Abstract

Nowadays, the functionalization of food products using natural health-promoting additives is of great interest. Betalains are the natural pigments of red beets and are known for their health-promoting characteristics. The aim of this study was to evaluate gummy candies formulated with red beet extract (0.1 or 0.3%) as the coloring agent, Salix aegyptiaca distillate as the flavoring agent, and gellan gum (0.5 or 1.5%) as the gelling co-agent. The prepared gummy candy samples were assessed via texture profile analysis, DPPH assay, sensory evaluation, and color analysis. The results revealed that hardness (~ 60 N) improved and gumminess (~ 15 N) decreased with an increment in gellan gum content in the gummy candy formulation. Statistical analysis indicated that by addition of red beet extract, the radical scavenging capacity of the samples increased (50%) significantly (p < 0.05). Furthermore, gellan gum usage lead to the generation of a glossy red color and enhanced the lightness of the samples in comparison with gelatin-based gummy candies. About sensory evaluation, the panelists confirmed that usage of Salix aegyptiaca improved the sensory characteristics of the gummy candy (overall acceptance from 7.4 to 8.2; out of 9). Our findings suggest that gellan gum (as a highly transparent, acid-resistant, gel-forming gum), red beet extract (as an acid-stabilized natural color), and Salix aegyptiaca distillate have immense potential in the food industry for use as structuring, coloring, and flavoring agents, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Soft confectionery products known as pastille, edible jelly and gummy candy are preferred by children compared with other types of candy as they are easy to swallow, have a glossy shape, and delicious taste (Amjadi et al. 2018). Gelatin, pectin and other hydrocolloids are widely applied as gel-forming agents in gummy jelly candy formulations. Gellan gum (GG) is a linear, negatively charged exopolysaccharide that is secreted from Pseudomonas elodea (previously known as Sphingomonas elodea). The most important characteristics of GG are its excellent gelling properties, texture, and malleability (Zia et al. 2017). It is capable of forming gels with all ions and is useful for its brittle gel, clean flavor release and high gelling yields (Fan et al. 2017). Gellan gum shows high resistance to low pH values and high temperatures, is highly transparent, has a rapid setting behavior as well as adjustable elasticity and hardness, and requires low gelling concentrations, thus presenting with many different industrial applications as a stabilizer, thickening agent, structural agent, and versatile gelling agent in a wide range of food products including confectionery products, jams and jellies, water-based gels, milkshakes, puddings, icings and frostings, and dairy products such as ice cream and yoghurt (Saha and Bhattacharya 2010; Costa et al. 2017; Zia et al. 2017; Moghaddas Kia et al. 2018; Alizadeh-Sani et al. 2019). Gellan can be formulated as a gelatin replacer in sweet candies which results in products acceptable to vegetarians and followers of religions that forbid materials from animals.

Due to a high protein content and consumer acceptability, gummy candies can be remarked as a favorable formulation for fortification with different bioactive compounds such as natural colorants, nutraceuticals and antioxidants (Morris et al. 2012; Cappa et al. 2015; Delgado and Bañón 2018). The color characteristics of food products, especially in jelly products, are important quality parameters that can determine the consumer’s first impression as a vital component of consumer acceptability. The high stability and hue of synthetic dyes have led to their widespread usage in a diverse range of processed foods. However, in recent years, synthetic pigments have lost popularity in the market due to possible adverse health effects including an association with the development of attention-deficit/hyperactivity disorder, which encompasses attention problems, hyperactivity, irritability, sleep disorder and aggressiveness in children (Cardoso-Ugarte et al. 2014). Though the topic still remains controversial, in 2010, the European Food Safety Authority made it mandatory that products containing artificial colors include a notice of the potentially “adverse effect on activity and attention in children” on their labelling (Cardoso-Ugarte et al. 2014).

Nowadays, different natural colorants have been studied for applications in food products such as jellies, candies, ice cream, some fruit chews, juices (Ghasempour et al. 2019). Khazaiy Pool et al. (2014) investigated the effects of various concentrations of Spirulina platensis microalgae on the color change of kiwifruit pastille. Yee and Wah (2017) studied the application of red pitaya powder as a coloring agent in fruit pastille; Assous et al. (2014) utilized red pigment extracted from purple carrots as an antioxidant and natural food colorant.

