Abstract

Solid state fermentation is currently used in a range of applications including classical applications, such as enzyme or antibiotic production, recently developed products, such as bioactive compounds and organic acids, new trends regarding bioethanol and biodiesel as sources of alternative energy, and biosurfactant molecules with environmental purposes of valorising unexploited biomass. This work summarizes the diversity of applications of solid state fermentation to valorize biomass regarding alternative energy and environmental purposes. The success of applying solid state fermentation to a specific process is affected by the nature of specific microorganisms and substrates. An exhaustive number of microorganisms able to grow in a solid matrix are presented, including fungus such as Aspergillus or Penicillum for antibiotics, Rhizopus for bioactive compounds, Mortierella for biodiesel to bacteria, Bacillus for biosurfactant production, or yeast for bioethanol.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

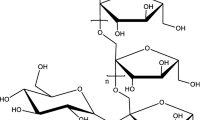

Solid state fermentation (SSF) has been described as the process that takes place in a solid matrix (inert support or support/substrate) in the absence or near absence of free water (Singhania et al. 2010), but the substrate requires moisture to support the growth and metabolic activity of microorganisms (Thomas et al. 2013). The microbiological process of SSF has generated great interest in recent years because it can be used for a variety of purposes (Thomas et al. 2013), supported by some authors who have even indicated numerous advantages over their liquid counterparts (submerged fermentation) (Singhania et al. 2009). The most important phenomenon attributed to SSF is the resistance of microorganisms (bacterial and fungal cells) to catabolic repression (inhibition of enzyme synthesis) in the presence of abundant substrates, such as glycerol, glucose or other carbon sources (Viniegra-González and Favela-Torres 2006). Another important factor is the possibility of using agro-industrial residues (A-IR) generated by current industrial processes and inclusively using unexploited biotic resources as support/substrate for metabolite production with value-added at low production costs (Bhargav et al. 2008), allowing SSF to be economically viable (Schmidt et al. 2014). Furthermore, reducing environmental problems (Rodríguez Couto 2008), such as A-IR, which may produce odour and soil pollution, represents problems for the industry (Torrado et al. 2011).

SSF was traditionally used for producing metabolites such as enzymes, antibiotics, organic acids, biosurfactants and aroma compounds; however, in reality, SSF received more attention due to the wide number of applications for metabolite production or remediation objectives that can be realized using this system (Wang et al. 2010). Currently, SSF is attracting new interest because of its wide range of applications in valorising unexploited biomass. With environmental problems being generated around the world, SSF has reached great relevance in this context because of the environmental benefits offered with the possibility of using A-IR (Thomas et al. 2013). In this way, a wide variety of applications can be achieved, such as bioremediation, production of lipids, biofuels (biodiesel, bioethanol, biobutanol, biohydrogen), aromas and flavours for the food industry, and production/extraction of bioactive compounds, among others. The aim of this work was to summarize the diversity of applications of SSF, from classical, such as enzyme or antibiotic production, to new trends regarding alternative energy, and environmental purposes, such as valorising unexploited biomass of A-IR.

Enzymes

Enzyme production by SSF has been a reference for this type of process, because of the wide variety of enzymes that can be produced, possibly at an industrial scale. The importance of SSF in enzyme production is due to the agro-industrial residues that are generally used for this purpose. Nutrients present in the substrate (A-IR) support growth and due to the natural metabolism of the microorganism, can secrete enzymes, while growing in the solid substrate (Kumar and Kanwar 2012). Indeed, authors have previously mentioned that several enzymes could be produced by the SSF system at pilot scale (He and Chen 2013) and the literature indicates a large variety of enzymes that are produced by SSF (Table 1). For enzyme production at industrial scale it is important to design reactors with control of important aspects of the process such as heat transfer and oxygen as well as moisture. Additionally, in the process design should be considered the search for the substrate and microorganism suitable for the enzyme to be produced. It is important to mention that in Japan enzymes are already produced at industrial scale using SSF (He and Chen 2013; Rodríguez Couto 2008). In addition, it can also be seen that the range of microorganisms used is very diverse in A-IR revalued for this purpose. Moreover, enzyme production by SSF has been considered the heart of biotechnology because of the importance in market sales of these molecules (Thomas et al. 2013). The market of industrial enzymes has shown gradual growth: for 1998, sales were estimated at $1 billion (Rao et al. 1998), but for 2015, they were estimated at $4.4 billion (Thomas et al. 2013). This significant progress demonstrate the importance of SSF in the enzyme market, however, it is important to note that the titers of enzyme activity expressed in SSF are higher than those expressed in submerged fermentation (SF), for example: 5000 and 1600 U l−1 for a pectinase produced by Aspergillus niger (Viniegra-González et al. 2003), 7150 and 1714 UI l−1 for a exopectinase produced by A. niger C28B25 (Diaz-Godinez et al. 2001), 30 and 8 U/g of dry substrate for a protease produced by Aspergillus oryzae (Sandhya et al. 2005), showed the importance of SSF in enzyme production.

