Abstract

The new catalyst silica-caffeine hydrogen sulfate [SiO2-caff.]HSO4 was conveniently prepared from commercially available 3-chloropropyltriethoxysilane via immobilization on silica followed by reaction with caffeine. The catalyst prepared was then characterized by the FT-IR spectroscopy, TGA, EDX, and SEM techniques. It was found that this heterogeneous catalyst was a highly efficient one for the synthesis of tetrahydrobenzo[b]pyrans in good-to-high yields, and could be recovered by a simple filtration of the reaction solution and reused for five consecutive runs. The attractive features of this method are simple procedure, clean reaction, easy work-up, use of a reusable catalyst, and performing a multi-component reaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the recent years, ionic liquids (ILs) have gained substantial attention as eco-friendly reagents, catalysts, and solvents in green synthesis due to their exclusive properties such as non-flammability, low volatility, negligible vapor pressure, high thermal stability, and ability to dissolve a broad range of materials [1,2,3,4,5,6]. Among different ILs, the Brønsted acidic ILs [7,8,9] are efficient, environmentally friendly, and simple acid catalysts that have been used in different organic transformations [10,11,12]. Chemical industries, however, still prefer to use heterogeneous catalysts, owing to their easy separation and efficiency compared to the homogenous ILs [13].

Recently, the immobilization process involving acidic ILs on solid supports has been suggested. The heterogenization of reagents and catalysts can offer significant benefits in handling the separation procedures. On the basis of the economic criteria, it is appealing to decrease the amount of IL used in a potential process. Immobilized acidic ILs have been utilized as novel solid catalysts for many acid-catalyzed reactions such as nitration reaction, esterification, and acetal formation [14, 15].

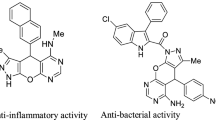

The generation of new methodologies for the production of tetrahydrobenzo[b]pyran moiety is a topic of uninterrupted attention to synthetic/medicinal chemists since their derivatives have versatile medicinal and biological properties [16,17,18], and are broadly available in different biologically active natural products [19]. Some heterogeneous catalysts such as silica nanoparticles [20], poly(dimethylaminoethyl acrylamide)-coated magnetic nanoparticles [21], and Bi2WO6 nanoparticles [22] have been used for the synthesis of tetrahydrobenzo[b]pyrans.

The use of bio-available, cheap, and non-toxic sources of compounds is highly desirable for the design of any green synthesis or process. Caffeine (1,3,7-trimethylpurine-2,6-dione) is a heterocyclic compound that has been classified by the Food and Drug Administration as “safe”. It consists of a pyrimidine ring fused to an imidazole ring having the chemical formula C8H10N4O2 [23]. Due to its unusual properties such as inexpensive price, non-toxicity, stability in moisture and air, and non-corrosive nature, caffeine has encouraged increasing research interests as an effective and important catalyst in organic synthesis [24]. We have recently reported the synthesis of pyrazolopyranopyrimidines using caffeine supported on boehmite nanoparticles [25].

A solvent-free multi-component reaction is an eco-friendly approach that has opened-up several likelihoods for conducting fast organic synthesis and functional group transformations [26, 27]. The purpose of this protocol was to give prominence to the synergistic influences of the combined usage of multi-component coupling reactions in solvent-free conditions and application of a solid Brønsted acid catalyst supported on silica for the generation of a new scheme for heterocyclic synthesis. Thus, we investigated a straightforward one-pot synthesis of tetrahydrobenzo[b]pyran derivatives using caffeine supported on silica [SiO2-caff.]HSO4 as an efficient, eco-environment, recyclable, and non-toxic solid acid catalyst under solvent-free conditions (Scheme 1).

