Abstract

Marine biomass (such as wild seaweed Gracilaria verrucosa) is highly abundant in Indonesia and has been highlighted as a potential biomass resource for bioenergy production. Furthermore, agro-industrial waste (such as tofu dregs/TD which arises from large-scale production in the country) is rich in carbohydrates and proteins, and is therefore considered a viable feedstock for production of high-value added products. This study aimed to investigate the co-digestion of wild seaweed G. verrucosa (WGv) with TD and its impacts on biogas and methane production. The biochemical methane potential (BMP) test was operated for 28 days at temperature of 37 °C. The co-digestion of WGv with TD at 90:10 and 80:20 ratios significantly increased the specific methane potential (SMP), giving an average of 98 LCH4/kgVS and 120 L CH4/kgVS, respectively. Addition of co-digestion substrates promoted co-metabolism in the digesters, increasing the ability of the microorganism to effectively digest the organic matter present in the feedstock’s mixture. The washing pre-treatment reduced the concentration of inorganic compounds and salts within the wild seaweed G. verucosa, leading to an improvement in biogas and methane yield. The mass balance illustrated that this process configuration led to a reduction in the quantity of digestate to be managed (i.e. dewatering, transport, and land/soil application). This will subsequently reduce the cost and energy requirements for sludge management, estimated at 37%. Therefore, the co-digestion of WGv with TD and the application of a washing pre-treatment stage prior to AD can positively enhance biogas and methane production. In-depth investigation for optimal valorisation using AD technology is highly essential.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Currently, the global world faces the complex challenge of increasing demands for energy and an increase in fossil fuels prices due to depletion of non-renewable energy supplies (i.e. coals and fossil fuels) [1, 2]. Therefore, progressing the development and implementation of biomass to energy-based generation is being prioritised in many countries globally [3]. In Indonesia, specifically, despite abundant resources, there remains a number of barriers and limitations in converting biomass or waste resources to bioenergy [4]. Several programmes and measures have been enforced by the Indonesian Government to expand renewable energy production from biomass. This is driven by the availability and sustainability of renewable biomass resources currently available across the country. According to the Ministry of Energy and Mineral Resources/MEMR [5], approximately 146.7 million tonnes of biomass is produced per year in Indonesia, which has an energy potential of 32,654 MWe. This highlights that valorisation of biomass for bioenergy production has the potential to address some of Indonesia’s critical energy needs and warrants further promotion in the country.

Biomass is defined as any organic and biodegradable materials derived from plants, animals, microorganisms, or wastes [6]. Agro-industrial waste is one of the potential waste streams that is also abundant and widely distributed in Indonesia [7]. However, many agro-industrial wastes remain under-utilised [8]. Furthermore, due to lack of waste management facilities and the technical skills and knowledge to support sustainable waste management, many small- and medium-scale enterprises (SMEs) dispose of their waste directly into the environment, leading to detrimental impacts on both health and the environment [9]. Therefore, further valorisation of agro-industrial waste is urgently needed [10, 11]. Various studies have reported the valorisation pathways of agro-industrial waste to bioenergy, such as biogas from fruit-based agro-industrial waste [12]; bioethanol from apple pomace [13] or from candy agro-industry wastes (i.e. raw residual of coconut milk, pineapple juice, and tuna juice) [14]; biodiesel from sugar beet agro-industrial waste [15]; biohydrogen from molasses, vinasse, and bagasse [16]; and bio-pellet production from cacao agro-industrial waste (i.e. cacao pod husk) [17].

One of the larger agro-industrial industries in Indonesia is the tofu processing industry. There are approximately 84,000 SME tofu processors in Indonesia and these are distributed in clusters within multiple cities across the country [18]. These tofu industries consumed an estimated 2.56 million tonnes of soybean per year with aproximately 1.024 million tonnes (or 40%) of tofu dregs (TD) produced as a waste product [19]. However, many of these industries have ongoing challenges with managing the wastewater and solid waste (i.e. TD) from processing due to inadequate or absent on-site waste treatment facilities. Li et al. [20] found that the main component of TD is polysacharides from the cell membrane of soybean, with a protein value of 27% (total solids/TS). They added that the elemental composition of TD was as follows: H of 6.99%, C of 46.34%, N of 3.99%, and S 0.25% (on a TS basis). Mateos-Aparicio et al. [21] added that TD contains protein (33.4%TS), crude fat (8.5%TS), crude fiber (54.3%TS), and ash (3.7%TS). The TD has been used for cattle feedstock, culture medium for single protein production [22]; and biogas production [23]. Furthermore, the Indonesian government supports the creation of sustainable agroindustry through waste to bioenergy approach. For example, in 2011, the Indonesian government through the Agency for the Assessment and Application of Technology (BPPT) has successfully implemented seven pilot-scale anaerobic digestion plants treating wastewater from the 183 tofu industries located in Banyuwangi City. The project was under the Renewable Energy and Energy Efficiency Partnership (REEEP) grant funded by the UK Department of Energy and Climate Change (DECC), which aimed to plan and provide policy support for biogas production from the Indonesian tofu industry. It is estimated that the application of this technology can substitute 56,000 tonnes of fossil fuels with biogas from tofu wastewater [18, 19]. Choe et al. [24] added that TD is an inexpensive and highly available biomass resources with excellent nutrient composition (i.e. high in carbohydrates and protein) and minerals (i.e. K, Ca, and Mg), which promotes the growth and the reproduction of microorganisms. Furthermore, Song et al. [25] reported that addition of tofu residue as a co-substrate in anaerobic digestion of food waste and garden waste influence the enrichment of methanogen bacteria, especially methanosarcina. Therefore, considering the TD characteristics, composition, and availability, there is good opportunity to utilise it as feedstock for biogas production.

As an archipelagic country, Indonesia has a diverse variety of marine biomass including both microalgae and macroalgae. In terms of macroalgae (or seaweed), the global production was reportedly 35.82 million tonnes in 2019, dominated by China as the first-largest producer (~ 20.4 million tonnes) and Indonesia as the second-largest producer accounting for ~ 10 million tonnes [26]. The species Gracilaria sp. is a macroalgae (or seaweed) that is highly abundant in Indonesia (particularly in northern parts of Java Island, Nusa Tenggara Barat, South Sulawesi, and Lampung). This species is either cultivated in shallow ponds or sourced as a wild species such as Gracilaria verrucosa [27]. Gracilaria sp. has been widely used for agar or agarose production [28]. However, Gracilaria sp. also has a high concentration of organic macro molecules such as carbohydrate (42.0%TS), fat (1.3%TS), protein (5.18%TS), and inorganic ash (43.2%TS) [29]. McDermid and Stuercke [30] found that the carbohydrate content of Gracilaria sp. was in the range of 4–83%, in the form of celullose, making it a good potential feedstock for bioenergy production. For example, use of Gracilaria sp. as feedstock for bioethanol has been reported by Meinita et al. [31], while a high methane potential from Gracilaria sp. was found by Kawaroe et al. [32].

Various approaches to transform macroalgae into bioenergy have been highlighted in several recent studies. Abomohra et al. [33] stated that using microwave vacuum co-pyrolysis technology for treating seaweeds and waste plastic was proven to improve recovery and economic feasibility of crude bio-oil. Yuan et al. [34] reported that the application of hydrothermal co-liquefaction of seaweed with rice husk has significantly increased bio-oil recovery by 71.7% with potential for large-scale commercialisation. Elshobary et al. [35] demonstrated that sequential biodiesel and bioethanol production from seaweeds improved the total energy recovery to 9.96 MJ/kg, which was sixfold or 28.3% higher than mono-production of biodiesel or of bioethanol. Abomohra et al. [36] highlighted the use of sequential fermentation and anaerobic digestion (AD) for dual bioethanol and biogas production from Cu-sorbed dry seaweeds. This approach resulted in the efficacy of energy recovery with value of 1597.3 GJ/year. Abomohra et al. [37] also emphasised the integrated valorisation of agar-free seaweed residues using AD technology coupled with microalgae cultivation for biogas and biodiesel production showing a superior technical and economical feasibility.

Anaerobic digestion (AD) is a process which promotes the degradation of ogranic material by microorganisms in the absence of oxygen (or anaerobic condition) [38]. AD generates methane (CH4), carbon dioxide (CO2), and a nutrient-rich waste product (digestate) which can be utilised as a substitute biofertiliser, soil conditioner, or cultivation media [39]. Biogas is comprised of methane and carbon dioxide, with a high-quality biogas having higher methane concentrations, usually in the range of 50–70% [40]. The biochemical methane potential (BMP) test is a standard method to measure the biodegradability of substrate under anaerobic conditions by monitoring the cumulative methane production during the test period [41]. The standard BMP test was developed by Angelidaki et al. [42]. This study identified the key operational considerations for conducting a BMP test including characteristics and composition of substrate samples, particle size, inoculum, nutrients (i.e. micro- and macro-nutrients), and mixing. Numerous studies have utilised this standard BMP test to investigate methane and biogas potential of biomass feedstock, such as fruit and vegetable waste (FVW) [43]; and thickened waste-activated sludge (TWAS) [44]. It was highlighted that addition of mineral can improve the stability of AD process. For example, Sliem et al. [45] added that after addition of 100 ppm nanoferrites Fe3O4 and CoFe2O4 to AD of cow-dung was found to enhance biogas cumulative volume by approximately twofold, with the value of 4929 mL and 5155 mL over 50 days operation.