Antibiotics

Antibiotic were traditionally produced by SF; however, some authors now indicate that production using SSF is better because fungal strains grow in near natural habitats (Vastrad et al. 2014). Furthermore, the use of A-IR is an important advantage for antibiotic production in SSF because these may serve as a source of carbon and nitrogen. Moreover, in some cases, nutrients contained in the substrate may be inductors or supplementary nutrients for such production (Adinarayana et al. 2003). To make more evident substrates used in antibiotics production by SSF, some examples are mentioned then: tetracycline by Streptomyces viridifaciens ATCC 11989 using sweet potato, rice bran, and soy meal (Yang and Ling 1989), neomycin by Streptomyces marinensis using raspberry seed powder, wheat rawa, wheat bran, rice bran (Adinarayana et al. 2003; Ellaiah et al. 2004), cephalosporin C by Acremonium chrysogenum C10 using sugarcane bagasse (Cuadra et al. 2008), meroparamycin by Streptomyces sp. MAR01 using rice, wheat bran, quaker, bread, and ground corn (El-Naggar et al. 2009), lovastatin by Penicillium funiculosum NCIM 1174 using green gram husk, black gram husk, wheat bran and orange peel (Reddy et al. 2011), rifamycin B by Amycolatopsis mediterranea MTCC14 and Nocardia mediterranei using coconut oil cake, groundnut oil cake, ground nut shell, rice husk and sunflower oil cake (Vastrad and Neelagund 2012; Vastrad et al. 2014), rifamycin SV by Amycolatopsis mediterranei OVA5-E7 using ragi bran (Nagavalli et al. 2015). The literature shows that some antibiotics have been produced historically by SSF using A-IR as a support, reflecting the importance of SSF for production of this type of metabolites.

Organic acids

The production of organic acids by SSF emerged as an alternative to SF, which due to the processes of acid production, is generally an expensive process (Kumar et al. 2003). SSF emerges as a cheap alternative because, as mentioned, it may use agro-industrial waste for the same purpose. There are many reports indicating the use of different A-IR for organic acid production, reducing production cost and environmental problems. Additionally, one important advantage of production by SSF is the feasibility and efficient extraction of acids from fermented matter (Dhillon et al. 2013). Table 2 shows variety of A-IR can be exploited for the production of organic acids, as occurs with the production of citric acid, lactic acid, gluconic and ellagic acid.

Bioactive compounds

Extraction of bioactive compounds from biotic materials has generally been realized using habitual extraction processes (solid–liquid/liquid–liquid). However, SSF has emerged as an alternative for the production/extraction of bioactive compounds (Martins et al. 2013). The implementation of SSF for extraction of bioactive compounds using microorganisms (bacteria, yeast and fungi) is a suitable alternative, due to these microorganisms being able to produce enzymes required for bioactive molecule liberation into cell walls of plants or biotic materials (e.g. pectinases, cellulases, α-amylases, xylanases, β-glucosidase, β-galactosidase, and β-hesperidinase) (Salar et al. 2012; Dey and Kuhad 2014). In the last few years, SSF has been implemented for the production/extraction of molecules with antioxidant activity, as can be seen in Table 3.

Biological control

In recent years, biological control agents has emerged as an alternative to environmental pollution caused by the excessive use of pesticides, these can be replaced by biopesticides for the control of plant pests and plant diseases (Cavalcante et al. 2008). Furthermore, generation of this type of products can be carried out by SSF as a strategy of A-IR management, impacting the environmental pollution caused by the use of pesticides and the generation of A-IR (Chen et al. 2011; Pham et al. 2010). The use of SSF for this purpose has been increasing due to some advantages compared with SF, e.g. when mycoinsecticides (conidia) are produced in SSF are more tolerant to drying and more stable during the manufacture of complex formulations compared to the conidia produced in SF (Angel-Cuapio et al. 2015). The principal advantage to produce agents of biological control by SSF is that the microorganisms used for these purposes has ability to grow on solid substrates and produce a wide range of extracellular enzymes and conidiospores important for this objective (Prakash et al. 2008). In the literature, several biological control agents produced by SSF are reported, as can be seen in the Table 4.

Lipids—biodiesel

Today with the depletion of fossil fuels and resultant environmental problems from their use, the search for renewable energy has become necessary. Furthermore, the carbon recycle period of biofuels is shorter than the carbon recycle period from fossil energy (Malilas et al. 2013). Recently, the production of biodiesel by trans-esterification of fats and lipids has received increased attention from many researchers because it can be an environmentally friendly and sustainable process (Fei et al. 2011). The problems of biodiesel production are operating costs for both the production of lipids and for the generation of biodiesel itself. In that regard, SSF has recently been considered as an alternative, due to the use of inexpensive substrates or A-IR in this process (Liu et al. 2013; Tsakona et al. 2014).

Microbial lipids have traditionally been produced using physicochemical methods operating at high temperature and pressure (Parfene et al. 2013). In some cases, SF using glucose as carbon source has been used, with the primary objective of being used for biodiesel production (Hui et al. 2010). Some reports indicate that there exist oleaginous microorganisms which can accumulate more than 20% of microbial lipids in oleaginous cells. These microorganisms may be used for lipid production in solid state fermentation, resulting in an alternative process for lipid production that is both cost effective and large scale, and that uses A-IR as a unique carbon source and energy (Liu et al. 2013). In the literature, there are several reports of lipid production using SSF (Table 5). Biodiesel production using oleaginous microorganisms is very attractive for the biofuel industry; because biodiesel may be produced using lipids and lipases produced using SSF.

