Abstract

Reducing the fat content in emulsions can give additional nutritional health benefits. Hence, developing low-fat oil-in-water emulsions, fortified with healthy microalgae providing advantageous properties, is an interesting topic. In this study, the addition of Arthrospira platensis (Spirulina), Chlorella vulgaris (Chlorella), and Dunaliella salina (Dunaliella) microalgae biomass on the physicochemical properties of low-fat oil-in-water emulsion formulations were evaluated. The rheological properties of food emulsions were measured in terms of the viscoelastic, flow behaviour, and textural properties, with all properties studied during 60 days. pH values of all the emulsions ranged between 3.0 and 3.7 and agreed to the Codex Alimentarius Commission. Moreover, their rheological behaviour may be classified as weak gel-like, a distinguishing characteristic of low-fat emulsion products. Substantial differences in rheological properties were observed between the fortified microalgae emulsions over the storage time (60 days). However, incorporating Spirulina or Dunaliella gave emulsions with stable texture, viscoelastic, and rheological properties. The prepared emulsions displayed good colour stability for Chlorella and Dunaliella. Overall, the fortified microalgae low-fat emulsions are expected to provide a blueprint for the design of low-fat mayonnaise-like food emulsions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Food emulsions are systems of two-phase immiscible liquids with restricted stability. An emulsion of oil droplets in water, a so called oil-in-water (O/W) emulsion is characterised by a dispersed phase of oil with oil-based ingredients, a combination of emulsifiers, and a continuous phase of water with water-based ingredients (Yang and Lai 2003; Morley 2016). Traditional oil-in-water emulsions, like mayonnaise, containing 70–80 g/100 g of fat is one of the most broadly used examples worldwide. In most western countries, dietary fat ingestion is higher than medical recommendation and is associated with the prevalence of cardiovascular diseases, obesity, and cancer (Mozaffarian 2017). Therefore, focus on creating more nutritional and healthier food products using fat replacers, promoting low-fat products formulation, particularly using hydrocolloids to help avoid diseases plus improve stability and viscosity giving a desired thick and spoon-able texture (Chang et al. 2017). Besides, adding novel ingredients like microalgae biomass to the emulsions can improve quality attributes like colour (Gouveia et al. 2006), emulsifying ability (Raymundo et al. 2005), and rheological characterisation (Batista et al. 2006b). Although microalgae has a great biodiversity, both science and industry have focused the most on Arthrospira platensis (Spirulina), Chlorella vulgaris (Chlorella), and Dunaliella salina (Dunaliella). These types of cyanobacteria and microalgae are cell organisms that can easily grow in either fresh water or sea water. They also provide various other nutrients including proteins (Chlorella; ≈ 55%, Spirulina, 65%; and Dunaliella; 57%), fatty acids (very high concentrations of long chain polyunsaturated fatty acids (PUFAs)), pigments (phycobiliproteins from Spirulina; canthaxanthin, astaxanthin, and lutein from Chlorella; and carotenoids from Dunaliella), minerals (iron, calcium, chromium, copper, magnesium, manganese, phosphorus, potassium, sodium, and zinc), vitamins (vitamin A (beta-carotene), C, and E; thiamine (B1), riboflavin (B2), niacin (B3), pantothenic acid (B5), pyridoxine (B6), folic acid (B9), and cobalamin (B12)), and antioxidants (Tang and Suter 2011; Buono et al. 2014; Sui and Vlaeminck 2020). These nutritional benefits make the microalgae a valuable and innovative ingredient and can cause significant and interesting physicochemical changes and nutritional improving in food products (Uribe-Wandurraga et al. 2020). However, to the best of our knowledge, no study has shown the incorporation of microalgae in low-fat oil-in-water food emulsions, despite the high interest of microalgae as a basic food ingredient with great importance in human nutrition (Priyadarshani and Rath 2012).

In this study, we focused on the addition of the three microalgae biomass, Arthrospira platensis (Spirulina); Chlorella vulgaris; and Dunaliella salina, in low-fat oil-in-water food emulsions. The objective was to investigate the effect of microalgae on water activity, pH, colour, texture, and rheological properties of the samples. The formulation was varied with the type of microalgae while retaining the same concentration. The results would provide theoretical guidance to produce low-fat oil-in-water food emulsions with microalgae fortification to enhance their properties, especially their innovative colour and appearance, producing a novel product for the current food market.

