Abstract

Reducing fat and cholesterol content is currently one of the primary trends in food product innovation. Fat plays an important role in maintaining food quality, particularly the texture, flavor, and stability of food emulsion products. The food industry faces major challenges in seeking to produce reduced-fat and low-cholesterol mayonnaise and dressings that have attributes similar to full-fat products. Efficient monitoring of products to ensure desirable quality requires knowledge of their physicochemical characteristics, including appearance, rheology, emulsion stability, microstructure, and flavor, as well as particle size and charge distribution. The purpose of this paper is to provide a comprehensive overview of trends in the development of reduced-fat and low-cholesterol dressings. The effects of reducing fat content or using various fat replacers on the physicochemical properties of dressing and mayonnaise products are detailed with supporting experimental results. The possibility of using plant-based ingredients or reduced-cholesterol egg yolk in the formulation of such products is also examined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Salad, which can be served as an appetizer, a side dish, or an entire meal, is one of the most popular and customized food choices. Salad dressings and mayonnaise are sauces used to enhance and modify the flavor of salads and other foods. Together, they account for a large part of the semi-solid foods market. There is a grey area between the definition of a salad dressing and mayonnaise (Sheldrake 2003). Salad dressings tend to have lower oil content, are more highly flavored, and may contain starch to give the required consistency, resulting in either spoonable or pourable products, whereas mayonnaise products are generally spoonable, less flavored, and have relatively higher oil content with or without starch.

Food decisions made by consumers influence their health and affect the success of food products in today's consumer-oriented food marketplace (Asp 1999). In North America, there is an increasing tendency toward reducing the content of food constituents, such as fat, salt, and cholesterol, which have been linked to human health concerns. In fact, more natural ingredients, reduced-calorie content, and allergy restrictions are among the primary trends driving current product innovation. Overconsumption of fat leads to obesity and is associated with several human health problems. However, removal of fat can cause significant changes in the sensory and bulk physicochemical properties of dressing and mayonnaise products which may be undesirable for consumers, as fat imparts properties such as texture, lubricity, stability, color, and flavor to foods. Food manufacturers, therefore, face major challenges in seeking to produce novel varieties of mayonnaise and dressing products, including products with higher levels of plant-based ingredients and reduced-calorie content. To achieve this goal, texture enhancers or fat substitutes must be added to maintain the texture and organoleptic attributes of dressings, as most consumers are not willing to sacrifice the taste or flavor of food products for health benefits. Fat substitutes are either carbohydrate-based (such as various gums, modified starch, polydextrose), protein-based (e.g., Simplesse® microparticulate proteins, Dairy-Lo® modified whey protein concentrates), or fat-based (e.g., OlestraTM, Salatrim®).

Traditionally, egg yolk has been the most commonly used emulsifier in salad dressing products. The high cholesterol content in egg yolk is a disadvantage, however, because of the role that cholesterol plays in heart disease. Moreover, the fact that egg is a common food allergen has stimulated the food industry to develop alternatives. A number of studies have examined the behavior of egg yolk with reduced cholesterol content (cholesterol extraction was achieved with different organic solvents) in stabilizing emulsions (Moros et al. 2002a; Paraskevopoulou et al. 1997b; Paraskevopoulou et al. 1999). The possibility of using plant-based proteins as an emulsifier, including soybean protein (Puppo et al. 2000; Diftis et al. 2005), lupin protein (Franco et al. 1998; Raymundo et al. 2002), pea protein (Franco et al. 2000), and wheat protein (Ghoush et al. 2008) has been extensively studied.

According to the US Food and Drug Administration (USFDA 2012), salad dressing must contain at least 30 % vegetable oil and the equivalent of 4 % liquid egg yolk (USFDA 2012; Smittle 2000). Health Canada regulations require that mayonnaise contain at least 65 % vegetable oil, and French dressing and other salad dressings, at least 35 % vegetable oil (Health 2011). Commercially available reduced-fat dressings or mayonnaise usually contain 3 g of fat or less per serving. Fat-free products contain no fat or only a physiologically inconsequential amount (<0.5 g fat) per serving. Although the general trend toward developing dressings with reduced oil content and plant-based dressing products is reflected in current market practices, the existing legislation is insufficient to regulate the composition of these low-fat/no-fat or low-cholesterol/no-cholesterol products. Therefore, there is a need for additional legislation governing reduced-calorie/no-calorie dressing and mayonnaise products as well as products containing plant-based ingredients.

Reviews on this topic are few. In a review dating back more than a decade, McClements and Demetriades (1998) examined the role of fat in food emulsions and made several suggestions related to the successful development of reduced-fat food emulsions. More recently, Sikora et al. (2008) published a comprehensive review on sauces and dressings which covered rheological and textural properties, chromatographic approaches for analyses, and microbiological and sensory evaluation. The authors also considered healthy sauces, such as those with low sodium and reduced fat. A review by Gallegos et al. (2004) examined the viscous and viscoelastic behavior of concentrated food emulsions and plant food suspensions and discussed the influence that processing variables have on rheological behavior. To help the food industry produce reduced-fat/low-cholesterol dressing and mayonnaise products with consistently high quality, it is important to understand (1) how processing variables influence the texture and microstructure of final products, in order to effectively control operational conditions; (2) how ingredients (such as oil, water, emulsifiers, thickeners, flavoring agent) contribute to the bulk emulsion system, in order to rationally select materials; (3) product characteristics (such as appearance, rheology, stability, microstructure, and flavor), in order to provide information on the relationship between droplet characteristics, bulk physical behavior, and sensory properties; (4) the potential for using alternative, plant-based ingredients, in order to partly reduce or eliminate animal-origin ingredients (e.g., when targeting products for vegetarians, as well as people seeking low cholesterol content and allergen-free ingredients and those seeking a better balance between ingredients from animal and plant sources); (5) how the sensory and bulk physicochemical properties relate to the composition and microstructural characteristics of reduced-fat products, in order to adjust and monitor processing and compositional variables. The present review focuses on the areas identified above, which were not addressed comprehensively in earlier reviews and provides information which should be helpful to food companies interested in capturing these emerging markets.

Role of Ingredients

Ingredients used in food emulsions such as salad dressing and mayonnaise products interact with each other either physically or chemically and determine the quality of the final products. Growing consumer interest in reduced-fat/cholesterol food products has made it necessary to identify appropriate ingredients for formulating these products as the removal of certain ingredients (e.g., fat) may have a significant influence on the quality and taste of food emulsions. The use of different types of emulsifiers, thickeners, and fat replacers has been studied by some researchers and has been tested by food manufacturers with the aim of maintaining the overall physicochemical and organoleptic properties of the reduced-fat/cholesterol dressing and mayonnaise product. Table 1 summarizes the types and quantities of ingredients used in the production of full-fat and reduced-fat dressing and mayonnaise products. The nature and role of individual raw materials commonly used in various dressing and mayonnaise products are examined below.

Oil

Oil contains different types of molecules, including acylglycerols, fatty acids, and phospholipids. Oil plays an important role in food emulsions since it contributes to the body (viscosity and cling), texture (creamy and smooth mouthfeel), lubricity (slipperiness), appearance (sheen), and flavor (intensity and duration) of products, in addition to enhancing shelf life (McClements and Demetriades 1998; Stauffer 1999). Oil is also responsible for dissolving ingredients such as vitamins, coloring agents, antioxidants, and surfactants. It is a major source of energy and nutrients. The types of oil commonly used in the formulation of dressing and mayonnaise include soybean, canola, and sunflower oil, and sometimes cottonseed and olive oil (Martin et al. 2000). The reduction of fat in salad dressing and mayonnaise could have an impact on their packing characteristics which therefore could change their rheological and textural behavior and has also profoundly influence their stability during storage. In addition, flavor perception of the reduced-fat dressing and mayonnaise products could also be significantly altered. In this regard, food industries face considerable challenges as no single ingredient can mimic the characteristics of fat.

Water

Water is one of the most important components in almost every type of food. Several ingredients in dressing and mayonnaise products are soluble in water, including protein, polysaccharides, sugars, salts, vitamins, colors, antioxidants, and surfactants. In normal practice, a mixture of polysaccharides and sugar is pre-gellified in water before mixing with other water-soluble ingredients. Interaction between these ingredients and water, which is governed by the pH of the aqueous solution, determines the solubility, partitioning, volatility, conformation, and chemical reactivity of the majority of the food ingredients in dressing and mayonnaise emulsions (McClements 2005b, d). Incorporation of water also reduces the viscosity and elastic modulus of the food system. Water activity (a w) is the measurement used to indicate the amount of “free water” in a sample, i.e., the water molecules that are not chemically or physically bound in the sample. Free water can serve as a medium for microbial reproduction, migration, and contamination. Therefore, a w is an important parameter for evaluating the quality and safety of salad dressing and mayonnaise products. Values for a w of 0.95 and 0.93 have been reported for mayonnaise samples containing 37 % to 41 % oil and 77 % to 79 % oil, respectively (Chirife et al. 1989). The combination of high a w (0.85 to 0.89/0.93) and low pH (3.3 to 4.1) can inhibit the growth of both yeast and lactobacillus organisms in food products (Martin et al. 2000).