On the other hand, lipases are important enzymes used for biodiesel production because processes for obtaining biofuel are less polluting than chemical catalysts, are less energy intensive, are more environmentally friendly, and have slight operating conditions (Liu et al. 2013). The main disadvantages of enzyme catalysis are the longer reaction time and the higher cost of the biocatalysts (Freire et al. 2011). In the literature, reports exist on lipase-catalysed biodiesel production; nevertheless, the processes are expensive, especially when the catalytic processes include commercial enzymes (Liu et al. 2013). The principal advantage of using lipases for biodiesel production is the feasibility of catalysing several reactions in non-aqueous media, such as that used for biofuel production (Kumar and Kanwar 2012). However, in recent years, SSF has acquired good credibility for metabolite production, including enzymes such as lipases, using cheap raw materials, such as A-IR, which lower production costs (Kumar and Kanwar 2012).

Lipases are enzymes that were traditionally produced in SF; however, in reality, some authors used SSF an alternative method because it presented some advantage over SF, such as the use of A-IR, demanding less water and energy, and easy aeration of medium, representing diminution of production cost (Coradi et al. 2013). Table 6 shows some lipases produced using SSF by different strains of microorganisms.

Bioethanol

Biofuels are important because they replace petroleum fuels. Production of bioethanol reduces consumption of crude oil and production of environmental pollution. Bioethanol can be produced from different kinds of raw materials. Bioethanol production was traditionally realized by SF; however, in recent years, some researchers have reported the feasibility of production by SSF, because with this process there is the possibility of using A-IR (Mohanty et al. 2009). The use of A-IR combined with SSF for bioethanol production is a sustainable alternative to SF (Rodríguez et al. 2010). These strategies represent efficient bioethanol production using different A-IR and yeast strains for these proposes, e.g. wheat straw (Chen et al. 2007), sweet sorghum (Yu and Tan 2008, Li et al. 2013, Molaverdi et al. 2013), Madhuca Latifolia L. (Mohanty et al. 2009), grape and sugar beet pomaces (Rodríguez et al. 2010) rice straw (Roslan et al. 2011), sugarcane bagasse (Shaibani et al. 2011), sweet potato (Swain et al. 2013) using Saccharomyces cerevisiae, carob pods using Zymomonas mobilis (Mazaheri et al. 2012), and sweet sorghum using Mucor indicus (Molaverdi et al. 2013). SSF presents some advantages for ethanol production contrasted with SF, e.g. easy operation, saving of time and energy; also cheap feedstock could be used as carbon source (Rodríguez et al. 2010). Actually SSF technology is used more frequently for ethanol production as an alternative source of energy.

Environmental applications

Biosurfactant production has been improved because it has characteristics such as biodegradability and low toxicity compared to synthetic surfactants, and it can be used in bioremediation, food emulsification and cosmetics, and has stable activity at extremes of pH, salinity and temperature (Kiran et al. 2010; Mukherjee et al. 2006; Bento et al. 2005). In addition, biosurfactants have applications in oil industries due to their capacity to produce surface tension and to disperse one system into another (Neto et al. 2008; Martins et al. 2009). Biosurfactants produced in SF are extensively used in bioremediation purposes (Bento et al. 2005), but one of the principal problems of biosurfactant production is high production costs. For this reason, it is important to use a raw material that has low cost, such as A-IR (Mukherjee et al. 2006), and low-cost culture systems, such as SSF. Although reports exist for biosurfactant production using different microorganisms such as Bacillus subtilis SPB1, and substrates such as millet in SSF (Ghribi et al. 2012), more information regarding diversified microorganisms and low-cost substrates are necessary. To go deeper into the basis or the reasons for using the SSF in environmental applications is necessary consider the next factors: (a) in a wider designation, SSF can be seen as including processes during which microorganisms are cultivated in the presence of a liquid phase at maximal substrate concentrations (Hölker and Lenz 2005), exactly the case of non-soluble substrates as hydrocarbons in non-soluble substrates as oil-spills, for example, (b) in SF, aeration and agitation could be an important economic cost (Md 2012) but in SSF this disadvantage is not present: the oxygen transfer from the gas phase are directly in contact with biomass and the bioprocess do not depends of the very low solubility of oxygen in water (less than 10 mg l−1), and (c) biosurfactants can be produced from very cheap raw materials which are available in large quantities (Md 2012), exactly the case of biomass proceeding of agro-industrial wastes.

Conclusion

Solid state fermentation is currently used in an important range of applications, including classical applications such as enzyme or antibiotic production, recently developed applications such as production of bioactive compounds and organic acids, and new applications regarding bioethanol and biodiesel as sources of alternative energy, biosurfactant molecules with environmental purposes, and biological control as an environmental alternative. The success of applying solid state fermentation to a specific process must take into account the nature of specific microorganisms or specific strains, due to specificity representing an important constraint in solid state fermentation systems, particularly in new trends as biosurfactants with environmental purposes. The SSF an alternative processes for produce some products with industrial interest valorising unexploited biomass.

