Abstract

Development of fermented flavour during storage reduces acceptability of Shughri pear. Therefore, the current study was designed to investigate the combined effect of 1-Methylcyclopropene (1-MCP) and hypobaric treatment on stability of Shughri pear during 120 days of storage. Fruit were treated individually or combinedly with 25, 50, and 75 kilo pascal hypobaric treatments for 4 h and 1-MCP (0.3 μLL−1 and 0.6 μLL−1) for 24 h, whereas control received no treatment. The pears were stored for 120 days at (0 ± 1 °C, 85 ± 5% RH), and were evaluated after every 30 days. After cold storage, pears were shifted to simulated retail conditions (20 ± 3 °C, 65 ± 5% RH). The combination of 25 kPa + 0.6 μLL−1 1-MCP significantly (P ≤ 0.05) delayed fruit ripening, reduced Alcohol dehydrogenase (ADH), and Pyruvate decarboxylase (PDC) activities, maintained the quality, and led to higher consumers’ acceptability of the pear followed by 50 kPa + 0.6 μLL−1 and 25 kPa + 0.3 μLL−1. The control fruit were marketable for a week after storage with relatively less acceptability due to fermented flavour compared to treated fruit, marketable for more than two weeks. Among all the treatments, the synergy of 1-MCP and hypobaric treatment 25 kPa + 0.6 μLL−1 1-MCP improved the postharvest storage life and quality parameters, preventing development of fermented flavour in the pears. The experiment was conducted on pilot scale, for commercial application, the results of this study should be validated on large scale.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pear (Pyrus communis L) is one of the most grown fruits in temperate regions of the world. Although there are almost 5000 varieties of pear, only 30 varieties are actively cultivated throughout the world (Abbas et al. 2018). Apart from providing a pleasant flavour, pear contains certain bioactive compounds that help in reducing cardiovascular diseases, diabetes, metabolic syndrome, and various form of cancer (Liaudanskas et al. 2017). Due to Pakistan's versatile climate, a wide diversity of fruits are grown, such as apple, apricot, cherry, mango, peach, and pear (Abbas et al. 2018). Among these fruits, pears are mostly grown in temperate regions of Khyber Pakhtunkhwa and Gilgit Baltistan provinces and ranked as the second grown fruit after apple in these areas. Pears are often consumed fresh or used in the preparation of processed foods like jam, jellies, and puree. ‘Shughri’ is mostly preferred among different pear varieties for its pleasant aroma, juiciness, and delicious taste (Abbas et al. 2018). Pears with better sensory attributes are often purchased at a premium price by consumers. However, long-term storage of the pears leads to shortened shelf life due to the development of fermented flavour that negatively impacts consumers' acceptability (Escribano et al. 2016). During storage period, an increase in the activities of Alcohol dehydrogenase (ADH) and Pyruvate decarboxylase (PDC) occur resulting in higher ethanol and acetaldehyde production, which are the key contributors to the fermented flavour in pear and other fruits (Shu et al. 2020). Consumers’ acceptability of Shughri pear is commonly affected due to the development of fermented flavour. Furthermore, higher ethylene production causes fast yellowing and softening that decrease the postharvest life of the pears (Saquet and Streif 2017).

Inspite of the development of different modern storage facilities, postharvest losses are still in the range of 10‒30%, however, recently 1-MCP has proved effective as a postharvest treatment in extending the shelf life of different pear varieties and other climacteric fruits (Li et al. 2020; Tomala et al. 2020). 1-MCP binds to ethylene receptors irreversibly and delay ethylene-regulated ripening (Liguori et al. 2017; Almeida et al. 2016). Compared to ethylene, the affinity of 1-MCP to ethylene receptors is ten times greater (Guan et al. 2015). Moreover, effectiveness at low temperature, non-toxic, negligible residues, and application in gaseous form has attracted researchers to use 1-MCP as a preferred postharvest treatment (Li et al. 2020). Furthermore, 1-MCP has been reported to control ADH and PDC activities, consequently, preventing development of off flavour in different fruits (Shu et al. 2020). However, different studies have proven that at higher concentrations, 1-MCP inhibits the ripening capacity of the fruits (Guo et al. 2020). Therefore, combining 1-MCP at lower concentration with other postharvest treatments is necessary to overcome this drawback. One such postharvest treatment is short-term hypobaric treatment.

Short-term hypobaric treatment involves the reduction of pressure below the normal atmospheric condition of 101.3 kPa. It was introduced as a short-term postharvest treatment technique by Romanazzi et al. (2001). Short-term hypobaric treatment improves keeping quality of fresh fruits by changing gas composition, removing indigenous ethylene, and activating defense-related enzymes without affecting the firmness and weight loss of the fruits (Huan et al. 2021; Hashmi et al. 2013).

Due to the versatile characteristics of 1-MCP, short-term hypobaric treatment, and significance of Shughri pear, the objectives of this research work were (1) to investigate the combined effect of 1-MCP and hypobaric treatment on the storage life of Shughri pear. (2) to evaluate the consumers' acceptability of treated fruit when shifted to simulated retail conditions after the long-term cold storage.