Emulsifiers

Emulsions are thermodynamically unstable systems due to the density difference and the energetically unfavorable contact between oil and water. The incorporation of emulsifiers and/or thickening agents is a critical part of emulsion preparation. Emulsifiers and thickening agents may be grouped together as stabilizers (McClements and Demetriades 1998). The difference between an emulsifier and a thickener lies in the different properties they impart to emulsion systems. Emulsifiers are used to prevent the oil and water droplets in an emulsion from separating and coalescing after they are intentionally disrupted to form a continuous phase during homogenization. As surface-active molecules, emulsifiers decrease the interfacial tension between the oil and water phase, and provide a protective coating around the emulsion droplets, thus preventing droplet aggregation. The mechanisms involved in preventing droplets from aggregating vary among the different emulsifiers used and include electrostatic, steric, hydration, and thermal fluctuation interactions (McClements 2008).

Emulsifying capacity is generally determined by the relative adsorption of proteins, which depends on their concentration, hydrophobicity, ability to unfold, and possible packing configurations at the interface (Parker 1987). Emulsifiers with better emulsifying capacity are able to reduce the average size of the oil droplets and increase the droplet interaction, they play an important role in developing an extensive connected network in emulsion structure. Selection of the type and levels of emulsifiers chosen vis-à-vis the level of oil to use in producing reduced-fat and reduced-cholesterol salad dressing and mayonnaise products could therefore affect product appearance, texture, and mouthfeel.

The main classes of food emulsifiers include dairy proteins (whey protein, caseinates), vegetable proteins (pea and soya proteins), phospholipids (lecithin), fat-derived emulsifiers (mono- and diglycerides, and esters of mono- and diglycerides), carbohydrate-derived emulsifiers (starch ester, sucrose ester, and polysorbates), and hydrocolloids (gum arabic) (Sheldrake 2003). These emulsifiers are mainly nonionic (e.g., monoacylglycerols, sucrose ester of fatty acids), anionic (e.g., fatty acids), or zwitterionic (e.g., lecithin) (McClements and Demetriades 1998; McClements 2005b). Specific examples of some emulsifiers and their properties are provided below.

Proteins

The kinetics of protein adsorption at the oil–water interface involve two major steps: first, the native protein molecules are diffused and penetrate at the interface; secondly, these adsorbed molecules are rearranged to achieve a state of minimum free energy.

(a) Egg Yolk

Egg yolk in liquid, frozen, and dried states or in the whole egg form has been used in the formulation of salad dressing and mayonnaise products. Their performance differs depending on the form in which they are used (Harrison and Cunningham 1985; Yang and Lai 2003). When whole egg is used, the final product is much stiffer than when egg yolk is used as an emulsifier, possibly because the presence of denatured egg albumin at the interface forms a matrix in the aqueous phase and provides more emulsification capacity (Stauffer 1999). Shenton (1979) showed that egg yolk stabilized an artificial cream emulsion by forming a strong membrane around the oil droplets, with apoliprotein entering into hydrophobic reaction and the long-chain saturated triglycerides becoming connected to the oil phase. Chang et al. (1972) examined electron microscope images of mayonnaise products and observed a continuous speckled layer around the oil droplets which they considered to be egg yolk lipoproteins. They also noticed a fibrous membrane on the surface of drops after washing with water, which they considered to be a livetin–phosvitin complex.

Egg yolk has a complex composition, with a protein:lipid ratio of 1:2. Lipoproteins, phospholipids, and cholesterol are the major components of egg yolk. The configuration of the complex lipoprotein molecule (Fig. 1) in dressing and mayonnaise emulsions can be altered by adjusting conditions such as pH, ionic strength, solvent composition, and temperature of the food emulsion. These effects are dependent on the extent to which the low-density lipoprotein micelles of yolks are degraded. The higher the degree of the degradation, the more the reactive groups which were previously confined within the interior of the micelles are available for subsequent crosslinking and network formation between droplets. Guilmineau and Kulozik (2007) found that pre-heating egg yolk at 68 °C for up to 11 min prior to emulsification resulted in a reduction (up to 40 %) in the average oil droplet size in mayonnaise compared with an emulsion stabilized with non-heated egg yolk. The rheological properties were also affected due to the presence of thermally unfolded proteins, which were more active (Kiosseoglou and Sherman 1983a, b; Kiosseoglou 2003).

Low-fat egg yolk protein concentrates can be prepared by extracting cholesterol and other lipids from yolks. Reduced-cholesterol yolk may have more or less effective adsorption behavior depending on the method of lipid extraction and the structural changes that occur during the extraction processes (Paraskevopoulou et al. 1997a).

(b) Other Proteins

In addition to the important emulsification capacity of lipoproteins from egg yolk, the performance of dairy proteins such as whey protein isolate and casein (Álvarez Cerimedo et al. 2010; Riscardo et al. 2003; Turgeon et al. 1996), vegetable proteins, such as soybean protein (Diftis et al. 2005; Puppo et al. 2000), lupin protein (Franco et al. 1998; Raymundo et al. 2002), pea protein (Franco et al. 2000), and wheat protein (Ghoush et al. 2008), have been extensively investigated in salad dressings applications.

When lupin protein isolates were treated at different temperatures (50–90 °C) for varied time periods (10 and 40 min), the rheological and textural parameters as well as the protein surface hydrophobicity increased with increasing temperature and heating time, and the Sauter diameter of the oil droplets decreased (Raymundo et al. 1998). From an economic point of view, however, proteins are frequently used in their native forms in the preparation of dressing and mayonnaise emulsions. Another approach to manipulate emulsion rheology and their gel-like properties is to apply thermal treatment after processing of the emulsion. Dickinson and Casanova (1999) observed a large increase in viscoelasticity upon heating (35–45 °C) of an oil-in-water emulsion stabilized by sodium caseinate with a controlled amount of ionic calcium. The increased rheological parameters were mainly attributed to increased hydrophobic interactions in the flocculated network with increasing temperatures. Moros et al. (2003) as well as Chen and Dickinson (1998) also found increased rheological behavior of egg yolk- and whey protein-stabilized emulsions due to thermal-induced droplet coalescence and flocculation.

Phospholipids and Lecithin

Lecithins are natural substances which are derived from various foods such as soybeans, egg yolks, corn, canola, sunflower, and wheat germ (Lecithins). Phospholipids are the functional ingredients of all forms of lecithin. Lecithins do not have a uniform chemical structure; instead, they are a group of similar but clearly differentiated components, classified as phospholipids (Whitehurst 2004). The structure of lecithin from egg yolk consists of triglycerides and phospholipids. It is different from the lecithin derived from soybean, which is composed mainly of four types of phospholipids, i.e., phosphatidylcholine (PC), phosphatidylethanolamine (PE), phosphatidylinositol (PI), and phosphatidic acid (PA), and may contain relatively large amounts of triglycerides (Hancer et al. 2002).The molecular structure of phospholipids, i.e., the major component of lecithin, is partly hydrophilic and partly hydrophobic, which makes lecithin an effective emulsifier at the oil and water interface. Lecithins or phospholipids could be used with other emulsifiers and hydrocolloids to stabilize reduced-fat and reduced-cholesterol salad dressing and mayonnaise products.

Small Molecule Surfactants

Small molecule surfactants are comprised mainly of lipid-based ingredients, such as fat-derived monoglycerides and their derivatives, as well as carbohydrate-based components, such as starch esters, sorbitan esters, and their derivatives, including polysorbates (Tweens) and sucrose esters. These ingredients can be used to control fat morphology and crystallization (Kalnin et al. 2004) and promote transient stability through complex interactions with proteins by changing the properties of the interfacial layers (Dickinson 1992, Eisner et al. 2007). These small molecule surfactants usually have an adverse impact on providing long-term stability as they often preferentially adsorb to the interface and inhibit the absorption of the large-molecule surfactants which function better at long-term stability (Ford et al. 2004).