Experimental

The reagents and solvents used were supplied from Merck, Fluka or Aldrich. Melting points were determined using an electro-thermal C14500 apparatus. The reaction progress and the purity of compounds were monitored using TLC analytical silica gel plates (Merck 60 F250). All the known compounds were identified by comparing their melting points and 1H NMR data with those in the authentic samples. The 1H NMR (300 MHz) and 13C NMR (75 MHz) spectroscopies were run on a Bruker Advance DPX-250 FT-NMR spectrometer. The chemical shift values were given as δ values against tetramethylsilane as the internal standard, and the J values were given in Hz. Microanalysis was performed on a Perkin-Elmer 240-B microanalyzer. Scanning electron microscopy (SEM) studies were conducted on a VEGA TESCAN instrument. Thermogravimetric analysis (TGA) curves were recorded using a BAHR STA 503.

Preparation of SiO2-3-propyl-imidazolopyridinium hydrogen sulfate [SiO2-Caff.]HSO4

Preparation of SiO2–Cl

For the preparation of the functionalized SiO2, silica (1.0 g) was stirred in 100 mL of 1.0 M NaOH at room temperature. Sodium silicate was filtered to remove undissolved particles. Then, 3-(chloropropyl)trimethoxysilane (2.0 mL) was added to the sodium silicate solution. The solution was titrated with nitric acid (3.0 M), and titration was continued until the pH of the solution reached 3.0. The white gel obtained was separated by centrifugation, washed six times with distilled water and acetone, and dried at room temperature to afforded SiO2–Cl as a with powder [28]. Elementary analysis showed that the carbon content of SiO2–Cl was 4.2%, which meant that 0.86 mmol/g of pending groups were covalently bonded to the surface of 1.00 g SiO2.

Preparation of [SiO2-Caff.]HSO4

SiO2–Cl (1.00 g) was refluxed with caffeine (5.0 mmol, 0.04 g) in acetone (10.0 mL) for 36 h to replace the terminal chlorine atoms. Caffeine-functionalized SiO2 [(SiO2-Caff.)Cl] was filtered-off, washed three times with warm acetone, and dried at 100 °C. Elementary analysis showed the nitrogen content to be 1.0% (0.68 mmol/g), which meant that 0.17 mmol of the pendant caffeine groups were covalently bonded to the surface of SiO2–Cl (1.00 g), which revealed that the caffeine loading near 20% of pending chlorine atoms of SiO2–Cl, was changed to caffeine by this reaction. In addition, the loading level of ion chlorides was determined by potentiometric titration of the chlorine content. For this purpose, 0.03 g of the sample was added to 5.0 mL of deionized water and titrated by Ag+ standard solution. The results showed that the loading level of ion chlorides was 0.16 mmol/g. Then, into a three-necked round-bottomed flask equipped with a stirrer, [SiO2-Caff]Cl (1.0 g) was dispersed in dichloromethane (30 mL), and sulfuric acid (98.99%) (0.1 g, 1 mmol) was added to this suspension. The mixture was warmed up to the room temperature and refluxed for 48 h. The [SiO2-Caff]HSO4 powder obtained was filtered-off and washed with dichloromethane (3 × 20 mL) and distilled water (3 × 20 mL), respectively, to remove additional acid, and then dried at 80 °C overnight. Elementary analysis showed the sulfur content to be 0.14% (0.04 mmol/g). According to the sulfur content, the number of H+ sites of [SiO2-caff]HSO4 was 0.04 mmol/g (4 × 10− 5 M), which meant that nearly 24% of pending ion chloride (Cl−), was changed to hydrogen sulfate (HSO4−) by this reaction. This result obtained was confirmed by back-titration analysis of the catalyst.

General procedure for synthesis of tetrahydrobenzo[b]pyran derivatives (4a–4t)

To a mixture of 1,3-cyclohexanedione or 5,5- dimethyl-1,3-cyclohexanedione (1.0 mmol), an aldehyde (1.0 mmol), and malononitrile (1.0 mmol) in a test tube was added [SiO2-Caff.]HSO4 (0.1 g, 0.09 mmol of H+), and the reaction mixture was heated at 100 °C. After completion of the reaction, monitored by thin-layer chromatography (TLC), the precipitate formed was washed with warm ethanol (3 × 30 mL) to separate the heterogeneous catalyst. The pure tetrahydrobenzo[b]pyran product was obtained after recrystallization from ethanol. To recover the catalyst, the separated catalyst was washed twice with acetone (5 mL) and reused after drying.

