Abstract

PbO nanoparticles were explored as a highly efficient, simple, cheap, and recyclable catalyst for the fast synthesis of 1H-pyrazolo[1,2-b]phthalazine-5,10-dione derivatives by means of a one-pot three-component reaction of phthalhydrazide, aromatic aldehyde, and malononitrile under solvent-free conditions at 80 °C. Furthermore, nanosized PbO was prepared by the two conventional methods of planetary ball milling and dispersion of commercial PbO in n-octane, and their catalytic performances were compared with the commercial bulk PbO. The prepared nano-PbO via ball milling was described by SEM, TEM, XRD, EDX, and FT-IR spectroscopy. The present protocol conveyed major proficiencies such as the use of a reasonable and readily available catalyst, simple work-up and purification of products by nonchromatographic strategy, low reaction times, and enhanced yields under relatively environmental benign conditions. The heterogeneous catalyst was appropriately recyclable and could be reused for several times without loss of activity.

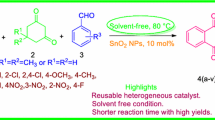

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanoparticles develop particularly unique properties from their bulk and molecular counterparts, while preserving chemical composition, and have shown assorted applications in various areas, for example in electronics and optoelectronics, biomedical and pharmaceutical, energy and environmental, magnetic, material science, and catalysis [1, 2]. Because of the widespread prospects of nanotechnology, there has been an overall consideration in investment in nanotechnology research and development [3, 4].

Lead oxide (PbO) is an important compound which has been broadly used in batteries, gas sensors, pigments, and paints [5, 6]. Among various metal oxide nanoparticles, PbO is mostly utilized as solid catalyst in synthetic organic chemistry, and despite its incredible significance, only a few reports exist in this area [7–13]. Recently, PbO has got impressive consideration because of its cost-effectiveness, air and water compatibility, the simplicity of handling, good reactivity, recyclability, and experimental simplicity in organic synthesis.

So far, a number of protocols have been developed to synthesize PbO nanoparticles including vapor phase growth [14, 15], vapor–liquid–solid process [16], electrophoretic deposition [17], sol–gel process [18], and homogeneous precipitation [19]. In spite of the fact that these methods are valuable, however, a number of these procedures have significant drawbacks such as using toxic reagents, long reaction times, and polydispersity of particle size [20, 21]. In this way, achieving new simple and efficient approaches to prepared nano-PbO is of great interest.

Multi-component reactions constitute potent and efficient synthetic procedures for quick and compelling essential transformations in organic and medicinal chemistry to produce different medicinal compounds, heterocyclic core structures [22–28]. These protocols are normally free from remarkable quantities of wastes via minimization of complex isolation steps and using toxic, hazardous, and costly solvents [29, 30]. Since many of the noteworthy drugs are incorporated in various types of polyfunctionalized heterocycles [31], research on the multi-component synthesis of polyfunctionalized heterocyclic compounds is an interesting challenge.

Nitrogen-containing heterocyclic compounds are pervasive in nature, and their applications to biologically active pharmaceuticals, agrochemicals, and useful materials are turning out to be prominent [32]. Thus, improvement of new effective strategies to synthesize these potential drugs is a significant issue in the diversity-oriented synthesis and combinatorial chemistry. Among a scope of nitrogen-containing heterocycles, those including bridgehead hydrazine moieties have gained significant consideration because of their pharmacological and clinical applications [33–37]. Likewise, pyrazoles are critical synthons which have an extensive variety of antiviral properties [38], anticonvulsant [39], vasorelaxant [40], cardiotonic [41], and antipyretic activities [42]. Until now, a few methods have been perceived for the synthesis of 1H-pyrazolo[1,2-b]phthalazine-5,10-diones [43–48]. In any case, most of the reported protocols have at least one disfavor, such as long reaction time, high temperature, need to volatile, and risky natural solvents [43].