Material and methods

Materials

Freeze-dried Arthrospira platensis (Spirulina) and Chlorella vulgaris (Chlorella) were supplied from AlgaEnergy S.A. (Madrid, Spain) and Dunaliella salina (Dunaliella), from Algalimento S.L. (Gran Canaria, Spain). Sunflower oil, sugar, vinegar, starch, egg yolk, salt, and potassium sorbate were supplied by Jumel Alimentaria S.A. (Spain).

Emulsions preparation

The oil-in-water emulsions were prepared according to the procedure by Jumel Alimentaria S.A. (Spain). The ingredients (w/w) of control emulsions were water (53.5%), sunflower oil (30%), granulated sugar (5%), vinegar (4%), starch (4%), egg yolk (2%), salt (1.4%), and potassium sorbate (0.1%). Three different types of emulsions with microalgae were formulated replacing part of the water with 1 wt% of freeze-dried microalgae biomass (Spirulina, Chlorella, or Dunaliella). The water phase was first prepared by mixing all the ingredients, apart from the oil and vinegar, with a blender (Braun GmbH, Frankfurt, Germany) at speed one for 2 min. The water phase was transferred to a kitchen appliance (Thermomix, TM31, Vorwerk Corporate Group, Wuppertal, Germany) and the sunflower oil was added dropwise during the blending at speed two. Last, the vinegar was added and blended for another 2 min at speed three. The emulsion samples were kept in a 500 mL beaker and stored at 4 °C for further studies. The samples produced were: CM: Control low-fat emulsion, SM: Spirulina low-fat emulsion, CHM: Chlorella low-fat emulsion and DM: Dunaliella low-fat emulsion.

Physicochemical analysis

Water activity (aw) of emulsion samples were determined by an AquaLab Dewpoint Water Activity Meter 4TE (Decagon Devices Inc., Pullman, WA, USA). pH values of samples were measured using a Consort C-830 pH meter (Turnhout, Belgium). Samples were analysed by triplicate at 25 °C on day 0, 15, 30, 45, and 60 of storage.

Colour measurement

Emulsion samples colour was measured using a Konica Minolta CM-700d colorimeter (Konica Minolta CM-700d/600d series, Tokyo, Japan) with the standard illuminant D65 and visual angle of 10°. The three emulsion samples were individually placed in a circular glass sample holder of 50 mm diameter and 10 mm height and were measured at three equidistant points, on days 0, 15, 30, 45, and 60 of storage. Colour parameters were determined by: L* lightness (0-black, 100-white), a* (− a* green, + a* red), and b* (− b* blue, + b* yellow), according to the CIEL*a*b* system. Chroma, C*ab (saturation) and hue angle, h°ab, were also calculated. The total colour difference (ΔE) between samples with and without microalgae was determined using L*a*b* values according to Eq. 1.

The measurements were conducted under constant lighting conditions, at 20 °C.

Textural analysis of emulsions

The texture was measured using a TA-XT2 Texture Analyser (Stable Micro Systems Ltd, Godalming, UK) with the software Texture Exponent (version 6.1.12.0). A standard size back extrusion container (50 mm diameter) was filled with 60 mL of sample. An extrusion disc (35 mm diameter) attached to a 50 kg load cell compress was positioned centrally over the container, compressing the sample at pre and test speeds of 1.0 mm/s and post-test speed of 10 mm/s. Firmness (N), consistency (N s), cohesiveness (N), and adhesiveness (N s) were measured in triplicate at 20 °C on days 0, 15, 30, 45 and 60 of storage for each blend and the results were averaged.

Rheological and viscoelastic properties of the emulsions

Flow and oscillatory tests were performed using a Kinexus pro + rotational rheometer (Malvern Instruments, Worcestershire, UK) and rSpace software; equipped with a 25 mm diameter parallel-plate geometry (DSR II, Upper Plate) with a 1.5 mm gap between plates and a heat-controlled sample stage (Peltier Cylinder Cartridge, Malvern Instruments, Worcestershire, UK). Before each measurement samples were loaded onto the geometry plate and rested for 5 min.