Monoglycerides and their derivatives account for about 75 % of world production of food emulsifiers and are considered the most important group of emulsifiers. The hydroxyl group in monoglycerides is usually replaced by other branches, such as the acetyl group, lactic acid, succinic acid, citric acid, diacetyltartaric acid, or the polyglyceryl group. This modification is aimed at improving the emulsifying or other functional properties of these chemicals. Polysorbate 60 is a common ingredient used in commercial dressing formulations; the addition of a maximum level of 0.3 % is permitted to enhance “home emulsification”.

An emulsion containing both small-molecule surfactants and proteins could lead to either competitive or cooperative interfacial adsorption. Additionally, the complex interactions between these emulsifiers, proteins, and carbohydrates and the influence on emulsion characteristics will vary according to their composition. The selection of the type of emulsifier as well as the ratio of small-molecule surfactant versus protein could be controlled to improve both the texture and shelf-life of the dressings including reduced-fat and reduced-cholesterol salad dressing and mayonnaise products.

Others

Mustard powders contain almost equal amounts of protein, carbohydrate, and oil. They are also rich in mucilaginous material, composed primarily of polysaccharides (Cserhalmi et al. 2000). Proteins and carbohydrates bind with oil in the mustard powder, contributing to its emulsifying capacity at the oil–water interface. The emulsifying properties of mustard powders are not only dependent on their chemical and physical properties but also on the method of incorporating mustard in food emulsions (Yang and Lai 2003).

Thickeners

Gums

A thickener is a chemical component or mixture of components that can impart long-term emulsion stability by thickening a food system (i.e., reducing the movement of the system) and by forming viscous, ordered networks in the continuous phase to prevent oil separation (Dickinson and Stainsby 1988). Thickeners function in emulsions either as a bulking agent (such as starch) or by forming networks (such as pectins). Polysaccharide macromolecules (gums), casein micelles, fat crystals, starch and modified starch all belong to the category of thickeners. Most gums used as thickeners are hydrophilic, except for gum arabic and propylene glycol alginate (PGA), which are amphoteric and are able to form a film at the oil–water interface.

Generally, biopolymer gums are obtained from trees, plants, tree gum exudates, fermentation of bacterial polymeric products, biosynthesis, and chemical modification (Sikora et al. 2008). Biopolymer gums are usually highly hydrated and extended molecules or molecular aggregates with a long polysaccharide chain which has numerous side branches of sugars or oligosaccharides. Their highly branched structure contributes to water solubility. The ability of such gums to increase the viscosity of emulsions depends principally on their molecular weight, degree of branching, conformation, and flexibility (Huang et al. 2001). Gums are often added to salad dressings and mayonnaise products for emulsion stability, control of pourability, cling improvement, and suspension of solid or spice particles (Ma and Barbosa-Canovas 1995a). Most biopolymers help to stabilize droplets against coalescence principally through a combination of physical and chemical interactions, including electrostatic and polymeric steric interactions, hydrogen bonding, hydrophobic association, and cation-mediated crosslinking. In addition to their stabilizing ability, these gums also contribute to the technical and functional properties of emulsions in terms of aqueous solubility, thickening ability, gelling and gel stabilizing ability, and most importantly sensory creation ability (Phillips and Williams 2009; Sikora et al. 2008). Recently, many gums including xantham, guar gums, gum arabic, and pectin have been recognized as providing health benefits on account of their role in reducing blood cholesterol levels and their prebiotic effects (Glueck et al. 1994; Behall 1997; Phillips and Williams 2009).

The behavior of various gums in formulated dressing and mayonnaise is significantly influenced by pH, ionic strength, concentration, and temperature of the gum solution. The gums used in the formulation of dressing products should be stable in an acidic environment. The tendency toward hydrolysis at low pH can decrease the viscosity of gum solutions and impair their performance. Xanthan, PGA, and hydroxypropyl methylcellulose are gums that are frequently used in low-fat or fat-free dressings. They exhibit high resistance to hydrolysis during storage at a low pH level. The viscosity of different gums may be low (e.g., arabic, ghatti), medium (PGA, tragacanth, xanthan), or high (guar and locust bean gum) (Yilmazer et al. 1991).

Cellulose is a group of important gums with substituted groups which improve its solubility. The most common cellulose gums used in low-fat dressing and mayonnaise are those substituted by carboxymethyl, methyl, and hydroxyproply plus methyl groups. Other cellulose gums, such as microcrystalline cellulose, usually have different uses in processed foods. In addition to the traditionally used gums, gums derived from flaxseed (Stewart and Mazza 2000), hsian tsao leaf (Lai and Lin 2004), and Lepidium perfoliatum seed (Koocheki et al. 2009) have been studied for development as potential new alternatives. Canada's Food and Drug Regulations have no provisions pertaining to the maximum permitted levels of different gums in formulated dressing products, which means that their use is governed by good manufacturing practices (Health 2011). Recently, permission to use gum arabic modified with octenyl succinic anhydride (OSA) as an emulsifier has been assessed according to Health Canada guidelines, and the maximum level use of 1 % has been approved in French dressing and salad dressing (Health Canada Amends, 2012). No related regulations regarding the maximum levels of using these gums in salad dressings and mayonnaise are specified according to USFDA (2012) and EU legislations (EEC 1992).

A variety of gums as described could be considered for use in the production of reduced-fat dressing and mayonnaise products to improve flow behavior, texture, appearance and, where required, organoleptic properties.

Gum Combinations

Synergistic interactions between hydrocolloids are of special interest, as they offer the possibility of novel functional properties and improved rheological behavior with possibly reduced cost (Katzbauer 1998). The addition of locust bean gum to kappa carrageenan yields softer, more transparent gels (Phillip and Williams 2003). Xanthan gum (XG), a hydrophilic polymer, is mostly used with propylene glycol alginate (PGA); the mixture provides enhanced stabilizing characteristics with decreased pseudoplasticity and increased loss moduli (Pettitt et al. 1995). Xanthan gum also interacts synergistically with galactomannans (such as locust bean gum and guar gum), which consist of a 1,4-β-d-mannan backbone with single 1,6-α-D-galactopyranosyl units attached (Katzbauer 1998). For example, the combination of xanthan gum and locust bean gum forms a firm, rubbery, thermoreversible gel. A mixture of xanthan and guar gum shows significantly enhanced viscosity. The use of gum combination could, thus, bring new functionalities and novel rheological properties which could improve the texture characteristics of reduced-fat and reduced-cholesterol salad dressing and mayonnaise products.

Starch and Modified Starch

Starch is composed mainly of linear amylose and branched amylopectin. Starch granules retain their integrity in the native form; they can be used to provide desired structure to finished dressing and mayonnaise products. Maltodextrins and dextrins, polysaccharides produced by starch hydrolysis, are often used as bulking agents or fat mimetics which impart body and mouthfeel to food products. Pre-gelatinized starches which have been subjected to hydration, swelling, crosslinking during heating, and retrogradation upon cooling are also used. The specific time and temperature for gelatinization differ depending on the source of the starch, which can affect properties of the pre-gelatinized starch.

Modified starch refers to starches which have been subjected to different treatments aimed at achieving broader applications in the food industry. Waxy maize starch, which is composed of nearly 100 % amylopectin, can be modified by crosslinking with sodium trimetaphosphate or stabilizing by hydroxypropyl substitution. Crosslinked starch has hydroxyl groups on adjacent chains joined by covalent bonding. Stabilized starch has hydroxyl groups formed of ester or ether bonds with other small molecules. The purpose of crosslinking is to prevent hydrolysis under the acidic environment characteristic of salad dressings. Starch gel tends to become soft if hydrolysis occurs. Modifying starch can interfere with recrystallization of the side chains of the starch molecules and it helps to maintain the creamy texture of dressings during storage in the refrigerator (Stauffer 1999). Starch modification, therefore, facilitates the formation of stable gels at low pH and shear and at increased or decreased gelatinization temperatures, and leads to gels with flexible alteration in mouthfeel, i.e., either much softer or firmer.

As a structuring agent due to its transformation during food processing, starch, and modified starch products are often selectively combined with non-starch hydrocolloids to obtain products such as reduced-fat salad dressing and mayonnaise with desirable textural properties. A dramatic textural change can be obtained due to specific interactions between starch and emulsifiers and non-starch hydrocolloids in these products. Furthermore, the combination of starch and hydrocolloids can reduce the long and slimy texture of reduced-fat products compared to when hydrocolloids are used alone.

Other Thickeners

In addition to gum and starch, the solid fibrous products from different sources such as potato, oat, and wheat can also be used as thickeners. They have the ability to bind water, reducing available free water, and therefore enhance the viscosity of emulsions (Sheldrake 2003). Unlike starch, these fibrous products are resistant to enzymatic breakdown within the gut. The possibility of using microalgal biomass, such as Chlorella vulgaris, as a fat mimetic (besides their possible advantages as coloring and antioxidant agent) in the application of protein stabilized food emulsions has also been explored (Raymundo et al. 2005). These ingredients could either improve emulsion stability via cooperative effects with vegetable protein or adversely affects their stability by displacement of protein from the interface (Dickinson and Hong 1995). Their judicious use could, therefore, be considered in the production of reduced-fat salad dressing and mayonnaise products.