Betalains are water-soluble, nitrogen-containing pigments found in high concentrations in red beet (Beta vulgaris). Betalains comprise two sub-classes: betaxanthins (yellow-orange pigments; e.g., vulgaxanthin I and II) and betacyanins (red-violet pigments; e.g., betanin and isobetanin). Betalains are more stable over a pH range of 3–7, which is suitable for low-acid foods where coloring with anthocyanin is not usually possible. Betacyanins and other phenolic compounds extracted from red beet exhibit antioxidant and radical-scavenging activities; in addition to demonstrating in vitro activity against cancer cells (Cardoso-Ugarte et al. 2014).

The main obstacle to the utilization of betalains in heat-processed food products is their susceptibility to high temperatures. However, the natural color of betalains can be reinforced using organic acids (preferably ascorbic acid; otherwise citric or gluconic acid) pre- or post-thermal processing. Otálora et al. (2019) fortified gummy candies with betanin microcapsules and reported the development of a novel, vivid, red–purple colored gummy candy with excellent stability of the betalain color.

The flavoring agents used in gummy candies are also of critical importance in product desirability. The distillate obtained from the male inflorescences of Salix aegyptiaca L. (pussy willow), locally called “Araghe Bidmeshk” in Iran and referred to as “Egyptian willow distillate” in English, has been used since ancient times as a medicinal; remedy (Enayat and Banerjee 2009; Karimi et al. 2011; Sayyari and Farahmandfar 2017) and a flavorful syrup (Sayyari and Farahmandfar 2017). A number of chemical constituents such as flavonoids (myricetin, kaempferol, quercetin, rutin and luteolin) and volatile substances have been identified from different parts of the plant and contribute to the anti-inflammatory and antioxidant functions of willow extracts (Enayat and Banerjee 2009; Sayyari and Farahmandfar 2017). In Iranian traditional medicine, Salix aegyptiaca extract has been employed as a laxative, cardioprotective, sedative, hypnotic, somnolent, aphrodisiac, orexigenic, carminative, gastroprotectant, and anthelmintic agent (Karimi et al. 2011; Sayyari and Farahmandfar 2017).

The aim of this research was to develop a gummy jelly candy supplemented with red beet extract as a coloring and antioxidant agent. In addition, Salix aegyptiaca distillate was applied as the flavoring agent in the gummy candies textured by gelatin, pectin (constant), and GG according to a factorial experimental design. Gummy candy formulations were evaluated through physico-chemical, textural and sensory tests.

Materials and methods

Red beet extract preparation

The beetroots were washed with tap water to remove their dust and contaminants, before being dried, peeled, and chopped to small pieces. Next, 250 g of fresh beetroot dices were added into 1000 mL of ethanol solution (30% v/v) containing 1.5% citric acid. The mixture was then put in a laboratory ultrasonic device for 1 h; during the first 15 min, the temperature was kept at 60 °C, before being altered to room temperature for the remaining time. After blanching and extraction, the mixture was centrifuged at 3800 rpm for 10 min using a laboratory centrifuge machine. Ethanol was then removed from the separated supernatant using a rotary evaporator (Heidolph, Laborata 4003, Schwabach, Germany), and the aqueous solution was finally put in a freeze-dryer (Christ Germany Alfa1-4) to obtain red beet extraction powder.

The solvent type (water, water/ethanol), citric acid addition, and implementation of blanching were preliminarily studied using a factorial design. The blanched treatment prepared in ethanol/water solvent containing citric acid resulted in maximum absorbance at 535 nm; accordingly, this treatment was selected for the subsequent experimentations.

Gummy candies manufacturing

Gummy candies were manufactured according to industrial procedures as following: Hydrocolloid-based gel was prepared using the experimental design (Table 1) by dissolving 7% gelatin, 0.5% pectin and GG (0.5 or 1.5%) in warm water at 60 °C till a transparent mixture appeared. Then, this mixture was combined with glucose syrup (DE: 42; °Brix: 82.5) containing 1.5% citric acid, which had previously been heated at almost 100 °C in a water bath until complete dissolution. The mixture was cooled, after which the red beet powder and Salix aegyptiaca distillate were added according to the experimental design (Table 1). The prepared jelly mixtures were cast in a 2 × 4 cubic frame and then refrigerated at 4 °C for 24 h prior to analysis. The pH value of the mixture was adjusted to 3–4. Prior to performing any measurements, the samples were allowed to balance at room temperature (Delgado and Banon 2017; Molaei and Jahanbin 2018).