Flow tests were used to study the behaviour of shear stress on applied shear rate and viscosity profiles of samples. For better evaluation of flow behaviour of prepared low-fat emulsions, a thixotropic loop measurement was carried out by firstly increasing the shear rate (\(\dot{\gamma }\)) logarithmically from 0.01 to 10 s−1 for 50 s and then, decreasing it logarithmically back to 0.01 for 50 s at 25 °C. For each up and down cycle, the area under the curve was calculated using SigmaPlot Software, version 11.0 (Systat Software Inc., USA). The difference between the two areas was considered as the hysteresis area. The experimental data obtained for the first up sweep was well fitted to the Herschel–Bulkley model (Eq. 2),

where σ is the shear stress (Pa), σ0 the yield stress (Pa), Κ the consistency coefficient (Pa sn), \(\dot{\gamma }\) the shear rate (s−1), and n the flow behaviour index. The parameters were calculated using SigmaPlot Software, version 11.0 (Systat Software Inc., USA).

The linear viscoelastic range for all the samples was determined with a strain sweep (0.001–100%) at a fixed frequency of 1.0 Hz, followed by oscillatory stress sweeps with a frequency range of 0.1–10 Hz for each sample using a constant strain of 0.01%. The mechanical spectra were obtained recording the elastic modulus (G′ (Pa)) and viscous modulus (G′′ (Pa)) as a function of the frequency range (ω (Hz)). G′ is the dynamic elastic or storage modulus, related to the material response as a solid. G′′ is the dynamic viscous or loss modulus, related to the material response as a fluid. The loss angle values (tan δ) as a function of frequency (ω (Hz)) were calculated. Tan δ is defined as the ratio of G′′ to G′.

For both tests, samples were performed in triplicate on days 0, 15, 30, 45, and 60 of storage and at 25 °C.

Statistical analysis

Analysis of variance (ANOVA) using Statgraphics Centurion XVII Software, version 17.2.04 with a confidence level of 95% (p < 0.05) was applied to evaluate the differences among emulsion samples. Furthermore, a correlation analysis among rheological and textural properties of the samples, with a 95% significance level, was conducted (Statgraphics Centurion XVII).

Results and discussion

Physicochemical properties

Water activity and pH of oil-in-water emulsions plays an important role in its structure, stability and food safety (Su et al. 2010; Nout and Rombouts 2000).

Water activity (aw) values were in the range 0.92 to 0.95 with slight differences between CM, SM, CHM, and DM and also during storage time. Water activity of low-fat emulsions present high aw values, ≈ 0.95, due to the increased of water holding capacity of the formulations (Su et al. 2010; Alu’datt et al. 2016).

The pH decreasing or increasing rates for different samples were affected by each microalgae addition. pH values slightly increased for CM, CHM and DM samples and slightly decreased for SM during storage time. The values were ranged between 3–3.46, 3.73–3.62, 3.58–3.70 and 3.54–3.62 for CM, SM, CHM and DM, respectively. Therefore, CM showed lower pH values than SM, CHM, and DM among all samples during storage time. However, pH values were ranging between 3.0 and 3.7 agreeing with the Codex Alimentarius Commission (Joint FAO/WHO Food Standards Programme 1987). Besides, pH values of mayonnaise and emulsions are typically between 3.0 and 4.0 because of the presence of acetic acid in formulations, having significant influence on the microbiological stability (Nout and Rombouts 2000).