Fat Mimetics

A variety of new fat substitutes have been developed to satisfy demands associated with the current trend toward reduced fat foods. Some commercial fat replacers that are protein-based, carbohydrate-based, or fat-based produce the desirable mouthfeel of fat without having the energy content of fat. Several of these products are described below.

Simplesse®, a mixture of heat-treated egg and dairy proteins in the form of spherical particles with diameters of about 0.5 to 2 mm, is claimed to have a “ball bearing” sensory effect on the palate (Stauffer 1999).

Kelcogel® gellan gum is a hydrocolloid produced by the microorganism Sphingomonas elodea. The acyl groups in its molecular structure have a profound influence on its gel characteristics. The product is available in two forms (high acyl content and low acyl content), which are obtained by deacylation under alkaline conditions. The low acyl gellan gum can form hard and brittle gels, whereas the high acyl gellan gum can form soft and elastic gels. Litesse®, or polydextrose (soluble fiber), can be used effectively as a low calorie bulking agent in various food products.

Olestra® is a compound synthesized from sucrose which can bond with six to eight fatty acids (normal fats usually have only three fatty acids). It has a similar taste and mouthfeel to fat but passes through the gastrointestinal tract undigested without contributing calories or nutritive value. However, Olestra inhibits the absorption of some vitamins and other nutrients and is therefore not recommended for use as a food additive in Canada. Caprenin® is a randomized triglyceride primarily comprised of caprylic (C8:0), capric (C10:0), and behenic (C22:0) acids. It has reduced energy value compared with regular fat due to the incomplete absorption of its long-chain saturated fatty acid (C20–C24) (Webb and Sanders 1991). Some of these fat substitutes are currently being used in food production, whereas others are still awaiting FDA approval.

A group of Japanese scientists developed a functional ingredient, medium- and long-chain triacylglycerol (MLCT)-Oil, as a replacement for vegetable oil, which is composed mainly of long-chain triacylglycerol (Koh et al. 2008). This product is intended for use in obesity management and serum total cholesterol control without changing food taste. A study was conducted to assess the possibility of developing MLCT-based salad dressings treated with different antioxidants (oleoresin sage extract, and tert-butylhydroquinone). The quantitative descriptive analysis showed no significant differences in the salad oil or salad dressings, except for the MLCT-based oil/dressings treated with oleoresin sage extracts. The overall quality of the physical appearance and organoleptic acceptability showed no significant differences in all systems which indicated the promising application of MLCT oil in terms of sensory acceptance. However, a few clinical studies have reported some negative effects for the consumption of medium-chain triacylglycerol, specifically, an increase in the risk of cardiovascular disease (Hill et al. 1990; Bourque et al. 2003).

Acidifying Ingredients

The acidification of salad dressing and mayonnaise is often achieved by the addition of acidifying ingredients, including vinegar, lemon juice, lime juice, and organic acid acidulants (citric acid, acetic acid, lactic acid, tartaric acid, and malic acid), or mineral acid acidulants (phosphoric and hydrochloric acids). The pH value of foods products influences their susceptibility to microbial growth. However, pH control alone is not sufficient to preserve dressings or mayonnaise products from spoilage. An acidic environment with a pH value of 3.0 to 4.5, together with the preservative effect of undissociated acetic acid (typically added in the form of vinegar, lactic acid, or other weak acids), is important for ensuring the microbiological stability of such products. The weak acids used in salad dressings differ in their preservative abilities. For example, citric acid reduces the pH level but has no antimicrobial activity, whereas undissociated acetic acid inhibits the growth of lactobacilli. The solubility of undissociated acid in the aqueous phase is also an important factor, since the portion that solubilizes in the oil phase has no preservation effect. The presence of more than 0.2 % undissociated acetic acid in the aqueous phase can control the growth of pathogens (Martin et al. 2000). The growth of Salmonela and L. monocytogenes in a typical reduced-calorie mayonnaise was decreased by 4 log in 3 days when the products had a pH below 4.1 and 0.7 % acetic acid in the aqueous phase.

Sugar and Salt

The presence of salt and sugar in dressing and mayonnaise products not only functions as seasoning but also helps to reduce water activity and therefore inhibit spoilage organisms. In some commercial dressing products, corn syrup (such as 15.5 % high-fructose corn syrup) is sometimes used as a sugar source because of its enhanced flavor.

The types and concentrations of salt in dressing and mayonnaise products contribute to the structure and overall textural attributes of these foods (Harrison and Cunningham 1986). Calcium, sodium, potassium, chloride, carbonate, and phosphate are common salts used in dressing products. Harrison and Cunningham (1986) reported that the addition of various types of salt significantly affected the structure and performance of liquid egg yolk in mayonnaise. Martínez et al. (2007) also found that salt content (from 0 to 2.3 %, w/w) had a significant effect on the rheological properties of salad dressing-type emulsions stabilized by binary blends of egg yolk and different types of amphiphilic molecules (e.g., Tween 20, sucrose laurate, and pea protein). The addition of salt produced a progressive increase in viscous and viscoelastic parameters of dressings; a markedly higher increase was observed when proteins (i.e., egg yolk and pea protein) were used as the predominant emulsifiers in the blends, a finding that may be attributable to an increase in interdroplet interactions and increased viscosity of the continuous phase induced by salt addition.

Spices and Flavoring Ingredients

Flavor plays an important role in determining consumer purchasing intention. Mustard is the principal flavor ingredient in mayonnaise. A greater diversity of flavoring ingredients is used in salad dressings. Spices or dried vegetable pieces, including pureed or dried celery, onion, carrot, garlic, paprika, green, and red peppers as well as parsley are commonly used in commercial dressing products. Some non-standard dressings on the market consist of very complex mixtures, which sometimes include dairy products (e.g., buttermilk powder, modified milk ingredients, Parmesan and Romano or blue cheese), as well as other flavoring ingredients, such as anchovy paste, monosodium glutamate (MSG), and sodium inosinate. Disodium inosinate is a common food additive, which is used as a flavor enhancer in commercial dressings; it is used in synergy with MSG to provide the savory taste known as umami; it is also added in conjunction with ingredients that are natural sources of glutamic acid, such as Parmesan cheese, tomatoes, or yeast extract (Wikipedia article). The solubility and hydrophobicity of spices and flavoring and coloring agents determine how and when these ingredients will be tasted; they can therefore influence the overall flavor of products and consumer perceptions. Flavor compounds must be released from and diffuse out of the droplets in dressing emulsions before they can be perceived by the taste receptor. Textural attributes of dressing and mayonnaise are thus able to modulate flavor perception.

Most of the aroma compounds in foods are fat soluble; the partition coefficient indicates that these compounds are associated with the lipid phase at equilibrium (de Roos 1997; Leland 1997). Flavor perception can be modified in reduced-fat or fat-free dressing and mayonnaise relative to full-fat products since the distribution of fat and water in an emulsion influences the balance of each flavor. Additionally, the matrix of other food ingredients markedly affects the rates and pattern of flavor release. McClements and Demetriades (1998) report that the sensation of less polar flavors tends to be tasted by the receptor after the sensation of more polar flavors (e.g., sugar, vinegar, acetic acid, and citric acid). With a decrease of fat content in dressing and mayonnaise, the sensation of the polar flavors tends to become more intense. For the food industry, therefore, developing products with reduced-fat content that will meet consumers' desire for fatty sensation with the required flavor release pattern, remains a big challege.

Food Preservatives

In addition to pH and undissociated organic acids, preservatives in legally allowed amounts are often used in dressing and mayonnaise products to ensure microbiological stability. Weak lipophillic organic acids are an important group of preservatives commonly used in food emulsions; they include ethylene diamine tetra-acetic acid, (EDTA), sorbic acid, potassium sorbate, calcium sorbate, benzoic acid, sodium benzoate, potassium benzoate, and calcium benzoate. The permitted levels of these different preservatives vary depending on the legislation in effect in different countries. The permitted levels of sorbic acid and benzoic acid are 2,000 and 1,000 ppm, respectively, for emulsified sources with less than 60 % fat within the European Community (Casas et al. 2000). Under Canada's Food and Drug Regulations, the maximum levels of sorbic acid and benzoate acid are 3350 ppm, and the maximum level of sodium benzoate is 1,000 ppm (Health 2011). Sequestrants (also known as chelating agents) such as EDTA and benzoates have preservation effects. These compounds are able to bind metals such as copper and iron; they can therefore inhibit the degradation of fats induced by the presence of undesirable metals and prevent the formation of unpalatable flavors.

