface and the energy of adsorption is constant (Won et al. 2006). The essential characteristic of the Langmuir isotherm may be expressed in terms of dimensionless separation parameter R L, which is indicative of the isotherm shape that predicts whether an adsorption system is favorable (0 < R L < 1) or unfavorable (R L > 1). R L from Langmuir equation was obtained 0.21 that showed adsorption of Cd2+ species on FePPC is favorable. qmax (mg/g) in the Langmuir equation indicates the measure of adsorption capacity under the experimental conditions which was for FePPC 22.72 mg/g and had a good agreement with experimental values reported in previous works on other adsorbents (Table 4). However, a direct comparison of adsorbent materials is difficult due to the differences in experimental conditions. The obtained biosorption capacity of Fe–PPC for removal of cadmium (II) ions from aqueous solutions shows that, except for some nanosorbents, the experimental data of the present study were found to be higher than other adsorbents. However, it is very important to consider the environment effect aspects of the nanoparticles to form an appropriate sorbent. As a result, it could be concluded that pomegranate peel carbon prepared from wastes of pomegranate juice processing used in this study had an additional advantage of being abundant and economic.

Freundlich adsorption isotherm

The Freundlich isotherm is an empirical equation which confirms that the stronger binding sites are first occupied and the binding strength decrease with the increasing degree of site occupation. In Freundlich isotherm, the parameter n is heterogeneous factor, indicative of bond energies between metal ion and the adsorbent and K F, related to bond strength. At pH of 6.35, K F and n F obtained to be 5.42 and 3.7 indicate that the binding capacity and the affinity between the FePPC and Cd(II) ions is strong.

Adsorption thermodynamic

Thermodynamic considerations of an adsorption process are necessary to conclude whether the process is spontaneous or not. The Gibbs free energy change thermodynamic parameter (ΔG°) is indicator of spontaneous reaction. The negative values of ΔG° confirm the feasibility of the process and the spontaneous nature of adsorption process. The standard Gibbs free energy change can be determined from the thermodynamic equilibrium constant, K 0 (or the thermodynamic distribution coefficient K d) in Eq. 12. Equilibrium constant was determined using directly from the equilibrium adsorption and isotherm models (Table 5). Negative ΔG° value indicates the adsorption of Cd2+ species onto FePPC is naturally spontaneous. Von Oepen et al. have obtained the adsorption free energy of several kinds of interactions as follows: Van der Waals forces 4–10 kJ/mol, hydrophobic interactions 5 kJ/mol, hydrogen bonding 2–40 kJ/mol, coordination exchange 40 kJ/mol, dipole forces 2–29 kJ/mol, chemical bonds more than 60 kJ/mol (Von Oepen et al. 1991). According to Table 4, there is a large difference between the free energy change of the Langmuir and Freundlich isotherm models. According to experimental data, the main interactions for adsorption of Cd2+ species onto the FePPC adsorbent are in the range of dipole forces.

Conclusion

The fixed at a time variable method was used to optimize the conditions for preparation of pomegranate peel carbons. At optimum carbonization temperature of 400 °C and combustion time of 3 h, the best carbonization yield was resulted. For chemical modification of pomegranate peel surfaces with Fe(III) ions, the impregnation ratio of 0.1 was used that caused suitable functional groups to increase on the surface of carbon samples and improved the capacity of adsorption and observed that Cd2+ species adsorption on FePPC reached to 22.72 mg/g capacity at pH = 6.36 (pHzpc).

The adsorption kinetic study of Cd2+ species onto the prepared carbons represented that the adsorption obeyed the pseudo-second-order and nonlinear intra-particle diffusion models. At equilibrium conditions, both of Langmuir and Freundlich isotherms showed similar results for adsorption of Cd2+ species onto the FePPC. This means that modification of pomegranate surfaces with Fe(III) ions caused monolayer and multilayer adsorption of Cd2+ species. The results indicated that FePPC has good potential for removal of Cd2+ species from contaminated aqueous solutions.