Colour stability

Colour is an important quality attribute of food products, contributing to its acceptability (Batista et al. 2006a). Figure 1 shows the colour changes of the emulsions during 60 days of storage at 5 °C, expressed as lightness (L*), redness (a*), yellowness (b*), hue (hºab), and chroma (C*ab) with a control sample as a reference. L*, a*, and b* values of the emulsion products made with microalgae were significantly different (p < 0.05) than the control emulsion. The evaluation of parameter L* shows that lightness decreased significantly (p < 0.05) with microalgae addition although, slight significant (p < 0.05) differences with the SM and CHM are found comparing each storage day, meaning adding Spirulina results in a darker emulsion than Chlorella and Dunaliella. The lightness (L*) of CM and SM increased during the first 15 days of storage, then consistently increased until the end of the storage period. The DM sample exhibited a slight increase in lightness (L*) by a range of 0.3–0.8 units at the end of the storage period, comparable behaviour observed by Santipanichwong and Suphantharika (2007), in β-carotene emulsion samples. The CHM sample showed almost unaffected L* values during storage time. These trends were also observed by Gouveia et al. (2006), in emulsions with Chlorella. The a* values of SM and CHM samples increased rapidly for the first 15 days before reaching a plateau, maintained throughout the remaining storage period. CM and DM were more stable, not showing significant differences (p > 0.05) during storage time. No significant differences (p > 0.05) are observed for b* of all samples. When Dunaliella was used, high values of a* and b* are observed, meaning that red and yellow hues are intensified, as expected owing to the β-carotene pigments (Buono et al. 2014). Likewise, when Spirulina and Chlorella are used, low values of a* and b* are observed, meaning that green and blue hues are intensified, due to its phycocyanin pigment contents in Spirulina (Park et al. 2018) and the lutein pigment in Chlorella (Dufossé 2016). Both microalgae were good sources of pigments for oil-in-water food emulsions, proving to impart a stable and appealing colour to them improving the product ranges during storage time (Gouveia et al. 2006). Here the C*ab remains constant for each sample along storage time. All emulsions samples showed good colour stability throughout the 60-days storage period, with variations being barely detected by the human eye (Bodart et al. 2008) and with ∆E* values being lower than 2.6. Nevertheless, for sample SM, total colour differences were higher than the other samples with increasing colour differences values, 4.8, 5.2, 5.9 and 6.2, during 15, 30, 45 and 60 days of storage time, respectively. Emulsions with Chlorella or Dunaliella have greater colour stability.

Effect of microalgae addition on textural properties

The textural properties were determined by firmness (N), consistency (N s), cohesiveness (N), and adhesiveness (N s) (Fig. 2). Firmness and consistency reveal the solid property of emulsions, while cohesiveness and adhesiveness reveal the liquid properties (Li et al. 2014); properties that may affect mouth feel and applicability. For all textural parameters, a significant (p < 0.05) difference with Chlorella addition was observed in all samples, with slight significant (p < 0.05) differences between CM, SM, and DM. Textural parameters of CM, SM, and CHM did not increase or decrease linearly during storage time, as the oscillatory behaviour stayed between 1 to 1.2 (N) for firmness, − 0.9 to − 0.7 (N s) for cohesiveness, and − 0.85 to − 0.65 (N s) for adhesiveness. The consistency of SM increases during the first 15 days and during the first 45 days for CM, after, decreasing until the end of the storage period. In contrast, the consistency of DM decreases from day 0. For CHM, firmness decreases from 1.29 N to 0.53–0.39 N and consistency from 5.79 to 3.48–2.74 N s, while cohesiveness increases from − 0.96 to − 0.38– 0.27 N and adhesiveness from − 0.70 to − 0.40–0.29 N s along storage time.

Rheological and viscoelastic characterisation

Rheological properties of emulsion samples were investigated by measuring their flow behaviour and dynamic rheological properties, important to determine their long term physical stability (Jain et al. 2019).

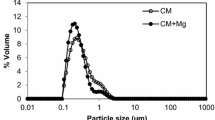

The viscosity of emulsion samples was evaluated through flow sweep tests and presented as the viscosity (η) as a function of the shear rate (\(\dot{\gamma }\)). Figures 3a–d show results for CM, SM, CHM, and DM, respectively. Viscosity decreases with shear rate increases, giving shear-thinning behaviour in all cases. When viscosity decreases during shear, the behaviour is said to be thixotropic (Jain et al. 2019). Figure 3 shows all the emulsions have the highest viscosity at day 0. Nevertheless, the viscosity versus shear rate curve trend for CM is higher than other samples, followed by SM, DM, and CHM, subsequently. Under the same shear rate, differences with CHM at day 0 and the other days of storage where pronounced, although viscosity profiles for days 15, 30, 45, and 60 showed no significant (p > 0.05) differences.