Physico-chemical properties of gummy candies

The total titratable acidity of the prepared gummy jellies was determined as described by Savedboworn et al. (2015). The pH value was determined using a pH meter (pH-Meter E520, Metrohm Herisau, Switzerland). Each sample (2 g) was homogenized with 6 mL of distilled water until complete dissolution. °Brix values were measured using a refractometer (Model RSG32ATC-515; China). Gummy candy samples (5 g) and 20 mL distilled water were homogenized until complete dissolution. Ash and moisture content were determined gravimetrically using oven set at 550 and 105 °C, respectively. Samples were heated before being transferred to oven for obtaining ash. The percentage of ash and moisture content were calculated via the following equation:

where W1 is the weight of the sample before treatment (g), W2 is the weight of the sample after treatment (g).

Instrumental textural profile analysis (TPA)

The texture properties of gummy candies were evaluated using a two-bite compression test conducted by a Texture Analyzer equipped with a 0.05 N load cell (TA-XT plus, Stable Micro Systems, UK). The samples were sliced carefully and rested at room temperature 30 min before the test. The employed compression ratio was 50% from the initial height of the samples; a test speed of 1 mm/s was used. The trigger force was 0.05 N, which was applied by a 4 mm diameter cylinder. The target parameters including hardness, cohesiveness and stringiness were obtained by the Exponent software (Version 6.0.6.0, Stable Microsystems) from TPA curves (Saha and Bhattacharya 2010).

Color parameters

The surface color of edible jellies was measured using a Hunterlab CR-400 (Konica Minolta Chroma Co., Japan) set to C illuminant/2° observer. Each sample was placed on a white standard plate to observe the degree of lightness (L*), redness (+ a*) or greenness (− a*), and yellowness (+ b*) or blueness (− b*) of the films; the chroma or saturation index (C*) was also evaluated. The following equation was applied to convert L*a*b* coordinates to C*:

Antioxidant activity

For each sample, a mass of 5 g was rigorously mixed with 20 mL of 50% ethanol. The mixture solution was then homogenized at 1000 rpm for 3 min using a stirrer. The homogenate was further solubilized by heating at 40 °C for about 20 min under stable magnetic stirring, which was followed by centrifugation at 10,000g for 20 min. The supernatant was then collected for determining the DPPH radical-scavenging activity following the method described by Hani et al. (2015) with a slight modification. A fixed volume of sample extract (1 mL) was added with 3 mL of 100 μM 2,2-diphenyl-1-picryl hydrazyl (DPPH) to an 80% ethanolic solution. Absorbance was read against absolute ethanol at 517 nm using a spectrophotometer after 30 min of incubation in dark conditions, and the percentage of DPPH radical-scavenging activity was calculated using following equation:

where Asample represents the absorbance of the edible film solution and Acontrol represents the absorbance of the blank solution (Hani et al. 2015).

Sensorial evaluation

A panel of ten trained panelists who were familiar with overall acceptability characteristics of jelly products were selected. An acceptance test using a nine-point hedonic scale was used to evaluate the overall acceptance, with a score of one indicating extreme dislike and a score of nine like extremely (ISO 5492:2008). Water was used for mouth-rinsing between evaluations. All panelists were aware of sensory procedure through signing the informed consent form.

Statistical analysis

A completely randomized 2 × 2 × 2 factorial design with 3 replicates was proposed with 3 factors: level of GG (1, 3%), concentration of red beet extract (0.1, 0.3%), and the presence or absence of Salix aegyptiaca distillate. Data were subjected to one-way analysis of variance (ANOVA) using Design Expert 10 software (USA) to determine significant differences among samples. The differences were considered significant when p < 0.05.

Results and discussion

Physical parameters, such °Brix and pH, are often measured in confectionary factories to control the degree of hydration. The primary characteristics of gummy candy samples were measured around pH = 3.8 ± 0.04 and °Brix = 75.6 ± 1.3.

