Abstract

Multi-walled carbon nanotubes were used successfully for the removal of Copper(II), Lead(II), Cadmium(II), and Zinc(II) from aqueous solution. The results showed that the % adsorption increased by raising the solution temperature due to the endothermic nature of the adsorption process. The kinetics of Cadmium(II), Lead(II), Copper(II), and Zinc(II) adsorption on Multi-walled carbon nanotubes were analyzed using the fraction power function model, Lagergren pseudo-first-order, pseudo-second-order, and Elovich models, and the results showed that the adsorption of heavy metal ions was a pseudo-second-order process, and the adsorption capacity increased with increasing solution temperature. The binding of the metal ions by the carbon nanotubes was evaluated from the adsorption capacities and was found to follow the following order: Copper(II) > Lead(II) > Zinc(II) > Cadmium(II). The thermodynamics parameters were calculated, and the results showed that the values of the free energies were negative for all metals ions, which indicated the spontaneity of the adsorption process, and this spontaneity increased by raising the solution temperature. The change in entropy values were positives, indicating the increase in randomness due to the physical adsorption of heavy metal ions from the aqueous solution to the carbon nanotubes’ surface. Although the enthalpy values were positive for all metal ions, the free energies were negative, and the adsorption was spontaneous, which indicates that the heavy metal adsorption of Multi-walled carbon nanotubes was an entropy-driving process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the discovery of carbon nanotubes (Iijima 1991), they have attracted considerable interest due to their outstanding structural characteristics, such as unique electronic properties, interesting physicochemical properties, excellent thermal conductivity, high thermal stability, and mechanical strength, which allows them to be used in various applications (Fam et al. 2011; Gomez-Gualdrón et al. 2011; Cheung et al. 2010; Khandoker et al. 2011; Chu et al. 2010). One of the promising applications of carbon nanotubes is their use as an adsorbent for the removal of different environmental contaminants such as heavy metals (Kosa et al. 2012; Abdel Salam et al. 2011; Vuković et al. 2011; Rao et al. 2007; Tofighy and Mohammadi 2011) and organic pollutants (Al-Johani and Abdel Salam 2011; Abdel Salam et al. 2010a; Ai et al. 2011) from polluted water. Industrial wastewater contaminated with heavy metals is commonly produced from various industrial activities. Therefore, efficient treatment of the wastewater is crucial as it can cause a serious environmental problem that will affect the natural ecosystem. Exposure to heavy metals such as cadmium, lead, copper, and zinc, even at very low levels, is believed to pose a risk to living organisms through their toxic effect. There are various techniques currently used for efficient removal of heavy metal from waters, such as electrochemical technologies, chemical precipitation, membrane filtration, ion exchange, and adsorption (Fu and Wang 2011; O’Connell et al. 2008; Kurniawan et al. 2006). Among these techniques, adsorption is considered the most effective because it offers flexibility in operation and design; it also has a reversible nature as adsorbents can be regenerated by suitable desorption processes for multiple use (Pan et al. 2009). In most cases, it produces high-quality treated effluent. Hence, the adsorption process has come to the forefront as one of the major techniques for heavy metal removal from wastewater. Consequently, the investigation of new classes’ adsorbents and their application for the removal of heavy metals became the main concern and challenge of environmental remediation scientists around the world.