To evaluate the flow behaviour of the emulsions, the flow curves, plotting the experimental shear stress (σ, Pa) as a function of the shear rate \(\dot{(\gamma },{\mathrm{s}}^{-1})\) data, are shown in Fig. 4. In order to perform a quantitative comparison of emulsions, it is generally required fitting the experimental data to some forms of best-fit mathematical equation or model. Thus, the data of the different emulsions obtained were then well fitted to the Herschel–Bulkley model and the behaviours are showed in Fig. 4 too. The behaviours of all samples confirm a non-linear relationship exhibiting a non-Newtonian plastic and time dependent shear-thinning (thixotropic) behaviour between the shear stress over the whole range of shear rate studied (0.01–10 s−1) for all the emulsions. Moreover, the hysteresis area, the Herschel–Bulkley obtained parameters and the rheological parameters of the different emulsions along the storage time are shown in Table 1.

Flow behaviour of the assayed emulsions. Values obtained from Herschel–Bulkley model (bookmarks) and Shear stress (σ) versus Shear rate (\(\dot{\upgamma }\)) (continuous and dotted lines) of a Control low-fat emulsion, b Spirulina low-fat emulsion c Chlorella low-fat emulsion, and d Dunaliella low-fat emulsion, during storage time: d0: day 0, d15: day 15, d30: day 30, d45: day 45 and d60: day 60

The hysteresis area provides an insight into the emulsion network structure where a greater loop area suggests a more structured emulsion and vice-versa. This is because when the network structure of a strong emulsion is deformed, it requires more time to retain its original structure following removal of shear stress (Jain et al. 2019). Therefore, the area enclosed by the hysteresis loop is related to the degree of structural breakdown that occurred in the samples while shearing. From the results obtained, it was observed that the SM and DM had a comparatively more structured systems than CM, showing slight significantly (p < 0.05) differences during the whole storage time. CHM showed a more structure system that CM at day 0. However, from day 15 to day 60, CHM presented a reduction of the hysteresis area values showing a structural breakdown while shearing during storage time. Thus, the microalgae-fortification emulsion structure was clearly reinforced, there being observed a higher resistance to structural breakdown.

Yield stress (σo) represents the minimum shear stress required to initiate the flow of material, indicating the transition from an elastic form to viscous deformation (Tadros 2013). Incorporating Spirulina, Chlorella or Dunaliella into emulsion formulations decreased the yield stress significantly (p < 0.05) than the control emulsion. Yield stress provides stability to food emulsions in low-stress situations, like those of storage, transportation, mixing, and pumping (Sun and Gunasekaran 2009). Significant (p < 0.05) differences were observed in σo for all samples at day 0 than the whole time under study. Both CM and SM showed a decrease of σo while CHM and DM showed an increase over storage time. However, CM shows the highest σo value and CHM the lowest over the long storage time and among all the samples (Table 1). Notably, added microalgae formulations require a lower yield stress to initiate their flow than the control emulsion, also a weaker network structure was seen (i.e., fewer interactions in the sample), which could result in a decreased resistance to flow (Ma and Boye 2013). This is seen in all cases due to the Herschel–Bulkley model could interpolate the yield stress of emulsion samples, showing a determination coefficient (R2adj) > 0.994 (Fig. 4).

The consistence coefficients (K) of the emulsions (Table 1) showed a significant difference (p < 0.05) in the consistency index of samples with and without microalgae at day 0. K values of emulsions were higher for both Chlorella and Dunaliella and low for the control sample at day 0. Higher K values in emulsions indicate a more pronounced viscous characteristic, which corresponds to a sample stronger network structure. Therefore, microalgal biomass can contribute to the reinforcement of the emulsion structure through the formation of physical entanglements (Raymundo et al. 2005). However, slight significant (p < 0.05) differences with K values were observed for long storage times of CM, SM, and DM. Although, a significant (p < 0.05) difference between day 0 and the other storage times for CHM, showing low K values exists.