Materials and methods

Source of fruit

Physiologically mature pear fruit of (150 Days After Full Bloom (DAFB), firmness ~ 80 Newton (N), and Total Soluble Solids (TSS) ~ 11obrix) were harvested from the local orchard in Chitral district (35°50′ 46″ N, 71°47′ 9″ E) of Khyber Pakhtunkhwa province, Pakistan. Pears packed in cardboard boxes were then transported to the Postharvest Laboratory, Department of Food Science and Technology, The University of Agriculture Peshawar-Pakistan. After sorting and grading, pears of uniform size and appearance were selected for the experiment. Pears were divided into 12 groups, each with three replicates, whereas each replicates had 10 pears. The first group served as control, three for hypobaric treatments (25, 50, and 75 kPa for 4 h), two for 1-MCP treatment (0.3 and 0.6 µLL−1 for 24 h), and the other six for a combination of hypobaric and 1-MCP treatments (25 kPa + 0.3 µLL−1 1-MCP, 50 kPa + 0.3 µLL−1 1-MCP, 75 kPa + 0.3 µLL−1 1-MCP, 25 kPa + 0.6 µLL−1 1-MCP, 50 kPa + 0.6 µLL−1 1-MCP, and 75 kPa + 0.6 µLL−1 1-MCP). The pears were then packed in perforated plastic packages.

Treatments

Hypobaric treatment

Pears in perforated plastic packages were placed in an automatic hypobaric chamber according to the method of Hashmi et al. (2013) with slight modification. Hypobaric pressure was generated using a vacuum pump attached to a hermetically sealed chamber at 20 °C. The pressure was set with 10 kPa accuracy. Each group of pears (25, 50, or 75 kPa) was placed in the hypobaric chamber for 4 h. The control group was also placed in the chamber for 4 h at normal (101.32 kPa) pressure. Pears reserved for the combined treatments of hypobaric and 1-MCP were directly placed in the 1-MCP chamber immediately after hypobaric treatment.

1-MCP treatment

Pears were placed inside a 16 L tin chamber, equipped with a fan to create a homogenous atmosphere inside. The chamber was sealed with semi-hard plastic film. One group of pears was treated with 1-MCP (Smart-FreshTM, 0.14% a.i., AgroFresh, Inc., Springhouse, PA, USA) @ 0.3 µLL−1 and another group @ 0.6 µLL−1, then left for 24 h at 20 ± 1 °C as per the method of Mahajan et al. (2010). Control pears were placed in a similar chamber without 1-MCP treatment. After the required time, pears were transferred to their respective perforated plastic containers and stored at 0 ± 1 °C and 85 ± 5% relative humidity for 120 days.

Physico-chemical characteristics

Percent weight and firmness

The initial weight of each pear was determined at the start of the study using a balance with an accuracy of 0.001 g (Mettler Toledo PG 503-S, Columbus, USA). Pears were kept at 20 °C for 24 h after every storage interval and reweighed to obtain final values. The average weight of all pears included in the replicate group was determined. Percentage weight loss was then calculated using initial and final average values for each replicate group (Kou et al. 2016). Firmness was determined using a Penetrometer (Lutron FR-5120, Lutron Electronic Enterprise co., Ltd., Taipei, Taiwan) on opposing peeled sides (1 mm) to a depth of 5 mm of the pears with an 8 mm plunger, with a speed of 5 mm/second and expressed as Newton (N). The average values of three replicates were then taken for analysis (Escribano et al. 2017).

Total soluble solids and titratable acidity

The juice was extracted, filtered through muslin cloth and the total soluble solids of the filtered homogenous juice were determined using a digital refractometer with an automatic temperature correction system. Results were expressed in degree brix (oBrix). Titratable Acidity (TA) was determined by taking 10 mL of pear juice, diluted in 100 mL distilled water, and titrated against 0.1 N NaOH solution to a pH value of 8.1, and results were expressed as % malic acid using automated (Metrohm) titrator (Hendges et al. 2018).

Peel colour

Peel colour was measured on the opposite sides of each pear using a colorimeter (Model PSE-CSM 2, PCE Instruments UK Ltd., United Kingdom) in L*, a*, and b* mode. The hue angle was then calculated to represent peel colour changes using the formula ArcTan (b*/a*) (Escribano et al. 2017).

Ethylene production and respiration rate

For ethylene and respiration, a closed system was used to measure the accumulated headspace. Pears of known weight were placed in a 3 L jar and each jar was hermetically sealed for 2 h. At time 0, 10 cm3 gas was taken from the headspace using an airtight syringe and injected into a portable ethylene analyser (F-900, Felix Instruments Inc. Camas, WA USA) and reading was observed. After two hours, gas was taken again, and the initial reading was subtracted from the final reading to get the ethylene production rate. Finally, using jar volume, the weight of pears, and ethylene analyser reading, the ethylene production rate was calculated and expressed as µmol kg−1 h−1 (Razzaq et al. 2016). Three samples per treatment were placed in a plastic jar (3 L) for two hours to record CO2 production using a portable CO2 infrared analyser (F-950, Felix Instruments Inc. Camas, WA USA). The respiration rate was then calculated and expressed as mmol kg−1 h−1 (Razzaq et al. 2016).

ADH and PDC analysis

Pears were allowed to ripe for 24 h at 20 °C after every interval. The method specified by Shu et al. (2020) was used to determine ADH and PDC activities by measuring absorbance (340 nm) and expressed as units per kilogram of fresh weight (U kg−1 FW). One unit of the enzyme activity was defined as an increase of 0.01 at OD340 per min.

