Abstract

Of six strains of lactic acid-producing alkaliphilic microorganisms, Halolactibacillus halophilus was most efficient. It produced the highest concentration and yield of lactic acid, with minimal amounts of acetic and formic acid when sucrose and glucose were used as substrate. Mannose and xylose were poorly utilized. In batch fermentation at 30°C, pH 9 with 4 and 8% (w/v) sucrose, lactic acid was produced at 37.7 and 65.8 g l−1, with yields of 95 and 83%, respectively. Likewise, when 4 and 8% (w/v) glucose were used, 33.4 and 59.6 g lactic acid l−1 were produced with 85 and 76% yields, respectively. l-(+)-lactic acid had an optical purity of 98.8% (from sucrose) and 98.3% (from glucose).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lactic acid is important for food, pharmaceutical, cosmetics and chemical production. The demand for it has steadily increased due to its use as raw material for the production of the biodegradable and renewable polymer, polylactic acid, to replace various petrochemical-based polymers. Lactic acid is produced either by chemical synthesis or by microbial fermentation. The latter is the more efficient producer of optically pure l- or d-isomers depending on the strain used, whereas chemical synthesis produces racemic mixture of lactic acid.

Several species of lactic acid bacteria (LAB) and some filamentous fungi can produce lactic acid (Litchfield 1996). The majority of LAB have optimum growth at pH 5.5–6.5 and are alkali intolerant. However, some alkaliphilic lactic acid-producing microorganisms are known: Marinilactibacillus psychrotolerans (Ishikawa et al. 2003), Alkalibacterium psychrotolerans (Yumoto et al. 2004), M. piezotolerans (Toffin et al. 2005), A. iburiense (Nakajima et al. 2005), Halolactibacillus halophilus (Ishikawa et al. 2005), H. miurensis (Ishikawa et al. 2005), H. alkaliphilus (Cao et al. 2008) and A. indicireducens (Yumoto et al. 2008). Nevertheless, the potential of these organisms for large scale production is uncertain. To our knowledge, this is the first attempt to explore the use of alkaliphilic microorganisms for lactic acid production.

Halolactibacillus halophilus is slightly halophilic and alkaliphilic, preferentially growing under the physicochemical conditions of seawater (Ishikawa et al. 2005). The use of this microorganism for lactic acid fermentation presents potential advantage over commonly used LAB. Its tolerance to high levels of salt and high pH values, for instance would minimize contamination problems during processing. The aim of this work is to investigate the ability of alkaliphiles, M. psychrotolerans, H. halophilus, and H. miurensis, to produce lactic acid and describe the optimum conditions for lactic acid production.

Materials and methods

Microorganisms and culture conditions

Marinilactibacillus psychrotolerans (JCM 21451, JCM 21457 and JCM 21458), M. piezotolerans (JCM 12337), H. halophilus (JCM 21694), and H. miurensis JCM 21699 were cultivated in the pre-culture medium containing (per liter) 20 g glucose, 5 g yeast extract, 10 g Bacto-peptone, 0.2 g MgSO4·7H2O, 0.005 g MnSO4·H2O, 5 g sodium acetate, 25 g NaCl. The pH was adjusted to 7.0 before sterilization at 121° C, 15 min. The buffer solution (NaHCO3/Na2CO3) was separately sterilized and added to obtain an initial pH of 9.0 in the medium.

Batch experiments were carried out in a 5 l jar fermentor with 2.5 l fermentation medium as previously described (Timbuntam et al. 2006), except for the addition of NaHCO3/Na2CO3 (100 mM) and 2.5% (w/v) NaCl. Fermentation was initiated by adding 5% (v/v) inoculum. The pH was automatically controlled at 9 by adding 25% (w/v) NaOH. The temperature and agitation were maintained at 30°C and 250 rpm, respectively. No aeration was used.