Textural parameters

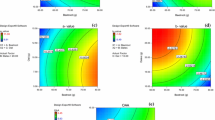

Texture is the result of the complicated arrangement of various interactions between constituents and structural elements at both macroscopic and microscopic scales (Periche et al. 2014). Hardness, gumminess and chewiness are texture descriptors particularly applicable to gelled confections (Borwankar 1992). Hardness, which is defined as the maximum force required for the samples to be deformed in the first compression, was dependent on GG and red beet extract concentrations (Fig. 1). The hardness of the samples enhanced as the incorporated amount of GG was increased. This phenomenon is in good agreement with the findings of Lau et al. (2000), who studied the effect of different ratios of gellan/gelatin on textural properties of mixed gels; which indicates the synergistic effect of gellan/gelatin mixture in controlling the moisture of jelly products which led to produce the firmer gummy candies. Also the mixture was strengthened in lower pH of samples. Hardness also increased with an increased content of red beet extract, which may be due to its sugar, phenolic and dry matter components. One of the factors that influence the texture of gellan gels is the presence of co-solutes such as sugar. In comparison with sugar free products, sugar-added samples exhibit less relaxation characteristics but greater relaxation times, considering elastic characteristics. Sugar binds water in jelly mixtures, thereby lowering the syneresis in gels and decreasing the lubrication effect caused by unbound water (Saha and Bhattacharya 2010).

Gumminess has been characterized by multiplying cohesiveness and hardness (Delgado and Bañón 2015). Candy hardness values were dependent on the solids contents. The results demonstrated a decrease in the gumminess of samples when GG and red beet extract were formulated (Fig. 2). Less energy is required for breaking the gel matrix when gumminess decreases during chewing process. Lau et al. (2000) investigated the effect of gellan (1.6 ± 0.2%) to gelatin (0 ± 1.4%) ratio on the textural properties of gellan/gelatin mixed gels. They reported the highest gumminess values at either higher or low proportion of gellan/gelatin mixture. Based on our results, gellan at higher levels reinforced the gelatin network in the structure of edible jellies and led to the production of firmer samples, which is stated in the results of Lee et al. (2004). It has been reported that incorporation of gellan into gelatin gels resulted in a synergistic increase of gel network strength. This synergistic pattern is related to the fact that the strength of gellan based gels are dependent on the ionic strength and pH and concentration, whereas those of gelatin gels depend primarily on the concentration of gelatin. Gumminess reduction due the presence of red beet extract, may be related to induced heterogeneity to network structure. Upon increasing the amount of red beet extract, the number of flexible cross-links in gummy confections decreases as the structural organization became less ordered and more heterogeneous (Hani et al. 2015). The rapid setting, low amount needed, and sparkling clarity of the gel are some of the attributes that introduce gellan as a preferable choice in the formulation of jellies based on gelatin (Saha and Bhattacharya 2010).

Antioxidant activity

The antioxidant activity of gummy confections containing gellan/red beet was determined by DPPH radical-scavenging assay. Considering the data analysis, increasing the red beet extract content from 0.1 to 0.3% led to a significant improvement in the antioxidant capacity, which was boosted from about 30–50% (Fig. 3). This phenomenon is probably related to the presence of betacyanins, in the red bet extract (Hani et al. 2015). Strack et al. (2003) reported that the presence of aromatic compounds in the betalamic acid fraction of the betalain structure improves the antioxidant activity of the substance. Apart from containing betalains, red beet extract is also comprised of a significant amount of phenolic acids such as catechin, epicatechin, ferulic, protocatechuic, vanillic, p-coumaric and p-hydroxybenzoic acid, which have been shown to possess antioxidative characteristics (Kumar et al. 2018).

All gummy candy formulations based on gelatin have some scarce antioxidative properties due to the gelling agent used; the antioxidant activity of gelatin is maybe due to particular amino acids such as glycine and proline present (Mendis et al. 2005). Furthermore, various antioxidative compounds can interact with the gelling matrix in different manners, facilitating the release of different antioxidative compounds in gummy candies. Also, it is noteworthy that the complex three-dimensional polymeric networks of hydrocolloid gels inhibit the transportation of small molecules (volatiles and flavorings) and entrap them, which eventually leads to a decline in flavor release. This phenomenon is related to the hydrocolloids’ hydrophobic and hydrophilic moieties, which interact with the volatiles. The triple helix structure of gelatin can have cross-linking and three-dimensional network formation, which entraps volatiles and retains antioxidative compounds, volatiles and flavorings in the jelly structure (Fan et al. 2017). Therefore, the application of red beet extract in gummy candy formulation can boost the consumption of these products and enhance the health attributes of consumers.