Consumers’ acceptability

Consumers’ acceptability of pear fruit was determined, by adapting the method of Escribano et al. (2016) in terms of colour, aroma, fermented aroma, taste, and juiciness after 120 days of cold storage. Three panels of trained judges, each with 10 members (5 males and 5 females) were selected from the Department of Food Science and Technology. The judges were previously trained with properly ripened pears to set standards of different sensory attributes mentioned above. The samples were analysed at 3 days intervals for 21 days at simulated retail conditions (20 ± 1 °C and 65 ± 5 °C).

Statistical analysis

The experiment was conducted in a completely randomized design (CRD). The data of physcio-chemical and consumers’ acceptability were evaluated for homogeneity of variance. Afterward, all data were subjected to analysis of variance (ANOVA) in a two-way interaction pattern using Statistix 10 software (Analytical Software 2105 Miller Landing Rd Tallahassee, FL 32,312). Means were separated by LSD at a significance level of P ≤ 0.05. All experiments were repeated twice with three replicates; one representative experiment is presented here due to similar results.

Results

Percent weight loss and firmness

Weight loss and shrinkage percentage increased (P < 0.05) in all treatments during storage at 0 ± 1 °C for 120 days. Data for only nine treatments are shown here as no effect of 75 kPa was observed. Both hypobaric and 1-MCP treatments were effective (P < 0.05) in lowering weight loss, however, quantitatively, the effect of individual hypobaric treatment was not as effective as 1-MCP (Fig. 1 A). A comparison of the individual hypobaric treatments revealed that initially, 25 kPa treatment caused water loss of 0.02% greater than 50 kPa; however, this weight loss did not cause shrinkage in pears. Furthermore, 25 kPa treated pears showed lower weight loss than 50 kPa during the cold storage. Similarly, data of the individual 1-MCP treatments revealed that 0.6 µLL−1 1-MCP was more effective than 0.3 µLL−1 1-MCP. Notably, the combination of hypobaric treatment and 1-MCP was much more effective than individual hypobaric or 1-MCP treatments. After cold storage for 120 days, 25 kPa + 0.6 µLL−1 1-MCP treatment significantly (P < 0.05) controlled weight loss (2.22%) compared to control (5.16%).

Effect of Control, 25 kPa, 50 kPa, 0.3 µL L-1 1-MCP, 0.6 µL L-1 1-MCP, 25 kPa + 0.3 µL L-1 1-MCP, 50 kPa + 0.3 µL L-1 1-MCP, 25 kPa + 0.6 µL L-1 1-MCP, 50 kPa + 0.6 µL L-1 1-MCP on (A) percent weight loss and (B) Firmness of pear fruit (cv. Shughri) during cold storage at 0 ± 1 °C and 85 ± 5% RH for 120 days. Vertical bars represent standard error of means for three replicates. Different letters show significant difference among mean values using LSD at (P ≤ 0.05)

Irrespective of the treatments, the firmness of Shughri pears decreased (P < 0.05) during extended cold storage for 120 days. Compared to control, higher (P < 0.05) firmness was observed in the treated pears throughout cold storage (Fig. 1 B). Among all the treatments, higher (P < 0.05) firmness was observed in pears treated with 25 kPa + 0.6 µLL−1 1-MCP (65.00 N) after 120 days of cold storage compared to control (35.17 N), 25 and 50 kPa treated pears (44.14 N and 40.51 N, respectively), 0.3 and 0.6 µLL−1 1-MCP treated pears (49.21 N and 56.74 N, respectively). These findings indicate that the combined effect of hypobaric and 1-MCP treatment was more effective in maintaining the firmness of pear fruit.

Total soluble solids and titratable acidity

A declining trend in TA and an increasing trend in TSS was observed during cold storage (Fig. 2 A and B). No significant (P > 0.05) difference was observed among treatments on day first. The difference in TA among combinedly treated pears was non-significant till day 30; however, the difference in TSS became significant after 60 days of storage. The decrease in TA and increase in TSS was higher in control, followed by individually treated pears compared to pears treated combinedly. It is clear from the results that the decrease in TA and increase in TSS varied significantly (P < 0.05) when the extent of hypobaric treatment was lowered and the concentration of 1-MCP was increased. After 120 days storage, pear treated with 25 kPa + 0.6 µLL−1 1-MCP showed lower (P < 0.05) TSS (12.50) and higher (P < 0.05) TA (0.37%) compared to control (13.78 oBrix and 0.21%). Hypobaric treated pears slightly retained TA and TSS, as 25 kPa treated showed (0.24% and 14.20 oBrix respectively); however, 25 kPa combined with 0.3 µLL−1 1-MCP gave results almost similar to 0.6 µLL−1 1-MCP (0.30% and 13.20 oBrix respectively).

