Abstract

The socket is the most critical part of every lower-limb prosthetic system, since it serves as the interfacial component that connects the residual limb with the artificial system. However, many amputees abandon their socket prostheses due to the high-level of discomfort caused by the poor interaction between the socket and residual limb. In general, socket prosthesis performance is determined by three main factors, namely, residual limb-socket interfacial stress, volume fluctuation of the residual limb, and temperature. This review paper summarizes the various sensing and actuation solutions that have been proposed for improving socket performance and for realizing next-generation socket prostheses. The working principles of different sensors and how they have been tested or used for monitoring the socket interface are discussed. Furthermore, various actuation methods that have been proposed for actively modifying and improving the socket interface are also reviewed. Through the continued development and integration of these sensing and actuation technologies, the long-term vision is to realize smart socket prostheses. Such smart socket systems will not only function as a socket prosthesis but will also be able to sense parameters that cause amputee discomfort and self-adjust to optimize its fit, function, and performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Limb amputation and the resulting physical disability adversely impacts the quality of life of amputees. According to a report published by the World Health Organization, there are ~ 40 million amputees worldwide. In the U.S., ~ 185,000 amputations are performed each year, and nearly 2 million people suffer from amputations [1]. Overall, ~ 54% of all amputations are due to vascular diseases, with the remaining ~ 46% caused by severe trauma and cancers [2]. These statistics have increased due to recent military conflicts. For example, the number of combat-related amputations increased from ~ 960 to 1200 between 2010 and 2012 [3]. While amputations need to be performed as a medical necessity, the main concern is to provide a better quality of life for amputees after limb loss.

Prostheses serve to restore the lost functionalities of amputees. It has been shown that consistent prosthetic use reduces secondary health issues and provides a larger degree of mobility and functional independence for those with amputation [4]. Increased prosthetic usage correlates with higher levels of employment [4], increased quality of life [5], decreased phantom limb pain, and lower levels of general psychiatric symptoms.

In the case of lower limb amputations, the prosthetic system functions as the crucial component that transfers loads from the upper body through the residual limb to the artificial limb. In particular, socket prostheses consist of a socket, a shank, the ankle, and foot, and its purpose is to replace the amputated limb. The socket is responsible for coupling the residual limb with the rest of the components of the prosthesis. Traditionally, the socket is a rigid or semi-rigid component that is purposefully designed to conform to the shape of each amputee’s residual limb. Yet, socket gold standards are an undefined topic in the field of prosthetics. Born out of a custom fabrication process that entails plaster casting followed by lamination, the socket continues to remain a one-off device. Although there have been advances in computer-aided design and manufacturing (CAD–CAM) technology or 3D printing, these are primarily manufacturing solutions. The end result, being a rigid device that gives a snapshot window of limb volume, size, and shape is still the standard solution. Unfortunately, the prosthetic socket and methods have seen little advancement in the past 50 years.

In fact, less than 50% of amputees wear their prosthesis regularly [6, 7], and the primary cause of prosthetic abandonment is due to socket discomfort [8] and fitment [9]. Prosthetic abandonment is especially prevalent among users with an above the knee amputation with a short femur, resulting in psychological problems, reduced quality of life, and lack of community engagement [10]. Chamlian et al. [11] observed elevated abandonment rates (62.5%) and daily usage decrements (31–85%) following discharge from rehabilitation. The inability for conventional sockets to respond to the daily needs of amputees leads to short-term and long-term consequences. The majority of users require multiple replacement sockets per year, costing upwards of $30,000 [12]. In severe cases, users are forced to undergo revisions of their amputation. This cyclic process creates not only financial burdens to amputees and the healthcare system but also reflects the fragmentation of the care continuum and the lack of coordinated efforts to ensure appropriate access to medical care.

To ensure proper fitment of the socket, the three main factors that should be considered are the pressure distribution at the socket-residual limb interface, local body (limb) temperature, and volume fluctuations of the residual limb. Nonuniform contact pressure can cause hotspots that result in pain and skin-related issues. Blood profusion and a change in metabolic rate can result in an increased temperature of the residual limb to cause sweating. In this case, excessive sweating can cause skin irritation and maceration, which can worsen and result in skin breakdown and acute infection. In unequal interfacial stress- and temperature-related issues, a change in the residual limb’s volume can result in excessive displacement (i.e., in the case of limb shrinkage) or increased shear forces between the residual limb and socket (i.e., in the case of limb expansion). Besides, the gait pattern of amputees can change due to improper fitment of the socket. Abnormalities in the gait patterns could result in walking instability [13] and an increase in energy consumption as a result of compensatory muscle activity [14], to name a few.

Therefore, the purpose of this review paper, which differentiates itself from other review articles on prostheses [15,16,17,18], is to summarize the different sensing technologies employed for measuring and modifying the three leading factors that govern socket prosthesis fitment: contact pressure distribution, local temperature, and volume fluctuations. The next three sections each begin with a description of technologies that have been used for measuring the specific physical phenomenon of interest and their associated challenges. Furthermore, to capture other issues that drive the development of next-generation smart socket prostheses, various sensing modalities for monitoring gait and infection are also briefly summarized. Then, new designs or proposed changes to the socket prosthesis that mitigate these effects are discussed. It should be mentioned that this paper is not meant to be an exhaustive review of all the technologies developed and presented to date. Instead, only certain technologies are highlighted to showcase the breadth and opportunities of this field. Finally, the paper concludes with a discussion of the vision for realizing next-generation smart socket prostheses.

2 Interfacial pressure distribution

One of the most critical factors in determining fitment and comfort depends on the distribution of contact pressure at the interface between the residual limb and socket prosthesis [19]. Pressure hotspots resulting from nonuniform pressure distributions acting on the residual limb for long periods of time can cause pressure ulcers, vascular occlusions, and skin irritations, to name a few [20]. These problems often hinder blood flow in the residual limb, which can lead to an increase in temperature, perspiration, and dermatitis [21,22,23]. If these issues are not addressed early, skin problems and tissue infection can follow. Furthermore, these issues can escalate, and the patient may need to undergo re-amputation [24]. Hence, pressure monitoring at the residual limb-sockets interface needs to be the first and foremost step taken to reduce discomfort and skin-related issues at the limb-prosthesis interface [25].

Although the relationship between the level of discomfort and interfacial pressure is highly subjective and depends on the condition of the muscles in the residual limb [26], Ogawa et al. [27] was able to quantify the pain-raising pressure threshold for the fossa popliteal and patellar tendon as ~ 50 kPa and ~ 120 kPa, respectively. However, it was found that the sensitivity of pain depends on the location of the residual limb. For example, pain sensitivity is relatively low near the front side of the thigh and higher in the rear. Kahle et al. [28] reported that a nondisabled person experiences negligible pressure on the ischial tuberosity while standing, while pressure can increase to as high as 300 mmHg during normal sitting. This is significant enough to cause tissue damage for sensory- and mobility-impaired individuals. Since it is not possible to define a single value of pain-causing pressure threshold, the first step to solve this problem would be to quantify the stress distribution at the residual limb-socket interface. In general, four main types of sensors are used for pressure measurements in the socket, which are: (1) strain gages (2) piezoresistive, (3) capacitive, and (4) optical sensors. Each type of these sensors, their integration in socket prostheses, and limitations are described in detail in the following subsections.

2.1 Strain gages

Strain gages are patches of patterned metal foil on a flexible plastic backing that exhibit a change in their resistance in response to applied strains [29]. Strain gages are regarded as the most well-known and widely used strain sensor because of their high accuracy, resolution, and reliability [30]. The use of strain gages in the lower limb prosthesis first began in the 1960s [31]. Strain gages are mainly used as a diaphragm deflection transducers inserted in the socket to measure normal stress [27] or as a piston-type transducer mounted on the socket wall to measure both normal and shear stresses [17].

The Kulite sensor is the most commonly used diaphragm deflection transducer for measuring stress in the socket prosthesis [32,33,34,35,36,37,38,39]. Here, 2- to 3-mm-diameter and 0.8-mm-thick sensing elements are tethered to four 0- to 5-mm-thick conductor ribbon cables on its bottom to achieve electrical connections. Kulite sensors are monolithic and employed on a silicone diaphragm in a Wheatstone bridge configuration for strain measurements. The sensor is employed symmetrically with respect to the central axis to ensure that it can only sense normal pressure. Besides its high sensitivity, lightweight structure, and easy deployment, the stiff backing used to prevent its out-of-plane deformation often causes stiffness mismatch with the surrounding tissue and liner material. This mismatch can result in stress concentration at the sensor edges, causing local tension in the tissue of the residual limb [40]. Besides, Kulite sensors can only measure stains at the location where they are instrumented (i.e., they are discrete or point sensors). They also need to be connected to a data acquisition system through electrical wirings. As a result, pressure measurement over a large area can only be achieved by employing an array of Kulite sensors on the residual limb [37]. However, such an implementation would restrict the range of motion of amputees and influence their normal gait, especially due to the large number of tethered electrical connections required. They are also susceptible to cross-talk due to their high stiffness.