Although there are many studies that focused on heavy metals removed from polluted water using carbon nanotubes (Kosa et al. 2012; Abdel Salam et al. 2011; Vuković et al. 2011; Rao et al. 2007; Tofighy and Mohammadi 2011), there is a need for more research to explore their adsorption on different types of carbon nanotubes from the kinetic and thermodynamic point of view to reveal the possible adsorption mechanism for efficient removal. The study of adsorption kinetics illustrates the adsorbate uptake rate. This rate governs the residence time of the adsorbate at the solid–solution interface. Adsorption kinetics is the study of the adsorption process rate to understand the factors that affect the adsorption process. The study of adsorption kinetics includes careful monitoring of the experimental conditions that influence the speed of adsorption, such as solution temperature, and hence help attain equilibrium in a reasonable length of time. Kinetic studies help to develop appropriate mathematical models to describe the interactions between the adsorbent and the adsorbate. Kinetic studies provide valuable information about the possible adsorption mechanism and the different transition states on the way to the formation of the final adsorbate–adsorbent complex. Once the adsorption rates and the dependent factors are clearly identified, the development of adsorbent materials for industrial application could be evaluated and optimized. Currently, there are quite a few mathematical models used for adsorption description. These mathematical models could be classified as adsorption reaction models; which consider the adsorption as one step, and adsorption diffusion models which assume that adsorption occurs in three main consecutive steps; liquid film diffusion, followed by intra-particle diffusion and finally adsorption and desorption between the adsorbate and adsorbent active sites (Qiu et al. 2009). The main objectives of this manuscript were first to study the adsorption of Cd(II), Pb(II), Cu(II), and Zn(II), from aqueous solution by MWCNTs kinetically and thermodynamically, and secondly to explore the potentiality of using carbon nanotubes as a promising adsorbent for environmental remediation. In this research paper, the effect of temperature on the adsorption of cadmium, lead, copper, and zinc ions by MWCNTs was investigated kinetically and thermodynamically. Both kinetic mathematical models; adsorption reaction models and adsorption diffusion models, were applied to the kinetic data, and different mechanisms were postulated and evaluated. Different thermodynamic parameters, Gibbs free energy change (ΔG), enthalpy change (ΔH), and entropy change (ΔS) were calculated to evaluate the thermodynamic feasibility and the spontaneous nature of the process. This research has been carried out in the Chemistry Department, Faculty of Science, King Abdulaziz University, (Jeddah, Saudi Arabia), in September 2011.

Materials and methods

Materials

Multi-walled carbon nanotubes with average diameter between 20 and 40 nm were obtained from Shenzhen Nanotech Port Co., Ltd and were used as received. Analytical grade cadmium, lead, copper and zinc nitrate (Fluka, Ion Solution, 1,000 mg/L) were employed to prepare stock solutions each containing 100 mg/L of Cd(II), Pb(II), Cu(II) and Zn(II). The stock solutions were further diluted to the desired ion concentrations. All other chemicals were of analytical grade and were obtained from Sigma-Aldrich. The experiments were performed using ultrapure water with resistivity not <18.2 MΩcm obtained with a Millipore Milli-Q system (Billerica, USA).

Characterization techniques

A transmission electron microscope (TEM) (type JEOLJEM-1230 operating at 120 kV attached to a CCD camera) was used to characterize the morphological structure of the MWCNTs. The specific surface area of the different MWCNTs was determined from nitrogen adsorption/desorption isotherms measured at 77 K using a model NOVA 3200e automated gas sorption system (Quantachrome, USA).

Analytical measurements

The total metal ion concentration was determined by voltammetric measurement using a Metrohm, 797 VA computrace (Switzerland) with a three electrode system, including hanging mercury as the working electrode, a platinum plate as the counter electrode, and Ag/AgCl (3.0 mol/L KCl) as the reference electrode. The metal ion determination was evaluated by differential pulse anodic stripping voltammetry (DPASV).

Adsorption experiments

Kinetic experiments were carried out to establish the effect of time and temperature on the adsorption process and to identify the adsorption rate. The experimental procedures are described as follows: (1) a series of 100 ml solutions containing 0.5 mg/L of Cd(II), Pb(II), Cu(II) and Zn(II) was prepared in 250 ml glass bottles and kept at 278, 298, 313, or 333 K, (2) the pH of the solution was adjusted to 7.0 using universal pH buffer (Britton–Robinson buffer), (3) the ionic strength was adjusted to 0.01 M using a 0.10 M KNO3 solution, (4) 125 mg of MWCNTs was added into the solution, (5) the solution was shaked continuously for a period of time starting from 1 to 120 min, (6) after the completion of preset time intervals, the solution was taken and immediately filtered through a filter paper to collect the supernatant, (7) the residual metal ion concentrations in the aqueous solution were then determined by DPASV and the amount of adsorbed metals ions were calculated as follows:

where q is the amount of metals ions adsorbed by the MWCNTs (mg/g), C 0 is the initial metals ion concentration (mg/L), C t is the final metal ion concentration after a certain period of time (mg/L), V is the initial solution volume (L) and m is the MWCNT dose (g). The percentage of removed metal ions in solution was calculated using Eq. (2):

It is noteworthy to mention that, the adsorption of metals ions on the walls of the glass flasks and the filter paper was determined by running a blank experiment without MWCNTs and found to be negligible.