Effect of Control, 25 kPa, 50 kPa, 0.3 µL L-1 1-MCP, 0.6 µL L-1 1-MCP, 25 kPa + 0.3 µL L-1 1-MCP, 50 kPa + 0.3 µL L-1 1-MCP, 25 kPa + 0.6 µL L-1 1-MCP, 50 kPa + 0.6 µL L-1 1-MCP on (A) TSS (obrix) and (B) Titratable Acidity (%) of pear fruit (cv. Shughri) during cold storage at 0 ± 1 °C and 85 ± 5% RH for 120 days. Vertical bars represent standard error of means for three replicates. Different letters show significant difference among mean values using LSD at (P ≤ 0.05)

Peel colour

In pears, Hue angle can be used as a reliable source for measuring colour changes during ripening. Lightness and Chroma add a little contribution to the description of peel colour changes (Saquet and Streif 2017). The initial Hue angle of Shughri pear was (117 ho), indicating the greenish colour of physiologically mature pear fruit (Fig. 3). After 120 days of cold storage, the highest Hue angle was observed in pear treated with hypobaric and 1-MCP combinedly, as 25 kPa + 0.6 µLL−1 1-MCP treated pear maintained a higher (P < 0.05) Hue angle of 108.33°. A significant difference was observed among control (90.33 ho), pear with single treatment (25 kPa and 50 kPa [93.33 ho and 92.00 ho respectively], 0.3 and 0.6 µLL−1 1-MCP [98.33 and 108.33 ho respectively]) and pears treated combinedly.

Effect of Control, 25 kPa, 50 kPa, 0.3 µL L-1 1-MCP, 0.6 µL L-1 1-MCP, 25 kPa + 0.3 µL L-1 1-MCP, 50 kPa + 0.3 µL L-1 1-MCP, 25 kPa + 0.6 µL L-1 1-MCP, 50 kPa + 0.6 µL L-1 1-MCP on Peel colour (Hue angle) of pear fruit (cv. Shughri) during cold storage at 0 ± 1 °C and 85 ± 5% RH for 120 days. Vertical bars represent standard error of means for three replicates. Different letters show significant difference among mean values using LSD at (P ≤ 0.05)

Ethylene production and respiration rate

The hypobaric and 1-MCP treatments significantly inhibited ethylene production rate and respiration rate (Fig. 4 A and B). Both ethylene production and respiration rate increased with progress in the storage period from 0 to 120 days. In control, ethylene production peak was observed on day 90, and ethylene production and respiration rate decreased thereafter. Lowest ethylene production was observed in pears treated with 25 kPa + 0.6 µLL−1 1-MCP (0.46 µmol kg h−1), followed by 50 kPa + 0.6 µLL−1 1-MCP (0.51 µmol kg h−1) significantly (P < 0.05) lower as compared to control (0.72 µmol kg h−1) after 120 days of cold storage. Similarly, lowest respiration rate was observed in pears treated with 25 kPa + 0.6 µLL−1 1-MCP (0.37 mmol kg h−1), followed by 50 kPa + 0.6 µLL−1 1-MCP (0.40 mmol kg h−1) significantly (P < 0.05) lower compared to control (0.49 mmol kg h−1) after cold storage.

Effect of Control, 25 kPa, 50 kPa, 0.3 µL L-1 1-MCP, 0.6 µL L-1 1-MCP, 25 kPa + 0.3 µL L-1 1-MCP, 50 kPa + 0.3 µL L-1 1-MCP, 25 kPa + 0.6 µL L-1 1-MCP, 50 kPa + 0.6 µL L-1 1-MCP on (A) Ethylene Production Rate (µmol kg−1 h−1) and (B) Respiration Rate (mmol kg−1 h−1) of pear fruit (cv. Shughri) during cold storage at 0 ± 1 °C and 85 ± 5% RH for 120 days. Vertical bars represent standard error of means for three replicates. Different letters show significant difference among mean values using LSD at (P ≤ 0.05)

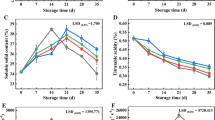

ADH and PDC activity

ADH and PDC activities increased throughout the storage period (Fig. 5 A and B). On day 30 no significant difference was observed between treated and control groups, however, differences started to be significant from day 60 onwards. In all treated groups ADH and PDC activities were significantly controlled and 25 kPa + 0.6 µLL−1 1-MCP treatment remained the most significant in controlling ADH and PDC activities. After 120 days of storage ADH and PDC activities in the control group were (10,167 U kg−1 FW and 31,333 U kg−1 FW respectively) compared to 25 kPa + 0.6 µLL−1 1-MCP treated pears (4767 U kg−1 FW and 7700 U kg−1 FW respectively).

Effect of Control, 0.3 µL L-1 1-MCP, 0.6 µL L-1 1-MCP, 25 kPa + 0.3 µL L-1 1-MCP, 25 kPa + 0.6 µL L-1 1-MCP on (A) ADH activity (U kg−1 FW) and (B) PDC activity (U kg−1 FW) of pear fruit (cv. Shughri) during cold storage at 0 ± 1 °C and 85 ± 5% RH for 120 days. Vertical bars represent standard error of means for three replicates. Different letters show significant difference among mean values using LSD at (P ≤ 0.05)

Consumers’ acceptability

Consumers’ acceptability was judged in terms of colour, pear aroma, fermented aroma, taste, and juiciness (Table 1). Data analysis indicated that after 3 days at simulated retail conditions, control was highly acceptable to the judges; however, it was not able to secure a score of 9 due to the development of fermented flavour. All other treated fruits were not ripened; therefore were not acceptable to consumers on day 3. On day 6, 25 kPa treated fruit was highly acceptable to the consumer, but the same fermented flavour was developed, leading to a lower score on hedonic scale. All other treated pears became slightly acceptable on day 6. On day 9, the fermented aroma in control and pear treated with 25 and 50 kPa hypobaric treatment became intense and the pears started to decay and were not acceptable to the consumers anymore. On day 12, 0.3 µLL−1 1-MCP treated pears were highly acceptable with a score (9.00), fully ripened with no fermented aroma. On day 15, pear treated with 0.6 µLL−1 1-MCP and 25 kPa + 0.3 µLL−1 1-MCP were highly acceptable. However, the score of pears treated with 0.3 µLL−1 1-MCP and 50 kPa + 0.3 µLL−1 1-MCP started to decline after day 15. On day 18, pears treated with 50 kPa + 0.6 µLL−1 1-MCP were highly acceptable and on day 21, pears treated with 25 kPa + 0.6 µLL−1 1-MCP were highly acceptable and remained acceptable to the consumer for a further one week (data not shown).