References

Abbasi H, Mortazavipour SR, Setudeh M (2011) Polygalacturonase (PG) production by fungal strains using agro-industrial bioproduct in solid state fermentation. Chem Eng Res Bull 15(1):1–5. doi:10.3329/cerb.v15i1.6368

Adinarayana K, Ellaiah P, Srinivasulu B, Devi RB, Adinarayana G (2003) Response surface methodological approach to optimize the nutritional parameters for neomycin production by Streptomyces marinensis under solid-state fermentation. Process Biochem 38(11):1565–1572. doi:10.1016/S0032-9592(03)00057-8

Ajila CM, Brar SK, Verma M, Tyagi RD, Valéro JR (2011) Solid-state fermentation of apple pomace using Phanerocheate chrysosporium—liberation and extraction of phenolic antioxidants. Food Chem 126(3):1071–1080. doi:10.1016/j.foodchem.2010.11.129

Angel-Cuapio A, Figueroa-Montero A, Favela-Torres E, Viniegra-González G, Perraud-Gaime I, Loera O (2015) Critical values of porosity in rice cultures of Isaria fumosorosea by adding water hyacinth: effect on conidial yields and quality. Appl Biochem Biotechnol 177(2):446–457. doi:10.1007/s12010-015-1754-4

Bento FM, de Oliveira CFA, Okeke BC, Frankenberger WT (2005) Diversity of biosurfactant producing microorganisms isolated from soils contaminated with diesel oil. Microbiol Res 160:249–255. doi:10.1016/j.micres.2004.08.005

Bhargav S, Panda BP, Ali M, Javed S (2008) Solid-state fermentation: an overview. Chem Biochem Eng 22(1):49–70

Buenrostro-Figueroa J, Ascacio-Valdés A, Sepúlveda L, De la Cruz R, Prado-Barragán A, Aguilar-González MA, Aguilar CN (2014) Potential use of different agroindustrial by-products as supports for fungal ellagitannase production under solid-state fermentation. Food Bioprod Process 92(4):376–382. doi:10.1016/j.fbp.2013.08.010

Cavalcante RS, Lima HL, Pinto GA, Gava CA, Rodrigues S (2008) Effect of moisture on Trichoderma conidia production on corn and wheat bran by solid state fermentation. Food Bioprocess Technol 1(1):100–104. doi:10.1007/s11947-007-0034-x

Cheirsilp B, Kitcha S (2015) Solid state fermentation by cellulolytic oleaginous fungi for direct conversion of lignocellulosic biomass into lipids: fed-batch and repeated-batch fermentations. Ind Crop Prod 66:73–80. doi:10.1016/j.indcrop.2014.12.035

Chen HZ, Xu J, Li ZH (2007) Temperature cycling to improve the ethanol production with solid state simultaneous saccharification and fermentation. Appl Biochem Microbiol 43(1):57–60. doi:10.1134/S0003683807010103

Chen L, Yang X, Raza W, Luo J, Zhang F, Shen Q (2011) Solid-state fermentation of agro-industrial wastes to produce bioorganic fertilizer for the biocontrol of Fusarium wilt of cucumber in continuously cropped soil. Bioresour Technol 102(4):3900–3910. doi:10.1016/j.biortech.2010.11.126

Coradi G, Da Visitação V, De Lima EA, Saito L, Palmieri D, Takita M, De Lima V (2013) Comparing submerged and solid-state fermentation of agro-industrial residues for the production and characterization of lipase by Trichoderma harzianum. Ann Microbiol 63(2):533–540. doi:10.1007/s13213-012-0500-1

Cuadra T, Fernandez FJ, Tomasini A, Barrios-González J (2008) Influence of pH regulation and nutrient content on cephalosporin C production in solid-state fermentation by Acremonium chrysogenum C10. Lett Appl Microbiol 46(2):216–220. doi:10.1111/j.1472-765X.2007.02285.x

Dey TB, Kuhad RC (2014) Enhanced production and extraction of phenolic compounds from wheat by solid-state fermentation with Rhizopus oryzae RCK2012. Biotechnol Rep 4:120–127. doi:10.1016/j.btre.2014.09.006

Dhillon GS, Brar SK, Kaur S, Verma M (2013) Bioproduction and extraction optimization of citric acid from Aspergillus niger by rotating drum type solid-state bioreactor. Ind Crop Prod 41:78–84. doi:10.1016/j.indcrop.2012.04.001

Diaz-Godinez G, Soriano-Santos J, Augur C, Viniegra-González G (2001) Exopectinases produced by Aspergillus niger in solid-state and submerged fermentation: a comparative study. J Ind Microbiol Biotechnol 26(5):271–275. doi:10.1038/sj.jim.7000113

Economou CN, Makri A, Aggelis G, Pavlou S, Vayenas DV (2010) Semi-solid state fermentation of sweet sorghum for the biotechnological production of single cell oil. Bioresour Technol 101(4):1385–1388. doi:10.1016/j.biortech.2009.09.028

Economou CN, Aggelis G, Pavlou S, Vayenas DV (2011) Single cell oil production from rice hulls hydrolysate. Bioresour Technol 102(20):9737–9742. doi:10.1016/j.biortech.2011.08.025

Ellaiah P, Srinivasulu B, Adinarayana K (2004) Optimisation studies on neomycin production by a mutant strain of Streptomyces marinensis in solid state fermentation. Process Biochem 39(5):529–534. doi:10.1016/S0032-9592(02)00059-6