Among various catalytic systems reported for the preparation of pyrazoles, homogeneous catalysts have received little consideration. Therefore, heterogeneous catalysis achieved much attention in most organic synthesis territories [49–52]. These catalysts have beneficial over traditional homogeneous ones as they can be easily recovered from the reaction mixture by simple filtration and can be reused after with or without activation, making the procedure more feasible. Meanwhile, decreasing global warming and investigation of solvent-free reactions achieved an important role in synthetic organic chemistry through the simplifying experimental procedure, necessitating less energy, and producing high yields of products by almost quantitative reactivity of the substrates.

In continuation of our endeavors to investigate new protocols and as well as our interest in performing heterogeneously catalyzed organic reactions [53–58], we reported herein a simple, quick, inexpensive, and one-step strategies to accomplish uniform PbO nanoparticles. Then, the synthesized nanoparticles were carried out as a heterogeneous catalyst for the one-pot synthesis of 1H-pyrazolo[1,2-b]phthalazine-5,10-diones through a three-component condensation reaction of phthalhydrazide, aromatic aldehyde, and malononitrile under solvent-free conditions at 80 °C (Scheme 1).

Experimental

Materials

All reagents and beginning materials were provided by Merck and Fluka and were used without further refinement. All products were known samples and were distinguished by comparison with their spectral and physical information with those already reported. Melting points were recorded on a Barnstead electrothermal 9200 melting point apparatus. A freeze dryer, model FD-10, Pishtaz Equipment Engineering Co, Iran, was utilized for drying the prepared PbO nanoparticles. X-ray diffraction patterns (XRD) were obtained from an XPert MPD diffractometer with Cu Kα radiation at 40 keV and 30 mA. The transmission electron microscopy (TEM) observations of the prepared PbO nanoparticles were carried out on a JEM 2010 operating at an acceleration voltage of 200 kV. The morphology and distribution of nanoparticles was studied by scanning electron microscopy (SEM) using a KYKY-EM3200 with an accelerating voltage of 25 and 30 kV. 1H and 13C NMR spectra were recorded on a Bruker AVANCE instrument operating at 300 MHz using TMS as internal reference. Fourier transform infrared (FT-IR) spectra were recorded (KBr pellets) on 8400 Shimadzu Fourier transform spectrophotometer.

Preparation of nano-PbO

Although there are several physical and chemical strategies for the preparation of nanosized metal oxides, in any case, planetary ball milling and solvothermal synthesis are the most common ways. Solvothermal synthesis is generally directed to crystal synthesis or crystal growth under high temperature and high-pressure solvent conditions from substances which are insoluble in normal customary temperature and pressure in an autoclave. In this report, nanosized PbO was prepared by the two specified methods. Then, as-synthesized nanostructures were characterized by several characterization methods such as XRD, TEM, SEM, EDX, and FT-IR. Finally, catalytic performance of the prepared nanoparticles of PbO were compared in the preparation of 1H-pyrazolo [1,2-b]phthalazine-5,10-diones.

Preparation of nano-PbO through up-to-bottom planetary ball milling

Commercial PbO powder was obtained from Merck and used without further purification. For the preparation of the nano-PbO, a planetary ball process in the dry state was applied for a period of 120 min, 10 balls of 20 mm per 30 g of powder and a milling rate of 350 rpm. The experiments were performed in a 250-ml stainless steel jar with a safety coat of zirconium oxide working in dry milling.

Solvothermal synthesis of nano-PbO through dispersion in n-octane

In this simple technique, 5 g of commercial bulk lead oxide was added to 50 ml of n-octane with strong stirring for 10 min. At that point, the mixture was further stirred at room temperature for 2 h. Thereafter, the mixture was transferred to a small Teflon steel and the closed container was heated to 100 °C for 24 h. Finally, the container was gradually cooled to room temperature and the separated solid material was dried at 80 °C for 12 h. To study the impact of drying conditions on the catalytic efficacy of PbO, freeze-drying technique was compared with the usual classic drying in an oven at 80 °C under air. Results showed no explicit advancements in the catalyst efficiency under the freeze-drying conditions.