To overcome these aforementioned limitations, Appoldt et al. [31] proposed a plunger-piston type force gage, where the gage-housing cylinder was placed inside the wall of the prosthesis by drilling a hole near the region of clinical interest. The piston was attached to a small steel beam whose ends were clamped to the main transducer frame. Similar to the diaphragm deflection transducer setup, four strain gages were arranged in a Wheatstone bridge configuration and employed for bending strain measurements, where normal stress was then evaluated using the measured bending strains. Although piston-type transducers are insensitive to cross-talk, they behave as a unidirectional transducer that is capable of only measuring direct pressure. The design of the socket also needs to be adjusted as the installation of piston-type transducers requires drilling holes in the wall of the prosthesis.

The total stress developed at the prosthesis-residual limb interface is a resultant of normal and shear stresses. Excessive shear stress between the residual limb and the prosthesis can cause reduced blood flow and skin-related issues [41]. Therefore, the measurement of shear stresses is just as important as measuring normal stresses. First shear stress measurement at the residual limb-socket interface was achieved by Appoldt et al. [32] by introducing a tangential pressure transducer in the wall of the socket. However, this system was unable to measure both normal and shear stresses simultaneously. The tangential pressure transducer needs to be replaced with the perpendicular pressure transducer for normal stress measurement.

Later, Sanders and Daly [42] developed transducers for simultaneous measurement of stresses in three orthogonal directions. The sensor was employed at four different locations within a prosthetic socket of a below-knee amputee for in situ stress measurement during gait. Each of the three transducers was oriented in three orthogonal directions over a 6.35-mm-diameter sensing area. Gages were employed on two opposite faces of an aluminum beam and a Wheatstone bridge network was formed. The shear force between the residual limb and the prosthesis was estimated from the measured difference in bending moment between the gage locations. The normal force was estimated by employing a full-bridge diaphragm strain gage network between the cap support and the Pelite disk. Besides achieving simultaneous measurements of normal and shear stresses, employment of piston-based transducer for in situ stress measurement at prosthesis-residual limb interface often gets hindered by its bulky size and intricate instrumentation. The design of strain gage-based in situ stress measuring systems was investigated and optimized by different groups of researchers [43,44,45,46,47].

2.2 Piezoresistive sensors

Piezoresistive force-sensing resistors (FSRs) are suitable for medical applications due to their thin, flexible, and conformable structure [48,49,50]. In general, FSRs are thin force sensors whose resistance decreases with applied normal forces [51]. The change in resistance is converted into a corresponding voltage output using the Wheatstone bridge configuration [52, 53]. FSRs can be made with different shapes, and they can measure the change in applied load. Stress is estimated by dividing the measured load with the surface area of the sensor. Being a thin sheet, piezoresistive sensors can be easily placed inside the socket for in situ pressure monitoring [54].

The Interlink FSR, LuSense PS3, and Tekscan FlexiForce A201 are three commercially available and most widely used FSRs. The Interlink FSRs are comprised of a conductive surface and inter-digitated electrodes [55]. Typically, their resistance changes from 1 MΩ to 10 KΩ for 1 N of applied load [56]. LuSense sensors come in different shapes and sizes with typical resistances that vary between 1 MΩ and 2 KΩ for sensing pressure between 0.5 and 100 N/cm2 [57]. The FlexiForce A201 FSR consists of two layers of polyester/polyimide film, which are painted with conductive silver ink and laminated with adhesive to form the sensor [58]. While the Interlink FSRs are more robust, FlexiForce sensors exhibit better performance in terms of linearity, repeatability, time drift, and dynamic accuracy [59]. Like strain gages, piezoresistive FSRs are also point sensors. An array of FSRs is required to monitor distributed stresses acting on a large surface area such as the residual limb-prosthesis interface. For example, Ruda et al. [60] configured five Flexiforce sensors to form an array and embedded it in a flexible thin acetate sheet for distributed pressure monitoring at residual limb-prosthesis interface. However, stress measurements were not very accurate due to the small surface area of each FSR.

The two most widely used and commercially available piezoresistive pressure sensors for in-socket pressure measurements are the Rincoe Socket Fitting (RG Rincoe and Associates, Golden, CO, USA) [61] and F-Socket system [62]. Rincoe Socket Fitting consists of six sensor strips between the liner and the prosthesis, where each strip contains 10 discrete sensors separated by 1.5 in. Each sensor dot features a resolution of 0.5 psi up to 12 psi.

On the other hand, the FSR-based F-Socket system consists of 96 discrete sensing elements arranged in a 16 × 6 matrix [63]. The large number of discrete sensors allows it to generate higher resolution pressure maps as compared to the Rincoe Socket System. Although the F-Socket system does not require intricate instrumentation, they need to be calibrated according to the manufacturer’s instructions as was studied by Luo et al. [64].

Polliack et al. [62] compared the performance of Rincoe and F-socket systems for in situ stress measurements at the residual limb-prosthesis interface in terms of their accuracy, hysteresis, drift, and the effect of surface curvature. The experiments were performed in both flatbed and customized pressure vessels. The Rincoe Socket System exhibited an accuracy error of 25% (flatbed) and 33% (pressure vessel) with a corresponding 15% (flatbed) and 23% (pressure vessel) hysteresis error, and 7% (flatbed) and 11% (pressure vessel) drift error. The F-Socket system outputted 8% (flatbed) and 11% (pressure vessel) accuracy errors, 42% (flatbed) and 24% (pressure vessel) hysteresis errors, and 12% (flatbed) and 33% (pressure vessel) drift errors. These results suggest that the F-Socket system performed better. However, one of its main drawbacks is its inability to measure shear stresses [53]. In addition, it is susceptible to low-frequency response errors due to its hysteresis [30, 53].

2.3 Capacitive sensors

Aside from piezoresistive pressure sensors, capacitive sensors have also been employed for monitoring the pressure distribution at the residual limb-prosthesis interface [65,66,67,68]. The first capacitive interfacial stress sensor designed and implemented for this application was by Meier et al. [69]. The 2-mm-thick, flexible capacitance sensor exhibited an accuracy of 20%. Later, another prototype capacitance pressure sensor was designed by Polliack et al. [70] for prosthetic socket use, where 16 sensors were mounted in a 2.5 × 2.5 × 0.064 cm3 silicone substrate in the form of a 4 × 4 matrix. The sensor array was highly flexible, capable of being stretched to 4%. It also featured a mean flatbed accuracy error of 2.42 ± 3.20%, whereas the mean hysteresis errors for the flatbed tests were 12.93 ± 4.63%. The mean hysteresis errors for the positive mould were similar at 12.95 ± 8.26%. The prototype sensor demonstrated a mean flatbed drift error of 4.40 ± 3.46% and a positive mould drift error of 6.20 ± 7.12%. These findings have proved the superiority and acceptability of capacitance-based pressure sensors over piezoresistive sensors for in situ stress measurements [71, 72]. However, these capacitance-based pressure sensors were still unidirectional and suitable for measuring only direct applied pressures.

A miniature capacitance-based triaxial load transducer was proposed by Williams et al. [73] for simultaneous measurement of normal and shear stresses on the socket wall. A 2 g-weight single element piezoelectric copolymer poly(vinylidene fluoride-trifluoroethylene) (P(VDF-TrFE))-based triaxial force transducer that was 10 × 10 × 2.7 mm3 in size was proposed by Razian et al. [74]. This sensor was also able to measure normal and shear stresses simultaneously. Although they exhibited good sensitivity, linearity, less hysteresis, and low cross-talk, their temperature dependence and sophisticated manufacturing made it difficult for large-scale production and use for distributed pressure monitoring.

2.4 Optical sensors

Fiber Bragg grating (FBG) sensors offer high sensitivity, durability, multiplexibility, immunity to electromagnetic interference, and resistance to the aggressive environment [75,76,77,78,79,80,81,82], and they have been widely used for measuring different quantities (e.g., strain, temperature, humidity, force, and pressure, to name a few). Kanellos et al. [83] developed a highly-sensitive pressure sensor by embedding an FBG sensor in a thin polymeric sheet to form a 20 × 20 × 2.5 mm3 sensing pad. This FBG sensor exhibited a maximum fractional pressure sensitivity of 12 MPa with a spatial resolution of 10 × 10 mm2. It was operated in real-time and demonstrated minimum hysteresis. The same group of researchers found that the sensor pad’s rigidity and durability are the two main fabrication parameters that can be tuned to enhance sensor reliability for in-socket applications [84].