El-Naggar MY, El-Assar SA, Abdul-Gawad SM (2009) Solid-state fermentation for the production of meroparamycin by Streptomyces sp. strain MAR01. J Microbiol Biotechnol 19(5):468–473. doi:10.4014/jmb.0807.457

Fakas S, Makri A, Mavromati M, Tselepi M, Aggelis G (2009) Fatty acid composition in lipid fractions lengthwise the mycelium of Mortierella isabellina and lipid production by solid state fermentation. Bioresour Technol 100(23):6118–6120. doi:10.1016/j.biortech.2009.06.015

Fei Q, Chang HN, Shang L (2011) Exploring low-cost carbon sources for microbial lipids production by fed-batch cultivation of Cryptococcus albidus. Biotechnol Bioprocess Eng 16(3):482–487. doi:10.1007/s12257-010-0370-y

Fleuri LF, de Oliveira MC, Arcuri MDLC, Capoville BL, Pereira MS, Delgado CHO, Novelli PK (2014) Production of fungal lipases using wheat bran and soybean bran and incorporation of sugarcane bagasse as a co-substrate in solid-state fermentation. Food Sci Biotechnol 23(4):1199–1205. doi:10.1007/s10068-014-0164-7

Freire DG, Sousa JS, Cavalcanti-Oliveira ED (2011) Biotechnological methods to produce biodiesel. In: Pandey A, Larroche C, Ricke SC, Dussap C-G, Gnansounou E (eds) Biofuels—alternative feedstocks and conversion processes. Elsevier, New York, pp 319–337

Ghribi D, Abdelkefi-Mesrati L, Mnif I, Kammoun R, Ayadi I, Saadaoui I, Chaabouni-Ellouze S (2012) Investigation of antimicrobial activity and statistical optimization of Bacillus subtilis SPB1 biosurfactant production in solid-state fermentation. Biomed Res Int. doi:10.1155/2012/373682

Hariharan S, Nambisan P (2012) Optimization of lignin peroxidase, manganese peroxidase, and Lac production from Ganoderma lucidum under solid state fermentation of pineapple leaf. BioRes 8(1):250–271

He Q, Chen H (2013) Pilot-scale gas double-dynamic solid-state fermentation for the production of industrial enzymes. Food Bioprocess Technol 6(10):2916–2924. doi:10.1007/s11947-012-0956-9

Hölker U, Lenz J (2005) Solid-state fermentation—are there any biotechnological advantages? Curr Opin Microbiol 8(3):301–306. doi:10.1016/j.mib.2005.04.006

Hui L, Wan C, Hai-Tao D, Xue-Jiao C, Qi-Fa Z, Yu-Hua Z (2010) Direct microbial conversion of wheat straw into lipid by a cellulolytic fungus of Aspergillus oryzae A-4 in solid-state fermentation. Bioresour Technol 101(19):7556–7562. doi:10.1016/j.biortech.2010.04.027

Imtiaz S, Mukhtar H (2013) Production of alkaline protease by Bacillus subtilis using solid state fermentation. Afr J Microbiol Res 7(16):1558–1568. doi:10.5897/AJMR12.1845

Jangbua P, Laoteng K, Kitsubun P, Nopharatana M, Tongta A (2009) Gamma-linolenic acid production of Mucor rouxii by solid-state fermentation using agricultural by-products. Lett Appl Microbiol 49(1):91–97. doi:10.1111/j.1472-765X.2009.02624.x

John RP, Nampoothiri KM, Pandey A (2006) Solid-state fermentation for l-lactic acid production from agro wastes using Lactobacillus delbrueckii. Process Biochem 41(4):759–763. doi:10.1016/j.procbio.2005.09.013

Kim JS, Kassa A, Skinner M, Hata T, Parker BL (2011) Production of thermotolerant entomopathogenic fungal conidia on millet grain. J Ind Microbiol Biot 38(6):697–704. doi:10.1007/s10295-010-0850-2

Kim JJ, Xie L, Han JH, Lee SY (2014) Influence of additives on the yield and pathogenicity of conidia produced by solid state cultivation of an Isaria javanica isolate. Mycobiology 42(4):346–352. doi:10.5941/MYCO.2014.42.4.346

Kiran GS, Thomas TA, Selvin J, Sabarathnam B, Lipton AP (2010) Optimization and characterization of a new lipopeptide biosurfactant produced by marine Brevibacterium aureum MSA13 in solid state culture. Bioresour Technol 101(7):2389–2396. doi:10.1016/j.biortech.2009.11.023

Kuhar F, Castiglia V, Levin L (2015) Enhancement of laccase production and malachite green decolorization by co-culturing Ganoderma lucidum and Trametes versicolor in solid-state fermentation. Int Biodeterior Biodegrad 104:238–243. doi:10.1016/j.ibiod.2015.06.017

Kumar A, Kanwar SS (2012) Lipase production in solid-state fermentation (SSF): recent developments and biotechnological applications. Dyn Biochem, Process Biotechnol Mol Biol 6(1):13–27

Kumar D, Jain VK, Shanker G, Srivastava A (2003) Utilisation of fruits waste for citric acid production by solid state fermentation. Process Biochem 38(12):1725–1729. doi:10.1016/S0032-9592(02)00253-4