Plant-Based vs. Animal-Based Ingredients

Animal-based ingredients such as egg yolk, milk protein, whey concentrates, whey peptide fractions, and casein have been widely used in the formulation of dressing and mayonnaise products. However, in the last few years, concerns have grown regarding the supplies of food that will be required to feed the expanding world population. The increasing pressure for a reduction in or removal of animal-based ingredients is one of the primary trends currently driving product innovation in developed countries, which is aimed at meeting the demands of consumers seeking meals with a better balance of animal- and plant-based ingredients, products with low cholesterol levels, and allergen-free ingredients. There is a push to identify and develop appropriate and inexpensive vegetable protein sources that can provide an adequate supply of energy with desired functionality. Most plant proteins have lower calorie content and little to no saturated fat compared to animal proteins; they are therefore associated with a significantly lower risk of coronary artery disease and stroke (Hu 2003). Utilization of plant sources such as lupin protein (Franco et al. 1998; Raymundo et al. 2002; Papalamprou et al. 2006), pea protein (Franco et al. 2000), lupin protein hydrolysate, soybean proteins (untreated, heat or enzyme, or chemically treated) (Chen et al. 1982; Puppo et al. 2000; Gao et al. 2003; Diftis et al. 2005), hydrolyzed canola protein (Vioque et al. 2000), and wheat protein (Ghoush et al. 2008) in potential salad dressing and mayonnaise applications have been studied. The results indicate that vegetable protein-based products had similar bulk physicochemical properties compared with those containing animal based ingredients, and that plant-based proteins have great potential for use in various food products in the future, including salad dressing and mayonnaise products.

Impact of Reducing Fat and Cholesterol on Salad Dressing and Mayonnaise Properties

Impact of Reducing Cholesterol on Salad Dressing and Mayonnaise Properties

Impact on Appearance

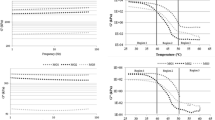

Mun et al. (2009) showed that the L value of full-fat (FF) mayonnaise (75 wt.%, oil) was significantly lower than that of the reduced-fat (RF) samples (37.5 wt.%, oil). In addition, as more starch and gum were incorporated in mayonnaise, the lightness increased correspondingly and was correlated with the smaller droplet size observed. a value also decreased with the addition of an increased amount of xanthan gum, indicating a less reddish hue in the samples. Worrasinchai et al. (2006) reported that FF mayonnaise exhibited a shiny bright yellow color, whereas the RF sample exhibited colors that were too pale (less colored) due to the addition of fat replacer. The a value (redness) increased, whereas the b value (yellowness) decreased as the levels of β-glucan substitution increased for the RF mayonnaise. Chroma, which represents the color intensity of samples, can give a better description of the spatial position of the measured color. As shown in Fig. 2c, a decrease in oil (50–20 %, w/w) and an increase in egg yolk levels (0–5 %, w/w) led to an increase in the color intensity of dressings prepared with pea protein isolates (Fig. 2c).

(a) Response surface plots for consistency coefficients obtained by fitting to the power law model for salad dressings formulated with egg yolk and Desi chickpea protein; (b) response surface plots for yield stress obtained by fitting to the Herschel–Buckley model for dressings formulated with egg yolk and yellow pea protein; (c) response surface plots for chroma for salad dressings formulated with egg yolk and yellow pea protein

Impact on Rheology

Fat content, known as the dispersed phase volume fraction ϕ, is one of the factors with the greatest influence on the rheological properties of food emulsions (McClements and Demetriades 1998). The influence of fat droplets on viscosity characteristics are summarized by several mathematical equations applied to different types of emulsions (e.g., dilute emulsion containing non-aggregated droplets and concentrated emulsions containing flocculated droplets) as reported in the review by McClements and Demetriades (1998). The common parameters that can be obtained from various mathematical models during different rheological tests are summarized in Table 2.

Response surface plots of consistency coefficients (m value) obtained with the power law model and the yield stress (σ value) obtained using the Herschel–Buckley model are shown in Fig. 2a, b respectively, for salad dressings formulated with egg yolk (0–5 %, w/w), oil (20–50 %, w/w), and pea protein isolates (3–8 %, w/w). These observations are generally in good agreement with those reported by other researchers (Gladwell et al. 1986; Ma and Barbosa-Canovas 1995a, b; Wang et al. 2010), who found that dressing and mayonnaise type emulsions generally showed a less compact network with decreased viscous nature due to the reduction in oil concentration. The zero-shear rate limiting viscosity (η 0) obtained with the Carreau model tended to increase with increasing lupin protein (x 1, 2–7 wt.%), xanthan gum (x 2, 0–0.49 wt.%) and oil content (x 3, 25–60 wt.%), whereas the critical shear rate (\( {\gamma_{\mathrm{C}}} \)), which represents the shear sensitivity in the most structured emulsions, decreased as the three variables (x 1, x 2, x 3) increased. Similarly, a decrease in protein, xanthan gum, and oil content also decreased the plateau modulus (\( G_{\mathrm{N}}^0 \)) obtained during oscillation tests, indicating an enhancement of shear sensitivity in the viscoelastic network for samples with low fat content (Raymundo et al. 2002). This agrees with the finding reported by Gallegos et al. (1992) and Moros et al. (2002b) who showed that an increase in oil content decreased the strain sensitivity in the network (with an increased \( G_{\mathrm{N}}^0 \) and decreased \( {\gamma_{\mathrm{C}}} \)). Franco et al. (1997) found that the plateau region increased as oil or emulsifier concentration increased, but decreased with starch concentration for dressings prepared with egg yolk (0–6 wt.%), oil (35–55 wt.%), sucrose ester (0–10 wt.%), and starch (0–2 wt.%).

The elastic properties of dressing- and mayonnaise-type emulsions are also greatly impacted by changes in oil content. An increase in oil concentration (20–70 wt.%) led to more elastic emulsions with a more dominant instantaneous elastic mechanism (Gladwell et al. 1985). Additionally, Peressini et al. (1998) found that the elastic modulus of a Hookean body increased with an increase in oil content, possibly due to the compact packing of oil droplets in the lipoproteic network characterizing the mayonnaise type emulsion. Ma and Barbosa-Cánovas (1995a, b) also found that mayonnaise samples with greater fat content showed higher storage modulus (G′) values during oscillation tests. According to Worrasinchai et al. (2006), however, RF mayonnaise with 50 % and 70 % substitution of β-glucan had higher G′ values than FF samples, possibly due to the smaller droplet sizes measured for the RF samples. They also observed that tan δ values were closely correlated with the droplet size of emulsions. RF samples with smaller droplets had lower tan δ values and exhibited more solid-like behavior compared with FF samples with large droplets.

The addition of a combination of non-fat ingredients, including protein, gums, starches, and other fat replacers with different functional roles is necessary to maintain the original viscoelastic properties of reduced-fat dressing and mayonnaise. Rheological properties of low-fat dressing emulsions were found to be dependent on the weight ratio of the binary emulsifier blends used (including pea protein, sodium caseinate, Tween-20, and sucrose distearate) (Riscardo et al. 2003). Mun et al. (2009) showed that the rheological behavior of a reduced-fat mayonnaise with oil content of 37.5 wt.% prepared with 5.6 wt.% modified starch and 0.1 wt.% xanthan gum was similar to that of a full-fat mayonnaise sample (75 wt.% oil) prepared with gum. They also found that xanthan gum markedly increased the yield stress and the consistency index of both the FF and the RF mayonnaise sample. The reduced-fat sample (37.5 wt.%) with added modified starch showed a higher yield stress than the full-fat mayonnaise prepared without gum addition.

Dolz et al. (2006) prepared a low-fat salad dressing by partially replacing the 4 wt.% modified starch in a low-fat emulsion formulation which was adapted from the commercial composition of low-oil mayonnaise (containing 34 wt.% oil) with xanthan gum (XG, 0.4 wt.%), locust bean gum (LBG, 0.4 wt.%), and synergistic blends of both gums (0.03 + 0.03 wt.% or 0.1+ 0.1 wt.%). Their results showed an increase in storage (G′) and loss moduli (G″) due to the replacement; furthermore, the higher the gum contents, the higher the G′ and G″ values.