As mentioned earlier, the stiffness of the matrix polymer influenced the performance of FBG sensors for stress measurements. Different matrix materials were investigated by Al-Fakih et al. [85] for attaining the most efficient and accurate stress measurements at the residual limb-prosthesis interface. The results revealed that harder and thicker matrix materials exhibit higher sensitivity and accuracy when used in the socket. In a sperate study conducted by the same group [86], FBG elements were embedded in a thin layer of epoxy-based sensing pad for in-socket stress measurements. The FBG-instrumented epoxy pad was embedded in a silicone polymer to form an in situ pressure sensor. The performance of the FBG-epoxy sensor was tested by inserting and inflating a heavy-duty balloon into the socket using compressed air to simulate the similar condition of a transtibial amputee’s patellar tendon bar. The sensors exhibited a sensitivity of 127 pm/N with full-scale output hysteresis of ~ 0.09. This study validated the reliability of FBG-based pressure sensors for in situ pressure measurement. However, like many piezoresistive pressure sensors, most FBG-based pressure sensors could only measure normal stresses. Zhang et al. [87] reported a soft polymer-based FBG (PFBG) for simultaneously measuring shear and normal stresses. The sensor was fabricated with one horizontal and another inclined PFBG embedded in a soft polydimethylsiloxanes (PDMS) matrix. The proposed sensor was tested by simultaneously applying normal and shear forces. The measured pressure sensitivity was found to be 0.8 pm/Pa within the range of 2.4 kPa, and its shear stress sensitivity was reported to be 1.3 pm/Pa for a full range of 0.6 kPa.

Optoelectronic sensors have also been used for pressure monitoring at human–machine (i.e., residual limb-prosthesis) interfaces. This type of sensors is made of an external silicone structure and a printed circuit board that contains an array of sensing elements. Each sensing element consists of a light transmitter, a light-emitting diode (LED), a receiver, and a photodiode. The silicone cover serves as the main component for the transduction process. An applied load on the sensor deforms the silicone cover, hence exhibiting a proportional change in output voltage as the light intensity received by the photodiode. However, the performance of these sensors was not evaluated for socket prosthesis applications [88, 89].

Instead, a thin and flexible sensor foil was presented by Missinne et al. [90] to monitor shear stresses for medical applications. The sensor works on the principle of shear stress-dependent coupling change of optical power between a Vertical-Cavity Surface-Emitting Laser (VCSEL) and a photodiode that was separated by a deformable sensing layer of PDMS. Shear stresses up to 139 kPa were measured with a sensitivity of − 7.9 µA/kPa in the linear portion of its range. A new type of optoelectronic sensor was proposed by Lincoln et al. [91], which was fabricated using a commercially available integrated circuit, a printed circuit board, and layers of silicone elastomers. Comparatively lower sensor drift, hysteresis, and some temperature sensitivity were reported. A similar design principle was used by Cutkosky et al. [92], where a VCSEL and a photodiode were assembled in an ultra-thin package and separated by a deformable polymer sensing layer. A total of five sensors were employed for normal and shear force measurements: one for detecting normal loads, two for detecting shear force in one direction, and the last two for detecting shear in the orthogonal direction. As a normal load was applied to the reflective material, the interstitial transparent material compressed, and the reflective material moved the light source (emitter) closer to the light sensor (detector). This caused the detector to detect an increase in reflected light from the emitter. Shear loads were sensed by adding absorptive regions to the reflective layer. An applied shear load changed the ratio of absorptive to reflective material between the emitter and the detector, which changed the amount of light reflecting back to the detector. Despite this interesting sensing mechanism, optoelectronic sensors may become damaged during normal gait, and they are also susceptible to electromagnetic interference [93].

Different solutions have been proposed and implemented to mitigate stress-related issues at the residual limb-prosthesis interface. For example, a liner system was used as a sock to provide a better cushioning effect on the residual limb [94]. A sub-atmospheric suspension system was also used to reduce stress-related discomfort by more efficiently distributing the applied stresses [28]. The effect of brimless interface design was compared with ischial ramus containment (IRC) prosthetic sockets when using vacuum-assisted suspension on persons with a unilateral transfemoral amputation. The peak/stance mean pressure in the medial proximal aspect of the socket was 322 mmHg in the IRC, as compared to 190 mmHg in the brimless condition. Both systems provided better friction, thereby ensuring improved load transfer from the residual limb to the socket [23].

A variable-impedance prosthetic socket was proposed by Sengeh and Herr [71], which was able to reduce pressure intensities at critical locations in the socket. CAD-CAM were employed to fabricate the socket on the basis of biomechanical data obtained through magnetic resonance imaging (MRI). The depths of tissue in the residual limb was inversely estimated from MRI images and impedance characteristics, which were thereafter used to adjust the geometry and shape of the socket to reduce contact pressure near the bony prominence of the residual limb. Depending on the tissue condition of the residual limb, 7–21% reduction in pressure was achieved. However, this design process is computationally intensive and case-specific for every amputee.

Another design considered the incorporation of a magnetorheological (MR) fluid bag in the socket [27]. The volume of the socket was adjusted by controlling the volume of the MR fluid bags with external magnetic sources. A 100 kPa reduction in pressure was achieved by applying a 0.38 T magnetic field at the patella area of the socket-residual limb system. However, a bulky mechanical and electrical control system and the requirement of a high-energy power supply are the two main drawbacks of this smart socket system.

3 Temperature

Amputees with lower limb amputations often suffer from thermal discomfort during their regular activities, since the reduced surface area of the residual limb often influences the thermoregulatory system. This situation often amplifies the amputees’ sweating rate, which invariably causes discomfort, irritations, and skin ulceration. In a recent study by Ghoseiri et al. [72], it has been reported that ~ 52% of the amputees with socket prostheses experience heat-related problems and a 1–2 °C rise in temperature in their residual limb during regular activities. The mean skin temperature of all subjects at the start of the test was 31.4 ± 1.3 °C. The temperature rose by 0.8 °C and reached 32.2 ± 1.7 °C at the end of the 15 min resting period [95]. This increase in body temperature was mainly caused by the poor heat conduction property and moisture permeability of the socket materials (i.e., the socket and the liner) [96]. Therefore, in addition to identifying socket materials that provided adequate frictional and stiffness properties, good heat conduction and moisture permeability should also be considered.

Ad hoc thermistors were integrated with a socket prosthesis to monitor the interfacial temperature between the residual limb and socket [97]. The in-socket temperature of five transtibial amputees at 14 different locations on the residual limb were investigated at four different stages (i.e., donning, steady-state resting, initial walking, and steady-state walking). The results indicated that the thermal dissipation characteristics of the socket and liner restricted heat loss from the residual limb, and the temperature increase was larger in areas where there was more muscle bulk. In a separate study by Huff et al. [98], the temperature at the residual limb-prosthesis interface was measured for five transtibial amputees wearing different socket systems. The subjects were asked to sit for 15 min, followed by 10 min of treadmill walking. Temperature was measured using 14 thermistors, and 38-gage wires were employed for connecting them with the data acquisition system. The results indicated that temperature varied with activity and location on the limb. However, multiple wire failures were reported at the distal posterior location. In addition, the duration of the experiments was too short to reach steady-state temperature during the activities [97]. Thus, the experimental design was modified to better quantify temperature at the skin-prosthesis interface during a 2.5 h protocol that included periods of resting and activity [98]. Here, 16 Thermometrics MA100GG thermistors with 2-mm-sensor head diameter were connected to a data acquisition system with a BNC-2090 analog to digital (A/D) board. The 28-gage wires that connected the thermistors to the data acquisition system were used to reduce the incidence of wire failure. An average steady-state temperature of 29.5 °C ± 0.9 °C was recorded during the last minute of the 1-h rest period. The residual limb temperature increased to 32.6 °C ± 0.8 °C after 30 min of treadmill walking. The temperature reached a maximum of 32.8 °C and thereafter decreased to 32.6 °C ± 0.6 °C during the last minute of the final rest period. It was found that, at the end of the final 1-h rest period, skin temperature did not return to their initial rest period values.