Results and discussion

Characterization of multi-walled carbon nanotubes

Figure 1 presents images produced by TEM imaging, which revealed the morphological structure of the MWCNTs. It is clear from the images that the MWCNTs were long and entangled with an average diameter between 20 and 40 nm and a length of 5 μm. The TEM analysis verified the hollow structure of MWCNTs used and showed that the inner diameter was between 3 and 10 nm. The nitrogen adsorption/desorption isotherms were determined from an N2 adsorption isotherm measured at 77 K, and the results are presented in Fig. 2. The specific surface area was calculated using the Brunauer–Emmett–Teller equation-specific surface areas and was found to be 69.0 m2/g.

Kinetic studies

The effect of temperature on the removal of Cd(II), Pb(II), Cu(II), and Zn(II) from aqueous solution by MWCNTs was studied kinetically, and the results are presented in Fig. 3. It is clear from Fig. 3 that the adsorption process was enhanced by increasing the solution temperature. The % removal of Cd(II) increased from 16.1 to 34.8 %, whereas for Pb(II), the % removed increased from 83.6 to 99.2 %, and for Zn(II), the % removed increased from 74.6 to 95.9 %, when the solution temperature raised from 278 to 333 K, respectively. In the case of Cu(II), there was not any significant change in the % removed by raising the solution temperature as the % removed was mostly 100 %. This enhancement in the adsorption of Cd(II), Pb(II), Cu(II), and Zn(II) with MWCNTs by raising the solution temperature may indicate the endothermic nature of the adsorption process. The Fig. 3 also showed that the adsorption reached equilibrium after 15 min in the case of Cd(II), Pb(II), and Zn(II), regardless of temperature, whereas in the case of Cu(II), the adsorption reached equilibrium after 1 min, at all temperatures, which indicates the strong binding of Cu(II) to MWCNTs compared to the other metal ions under investigation. At 298 K, The binding of the metal ions by MWCNTs followed this order: Cu(II) > Pb(II) > Zn(II) > Cd(II), which is consistent with the authors’ previous study (Kosa et al. 2012). The high percentage of Cu(II) removed from solution by MWCNTs; almost 100 %, was explained earlier in previous study and could be summarized as: Cu(II) usually form inner-sphere complexation, the Cu(II) complexes stabilized by the Jahn–Teller effect, and its ability to be reduced by the carbonaceous surface (Kosa et al. 2012). As was explained earlier, the lower adsorption of Cd(II) might be due to its lower tendency to form hydrolysis products and because its ions do not compete effectively for variable charge surfaces, such as MWCNTs, which restrict its adsorption to permanently charged sites (Srivastava et al. 2005).

Many kinetic models could be used to describe the adsorption of heavy metal ions by MWCNTs from aqueous solution at different temperatures. The kinetics of Cd(II), Pb(II), Cu(II), and Zn(II) adsorption on MWCNTs were analyzed using the chemical reaction models such as fraction power function (Khambhaty et al. 2009), Lagergren pseudo-first-order (Lagergren 1898), pseudo-second-order (Ho et al. 2000), and Elovich models (Ho and McKay 2002).

The fractional power function model is a modified form of the Freundlich equation and can be written in its linearized form as follows:

where q t (mg/g) is the amount of metal ion adsorbed per unit mass of MWCNTs at any time t while a and b are coefficients with b < 1. The function ab is the specific sorption rate when t = 1 min. By the application of the fractional power function equation to the adsorption of the target metal ions on MWCNTs at different solution temperatures, a linear relationship that exists between ln q t and ln t with very low correlation coefficients was obtained. This may indicate that the fractional power function model was not the appropriate model to describe the adsorption of the Cd(II), Pb(II), Cu(II), and Zn(II) on MWCNTs.