In another study that evaluated the rheological properties of low-fat salad dressings prepared with PGA, XG and a novel stabilizer consisting of decolorized hsian-tsao gum (dHG), the dressing with addition of PGA showed the lowest degree of pseudoplasticity, followed by those prepared with dHG and then XG. The dressings containing each single gum showed that XG tends to impart body and strong shear-thinning characteristics to the oil in water emulsion, on the other hand, PGA confers low viscosity and low pseudoplasticity that may promote creaminess without significant change in rheological properties; dHG gum, in contrast, imparts strong elasticity that may promote storage stability (Lai and Lin 2004).

A comparative study on the rheological properties of a low-fat (7 wt.%) salad dressing stabilized by whey (79 wt.%), PGA, XG, and CMC was done by De Cássia da Fonseca et al. (2009); their results showed that the addition of PGA to salad dressing generated an increased flow behavior index (n). The consistency coefficient (m) similarly increased with the addition of XG and PGA. The apparent viscosity as measured during the steady-state flow test was mostly influenced by the addition of CMC compared with other gums, with highest value obtained in the proportion of 0.25 %/0.25 %/0.5 % (PGA/XG/CMC).

The impact of incorporating other fat mimetics and coloring agents (which enabled the production of food emulsions with lesser oil content) on product rheological properties have also been reported. The addition of a natural pigment phycocyanin in food emulsions led to a significant increase in viscous and viscoelastic properties and resulted in a reinforcement of the emulsion structure (Batista et al. 2006). The use of a microalgal biomass C. vulgaris also enhanced the rheological properties of a pea protein stabilized emulsion (Raymundo et al. 2005).

Impact on Emulsion Stability

Emulsion stability is often improved with an increase in the oil phase volume fraction due to the increase in the packing fraction of oil droplets, as the droplets are more closely packed and the creaming/sedimentation rates are therefore lowered. When the oil content is reduced below a certain critical level in reduced-fat salad dressing or mayonnaise, the emulsion tends to become highly unstable. A reduction in droplet size, caused by more intensive homogenization conditions, or the addition of thickening agents such as starch and gums, is necessary to prevent the acceleration of emulsion instability (McClements and Demetriades 1998).

The addition of XG at concentrations ranging from 0.05 to 0.7 wt.% produced an emulsion with improved stability (Paraskevopoulou et al. 2005). Mun et al. (2009) found that the RF mayonnaise sample (37.5 wt.%, oil) showed a higher stability than the FF samples (75 wt.%, oil) due to the increased viscosity of the aqueous phase from the addition of 3.8 % 4αGTase-modified starch and xanthan gum. Worrasinchai et al. (2006) reported that β-glucan prepared from spent brewer's yeast as a fat replacer efficiently stabilizes oil-in-water mayonnaise-type emulsions, possibly due to the increase in viscosity of the continuous phase and the formation of a weak gel network with small initial droplets due to the addition of β-glucan. In earlier shelf life studies of oil-in-water emulsions (40 wt.%, oil) prepared using different hydrocolloids, it was reported that the incorporation of propylene glycol alginate (PGA) promoted creaminess without significantly contributing to the rheological properties; the addition of xanthan gum (XG) contributed to body texture but led to oiling off in the samples; the use of gum tragacanth (GT) and a combination of three gums (XG:GT:PGA = 1:1:1) controlled both oiling off and texture of the emulsion (Coia and Stauffer 1987). A low-fat salad dressing emulsion (7 wt.%, oil) stabilized by combined whey protein and hydrocolloids (PGA, XG, and CMC) remained stable for a period of 4 months with no creaming (De Cássia da Fonseca et al. 2009).

Another study on the effect of xanthan gum on the creaming profile of an o/w RF emulsion (20 v/v% oil) stabilized with whey protein was carried out by Sun et al. (2007). They reported that the degree of flocculation depended on the XG concentration. Little or no flocculation was observed when the samples contained 0.5 wt.% xanthan gum; however, when the addition of xanthan gum increased from 0.02 wt.% to 0.2 wt.%, extensive flocculation was observed in the samples. A comparative study was conducted on an oil-in-water emulsion with an oil volume fraction of 0.33 which was emulsified by native whey soy protein (NWSP) and denatured whey soy protein (DWSP) (Palazolo et al. 2004). The emulsion prepared with NWSP showed the lowest stability against creaming; in comparison, the samples emulsified with DWSP showed increased stability due to the availability of more thermally unfolded proteins in the denatured samples.

Impact on Microstructure

A scanning electron micrograph (SEM) of a salad dressing containing 35 wt.% oil prepared using an Ultra-Turrax homogenizer is presented in Fig. 3. Fat globules are distorted from their normal spherical shape and are linked forming a continuous three-dimensional network in the SEM. The homogenization techniques applied often has a critical impact on the microstructure of emulsions. By using a colloid mill or high pressure homogenizer, fat globules are often maintained uniform in size and shape (Fig. 4). However, homogenization method is not the only factor that influences emulsion microstructure. Indeed, oil concentration, types and levels of different ingredients incorporated, the order of ingredient addition during homogenization are all factors that determine the microstructure of emulsions. For example, in one study, although an Ultra Turrax homogenizer was consistently used during mayonnaise production (Fig. 5a–d), the microstructure of the emulsions was impacted to different extents due to the different types/levels of emulsifiers used (Laca et al. 2010). In this study, the application of egg yolk granules at different levels with low cholesterol content was compared with those of regular yolks having high cholesterol content. Differences in both the composition and production processes caused the variations observed in the SEM (Fig. 5E). Similar observations were also reported by Worrasinchai et al. (2006). RF mayonnaise (with 41.1 % and 25.6 % of oil) prepared with β-glucan compared with the FF samples (with 82.19 % of oil) had relatively open, loose SEM structures with a network of aggregated droplets containing more interspaced voids of varying dimensions which represented the aqueous phase (Fig. 4). The reduction in oil content appeared to increase the dimensions of the void spaces in the micrographs of the mayonnaise samples (Fig. 4a–d).

Scanning electron micrographs of salad dressings formulated with canola oil (35 wt.%), egg yolk (5 wt.%), vinegar (7 wt.%), lemon juice (5 wt.%), salt (1 wt.%), sugar (3.5 wt.%), xanthan gum (0.25 wt.%). The emulsification was achieved using an Ultra-Turrax homogenizer (Model T25, Janke and Kunkel, Ika-Labortechnik, Staufen, Germany) with a 2.5-cm diameter head at 13,800 rpm for 3 min

Scanning electron micrographs of mayonnaise prepared using a high pressure homogenizer made with (a) FF, full fat (82.19 %, oil); (b) 25B, 25 % β-glucan substitution (61.6 %, oil); (c) 50B, 50 % β-glucan substitution (41.1 %, oil); and (d) 75B, 75 % β-glucan substitution (20.6 %, oil). Reprinted from Worrasinchai et al. 2006, with permission from Elservier

Scanning electron micrographs of mayonnaise samples. The mayonnaise was prepared with 9 mL white wine vinegar (6 % acidity), 0.94 g salt, 1.3 g sugar, 70 mL sunflower oil, and emulsifying agent, as follows: 10 g fresh yolk (mayonnaise A), 10 g fresh granules (mayonnaise B), 6 g fresh granules (mayonnaise C), and 10 g reconstituted lyophilized granules (4.2 g lypophilized granules and 5.8 g of water) achieving the same moisture content as fresh granules (mayonnaise D). Mayonnaise E is a commercial standard prepared with water, wine vinegar, salt, sugar, sunflower oil, egg yolk, lemon extract, corn starch, modified corn starch, antioxidant, and coloring. Magnification is 10,000×, bar 5 μm. Reprinted from Laca et al. 2010, with permission from Elsevier

The incorporation of various thickeners increased the extent of the three-dimensional network throughout the volume of the emulsion. In addition, the greater the degree of substitution (i.e., the lower the oil volume fraction), the larger the spaces surrounded by looser aggregated droplets became and the more extensive the gel network. The microstructure of RF mayonnaise containing 37.5 % fat and modified starch (3.8 % or 5.6 %) exhibited a more uniform size distribution and small droplets compared with the FF samples containing 75 % oil (Mun et al. 2009). Thus, the SEM indicates that RF mayonnaise may have a wide variety of microstructures depending on production conditions and their composition.

Impact on Flavor

The food industry faces a considerable challenge in striving to produce reduced-fat dressing and mayonnaise products with a similar flavor profile to that of full-fat products. Fat plays an important role in food flavor. For example, (1) fat has a significant effect on flavor perception since it serves as a vehicle for the flavor notes of many spices which are fat soluble; (2) fat affects the order in which flavors are released (i.e., aroma perception threshold); it helps to slow the rate of interaction and modifies the way flavor notes interact with taste receptors on the tongue; (3) fat also influences the duration of perception (Vroom et al. 1996).