Attempts have been made to mitigate these temperature-related issues by designing well-perforated fabrics that can be easily integrated with the socket and liner. A breathable liner system was proposed by Caldwell et al. [99] to mitigate problems due to heat and sweating in the socket. A silicone-based prosthesis liner was perforated to expel sweat and heat from the lower-limb prosthesis. Holes were intentionally made approximately 1 cm apart using a perforating tool. The initial clinical experience with this technique suggested that expulsion of sweat occurred, and user feedback indicated improved prosthesis performance. Bartlet et al. [100] proposed a new liner, which was made of spacer fabric in combination with a partial silicone coating, to maintain the functionality of the skin inside the socket. The temperature inside the socket was regulated based on the liner’s permeability to gas and humidity. The sides of the prosthesis facing the skin were provided with bacteriostatic fibers that contained silver ions (Ag+). Ag+ prevents bacterial growth in the socket and helped reduce odors. Fibers with large surfaces were also included in the middle layer of the liner textile to expel moisture.

A phase change material (PCM) was incorporated in smartTemp liner [101]. It was reported that the mean increase in temperature of the residual limb during activity was 0.2 °C lower when wearing the smartTemp liner versus the placebo liner. Overall, the temperature was ~ 0.9 °C lower at the end of daily activities. A new cooling device that could maintain a constant temperature on the residual limb surface was proposed by Han et al. [102]. The excess metabolic heat in the residual limb was removed by a cooling pipe and dissipated to an external ice pack. A cooling capacity ranging from 6.6 to 15.6 W was achieved by using a flow channel array. It was demonstrated that under two simulated walking activities, skin temperature was kept constant (31.4 °C ± 0.2 °C) by using the proposed cooling system. These results demonstrated the device’s ability of removing excess heat from the residual limb during regular physical activities of amputees. Ghoseiri et al. [103] proposed a smart thermoregulatory system for temperature control in the socket prosthesis. The system was designed and installed in a phantom model of a prosthetic socket. It captured temperature data from 16 discrete sensors positioned at the interface between the phantom model and a silicone liner. The average of the collected set of measurements was compared with a predefined temperature value in order for the system to apply necessary heating or cooling to achieve thermal equilibrium. A thin layer of aluminum sheet was used to ensure good heat transfer between the thermal pump and sites around the phantom model. To decrease the prosthetic socket’s thermal resistance, heat pipes were used to concentrate heat flux from the residual limb’s skin surface to a cooling region on the outer surface of the socket where a compact heat sink was attached. A small fan was used to convect heat from the heat sink to the ambient surroundings. Experiments showed that the cooling capacity of the prototype device ranged from 2.1 to 7.0 W at an ambient temperature of 23 °C. The analysis showed that the device could potentially maintain a constant skin temperature for a 9.4 W thermal load [104]. Furthermore, the prosthetic socket was modified by incorporating a helical cooling channel within the socket wall using additive manufacturing [105]. Computer simulations and laboratory experiments were performed to assess the ability of the modified design to create a greater temperature difference across the socket wall. It was found that the modified socket exhibited greater temperature differences of 11.11 °C and 6.41 °C based on numerical simulations and experiments, respectively. These findings suggested that cooling channel-assisted prosthesis could provide effective temperature control of an amputee’s residual limb.

Zhe et al. [106] proposed a modified socket with a heat pipe, including a working fluid and a wicking structure. The heat pipe had a socket section and a heat sink that was extended along its length through the socket wall. The working fluid had a boiling point from about 0 to 90 °C. The working fluid could be selected in such a way that it could evaporate to form vapor due to heat from the residual limb in the socket, thus drawing latent heat of vaporization from the residual limb. A porous wicking material, attached to a hypobaric assisted vacuum liner, was also suggested to allow moisture escapement [107]. A dedicated liner with different conical holes was proposed [108], where the holes were placed to eliminate moisture at the skin through airflow channels used also for the suspension.

4 Volume fluctuations

The volume of the residual limb experiences short- and long-term changes due to fluid level fluctuations. Therefore, socket fitment should be optimized to consider these volume fluctuations. It was reported that a maximum decrease of 11% decrement and an increase of 7% in residual limb volume can be observed during an amputee’s daily activities [109]. However, just a 3.5% volume change is sufficient to cause a high-level discomfort [110]. A decrease in the volume of the residual limb can lead to excessive relative displacement between the residual limb and socket. On the other hand, the amputee can experience excessive shear stress and normal pressure in the case of volume enhancement [109]. Different techniques are available for measuring volume fluctuations, including the use of water displacement techniques [111], optical scanning [112, 113] contact probes [114], ultrasound [115], computed tomography (CT) scanning [116], laser scanning [117], MRI [118], and bioimpedance measurements [119].

Inflatable insert products were used to overcome volume change of the residual limb under compressive loading conditions. Sanders et al. [120] reviewed the mechanical features of commercially available air-filled bladders. Pressure-loss tests under static loading demonstrated that, after inserts were inflated to 43.4–45.6 kPa, insert pressures reduced from 0.09%/min to 1.36%/min in the first 5 min and from 0.00%/min to 0.27%/min in the subsequent 55 min. This result suggests that the stress to resist insert expansion was better absorbed by the residual limb and socket than by the insert itself. However, high air pressure should be maintained throughout the process to mitigate the effect of volume fluctuation of the residual limb. Underinflation could result in inadequate support, while overinflation could induce localized tissue compression [121]. On the other hand, Carrigan et al. [122] showed an effort to develop adjustable inserts that consisted of arrays of small, sensorized, inflatable pressure actuators. Here, an F-Socket system was used to measure the pressure distribution at the residual limb-prosthesis interface. An air supply, comprising of a pump and air pressure regulator, was distributed to the inserts through a solenoid manifold to control each individual actuator on the basis of the measured pressure distribution. The actuators then expanded in response to residual limb volume change.

It was arguably more challenging to control volume change by means of air inflation than by using fluid [123]. A fluid-controlled actuation system was proposed by Greenwald et al. [121] to compensate for the residual limb’s volume change. The system consists of a fluid reservoir, a mechanical control circuit, and an array of discrete bladders located inside the socket. Water was used as the working fluid, which was drawn from the reservoir and supplied to the bladders. Another fluidic solution was one based on MR fluids [27]. Fluidic flexible matrix composite wafers (f2mc) were integrated into the prosthetic socket for volume regulation. These wafers were connected to a reservoir, and contain an internal fluid. Fluid flow between the tubes and reservoir was controlled by valves. The f2mc demonstrated more than 300% increase in volume and potentially several orders of magnitudes of changes in stiffness. The experiments conducted using a prosthetic socket showed that the flexible matrix composite wafers could be used to mitigate the effects of volume changes [124].

Instead of an active actuation system, the mechanical design of the socket can also be modified to mitigate the effects of residual limb volume fluctuations. A movable panel-based socket system was introduced by several researchers, where fitment could be adjusted manually through the use of straps [125, 126] and clamps [127, 128]. The Infinite Socket™ (LIM Innovations, San Francisco, CA, USA) is a commercially available, adjustable, custom-molded, four-strut design combined with a textile brim and tensioner [129]. The dynamic frame of the Infinite socket™ has a textile interface that is low in friction, anti-microbial, durable, and washable [28]. Adjustments can be made by both the clinicians and patients to manage long-term and daily volume fluctuations. The pivoting and sliding connection between the struts and base provides additional flexibility in adjustability and shock absorption. However, to avoid excessive tightening, which could result in severe consequences over time (e.g., stump deformation and mass loss), these prosthetic systems should evolve and become fully automated and self-adjustable based on sensor inputs.

5 Other socket issues and their solutions

Although the aforementioned factors are the three key parameters that need to be monitored for maximizing amputee comfort, there exist other issues that also affect socket and amputee performance. For instance, walking on varying terrains remains challenging for amputees with lower limb amputations. Different structural components of the amputated lower limb (e.g., ankle joint) are adaptive in nature, which can change their stiffness to perform dorsiflexion–plantarflexion and provide propulsion power for walking. Conventional socket prostheses today do not provide such adaptive features, which results in amputees suffering from poor gait during activities such as normal walking. Therefore, monitoring gait patterns and gait phases could be useful for future designs of advanced prosthetic systems, especially if next-generation smart socket prostheses contain actuators and dampers that require sensory feedback for achieving optimal control. On the other hand, the skin on the residual limb are vulnerable to skin-related issues and infections. If a good skin condition cannot be ensured, infection can occur, and the prosthesis cannot be worn. In this section, sensing technologies and measurement strategies to monitor and assist gait are briefly reviewed. Infection monitoring strategies are also summarized.