Several studies have reported the potential of native macroalgae which is a non-edible macroalgae in Indonesia for biogas production using the AD process [32, 46, 47]. Our previous studies have also highlighted that cultivated seaweed (as opposed to wild) G. verrucosa offers good potential to be co-digest with TD, food waste (FW), and wastewater [48]. Furthermore, several studies have also investigated the methane potential from TD as a mono- or co-digestion feedstock in AD process. For example, Kristanto and Asaloe [23] reported that methane production from AD of TD was 77 mL from 195 mg COD/kg TD in 30 days, while Ni’mah [49] found that when mixing TD with cattle manure at ratio of 50:50 with volatile solids/VS of 3%, methane concentration increase to 68.98%. In addition, various studies have also reported that pre-treatments are often required for improving AD of macroalgae, such as grinding [50]; beating [51]; hydrolysis with enzymatic and alkaline solution [52, 53]; ultrasonic, hydrolysis with acid and thermo-alkaline [53]; drying and maceration [54]; and washing [55, 56]. Washing with water (potable or otherwise) is considered as a sustainable pre-treatment that can significantly increase the biogas and methane yield of macroalgae [54,55,56]. Yet, in the case of Indonesia, there is limited information on washing pre-treatment and co-digestion of wild seaweed G. verrucosa (WGv) with locally available biomass. Therefore, this study aimed to investigate the effect of co-digestion of WGv with TD and washing as a pre-treatment to improve the biogas/methane production. This study also investigated the effect of washing pre-treatment on the characteristics of WGv.

2 Materials and methods

2.1 Feedstocks, control positive, and inoculums

Dried WGv was collected from Ujungpangkah Beach, Gresik City, East Java, Indonesia, upon arival at the Bioindustry Laboratory, Department of Agro-industrial Technology, Faculty of Agricultural Technology, Universitas Brawijaya. The WGv sample was ground using a comercial blender and kept at room temperature (~ 27 °C). The TD was freshly collected from the tofu small-scale agro-industry in Kendalsari, Malang City, East Java, Indonesia, and directly kept at fridge upon arrival at Bioindustry Laboratory. The TD samples were collected from the closest area to keep the fresh quality of the sample. Also, tofu industry is locally available and implementing similar processing method; hence, the characteristics of TD samples were assumed to be not significantly different. Control positive used in this study was α-cellulose powder C8002 (Sigma Alrdrich, Singapore). Control inoculum was prepared using digestate from a full-scale digester treating cattle manure at Balai Besar Pelatihan Peternakan in Batu City, which operated under mesophilic condition, as previously used in our previous studies [12, 48, 57, 58]. The digestate was sieved using a 1-mm screen for removing larger particles, then it was deggased for 48 h at 37 °C to eliminate the residual biogas. The feedstocks and inoculum were analysed for pH, moisture content (MC), ash, total solids (TS), and volatile solids (VS), while the elemental analysis (C, H, O, N, S) and calorific value (CV) were carried out for feedstock substrates. C/N ratio of the substrates was calculated from the carbon concentration divide by the nitrogen concentration. The characteristics of inoculum, α-cellulose, and feedstocks used in this study are shown in Table 1.

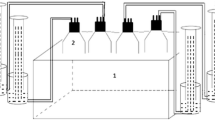

2.2 BMP test set-up

A manual BMP test was used in this study, operated for 28 days at 37 °C, following the method explained in our previous studies [12, 48, 57, 58]. Each sample was prepared in triplicate using a 250-mL serum bottle with working volume of 40 mL. The control inoculum samples were prepared to measure the ability of inoculum in generating the indigenous methane production. The control α-cellulose was used to measure the inoculum’s activity. Samples of mono-digestion and co-digestion of WGv with TD at ratio of 100:0, 80:20, 90:10, and 0:100 (on a VS basis) were tested in this study. These selected substrate ratios were aimed to add nutrient composition and to balance the C/N ratio, as important factors in co-digestion system [59]. The pressure of the serum bottle was measured on a daily basis using a digital manometre (Digitron 2026P, Electron Technology-UK), and the measured pressure was used for calculating the headspace biogas volume, following the method and formula described by Suhartini et al. [60].

2.3 Washing pre-treatment

The washing pre-treatment was carried out following the procedures described in our previous study [61]. The WGv samples were washed for 10 min using a flowing cold tap water (which is non-saline and chlorinated water), followed by a draining step to reduce excess water. The washed WGv samples were then analysed for the parameters of TS, VS, MC, ash, CV, elemental analysis (CHON), protein, lipids, carbohydrates, and C/N ratio, as well as the morphology and its element, and functional bonds units.

2.4 Analysis

pH was measured using a digital pH metre previously calibrated with buffers solution (pH 7 and 9.2) while TS and VS were analysed following the Standard Method 2540 G [62]. Daily biogas production was measured at standard temperature and pressure (STP) conditions, following the procedure and formula described in Suhartini et al. [57]. The C, H, O, and N content of the feedstock samples were analysed using elemental analyser (628 Series Elemental Determinator, LECO) [63], while the CV was analysed using Bomb Calorimetry method using ASTM standard D2015 [64]. The morphology and element of unwashed and washed WGv was analysed using scanning electron microscopy-energy dispersive X-ray (SEM–EDX) (FEI Inspect-S50 and EDAX AMETEK) operated at ~ 20 kV, with the procedure following the equipment manual book. The Fourier transform infrared (FTIR) spectra of unwashed and washed wild G. verrucosa were recorded using the Shimadzu type IRPrestige21 in the wavenumber scope 4000–400 cm−1 to identify the structures and bonds present in both samples, with the procedure following the equipment manual book.

The theoretical methane concentration was calculated using the Buswell equation [65] using an assumption that the seaweed samples have a biodegradation degree of 46% [66] and 62.57% for TD samples [25]. The biogas and methane potential is the daily amount of biogas and methane production, also known as the specific biogas potential (SBP) and specific methane potential (SMP) which were calculated using the equation reported by Strömberg et al. [67], using the theoretical methane concentration. Electrical conductivity (EC) of digestate was measured using electrical conductivity metre (Hanna, UK), according to the Standard Method 2510 [62]. Salinity of digestate was measured as total dissolved salt (TDS) based on Eq. 1, as explained by Lloyd and Heathcote [68], with the Ke factor selected of 0.8 for inorganic nutrient.

where Ke is the conductivity factor (0.8) and EC is the electrical conductivity (in µS/cm).

2.5 VS destruction

VS destruction was calculated using the formula explained in our previous study [69], as shown on Eq. 2. In this calculation, the mass of biogas was calculated using the average biogas volume obtained from the laboratory experiment, using the theoretical methane concentration calculated previously using Buswell equation, with the weight of 1 mol biogas as 1.34 g/l (water vapour and other trace gases present in biogas were not taken into consideration).

where Min is mass of substrate added (kg ww), VSin is the VS amount of the substrate added (g VS/kg ww), VSdigestate is the VS amount of the digestate removed (gVS/kg ww), and Mbiogas out is mass of biogas (kg ww).

2.6 The mass balance calculation

The mass balance calculation estimates the amount of biomass converted into biogas and the amount of residual digestate to be used biofertilizer (i.e. for land application or for synthetic fertiliser replacement), with and without dewatering processes. The calculation of biogas production and mass balance was made from the experimental data. The calculation formula was described in previous research, using CH4 density of 0.71 kg/m3 and CO2 density of 1.96 kg/m3 (this is on the basis that 1 kmol of a perfect gas occupies 22.4 m3) [69]. This calculation was based on 1000 kg of feedstock input on a basis of dry weight (TS).

2.7 Calculation of synergistic or antagonistic effect

The synergistic or antagonistic effects of combining feedstocks for co-digestion (and the subsequent impacts on AD performance and biogas yield) can be evaluated. Combining feedstocks in various ratios can provide a better understanding of these effects and support process optimisation. The estimation of weighted SMP was calculated using the experimental data based on the formula described in Kim et al. [70] as follows:

where weighted SMP is the estimation of SMP from co-digestion, measured SMPn is the SMP values from the laboratory experiment for substrates n, Pn is the percentage of substrate added in the feed mixture, and n is substrate 1, 2, … n.

2.8 Statistical analysis

Microsoft Excel software was used to calculate error bars or standard deviation. The R Software was used for Cronbach’s alpha reliability test, aiming to evaluate the reproducibility of the BMP trials in this study. The test was carried out on all replicates in BMP test trials with a confidence level of 95%. The BMP test trials can be considered as reliable and valid if having Chronbach’s alpha value higher than 0.6 or in the range of 0.70 to 0.99 [71].

3 Results and discussions

3.1 Feedstock characteristics

Table 1 shows that, for TD, the VS values were greater than 95%TS whereas for the WGv samples, the VS were observed to be 79.14%TS (unwashed) and 80.43%TS (washed). This indicates that the TD samples have a relatively higher organic content. When WGv substrates were mixed with TD at ratio of 80:20 and 90:10, the VS values were increased to 81.38%TS and 84.12%TS, respectively. However, TD samples have a higher MC value than unwashed and washed MGv samples. In this study, the TD samples had a higher C/N ratio than that of the WGv samples. The addition of TD as a co-substrate in AD of WGv slightly increased the C/N ratio. Despite the value which is still lower than the ideal condition (20–30), a slight increase in C/N ratio of mixture substrate may contribute to increase the biogas and methane yield, as previously reported in Hagos et al. [59]. Tait et al. [72] added that factors such as substrate compositions (i.e. carbon-rich or nitrogen-rich substrates), biodegradability, trace elements, and organic loading rate are important when considering potential co-digestion substrates. The TD samples also exhibited a higher carbon content (~ 43%TS) than the WGv sample of 35%TS (unwashed) and 33.7%TS (washed). The carbohydrate content of TD was higher than WGv sample. A previous study revealed that addition of carbon-rich substrates can enhance the organic loading in the substrate mixture, thus boosting and stimulating the microbial activity within the AD process [72]. It can also be seen that the WGv sample has a higher CV than the TD sample..