Full-fat dressing products are usually characterized by longer lasting but less intense flavor perception. Fat tends to mask some low-level off-flavors and mitigates unfavorable interactions between flavor notes. Reduced-fat dressings, on the other hand, often have a more intense initial taste and a more rapidly fading flavor and tend to leave only the acidity of vinegar on the palate (Stauffer 1999). If a non-polar flavor is added, reducing the fat content will cause the opposite perception, which means the initial taste would be perceived as less intense (McClements and Demetriades 1998). When thickeners are added to reduced-fat dressings, reversible or irreversible binding of certain flavor compounds may occur (McClements and Demetriades 1998). The macromolecules in thickeners affect the mobility and the dynamic release of flavor and therefore reduce the flavor intensity of dressing products (de Roos 1997).

Charles et al. (2000) found that lemon smell and citrus aroma are significantly increased, whereas the egg note, mustard, and butter aroma are significantly decreased, when the droplet size of a model salad dressing emulsion was increased during QDA tests. Salad dressings prepared with varying levels of canola oil (0 %, 6.75 % and 13.5 %, w/v) and resoleum garlic (0.12 %, 0.36 %, and 0.6 %, w/v) were evaluated for changes in garlic, pepper, and sourness intensity by time-intensity profiling (Guinard et al. 2002). A reduction in fat content resulted in more intense flavor release, i.e., the flavor release of garlic, pepper, and sourness decreased in the high-fat salad dressings as the thickness and viscosity of the samples increased compared with the low-fat samples with lower viscosity. Delayed sourness perception was associated with higher fat content. The results suggest that flavor release properties are affected by the molecular interactions with the lipid phase and physical entrapment in the food matrix. By using a purge-and-trap dynamic headspace GC method, Jo and Ahn (1999) found that the amount of volatiles released from oil emulsions was negatively correlated with fat content. The results indicate that the production of volatiles is influenced not only by the polarity and partition coefficients of volatile compounds but also by the composition and characteristics of the medium in model food system.

Wendin and Hall (2001) evaluated the effects of fat, thickener, and emulsifier content on the sensory properties of salad dressings, and reported that all the constituents studied had a significant influence on the attributes of texture and mouthfeel, with fat content having the greatest influence. The interactive effects showed that emulsifier content was less critical when the levels of fat and thickener increased. In another study, Worrasinchai et al. (2006) had 30 trained panelists participate in a sensory evaluation of mayonnaise prepared with β-glucan (a fat replacer) to assess attributes including appearance, color, odor, texture, taste, and overall acceptability based on a 9-point hedonic scale (where 1 = the least/the lowest and 9 = the most/the highest). The scores for appearance and color were significantly decreased with increasing substitution levels of β-glucan in reduced-fat mayonnaise. The effects of fat and thickeners, including PGA (1.4 wt.%) and guar gum (1.55 wt.%), on the sensory quality of reduced-fat (15 and 30 wt.%) mayonnaise were also examined (Wendin et al. 1997). A higher fat content increased the thickness, fattiness, and toughness scores. The addition of guar gum yielded mayonnaise that was perceived as thicker and tougher than the mayonnaise prepared with PGA.

Impact on Particle Size

Droplet characteristics (i.e., their concentration, size, charge, interfacial properties, and interactions) greatly influence the physicochemical properties of food emulsions (McClements 2005c, e). The impact of reduced oil content in reduced-fat dressing and mayonnaise on droplet size and charge is briefly reviewed below.

An increase in protein (2–7 wt.%), xanthan gum (0–0.49 wt.%), and oil content (25–60 wt.%) tended to decrease the Sauter diameter in low-fat mayonnaise-type emulsions (Raymundo et al. 2002). However, in other studies (Moros et al. 2002b), the Sauter diameter was found to increase with increasing oil content (65–77.5 wt.%) and to have a minimum value with an intermediate egg yolk content (3–3.5 wt.%). The effect of using β-glucan as a fat replacer in mayonnaise was also studied in relation to droplet characteristics (Worrasinchai et al. 2006). Droplet size was greater in the FF mayonnaise than in the RF samples. RF mayonnaise prepared with 25 % β-glucan had the largest droplet size, whereas RF mayonnaise prepared with 50 % β-glucan had the smallest droplet size. The impact of various levels of XG on the surface area average droplet size (D[3,2]) of whey protein-stabilized o/w emulsions (20 v/v%) was studied by Sun et al. (2007), who found that the addition of XG at different concentrations to the low-fat emulsion did not have a significant effect on D[3,2]. XG is a non-adsorbing gum and did not bind to the droplet surface.

An increase in the oil-phase volume fraction (0 %, 5 %, 10 % to 20 %) of emulsions prepared with flaxseed protein concentrate containing mucilage (FPCCM, 0.5–1.5 %) significantly increased the Z-average diameter (defined as the mean diameter based on the intensity of scattered light), suggesting an insufficient adsorption layer and therefore the formation of flocculated droplets (Wang et al. 2010). Similar results were found for emulsions prepared with bovine serum albumin (Rangsansarid and Fukada 2007) and emulsions stabilized by whey protein (Lizarraga et al. 2008).

Impact of Reducing Cholesterol on Salad Dressing and Mayonnaise Properties

The US National Institute of Health Consensus Conference recommended limiting daily intake of egg yolk because of its high cholesterol content, which has been linked to high serum cholesterol and heart disease (NIH 1984). The high cholesterol content in egg yolk can be reduced by extraction with various organic solvents or with supercritical CO2. The adsorption behavior of reduced-cholesterol yolks may vary depending on (1) the method of extraction; (2) lipoprotein structure rearrangement; (3) and changes in concentrations of surface-active agents induced by cholesterol removal (Moros et al. 2002a). Extensive research has been done involving comparisons of dressing and mayonnaise emulsions prepared either with native egg yolk or reduce-cholesterol yolk. In addition, the effect that various extraction media have on the interfacial behavior, functional properties, and rheological properties of such emulsions has been widely investigated.

Moros et al. (2002a) conducted a study on the behavior of mayonnaise stabilized with reduced-cholesterol egg yolk, in which cholesterol extraction (14–80 wt.% of cholesterol removed) was done with supercritical CO2. The results showed that the rheological parameters (\( G_{\mathrm{N}}^0 \) and ƞ 0) increased with the level of cholesterol reduction up to 40 to 80 wt.%. An egg yolk protein concentrate with 45 % and 75 % reductions in total lipids and cholesterol content, respectively, was used to emulsify a mayonnaise-type emulsion (Paraskevopoulou et al. 1997a). Lower consistency index (m value) and yield stress (σ value) values, as well as less pronounced pseudoplasticity behavior, were observed compared with the values for mayonnaise prepared with native dried yolk.

The effect of cholesterol reduction on the rheological behavior of egg yolk-stabilized emulsion was evaluated by Paraskevopoulou et al. (1997a). Results of oscillation and creep tests showed that an emulsion made with low-cholesterol yolk had a stronger structure and more elastic properties than commercial dressings prepared with regular egg yolk. The viscoelasticity of the reduced-cholesterol emulsion was comparable to that of high-cholesterol commercial mayonnaise. In later studies by the same authors (Paraskevopoulou et al. 1999), mayonnaise prepared with native spray-dried egg yolk exhibited the lowest viscoelastic properties and had the highest emulsion stability than emulsions made with reduced-cholesterol yolk. In addition, the emulsion prepared with yolk from which cholesterol was extracted using a mixture of ethanol and water containing 1.5 % polysorbate 80 showed higher viscoelastic moduli (G′ and G″) than the emulsion made with supercritical CO2-extracted yolk.

Increased foaming activity and foaming stability was also observed with the use of reduced-cholesterol egg yolk in comparison with regular egg yolk. Paraskevopoulou and Kiosseoglou (1994) found a significant deterioration in emulsifying properties when cholesterol extraction was done with a mixture of petroleum ether and ethanol, whereas cholesterol-reduced egg yolk produced by petroleum ether extraction had similar emulsifying properties to native dried yolk. Other organic solvents used for extraction include hexane/isopropanol, ethanol, and petroleum ether. Overall, extraction with supercritical CO2 is more attractive from the standpoint of selectivity and safety concerns.

In addition to the above, replacement of egg yolk with plant-based proteins as discussed earlier may be another approach to lower cholesterol and remove allergenic ingredients in mayonnaise and salad dressings.