5.1 Gait monitoring and assistive technologies

Among many data collection methods used for gait analysis, the stereometric method is the most popular and widely used [130]. Visible markers are attached directly onto the skin of the body, and their motions are tracked through imaging equipment. In general, charge-coupled device (CCD) cameras and frame-grabber electronics are employed to capture digital images of the amputees while walking. Digital image analysis is performed to extract the exact location of the markers using triangulation of different camera viewpoints. For example, a VICON commercial system was used by Koktas et al. [131] for gait analysis. Amputees were asked to walk on the platform. Temporal change of joint angles, joint moments, joint powers, force ratios, and time–distance parameters were recorded. In this study, a semi-automated gait classification system was designed and implemented for gait analysis. The gait data were categorized by combining the joint angle and time–distance data by multilayer perceptrons (MLPs) classifiers. In general, since this technique uses visual markers and does not require active sensors to be attached to the patient, this technique has a minimum effect on the natural motion of the amputees. However, multiple sets of walking data need to be collected to study the amputee’s gait pattern, since it cannot be quantified from a single traversal of the instrumented walkway [130]. Furthermore, prolonged walking on the walkway may cause amputee fatigue.

Besides such video-based gait analysis methods, the automatic classification of gait phases has been done using FSRs. An FSR-based on-shoe device was proposed by Morris et al. [132] for continuous and real-time monitoring of gait. Wireless transmission of the measured data was achieved to provide real-time information about the three-dimensional motion, position, and pressure distribution of the foot. A pattern recognition algorithm was implemented to analyze the collected data in real-time, and the results were compared with a commercial optical gait analysis system. Although FSRs embedded in the shoe soles can serve as footswitches [133], they often fail to classify foot flat [134].

On the other hand, Williamson and Andrews [135] used accelerometers for gait event detection. An array of accelerometers was worn by a subject on the shank of the leg. The ADXL05 uniaxial accelerometer was selected for its high signal-to-noise ratio. A 12-bit analog to digital converter (NI-DAQ AT-MIO 16L board, National Instruments Inc.) with a sampling frequency of 100 Hz was employed to record the signals. It was demonstrated that the vibration data measured by the accelerometers could be used to train a machine-learning algorithm to reliably detect the various phases of gait. Similarly, built-in accelerometers in smart mobile devices were also used for gait measurements. Today, many smart mobile devices have accelerometers to detect their orientation. Chan et al. [136] explored the capabilities of the embedded accelerometers of iPhones to identify different gait events, while the subject was engaged to walk along a flat surface. It was shown that iPhone-recorded acceleration data could be used to detect steps, stride time, and cadence. However, the position of the iPhone should be judiciously selected to obtain the most meaningful acceleration data with minimal noise.

Since the lower limb’s angular velocity has distinct signal features during heel-strike and toe-off [134], Aminian et al. [137] used a gyroscope to measure the angular movement of the lower limbs of subjects during walking. In short, a gyroscope consists of a vibrating component coupled with a sensing element for Coriolis force measurement. The study was intended to estimate spatial–temporal parameters during long periods of walking. Three miniature low-power piezoelectric gyroscopes (Murata, ENC-03J) were used for measurements. The measured signals were amplified, and noise was removed with a low-pass filter. The gyroscopes were directly mounted to each shank and the right thigh of the amputees using a rubber band. The signals were digitized using a portable data logger (Physilog, BioAGM, CH) that sampled data at 200 Hz. A wavelet transformation-based algorithm was implemented to compute gait parameters from the measured angular velocities of the lower limbs. In contrast to accelerometers, gyroscope measurements do not depend on the position of the sensors. [138] The gyroscope-measured angular velocity is less noisy, since rotational motion is calculated by integrating the recorded data. However, gyroscope measurement is sensitive to shock due to the mechanical fastening of the beam inside the gyroscope.

In addition to measure the angular motion of the residual limb, it is important to estimate the forces exerted by the residual limb on the socket prostheses during walking for analyzing the gait cycle [134]. Pappas et al. [139] employed three FSRs with a miniature gyroscope for force and angular velocity measurements during gait cycles. The FSRs were employed to measure load on a shoe insole, and the gyroscope measured the rotational velocity of the foot. Indoor and outdoor experiments were performed on subjects with impaired gaits. It was shown that the system could accurately and reliably detect various phases of gait (e.g., stance, heel-off, swing, and heel-strike). In addition, the proposed method could distinguish between the feet sliding and true walking, as well as shifting of the weight from one leg to the other.

Apart from motion and force measuring sensors, different kinds of stimuli are also used to study the motion of the residual limb within socket prostheses during gait. Radiographic techniques were used by several groups to analyze residual tibial movement within transtibial sockets [140,141,142] and residual femoral movement within transfemoral sockets [143,144,145]. However, ionizing radiation used in radiography limits its application for gait monitoring of amputees. As a result, they are only used for static analysis at simulated instants of the gait cycle. Since ultrasound does not have any known detrimental health effects, it was used to monitor the static position of the residual femur in transfemoral sockets during gait [146]. Measurements were recorded from two simultaneously transmitting ultrasound transducers. It was found that the pattern of femoral motion was consistent with a rapid change in motion during the early and late prosthetic stance phase. However, this method was unable to determine the correct orientation of the socket relative to the ground from a partial gait analysis study.

In addition to the variety of sensing technologies for gait monitoring, researchers have proposed various systems for assisting patients with impaired gait. For example, Ward et al. [147] developed a modified walking frame with a linkage system to assist patients to perform normal gait. The device was named the R-Link Trainer (RLT). It was found that peak hip extension and knee flexion were reduced bilaterally when walking with the RLT. Constrained limb (i.e., the left limb) experienced a significantly increased peak hip flexion, while peak plantarflexion was significantly reduced. The right limb experienced a late peak knee flexion and plantarflexion. A significant bilateral reduction in peak electromyography amplitude occurred when walking in the RLT. This study validated that RLT imposes significant constraints along with asymmetries in lower limb kinematics and muscle activity patterns. McDaid et al. [148] presented a multi-input multi-output (MIOM) force controller for ankle rehabilitation. This MIMO actuator force controller was designed in such a way that the gains along the decoupled directions could be pushed closer to their corresponding gain margins. Kora et al. [149] developed a new gait rehabilitation device termed the “Linkage Design Gait Trainer,” which was based on a simple walking frame. This frame was designed following the four-bar linkage “end-effector” mechanism to generate normal gait trajectories during daily activities. It was shown that the proposed mechanism could assist the leg of the user during over-ground walking. Although these gait assisting technologies were not proposed for amputees with socket prostheses, their designs and implementation procedures could be adjusted in the future to serve such purposes.

5.2 Infection monitoring

Besides gait monitoring, inflammation and infection monitoring in the residual limb is also important for patients living with socket prostheses. Cutti et al. [150] explored the potential of infrared thermography with wearable devices to monitor the temperature and relative humidity inside the socket. A thermal imaging camera was employed to measure the superficial temperature distribution of the residual limb. Parallel measurements through thermal imaging cameras and wearable sensors provided complimentary information. A 20% increment in hot areas were found after walking as compared to resting. Humidity inside the socket increased ~ 4.1 ± 2.3% because of the sweat produced. Increased temperature and excessive humidity inside the socket prostheses could be a sign of skin inflammation and infection. Hence, temperature and humidity monitoring inside the socket could be useful for early prevention of skin-related issues in the residual limb.

There is little published data related to the diagnosis of stump infections. It was found that poor hygiene is responsible for most of the bacterial and fungus infections in the residual limb of the amputees [151]. Regular inspection and cleaning of the residual limb can prevent most of infections caused by various microorganisms. A so-called “sausage-toe”-like red swollen mark on the stump often indicate an infection in the form of osteomyelitis [152]. Physicians generally perform a “probe-to-bone” test, where a sterile blunt metal probe is used to probe an ulcer in the residual limb. A gritty or stony feeling of bone indicates the presence of osteomyelitis [153, 154]. Besides such clinical diagnostic approaches, blood tests are often performed to identify infections in the human body. Erythrocyte sedimentation rate (ESR) and C-reactive protein (CRP) are extensively used to detect infections [155]. Three-phase technetium bone scanning, leukocyte scanning, labeled immunoglobulins, and labeled anti-white cell monoclonal antibodies are some of the widely used isotope scanning scintigraphy techniques for infection diagnosis [156, 157]. Despite some promising results, none of them has emerged as a reliable, robust, and useful method for infection detection, especially if monitoring is needed over extended periods of time.