Discussion

Physiological weight loss is considered an important factor that influences the postharvest quality of fresh agricultural commodities. During postharvest storage, water loss not only causes shrinkage but can also affect the visual appearance and firmness of the fruits and consequently reduces the market price of the fruits. Previously, hypobaric treatment has proved effective in reducing the percent weight loss of kiwifruit and tomato fruits (Huan et al. 2021; Kou et al. 2016). In the same way, 1-MCP had been found to reduce weight loss in Ankara and Pathamakh pears (Kurubas and Erkan 2018; Mahajan et al. 2010). The combination of hypobaric and 1-MCP treatment used in this study showed very promising results. Because, on one hand, the hypobaric treatment removed endogenous ethylene and toxic gases from pears, resulting in an increased number of vacant ethylene receptors and also reduced the respiration rate. As a result, no catabolic water was produced, and cell integrity was maintained, consequently reducing weight loss (Huan et al. 2021). On the other hand, 1-MCP bind to the vacant ethylene receptors and block the ethylene signalling pathway, reducing ethylene-regulated ripening (Escribano et al. 2017). In this study, a slight effect of hypobaric treatment was observed on the fruit's weight loss. The effect of 1-MCP was more pronounced; however, integration of 25 kPa hypobaric with 0.6 µLL−1 1-MCP amplified the slowing down of percent weight loss in the pears (Fig. 1 A).

Firmness is one of the important quality parameters of fruits (Hashmi et al. 2013). Hydrolysis of starch or conversion of protopectin into soluble pectin may cause softening of the fruits (Mahajan et al. 2010). During the ripening process, pectic substances of the middle lamella of the cell wall are lost and led to a loss of firmness as the storage life progresses. Previously 1-MCP has been reported to be effective against the loss of firmness in different fruits (Lv et al. 2020). Removal of indigenous ethylene by hypobaric treatment and blocking of ethylene receptors by 1-MCP led to reduce water loss (Fig. 1 A) and delayed ethylene production (Fig. 4 A); as a result, the firmness of the pear was maintained (Fig. 1 B). Previously 1-MCP treatment has maintained the firmness of Bartlett pear (Escribano et al. 2016), Yali pear (Cheng et al. 2019), Conference and Alexander Lucas pears (Hendges et al. 2018), apple (Lv et al. 2020), and mango (Razzaq et al. 2016). Moreover, 1-MCP has been reported to inhibit cellulose dissolution in cell walls (Zhang et al. 2021).

TSS is the refractometric index representing the amounts (%) of dissolved solids in a solution. It includes sucrose and hexoses, acids, and other minor components such as soluble pectin, phenols, amino acids, and minerals. TSS is one of the several parameters that have key importance in determining the commercial quality of fruits and vegetables (Kurubas and Erkan 2018). A rise in TSS of pear was observed at each storage interval (Fig. 2 A); however, a decline was observed in the control treatment after reaching 14.3 obrix, indicating the utilization of sugar as a substrate during respiration (Zhao et al. 2020). Both hypobaric and 1-MCP treatment showed a significant effect in inhibiting the rise in TSS levels. Moreover, the combination of hypobaric and 1-MCP remained the best treatment for controlling the rise in TSS levels. The rise in TSS might be due to the degradation of large and complex carbohydrates into simple sugars. Loss of water from fresh agricultural commodities might also result in a high TSS level (Ramin et al. 2009). After complete hydrolysis of starch, no further rise in TSS is observed and it tends to decline, making it clear that sugars and other primary acids are used as a substrate during the respiration (Mahajan et al. 2010). The concentration of acid present within the food is represented in the form of titratable acidity, and both flavour and quality of fruit depend on organic acid's abundance (Guan et al. 2015). The reduction in acidity might be due to the oxidation of organic acids to meet energy requirements during ripening, which serves as major respiratory substrates after carbohydrates (Huan et al. 2021). Hence, lowering respiration rate (Fig. 4 B) might have reduced organic acid utilisation (Kou et al. 2016).

The primary factor that influences the consumer's purchasing decision is the colour of that fruit product. Natural pigments (chlorophyll and carotenoids) present in pears are responsible for imparting colour to them (Barrett et al. 2010). The colour changes from green to yellow might be due to the degradation of chlorophyll and synthesis of carotenoids and 1-MCP was observed effective against chlorophyll degradation in Comice pears (Zhao et al. 2020). Charoenchongsuk et al. (2018) observed that 1-MCP suppressed enzymes involved in chlorophyll degradation in Gorham and Grand Champion pears. With increasing storage time, the effect of 1-MCP on peel colour decreased (Razzaq et al. 2016). A slight effect of hypobaric treatment was observed however, 1-MCP alone or in combination with hypobaric treatment significantly reduced the green colour loss (Fig. 3).