2-amino-3-cyano-4-phenyl-5-oxo-4H-5,6,7,8-tetrahydrobenzo[b]pyran (4a)

White solid; M.p., 211–213 °C; 1H NMR (300 MHz, DMSO-d6): δ 1.95 (m, 2H, CH2), 2.25 (t, 2H, CH2), 2.62 (t, 2H, CH2), 4.18 (s, 1H, CH), 7.00 (s, 2H, NH2), 7.14–7.21 (m, 3H, H-Ar), 7.26–7.31 (m, 2H, H–Ar); IR ʋ (KBr): 3310, 3190, 2920, 2195, 1680, 1650, 1600, 1400, 1364, 1000/cm; MS (EI), m/z [M]+ 266; Anal. Calcd. for C16H14N2O2: C, 72.16; H, 5.30; N, 10.52%. Found: C, 72.36; H, 5.22; N, 10.40%.

2-amino-3-ethoxycarbonil-4-(4-cyanophenyl)-5-oxo-4H-5,6,7,8-tetrahydrobenzo[b]pyran (4 h)

White solid; M.p., 187–190 °C; 1H NMR (300 MHz, CDCl3): δ 1.016–1.063 (t, J = 6.9 Hz, 3H, CH3), 1.80–2.01 (m, 2H, CH2), 2.24–2.29 (t, 2H, CH2), 2.48–2.53 (t, 2H, CH2), 3.91–3.98 (q, 2H, CH2), 4.68 (s, 1H, CH), 6.19 (s, 2H, NH2), 7.30–7.33 (d, J = 8.1 Hz, 2H, H–Ar), 7.42–7.45 (d, J = 8.4 Hz, 2H, H–Ar); 13C NMR (75 MHz, CDCl3): δ 14.2, 20.1, 26.9, 34.4, 36.7, 59.8, 79.4, 109.8, 116.9, 119.2, 129.2, 131.7, 151.5, 158.3, 163.5, 168.6, 196.4; IR ʋ (KBr): 3400, 3200, 2860, 2229, 1685, 1660, 1595, 1484, 1439, 1375, 1240, 1015/cm; MS (EI), m/z [M]+ 338; Anal. Calcd. for C19H18N2O4: C, 67.44; H, 5.36; N, 8.28%. Found: C, 67.25; H, 5.27; N, 8.10%.

2-amino-3-ethoxycarbonil-4-(3-hydroxy-4-methoxyphenyl)-5-oxo-4H-5,6,7,8-tetrahydrobenzo[b]pyran (4i)

White solid; M.p., 187–190 °C; 1H NMR (300 MHz, CDCl3): δ 1.17–1.22 (t, J = 7.2 Hz, 3H, CH3), 1.93–2.07 (m, 2H, CH2), 2.32–2.38 (t, 2H, CH2), 2.52–2.59 (t, 2H, CH2), 3.83 (s, 3H, OCH3), 4.01–4.10 (q, 2H, CH2), 4.67 (s, 1H, CH), 5.60 (s, 1H, OH), 6.19 (s, 2H, NH2), 6.70–6.72 (dd, J = 8.1 Hz, 1H, H-Ar), 6.79–6.80 (d, 1H, H–Ar), 6.84–6.88 (dd, J = 8.4 Hz, 1H, H–Ar); IR ʋ (KBr): 3410, 3322, 2964, 1688, 1684, 1620, 1465, 1340, 1312/cm; MS (EI), m/z [M]+ 359; Anal. Calcd. for C19H21NO6: C, 63.50; H, 5.89; N, 3.90%. Found: C, 63.29; H, 5.80; N, 3.75%.