The flow behaviour indicator (n) is an index to recognise the properties of the liquid product; n = 1, Newtonian fluid; n < 1 (a shear-thinning liquid), and shear-thickening or dilatant fluid; n > 1. All samples show shear-thinning behaviour with a flow behaviour index n < 1 (Table 1). No significant (p > 0.05) differences for CM, slight significant (p < 0.05) differences for SM and DM, and significant (p < 0.05) differences for CHM; with n ranging from 0.53 to 0.19; were observed over the long storage time than day 0. Notably, the data confirmed the shear-thinning liquid behaviour of the emulsions: CHM and DM showed the greatest K values and the lowest n values at day 0, confirming CHM and DM have greater consistency and less Newtonian behaviour than samples without microalgae. The addition of a combination of non-fat ingredients like protein, gums, starches, and other fat replacers with different functional roles is necessary to maintain the original viscoelastic properties of reduced-fat dressings and mayonnaise (Yildirim et al. 2016).

Figure 5 shows the dynamic mechanical spectra of the emulsions during 60 days of storage. Elastic modulus (G′) was higher than the viscous modulus (G′′) for all samples, and both parameters progressively increased, throughout the studied frequency range. Moreover, loss angle (tan δ) values for all emulsions were larger than 0.1 during the frequency range and storage time (60 days). This behaviour may be classified rheologically as a weak gel-like character (Liu et al. 2007; Ma and Boye 2013), which is in good agreement with previous reports in reduced-fat emulsion products (Santipanichwong and Suphantharika 2007; Li et al. 2014). In comparison to CM, CHM, and DM; SM presented the highest G′ and G′′ values at day 0 (Table 1), this can relate to the Spirulina having a high protein (65%) content (Ejike et al. 2017) giving up a slight reinforcement of the structure (Batista et al. 2011) and forming a flocculated and entangled network (Raymundo et al. 2005). During storage time, significant (p < 0.05) differences were seen for all the samples between day 0 and day 60 for G′ and G′′ values (Table 1), especially for CHM (Fig. 5c); with significant (p < 0.05) differences with G′ and G′′ values were showed for all the samples from day 15 to day 60 compared to day 0. Considering that some authors have attempted to prepare emulsions without any protein addition, using microalgae as the sole emulsifier, at concentrations lower than 2%, obtaining a very unstable suspension (Raymundo et al. 2005). CHM behaviour after day 15 may be because of physical or chemical emulsion changes where differing interactions with the matrix material (low content of oil (30% wt) and microalgae (1% wt)) resulting in modified stability characteristics during storage.

Frequency sweeps of emulsions. Elastic modulus (G′), viscous modulus (G′′) and loss angle (tan δ) of a Control low-fat emulsion, b Spirulina low-fat emulsion c Chlorella low-fat emulsion, and d Dunaliella low-fat emulsion, during storage time: d0: day 0, d15: day 15, d30: day 30, d45: day 45 and d60: day 60

Correlation between rheological and viscoelastic properties

Using Pearson correlation analysis, a range of correlation coefficients (r) (from 0.2809 to 0.9888) show the relationships between textural characteristics and dynamic viscoelastic properties. A positive relationship (r = 0.9140) was found between the flow behaviour index and loss tangent, fundamental rheological parameters, showing the emulsion has a solid-like viscoelastic behaviour. Other positive correlations were also found between the firmness versus consistency coefficient and cohesiveness versus flow behaviour index. The mechanical loss angle (r = 0.9457; r = 0.9152) were positively correlated with cohesiveness and adhesiveness while negatively correlated (r = 0.951; r = 0.9224) with firmness and consistency. Emulsions with microalgae have the potential to form solid-like structures giving more resistance to penetration; nevertheless, resulting in an increase of cohesiveness and adhesiveness.