In addition to the aforementioned methods, imaging of the residual limb can be helpful for early detection of infection in the residual limb [158]. Traditional X-ray imaging could be beneficial for detecting infection in the residual limb. By using X-ray imaging, the condition of the skeletal and soft tissues could be monitored [159]. CT and MRI are two of the most widely used imaging techniques to detect subcutaneous infection in the human body [158, 160]. Although MRI is considered the best imaging modality for diagnosis of various infections, there could be problems related to the interpretation of MRI images, especially after any surgery or due to artifacts produced by metallic implants [161, 162]. Dutronc et al. [163] made an observational study on 72 patients with lower-limb amputation. Ultrasonography and CT scan coupled with fistulography were used to diagnose the extension of infection. It was found that 44% of the patients needed surgical revision in addition to antibiotic treatment. Although these imaging techniques have high accuracy and reliability, the patients need to visit specialized facilities for imaging and for receiving treatment. The imaging instruments are also bulky, which eliminates the possibility of in situ applications. Furthermore, a patient’s residual limb needs to be exposed to harmful radiation that would cause detrimental health effects at high doses.

Among all of these abovementioned techniques, bone-biopsy is regarded as the most robust method to detect infection. Specimens are obtained from a previously unexposed bone to culture the bacteria to determine the cause of infection. However, a limited amount of materials obtained for culture can be problematic as it may cause false-negative results [164, 165].

On the other hand, infection often occurs due to microbial attack, which causes a change in pH of the infected cells [166]. Gupta and Loh [167] developed a pH-sensitive nanocomposite thin film sensor for monitoring infection in implantable prostheses. Thin films can be deposited onto the surface of osseointegrated prostheses prior to the implant surgery and can stay inside the human body, functioning as a passive (unpowered) sensor. The dielectric property of the thin film changes due to a change in pH of its surroundings in response to infection. A noncontanct, portable, and radiation-free imaging technique was developed and implemented to map the cross-sectional distribution of dielectric properties of the residual limb and embedded passive sensor. Experimental test results showed that the proposed electrical capacitance tomography approach could detect changing pH environments in a noncontact fashion. Although this technique was proposed for infection monitoring at the tissue-prosthesis interface of the amputees with osseointegrated prostheses, its application can be potentially extended for socket prosthesis applications.

6 Future outlook

In general, there still remains a significant challenge around data the future of smart and connected sockets is promising, but several challenges still lie ahead. An important basis for optimal and long-term management of amputees is an in-depth understanding of the patient and the functional consequences of the amputation. A comprehensive understanding of the amputee and their environment, as well as sound objectives and functional outcome measures, are important to obtain. Establishing prosthetic socket effectiveness guidelines will provide a much-needed tool to deliver the best prosthetic care to individuals who have sustained lower limb extremity loss. Sensor technology provides the next technological solution to explore and address this lack of data. Understanding the integration of sensor technology with prosthetic devices and their ability to relay real-time biological and mechanical data to the amputee will be a key concept in the rehabilitative process. The strategy of leveraging cloud computing algorithms and machine learning to process and relay this information to an end-user application will have vast implications including the opportunity to use telehealth platforms, the potential integration of patient-reported outcomes into electronic health record (HER) systems and the ability to improve the collection clinical outcome metrics. The goal is to include early identification of physical conditions affecting performance and efficient recovery to optimize physical wellness.

As discussed earlier, many of the sensors used today are point sensors and focus only on measuring a single parameter. Nanotechnology-enabled sensors can potentially provide more suitable sensing solutions for next-generation socket prostheses. For example, Wang et al. [19, 168] developed a fabric-based sensor that conforms to the interior of a socket prosthesis and maps the pressure distribution at the human-socket interface. The carbon nanotube-based thin film sensor can be integrated with socket liners, while electrical impedance tomography could map pressure distributions using only a limited number of measurements. Furthermore, bioimpedance measurements can also be implemented to provide deeper insights regarding limb conditions and volume fluctuations. However, this technique has not yet transitioned from the research arena to clinical practice. More research is required to design appropriate instruments, clinical protocols, and algorithms to interpret bioimpedance sensor data. Overall, the future direction points to the development of multi-modal sensors that can selectively and simultaneously measure multiple parameters necessary for assessing residual limb health and socket performance.

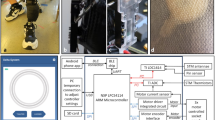

The development of higher performance sensors and real-time sensors that offer distributed measurement capabilities and more data will ultimately provide more detailed information regarding residual limb health. These sensing streams will serve as the basis for which self-adjusting sockets can be realized, where socket and liner properties (e.g., stiffness) can be autonomously varied to ensure optimal fitment and comfort. For example, an electromagnetic excitation system can be actuated based on recorded pressure maps to selectively alter the stiffness of MR fluid at precise locations [169]. Such smart sockets that feature active stiffness modulation and a sensor-driven closed-loop control system can simultaneously address pressure-, temperature-, and volume-related issues autonomously. Besides relieving pressure hotspots and accommodating changes in limb volumes, future smart sockets should be able to adjust their properties for maximizing patient comfort.

Realization of smart socket prostheses further opens up opportunities for developing a “digital twin” of the residual limb and socket system or of the patient as a whole. A digital twin is a digital representation of a physical object or system [170]. Today, digital twins have been developed and proposed for a wide variety of systems such as buildings, factories, airplane, and space shuttles. This concept can be further expanded for an amputee’s residual limb and socket to better understand and predict patient comfort and health. Information acquired from different digital twins can also help refine and guide future smart socket designs. Digital twin simulations can be conducted to characterize how different socket designs and inputs would affect socket performance. For instance, physicians can use the digital twin to test socket alterations before implementing them in clinical settings.

7 Summary

Lower limb prostheses have significantly advanced in all respects except for the socket, but traditional prosthetic socket technology and methods have seen little advancement in the past 50 years. The inability for conventional sockets to respond to the daily needs of amputees leads to short-term and long-term consequences. In fact, most amputees require multiple replacement sockets per year, with many amputees abandoning their socket prostheses due to discomfort and poor fitment. It has been found that volume fluctuations, unequal stress distributions at the residual limb-socket interface, and temperature inside the socket prosthesis are major issues that ultimately lead to amputees abandoning their prostheses. As discussed earlier, interfacial stress at the residual limb-prosthesis interface should be measured. Similarly, proper and comfortable socket fitment of the socket is challenging due to volume fluctuations of the residual limb, especially during the early post-surgery period [171]. Thus, the development and integration of advanced materials, electronic systems, miniaturized distributed sensors, and efficient actuators will pave way for the design of next-generation smart sockets. These smart sockets will not only be able to sense the level of amputee discomfort but will also be able to self-adjust itself to relieve interfacial stresses, volume changes, and temperature fluctuations in real-time.

References

Owings MF, Kozak LJ. Ambulatory and inpatient procedures in the United States, 1996. Vital Health Stat. 1998;13(139):1–119.

Ziegler-Graham K, MacKenzie EJ, Ephraim PL, Travison TG, Brookmeyer R. Estimating the prevalence of limb loss in the United States: 2005 to 2050. Arch Phys Med Rehabilit. 2008;89(3):422–9.

Stinner DJ, Burns TC, Kirk KL, Scoville CR, Ficke JR, Hsu JR. Prevalence of late amputations during the current conflicts in Afghanistan and Iraq. Mil Med. 2010;175(12):1027–9.

Raichle KA, Hanley MA, Molton I, Kadel NJ, Campbell K, Phelps E, Ehde D, Smith DG. Prosthesis use in persons with lower and upper-limb amputation. J Rehabil Res Dev. 2008;45(7):961–72.

Akarsu S, Tekin L, Safaz I, Göktepe AS, Yazicioğlu K. Quality of life and functionality after lower limb amputations: comparison between uni- vs. bilateral amputee patients. Prosthet Orthot Int. 2013;37(1):9–13.

Reiber GE, McFarland LV, Hubbard S, Maynard C, Blough DK, Gambel JM, Smith DG. Servicemembers and veterans with major traumatic limb loss from Vietnam war and OIF/OEF conflicts: survey methods, participants, and summary findings. J Rehabil Res Dev. 2010;47(4):275–98.

Roffman CE, Buchanan J, Allison GT. Predictors of non-use of prostheses by people with lower limb amputation after discharge from rehabilitation: development and validation of clinical prediction rules. J Physiother. 2014;60(4):224–31.

Gailey R, McFarland LV, Cooper RA, Czerniecki J, Gambel JM, Hubbard S, Maynard C, Smith DG, Raya M, Reiber GE. Unilateral lower-limb loss: prosthetic device use and functional outcomes in servicemembers from Vietnam war and OIF/OEF conflicts. J Rehabil Res Dev. 2010;47(4):317–32.

Paternò L, Ibrahimi M, Gruppioni E, Menciassi A, Ricotti L. Sockets for limb prostheses: a review of existing technologies and open challenges. IEEE Trans Biomed Eng. 2018;65(9):1996–2010.

Durmus D, Safaz I, Adıgüzel E, Uran A, Sarısoy G, Goktepe AS, Tan AK. The relationship between prosthesis use, phantom pain and psychiatric symptoms in male traumatic limb amputees. Compr Psychiatry. 2015;1(59):45–53.