Kumar D, Verma R, Bhalla TC (2010) Citric acid production by Aspergillus niger van. Tieghem MTCC 281 using waste apple pomace as a substrate. J Food Sci Technol 47(4):458–460. doi:10.1007/s13197-010-0077-2

Li S, Li G, Zhang L, Zhou Z, Han B, Hou W, Li T (2013) A demonstration study of ethanol production from sweet sorghum stems with advanced solid state fermentation technology. Appl Energy 102:260–265. doi:10.1016/j.apenergy.2012.09.060

Liu Y, Li C, Meng X, Yan Y (2013) Biodiesel synthesis directly catalyzed by the fermented solid of Burkholderia cenocepacia via solid state fermentation. Fuel Process Technol 106:303–309. doi:10.1016/j.fuproc.2012.08.013

Malilas W, Kang SW, Kim SB, Yoo HY, Chulalaksananukul W, Kim SW (2013) Lipase from Penicillium camembertii KCCM 11268: optimization of solid state fermentation and application to biodiesel production. Korean J Chem Eng 30(2):405–412. doi:10.1007/s11814-012-0132-y

Martins VG, Kalil SJ, Costa JAV (2009) In situ bioremediation using biosurfactant produced by solid state fermentation. World J Microbiol Biotech 25(5):843–851. doi:10.1007/s11274-009-9955-z

Martins S, Teixeira JA, Mussatto SI (2013) Solid-state fermentation as a strategy to improve the bioactive compounds recovery from Larrea tridentata leaves. Appl Biochem Biotechnol 171(5):1227–1239. doi:10.1007/s12010-013-0222-2

Mazaheri D, Shojaosadati SA, Mousavi SM, Hejazi P, Saharkhiz S (2012) Bioethanol production from carob pods by solid-state fermentation with Zymomonas mobilis. Appl Energy 99:372–378. doi:10.1016/j.apenergy.2012.05.045

McKinney K, Combs J, Becker P, Humphries A, Filer K, Vriesekoop F (2015) Optimization of phytase production from Escherichia coli by altering solid-state fermentation conditions. Ferment 1(1):13–23. doi:10.3390/fermentation1010013

Md F (2012) Biosurfactant: production and application. J Pet Environ Biotechnol 3(124):2

Mendoza-Cal A, Cuevas-Glory L, Lizama-Uc G, Ortiz-Vázquez E (2010) Naringinase production from filamentous fungi using grapefruit rind in solid state fermentation. Afr J Microbiol Res 4(19):1964–1969

Mohanty SK, Behera S, Swain MR, Ray RC (2009) Bioethanol production from mahula (Madhuca latifolia L.) flowers by solid-state fermentation. Appl Energy 86(5):640–644. doi:10.1016/j.apenergy.2008.08.022

Molaverdi M, Karimi K, Khanahmadi M, Goshadrou A (2013) Enhanced sweet sorghum stalk to ethanol by fungus Mucor indicus using solid state fermentation followed by simultaneous saccharification and fermentation. Ind Crop Prod 49:580–585. doi:10.1016/j.indcrop.2013.06.024

Mukherjee S, Das P, Sen R (2006) Towards commercial production of microbial surfactants. Trends Biotechnol 24(11):509–515. doi:10.1016/j.tibtech.2006.09.005

Nagavalli M, Ponamgi SPD, Girijashankar V, Venkateswar Rao L (2015) Solid state fermentation and production of rifamycin SV using Amycolatopsis mediterranei. Lett Appl Microbiol 60(1):44–51. doi:10.1111/lam.12332

Naveena BJ, Altaf M, Bhadriah K, Reddy G (2005) Selection of medium components by Plackett–Burman design for production of l (+) lactic acid by Lactobacillus amylophilus GV6 in SSF using wheat bran. Bioresource Technol 96(4):485–490. doi:10.1016/j.biortech.2004.05.020

Neto DC, Meira JA, de Araújo JM, Mitchell DA, Krieger N (2008) Optimization of the production of rhamnolipids by Pseudomonas aeruginosa UFPEDA 614 in solid-state culture. Appl Microbiol Biotechnol 81(3):441. doi:10.1007/s00253-008-1663-3

Özdemir S, Matpan F, Okumus V, Dündar A, Ulutas MS, Kumru M (2012) Isolation of a thermophilic Anoxybacillus flavithermus sp. nov. and production of thermostable α-amylase under solid-state fermentation (SSF). Ann Microbiol 62(4):1367–1375. doi:10.1007/s13213-011-0385-4

Parfene G, Horincar V, Tyagi AK, Malik A, Bahrim G (2013) Production of medium chain saturated fatty acids with enhanced antimicrobial activity from crude coconut fat by solid state cultivation of Yarrowia lipolytica. Food Chem 136(3):1345–1349. doi:10.1016/j.foodchem.2012.09.057

Pham TA, Kim JJ, Kim K (2010) Optimization of solid-state fermentation for improved conidia production of Beauveria bassiana as a mycoinsecticide. Mycobiology 38(2):137–143

Prakash GB, Padmaja V, Kiran RS (2008) Statistical optimization of process variables for the large-scale production of Metarhizium anisopliae conidiospores in solid-state fermentation. Bioresour Technol 99(6):1530–1537. doi:10.1016/j.biortech.2007.04.031