Lagergren pseudo-first-order kinetics is one of the most used equations to describe adsorption from aqueous solution by solid adsorbent:

where k 1 (min−1) is the pseudo-first-order adsorption rate coefficient, and q e and q t are the values of the amount adsorbed per unit mass at equilibrium and at any time t, respectively. Plotting ln (q e − q t ) versus t for the four metal ions at the four different temperatures under investigation did not converge well and did not give straight lines (Fig. 4), which indicates that the pseudo-first-order Lagergren equation was inappropriate to describe the adsorption of the Cd(II), Pb(II), Cu(II), and Zn(II) on MWCNTs.

The pseudo-second-order equation has also been considered to describe the adsorption of the Cd(II), Pb(II), Cu(II), and Zn(II) on MWCNTs. The pseudo-second-order model assumed that the adsorption; in general, might be second order, the rate limiting step may be chemical adsorption involving sharing or exchange of electrons between the solid adsorbent and divalent metal ions, and finally the adsorption follows the Langmuir equation (Ho and McKay 2000). The linearized form of the pseudo-second-order rate equation is as follows:

where k 2 (g/mg min) is the pseudo-second-order rate coefficient, and q e and q t are the values of the amount adsorbed per unit mass at equilibrium and at any time t, respectively. The plot of t/q t and t of Eq. (4) must give a linear relationship from which q e and k 2 can be estimated from the slope and intercept of the plot, respectively. Applying the pseudo-second-order rate equation to the adsorption of Cd(II), Pb(II), Cu(II), and Zn(II) experimental data converged very well for all the metal ions with excellent regression coefficients (R 2 > 0.99) and straight lines (Fig. 5). These findings prove the suitability of the pseudo-second-order rate equation for the description of the Cd(II), Pb(II), Cu(II), and Zn(II) adsorption by MWCNTs from aqueous solution. The pseudo-second-order rate equation parameters; q e, and k 2, calculated from the slope and intercept of the plot of t/q t versus t are showed in Table 1. It is clear from the table that the amount of metal ions adsorbed per unit mass of MWCNTs at equilibrium (q e,calc) calculated from the slope of the pseudo-second-order plot was in good agreement with experimental values (q e,exp). In general, the amount adsorbed at equilibrium (q e) increased by raising the solution temperature, indicating the endothermic nature of the adsorption process of the target heavy metal ions on MWCNTs from aqueous solution, which is consistent with other adsorbents such as MWCNTs/chitosan composite (Abdel Salam et al. 2011), silica-supported dithiocarbamate (Bai et al. 2011), and amine-functionalized mesoporous Fe3O4 nanoparticles (Xin et al. 2012). The applicability of the pseudo-second-order rate equation for the adsorption of Cd(II), Pb(II), Cu(II), and Zn(II) by MWCNTs agreed well with previous studies, but the current study is distinguished by the low equilibration time (Tofighy and Mohammadi 2011; Bai et al. 2011; Lu et al. 2006; Ruparelia et al. 2008).

The Elovich equation is another kinetic model that describes the adsorption of adsorbate by a solid in an aqueous medium (Ho and McKay 2002). The linear form of the Elovich equation is as follows:

where α and β are the Elovich coefficients that represent the initial adsorption rate [g/(mg min)] and the desorption coefficient [mg/(g min)], respectively. The Elovich coefficients were calculated from the plots of q t versus ln t after applying the Elovich equation to the experimental data and the results are presented at Fig. 6. The Elovich coefficients α and β were calculated from the slope and intercept of the plots of Fig. 6. The correlation coefficients of the Elovich plots were not satisfactory in most cases, which indicate the unsuitability of the Elovich equation to describe the adsorption of the metal ions under investigation.