2-amino-3-ethoxycarbonil-4-(2-bromophenyl)-5-oxo-4H-5,6,7,8-tetrahydrobenzo[b]pyran (4j)

White solid; M.p., 200–203 °C; 1H NMR (300 MHz, CDCl3): δ 1.12–1.16 (t, J = 6.9 Hz, 3H, CH3), 1.91–2.07 (m, 2H, CH2), 2.31–2.35 (t, J = 6.0 Hz, 2H, CH2), 2.54–2.60 (t, 2H, CH2), 3.99–4.10 (q, 2H, CH2), 5.03 (s, 1H, CH), 6.29 (s, 2H, NH2), 6.95–7.00 (t, J = 8.1 Hz, 1H, H–Ar), 7.16–7.21 (t, J = 7.2 Hz, 1H, H–Ar), 7.30–7.32 (d, J = 7.8 Hz, 1H, H–Ar), 7.43–7.46 (d, J = 6.9 Hz, 1H, H–Ar); 13C NMR (75 MHz, DMSO-d6): δ 14.7, 20.3, 26.9, 34.7, 36.9, 59.1, 77.2, 115.8, 123.6, 127.5, 128.0, 132.4, 132.9, 145.1, 159.5, 164.4, 168.6, 196.1; IR ʋ (KBr): 3400, 3200, 2860, 1685, 1660, 1595, 1484, 1439, 1375, 1240, 1015, 590/cm; MS (EI), m/z [M]+ 391; Anal. Calcd. for C18H18BrNO4: C, 55.12; H, 4.63; N, 3.57%. Found: C, 55.30; H, 4.56; N, 3.40%.

2-amino-3-ethoxycarbonil-4-(3-hydroxy-4-methoxyphenyl)-7,7-dimethyl-5-oxo-4H-5,6,7,8-tetrahydrobenzo[b]pyran (4q)

White solid; M.p., 180–183 °C; 1H NMR (300 MHz, CDCl3): δ 1.00 (s,3H, CH3), 1.10 (s,3H, CH3), 1.18–1.23 (t, J = 7.2 Hz, 3H, CH3), 2.15–2.27 (dd, J = 16.2 Hz, 2H, CH2), 2.42 (dd, 2H, CH2), 3.82 (s, 3H, OCH3), 4.01–4.12 (q, 2H, CH2), 4.64 (s, 1H, CH), 5.62 (s, 1H, OH), 6.19 (s, 2H, NH2), 6.69–6.72 (dd, J = 8.1 Hz, 1H, H–Ar), 6.79–6.80 (dd, 1H, H–Ar), 6.81–6.85 (dd, J = 8.1 Hz, 1H, H-Ar); 13C NMR (75 MHz, CDCl3): δ 14.2, 27.6, 29.0, 32.2, 33.1, 40.6, 50.7, 55.8, 59.6, 80.8, 109.9, 114.1, 116.8, 120.1, 139.2, 144.8, 145.0, 158.3, 161.3, 169.1, 196.5; IR ʋ (KBr): 3400, 3300, 3186, 2933, 1675, 1643, 1590, 1460, 1360, 1000 /cm; MS (EI), m/z [M]+ 387; Anal. Calcd. for C21H25NO6: C, 65.10; H, 6.50; N, 3.62%. Found: C, 64.90; H, 6.58; N, 3.48%.

2-amino-3-ethoxycarbonil-4-(2,6-dichlorophenyl)-7,7-dimethyl-5-oxo-4H-5,6,7,8-tetrahydrobenzo[b]pyran (4r)

White solid; M.p., 241–243 °C; 1H NMR (300 MHz, CDCl3): δ 0.721 (s, 3H, CH3), 0.826 (s, 3H, CH3), 0.916–0.958 (t, J = 7.2 Hz, 3H, CH3), 2.32–2.37 (t, J = 6.3 Hz, 2H, CH2), 2.52–2.57 (t, 2H, CH2), 4.00–4.07 (q, 2H, CH2), 5.54 (s, 1H, CH), 6.35 (s, 2H, NH2), 6.98–7.04 (t, J = 7.8 Hz, 1H, H–Ar), 7.15 (d, 1H, H–Ar), 7.33 (d, 1H, H–Ar); 13C NMR (75 MHz, DMSO-d6): δ 11.2, 11.5, 14.4, 20.3, 26.9, 31.6, 37.0, 59.0, 74.2, 112.9, 128.2, 128.5, 130.1, 134.4, 138.2, 138.7, 160.2, 165.2, 168.6, 196.2; IR ʋ (KBr): 3424, 3312, 2944, 1686, 1644, 1616, 1460, 1450, 1380, 1300, 1000, 769 /cm; MS (EI), m/z [M]+ 409; Anal. Calcd. for C20H21Cl2NO4: C, 58.55; H, 5.16; N, 3.41%. Found: C, 58.38; H, 5.08; N, 3.27%.