The feedstock characteristics, as shown in Table 1, revealed that addition of TD to WGv at ratio 20 and 10% VS have a significant effect on reducing the TS, VS, and ash concentration (on a ww basis). However, the VS concentration (on a TS basis) increased by 2.83% and 6.29%, respectively. The MC value was also found to be greatly affected by the addition of TD to the WGv by 3.38- and 3.58-fold. A high carbohydrate content, VS values (on a TS basis), and MC of TD sample appear to play a significant factor. According to Panichnumsin et al. [74], the composition of co-substrates affect the characteristics of the co-digestion mixture, thus influencing the digestion process stability. They added that an increase of an easily degradable fraction from the co-substrates was parallel to an increase in methane yield and biodegradability. Therefore, addition of higher concentrations of TD as co-substrates enhanced the amount of easily degraded organic matter (measured as VS) in the mixture. Li et al. [20] stated that carbohydrates in TD were composed of xylose, manose, galactose, glucose, and sucrose, which categorised as an easily biodegradable carbohydrate. While in Gracilaria sp., the carbohydrate was present in the form of cellulose, lignin, and agar [75], which are considered more complex and therefore more difficult to degrade. In addition, a lower C/N ratio of the feedstock may affect the AD process performance, where the ideal C/N ratio for biogas production is between 20 and 30 [76]. Milledge and Harvey [77] reported that C/N ratio in the range of 8–15 could contribute to inhibition of biogas and methane production in the AD of macroalgae biomas (i.e. Sargassum muticum).

3.2 The effect of co-digestion of WGv with TD at different ratio

3.2.1 Specific biogas and methane potential

Figure 1 shows daily SBP and SMP of mono-digestion and co-digestion of WGv with TD at different ratios over 28 days operation. Mono-digestion of WGv shows a low biogas and methane production from day 1 to day 6 possibly due to the adaptation stage, as shown in Fig. 1a. Starting from day 7 to day 28, a continuous increase in biogas production was evident, giving the average value of 119 L biogas/kg VSadded (Table 2). However, when co-digesting WGv with TD at ratio of 80:20 and 90:10, biogas was rapidly produced from day 1 to day 8, followed by stable and plateaued biogas production until day 28 (Fig. 1a). The results show that co-digestion of WGv with TD significantly improved the SBP by ~ 155% and ~ 112%, giving the average values of 302 L biogas/kg VSadded (WGv:TD, 80:20) and 253 L biogas/kg VSadded (WGv:TD, 90:10), respectively (Table 2).

The daily SMP values are shown in Fig. 1b and reflect a similar trend to the SBP values. Anaerobic mono-digestion of WGv resulted in a lower SMP compared to that of co-digestion of WGv with TD at all feeding ratio tested. Table 2 shows that the average SMP values of each sample were 45 L CH4/kg VSadded (WGv alone), 98 L CH4/kg VSadded (WGv:TD, 90:10), and 120 L CH4/kg VSadded (WGv:TD, 80:20), respectively. This indicated that co-digestion of WGv with TD at ratio of 90:10 and 80:20 improved the SBP and SMP by ~ 2.1-fold and ~ 2.6-fold. The SBP and SMP values for control α-cellulose were 284 L biogas/kg VSadded and 133 L CH4/ kg VSadded, which were much lower than the theoretical SBP or SMP for α-cellulose. The reliability test, however, shows that all tested samples in mono- and co-digestion BMP test trials have Cronbach’s alpha values in the range of 0.972–0.995 (Table 2).

It can be seen in Fig. 1 that there was a reduction in biogas and methane production from the digestion of WGv alone. Kawaroe et al. [32] also reported that G. verrucosa has a low methane potential, giving the value of 11.6 L CH4/kg ww. The organic content (particularly carbohydrate and lignin) in marine macroalgae substrate may play a significant role in AD performance, and thus on the biogas and methane yield. For instance, Costa et al. [75] found that the concentration of macroalgae (i.e. 1, 2.5, and 5% of TS) and type of macroalgae (i.e. Ulva sp., Enteromorpha sp., and Gracilaria sp.) have an effect on the stability and performance of the AD process. Their results showed that the SMP of each macroalage sample was as follows: Ulva sp. (167–196 L CH4/kg VS), Gracilaria sp. (148–182 L CH4/kg VS), and Enteromorpha sp. (148–154 L CH4/kg VS). They further added that Ulva sp. has a higher carbohydrate and a lower lignin concentration compared to other macroalgae, making it more suitable for methanisation. Gracilaria sp. has a slightly lower SMP due to its slightly lower carbohydrate and a higher lignin concentration than that of Ulva sp. Enteromorpha sp. generated the lowest SMP because of its lowest carbohydrate and its highest lignin concentration than the other two macroalgae. Furthermore, since the macroalgae sample used was wild marine macroalgae and directly used without washing pre-treament, the sea salts’ content in the feedstock may hinder the AD process. Previous studies have also reported that sea salt (or salinity) content from marine macroalgae inhibited the microorganism consortia and AD performance overall [78, 79]. Similarly, a high salinity contributes to a low biogas production as it limits the growth of the microorganism consortia in the AD digester [56]. Kawaroe et al. [47] also reported that biogas production from macroalgae under high salinity condition was lower than that of under low salinity condition.

Figure 1 also shows that co-digestion of WGv with TD gave a significant improvement both in SBP and SMP compared to that of the mono-digestion of WGv. This result is in agreement with previous result reported by Oliveira et al. [80] who found an improvement of methane yield by 19–56% from co-digestion of Sargassum sp. with glycerol or with waste cooking oil. Kumar et al. [81] reported that co-digestion of waste algal biomass with cattle dung resulted in high methane potential (315 L/kgVSadded) at OLR 5 gVS/L. Various studies have also reported significant improvement in biogas and methane yield following co-digestion of macroalgae with other substrates, such as FW and TD [48]; glycerol and sewage sludge (SS) [54]; FVW [82]; TWAS [83]; cattle manure [84]; and waste paper (WP) [85]. Comparison of other studies on BMP of marine macroalgae in mono- and co-digestion system is shown in Table 2.

The results highlighted that increasing co-substrate (TD) concentration was found to enhance biogas and methane yield, as well as the biodegradability. This is in line with Panichnumsin et al. [74], as explained previously. Furthermore, the ability of microorganisms to digest the organic matter in the substrates may play significant roles in enhancing the biogas and methane yield. Gu [87] added that changes in the concentration of co-substrates play a significant role in the presence and the activity of microbial population, as well as the metabolic utilisation of targeted organic matter. In AD systems, the addition of co-substrates may provide carbon and energy sources; furthermore, its co-metabolic matrix can also offer a large number of electron donors for anaerobic consortia to efficiently degrade organic matter [88]. Suhartini et al. [82] also reported that the co-substrate can add nutrient supply, thus enhancing the production of biogas and methane in co-digestion systems. This mechanism is identified as co-metabolism and various studies have highlighted that this enhanced the ability of microorganism to effectively digest the substrates [87, 88]. In more detail, Jin et al. [89] reported that co-metabolism, in AD systems inoculated with rumen microorganisms, enhances performance and therefore biogas production. They added that co-metabolism improves the efficacy of microbial-digestion substrates not only providing carbon or energy sources through readily biodegradable substances, but also by generating specific enzyme stimulated by the degradation process. Chen et al. [90] also reported that co-metabolism processes in anaerobic co-digestion system promoted high organic matter degradation (i.e. high digestion rate), enhanced nutrient balance and availability, better synergistic effects on microorganism, and improved potential detoxification from toxic/inhibitory substances or derivatives. Furthermore, Riggio et al. [91] studied anaerobic co-digestion of cow slurry with olive pomace and apple pulp at different ratios. The study emphasised a positive impact of co-metabolism and subsequent benefits including improved biogas production, enhanced process stability, and reduced inhibitory effects. These findings confirm that anaerobic co-digestion of wild G. verrucosa with TD substrate offers numerous benefits in terms of process stability and performance. Further studies on optimisation of operational parameters and identification of other potential co-digestion substrates are advised.

Another factor which may contribute to impact on performance is the combined MC and TS values of the substrate mixture. The WGv utilised in these trials were added in a dried condition (has higher TS, lower MC) and fresh TD was in wet condition (has lower TS, high MC); thus, adding WGv at different concentrations has an impact on the MC and TS values (see Table 1). Figure 2 also shows that a decrease in TS and an increase in MC values resulted in an increase in methane potential, with R2 values of 0.7761 and 0.7221, respectively. The results indicating that dried biomass feedstock may lower the ability microorganism to degrade its organic materials. Ahmadi-Pirlou et al. [92] reported that AD process with low solid concentration (5–10% TS) exhibited higher organic matter degradation and higher biogas/methane yield than that of at high solid concentration (15–20% TS). Abbassi-Guendouz et al. [93] studied the effect of TS concentration of AD performance. Their study identified that TS concentrations ≥ 30% led to a significant reduction in methane production. A high TS concentration resulted in a reduction in hydrolysis rate and an inhibition in methanogenesis due to mass transfer limitations. A previous study also found that an increase in MC values has correlation to an increase in SMP values, and vice versa [48].