Homogenization Techniques and Equipment

In addition to the ingredients used in salad dressing and emulsion preparation, the homogenization technique used and equipment can also influence product texture and quality. Homogenization is the process of converting two immiscible liquids into an emulsion or of reducing the size of the droplets in an existing emulsion. A mechanical device known as a homogenizer is used to achieve homogenization by applying intense energy in order to disrupt and mix the oil and water phases. Examples of commonly used homogenizers include the Ultra-Turrax homogenizer, the Polytron PT homogenizer, the Warring blender, colloidal mills, and high-pressure valve homogenizers (Table 3). In most cases, a coarse emulsion is prepared by premixing the emulsion ingredients which have been dosed separately and then feeding the resulting emulsion into the homogenizer for fine emulsification. Homogenization is an important step in the production of reduced-fat/reduced-cholesterol dressings, since the device and process selected have considerable influence on the bulk physicochemical, rheological, and sensory properties of the emulsion. The type of homogenization treatment used can, thus, determine the acceptability of the final product. The choice of a homogenization device depends on the volume or amount of sample, the nature of the starting materials, the desired physicochemical properties, and the overall quality attributes of the final products, as well as the cost and the operating context ( i.e., laboratory, pilot plant, or industrial food processing) (McClements 2005a). The choice of equipment is also driven by product formulation. For example, high-pressure homogenizers are not suitable for producing reduced-fat dressings and mayonnaise products containing starch and high levels of hydrocolloids due to the high viscosity of these products (Table 3). Additionally, the residence time in the equipment during homogenization is also driven by the choice of emulsifiers used in the reduced-fat emulsions, i.e., fast emulsifiers and/or low fat levels may be better suited to homogenizers with little residence time (although for most equipments, residence time is in the order of seconds), whereas high oil levels and slow emulsifiers may be more suited to equipment which provides sufficient residence time to allow for droplet stabilization (Ford et al. 2004).

Several studies have focused on the impact of processing parameters during the emulsification process on the physical properties of salad dressing type emulsions. In general, an increase in energy input (emulsification time and energy input) generally leads to increased values of rheological and textural parameters as well as decreased droplet size and polydispersity (Franco et al. 1998; Franco et al. 1995).

Conclusion

There is a growing trend toward reducing the fat and cholesterol content of food products because of concerns related to the risk of cardiovascular disease, obesity, and diabetes. Successful development of reduced-fat and reduced-cholesterol salad dressing and mayonnaise products requires a comprehensive understanding of the influence of homogenization conditions and the roles of different ingredients on bulk physicochemical properties and sensory attributes. Although some work has been done, further studies are still required on the identification and performance of various fat replacers and their effect on rheological and sensory attributes of RF o/w emulsions. Additionally, further research is required to explore the possibility of using alternative ingredients (e.g., plant-based ingredients) in the formulation of dressing and mayonnaise products in order to meet the growing consumer demand for healthier and allergen-free foods.

References

Álvarez Cerimedo, M. S., Iriart, C. H., Candal, R. J., & Herrera, M. L. (2010). Stability of emulsions formulated with high concentrations of sodium caseinate and trehalose. Food Research International, 43(5), 1482–1493.

Asp, E. H. (1999). Factors affecting food decisions made by individual consumers. Food Policy, 24(2–3), 287–294.

Atiemo-Obeng, V. A., & Calabrese, R. V. (2004). Rotor-stator mixing devices. In E. L. Paul, V. A. Atiemo-Obeng, & S. M. Kresta (Eds.), Handbook of industrial mixing: science and practice. New Jersey, USA: John Wiley & Sons.

Bakal, A. I., Galbreath, T., & Cash, P. A. (1992). Fat-free and low fat mayonnaise-like dressings. US Patent 5137742 (In English).

Batista, A. P., Raymundo, A., Sousa, I., Empis, J., & Franco, J. M. (2006). Colored food emulsions—implications of pigment addition on the rheological behavior and microstructure. Food Biophysics, 1(4), 216–227.

Bauer, R., Cuccurullo, J.A., Dazo, P.E., Kochakji, D.J., Rikon, S.M. & Rubow, R.E. (1993). Low fat/no fat salad dressing having mimetic functional properties fat and a process therefor. US Patent 5209942 (In English).

Behall, K. M. (1997). Dietary fiber: nutritional lessons for macronutrient substitutes. Annals of the New York Academy of Sciences, 819(1), 142–154.

Bourque, C., St-Onge, M. P., Papamandjaris, A. A., Cohn, J. S., & Jones, P. J. H. (2003). Consumption of an oil composed of medium chain triacyglycerols, phytosterols, and n-3 fatty acids improves cardiovascular risk profile in overweight women. Metabolism, 52(6), 771–777.

Breitbart, D.J., Aguilar, Z.C., Piccininni, D., De Fouw, N.J. & Harcksen, G.D.J. (2000). Opaque low fat salad dressing with an improved mouthfeel. US Patent 6060106 (In English).

Casas, J. A., Mohedano, A. F., & García-Ochoa, F. (2000). Viscosity of guar gum and xanthan/guar gum mixture solutions. Journal of the Science of Food and Agriculture, 80(12), 1722–1727.

Chang, C. M., Powrie, W. D., & Fennema, O. (1972). Electron microscopy of mayonnaise. Journal de l'Institut Canadien de Science et Technologie Alimentaire, Aliment, 5(3), 134–137.

Charles, M., Rosselin, V., Beck, L., Sauvageot, F., & Guichard, E. (2000). Flavor release from salad dressings: sensory and physicochemical approaches in relation with the structure. Journal of Agricultural and Food Chemistry, 48(5), 1810–1816.

Chen, J., & Dickinson, E. (1998). Viscoelastic properties of heat-set whey protein emulsion gels. Journal of texture studies, 29(3), 285–304.

Chen, H.J., Liu, T.Y., Sung, H.Y., & Su, J.C. (1982). Preparation of chemically phosphorylated soy proteins and the products therefrom. US Patent 1322344 (In English).

Chiralt, A., Ferragut, V., & Salazar, J. A. (1992). Rheological characterization of low calorie milk based salad dressings. Journal of Food Science, 57(1), 200–202.

Chirife, J., Vigo, M. S., GÓmez, R. G., & Favetto, G. J. (1989). Water activity and chemical composition of mayonnaises. Journal of Food Science, 54(6), 1658–1659.

Coia, K. A., & Stauffer, K. R. (1987). Shelf life study of oil/water emulsions using various commercial hydrocolloids. Journal of Food Science, 52(1), 166–172.

Cserhalmi, Z., Márkus, Z., Czukor, B., Baráth, Á., & Tóth, M. (2000). Physico-chemical properties and food utilization possibilities of RF-treated mustard seed. Innovative Food Science & Emerging Technologies, 1(4), 251–254.

De Cássia da Fonseca, V., Haminiuk, C. W. I., Izydoro, D. R., Waszczynskyj, N., De Paula Scheer, A., & Sierakowski, M. R. (2009). Stability and rheological behaviour of salad dressing obtained with whey and different combinations of stabilizers. International Journal of Food Science and Technology, 44(4), 777–783.

de Roos, K. B. (1997). How lipids influence food favor. Food Technology, 51(1), 60–62.

Dickinson, E. (Ed.). (1992). An introduction to food colloids. Oxford, UK: Oxford University Press.

Dickinson, E., & Casanova, H. (1999). A thermoreversible emulsion gel based on sodium caseinate. Food Hydrocolloids, 13(4), 285–289.

Dickinson, E., & Stainsby, G. (Eds.). (1988). Advances in food emulsions and foams. Barking, Essex, UK: Elsevier Applied Science Publishers Ltd.

Dickinson, E., & Hong, S. T. (1995). Influence of water-soluble nonionic emulsifier on the rheology of heat-set protein-stabilized emulsion gels. Journal of Agricultural and Food Chemistry, 43(10), 2560–2566.

Diftis, N. G., Biliaderis, C. G., & Kiosseoglou, V. D. (2005). Rheological properties and stability of model salad dressing emulsions prepared with a dry-heated soybean protein isolate–dextran mixture. Food Hydrocolloids, 19(6), 1025–1031.

Dolz, M., Hernández, M. J., & Delegido, J. (2006). Oscillatory measurements for salad dressings stabilized with modified starch, xanthan gum, and locust bean gum. Journal of Applied Polymer Science, 102(1), 897–903.

Dolz, M., Hernández, M. J., & Delegido, J. (2008). Creep and recovery experimental investigation of low oil content food emulsions. Food Hydrocolloids, 22(3), 421–427.

EEC (1992). European Union Commission, J. Eur. Communities, Commission Regulation EEC Legislation (2nd ed.), Leatherhead Food RA, UK.

Eisner, M. D., Jeelani, S. A. K., Bernhard, L., & Windhab, E. J. (2007). Stability of foams containing proteins, fat particles and nonionic surfactants. Chemical Engineering Science, 62(7), 1974–1987.