Ethylene regulates the ripening process of fruits by coordinating the expression of genes that control different kinds of processes, includes changes in colour, flavour, texture, rise in respiratory processes and autocatalytic ethylene production (Pech et al. 2018). Even after harvest, fruits continue respiration; therefore, they are considered living tissues. All storage techniques focus on controlling respiration occurring in fruits. Fruit shelf life can be increased through decreasing respiration rate (Razzaq et al. 2016). With progress in storage life, a rise in ethylene production and respiration rate occurred, which was considerably inhibited by the combination of hypobaric and 1-MCP treatment (Fig. 4 A and B). The effectiveness of hypobaric treatment in reducing ethylene production rate might be due to the removal of internal ethylene and water molecules to equilibrate vacuum conditions (Huan et al. 2021). As far as 1-MCP is concerned, it binds to the ethylene receptors and blocks ethylene synthesis, thereby inhibiting fruit respiration and suppressing climacteric peak (Razzaq et al. 2016). Moreover, the storage life of pear varieties increased by 30–40% if the temperature is decreased from 0 to − 1 °C (Villalobos-acuna and Mitcham 2008). With increasing the storage life, the fruit regains ethylene synthesis and the effectiveness of 1-MCP and hypobaric treatment tends to reduce.

ADH and PDC activities have previously been reported to increase anaerobic respiration consequently raising acetaldehyde and alcohol concentrations in the fruits (Shu et al. 2020). In our case, 1-MCP alone and in combination with hypobaric treatment significantly reduced ADH and PDC activities, which are highly ripening-dependent and ethylene-regulated (Liu et al. 2018). 25 kPa + 0.6 µLL−1 1-MCP was the most significant treatment in reducing their activities, and prevented fermented flavour development during simulated retail condition after 120 days of cold storage, as a result, consumers’ acceptability score was higher (Table 1).

One of the focuses of food growers is to gain an acceptable price for their commodities. The fruits must meet consumer preferences regarding colour, aroma, and taste (Barrett et al. 2010). Previously 1-MCP has been reported to improve organoleptic characteristics of Pathmakh and Ankara pears (Mahajan et al. 2010; Kurubas and Erkan 2018). This is because of the fact that 1-MCP effectively controlled ADH and PDC activities, thus lowered down anaerobic respiration and prevent the production of ethanol and acetaldehyde, which are the major cause of off-flavour in the pear (Shu et al. 2020).. However, no information is available in the literature related to the effect of hypobaric treatment and the integrated effect of hypobaric and 1-MCP treatment on the acceptability of fruits after long-term cold storage. In this work, hypobaric treated fruits showed little difference, ripened on days 3 and 6, and then rotted. Initially, the acceptability of 1-MCP treated pears was lower; however, with increasing ripening days, their acceptability greatly increased. This might be due to the fact that 1- MCP reduced respiration rate (Cheng et al. 2019; Hendges et al. 2018), maintained higher firmness than that required by the consumers (Tomala et al. 2020). 1- MCP also reduced chlorophyll degradation and retained the greenish colour while ripened pears were acceptable to the consumers due to the yellow colour (Zhao et al. 2020; Escribano et al. 2017; Saquet and Streif 2017). 1- MCP also reduced the development of volatile compounds that are responsible for the particular aroma of the fruit (Guan et al. 2015), and retained TSS (Kaur and Dhillon 2015), and TA levels (Wang and Sugar 2015), thereby affecting the taste of the fruits. Hypobaric treatment removed indigenous ethylene and some toxic substances through diffusion (Huan et al. 2021) and 1-MCP binds to the ethylene receptors, which is 10 times more active than ethylene. Thus, pears need more time to ripe to the desired acceptability along with no fermented flavour development at 20 ± 3 °C compared to the control.

Conclusion

In this study, individual hypobaric and 1-MCP treatment effectively reduced weight loss, shrinkage, loss of TA, rise in TSS, loss of green colour, respiration and ethylene production rate. However, at simulated retail conditions after 120 days of storage, hypobaric treatment's effectiveness was minimal. 1-MCP treated fruits remained fresh and acceptable for 21 days at ambient storage conditions with improved aroma, taste, juiciness, and properly developed yellow colour. Interestingly, the combination of 25 kPa hypobaric 0.3 µLL-1 1-MCP has a similar response as that of 0.6 µLL-1 1-MCP on all the measured parameters during 120 days of storage. This indicates that the combination of hypobaric and lower concentration (0.3 µLL−1) of 1-MCP is as effective as the higher concentration (0.6 µLL−1) of 1-MCP treatment alone. Moreover, growers can use 25 kPa + 0.3 µLL−1 1-MCP to ripen the pear within 2 weeks and 25 kPa + 0.6 µLL−1 1-MCP to ripen the pear within three weeks. Hence, manipulation of 1-MCP concentration and the extent of hypobaric treatment could control the degree of pear ripening per market requirement. The combination of hypobaric and 1-MCP is a low-cost postharvest treatment and should be tested on a commercial scale. However, this study was conducted on a pilot scale, therefore, the results should be validated on large scale before commercialization.

Availability of data and material

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Not Applicable.