3.2.2 Synergistic and antagonistic effects

The synergistic or antagonistic effects of co-digesting several substrates can be evaluated and the findings were used to optimise the ratio of substrates added in the AD system. Several studies found that synergistic effects are evident if the addition of co-substrates can positively contribute to enhance the biogas/methane yield [70, 85, 86], while antagonistic effects are confirmed when addition of co-substrates leads to reduction in biogas/methane yield. The synergistic effects of substrates mixing resulted in improvement of the biodegradability because of additional nutrients, carbon, trace elements, enzyme, or other ingredients that main substrates are lacking. From Table 3, it can be seen that synergistic effects were observed from co-digestion of WGv with TD at ratio of 90:10 and 80:20. This indicates that addition of higher concentration of TD gave an additive impact on improving the SMP values. An inhibitory effect can also result from co-digesting substrates due to the compositions or supply of nutrients/trace elements, as explained by Pan et al. [94]. A previous study by Cogan and Antizar-Ladislao [86] reported a synergistic effect from co-digestion of food waste with seaweed at ratio of 90:10, and antagonistic effects at ratio of 75:25 and 50:50. Their study indicated that an increase in seaweed concentration added contributed to a reduction in methane potential, potentially due to the sulphur content in the seaweed samples. A study from Rodriguez et al. [85], also reported synergistic effects of co-digestion waste paper (WP) with macroalgae/MA (Pelvetia canaliculata) at ratio of 75:25, 50:50, and 25:75. Their study highlighted that co-digestion of WP:MA at ratio 50:50 gave the highest synergistic effects, possibly due to its ideal C/N ratio of 26 than that of other treatments WP:MA 25:75 (C/N ratio of 18) and WP:MA 75:25 (C/N ratio of 42), respectively.

3.2.3 Digestate characteristics

Table 4 shows that mono- and co-digestion of WGv with TD at various feeding ratio has a good performance in terms of operational stability. For example, the pH value before and after the BMP test was well within the optimum value for digestion (6.8–8.2). The pH of all samples tested were in the range of 7.50–7.70 (before) and 7.30–7.43 (after). This shows that the AD process was relatively stable. The VS values of the samples decreased after the BMP test, within the range of ~ 65–78%TS. Furthermore, at the end of BMP test, the acetic acid concentrations from the digestate samples were low at values in the range of 0.03–0.25%, respectively.

From Table 4, it is clear that the pH values of digestate in all tested samples, before and after the BMP test, were well within the ideal range of AD (6.5–8.5). Despite a slight reduction of pH values in unwashed and washed WGv, the results indicate that pH is not considered as limiting factor in this AD process. The results also showed that the washing pre-treatment had an impact on the digestate quality, especially on the reduction of ash (an indicator of inorganic concentrations), as previously reported by Tabassum et al. [95]. This demonstrates that the biological degradation of organic materials was effective and this was transformed into biogas, as stated by Gelegenis et al. [96]. The remaining VS in the digestate also indicates that the digestate still contains high concentration of organics matter, which has potential for further application as biofertiliser (either via composting or direct use), as previously stated by Alburquerque et al. [97]. This indicates that the process of degrading organic matter into biogas or methane by microorganisms occurred during the AD process, as explained in various studies [48, 96]. Yet, further in-depth investigation of the organic and inorganic nutrients present in the digestate is needed to evaluate the potential of valorising the digestate either as biofertiliser [97] or as medium for algal cultivation [98].

3.3 The effect of washing pre-treatment

3.3.1 Characteristics of WGv before and after washing pre-treatment

The findings in this study demonstrate that washing pre-treatment has a significant impact on the characteristics, morphology, elements, functional groups, and biogas/methane potential of wild G. verrucosa. Table 1 shows the characteristics of WGv before (unwashed) and after washing (washed) pre-treatment. The results showed that washing pre-treatment caused significant changes to the characteristics of WGv. The MC was found to increase after washing pre-treatment. Unwashed WGv contains a high ash concentration which can be attributed to the salt or mineral content. After washing pre-treatment, the ash content of washed WGv was reduced by 65%, possibly due to the removal of dirt and non-organic compounds such as sea salts. Similarly, as stated by Tabassum et al. [95], high ash (or salt) content in macroalgae can be a trigger for operational problems and process instability in AD systems due to the accumulation of salt in digester which can impact on the microconsortia. Their study further reported that washing pre-treatment was able to reduce ash (or salt) by 54%, which subsequently results in increasing VS content by up to 31% and methane yield by 25%. The experimental results also indicate that the CV value showed a slight increase after washing pre-treatment from 13.74 to 14.95 MJ/kg TS, respectively. Similarly, the VS content was also found to slightly increase after washing pre-treatment by 1.6%.

Figure 3 shows the elemental composition and morphology of unwashed and washed WGv, analysed using SEM–EDX, which further confirm the results that washing pre-treatment was able to remove inorganic nutrients or salt, in accordance with the findings reported by Milledge et al. [56]. The SEM images show that both unwashed and washed WGv samples have a rough surface and ridged texture. The SEM image of the unwashed WGv (Fig. 3a) shows the presence of white deposits (impurities or potentially sea salt content) on the surface. In contrast, the washed WGv exhibits more consistent surface and no white deposits (Fig. 3c), indicating that washing pre-treatment was effective in removing any impurities or remained sea salts on the surface of the biomass sample. Evaluation between these two samples helps to better recognise the effect of washing pre-treatment on the characteristic of substrates, hence on the biogas and methane production. The EDX spectra, as shown in Fig. 3b and 3d, indicate that unwashed WGv contains higher concentration of elements than that of its counterpart.

The EDX spectra also shows in more details on the percentage of all elements contain in both unwashed and washed WGv (see Table 5). The results demonstrated the presence of carbon (C), sulphur (S), calcium (Ca), silicon (Si), aluminum (Al), and magnesium (Mg) as dominant elements in unwashed samples, while element of sodium (Na) and potassium (K) were not present in unwashed WGv. The washed WGv has dominant elements of C, S, Ca, Si, Mg, Na, and K, without Al element was detected. The EDX spectra help to identify the elements presents in both samples, which further be used to evaluate their organic matter content and suitability as feedstock for biogas (or methane) production. These SEM–EDX results indicate that higher concentration of the elements S, Ca, Si, and Mg were present on the surface of unwashed WGv than that of the washed WGv. The washed WGv sample has the highest concentration for carbon with values of 42.59% compared to 22.82% for unwashed WGv sample. Carbon is one of the main components of carbohydrates which is an organic matter and energy sources for microorganisms in the AD system, thus improving the microbial degrading-ability, as highlighted in several studies [86, 99]. A previous study has reported that washing pre-treatment, especially using hot water, is effective for reducing problematic elements (such as K, Na, Ca, Mg, Fe, Cl, S, and P) in biomass, hence improving the biomass conversion yield, as well as reducing ash deposition and air emissions problems [100]. Costa et al. [101] found that the SEM–EDX results of the Sargassum filipendula residues show a reduction in the elements concentration which associated with removal of diatoms after washing pre-treatments. A diatom is a unicellular algae which is mainly composed of biosilica (SiO2) [102], hence contributed a high Si concentration in unwashed wild G. verrucosa samples. Figure S1 also shows that unwashed WGv contains distinct diatoms with a heterogeneous distribution, while no diatoms were present in washed WGv sample, similar to previous studies [101, 102].

The effect of washing pre-treatment on the presence of functional groups was also clearly evidenced from the FTIR spectra as as transmittance (%) against wavenumber (1/cm) (Fig. 4). Unwashed WGv, as shown in Fig. 3a, shows the more complex nature of biomass due to its large number of peaks compared to its counterpart. This sample has recorded peak bands at wavelength of 675–995 cm−1, 690–990 cm−1, 1500–1570 cm−1, 1500–1600 cm−1, 2100–2260 cm−1, 2850–2970 cm−1, and 3200–3600 cm−1, while the washed WGv (Fig. 3b) spectra indicated lesser peak bands, which recorded as of 675–995 cm−1, 690–990 cm−1, 2850–2970 cm−1, and 3200–3600 cm−1. Washing pre-treatment seems to reduce the presence of functional groups in wild G. verrucosa. The peaks located at 675–995 cm−1 represent the bond stretching of C-H, indicating the presence of alkenes, which is similar to that in Sargassum sp. [102]. The stretching vibrations of peaks at 690–990 cm−1 and 1500–1600 cm−1 demonstrate the presence of C-H and C = C of aromatic ring [103]. The functional groups recorded at peaks of 1500–1570 cm−1 represent the bending of NO2, identifying that the nitro compounds are present in the samples, similar to those in the powder of the Ampelocissus latifolia leaf [104]. Peaks located at 2100–2260 cm−1 demonstrates the bond bending of C = C of alkynes functional group [104, 105]. Also, the peak region band at 2850–2970 cm−1 corresponds to the presence of aliphatic group of alkanes, similar to that of natural and enriched Cladophora glomerata [106] and Ecklonia maxima residues [107]. The distinct stretching and bending from 3200 to 3600 cm−1, indicating the presence of O–H of hydrogen bonded alcohol and phenols, similar to previously reported in various studies [102, 104, 106, 107]. The unwashed WGv contains alkenes, alkynes, alkanes, C-H and C = C aromatic compounds, nitro compounds, hydrogen bonded alcohol, and phenols, while washed WGv shows the presence of alkenes, C-H aromatic compounds, alkane, hydrogen-bonded alcohol, and phenols. These results confirm that washing pre-treatment has impact on the presence the functional groups.