Comparing the results obtained from application of different chemical reaction models; fractional power function model, the Lagergren pseudo-first-order model, the pseudo-second-order model, and the Elovich equation, to fit the experimental data, it could conclude that the adsorption of Cu(II), Pb(II), Cd(II), and Zn(II) from an aqueous solution by MWCNTs could be expressed well by the pseudo-second-order model. Fitting the experimental data with the pseudo-second-order model yielded straight lines with excellent regression coefficients (R 2 > 0.99) and with good agreement between experimental and calculated amount of metal ions adsorbed per unit mass of MWCNTs at equilibrium. The finding agrees with previous results for the adsorption of heavy metals on different adsorbents (Ho and McKay 2002; Kwon et al. 2010; Liu et al. 2011). Although the application of the present MWCNTs for the removal of Cd(II), Pb(II), Cu(II), and Zn(II) from aqueous solution characterized with low adsorption capacities; 0.084, 0.386, 0.398, and 0.325 mg/g; at 298 K, respectively, compared with other MWCNTs reported in literature (Tofighy and Mohammadi 2011; Lu et al. 2006; Ruparelia et al. 2008), the present work characterized with short equilibration time; almost 5 min, whereas the other studies have more equilibration time (Tofighy and Mohammadi 2011; Bai et al. 2011; Lu et al. 2006; Ruparelia et al. 2008). Also, the calculated pseudo-second-order rate constants in the present study were significantly higher compared with the previous studies (Tofighy and Mohammadi 2011; Vukovića et al. 2010).

From the adsorption diffusion approach, the adsorption of the Cu(II), Pb(II), Cd(II), and Zn(II) from an aqueous solution by MWCNTs takes place at different steps, film diffusion, followed by intra-particle diffusion, followed by mass action (adsorption/desorption). In this study, it was observed that the adsorption of the heavy metal ions under investigation by MWCNTs took place in two distinctive steps. This agreed well with the physical adsorption through the adsorption diffusion approach where the mass transfer is a very fast step, and the adsorption process always controlled by liquid film diffusion or intra-particle diffusion or both of them together (Qiu et al. 2009). Therefore, it is important to use adsorption diffusion models for the description of the kinetic process.

The intra-particle diffusion model by Weber and Morris (1963) could be expressed as follows:

where, q t is adsorption capacity at any time t; k id is the intra-particle diffusion rate constant (mg/g min1/2); and C (mg/g) is a constant proportional to the thickness of the boundary layer. Applying the intra-particle diffusion model to the experimental data for the metal ions under investigation at different temperatures did not converge well and did not give straight lines to pass through the origin (Fig. 7). This may indicate that the intra-particle diffusion model is not the rate determining step.

Liquid film diffusion is another kinetic model that assumes that the flow of the adsorbate molecules through a liquid film surrounding the solid adsorbent is the slowest step in the adsorption process and determines the kinetics of the rate processes. The liquid film diffusion model is given by the following equation (Boyd et al. 1947):

where F is the fractional attainment of equilibrium (F = q t /q e), and k fd (min−1) is the film diffusion rate coefficient. A linear plot of −ln(1 − F) versus t with zero intercept suggests that the kinetics of the adsorption process are controlled by diffusion through the liquid film. The application of the liquid film diffusion model to the adsorption of Cu(II), Pb(II), Cd(II), and Zn(II) by MWCNTs at different temperatures did not converge well and did not provide a straight line through the origin, which indicated that the liquid film diffusion model is not the rate determining step.

According to the adsorption diffusion models, it could be concluded that the removal of the Cu(II), Pb(II), Cd(II), and Zn(II) by MWCNTs from an aqueous solution involves different steps, including the migration of metal ions from the bulk solution to the external surface of MWCNTs, followed by the diffusion of metal ions through the boundary layer to the external surface of MWCNTs. This is then followed by the adsorption of metal ions at an active site on the MWCNTs’ surface and finally the intra-particle diffusion and adsorption of metal ions through the MWCNTs aggregates. However, in this study the adsorption kinetics may be controlled by both film diffusion and intra-particle diffusion simultaneously. Finally, it is noteworthy to mention that the adsorption is mainly due to the electrostatic attraction between the positively charged metal ions and the delocalized π electrons at the MWCNTs’ surface (Abdel Salam and Burk 2008).

The pseudo-second-order rate constant for the removal of heavy metal ions under investigation could be expressed as a function of temperature by the Arrhenius type relationship:

where E a is the Arrhenius activation energy of adsorption, representing the minimum energy that reactants must have for the reaction to proceed; A is the Arrhenius factor; R is the gas constant and is equal to 8.314 J/mol/K; and T is the solution temperature. The adsorption activation energies obtained were 6.30, 18.1, 9.94, and 11.2 kJ/mol for Cu(II), Pb(II), Cd(II), and Zn(II) adsorbed by MWCNTs, respectively. These low activation energies indicate that the adsorption of the heavy metal ions was physical in nature; the physical adsorption is characterized by activation energy between 5 and 40 kJ/mol (Nollet et al. 2003).