It was also crystallized from ethanol in the form of white needles, and was characterized by single-crystal X-ray crystallography. This analysis showed that it was crystallized in the triclinic system with space group P-1, and there were also two molecules present in each unit cell. Figure 1 shows a perspective view of the molecular structure of 4r.

Results and discussion

Catalyst preparation

Silica-caffeine hydrogen sulfate ([SiO2-caff]HSO4) was synthesized as shown in Scheme 1, wherein the first step was the synthesis of silica-bonded n-propyl chloride according to an earlier report [28]. The second step was the pending chlorine atoms of SiO2–Cl changing to imidazolopyridinium chloride by refluxing with caffeine in acetone to afford [SiO2-caff]Cl. Finally, [SiO2-caff]Cl and sulphuric acid were refluxed in dichloromethane to generate [SiO2-caff]HSO4. The catalyst produced was characterized by the FT-IR spectroscopy, TGA, DTA, SEM, and EDX techniques.

Catalyst characterization

The FT-IR spectra for SiO2 (a), SiO2-bonded n-propyl chloride ([SiO2–Cl]) (b), and silica-caffeine hydrogen sulfate ([SiO2-caff]HSO4) (c) are shown in Fig. 2. A broad band was observed in the range of 3413–3321/cm in all samples, assigned to the O–H stretching vibration. In addition, the characteristic bands for SiO2 were observed in 1168, 810, and 478/cm, which were assigned to the stretching and bending vibrations of its Si–O–Si (Fig. 2a). Moreover, the band at 2950/cm for the SiO2-bonded n-propyl chloride was assigned to the streching vibration of the C–H bonds (Fig. 2b). Attachment of caffeine onto the SiO2-bonded n-propyl chloride was confirmed by the appearance of new bands at 1704 and 1650/cm due to the C=O and C=N stretching vibrations, respectively.

EDX analysis also confirmed the presence of sulfur atoms on the surface of [SiO2-caff.]HSO4 in addition to the carbon, oxygen, nitrogen, chlorine, and silicon atoms (Fig. 3).

Figure 4 shows the TG/DTG thermogram of the [SiO2-caff.]HSO4 catalyst. There was an important weight loss region in the TG curve in the temperature range of 295–500 °C, accompanied by an endothermic peak in the DTG curve, which could be related to the decomposition of the organic residue on the surface of SiO2.

The morphology of the SiO2 and [SiO2-caff.]HSO4 samples were also investigated by SEM in Fig. 5. The comparison between their SEM images showed that the reaction procedure for the preparation of the [SiO2-caff.]HSO4 samples from SiO2 changed the morphology of the particles.

Catalytic activity

To test the catalytic activity of [SiO2-caff.]HSO4 in the synthesis of tetrahydrobenzo[b]pyrans, the reaction between benzaldehyde, malononitrile, and 1,3-cyclohexanedione was selected as a model reaction to optimize the reaction conditions, and the results obtained were tabulated in Table 1. The influence of different parameters was examined to obtain the best possible combination. The parameters included the solvent, reaction temperature, and catalyst concentration. As shown in Table 1, several solvents were screened for the reaction in the presence of a catalytic amount of [SiO2-caff.]HSO4. The results obtained showed that the efficiency and yield of the reaction under solvent-free conditions at 100 °C were higher than those obtained in solvents such as H2O, EtOH, CH3CN, DMF, and toluene (Table 1, entries 1–6).