3.3.2 Biogas and methane potential of WGv before and after washing pre-treatment

Table 2 shows that the average SBP and SMP of washed WGv was 247 L biogas/kg VSadded and 92 L CH4/kg VS, respectively. While unwashed WGv has the average SBP and SMP of 183 L biogas/kg VSadded and 69 L CH4/kg VS added. The results shows that washed WGv produced higher SBP and SMP values than that of unwashed WGv. This is in accordance with other studies reported that washing pre-treatment significantly enhanced biogas and methane potential from macroalgae samples [47, 56, 61], possibly due to loss of inorganic contents such as salts (or ash) or salinity [78, 79, 95], as well as characteristic differences as explained before. Figure S2 demonstrates the effect of washing pre-treatment on SBP and SMP from AD of WGv. Starting on day 0 to day 4, there was an adaption phase both of BMP of unwashed and washed WGv. From day 5 to day 16, the BMP test enters the lag phase where rapid production of biogas and methane occurred. This was followed by a stationary phase where biogas or methane was produced in small but constant volume. The results indicated that, starting from day 14 to day 25, biogas and methane produced from the AD of washed WGv were much higher than that of unwashed WGv. The washing treatment was found to improve the efficiency of biogas and methane production by 33.11%. A study by Oliveira et al. [54] also reported a better AD performance when it combined with washing pre-treatment, giving the efficiency of 45.76% improvement in methane potential. In comparison, enzymatic pre-treatment using fungal crude enzyme or combined with mechanical pre-treatment were also able to enhance the efficiency of AD process, hence increasing the methane and biogas yields. Thermochemical pre-treatment at higher temperature (above 100 °C), however, was found to reduce the efficiency of AD performance as indicated by lower methane potential. Karay et al. [53] and Jard et al. [108] found that the presence of inhibitors compounds (i.e. furfural, hydroxymethyl-furfural/HMF) during thermochemical pre-treatment may contribute to limit the ability of microorganism in degrading organic material during AD process. In details, the comparison of the efficiency of the washing pre-treatment with other methods in mono- or co-digestion of macroalgae can be seen in Table 6.

The reliability test shows that the SBP and SMP values of all tested samples have Cronbach’s alpha values in the range of 0.976–0.981 (Table 2). These findings indicate the BMP test were acceptable and reliable in term of the degree of reproducibility and consistency, as explained by Fraenkel et al. [71].

3.3.3 Digestate characteristics

The characteristics of the digestate resulting from the BMP test can be seen in Table 4. This indicates that all samples have pH values well within the ideal range for an optimal AD process in the range of 7.55–7.67 (start of BMP test) and 6.62–6.83 (end of BMP test). In addition, the digestate from the unwashed WGv samples have TS and VS values that were ~ 1.9-fold and ~ 2.2-fold higher than that of washed WGv digestate samples, respectively. Similarly, the VS content (in % of TS) of unwashed WGv digestate was greater than the washed WGv digestate, by 13.22%. Furthermore, the ash content was also found to be 36.36% higher in unwashed WGv than in washed WGv digestate sample. Other parameters such as EC and salinity were not significantly different in both samples.

3.4 Mass balance around digester

The mass balance estimation, as shown in Table 7, indicates that more biogas is produced from co-digestion than mono-digestion, or washed than unwashed WGv samples. This correlates with more organic matter being degraded, hence reducing the amount of organic matter remained in the digestate. Consequently, less volume of digestate is produced. In general, the digestate generated from co-digestion of WGv with TD and washed WGv were much lower than that of the mono-digestion and unwashed WGv. Co-digestion of WGv with TD at all concentration produced a lower quantity of digestate to be further transferred for dewatering, transportation, and land application, compared with mono-digestion of WGv. These findings confirm that co-digestion and pre-treatment prior to AD enhances the biodegradability of organic matter, thus reducing the volume of digestate to be managed for application to soil or land. Similarly, a previous study by Pilli et al. [111] also reported that AD of ultrasonic treated sludges (i.e. primary sludge, secondary sludge, and mixed sludge) produced significantly lower volume of digestate than without pre-treatment. Their study further demonstrated that if there is less digestate generated then this may offer indirect benefits in terms of disposal, dewatering process, transportation, and land application of digestate sludge. Thus, the energy input and operational cost associated with managing the digestate can be effectively reduced. A study reported that anaerobic co-digestion can contribute to 37% reduction in the net cost [112] and provide overall electricity saving at 88–170 €/t TSadded [113]. Furthermore, Fasahati et al. [114] concluded that, based on the material and energy balance, as well as economic analysis, AD of brown algae (Laminaria japonica) has good potential. Their study suggested that co-digestion of brown algae with organic waste from neighbouring plants offers a good alternative to improve biogas/methane yields and electricity, as well as simultaneously reducing the waste treatment cost of the industrial plants area. This is also in line with other studies using different substrates which highlighted the positive effects of co-digestion in AD system. For instance, Tait et al. [72] use co-digestion of agro-industrial organic waste. Oladejo et al. [115] reported that co-digestion of FW, cow dung (CD), and piggery dung (PG) showed the highest mass balance and better biogas yield. Another study by Kumar et al. [116], for instance, also showed that co-digestion of microalgal biomass with cow dung produced higher biogas potential at value of 720–1040 L/kgVSadded/day (during summer) and 96–336 L/kgVSadded/day (during winter).

Hence, co-digestion and/or application of pre-treatment prior to AD processes may contribute to better AD performance, higher biogas/methane production, and cost-effective conversion routes to biogas production. Many studies have highlighted the impact of pre-treatment prior anaerobic co-digestion. For instance, Unpaprom et al. [117] studied anaerobic co-digestion of water hyacinth with swine dung, after physical (i.e. crushed) and chemical (NaOH) pre-treatment. The results showed that at mixing ratio of 1:1, the highest methane production and concentration (68.89%) was achieved, combined with production of digestate containing higher nutrient suitable as biofertilizer. Nong et al. [118] also found that alkaline pre-treatment following co-digestion of water primrose and cow dung enhanced biogas production and methane concentration, in particular at ratio of 2:1 gave the superior performance.

4 Conclusion

The findings confirm that co-digestion of the wild seaweed species Gracilaria verrucosa with tofu dregs offer superior anaerobic digestion performance than that of mono-digestion process. Increasing ratio of co-substrates demonstrated positive co-metabolism, thus increasing the microbial-digesting ability, leading to higher biodegradability and biogas/methane yield. Performance of mono-digestion of Gracilaria verrucosa can be improved by reducing or removing the salt concentration or salinity through washing pre-treatment. Combination of biomass or waste resources as co-substrates in anaerobic digestion system should consider both the availability and the nutrient composition. Furthermore, given the scale of supply of both macroalgae and TD in Indonesia, this presents a good opportunity to address both waste and energy challenges in the country.

Abbreviations

- AD:

-

Anaerobic digestion

- BMP:

-

Biochemical methane potential

- CGv:

-

Cultivated seaweed Gracilaria verrucosa

- CM:

-

Cattle manure

- CRS:

-

Carbonised rice straw

- CV:

-

Calorific value

- EC:

-

Electrical conductivity

- EDX:

-

Energy dispersive X-ray

- FVW:

-

Fruit and vegetable waste

- FW:

-

Food waste

- MA:

-

Macroalgae

- MB:

-

Municipal biosludge

- MC:

-

Moisture content

- MEMR:

-

Ministry of Energy and Mineral Resources, Republic of Indonesia

- SBP:

-

Specific biogas production

- SEM:

-

Scanning electron microscopy

- SMP:

-

Specific methane potential

- SMEs:

-

Small- and medium-scale enterprises

- SS:

-

Sewage sludge

- SW:

-

Seaweed waste

- STP:

-

Standard temperature and pressure

- TD:

-

Tofu dregs

- TDS:

-

Total dissolved salt

- TS:

-

Total solids

- TWAS:

-

Thickened waste activated sludge

- VFA:

-

Volatile fatty acid

- VS:

-

Volatile solids

- WFO:

-

Waste frying oil

- WGv:

-

Wild seaweed Gracilaria verrucosa

- WP:

-

Waste paper

- WW:

-

Wet weight

References

Abas N, Kalair A, Khan N (2015) Review of fossil fuels and future energy technologies. Futures 69:31–49. https://doi.org/10.1016/j.futures.2015.03.003

York R, Bell SE (2019) Energy transitions or additions?: why a transition from fossil fuels requires more than the growth of renewable energy. Energy Res Soc Sci 51:40–43. https://doi.org/10.1016/j.erss.2019.01.008

Gielen D, Boshell F, Saygin D, Bazilian MD, Wagner N, Gorini R (2019) The role of renewable energy in the global energy transformation. Energy Strateg Rev 24:38–50. https://doi.org/10.1016/j.esr.2019.01.006

Simangunsong BCH, Sitanggang VJ, Manurung EGT, Rahmadi A, Moore GA, Aye L, Tambunan AH (2017) Potential forest biomass resource as feedstock for bioenergy and its economic value in Indonesia. For Pol Econ 81:10–17. https://doi.org/10.1016/j.forpol.2017.03.022

MEMR (2020) Strategic plan of the directorate general of new, renewable energy and energy conservation (NREEC) 2020–2024. Minist Energy Miner Resour. Jakarta. https://ebtke.esdm.go.id/post/2020/05/18/2540/rencana.strategis.renstra.ditjen.ebtke.2020-2024. Accessed 18 Nov 2021