Qi B, Yao R (2007) l-lactic acid production from Lactobacillus casei by solid state fermentation using rice straw. BioResources 2(3):419–429

Rao MB, Tanksale AM, Ghatge MS, Deshpande VV (1998) Molecular and biotechnological aspects of microbial proteases. Microbiol Mol Biol R 62(3):597–635

Reddy DSR, Latha DP, Latha KPJ (2011) Production of lovastatin by solid state fermentation by Penicillium funiculosum NCIM 1174. Drug Invent Today 3(6):75–77

Robledo A, Aguilera-Carbó A, Rodríguez R, Martínez JL, Garza Y, Aguilar CN (2008) Ellagic acid production by Aspergillus niger in solid state fermentation of pomegranate residues. J Ind Microbiol Biotechnol 35(6):507–513. doi:10.1007/s10295-008-0309-x

Rodríguez Couto S (2008) Exploitation of biological wastes for the production of value-added products under solid-state fermentation conditions. Biotechnol J 3(7):859–870. doi:10.1002/biot.200800031

Rodríguez LA, Toro ME, Vazquez F, Correa-Daneri ML, Gouiric SC, Vallejo MD (2010) Bioethanol production from grape and sugar beet pomaces by solid-state fermentation. Int J Hyd Energy 35(11):5914–5917. doi:10.1016/j.ijhydene.2009.12.112

Roslan AM, Yee PL, Shah UKM, Aziz SA, Hassan MA (2011) Production of bioethanol from rice straw using cellulase by local Aspergillus sp. Int J Agric Res 6(2):188–193. doi:10.3923/ijar.2011.188.193

Sahoo RK, Subudhi E, Kumar M (2014) Quantitative approach to track lipase producing Pseudomonas sp. S1 in nonsterilized solid state fermentation. Lett Appl Microbiol 58(6):610–616. doi:10.1111/lam.12235

Salar RK, Certik M, Brezova V (2012) Modulation of phenolic content and antioxidant activity of maize by solid state fermentation with Thamnidium elegans CCF 1456. Biotechnol Bioprocess Eng 17(1):109–116. doi:10.1007/s12257-011-0455-2

Sandhya C, Sumantha A, Szakacs G, Pandey A (2005) Comparative evaluation of neutral protease production by Aspergillus oryzae in submerged and solid-state fermentation. Process Biochem 40(8):2689–2694. doi:10.1016/j.procbio.2004.12.001

Santa HSD, Santa ORD, Brand D, Vandenberghe LPS, Soccol CR (2005) Spore production of Beauveria bassiana from agro-industrial residues. Braz Arch Biol Techn 48:51–60. doi:10.1590/S1516-89132005000400007

Saratale GD, Kshirsagar SD, Sampange VT, Saratale RG, Oh SE, Govindwar SP, Oh MK (2014) Cellulolytic enzymes production by utilizing agricultural wastes under solid state fermentation and its application for biohydrogen production. Appl Biochem Biotechnol 174(8):2801–2817. doi:10.1007/s12010-014-1227-1

Schmidt CG, Gonçalves LM, Prietto L, Hackbart HS, Furlong EB (2014) Antioxidant activity and enzyme inhibition of phenolic acids from fermented rice bran with fungus Rizhopus oryzae. Food Chem 146:371–377. doi:10.1016/j.foodchem.2013.09.101

Sepúlveda L, Aguilera-Carbó A, Ascacio-Valdés JA, Rodríguez-Herrera R, Martínez-Hernández JL, Aguilar CN (2012) Optimization of ellagic acid accumulation by Aspergillus niger GH1 in solid state culture using pomegranate shell powder as a support. Process Biochem 47(12):2199–2203. doi:10.1016/j.procbio.2012.08.013

Shaibani N, Ghazvini S, Andalibi MR, Yaghmaei S (2011) Ethanol production from sugarcane bagasse by means of enzymes produced by solid state fermentation method. World Acad Sci Eng Technol 59:1836–1839

Sharma A, Vivekanand V, Singh RP (2008) Solid-state fermentation for gluconic acid production from sugarcane molasses by Aspergillus niger ARNU-4 employing tea waste as the novel solid support. Bioresour Technol 99(9):3444–3450. doi:10.1016/j.biortech.2007.08.006

Singh OV, Jain RK, Singh RP (2003) Gluconic acid production under varying fermentation conditions by Aspergillus niger. J ChemTechnol Biotechnol 78(2–3):208–212. doi:10.1002/jctb.748

Singhania RR, Patel AK, Soccol CR, Pandey A (2009) Recent advances in solid-state fermentation. Biochem Eng J 44(1):13–18. doi:10.1016/j.bej.2008.10.019

Singhania RR, Sukumaran RK, Patel AK, Larroche C, Pandey A (2010) Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme Microb Technol 46(7):541–549. doi:10.1016/j.enzmictec.2010.03.010

Soares D, da Silva Serres JD, Corazza ML, Mitchell DA, Gonçalves AG, Krieger N (2015) Analysis of multiphasic behavior during the ethyl esterification of fatty acids catalyzed by a fermented solid with lipolytic activity in a packed-bed bioreactor in a closed-loop batch system. Fuel 159:364–372. doi:10.1016/j.fuel.2015.06.087