Abbreviations

- 1-MCP:

-

1-Methylcyclopropene

- ADH:

-

Alcohol dehydrogenase

- CRD:

-

Completely randomized design

- DAFB:

-

Days after full bloom

- ho :

-

Hue angle

- mmol:

-

Millimole

- PDC:

-

Pyruvate decarboxylase

- OD:

-

Optical density

- TA:

-

Titratable acidity

- TSS:

-

Total soluble solids

- µmol:

-

Micromole

- µL:

-

Microliter

References

Abbas MM, Fai H, Aziz MM, Rashid S, Ullah H, Qadri R, Azam M (2018) Evaluation of pear varieties for physiochemical traits grown under climatic conditions of Soon Valley, Pakistan. Am J Plant Sci 9(11):2217. https://doi.org/10.4236/ajps.2018.911160

Almeida DP, Carvalho R, Dupille E (2016) Efficacy of 1-methylcyclopropene on the mitigation of storage disorders of “Rocha” pear under normal refrigerated and controlled atmospheres. Food Sci Technol Int 22(5):399–409. https://doi.org/10.3390/foods9091299

Barrett DM, Beaulieu JC, Shewfelt R (2010) Colour, flavour, texture, and nutritional quality of fresh-cut fruits and vegetables: desirable levels, instrumental and sensory measurement, and the effects of processing. Crit Rev Food Sci Nutr 50(5):369–389. https://doi.org/10.1080/10408391003626322

Charoenchongsuk N, Matsumoto D, Itai A, Murayama H (2018) Ripening characteristics and pigment changes in Russeted pear fruit in response to ethylene and 1-MCP. Horticulturae 4(3):22. https://doi.org/10.3390/horticulturae4030022

Cheng Y, Liu L, Feng Y, Dong Y, Guan J (2019) Effects of 1-MCP on fruit quality and core browning in ‘Yali’pear during cold storage. Sci Hortic 243:350–356. https://doi.org/10.1016/j.scienta.2018.08.041

Escribano S, Lopez A, Sivertsen H, Biasi WV, Macnish AJ, Mitcham EJ (2016) Impact of 1-methylcyclopropene treatment on the sensory quality of ‘Bartlett’pear fruit. Postharvest Biol Technol 111:305–313. https://doi.org/10.1016/j.postharvbio.2015.09.015

Escribano S, Sugimoto N, Macnish AJ, Biasi WV, Mitcham EJ (2017) Efficacy of liquid 1-methylcyclopropene to delay ripening of ‘Bartlett’pears. Postharvest Biol Technol 126:57–66. https://doi.org/10.1016/j.postharvbio.2016.11.007

Guan J, Hu M, Shen C, Zhou S, Cheng Y, and He J (2015) Effects of 1-methylcyclopropene on active composition in fruits. In: Processing and impact on active components in food. Academic Press pp. 133–137. Doi: https://doi.org/10.17576/jsm-2020-4903-10

Guo J, Wei X, Lü E, Wang Y, Deng Z (2020) Ripening behavior and quality of 1-MCP treated d’Anjou pears during controlled atmosphere storage. Food Control 117:107364. https://doi.org/10.1016/j.foodcont.2020.107364

Hashmi MS, East AR, Palmer JS, Heyes JA (2013) Hypobaric treatment stimulates defence-related enzymes in strawberry. Postharvest Biol Technol 85:77–82. https://doi.org/10.1016/j.postharvbio.2013.05.002

Hendges MV, Neuwald DA, Steffens CA, Vidrih R, Zlatić E, do Amarante CVT (2018) 1-MCP and storage conditions on the ripening and production of aromatic compounds in conference and Alexander Lucas pears harvested at different maturity stages. Postharvest Biol Technol 146:18–25. https://doi.org/10.1016/j.postharvbio.2018.08.006

Huan C, Li H, Jiang Z, Shen S, Zheng X (2021) Effect of hypobaric treatment on off-flavour development and energy metabolism in ‘Bruno’kiwifruit. Lebensmittel-Wissenschaft Technol 136:110349. https://doi.org/10.1016/j.lwt.2020.110349

Kaur K, Dhillon WS (2015) Influence of maturity and storage period on physical and biochemical characteristics of pear during post cold storage at ambient conditions. J Food Sci Technol 52(8):5352–5356. https://doi.org/10.1007/s13197-014-1620-3

Kou X, Wu JY, Wang Y, Chen Q, Xue Z, Bai Y, Zhou F (2016) Effects of hypobaric treatments on the quality, bioactive compounds, and antioxidant activity of tomato. J Food Sci 81(7):H1816–H1824. https://doi.org/10.1111/1750-3841.13360

Kurubas MS, Erkan M (2018) Impacts of 1-methylcyclopropene (1-MCP) on postharvest quality of “Ankara” pears during long-term storage. Turk J Agric For 42(2):88–96. https://doi.org/10.3906/tar-1706-72

Li L, Li C, Sun J, Sheng J, Zhou Z, Xin M, Tang J (2020) The effects of 1-methylcyclopropene in the regulation of antioxidative system and softening of mango fruit during storage. J Food Qual 2020:11. https://doi.org/10.1155/2020/6090354

Liaudanskas M, Zymonė K, Viškelis J, Klevinskas A, Janulis V (2017) Determination of the phenolic composition and antioxidant activity of pear extracts. J Chem 2017:9. https://doi.org/10.1155/2017/7856521