Bulkowska K, Mariusz Z, Ewa G, Artur K (2016) Biomass for biofuel. Taylor and Francis Group, London

Carlos RM, Khang DB (2008) Characterization of biomass energy projects in Southeast Asia. Biomass Bioenergy 32:525–532. https://doi.org/10.1016/j.biombioe.2007.11.005

Sadh PK, Duhan S, Duhan JS (2018) Agro-industrial wastes and their utilization using solid state fermentation: a review. Bioresour Bioprocess 5:1–15. https://doi.org/10.1186/s40643-017-0187-z

McCarthy J, Zen Z (2010) Regulating the oil palm boom: assessing the effectiveness of environmental governance approaches to agro-industrial pollution in Indonesia. Law Policy 32:153–179. https://doi.org/10.1111/j.1467-9930.2009.00312.x

Federici F, Fava F, Kalogerakis N, Mantzavinos D (2009) Valorisation of agro-industrial by-products, effluents and waste: concept, opportunities and the case of olive mill wastewaters. J Chem Technol Biotechnol 84:895–900. https://doi.org/10.1002/jctb.2165

Berbel J, Posadillo A (2018) Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 10:1–9. https://doi.org/10.3390/su10010237

Suhartini S, Nurika I, Paul R, Melville L (2021) Estimation of biogas production and the emission savings from anaerobic digestion of fruit-based agro-industrial waste and agricultural crops residues. BioEnergy Res 14:844–859. https://doi.org/10.1007/s12155-020-10209-5

Evcan E, Tari C (2015) Production of bioethanol from apple pomace by using cocultures: conversion of agro-industrial waste to value added product. Energy 88:775–782. https://doi.org/10.1016/j.energy.2015.05.090

Domínguez-Bocanegra AR, Torres-Muñoz JA, López RA (2015) Production of bioethanol from agro-industrial wastes. Fuel 149:85–89. https://doi.org/10.1016/j.fuel.2014.09.062

Abdelhady HH, Elazab HA, Ewais EM, Saber M, El-Deab MS (2020) Efficient catalytic production of biodiesel using nano-sized sugar beet agro-industrial waste. Fuel 261:1–12. https://doi.org/10.1016/j.fuel.2019.116481

Oceguera-Contreras E, Aguilar-Juárez O, Oseguera-Galindo D, Macías-Barragán J, Bolaños-Rosales R, Mena-Enríquez M, Arias-García A, Montoya-Buelna M, Graciano-Machuca O, De León-Rodríguez A (2019) Biohydrogen production by vermihumus-associated microorganisms using agro industrial wastes as substrate. Int J Hydrogen Energy 44:9856–9865. https://doi.org/10.1016/j.ijhydene.2018.10.236

Damayanti R, Sandra S, Nanda NR (2020) The effect of adding rice straw charcoal to the processing of bio-pellet from cacao pod husk. Adv Food Sci Sustain Agric Agroind Eng 3:81–90. https://doi.org/10.21776/ub.afssaae.2020.003.02.6

REEEP (2012) Planning and policy support for producing RE biogas in the Indonesian tofu industry. https://www.reeep.org/projects/planningand-policy-support-producing-re-biogas-indonesian-tofu-industry. Accessed 2 Feb 2022

REEEP (2012) Tofu production: a massive opportunity for RE biogas in Indonesia. https://www.reeep.org/news/tofu-production-massive-opportunity-re-biogas-indonesia. Accessed 2 Feb 2022

Li S, Dan Z, Kejuan L, Yingnan Y, Zhongfang L, Zhenya Z (2013) Soybean curd residue: composition, utilization and related limiting factors. Int Sch Res Not 2013:1–8. https://doi.org/10.1155/2013/423590

Mateos-Aparicio I, Redondo-Cuenca M, Villanueva-Suarez A (2010) Isolation and characterization of cell wall polysaccharides from legume by-products: Okara (soymilk residue), peapod and broad bean pod. Food Chem 122:339–345. https://doi.org/10.1016/j.foodchem.2010.02.042

Ugwuanyi JO, McNeil B, Harvey LM (2009) Production of protein-enriched feed using agro-industrial residues as substrates. In: Pandey A (ed) Nee’Nigam PS. Biotechnology for Agro-Industrial Residues Utilisation. Springer, Dordrecht, pp 77–103

Kristanto GA, Asaloe H (2017) Assessment of anaerobic biodegradability of five different solid organic wastes. AIP Conf Proc 1826(0020029):1–7. https://doi.org/10.1063/1.4979245

Choe U, Mustafa AM, Zhang X, Sheng K, Zhou X, Wang K (2021) Effects of hydrothermal pretreatment and bamboo hydrochar addition on anaerobic digestion of tofu residue for biogas production. Bioresour Technol 336:1–10. https://doi.org/10.1016/j.biortech.2021.125279

Song Y, Meng S, Chen G, Yan B, Zhang Y, Tao J, Li Y, Li J (2021) Co-digestion of garden waste, food waste, and tofu residue: effects of mixing ratio on methane production and microbial community structure. J Environ Chem Eng 9:1–10. https://doi.org/10.1016/j.jece.2021.105901

FAO (2021) Global seaweeds and microalgae production, 1950–2019. https://www.fao.org/3/cb4579en/cb4579en.pdf. Accessed 2 Feb 2022

Roberts DA, Paul NA, Dworjanyn SA, Bird MI, De Nys R (2015) Biochar from commercially cultivated seaweed for soil amelioration. Sci Rep 5:1–5. https://doi.org/10.1038/srep09665

Efendi F, Handajani R, Nursalam N (2015) Searching for the best agarose candidate from genus Gracilaria, Eucheuma, Gelidium and local brands. Asian Pac J Trop Biomed 10:865–869. https://doi.org/10.1016/j.apjtb.2015.06.009

Baghel RS, Kumari P, Reddy CRK, Jha B (2014) Growth, pigments, and biochemical composition of marine red alga Gracilaria crassa. J App Phycol 26:2143–2150. https://doi.org/10.1007/s10811-014-0250-5

McDermid KJ, Stuercke B (2003) Nutritional composition of edible Hawaiian seaweeds. J Appl Phycol 15:513–524. https://doi.org/10.1023/B:JAPH.0000004345.31686.7f

Meinita MDN, Marhaeni B, Oktaviani DF, Jeong GT, Hong YK (2018) Comparison of bioethanol production from cultivated versus wild Gracilaria verrucosa and Gracilaria gigas. J Appl Phycol 30:143–147. https://doi.org/10.1007/s10811-017-1297-x

Kawaroe M, Dohong S, Lestari D (2017) Great potency of rejected macroalgae Gracilaria verrucosa for biogas production by anaerobic digestion and HS scrubber. World Appl Sci J 35:661–668

Abomohra AE-F, Sheikh HM, El-Naggar AH, Wang Q (2021) Microwave vacuum co-pyrolysis of waste plastic and seaweeds for enhanced crude bio-oil recovery: experimental and feasibility study towards industrialization. Renew Sustain Energy Rev 149:1–13. https://doi.org/10.1016/j.rser.2021.111335

Yuan C, Wang S, Cao B, Hu Y, Abomohra AE-F, Wang Q, Qian L, Liu L, Liu X, He Z, Sun C (2019) Optimization of hydrothermal co-liquefaction of seaweeds with lignocellulosic biomass: merging 2nd and 3rd generation feedstocks for enhanced bio-oil production. Energy 173:413–422. https://doi.org/10.1016/j.energy.2019.02.091

Elshobary ME, El-Shenody RA, Abomohra AEF (2021) Sequential biofuel production from seaweeds enhances the energy recovery: a case study for biodiesel and bioethanol production. Int J Energy Res 45:6457–6467. https://doi.org/10.1002/er.6181

Abomohra AE-F, El-Hefnawy ME, Wang Q, Huang J, Li L, Tang J, Mohammed S (2021) Sequential bioethanol and biogas production coupled with heavy metal removal using dry seaweeds: towards enhanced economic feasibility. J Clean Prod 316:1–10. https://doi.org/10.1016/j.jclepro.2021.128341

Abomohra AE-F, Almutairi AW (2020) A close-loop integrated approach for microalgae cultivation and efficient utilization of agar-free seaweed residues for enhanced biofuel recovery. Bioresour Technol 317:1–11. https://doi.org/10.1016/j.biortech.2020.124027

Pullen T (2015) Anaerobic digestion – making biogas – making energy: the Earthsan Expert Guide. Taylor & Francis Group, New York

Taricska JR, Long DA, Chen JP, Hung YT, Zou SW (2009) Anaerobic digestion. In: Wang LK, Pereira NC, Hung YT (eds) Biological Treatment Processes, Handbook of Environmental Engineering, 8th edn. Humana Press, Totowa, pp 589–634

Ibrahim MM, Narasimhan JV, Ramesh A (2015) Comparison of the predominantly premixed charge compression ignition and the dual fuel modes of operation with biogas and diesel as fuels. Energy 89:990–1000. https://doi.org/10.1016/j.energy.2015.06.033

Jensen PD, Ge H, Batstone DJ (2011) Assessing the role of biochemical methane potential tests in determining anaerobic degradability rate and extent. Water Sci Technol 64:880–886. https://doi.org/10.2166/wst.2011.662

Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, Kalyuzhnyi S, Jenicek P, Van Lier JB (2009) Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol 59:927–934. https://doi.org/10.2166/wst.2009.040