References

Almasi A, Omidi M, Khodadadian M, Khamutian R, Gholiv MB (2012) Lead(II) and cadmium(II) removal from aqueous solution using processed walnut shell: kinetic and equilibrium study. Toxicol Environ Chem 94:660–671

Amin NK (2009) Removal of direct blue-106 dye from aqueous solution using new activated carbons developed from pomegranate peel: adsorption equilibrium and kinetics. J Hazard Mater 165:52–62

Anayurt RA, Sari A, Tuzen M (2009) Equilibrium, thermodynamic and kinetic studies on biosorption of Pb(II) and Cd(II) from aqueous solution by macrofungus (Lactarius scrobiculatus) biomass. Chem Eng J 151:255–261

Azouaou N, Sadaoui Z, Djaafri A, Mokaddem H (2010) Adsorption of cadmium from aqueous solution onto untreated coffee grounds: equilibrium, kinetics and thermodynamics. J Hazard Mater 184:126–134

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97:219–243

Chong Lua A, Yow Lau F, Guo J (2009) Influence of pyrolysis conditions on pore development of oil–palm–shell activated carbons. J Anal Appl Pyrolysis 76:96–102

El Nemr A (2009) Potential of pomegranate husk carbon for Cr(VI) removal from wastewater: kinetic and isotherm studies. J Hazard Mater 161:132–141

El-Ashtoukhy SZ, Amin NK, Abdelwahab O (2008) Removal of lead(II) and copper(II) from aqueous solution using pomegranate peel as a new adsorbent. Desalination 223:162–173

Guo Y, Rockstraw DA (2006) Physicochemical properties of carbons prepared from pea nut by phosphoric acid activation. Bioresource Technol 98:1513–1528

Gupta VK, Nayak A (2012) Cadmium removal and recovery from aqueous solutions by novel adsorbents prepared from orange peel and Fe2O3 nanoparticles. Chem Eng J 180:80–90

Huang X, Gao N, Zhang Q (2007) Thermodynamics and kinetics of cadmium adsorption onto oxidized granular activated carbon. J Environ Sci 19:1287–1292

Hussein MH, Tarmizi RSH, Zainal Z, Ibrahim R, Badri M (1996) Preparation and characterization of active carbons from oil palm shell. Carbon 34:1447–1454

Ioannidou O, Zabaniotou A (2007) Agricultural residues as precursors for activated carbon production: a review. Renew Sust Energy Rev 11:1966–2005

Jain M, Garg VK, Kadirvelu K, Sillanpaa M (2016) Adsorption of heavy metals from multi-metal aqueous solution by sunflower plant biomass-based carbons. Int J Environ Sci Technol 13:493–500

Kannan N, Sundaram MM (2001) Kinetics and mechanism of removal of methylene blue by adsorption on various carbons-a comparative study. Dyes Pigments 51:25–40

Kipling JJ, Wilson RB (1960) Adsorption of methylene blue in the determination of surface areas. J Appl Chem 10:109–113

Krika F, Azzouz N, Ncibi MC (2015) Adsorptive removal of cadmium from aqueous media using Posidonia oceanica biomass: equilibrium, dynamic and thermodynamic studies. Int J Environ Sci Technol 12:983–994

Laine J, Yunes S (1992) Effect of the preparation method on the pore size distribution of activated carbon from coconut shell. Carbon 30:601–604

Li W, Yang K, Peng J, Zhang L, Guo S, Xia H (2008) Effects of carbonization temperatures on characteristics of porosity in coconut shell chars and activated carbons derived from carbonized coconut shell chars. Ind Crops Prod 28:190–198

Mohammad-Khah A, Ansari R (2009) Activated charcoal: preparation, characterization and applications: a review article. Int J Chem Technol Res 4:859–864

Oh GH, Park CR (2002) Preparation and characteristics of rice-straw-based porous carbons with high adsorption capacity. Fuel 81:327–336

Onal Y, Akmil-Basar C, Sarici-Ozdemir C, Erdoğan S (2007) Textural development of sugar beet bagasse activated with ZnCl2. J Hazard Mater 142:138–143