Thermodynamic parameters were evaluated to confirm the adsorption nature of the heavy metal ions under investigation by MWCNTs. The thermodynamic parameters, Gibbs free energy change (ΔG), enthalpy change (ΔH), and entropy change (ΔS) were calculated to evaluate the thermodynamic feasibility and the spontaneous nature of the process. Thermodynamic parameters were calculated from the variation of the thermodynamic equilibrium constant K 0 with a change in temperature (Dąbrowski et al. 2005; Abdel Salam and Burk 2010b). K 0 for the adsorption reaction can be defined as follows:

where a s and a e are the activities of the adsorbed metal ions on the MWCNTs’ surface and in solution at equilibrium, respectively; γs and γ e are the activity coefficients of the adsorbed metal ions on the MWCNTs’ surface and in solution at equilibrium, respectively; C s is the surface concentration of metal ions in mole per gram of MWCNTs; C e, is the aqueous concentration of the metal ions at equilibrium (mol/L); \( C_{\text{s}}^{0} \) is the surface concentration of the metal ions at monolayer coverage of the adsorbent and its value calculated from the adsorption isotherm (unpublished data); \( C_{\text{e}}^{0} \) is the molar concentration of the metal ions at conditions (1 M). In diluted solution and at low surface coverage, γs and γe approach unity and Eq. (10) reduced to the following:

The free energy change (∆G) for adsorption can be calculated using the following equation:

The average enthalpy change ΔH could be estimated using the Van’t Hoff equation:

The entropy changes (∆S) are calculated as follows:

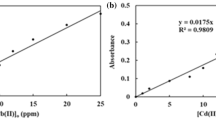

Using Eqs. 7–10, the free energy change, ∆G; the enthalpy change, ∆H; and the change in the entropy, ∆S were calculated from the variation of the thermodynamic equilibrium constant; K 0, with a change in temperature. Table 2 presents the thermodynamic parameters for the adsorption of Cd(II), Pb(II), Cu(II), and Zn(II) by MWCNTs from an aqueous solution at different temperatures. It is obvious from the table that the free energy change, ∆G, is always negative for the adsorption of the four target metal ions under investigation by MWCNTs, as would be expected for a product-favored reaction. These ∆G values became less negative as the temperature increased, indicating the endothermic nature of the adsorption of Cd(II), Pb(II), Cu(II), and Zn(II) by MWCNTs from an aqueous solution. Figure 8 shows the linear plots of ln(K 0) versus (1/T) for the adsorption of heavy metal ions under investigation on MWCNTs and the values of ∆H were calculated from the slope. The enthalpy change (∆H) values were +14.5, +41.7, +22.9, and +25.8 kJ/mol, for Cd(II), Pb(II), Cu(II), and Zn(II) adsorbed by MWCNTs, respectively. These positive values verify the endothermic nature of the heavy metal adsorption on MWCNTs, which explains the decrease in adsorption at higher temperatures. The positive values of ∆S suggested the increase in the degree of freedom at the solid–liquid interface mostly encountered in metal binding due to the release of water molecules of the hydration sphere during the adsorption processes. Although the enthalpy values were positive for all metal ions, the free energies were negative, and the adsorption was spontaneous, which indicates that the heavy metal adsorption on MWCNTs was an entropy-driving process.

Conclusion

The removal of Cd(II), Pb(II), Cu(II), and Zn(II) from an aqueous solution at different temperatures by multi-walled carbon nanotubes was studied kinetically and thermodynamically. The results showed the enhancement of the adsorption by raising the solution temperature, which indicated the endothermic nature of the adsorption process. At 298 K, the binding of the metal ions by MWCNTs was found to follow the following order: Cu(II) > Pb(II) > Zn(II) > Cd(II). The kinetics of Cd(II), Pb(II), Cu(II), and Zn(II) adsorption on MWCNTs were analyzed using different kinetic models, and the results revealed that the adsorption of the heavy metal ions process was a pseudo-second-order process. The thermodynamics study showed that the adsorption process is spontaneous in the experimental temperature range and becomes more spontaneous by raising the solution temperature. The positive values of enthalpy for the adsorption of Cd(II), Pb(II), Cu(II), and Zn(II) by MWCNTs from an aqueous solution verified the endothermic nature of the heavy metal adsorption. The changes in entropy values were positives, indicating the increase in randomness due to the physical adsorption of heavy metal ions from the aqueous solution to the carbon nanotubes surface. Finally, carbon nanotubes demonstrated that they are a promising adsorbent for the removal of heavy metal ions from an aqueous solution.