Gunaseelan VN (2004) Biochemical methane potential of fruits and vegetable solid waste feedstocks. Biomass Bioenergy 26:389–399. https://doi.org/10.1016/j.biombioe.2003.08.006

Suhartini S, Melville L, Amato T (2017) Pre-treatment of thickened waste activated sludge (TWAS) for enhanced biogas production via the application of a novel radial horn sonication technology. Water Sci Technol 75:2179–2193. https://doi.org/10.2166/wst.2017.069

Sliem MA, El-Ansary S, Soliman W, Badr Y (2021) Enhancing biogas production of cow dung during anaerobic digestion using nanoferrites. Biomass Convers Biorefinery 1–8. https://doi.org/10.1007/s13399-021-01683-8

Krisye K, Kawaroe M, Hasanudin U (2016) Anaerobic biodegradation of macroalgae Ulva sp. For biogas production with batch method. Oseanologi Limnol di Indones 1:57–65. https://doi.org/10.14203/oldi.2016.v1i1.48

Kawaroe M, Salundik RW, Lestari D (2017) Comparison of biogas production from macroalgae Eucheuma cottonii in anaerobic degradation under different salinity conditions. World Appl Sci J 35:344–351

Suhartini S, Nurika I, Rahmah NL, Paul R, Melville L (2020) Potential of Gracilaria sp. as single- or co-digestion feedstock for biogas production. IOP Conf Ser Earth Environ Sci 460:012032. https://doi.org/10.1088/1755-1315/460/1/012032

Ni’mah L, (2014) Biogas from solid waste of tofu production and cow manure mixture: composition effect. Chemica 1:1–9

Tedesco S, Mac Lochlainn D, Olabi A (2014) Particle size reduction optimization of Laminaria spp. biomass for enhanced methane production. Energy 76:857–862. https://doi.org/10.1016/j.energy.2014.08.086

Montingelli ME, Benyounis KY, Stokes J, Olabi A (2016) Pretreatment of macroalgal biomass for biogas production. Energy Convers Manag 108:202–209. https://doi.org/10.1016/j.enconman.2015.11.008

Farghali M, Yuhendra AP, Mohamed IM, Iwasaki M, Tangtaweewipat S, Ihara I, Sakai R, Umetsu K (2021) Thermophilic anaerobic digestion of Sargassum fulvellum macroalgae: biomass valorization and biogas optimization under different pre-treatment conditions. J Environ Chem Eng 9:1–9. https://doi.org/10.1016/j.jece.2021.106405

Karray R, Hamza M, Sayadi S (2015) Evaluation of ultrasonic, acid, thermo-alkaline and enzymatic pre-treatments on anaerobic digestion of Ulva rigida for biogas production. Bioresour Technol 187:205–213. https://doi.org/10.1016/j.biortech.2015.03.108

Oliveira J, Alves M, Costa J (2014) Design of experiments to assess pre-treatment and co-digestion strategies that optimize biogas production from macroalgae Gracilaria vermiculophylla. Bioresour Technol 162:323–330. https://doi.org/10.1016/j.biortech.2014.03.155

Adams JMM, Schmidt A, Gallagher JA (2015) The impact of sample preparation of the macroalgae Laminaria digitata on the production of the biofuels bioethanol and biomethane. J Appl Phycol 27:985–991. https://doi.org/10.1007/s10811-014-0368-5

Milledge JJ, Nielsen BV, Sadek MS, Harvey PJ (2018) Effect of freshwater washing pretreatment on Sargassum nuticum as a feedstock for biogas production. Energies 11:1–10. https://doi.org/10.3390/en11071771

Suhartini S, Lestari YP, Nurika I (2019) Estimation of methane and electricity potential from canteen food waste. IOP Conf Ser Earth Env Sci 230(230):1–6. https://doi.org/10.1088/1755-1315/230/1/012075

Hidayat N, Suhartini S, Utami RN, Pangestuti MB (2020) Anaerobic digestion of fungally pre-treated oil palm empty fruit bunches: energy and carbon emission footprint. IOP Conf Ser Earth Environ Sci 524:1–9. https://doi.org/10.1088/1755-1315/524/1/012019

Hagos K, Zong J, Li D, Liu C, Lu X (2017) Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew Sustain Energy Rev 76:1485–1496. https://doi.org/10.1016/j.rser.2016.11.184

Suhartini S, Heaven S, Zhang Y, Banks CJ (2019) Antifoam, dilution and trace element addition as foaming control strategies in mesophilic anaerobic digestion of sugar beet pulp. Int Biodeterior Biodegrad 145:1–13. https://doi.org/10.1016/j.ibiod.2019.104812

Suhartini S, Sihaloho S, Rahmah NL, Nurika I, Junaidi MA, Paul R, Melville R (2020) Effect of pre-treatment on anaerobic biodegradability of Gracilaria verrucosa. IOP Conf Ser Earth Environ Sci 475:1–9. https://doi.org/10.1088/1755-1315/475/1/012064

APHA (2005) Standard methods for the examination of water and wastewater. American Water Works Association, Water Environment Federation. Washington, D.C.

Farina A, Piergallini R, Doldo A, Salsano EP, Abballe F (1991) The determination of C-H-N by an automated elemental analyzer. Microchem J 43:181–190. https://doi.org/10.1016/S0026-265X(10)80003-7

ASTM (1996) ASTM D2015: Standard test method for gross calorific value of solid fuel by the adiabatic bomb calorimeter. American Soc Test Mater. Washington, D.C.

Buswell AM, Mueller HF (1952) Mechanisms of methane fermentation. Ind Eng Chem 44:550–552. https://doi.org/10.1021/ie50507a033

Shi B, Lortscher P, Palfery D (2013) Algal biomass anaerobic biodegradability. J Appl Phycol 25:757–761. https://doi.org/10.1007/s10811-012-9912-3

Strömberg S, Nistor M, Liu J (2014) Toward eliminating systematic errors caused by the experimental condition in biochemical methane potential (BMP) tests. Waste Manag 34:1939–1948. https://doi.org/10.1016/j.wasman.2014.07.018

Lloyd JW, Heathcote JA (1985) Natural inorganic hydrochemistry in relation to ground water. Clarendon Press, Oxford

Suhartini S (2014) The anaerobic digestion of sugar beet pulp. Doctoral Thesis. Faculty of Engineering and the Environment, University of Southampton, Southampton, United Kingdom

Kim J, Baek G, Kim J, Lee C (2019) Energy production from different organic wastes by anaerobic co-digestion: maximizing methane yield versus maximizing synergistic effect. Renew Energy 136:683–690. https://doi.org/10.1016/j.renene.2019.01.046

Fraenkel JR, Wallen N, Hyun H (2006) Hot to design and evaluate research in education. Mc.Graw-Hill Inc, USA

Tait S, Harris PW, McCabe BK (2021) Biogas recovery by anaerobic digestion of Australian agro-industry waste: a review. J Clean Prod 229:1–16. https://doi.org/10.1016/j.jclepro.2021.126876

Lim SJ, Fox P (2013) Biochemical methane potential (BMP) test for thickened sludge using anaerobic granular sludge at different inoculum/substrate ratios. Biotechnol Bioprocess Eng 18:306–312. https://doi.org/10.1007/s12257-012-0465-8

Panichnumsin P, Nopharatana A, Ahring B, Chaiprasert P (2010) Production of methane by co-digestion of cassava pulp with various concentrations of pig manure. Biomass Bioenerg 34:1117–1124. https://doi.org/10.1016/j.biombioe.2010.02.018

Costa JC, Gonçalves PR, Nobre A, Alves MM (2012) Biomethanation potential of macroalgae Ulva spp. and Gracilaria spp. and in co-digestion with waste activated sludge. Bioresour Technol 114:320–326. https://doi.org/10.1016/j.biortech.2012.03.011

Dioha IJ, Ikeme CH, Nafi’u T, Soba NI, Yusuf MBS (2014) Effect of carbon to nitrogen ratio on biogas production. Int Res J Nat Sci 2:27–36. https://doi.org/10.1016/0141-4607(79)90011-8

Milledge J, Harvey P (2016) Ensilage and anaerobic digestion of Sargassum muticum. J Appl Phycol 28:3021–3030. https://doi.org/10.1007/s10811-016-0804-9

Tsapekos P, Alvarado-Morales M, Kougias PG, Konstantopoulos K, Angelidaki I (2019) Co-digestion of municipal waste biopulp with marine macroalgae focusing on sodium inhibition. Energy Conver Manag 180:931–937. https://doi.org/10.1016/j.enconman.2018.11.048

Zhang Y, Alam MA, Kong X, Wang Z, Li L, Sun Y, Yuan Z (2017) Effect of salinity on the microbial community and performance on anaerobic digestion of marine macroalgae. J Chem Technol Biotechnol 92:2392–2399. https://doi.org/10.1002/jctb.5246

Oliveira J, Alves M, Costa J (2015) Optimization of biogas production from Sargassum sp. using a design of experiments to assess the co-digestion with glycerol and waste frying oil. Bioresour Technol 175:480–485. https://doi.org/10.1016/j.biortech.2014.10.121

Kumar P, Prajapati SK, Malik A, Vijay VK (2019) Evaluation of biomethane potential of waste algal biomass collected from eutrophied lake: effect of source of inocula, co-substrate, and VS loading. J Appl Phycol 31:533–545. https://doi.org/10.1007/s10811-018-1585-0

Suhartini S, Naraswati A, Nurika I (2021) Effect of mixture ratio on co-digestion of vegetable and fruit waste with macro-algae, chicken manure and tofu dregs. IOP Conf Ser Earth Environ Sci 733:1–9. https://doi.org/10.1088/1755-1315/733/1/012140