General procedure for the preparation of 1H-pyrazolo[1,2-b]phthalazine-5,10-diones

A mixture of phthalhydrazide (1 mmol), aromatic aldehyde (1 mmol), malononitrile (1 mmol), and PbO (5 mol% for the commercial and 1 mol% in the case of the nanopowders) was stirred at 80 °C under solvent-free conditions for the required times. The progress of the reactions was observed by TLC in a mixture of ethyl acetate:n-hexane (1:4). After consummation of reaction, ethanol (5 ml) was added with stirring. Then, the catalyst was exhausted by filtration and the filtrate was poured into cold water to afford the desired product as a yellow residue which was further refined by recrystallized in ethanol. Spectral data for some illustrative 1H-pyrazolo[1,2-b]phthalazine-5,10-diones are given in the supporting data part.

Results and discussion

Characterization of PbO nanoparticles

Vibrational frequencies of nanoparticles might be influenced by some important parameters, for example dipolar interactions, quantum repressions, interfacial effects, size, and surface amorphousness. The FT-IR spectra of the three kinds of PbO samples including commercial bulk (a), nanoparticles prepared via dispersion in n-octane (b), and nanoparticles prepared through ball milling (c) appear in Fig. 1 due to the small size of the grains and the large surface-to-volume ratio of nanoparticles, the atomic arrangements on the limits differ enormously from that of bulk particles (surface amorphousness), and a blueshift of the characteristic bands of PbO nanoparticles to higher wave numbers compared to the bulk one was observed in the FT-IR. In addition, the sharp peaks around 1410 cm−1 for all samples confirmed bonding of oxygen to Pb [59]. Weak absorption bands around 844 cm−1 with a relatively strong vibration at 684 cm−1 were because of Pb–O stretching and asymmetric bending of Pb–O–Pb, respectively [60–62]. Obviously, variations in the band position may be due to variations in the cation–oxygen bond length coming from the alterations in particles size; the observed blueshift in Fig. 1a–c affirmed diminishing particle size. The absorption bands above 3600 cm−1 are ascribed to the stretching vibrations of OH groups of water molecules.

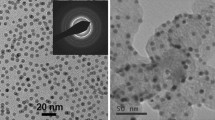

The SEM and TEM pictures indicated morphology and size of the synthesized PbO nanoparticles by means of ball processing, which proposed the ellipsoidal–spherical structures for PbO nanoparticles with discrete appearance (Fig. 2). Besides, the elemental investigation (EDAX) confirmed the material contains Pb and O elements (Fig. S1). The XRD pattern suggested that the PbO nanoparticles prepared through ball milling contain specific crystal planes reported previously for the orthorhombic structure (JCPDS Card No. 76-1796) [63]. Moreover, sharp diffraction peaks indicated that well-crystallized lead oxide crystals are prepared under current synthetic procedure. The average particle size of <60 nm was determined for the PbO nanoparticles using Debye–Scherer equation.

Catalytic tests

Effect of solvent on the catalytic efficiency

In order to improve the reaction conditions, effects of different solvents on the reaction progress and as well as yield of the appropriate products were explored in the condensation reaction of benzaldehyde (1 mmol), phthalhydrazide (1 mmol), and malononitrile (1 mmol) catalyzed by 5 mol% of the commercial PbO in various solvents at 80 °C (Table 1). In acetonitrile, ethanol, and 1,2-dichloroethane, as polar solvents, the reaction was effective and great reaction rates as well as product yields were achieved. While toluene and n-hexane, as nonpolar solvents, were wasteful and very low amounts of the product was picked up, since these solvents would be inefficient to approach the reactants at the catalyst surface. In addition, adsorption of nonpolar solvent molecules on the catalyst surface deactivates the catalyst surface and would diminish the quantity of active locations. The lower yield obtained with chloroform compared to acetonitrile and 1,2-dichloroethane would be due to the lower reaction temperature, due to the lower boiling point of chloroform. However, when a similar reaction was done in water as an economical, nonflammable, and natural favorable solvent, the expected product was acquired just in low yield (17%) even after 120 min. Lower product yield in the case of water as solvent would be likely because of the insolubility of the reactants. Furthermore, we also led the solvent-free condensation reaction under the optimized conditions. As shown in Table 1, the yield % was the highest and the reaction time was shorter than under the solvent conditions. Better yield under the solvent-free condition would be clarified considering uniform dissemination of the eutectic mixture of reactants, being in closer proximity to react than under the solvent conditions.