Chamlian TR. Use of prostheses in lower limb amputee patients due to peripheral arterial disease. Einstein (São Paulo). 2014;12(4):440–6.

Pasquina CP, Carvalho AJ, Sheehan TP. Ethics in rehabilitation: access to prosthetics and quality care following amputation. AMA J Ethics. 2015;17(6):535–46.

Pinzur MS, Cox W, Kaiser J, Morris T, Patwardhan A, Vrbos L. The effect of prosthetic alignment on relative limb loading in persons with trans-tibial amputation: a preliminary report. J Rehabil Res Dev. 1995;32(4):373–7.

Schmalz T, Blumentritt S, Jarasch R. Energy expenditure and biomechanical characteristics of lower limb amputee gait: the influence of prosthetic alignment and different prosthetic components. Gait Posture. 2002;16(3):255–63.

Al-Fakih E, Osman NA, Adikan FM. Techniques for interface stress measurements within prosthetic sockets of transtibial amputees: a review of the past 50 years of research. Sensors. 2016;16(7):1119.

Gaine WJ, Smart C, Bransby-Zachary M. Upper limb traumatic amputees: review of prosthetic use. J Hand Surg. 1997;22(1):73–6.

Petron A, Duval JF, Herr H. Multi-indenter device for in vivo biomechanical tissue measurement. IEEE Trans Neural Syst Rehabil Eng. 2016;25(5):4326–435.

Pirouzi G, Osman A, Azuan N, Oshkour A, Ali S, Gholizadeh H, Abas WW. Development of an air pneumatic suspension system for transtibial prostheses. Sensors. 2014;14(9):16754–65.

Wang L, Loh KJ. Nanocomposite fabric sensors for socket prostheses and pressure ulcer prevention. In: Conf proc 7th world conference on structural control and monitoring. 2018.

Meulenbelt HE, Geertzen JH, Jonkman MF, Dijkstra PU. Determinants of skin problems of the stump in lower-limb amputees. Arch Phys Med Rehabil. 2009;90(1):74–81.

Levy SW. Skin problems of the leg amputee. Prosthet Orthot Int. 1980;4(1):37–44.

Lyon CC, Kulkarni J, Zimersonc E, Ross EV, Beck MH. Skin disorders in amputees. J Am Acad Dermatol. 2000;42(3):501–7.

Mak AF, Zhang M, Boone DA. State-of-the-art research in lower-limb prosthetic biomechanics-socket interface: a review. J Rehabil Res Dev. 2001;38(2):161–74.

Ali S, Osman NA, Eshraghi A, Gholizadeh H, Abas WA. Interface pressure in transtibial socket during ascent and descent on stairs and its effect on patient satisfaction. Clin Biomech. 2013;28(9–10):994–9.

Lee WC, Zhang M, Mak AF. Regional differences in pain threshold and tolerance of the transtibial residual limb: including the effects of age and interface material. Arch Phys Med Rehabil. 2005;86(4):641–9.

Colombo G, Facoetti G, Rizzi C. Automatic below-knee prosthesis socket design: a preliminary approach. In: Conf proc international conference on digital human modeling and applications in health, safety, ergonomics and risk management. 2016; pp. 75–81.

Ogawa A, Obinata G, Hase K, Dutta A, Nakagawa M. Design of lower limb prosthesis with contact pressure adjustment by MR fluid. In: Conf proc 30th annual international conference of the ieee engineering in medicine and biology society. 2008.

Kahle JT, Highsmith MJ. Transfemoral sockets with vacuum-assisted suspension comparison of hip kinematics, socket position, contact pressure, and preference: ischial containment versus brimless. J Rehabil Res Dev. 2013;50(9):1241–52.

Lu N, Lu C, Yang S, Rogers J. Highly sensitive skin-mountable strain gauges based entirely on elastomers. Adv Funct Mater. 2012;22(19):4044–50.

Tiwana MI, Redmond SJ, Lovell NH. A review of tactile sensing technologies with applications in biomedical engineering. Sens Actuators A Phys. 2012;179:17–31.

Appoldt F, Bennett L, Contini R. Stump-socket pressure in lower extremity prostheses. J Biomech. 1968;1(4):247–57.

Appoldt FA, Bennett L, Contini R. Tangential pressure measurements in above-knee suction sockets. Bull Prosthet Res. 1970;10(13):70–86.

Burgess EM, Moore AJ. Physiological suspension: an interim report. Bull Prosthet Res. 1977;16(2):58–70.

Leavitt LA, Peterson CR, Canzoneri J, Pza R, Muilenburg AL, Rhyne VT. Quantitative method to measure the relationship between prosthetic gait and the forces produced at the stump-socket interface. Am J Phys Med Rehabil. 1970;49(3):192–203.

Leavitt LA, Zuniga EN, Calvert JC, Canzoneri J, Peterson CR. Gait analysis and tissue-socket interface pressures in above-knee amputees. South Med J. 1972;65(10):1197.

Pearson JR, Holmgren G, March L, Oberg K. Pressures in critical regions of the below-knee patellar-tendon-bearing prosthesis. Bull Prosthet Res. 1973;10(19):52–76.

Rae JW, Cockrell JL. Interface pressure and stress distribution in prosthetic fitting. Bull Prosthet Res. 1971;10(15):64–111.

Sonck WA, Cockrell JL, Koepke GH. Effect of liner materials on interface pressures in below-knee prostheses. Arch Phys Med Rehabil. 1970;51(11):666–9.

Winarski DJ, Pearson JR. Least-squares matrix correlations between stump stresses and prosthesis loads for below-knee amputees. J Biomech Eng. 1987;109(3):238–46.

Dickinson AS, Steer JW, Worsley PR. Finite element analysis of the amputated lower limb: a systematic review and recommendations. Med Eng Phys. 2017;43:1–8.

Zhang M, Turner-Smith A, Tanner A, Roberts V. Clinical investigation of the pressure and shear stress on the trans-tibial stump with a prosthesis. Med Eng Phys. 1998;20:188–98.

Sanders JE, Daly CH. Measurement of stresses in three orthogonal directions at the residual limb-prosthetic socket interface. IEEE Trans Rehabil Eng. 1993;1(2):79–85.

Dou P, Jia X, Suo S, Wang R, Zhang M. Pressure distribution at the stump/socket interface in transtibial amputees during walking on stairs, slope and non-flat road. Clin Biomech. 2006;21(10):1067–73.

Hafner BJ, Sanders JE. Considerations for development of sensing and monitoring tools to facilitate treatment and care of persons with lower limb loss. J Rehabil Res Dev. 2014;51(1):1–14.

Osman NA, Spence WD, Solomonidis SE, Paul JP, Weir AM. The patellar tendon bar! Is it a necessary feature? Med Eng Phys. 2010;32(7):760–5.

Sanders JE, Lain D, Dralle AJ, Okumura R. Interface pressures and shear stresses at thirteen socket sites on two persons with transtibial amputation. J Rehabil Res Dev. 1997;1(34):19–43.

Sanders JE, Zachariah SG, Jacobsen AK, Fergason JR. Changes in interface pressures and shear stresses over time on trans-tibial amputee subjects ambulating with prosthetic limbs: comparison of diurnal and six-month differences. J Biomech. 2005;38(8):1566–73.

Parmar S, Khodasevych I, Troynikov O. Evaluation of flexible force sensors for pressure monitoring in treatment of chronic venous disorders. Sensors. 2017;17(8):1923.

Kane BJ, Cutkosky MR, Kovacs GT. A traction stress sensor array for use in high-resolution robotic tactile imaging. J Microelectromech Syst. 2000;9(4):425–34.

Schofield JS, Evans KR, Hebert JS, Marasco PD, Carey JP. The effect of biomechanical variables on force sensitive resistor error: implications for calibration and improved accuracy. J Biomech. 2016;49(5):786–92.

Fraden J. Handbook of modern sensors. Physics, design and applications. San Diego: Springer; 2004.

Barlian AA, Park WT, Mallon JR, Rastegar AJ, Pruitt BL. Semiconductor piezoresistance for microsystems. Proc IEEE. 2009;97(3):513–52.

Saccomandi P, Schena E, Oddo CM, Zollo L, Silvestri S, Guglielmelli E. Microfabricated tactile sensors for biomedical applications: a review. Biosensors. 2014;4(4):422–48.

Dabling JG, Filatov A, Wheeler JW. Static and cyclic performance evaluation of sensors for human interface pressure measurement. In: Conf proc annual international conference of the IEEE engineering in medicine and biology society. 2012; pp. 162–165.