Pearson RG (1968) Hard and soft acids and bases, HSAB, part 1: fundamental principles. J Chem Educ 45:581–586

Puri BR, Bansal RC (1965) Iodine adsorption method for measuring surface area of carbon blacks. Carbon 3:227–230

Ramos RL, Rangl JR (1997) Adsorption of cadmium from aqueous solution onto activated carbon. Water Sci Technol 35:205–211

Saad H, Bouhtoury C, Pizzi A, Rode K, Charrier B, Ayed N (2012) Characterization of pomegranate peels tannin extractives. Ind Crops Prod 40:239–246

Salam MA (2013) Removal of heavy metal ions from aqueous solutions with multi-walled carbon nanotubes: kinetic and thermodynamic studies. Int J Environ Sci Technol 10(4):677–688

Sari A, Tuzen M (2009) Kinetic and equilibrium studies of biosorption of Pb(II) and Cd(II) from aqueous solution by macrofungus (Amanita rubescens) biomass. J Hazard Mater 164:1004–1011

Sari A, Mendil D, Tuzen M, Soylak M (2008) Biosorption of Cd(II) and Cr(III) from aqueous solution by moss (Hylocomium splendens) biomass: equilibrium, kinetic and thermodynamic studies. Chem Eng J 144:1–9

Soleimani M, Kaghazchi T (2007) Agricultural waste conversion to activated carbon by chemical activation with phosphoric acid. Chem Eng Technol 30:649–654

Sukpreabprom H, Arquero OA, Naksata W, Sooksamiti P, Janhom S (2014) Isotherm, kinetic and thermodynamic studies on the adsorption of Cd(II) and Zn(II) ions from aqueous solutions onto bottom ash. Int J Environ Sci Dev 5:161–170

Tehranifar A, Zarei M, Nemati Z, Esfandiyari B, Vazifeshenas MR (2010) Investigation of physico-chemical properties and antioxidant activity of twenty Iranian pomegranate (Punica granatum L.) cultivars. Sci Hortic Amst 126:180–185

Tsai WT, Chang CY, Lee SL (1998) A low cost adsorbent from agricultural waste corn cob by zinc chloride activation. Bioresour Technol 64:211–217

Vijayaraghavan K, Padmesh TVN, Palanivelu K, Velan M (2006) Biosorption of nickel(II) ions onto Sargassum wightii: application of two-parameter and three-parameter isotherm models. J Hazard Mater B 133:304–308

Von Oepen B, Kordel W, Klein W (1991) Sorption of nonpolar and polar compounds to soils: processes, measurement and experience with the applicability of the modified OECD guideline 106. Chemosphere 22:285–304

Wang SL, Tzou YM, Lu YH, Sheng G (2007) Removal of 3-chlorophenol from water using rice straw based carbon. J Hazard Mater 147:313–318

Won SW, Wu G, Ma H, Lio Q, Yan Y, Cui L, Liu C, Yun YS (2006) Adsorption performance and mechanism in binding of Reactive Red 4 by coke waste. J Hazard Mater B 138:370–377

Yang T, Guo J (2004) Effects of pyrolysis conditions on the properties of activated carbons prepared from pistachio–nut shells. J Anal Appl Pyrol 72:279–287

Zhao Y, Fang F, Xiao HM, Feng QP, Xiong LY, Fu ShY (2015) Preparation of pore-size controllable activated carbon fibers from bamboo fibers with superior performance for xenon storage. Chem Eng J 270:528–534

Acknowledgments

We thank the Iranian Research Organization for Science and Technology (IROST) and Shahid Sadoughi University of Medical Science which supported this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Abedi, M., Salmani, M.H. & Mozaffari, S.A. Adsorption of Cd ions from aqueous solutions by iron modified pomegranate peel carbons: kinetic and thermodynamic studies. Int. J. Environ. Sci. Technol. 13, 2045–2056 (2016). https://doi.org/10.1007/s13762-016-1002-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-016-1002-7