Conclusion

In this study, the effect of microalgae fortification on the physical and rheological properties of low-fat oil-in-water emulsions was investigated during 60 days of storage. Microalgae addition changed properties such as aw, pH, colour, rheological, and textural properties regarding the control emulsion. However, aw and pH values follow the regulations required for these type of products. Microalgae (Spirulina, Chlorella, and Dunaliella) addition proved to give a stable and appealing colour to food emulsions during storage time, with green tonalities for Spirulina and Chlorella and yellow for Dunaliella, which might influence their sensory perception among consumers. However, incorporating Spirulina or Dunaliella in the formulation gives emulsions more stable in textural, viscoelastic, and rheological properties which can be very useful to determine their shelf life. Future studies should focus on using microalgae biomass at different levels of concentration as an ingredient for emulsions to obtain quality products with good appearance and nutritional value.

References

Alu’datt MH, Rababah T, Gammoh S et al (2016) Emulsified protein filaments: types, preparation, nutritional, functional, and biological properties of mayonnaise. In: Alexandru MG (ed) Emulsions nanotechnology in the agri-food industry, vol 3. Elsevier Inc, Amsterdam, pp 557–572

Batista AP, Nunes MC, Raymundo A et al (2011) Microalgae biomass interaction in biopolymer gelled systems. Food Hydrocoll 25:817–825. https://doi.org/10.1016/j.foodhyd.2010.09.018

Batista AP, Raymundo A, Sousa I et al (2006a) Colored food emulsions-implications of pigment addition on the rheological behavior and microstructure. Food Biophys 1:216–227. https://doi.org/10.1007/s11483-006-9022-3

Batista AP, Raymundo A, Sousa I, Empis J (2006b) Rheological characterization of coloured oil-in-water food emulsions with lutein and phycocyanin added to the oil and aqueous phases. Food Hydrocoll 20:44–52. https://doi.org/10.1016/j.foodhyd.2005.02.009

Bodart M, de Peñaranda R, Deneyer A, Flamant G (2008) Photometry and colorimetry characterisation of materials in daylighting evaluation tools. Build Environ 43:2046–2058. https://doi.org/10.1016/j.buildenv.2007.12.006

Buono S, Langellotti AL, Martello A et al (2014) Functional ingredients from microalgae. Food Funct 5:1669–1685. https://doi.org/10.1039/c4fo00125g

Chang C, Li J, Li X et al (2017) Effect of protein microparticle and pectin on properties of light mayonnaise. LWT Food Sci Technol 82:8–14. https://doi.org/10.1016/j.lwt.2017.04.013

Dufossé L (2016) Current and potential natural pigments from microorganisms (bacteria, yeasts, fungi, microalgae). In: Carle R, Schweiggert RM (eds) Handbook on natural pigments in food and beverages: industrial applications for improving food color. Elsevier Ltd, Amsterdam, pp 337–354

Ejike CECC, Collins SA, Balasuriya N et al (2017) Prospects of microalgae proteins in producing peptide-based functional foods for promoting cardiovascular health. Trends Food Sci Technol 59:30–36. https://doi.org/10.1016/j.tifs.2016.10.026

Gouveia L, Raymundo A, Batista AP et al (2006) Chlorella vulgaris and Haematococcus pluvialis biomass as colouring and antioxidant in food emulsions. Eur Food Res Technol 222:362–367. https://doi.org/10.1007/s00217-005-0105-z

Jain S, Winuprasith T, Suphantharika M (2019) Design and synthesis of modified and resistant starch-based oil-in-water emulsions. Food Hydrocoll 89:153–162. https://doi.org/10.1016/j.foodhyd.2018.10.036

Joint FAO/WHO Food Standards Programme (1987) Codex alimentarius commission. Jt FAO/WHO FOOD Stand Program CODEX Comm FOOD Addit Contam Thirty-first. https://doi.org/10.1007/BF02582346

Li J, Wang Y, Jin W et al (2014) Application of micronized konjac gel for fat analogue in mayonnaise. Food Hydrocoll 35:375–382. https://doi.org/10.1016/j.foodhyd.2013.06.010

Liu H, Xu XM, Guo SD (2007) Rheological, texture and sensory properties of low-fat mayonnaise with different fat mimetics. LWT Food Sci Technol 40:946–954. https://doi.org/10.1016/j.lwt.2006.11.007