Phthalhydrazide (1 mmol), benzaldehyde (1 mmol), malononitrile (1 mmol), and commercial bulk PbO (5 mol%) were stirred at 80 °C in the presence of the desired solvent (1 ml). Progress of the reactions and work-up of the products are described in the experimental section.

Effect of catalyst amount on the catalytic efficiency of the system

In next step, a study was set out to determine the ideal amount of PbO in the creation of APhDPyC. Hence, the reaction was done by fluctuating amount of the catalyst (Fig. S3). As is expected, product yield was affected by the amount of loaded PbO in the reaction medium. When 1 mol% of commercial PbO was used, the condensation reaction of benzaldehyde (1 mmol), phthalhydrazide (1 mmol), and malononitrile (1 mmol) progressed very easily and gave the desired product in 48% yield after 15 min. However, when 5 mol% of the commercial PbO was used as catalyst, the reaction proceeded smoothly and the intended product was accomplished in 92% yield after 15 min. Consequently, yield % was increased by the amount of the loaded commercial catalyst. When 3, 5, 10, and 15 mol% of the commercial PbO were used, yields were 73, 92, 94, and 96%, respectively, after 15 min. In this way, 5 mol% of the commercial PbO was adequate. Moreover, a further increase in the amount of the catalyst in the aforementioned reaction did not a noteworthy effect on the product yield and reaction time.

Effect of reaction temperature on the catalytic efficiency of PbO

To upgrade the reaction temperature, a mixture of benzaldehyde (1 mmol), phthalhydrazide (1 mmol), malononitrile (1 mmol), and commercial PbO (5 mol%) was heated at various temperatures ranging from 20 to 100 °C for 15 min (Fig. S4). The yield of the desired product was increased when the reaction temperature was raised from 20 to 80 °C. However, no more addition was found when the reaction temperature was raised from 80 to 100 °C. Subsequently, 80 °C was picked as the best reaction temperature for all further reactions.

Studying effect of particle size on the optimum catalyst amount and reaction time

Effect of lead oxide particle size was investigated on the ideal amount of the needed catalyst and reaction time for the preparation of APhDPyC under the standard reaction conditions delineated in the experimental section. As Fig. 3 shows, only 1 mol% of nanosized PbO was adequate to give 86% yield after 5 min (Fig. 3b); however, 5 mol% of commercial bulk PbO was needed to achieve 65% yield during the similar time (Fig. 3a). Albeit, both catalysts managed 92–95% yield after 15 min, but the nanosized PbO was a more proficient catalyst in the preliminary steps of the reaction (<10 min). However, no obvious increase in yield % was distinguished after a delayed reaction time for both catalysts.

Synthesis of APhDPyC catalyzed by different kinds of PbO particles

Three kinds of lead oxides were conducted in the titled condensation reaction (Table 2). As a matter of first importance, commercial bulk PbO was screened as catalyst. Findings demonstrated that 1 mol% of this material provided 48% of the demanded product after 15 min; however, the nanosized lead oxides prepared by ball milling (1 mol%) and the other one prepared from dispersion of commercial PbO in n-octane led to 95 and 81% of the desired product, respectively, after 15 min. These results clearly confirmed the higher efficacy of the nanosized PbO due to its higher surface area. Moreover, fewer amounts of nano-PbO (1 instead of 5 mol%) were sufficient to attain the maximum yield. Comparison of the results obtained for the two kinds of nano-PbO (1 mol%) showed that the sample prepared via ball milling was the most effective catalyst. The first led to 95% yield after 15 min, whereas the nano-PbO prepared through dispersion in n-octane afforded 81% yield under the same reaction conditions and similar reaction time.

General reaction conditions are described in Table 1. All reactions were carried out at 80 °C for 15 min.