References

Abdel Salam M, Burk RC (2008) Novel application of modified multi-walled carbon nanotubes as a solid-phase extraction adsorbent for the determination of polyhalogenated organic pollutants in aqueous solution. Anal Bioanal Chem 390:2159–2170

Abdel Salam M, Burk RC (2010) Thermodynamics and kinetics studies of pentachlorophenol adsorption from aqueous solutions by multi-walled carbon nanotubes. Water Air Soil Pollut 210:101–111

Abdel Salam M, Mokhtar M, Basahel SN, Al Thabaiti SA, Obaid AY (2010) Removal of chlorophenol from aqueous solution by multi-walled carbon nanotubes: kinetic and thermodynamic studies. J Alloy Compd 500:87–92

Abdel Salam M, Makki MSI, Abdelaal MY (2011) Preparation and characterization of multi-walled carbon nanotubes/chitosan nanocomposite and its application for the removal of heavy metals from aqueous solution. J Alloy Compd 509:2582–2587

Ai L, Zhang C, Liao F, Wang Y, Li M, Meng L, Jiang J (2011) Removal of methylene blue from aqueous solution with magnetite loaded multi-wall carbon nanotube: kinetic, isotherm and mechanism analysis. J Hazard Mater 198:282–290

Al-Johani H, Abdel Salam M (2011) Kinetics and thermodynamic study of aniline adsorption by multi-walled carbon nanotubes from aqueous solution. J Colloid Interface Sci 360:760–767

Bai L, Hu H, Fu W, Wan J, Cheng X, Zhuge L, Xiong L, Chen Q (2011) Synthesis of a novel silica-supported dithiocarbamate adsorbent and its properties for the removal of heavy metal ions. J Hazard Mater 195:261–275

Boyd GE, Adamson AW, Myers LS (1947) The exchange adsorption of ions from aqueous solutions by organic zeolites II kinetics. J Am Chem Soc 69:2836–2848

Cheung W, Pontoriero F, Taratula O, Chen AM, He H (2010) DNA and carbon nanotubes as medicine. Adv Drug Deliv Rev 62:633–649

Chu H, Wei L, Cui R, Wang J, Yan L (2010) Carbon nanotubes combined with inorganic nanomaterials: preparations and applications. Coord Chem Rev 254:1117–1134

Dąbrowski A, Podkościenly P, Hubicki Z, Barczak M (2005) Adsorption of phenolic compounds by activated carbon—a critical review. Chemosphere 58:1049–1070

Fam DWH, Al Palaniappan, Tok AIY, Liedberg B, Moochhala SM (2011) A review on technological aspects influencing commercialization of carbon nanotube sensors. Sens Actuators B Chem 157:1–7

Fu FL, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manag 92:407–418

Gomez-Gualdrón DA, Burgos JC, Yu J, Balbuena PB (2011) Carbon nanotubes: engineering biomedical applications. Prog Mol Biol Transl Sci 104:175–245

Ho YS, McKay G (2000) The kinetics of sorption of divalent metal ions onto sphagnum moss peat. Water Res 34:735–742

Ho YS, McKay G (2002) Application of kinetic models to the sorption of copper(II) on to peat. Adsorpt Sci Technol 20:797–815

Ho YS, McKay G, Wase DAJ, Forster CF (2000) Study of the sorption of divalent metal study of the sorption of divalent metal ions on to peat. Adsorpt Sci Technol 18:639–650

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Khambhaty Y, Mody K, Basha S, Jha B (2009) Kinetics equilibrium and thermodynamic studies on biosorption of hexavalent chromium by dead fungal biomass of marine Aspergillus niger. Chem Eng J 145:489–495