Sensory evaluation

The results showed that the usage of Salix aegyptiaca distillate significantly developed the sensory scores of gummy candies (p < 0.05). Hence, a pleasant taste had considered, which was strongly embraced by the panelists. The pleasant taste and odor is directly related to the flavonoids and volatile substances of Salix aegyptiaca such as 1,4-dimethoxybenzene, phenylethyl alcohol, carvone, citronellol, methyleugenol, eugenol, n-tetradecane and 4-methoxyacetophenone as its major constituents (Karimi et al. 2011). These aromatic and volatile substances are well kept in the gellan/gelatin matrix. Also, pussy willow extract has been used for decades in the northwest of Iran as a fragrance additive in the preparation of local hard candies (“Noghl-e Urmia”), as well as in folk medicine as a cardiotonic and an agent for the treatment of anemia and vertigo (Khazaiy et al. 2014). Gummy candies are considered as products that come in a variety of flavors and fragrances; hence, the incorporation of this distillate with its potent antioxidative and medicinal characteristics has immense potential for consumption of the related food products by both adults and children (Jooyandeh et al. 2017).

Color parameters

CIE is one of color measurement systems for calculating the L*a*b* indices based on human vision. Here, L* considers the lightness (which is adjustable between 0 and 100) and the a* and b* are characterizes the red-green and yellow-blue spectrums, respectively (Amjadi et al. 2018) The results of the color changes of gummy candies showed that redness parameter followed an ascending trend with the increase of red beet extract concentration in the formulation. The difference in color was also significantly (p < 0.05) influenced by the interaction effect of GG and red beet extract addition. The incorporation of GG improved the lightness of the gummy candies; however, as expected, lightness decreased proportionally to red beet extract content (Fig. 4); which is in accordance with Amjadi et al. (2018) findings. This pattern for natural pigments has been reported in many studies (Escribano et al. 2017; Hani et al. 2015). Besides, Güneşer (2016) showed a negative correlation of betalains amount and L* value, while a* value had a positive correlation with added betalains in milk samples. Maximum of chroma value was obtained when 0.3% red beet extract and 1.5% GG was applied, resulting in a transparent appearance for GG formed candies (Banerjee and Bhattacharya 2011; Otálora et al. 2019). These findings indicate that the combined usage of red beet extract and GG enhances the surface glossiness of gummy candies, generating greater attractiveness for consumers.

Conclusion

Nutraceutical red beet pigments, betalains, can replace synthetic colorants in the formulation of edible jellies, which are mostly consumed by children. Gellan/gelatin based gummy candies containing Salix aegyptiaca distillate and red beet extract were evaluated in terms of sensorial, textural and visual aspects. In this study, the red beet extract amount directly affected the antioxidative properties and redness and chroma of the prepared gummy candies. Overall acceptability was more pronounced in samples containing Salix aegyptiaca distillate. Gellan gum usage led to the preparation of more transparent gummy candies. Textural characteristics including the hardness and gumminess of gummy candies were improved by the usage of gellan gum. As a good result, gellan gum as gelling co-agent beside using red beet extract and Salix aegyptiaca distillate as coloring and flavoring agent provided a healthy product with improved characteristics. Future studies can be conducted on flavor release of gellan-gelatin mixture, sugar replacing and red beet color stability during storage time in this formulation.

References

Alizadeh-Sani M, Ehsani A, Moghaddas Kia E, Khezerlou A (2019) Microbial gums: introducing a novel functional component of edible coatings and packaging. Appl Microbiol Biotechnol 103:6853–6866. https://doi.org/10.1007/s00253-019-09966-x

Amjadi S, Ghorbani M, Hamishehkar H, Roufegarinejad L (2018) Improvement in the stability of betanin by liposomal nanocarriers: its application in gummy candy as a food model. Food Chem 256:156–162. https://doi.org/10.1016/j.foodchem.2018.02.114

Assous MTM, Abdel-Hady MM, Medany GM (2014) Evaluation of red pigment extracted from purple carrots and its utilization as antioxidant and natural food colourants. AOAS 59:1–7. https://doi.org/10.1016/j.aoas.2014.06.001