Synthesis of APhDPyC catalyzed by different simple and complex oxides

Because of the important role of catalyst in a multi-component catalytic organic synthesis, effect of various catalysts was examined by controlling the improved reaction conditions under the solvent-free conditions (Table 3). Without catalyst, the reaction progress was unacceptable and the product was acquired in a very low yield after delayed reaction time (entry 1). Therefore, our endeavors were concentrated to find other reasonable catalysts. At first, some Keggin– and Wells–Dawson heteropolyacids were inspected. All the selected heteropolyacids provided comparable function and prompted to 59–64% yield with 0.003 mmol catalyst after 15 min (entries 2–5). However, ZrOCl2∙8H2O produced 54% yield with 0.03 mmol of the catalyst during the same time (entry 6). Commercial PbO acted better and gave 73% yield under the same conditions and time (entry 7). Moreover, nano-PbO behaved better than the commercial one and led to 94% yield with 0.01 mmol catalyst after 15 min (entry 8). Different oxides such as CuO, SiO2, and CeO2 (even in the nanorange) were less effective than PbO and 0.015 mmol of each catalyst provided the aspired product with 22–41% yield after 30 min (entries 9–11). Considering accessibility, price, ease of work-up, and reusability aspects which determine the appropriateness of a catalyst from financial and consensus points of view, PbO was discovered better among all the screened catalysts to perform the titled multi-component condensation reaction with respect to reaction time and product yield.

General reaction conditions are described in Table 1. All reactions were carried out at 80 °C. H3PW12O40 and H3PMo12O40 obtained commercially. H5PW10V2O40 and H6P2W18O62 were prepared according to the reported procedures [54, 58].

Synthesis of different substituted 1H-pyrazolo[1,2-b]phthalazines

Next, using the optimized reaction conditions, the extension and scope of the method were investigated for the synthesis of an assortment of substituted 1H-pyrazolo[1,2-b]phthalazines in the presence of commercial bulk and nanosized PbO (Table 4). The electronic nature of the substituents on the aromatic ring revealed no critical effect on the yield % and aromatic aldehydes bearing substituents on the ortho-, meta-, and para-positions including electron donating and/or electron-withdrawing substituents participated well in the reaction and gave the corresponding products in high yields. Additionally, para-substituted aldehydes led to good results compared to the ortho-substituents, as there are more steric hindrances for the ortho-substituted aldehydes for the product formation than the para-substituted ones.

Reactions were carried out as described in the experimental section. Yields refer to the isolated pure products. Bulk PbO (5 mol%) and nano-PbO (1 mol%) were used. All reactions were carried out at 80 °C for 15 min. The desired pure products were characterized by comparison of their physical data with those of known compounds.

Comparison of the catalytic efficacy of the nanosized PbO as catalyst with other reported catalysts in the preparation of 1H-pyrazolo[1,2-b]phthalazine-5,10-diones

The productivity of the present heterogeneous catalytic framework was concentrated on some reported catalysts (Table 5). The reaction of benzaldehyde was chosen as a model reaction, and the comparison was in terms of mol% of catalyst, temperature, reaction time, and percentage yields. Obviously, the present method behaved better than most of the catalysts mentioned in Table 5. The present methodology utilized a very low amount of PbO as a simple and cheap catalyst under solvent-free conditions.

Studying reusability of PbO in the synthesis of APhDPyC

So as to examine the catalytic activity and probability of catalyst reusability, the reusing of PbO was considered under the solvent-free conditions using the model reaction with benzaldehyde. After finishing of the reaction, the catalyst was recovered from the reaction mixture by simple filtration in hot EtOH. The isolated catalyst was dried in a vacuum oven at 100 °C and was reused under comparable reaction conditions. The outcomes demonstrated that PbO is steady in the reaction medium and can be reused several times without significant loss of catalytic activity (Fig. 4). Moreover, as specified before, drying of the reused catalyst under freeze condition had no a vital effect on the catalyst efficacy.