Decreasing the loading of the catalyst to 0.4 mol% lowered the reaction yield dramatically (Table 1, entry 7). However, increasing the amount of catalyst to 2 mol% showed no substantial improvement in the yield (Table 1, entry 9). Furthermore, the effect of temperature on the conversion was checked, and the results obtained were tabulated in Table 1. It is obvious that at 80 °C, a low reaction yield was formed (Table 1, entry 10). Increasing the temperature did not improve the reaction yield (Table 1, entry 11). In addition, when the reaction was carried out in the absence of a catalyst, only a low reaction yield was obtained, even after the reaction time was prolonged to 6 h (Table 1, entry 12). To find out the roles of [SiO2-Caff.]Cl and [SiO2-caff.]HSO4 during the reactions, the synthesis of of tetrahydrobenzo[b]pyran 4a was examined in the presence of [SiO2-Caff.]Cl. As shown in Table 1, the products were obtained in 30% yield in the presence of SiO2 (Table 1, entry 13).

Under the optimized reaction conditions, the generality of this three-component reaction was studied under the optimal reaction conditions by varying the structures of the aldehydes involved. The results obtained are summarized in Table 2.

As shown in this table, the variation in the electronic properties and the position of the functional groups on the aromatic ring of the aldehyde did not show a clear effect on the reaction yields. For example, aldehydes with electron-donating groups (Table 2, entries 2, 6, 9, 11, 13, 16, and 17) or electron-withdrawing groups (entries 3, 7, 8, 14, 19, and 20) were condensed into the corresponding tetrahydrobenzo[b]pyrans in high yields. Moreover, the steric effects of the substituents at the ortho-position of the aldehydes did not have a clear effect on the reaction yields (Table 2, entries 10 and 18).

We also investigated the recyclability of [SiO2-caff.]HSO4 using the reaction of benzaldehyde, malononitrile, and 1,3-cyclohexanedione at 100 °C under solvent-free conditions. The catalyst was recovered by a simple filtration and reused over five runs without significant losses in the catalytic activity.

A proposed mechanism for the synthesis of tetrahydrobenzo[b]pyran 4a from benzaldehyde, malononitrile, and 1,3-cyclohexandion catalyzed by [SiO2-Caff.]HSO4 is shown in Scheme 2. 1,3-cyclohexanedione was converted to its corresponding enolate form (II) in the presence of [BNPs-caff.]HSO4. The acidic catalyst played a major role in its promoting activity for the formation of phenylidenemalononitrile III, which was readily prepared in situ by the Knoevenagel condensation of benzaldehyde 2a with the highly active CH acidic malononitrile 3. Finally, the Michael-type addition of the enolate form II to phenylidenemalononitrile III followed by cyclization and tautomerization yielded tetrahydrobenzo[b]pyran 4a (Scheme 2).

Conclusion

We described an environment friendly method for the synthesis of tetrahydrobenzo[b]pyrans using silica-caffeine hydrogen sulfate [SiO2-caff]HSO4, as an efficient and reusable catalyst. This method offers several advantages such as shorter reaction time, cleaner reaction, green and reusability of the catalyst, and high reaction yield. The recycling experiments showed that the catalyst could be used for several times without a significant loss in its catalytic activity. Moreover, the catalyst was characterized by various methods including TGA, SEM, EDX, and FT-IR spectroscopy.

References

M. Baghernejad, K. Niknam, Inter. J. Chem. 4, 52 (2012)

K. Niknam, A. Piran, Green Sus. Chem. 3, 1 (2013)

F. Shirini, M. Seddighi, M. Mazloumi, M. Makhsous, M. Abedini, J. Mol. Liq. 208, 291 (2015)

A.R. Moosavi-Zare, M.A. Zolfigol, M. Zarei, A. Zare, V. Khakyzadeh, J. Mol. Liq. 211, 373 (2015)

M. Seddighi, F. Shirini, M. Mamaghani, C. R. Chim. 18, 573 (2015)

K. Niknam, A. Piran, Z. Karimi, J. Iran. Chem. Soc. 13, 859 (2016)

N.G. Khaligh, J. Mol. Catal. A Chem. 349, 63 (2011)