Hollinger A, Wanderley MM. Evaluation of commercial force-sensing resistors. In: Conf proc international conference on new interfaces for musical expression. 2006.

Interlink Electronics Inc. FSR 400 series data sheet. https://www.interlinkelectronics.com/datasheets/Datasheet_FSR.pdf. Accessed 17 Jul 2019.

IEE International Electronics & Engineering. Specification sheet for standard LuSense sensors of the PS3 family. Revision 0, March 29, 2001.

Tekscan Inc. https://www.tekscan.com/products-solutions/force-sensors/a301. Accessed 3 Jul 2019.

Vecchi F, Freschi C, Micera S, Sabatini A, Dario P, Sacchetti R. Experimental evaluation of two commercial force sensors for applications in biomechanics and motor control. In: Conf proc 5th annual conference of the international functional electrical stimulation society. 2000.

Ruda EM, Sanchez OFA, Mejia JCH, Gomez SJ, Flautero OIC. Design process of mechatronic device for measuring the stump stresses on a lower limb amputee. In: Conf proc 22nd international congress of mechanical engineering (COBEM 2013). 2013; pp. 4620–4628.

Polliack A, Landsberger S, McNeal D, Sieh R, Craig D, Ayyappa E. Socket measurement systems perform under pressure. Biomechanics. 1999;6:71–80.

Polliack AA, Sieh RC, Craig DD, Landsberger S, McNeil DR, Ayyappa E. Scientific validation of two commercial pressure sensor systems for prosthetic socket fit. Prosthet Orthot Int. 2000;24(1):63–73.

Almassri AM, Hasan W, Ahmad S, Ishak A, Ghazali A, Talib D, Wada C. Pressure sensor: state of the art, design, and application for robotic hand. J Sens. 2015. https://doi.org/10.1155/2015/846487.

Luo ZP, Berglund LJ, An KN. Validation of f-scan pressure sensor system: a technical note. J Rehabil Res Dev. 1998;35(2):186–91.

Lai CH, Li-Tsang CW. Validation of the Pliance x system in measuring interface pressure generated by pressure garment. Burns. 2009;35(6):845–51.

Safari MR, Tafti N, Aminian G. Socket interface pressure and amputee reported outcomes for comfortable and uncomfortable conditions of patellar tendon bearing socket: a pilot study. Assist Technol. 2015;27(1):24–31.

Tiwana MI, Shashank A, Redmond SJ, Lovell NH. Characterization of a capacitive tactile shear sensor for application in robotic and upper limb prostheses. Sens Actuators A Phys. 2011;165(2):164–72.

Wolf SI, Alimusaj M, Fradet L, Siegel J, Braatz F. Pressure characteristics at the stump/socket interface in transtibial amputees using an adaptive prosthetic foot. Clin Biomech. 2009;24(10):860–5.

Meier RH, Meeks ED, Herman RM. Stump-socket fit of below-knee prostheses: comparison of three methods of measurement. Arch Phys Med Rehabil. 1973;54(12):553–8.

Polliack A, Craig D, Sieh R, Landsberger S, McNeal D. Laboratory and clinical tests of a prototype pressure sensor for clinical assessment of prosthetic socket fit. Prosthet Orthot Int. 2002;26(1):23–34.

Sengeh DM, Herr H. A variable-impedance prosthetic socket for a transtibial amputee designed from magnetic resonance imaging data. J Prosthet Orthot. 2013;25(3):129–37.

Ghoseiri K, Safari MR. Prevalence of heat and perspiration discomfort inside prostheses: literature review. J Rehabil Res Dev. 2014;51(6):855–68.

Williams RB, Porter D, Roberts VC, Regan JF. Triaxial force transducer for investigating stresses at the stump/socket interface. Med Biol Eng Comput. 1992;30(1):89–96.

Razian MA, Pepper MG. Design, development, and characteristics of an in-shoe triaxial pressure measurement transducer utilizing a single element of piezoelectric copolymer film. IEEE Trans Neural Syst Rehabil Eng. 2003;11(3):288–93.

Rocha RP, Gomes JM, Carmo JP, Silva AF, Correia JH. Low-cost/high-reproducibility flexible sensor based on photonics for strain measuring. Opt Laser Technol. 2014;56:278–84.

Fresvig T, Ludvigsen P, Steen H, Reikerås O. Fibre optic bragg grating sensors: an alternative method to strain gauges for measuring deformation in bone. Med Eng Phys. 2008;30(1):104–8.

Yu Q, Zhou X. Pressure sensor based on the fiber-optic extrinsic fabry-perot interferometer. Photon Sens. 2011;1(1):72–83.

Liu X, Iordachita II, He X, Taylor RH, Kang JU. Miniature fiber-optic force sensor based on low-coherence fabry-pérot interferometry for vitreoretinal microsurgery. Biomed Opt Express. 2012;3(5):1062–76.

Bartelt H, Elsmann T, Habisreuther T, Schuster K, Rothhardt M. Optical bragg grating sensor fibers for ultra-high temperature applications. In: Conf proc 5th Asia pacific optical sensors conference. 2015.

Gao R, Jiang Y, Ding W, Wang Z, Liu D. Filmed extrinsic fabry–perot interferometric sensors for the measurement of arbitrary refractive index of liquid. Sens Actuators B Chem. 2013;177:924–8.

Sante RD. Fibre optic sensors for structural health monitoring of aircraft composite structures: recent advances and applications. Sensors. 2015;15(8):18666–713.

Mihailov SJ. Fiber Bragg grating sensors for harsh environments. Sensors. 2012;12(2):1898–918.

Kanellos GT, Papaioannou G, Tsiokos D, Mitrogiannis C, Nianios G, Pleros N. Two dimensional polymer-embedded quasi-distributed FBG pressure sensor for biomedical applications. Opt Express. 2010;18(1):179–86.

Kanellos GT, Tsiokos D, Pleros N, Papaioannou G, Childs P, Pissadakis S. Enhanced durability FBG-based sensor pads for biomedical applications as human–machine interface surfaces. In: Conf proc international workshop on biophotonics. 2011.

Al-Fakih EA, Osman NA, Adikan FR, Eshraghi A, Jahanshahi P. Development and validation of fiber Bragg grating sensing pad for interface pressure measurements within prosthetic sockets. IEEE Sens J. 2015;16(4):965–74.

Al-Fakih E, Osman N, Eshraghi A, Adikan F. The capability of fiber Bragg grating sensors to measure amputees’ trans-tibial stump/socket interface pressures. Sensors. 2013;13(8):10348–57.

Zhang ZF, Tao XM, Zhang HP, Zhu B. Soft fiber optic sensors for precision measurement of shear stress and pressure. IEEE Sens J. 2013;13(5):1478–82.

Donati M, Vitiello N, Rossi SD, Lenzi T, Crea S, Persichetti A, Giovacchini F, Koopman B, Podobnik J, Munih M, Carrozza M. A flexible sensor technology for the distributed measurement of interaction pressure. Sensors. 2013;13(1):1021–45.

Rossi SD, Lenzi T, Vitiello N, Donati M, Persichetti A, Giovacchini F, Vecchi F, Carrozza MC. Development of an in-shoe pressure-sensitive device for gait analysis. In: Conf proc international conference of the IEEE engineering in medicine and biology society, EMBC. 2011; pp. 5637–5640.

Missinne J, Bosman E, Hoe BV, Verplancke R, Steenberge GV, Kalathimekkad S, Daele PV, Vanfleteren J. Two axis optoelectronic tactile shear stress sensor. Sens Actuators A Phys. 2012;186:63–8.

Lincoln LS, Quigley M, Rohrer B, Salisbury C, Wheeler J. An optical 3d force sensor for biomedical devices. In: Conf Proc 4th IEEE RAS & EMBS international conference on biomedical robotics and biomechatronics (BioRob). 2012; pp. 1500–1505.

Cutkosky MR, Howe RD, Provancher WR. Force and tactile sensors. Berlin: Springer; 2008.

Yousef H, Boukallel M, Althoefer K. Tactile sensing for dexterous in-hand manipulation in robotics—a review. Sens Actuators A Phys. 2011;167(2):171–87.

Baars EC, Geertzen JH. Literature review of the possible advantages of silicon liner socket use in trans-tibial prostheses. Prosthet Orthot Int. 2005;29(1):27–37.

Peery TJ, Ledoux WR, Klute GK. Residual-limb skin temperature in transtibial sockets. J Rehabil Res Dev. 2005;42(2):147–54.

Klute GK, Rowe GI, Mamishev AV, Ledoux WR. The thermal conductivity of prosthetic sockets and liners. Prosthet Orthot Int. 2007;31(3):292–9.