Plausible reaction pathway

Considering the above results into account, the accompanying reaction pathway is proposed for the catalytic transformation (Scheme S1) [46, 66]. The reaction is thought to continue in a stepwise manner by means of Knoevenagel condensation of malononitrile anion with the aromatic aldehyde and elimination of hydroxide anion and originating lidenemalononitrile intermediate. This would happen through the initiation of C–H bond in malononitrile by basic oxygen in the catalyst in one hand, and activation of the carbonyl group in aldehyde by the acidic part (Pb2+) of the catalyst on the other. Then, Michael addition of phthalhydrazide to the C=C bond of electron-deficient Knoevenagel adduct prompted to the formation of an iminomethylene. Michael-type addition of intermediate (A) to phthalhydrazide under the catalytic role of PbO was occurred to yield a second intermediate (B) which progressively experienced cyclization to (C) and lastly tautomerized to the expected product. Thus, the titled compound would be framed by intramolecular concerted cyclization by tautomerization of the Michael adduct. Lewis acidity of PbO would help initiation of nitrile to be transformed into the amine. In addition, it should be mentioned that PbO possesses both Lewis acidic and basic properties. Accordingly, PbO would actuate the C–H bond of malononitrile via the mediation of the basic O2− in one hand, and activation of the carbonyl group of aldehyde via the acidic part Pb2+ on the other.

Conclusion

In conclusion, well-crystallized lead (II) oxide nanoparticles were effectively prepared by means of ball milling and solvothermal conditions. The connected synthetic methodology was quick, and the PbO nanoparticles had good separation with uniform nanometer scale without expecting any additive and stabilizer. Finally, the prepared PbO nanoparticles were connected as productive and recyclable nanocatalyst in the one-pot high yielding synthesis of 1H-pyrazolo[1,2-b]phthalazine-5,10-diones under environmentally friendly conditions. The proposed condensation reaction of aromatic aldehydes, phthalhydrazide, and malononitrile was clean, and no side products were recognized. In all cases, the reactions continued proficiently at 80 °C under solvent-free conditions in the presence of a little amount of PbO. The simplicity and the use of an inexpensive catalyst under solvent-free reaction conditions are some important elements of the present protocol.

References

S. Bhatia, in Nanoparticles Types, Classification, Characterization, Fabrication Methods and Drug Delivery Applications, 1st edn. (Springer, 2016), pp. 33–93. doi:10.1007/978-3-319-41129-3_2

M. Björnmalm, J. Cui, N. Bertleff-Zieschang, D. Song, M. Faria, MdA Rahim, F. Carus, Chem. Mater. (2016). doi:10.1021/acs.chemmater.6b02848

S. Leininger, B. Olenyuk, P.J. Stang, Chem. Rev. 100, 853 (2000)

S. Karasawa, Y. Sano, T. Akita, N. Koga, T. Itoh, H. Iwamura, P. Rabu, M. Drillon, J. Am. Chem. Soc. 120, 10080 (1998)

P. Veluchamy, M. Sharon, M. Shimizu, H. Minoura, J. Electroanal. Chem. 365, 179 (1994)

S. Ghasemi, M.F. Mousavi, M. Shamsipur, H. Karami, Ultrason. Sonochem. 15, 448 (2008)

S. Wang, C. Li, Z. Xiao, T. Chen, G. Wang, J. Mol. Catal. A Chem. 420, 26 (2016)

S.K. Pasha, V.S.V. Satyanarayana, A. Sivakumar, K. Chidambaram, L.J. Kennedy, Chin. Chem. Lett. 22(8), 891 (2011)

W. Bytyn, M. Baerns, Appl. Catal. 28, 199 (1986)

M. Cao, Y. Meng, Y. Lu, Catal. Commun. 6, 802 (2005)

L. Tao, L. Chen, S.-F. Yin, S.-L. Luo, Y.-Q. Ren, W.-S. Li, X.-P. Zhou, C.-T. Au, Appl. Catal. A Gen. 367, 99 (2009)

A.V. Borhade, B.K. Uphade, D.R. Tope, J. Chem. Sci. 125, 583 (2013)

P.P. Upare, M. Lee, D.W. Hwang, Y.K. Hwang, J.-S. Chang, Catal. Commun. 56, 179 (2014)