A. Zare, A.R. Moosavi-Zare, M. Merajoddin, M.A. Zolfigol, T. Hekmat-Zadeh, A. Hasaniniejad, A.A. Khazaei, M. Mokhlesi, V. Khakyzadeh, F. Derakhshan-Panah, M.H. Beyzavi, E. Rostami, A. Arghoon, R. Roohandeh, J. Mol. Liq. 167, 69 (2012)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, V. Khakyzadeh, Appl. Catal. A Gen. 400, 1365 (2011)

M. Nouri Sefat, D. Saberi, K. Niknam, Catal. Lett. 141, 1713 (2011)

A. Chrobok, S. Baj, W. Pudlo, A. Jarzebski, Appl. Catal. A 366, 22 (2009)

J.M. Xu, B.K. Liu, W.B. Wu, C. Qian, Q. Wu, X.F. Lin, J. Org. Chem. 71, 3991 (2006)

C. Paun, J. Barklie, P. Goodrich, H. Gunaratne, A. McKeown, V. Parvulescu, C. Hardacre, J. Mol. Catal. A Chem. 269, 64 (2007)

K. Qiao, H. Hagiwara, C. Yokoyama, J. Mol. Catal. A Chem. 246, 65 (2006)

R. Sugimara, K. Qiao, D. Tomida, C. Yokoyama, Catal. Commun. 8, 770 (2007)

A.A. Hassanien, M.A. Zahrran, M.S.A. El-Gaby, M.M. Ghorab, J. Indian Chem. Soc. 76, 350 (1999)

K. Niknam, N. Borazjani, R. Rashidian, A. Jamli, Chin. J. Catal. 34, 2245 (2013)

K. Niknam, M. Khataminejad, F. Zeyaei, Tetrahedron Lett. 57, 361 (2016)

S. Gao, C.H. Tsai, C. Tseng, C.-F. Yao, Tetrahedron 64, 9143 (2008)

S. Banerjee, A. Horn, H. Khatri, G. Sereda, Tetrahedron Lett. 52, 1878 (2011)

N. Zohreh, S.H. Hosseini, A. Pourjavadi, C. Bennett, RSC Adv. 4, 50047 (2014)

B. Paplal, S. Nagaraju, P. Veerabhadraiah, K. Sujatha, S. Kanvah, B.V. Kumar, D. Kashinath, RSC Adv. 4, 54168 (2014)

J. Schütz, W.A. Herrmann, J. Organomet. Chem. 689, 2995 (2004)

F.T. Luo, H.K. Lo, J. Organomet. Chem. 696, 1262 (2011)

M. Bakherad, R. Doosti, M. Mirzaee, K. Jadidi, Iran. J. Catal. 7, 27 (2017)

M.A.P. Martins, C.P. Frizzo, D.N. Moreira, L. Buriol, P. Machado, Chem. Rev. 109, 4140 (2009)

R. Kumar, K. Raghuvanshi, R.K. Verma, M.S. Singh, Tetrahedron Lett. 51, 5933 (2010)

F. Adam, H. Osman, K.M. Hello, J. Coll. Inter. Sci. 331, 143 (2009)

H.R. Safaei, M. Shekouhy, S. Rahmanpur, A. Shirinfeshan, Green Chem. 14, 1696 (2012)

O.H. Qareaghaj, S. Mashkouri, M.R. Naimi-Jamal, G. Kaupp, RSC Adv. 4, 48191 (2014)

O. Rosati, A. Pelosi, A. Temperini, V. Pace, M. Curini, Synthesis 48, 1533 (2016)

A. T. Khan, M. Lal, S. Ali, M.M. Khan, Tetrahedron Lett. 52, 5327 (2011)

M.G. Ahmed, U. Romman, K. Akhter, K. Jahan, M.N.H. Bhuiyan, M.E. Halim, Synth. Commun. 41, 2822 (2011)

Acknowledgements

We gratefully acknowledge the financial support of the Research Council of the Shahrood University of Technology.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bakherad, M., Keivanloo, A., Moradian, E. et al. Practical and efficient synthesis of tetrahydrobenzo[b]pyran using caffeine supported on silica as an ionic liquid solid acid catalyst. J IRAN CHEM SOC 15, 2811–2819 (2018). https://doi.org/10.1007/s13738-018-1468-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-018-1468-y