Ma Z, Boye JI (2013) Advances in the design and production of reduced-fat and reduced-cholesterol salad dressing and mayonnaise: a review. Food Bioprocess Technol 6:648–670. https://doi.org/10.1007/s11947-012-1000-9

Morley WG (2016) Mayonnaise. In: Caballero B, Finglas P, Toldra F (eds) Encyclopedia of food and health, 1st edn. Academic Press, Cambridge, pp 669–676

Mozaffarian D (2017) Dietary and policy prioritites for CVD, diabetes and obesity: a comprehensive RV. Circulation 133:187–225. https://doi.org/10.1161/CIRCULATIONAHA.115.018585.Dietary

Nout MJR, Rombouts FM (2000) The microbiological safety and quality of food. Fermented and acidified plant foods. Aspen Publishers Inc, Gaithersburg, pp 696–701

Park WS, Kim HJ, Li M et al (2018) Two classes of pigments, carotenoids and c-phycocyanin, in spirulina powder and their antioxidant activities. Molecules 23:1–11. https://doi.org/10.3390/molecules23082065

Priyadarshani I, Rath B (2012) Commercial and industrial applications of microalgae: a review. J Algal Biomass Util 3:89–100

Raymundo A, Gouveia L, Batista AP et al (2005) Fat mimetic capacity of Chlorella vulgaris biomass in oil-in-water food emulsions stabilized by pea protein. Food Res Int 38:961–965. https://doi.org/10.1016/j.foodres.2005.02.016

Santipanichwong R, Suphantharika M (2007) Carotenoids as colorants in reduced-fat mayonnaise containing spent brewer’s yeast β-glucan as a fat replacer. Food Hydrocoll 21:565–574. https://doi.org/10.1016/j.foodhyd.2006.07.003

Su H, Lien C, Lee T, Ho J (2010) Development of low-fat mayonnaise containing polysaccharide gums as functional ingredients. J Sci Food Agric 90(5):806–812. https://doi.org/10.1002/jsfa.3888

Sui Y, Vlaeminck SE (2020) Dunaliella microalgae for nutritional protein: an undervalued asset. Trends Biotechnol 38:10–12. https://doi.org/10.1016/j.tibtech.2019.07.011

Sun A, Gunasekaran S (2009) Yield stress in foods: measurements and applications. Int J Food Prop 12:70–101. https://doi.org/10.1080/10942910802308502

Tadros T (2013) Rheology. In: Tadros T (ed) Encyclopedia of colloid and interface science. Springer, Berlin, Heidelberg, pp 1020–1042

Tang G, Suter PM (2011) Vitamin A, nutrition, and health values of algae: spirulina, chlorella, and dunaliella. J Pharm Nutr Sci 1:111–118. https://doi.org/10.6000/1927-5951.2011.01.02.04

Uribe-Wandurraga ZN, Igual M, García-Segovia P, Martínez-Monzó J (2020) In vitro bioaccessibility of minerals from microalgae-enriched cookies. Food Funct 11:2186–2194. https://doi.org/10.1039/c9fo02603g

Yang SC, Lai LS (2003) Dressings and mayonnaise | chemistry of the products. In: Caballero B, Finglas P, Toldra F (eds) Encyclopedia of food sciences and nutrition, 2nd edn. Academic Press, Cambridge, pp 1898–1903

Yildirim M, Sumnu G, Sahin S (2016) Rheology, particle-size distribution, and stability of low-fat mayonnaise produced via double emulsions. Food Sci Biotechnol 25:1613–1618. https://doi.org/10.1007/s10068-016-0248-7

Acknowledgements

The authors want to thank the Ministerio de Ciencia, Innovación y Universidades, CDTI, and Fondo Europeo de Desarrollo Regional (FEDER) for their financial support throughout the ALGAVITAE Project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uribe-Wandurraga, Z.N., Martínez-Sánchez, I., Savall, C. et al. Microalgae fortification of low-fat oil-in-water food emulsions: an evaluation of the physicochemical and rheological properties. J Food Sci Technol 58, 3701–3711 (2021). https://doi.org/10.1007/s13197-020-04828-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04828-1