Analytical methods

Cell growth was determined as c.f.u. using the pre-culture medium agar. Fermentation products were analyzed by HPLC using UV (210 nm) and RI detectors with a Shim-pack SPR-H (G) (Shimadzu, Japan) column at 40°C and eluted with 4 mM perchloric acid at 0.6 ml min−1. HPLC analysis for residual sugar was performed on a Tosoh LC-8010 apparatus (column: Shodex Asahipak NH2P-50 4E), mobile phase, acetonitrile/H2O 75/25 (v/v) at 0.5 ml min−1, injection 0.1 ml, detection at 210 nm. The D/L ratio of produced lactic acid was analyzed using an enzymatic bioanalysis kit (Boehringer Mannheim GmbH).

Results and discussion

Among the six alkaliphiles screened for fermentation, H. halophilus produced the highest lactic acid concentration at pH 9 (P < 0.05) using 2% (w/v) glucose (Fig. 1).

Screening of alkaliphilic microorganisms for lactic acid production at different pH without pH control. Experiments were conducted in test tubes containing 10 ml pre-culture medium and 200 μl of inoculum. The tubes were statically incubated at 30°C for 24 h. M. psychrotolerans (JCM 21451, JCM 21457, and JCM 21458), H. halophilus (JCM 21694), H. miurensis (JCM 21699) and M. piezotolerans (JCM 12337). Data are means ± SD of duplicate samples

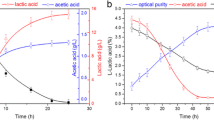

Figure 2 shows the time course of lactic acid production from sucrose, glucose, mannose and xylose at 4% (w/v). H. halophilus preferred sucrose and glucose as carbon sources, with the former being more efficiently utilized after 36 h (Fig. 2, Table 1). Lactic acid production at 3.6 and 1.7 mol for every mol of sucrose and glucose, respectively, suggests a homolactic type of fermentation mediated by H. halophilus. This strain produced l-lactic acid with high optical purity of 98.8% (from sucrose) and 98.3% (from glucose). Lactic acid production increased with increasing sucrose and glucose concentration up to 8% (w/v).

Time course of lactic acid fermentation by H. halophilus using 4% (w/v) sugars. Sugar concentration g l−1 (open circle); lactic acid g l−1 (closed triangle); acetic acid g l−1 (closed circle); formic acid g l−1 (open triangle); viable cell count c.f.u. (closed diamond). Each point represents the mean ± SD of the results of two independent experiments

However, when the concentration of these substrates was increased to 10% (w/v), viable cell count, lactic acid production and yield decreased (Fig. 3, Table 1). Bulut et al. (2004) also reported similarly. Likewise, 10% (w/v) sucrose decreased lactic acid production possibly due to the increase in medium viscosity. Furthermore, the substrates were not completely metabolized and approximately 50% of the initial sugar remained in the fermentation medium.

Mannose and xylose were poorly utilized with very low lactic acid production (Fig. 2c, d). Tanaka et al. (2002) also reported low yields from xylose. Moreover with xylose, the undesirable production of formic acid and acetic acid was as high as previously reported (Taniguchi et al. 2004).

Lactic acid production and yield using sucrose and glucose were comparable to other work using the common lactic acid bacteria: L. casei (Yoo et al. 1996), L. lactis (Akerberg et al. 1998), L. rhamnosus (Berry et al. 1999) and the fungus Rhizopus oryzae (Bulut et al. 2004). The lactic acid yield from these previous reports ranged from 79 to 90% with the l-lactic acid optical purity from 95 to 99%.

For the first time, this study has demonstrated that an alkaliphilic strain, H. halophilus, is effective for the direct production of l-lactic acid with high optical purity from sucrose and glucose.