Swain MR, Mishra J, Thatoi H (2013) Bioethanol production from sweet potato (Ipomoea batatas L.) flour using co-culture of Trichoderma sp. and Saccharomyces cerevisiae in solid-state fermentation. Braz Arch Biol Technol 56(2):171–179. doi:10.1590/S1516-89132013000200002

Tarocco F, Lecuona RE, Couto AS, Arcas JA (2005) Optimization of erythritol and glycerol accumulation in conidia of Beauveria bassiana by solid-state fermentation, using response surface methodology. Appl Microbiol Biotechnol 68(4):481–488. doi:10.1007/s00253-005-1901-x

Thomas L, Larroche C, Pandey A (2013) Current developments in solid-state fermentation. Biochem Eng J 81:146–161. doi:10.1016/j.bej.2013.10.013

Torino MI, Limón RI, Martínez-Villaluenga C, Mäkinen S, Pihlanto A, Vidal-Valverde C, Frias J (2013) Antioxidant and antihypertensive properties of liquid and solid state fermented lentils. Food Chem 136(2):1030–1037. doi:10.1016/j.foodchem.2012.09.015

Torrado AM, Cortés S, Salgado JM, Max B, Rodríguez N, Bibbins BP, Domínguez JM (2011) Citric acid production from orange peel wastes by solid-state fermentation. Braz J Microbiol 42(1):394–409. doi:10.1590/S1517-83822011000100049

Toscano L, Montero G, Stoytcheva M, Gochev V, Cervantes L, Campbell H, Gil-Samaniego M (2013) Lipase production through solid-state fermentation using agro-industrial residues as substrates and newly isolated fungal strains. Biotechnol Biotechnol Eq 27(5):4074–4077. doi:10.5504/BBEQ.2012.0145

Tsakona S, Kopsahelis N, Chatzifragkou A, Papanikolaou S, Kookos IK, Koutinas AA (2014) Formulation of fermentation media from flour-rich waste streams for microbial lipid production by Lipomyces starkeyi. J Biotechnol 189:36–45. doi:10.1016/j.jbiotec.2014.08.011

Vastrad BM, Neelagund SE (2012) Optimization of process parameters for rifamycin b production under solid state fermentation from Amycolatopsis mediterranean MTCC14. Int J Curr Pharm Res 4(2):101–108

Vastrad BM, Neelagund SE, Iiger SR, Godbole AM, Kulkarni V (2014) Improved rifamycin B production by Nocardia mediterranei MTCC 14 under solid-state fermentation through process optimization. Biochem Res Int. doi:10.1155/2014/621309

Venkatesagowda B, Ponugupaty E, Barbosa AM, Dekker RF (2015) Solid-state fermentation of coconut kernel-cake as substrate for the production of lipases by the coconut kernel-associated fungus Lasiodiplodia theobromae VBE-1. Ann Microbiol 65(1):129–142. doi:10.1007/s13213-014-0844-9

Viniegra-González G, Favela-Torres E (2006) Why solid-state fermentation seems to be resistant to catabolite repression? Food Technol Biotechnol 44(3):397–406

Wang EQ, Li SZ, Tao L, Geng X, Li TC (2010) Modeling of rotating drum bioreactor for anaerobic solid-state fermentation. Appl Energy 87(9):2839–2845. doi:10.1016/j.apenergy.2009.05.032

Xiao Y, Xing G, Rui X, Li W, Chen X, Jiang M, Dong M (2014) Enhancement of the antioxidant capacity of chickpeas by solid state fermentation with Cordyceps militaris SN-18. J Funct Foods 10:210–222. doi:10.1016/j.jff.2014.06.008

Yadegary M, Hamidi A, Alavi SA, Khodaverdi E, Yahaghi H, Sattari S, Yahaghi E (2013) Citric acid production from sugarcane bagasse through solid state fermentation method using Aspergillus niger mold and optimization of citric acid production by Taguchi method. Jundishapur J Microbiol 6(9):e7625. doi:10.5812/jjm.7625

Yang SS, Ling MY (1989) Tetracycline production with sweet potato residue by solid state fermentation. Biotechnol Bioeng 33(8):1021–1028. doi:10.1002/bit.260330811

Yu J, Tan T (2008) Ethanol production by solid state fermentation of sweet sorghum using thermotolerant yeast strain. Fuel Process Technol 89(11):1056–1059. doi:10.1016/j.fuproc.2008.04.008

Zhang J, Hu B (2012) Solid-state fermentation of Mortierella isabellina for lipid production from soybean hull. Appl Biochem Biotechnol 166(4):1034–1046. doi:10.1007/s12010-011-9491-9

Zhihui BAI, Bo JIN, Yuejie I, Jian CHEN, Zuming LI (2008) Utilization of winery wastes for Trichoderma viride biocontrol agent production by solid state fermentation. J Environ Sci 20(3):353–358. doi:10.1016/S1001-0742(08)60055-8

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest in the publication.

Rights and permissions

About this article

Cite this article

Lizardi-Jiménez, M.A., Hernández-Martínez, R. Solid state fermentation (SSF): diversity of applications to valorize waste and biomass. 3 Biotech 7, 44 (2017). https://doi.org/10.1007/s13205-017-0692-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0692-y