L. Zhang, F. Guo, X. Liu, J. Cui, Y. Qian, J. Cryst. Growth 280, 575 (2005)

J.Z. Liu, P.X. Yan, G.H. Yue, L.B. Kong, R.F. Zhuo, D.M. Qu, Mater. Lett. 60, 3471 (2006)

J. Liqiang, W. Baiqi, X. Baifu, L. Shudan, S. Keying, C. Weimin, F. Honggang, J. Solid State Chem. 177, 4221 (2004)

L. Vayssieres, Adv. Mater. 15, 464 (2003)

C.H. Liu, J.A. Zapien, Y. Yao, X.M. Meng, C.S. Lee, S.S. Fan, Y. Lifshitz, S.T. Lee, Adv. Mater. 15, 838 (2003)

F. Bigdeli, A. Morsali, Mater. Lett. 64, 4 (2010)

M. Ghaedi, A.M. Ghaedi, B. Mirtamizdoust, S. Agarwal, V.K. Gupta, J. Mol. Liq. 213, 48 (2016)

M. Ranjbar, M. Yousefi, Int. J. Nanosci. Nanotechnol. 12(2), 109 (2016)

J. Sinkkonen, V. Ovcharenko, K.N. Zelenin, I.P. Bezhan, B.A. Chakchir, F. Al-Assar, K. Pihlaja, Eur. J. Org. Chem. 2002, 2046 (2002)

R.P. Jain, J.C. Vederas, Bioorg. Med. Chem. Lett. 14, 3655 (2004)

A. Kumar, M.K. Gupta, M. Kumar, Green Chem. 14, 290 (2012)

I. Ugi, A. Dömling, W. Hörl, Endeavour 18, 115 (1994)

M.M. Heravi, B. Baghernejad, H.A. Oskooie, Tetrahedron Lett. 50, 767 (2009)

J. Gerencsér, G. Dormán, F. Darvas, QSAR Comb. Sci. 25, 439 (2006)

D.J. Ramón, M. Yus, Angew. Chem. Inter. Ed. 44, 1602 (2005)

F. Bergstrom, Chem. Rev. 35, 77 (1944)

F.W. Lichtenthaler, Acc. Chem. Res. 35, 728 (2002)

M. Kidwai, N.K. Mishra, D. Bhatnagar, A. Jahan, Green Chem. Lett. Rev. 4, 109 (2011)

E.C. Franklin, Chem. Rev. 16, 305 (1935)

W.R. Vaughan, Chem. Rev. 43, 447 (1948)

H.W. Heine, R. Henrie, L. Heitz, S.R. Kovvali, J. Org. Chem. 39, 3187 (1974)

S. Rostamizadeh, M. Nojavan, R. Aryan, H. Sadeghian, M. Davoodnejad, Chin. Chem. Lett. 24, 629 (2013)

N.K. Terrett, A.S. Bell, D. Brown, P. Ellis, Bioorg. Med. Chem. Lett. 6, 1819 (1996)

S.K. Singh, P.G. Reddy, K.S. Rao, B.B. Lohray, P. Misra, S.A. Rajjak, Y.K. Rao, A. Venkateswarlu, Bioorg. Med. Chem. Lett. 14, 499 (2004)

M.J. Genin, C. Biles, B.J. Keiser, S.M. Poppe, S.M. Swaney, W.G. Tarpley, Y. Yagi, D.L. Romero, J. Med. Chem. 43, 1034 (2000)

L. Zhang, L.P. Guan, X.Y. Sun, C.X. Wei, K.Y. Chai, Z.S. Quan, Chem. Biol. Drug Des. 73, 313 (2009)

N. Watanabe, Y. Kabasawa, Y. Takase, M. Matsukura, K. Miyazaki, H. Ishihara, K. Kodama, H. Adachi, J. Med. Chem. 41, 3367 (1998)

Y. Nomoto, H. Obase, H. Takai, T. Hirata, M. Teranishi, J. Nakamura, T. Ohno, K. Kubo, Chem. Pharm. Bull. 38, 2467 (1990)