Khandoker N, Hawkins SC, Ibrahim R, Huynh CP, Deng F (2011) Tensile strength of spinnable multiwall carbon nanotubes. Proc Eng 10:2572–2578

Kosa SA, Al-Zhrani G, Abdel Salam M (2012) Removal of heavy metals from aqueous solutions by multi-walled carbon nanotubes modified with 8-hydroxyquinoline. Chem Eng J 181–182:159–168

Kurniawan TA, Chan GYS, Lo WH, Babel S (2006) Physico-chemical treatment techniques for wastewater laden with heavy metals. Chem Eng J 118:83–98

Kwon J, Yun S, Lee J, Kim S, Jo HY (2010) Removal of divalent heavy metals (Cd, Cu, Pb, and Zn) and arsenic(III) from aqueous solutions using scoria: kinetics and equilibria of sorption. J Hazard Mater 174:307–313

Lagergren S (1898) Zur theorie der sogenannten adsorption geloster stoffe Kungliga Svenska Vetenskapsakademiens. Handlingar 24:1–39

Liu F, Li L, Ling P, Jing X, Li C, Li A, You X (2011) Interaction mechanism of aqueous heavy metals onto a newly synthesized IDA-chelating resin: isotherms, thermodynamics and kinetics. Chem Eng J 173:106–114

Lu C, Chiu H, Liu C (2006) Removal of zinc(II) from aqueous solution by purified carbon nanotubes: kinetics and equilibrium studies. Ind Eng Chem Res 45:2850–2855

Nollet H, Roels M, Lutgen P, Van der Meeren P, Verstraete W (2003) Removal of PCBs from wastewater using fly ash. Chemosphere 53:655–665

O’Connell DW, Birkinshaw C, O’Dwyer TF (2008) Heavy metal adsorbents pre-pared from the modification of cellulose: a review. Bioresour Technol 99:6709–6724

Pan BJ, Pan BC, Zhang WM, Lv L, Zhang QX, Zheng SR (2009) Development of polymeric and polymer-based hybrid adsorbents for pollutants removal from waters. Chem Eng J 151:19–29

Qiu H, Lu LV, Pan B, Zhang Q, Zhang W, Zhang Q (2009) Critical review in adsorption kinetic models. J Zhejiang Univ Sci A 10:716–724

Rao GP, Lu C, Su F (2007) Sorption of divalent metal ions from aqueous solution by carbon nanotubes: a review. Sep Purif Technol 58:224–231

Ruparelia JP, Duttagupta SP, Chatterjeec AK, Mukherji S (2008) Potential of carbon nanomaterials for removal of heavy metals from water. Desalination 232:145–156

Srivastava P, Singh B, Angove M (2005) Competitive adsorption behavior of heavy metals on kaolinite. J Colloid Interface Sci 290:28–38

Tofighy MA, Mohammadi T (2011) Adsorption of divalent heavy metal ions from water using carbon nanotube sheets. J Hazard Mater 185:140–147

Vuković GD, Marinković AD, Škapin SD, Ristić MĐ, Aleksić R, Perić-Grujić AA, Uskoković PS (2011) Removal of lead from water by amino modified multi-walled carbon nanotubes. Chem Eng J 173:855–865

Vukovića GD, Marinkovića AD, Čolićb M, Ristića MĐ, Aleksića R, Perić-Grujića AA, Uskokovića PS (2010) Removal of cadmium from aqueous solutions by oxidized and ethylenediamine-functionalized multi-walled carbon nanotubes. Chem Eng J 157:238–248

Weber WJ, Morris JC (1963) Kinetics of adsorption on carbon from solution. J Sanit Eng Div Am Soc Civ Eng 89:31–60

Xin X, Wei Q, Yang J, Yan L, Feng R, Chen G, Du B, Li H (2012) Highly efficient removal of heavy metal ions by amine-functionalized mesoporous Fe3O4 nanoparticles. Chem Eng J 184:132–140

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdel Salam, M. Removal of heavy metal ions from aqueous solutions with multi-walled carbon nanotubes: Kinetic and thermodynamic studies. Int. J. Environ. Sci. Technol. 10, 677–688 (2013). https://doi.org/10.1007/s13762-012-0127-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-012-0127-6