References

Akerberg C, Hofvendahl K, Zacchi G, Hagerdal BH (1998) Modeling the influence of pH, temperature, glucose, and lactic acid concentrations on the kinetics of lactic acid production by Lactococcus lactis ssp. lactis ATCC 19435 in whole wheat flour. Appl Microbiol Biotechnol 49:682–690

Berry AR, Franco CMM, Zhang W, Middelberg APJ (1999) Growth and lactic acid production in batch culture of Lactobacillus rhamnosus in a defined medium. Biotechnol Lett 21:163–167

Bulut S, Elibol M, Ozer D (2004) Effect of different carbon sources on l (+)-lactic acid production by Rhizopus oryzae. Biochem Eng J 21:33–37

Cao SJ, Qu JH, Yang JS, Qing S, Yuan HL (2008) Halolactibacillus alkaliphilus sp.nov., a moderately alkaliphilic and halophilic bacterium isolated from a soda lake in Inner Mongolia, China, and emended description of the genus Halolactibacillus. Int J Syst Evol Microbiol 58:2169–2173

Ishikawa M, Nakajima K, Yanagi M, Yamamoto Y, Yamasato K (2003) Marinilactibacillus psychrotolerans gen. nov., sp. nov., a halophilic and alkaliphilic marine lactic acid bacterium isolated from marine organisms in temperate and subtropical areas of Japan. Int J Syst Evol Microbiol 53:711–720

Ishikawa M, Nakajima K, Itamiya Y, Furukawa S, Yamamoto Y, Yamasato K (2005) Halolactibacillus halophilus gen. nov., and Halolactibacillus miurensis sp.nov., halophilic and alkaliphilic marine lactic acid bacteria constituting a phylogenetic lineage in Bacillus rRNA group 1. Int J Syst Evol Microbiol 55:2427–2439

Litchfield JH (1996) Microbiological production of lactic acid. Adv Appl Microbiol 42:48–95

Nakajima K, Hirota K, Nodasaka Y, Yumoto I (2005) Alkalibacterium iburiense sp. nov., an obligate alkaliphile that reduces an indigo dye. Int J Syst Evol Microbiol 55:1525–1530

Tanaka K, Komiyama A, Sonomoto K, Ishizaki A, Hall SJ, Stanbury PF (2002) Two different pathway for d-xylose metabolism and the effect of xylose concentration on the yield coefficient of l-lactic acid in mixed-acid fermentation by the lactic acid bacterium Lactococcus lactis 10–1. Appl Microbiol Biotechnol 60:160–167

Taniguchi M, Tokunaga T, Horiuchi K, Hoshino K, Sakai K, Tanaka T (2004) Production of l-lactic acid from a mixture of xylose and glucose by co-cultivation of lactic acid bacteria. Appl Microbiol Biotechnol 66:160–165

Timbuntam W, Sriroth K, Tokiwa Y (2006) Lactic acid production from sugar-cane juice by a newly isolated Lactobacillus sp. Biotechnol Lett 28:811–814

Toffin L, Zink K, Kato C, Pignet P, Bidaul A, Bienvenu N, Birrien JL, Prieur D (2005) Marinilactibacillus piezotolerans sp. nov., a novel marine lactic acid bacterium isolated from deep sub-seafloor sediment of the Nankai Trough. Int J Syst Evol Microbiol 55:345–351

Yoo IK, Chang HN, Lee EG, Chang YK, Moon SH (1996) Effect of pH on the production of lactic acid and secondary product in batch cultures of Lactobacillus casei. J Microbiol Biotechnol 6:482–486

Yumoto I, Hirota K, Nodasaka Y, Yokota Y, Hoshino T, Nakajima K (2004) Alkalibacterium psychrotolerans sp. nov., a psychrotolerant obligate alkaliphile that reduces an indigo dye. Int J Syst Evol Microbiol 54:2379–2383

Yumoto I, Hirota K, Nodasaka Y, Yutaka T, Nakajima K (2008) Alkalibacterium incidireducens sp. nov., an obligate alkaliphile that reduces indigo dye. Int J Syst Evol Microbiol 58:901–905

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Calabia, B.P., Tokiwa, Y. & Aiba, S. Fermentative production of l-(+)-lactic acid by an alkaliphilic marine microorganism. Biotechnol Lett 33, 1429–1433 (2011). https://doi.org/10.1007/s10529-011-0573-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-011-0573-0