Liguori G, Farina V, Corona O, Mazzaglia A, Barone E, Inglese P (2017) Effects of 1-MCP on postharvest quality and internal browning of white-flesh loquat fruit during cold storage. Fruits 72(2):67–73. https://doi.org/10.17660/th2017/72.2.1

Liu H, Jiang W, Cao J, Ma L (2018) A combination of 1-methylcyclopropene treatment and intermittent warming alleviates chilling injury and affects phenolics and antioxidant activity of peach fruit during storage. Sci Hortic 229:175–181. https://doi.org/10.1016/j.scienta.2017.11.010

Lv J, Zhang M, Bai L, Han X, Ge Y, Wang W, Li J (2020) Effects of 1-methylcyclopropene (1-MCP) on the expression of genes involved in the chlorophyll degradation pathway of apple fruit during storage. Food Chem 308:125707. https://doi.org/10.1016/j.foodchem.2012.05.017

Mahajan BVC, Singh K, Dhillon WS (2010) Effect of 1-methylcyclopropene (1-MCP) on storage life and quality of pear fruits. J Food Sci Technol 47(3):351–354. https://doi.org/10.1007/s13197-010-0058-5

Pech JC, Purgatto E, Bouzayen M, Latché A (2018) Ethylene and fruit ripening. Ann Plant Rev Online 44:275–304. https://doi.org/10.1002/9781118223086.ch11

Ramin AA, Rezaei A, and Shams M (2009) Potassium permanganates and short term hypobaric enhances shelf-life of kiwifruits. In: VI international postharvest symposium 877: 849–852. Doi: https://doi.org/10.17660/ActaHortic.2010.877.113

Razzaq K, Singh Z, Khan AS, Khan SAKU, Ullah S (2016) Role of 1-MCP in regulating ‘Kensington Pride’mango fruit softening and ripening. Plant Growth Regul 78(3):401–411. https://doi.org/10.1007/s10725-015-0101-7

Romanazzi G, Nigro A, Ippolito A, Salerno A (2001) Effect of short hypobaric treatments on postharvest rots of sweet cherries, strawberries and Table grapes. Postharvest Biol Technol 22(1):1–6. https://doi.org/10.1016/S0925-5214(00)00188-5

Saquet AA, Streif J (2017) Respiration rate and ethylene metabolism of ‘Jonagold’apple and ‘Conference’pear under regular air and controlled atmosphere. Bragantia 76:335–344. https://doi.org/10.1590/1678-4499.189

Shu P, Min D, Zhou J, Ai W, Li J, Li Z, Zhang X, Shi Z, Sun Y, Li F, Li X (2020) The synergism of 1-methylcyclopropene and ethephon preserves quality of “Laiyang” pears with recovery of aroma formation after long-term cold storage. Front Plant Sci 11:490. https://doi.org/10.3389/fpls.2020.00490

Tomala K, Grzęda M, Guzek D, Głąbska D, Gutkowska K (2020) The effects of preharvest 1-Methylcyclopropene (1-MCP) treatment on the fruit quality parameters of cold-stored ‘Szampion’cultivar apples. Agriculture 10(3):80. https://doi.org/10.3390/agriculture10030080

Villalobos-Acuña M, Mitcham EJ (2008) Ripening of European pears: the chilling dilemma. Postharvest Biol Technol 49(2):187–200. https://doi.org/10.1016/j.postharvbio.2008.03.003

Wang Y, Sugar D (2015) 1-MCP efficacy in extending storage life of ‘Bartlett’pears is affected by harvest maturity, production elevation, and holding temperature during treatment delay. Postharvest Biol Technol 103:1–8. https://doi.org/10.1016/j.postharvbio.2015.02.013

Zhang W, Jiang H, Zhang Y, Cao J, Jiang W (2021) Synergistic effects of 1-MCP and hot air treatments on delaying softening and promoting anthocyanin biosynthesis in nectarines. Postharvest Biol Technol 180:111598. https://doi.org/10.1016/j.postharvbio.2021.111598

Zhao J, Xie X, Wang S, Zhu H, Dun W, Zhang L, Fang C (2020) 1-Methylcyclopropene affects ethylene synthesis and chlorophyll degradation during cold storage of ‘Comice’pears. Sci Hortic 260:108865. https://doi.org/10.1016/j.scienta.2019.108865

Acknowledgements

This work was carried out as a requirement of M.Sc. (Hons) degree of the first author. This work was part of M.Sc. (Hons) thesis of the first author (Mr. Ayaz Ahmad) in the University of Agriculture Peshawar – Pakistan. Thanks to the Higher Education Commission, Pakistan for funding this project under National Research Program for Universities (NRPU).

Funding

This research was carried out in The University of Agriculture, Peshawar – Pakistan, under National Research Program for Universities (NRPU 6301) with financial support from The Higher Education Commission Pakistan.

Author information

Authors and Affiliations

Contributions

The research was designed by MSH, carried out by AA, data analysis was done by YD and NAK, and the paper was formatted by WUR and AR. MRK, MZS and MA assisted in editing the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflict of interests among authors of this manuscript.

Ethics approval

Not Applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahmad, A., Hashmi, M.S., Durrani, Y. et al. Synergy of 1-MCP and hypobaric treatments prevent fermented flavour and improve consumers’ acceptability of ‘Shughri’ pear. J Food Sci Technol 60, 200–210 (2023). https://doi.org/10.1007/s13197-022-05605-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05605-y