F. Al’-Assar, K. Zelenin, E. Lesiovskaya, I. Bezhan, B. Chakchir, Pharm. Chem. J. 36, 598 (2002)

G. Karthikeyan, A. Pandurangan, J. Mol. Cat. A Chem. 361, 58 (2012)

R. Ghahremanzadeh, G. Imani Shakibaei, A. Bazgir, Synlett. 08, 1129 (2008)

D.S. Raghuvanshi, K.N. Singh, Tetrahedron Lett. 52, 5702 (2011)

S.-H. Song, J. Zhong, Y.-H. He, Z. Guan, Tetrahedron Lett. 53, 7075 (2012)

M.R. Nabid, S.J.T. Rezaei, R. Ghahremanzadeh, A. Bazgir, Ultras. Sonochem. 17, 159 (2010)

M.V. Reddy, Y.T. Jeong, Tetrahedron Lett. 54, 3546 (2013)

A. Khazaei, A.R. Moosavi-Zare, Z. Mohammadi, A. Zare, V. Khakyzadeh, G. Darvishi, RSC Adv. 3, 1323 (2013)

F. Zamani, E. Izadi, Catal. Commun. 42, 104 (2013)

A. Rostami, B. Atashkar, H. Gholami, Catal. Commun. 37, 69 (2013)

I. Mohammadpoor-Baltork, S. Tangestaninejad, M. Moghadam, V. Mirkhani, S. Anvar, A. Mirjafari, Synlett. 3104 (2010)

R. Tayebee, M. Jarrahi, B. Maleki, M.K. Razi, Z. Mokhtari, S. Baghbanian, RSC Adv. 5, 10869 (2015)

R. Tayebee, S. Tizabi, Chin. J. Catal. 33, 923 (2012)

R. Tayebee, M. Amini, M. Akbari, A. Aliakbari, Dalton Trans. 44, 9596 (2015)

R. Tayebee, B. Maleki, J. Chem. Sci. 125, 335 (2013)

R. Tayebee, M.M. Amini, M. Ghadamgahi, M. Armaghan, J. Mol. Cat. A Chem. 366, 266 (2013)

R. Tayebee, M.M. Amini, F. Nehzat, O. Sadeghi, M. Armaghan, J. Mol. Cat. A Chem. 366, 140 (2013)

S. Gnanam, V. Rajendran, Int. J. Nanomater Biostruct. 1, 12 (2011)

S.K. Pasha, L.J. Kennedy, J.J. Vijaya, K. Chidambaram, Sensors & Transducers 122, 20 (2010)

P. Praveen, G. Viruthagiri, S. Mugundan, N. Shanmugam, Spectrochim. Acta A Mol. Biomol. Spect. 117, 622 (2014)

K. Arulmozhi, N. Mythili, AIP Adv. 3, 122122 (2013)

A.V. Borhade, B.K. Uphade, D.R. Tope, J. Chem. Sci. 125(3), 583 (2013)

B. Maleki, S.B.N. Chalaki, S.S. Ashrafi, E.R. Seresht, F. Moeinpour, A. Khojastehnezhad, Appl. Organomet. Chem. 29(5), 290 (2015)

M.R. Nabid, S.J.T. Rezaei, R. Ghahremanzadeh, A. Bazgir, Ultras. Sonochem. 17(1), 159 (2010)

H. Kefayati, S.H. Amlashi, R. Kazemi-Rad, A. Delafrooz, Comp. Ren. Chim. 17(9), 894 (2014)

R. Ghahremanzadeh, G.I. Shakibaei, A. Bazgir, Synlett 8, 1129 (2008)

J. Safaei-Ghomi, H. Shahbazi-Alavi, A. Ziarati, R. Teymuri, M.R. Saberi, Chin. Chem. Lett. 25(3), 401 (2014)

Acknowledgements

Partial financial support from the Research Councils of Hakim Sabzevari was greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tayebee, R., Maleki, B. & sabeti, M. A new simple method for the preparation of PbO nanoparticles and implementation of an efficient and reusable catalytic system for the synthesis of 1H-pyrazolo[1,2-b]phthalazine-5,10-diones. J IRAN CHEM SOC 14, 1179–1188 (2017). https://doi.org/10.1007/s13738-017-1068-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-017-1068-2