Elalami D, Monlau F, Carrere H, Abdelouahdi K, Charbonnel C, Oukarroum A, Zeroual Y, Barakat A (2020) Evaluation of agronomic properties of digestate from macroalgal residues anaerobic digestion: impact of pretreatment and co-digestion with waste activated sludge. Waste Manag Res 108:127–136. https://doi.org/10.1016/j.wasman.2020.04.019

Sun H, Kovalovszki A, Tsapekos P, Alvarado-Morales M, Rudatis A, Wu S, Dong R, Kougias P, Angelidaki I (2019) Co-digestion of Laminaria digitata with cattle manure: a unimodel simulation study of both batch and continuous experiments. Bioresour Technol 276:361–368. https://doi.org/10.1016/j.biortech.2018.12.110

Rodriguez C, Alaswad A, El-Hassan Z, Olabi AG (2018) Waste paper and macroalgae co-digestion effect on methane production. Energy 154:119–125. https://doi.org/10.1016/j.energy.2018.04.115

Cogan M, Antizar-Ladislao B (2016) The ability of macroalgae to stabilise and optimise the anaerobic digestion of household food waste. Biomass Bioenerg 86:146–155. https://doi.org/10.1016/j.biombioe.2016.01.021

Gu J (2016) Biodegradation testing: so many tests but very little new innovation. Appl Environ Biotechnol 1:92–95. https://doi.org/10.26789/AEB.2016.01.007

Li Y, Liu L, Wang Q, Wu J, Liu T, Liu H, Hong Y, Huang T (2021) Enhanced anaerobic co-metabolism of coal gasification wastewater via the assistance of zero-valent iron. J Water Process Eng 40:1–10. https://doi.org/10.1016/j.jwpe.2020.101817

Jin W, Xu X, Yang F, Li C, Zhou M (2018) Performance enhancement by rumen cultures in anaerobic co-digestion of corn straw with pig manure. Biomass Bioenerg 15:120–129. https://doi.org/10.1016/j.biombioe.2018.05.001

Chen Y, He J, Wang YQ, Kotsopoulos TA, Kaparaju P, Zeng RJ (2016) Development of an anaerobic co-metabolic model for degradation of phenol, m-cresol and easily degradable substrate. Biochem Eng J 106:19–25. https://doi.org/10.1016/j.bej.2015.11.003

Zhang C, Su H, Baeyens J, Tan T (2014) Reviewing the anaerobic digestion of food waste for biogas production. Renew Sustain Energy Rev 38:383–392. https://doi.org/10.1016/j.rser.2014.05.038

Ahmadi-Pirlou M, Ebrahimi-Nik M, Khojastehpour M, Ebrahimi SH (2017) Mesophilic co-digestion of municipal solid waste and sewage sludge: effect of mixing ratio, total solids, and alkaline pretreatment. Int Biodeterior Biodegradation 125:97–104. https://doi.org/10.1016/j.ibiod.2017.09.004

Abbassi-Guendouz A, Brockmann D, Trably E, Dumas C, Delgenès JP, Steyer JP, Escudié R (2012) Total solids content drives high solid anaerobic digestion via mass transfer limitation. Bioresour Technol 111:56–61. https://doi.org/10.1016/j.biortech.2012.01.174

Pan Y, Zhi Z, Zhen G, Lu X, Bakonyi P, Li YY, Zhao Y, Banu JR (2019) Synergistic effect and biodegradation kinetics of sewage sludge and food waste mesophilic anaerobic co-digestion and the underlying stimulation mechanisms. Fuel 253:40–49. https://doi.org/10.1016/j.fuel.2019.04.084

Tabassum MR, Xia A, Murphy JD (2016) The effect of seasonal variation on biomethane production from seaweed and on application as a gaseous transport biofuel. Bioresour Technol 209:213–219. https://doi.org/10.1016/j.biortech.2016.02.120

Gelegenis J, Georgakakis D, Angelidaki I, Mavris V (2007) Optimization of biogas production by co-digesting whey with diluted poultry manure. Renew Energy 32:2147–2160. https://doi.org/10.1016/j.renene.2006.11.015

Alburquerque JA, De la Fuente C, Campoy M, Carrasco L, Nájera I, Baixauli C, Caravaca F, Roldán A, Cegarra J, Bernal M (2012) Agricultural use of digestate for horticultural crop production and improvement of soil properties. Eur J Agron 43:119–128. https://doi.org/10.1016/j.eja.2012.06.001

Prajapati SK, Kumar P, Malik A, Vijay VK (2014) Bioconversion of algae to methane and subsequent utilization of digestate for algae cultivation: a closed loop bioenergy generation process. Bioresour Technol 158:174–180. https://doi.org/10.1016/j.biortech.2014.02.023

Yuan X, Wen B, Ma X, Zhu W, Wang X, Chen S, Cui Z (2014) Enhancing the anaerobic digestion of lignocellulose of municipal solid waste using a microbial pretreatment metho. Bioresour Technol 154:1–9. https://doi.org/10.1016/j.biortech.2013.11.090

Gudka B, Jones JM, Lea-Langton AR, Williams A, Saddawi A (2016) A review of the mitigation of deposition and emission problems during biomass combustion through washing pre-treatment. J Energy Inst 89:159–171. https://doi.org/10.1016/j.joei.2015.02.007

Costa CS, Cardoso SL, Nishikawa E, Vieira MG, da Silva MG (2016) Characterization of the residue from double alginate extraction from Sargassum filipendula seaweed. Chem Eng Trans 52:133–138. https://doi.org/10.3303/CET1652023

Oliveira RC, Hammer P, Guibal E, Taulemesse JM, Garcia O Jr (2014) Characterization of metal–biomass interactions in the lanthanum (III) biosorption on Sargassum sp. using SEM/EDX, FTIR, and XPS: preliminary studies. Chem Eng J 239:381–391. https://doi.org/10.1016/j.cej.2013.11.042

P’yanova LG, Baklanova ON, Likholobov VA, Drozdov VA, Salanov AN, Talzi VP, Knyazheva OA (2013) Studies of the effect of surface modification of carbon sorbents by poly-N-vinylpyrrolidone using a complex of physicochemical and microbiological methods. Prot Met Phys Chem Surfaces 49:430–439. https://doi.org/10.1134/S2070205113040114

Pednekar PA, Raman B (2013) Antimicrobial and antioxidant potential with FTIR analysis of Ampelocissus latifolia (Roxb.) Planch. leaves. Asian J Pharm Clin Res 6:157–162

Mungasavalli DP, Viraraghavan T, Jin YC (2007) Biosorption of chromium from aqueous solutions by pretreated Aspergillus niger: batch and column studies. Colloids Surfaces A Physicochem Eng Asp 301:214–223. https://doi.org/10.1016/j.colsurfa.2006.12.060

Michalak I, Mironiuk M, Marycz K (2018) A comprehensive analysis of biosorption of metal ions by macroalgae using ICP-OES, SEM-EDX and FTIR techniques. PLoS One 13:e0205590. https://doi.org/10.1371/journal.pone.0205590

Darko CNS, Agyei-Tuffour B, Faloye DF, Goosen NJ, Nyankson E, Dodoo-Arhin D (2022) Biomethane production from residual algae biomass (Ecklonia maxima): effects of inoculum acclimatization on yield. Waste Biomass Valor 13: 497–509. https://doi.org/10.1007/s12649-021-01497-9

Jard G, Dumas C, Delgenès JP, Marfaing H, Sialve B, Steyer JP, Carrère H (2013) Effect of thermochemical pretreatment on the solubilization and anaerobic biodegradability of the red macroalga Palmaria palmata. Biochem Eng J 79:253–258. https://doi.org/10.1016/j.bej.2013.08.011

Pastare L, Aleksandrovs I, Lauka D, Romagnoli F (2016) Mechanical pre-treatment effect on biological methane potential from marine macro algae: results from batch tests of Fucus vesiculosus. Energy Procedia 95:351–357. https://doi.org/10.1016/j.egypro.2016.09.021

Rodriguez C, Alaswad A, Mooney J, Prescott T, Olabi AG (2015) Pre-treatment techniques used for anaerobic digestion of algae. Fuel Process Technol 138:765–779. https://doi.org/10.1016/j.fuproc.2015.06.027

Pilli S, Yan S, Tyagi RD, Surampalli R (2016) Anaerobic digestion of ultrasonicated sludge at different solids concentrations - computation of mass-energy balance and greenhouse gas emissions. J Environ Manage 166:374–386. https://doi.org/10.1016/j.jenvman.2015.10.041

Koupaie EH, Leiva MB, Eskicioglu C, Dutil C (2014) Mesophilic batch anaerobic co-digestion of fruit-juice industrial waste and municipal waste sludge: process and cost-benefit analysis. Bioresour Technol 152:66–73. https://doi.org/10.1016/j.biortech.2013.10.072

Wehner M, Lichtmannegger T, Robra S, Lopes ADCP, Ebner C, Bockreis A (2021) Determination of the dewatered digestate amounts and methane yields from the co-digestion of biowaste as a basis for a cost-benefit analysis. Waste Manag 126:632–642. https://doi.org/10.1016/j.wasman.2021.03.030

Fasahati P, Saffron C, Woo H, Liu J (2017) Potential of brown algae for sustainable electricity production through anaerobic digestion. Energy Convers Manag 135:297–307. https://doi.org/10.1016/j.enconman.2016.12.084