Banerjee S, Bhattacharya S (2011) Compressive textural attributes, opacity and syneresis of gels prepared from gellan, agar and their mixtures. J Food Eng 102:287–292. https://doi.org/10.1016/j.jfoodeng.2010.08.025

Borwankar RP (1992) Food texture and rheology: a tutorial review. In: Borwankarm RP, Shoemaker CF (eds) Rheology of foods. Elsevier, Amsterdam, pp 1–16. https://doi.org/10.1016/0260-8774(92)90016-y

Cappa C, Lavelli V, Mariotti M (2015) Fruit candies enriched with grape skin powders: physicochemical properties. LWT-Food Sci Technol 62:569–575. https://doi.org/10.1016/j.lwt.2014.07.039

Cardoso-Ugarte GA, Sosa-Morales ME, Ballard T, Liceaga A, San Martín-González MF (2014) Microwave-assisted extraction of betalains from red beet (Beta vulgaris). LWT-Food Sci Technol 59:276–282. https://doi.org/10.1016/j.lwt.2014.05.025

Costa ALR, Gomes A, Ushikubo FY, Cunha RL (2017) Gellan microgels produced in planar microfluidic devices. J Food Eng 209:18–25. https://doi.org/10.1016/j.jfoodeng.2017.04.007

Delgado P, Bañón S (2015) Determining the minimum drying time of gummy confections based on their mechanical properties. CYTA J Food 13:329–335. https://doi.org/10.1080/19476337.2014.974676

Delgado P, Bañón S (2018) Effects of replacing starch by inulin on the physicochemical, texture and sensory characteristics of gummy jellies. CYTA J Food 16:1–10. https://doi.org/10.1080/19476337.2017.1327462

Enayat S, Banerjee S (2009) Comparative antioxidant activity of extracts from leaves, bark and catkins of Salix aegyptiaca sp. Food Chem 116:23–28. https://doi.org/10.1016/j.foodchem.2009.01.092

Escribano J, Cabanes J, Jiménez-Atiénzar M, Ibañez-Tremolada M, Gómez-Pando LR, García-Carmona F, Gandía-Herrero F (2017) Characterization of betalains, saponins and antioxidant power in differently colored quinoa (Chenopodium quinoa) varieties. Food Chem 234:285–294. https://doi.org/10.1016/j.foodchem.2017.04.187

Fan Y, Yi J, Hua X, Zhang Y, Yang R (2017) Preparation and characterization of gellan gum microspheres containing a cold-adapted β-galactosidase from Rahnella sp. R3. Carbohydr Polym 162:10–15. https://doi.org/10.1016/j.carbpol.2017.01.033

Ghasempour Z, Khaled-Abad MA, Vardast MR, Bari MR, Moghaddas Kia EM (2019) Fabrication of betanin imprinted polymer for rapid detection of red beet adulteration in pomegranate juice. Polym Bull 76:1793–1805. https://doi.org/10.1007/s00289-018-2444-5

Güneşer O (2016) Pigment and color stability of beetroot betalains in cow milk during thermal treatment. Food Chem 196:220–227. https://doi.org/10.1016/j.foodchem.2015.09.033

Hani NM, Romli SR, Ahmad M (2015) Influences of red pitaya fruit puree and gelling agents on the physico-mechanical properties and quality changes of gummy confections. Int J Food Sci Technol 50:331–339. https://doi.org/10.1111/ijfs.12638

Jooyandeh H, Goudarzi M, Rostamabadi H, Hojjati M (2017) Effect of Persian and almond gums as fat replacers on the physicochemical, rheological, and microstructural attributes of low-fat Iranian White cheese. Food Sci Nutr 5:669–677. https://doi.org/10.1002/fsn3.446

Karimi I, Hayatgheybi H, Kamalak A, Pooyanmehr M, Marandi Y (2011) Chemical composition and effect of an essential oil of Salix aegyptiaca L., Salicaceae, (musk willow) in hypercholesterolemic rabbit model. Rev Bras Farmacogn 21:46–57. https://doi.org/10.1590/S0102-695X2011005000030

Khazaiy Pool E, Shahidi F, Mortazavi SA, Mohebbi M (2014) Study of different levels of micro-algae Spirulina Platensis on the microstructure and psychochemical and sensory characteristics of Kiwi pastille. Iran Food Sci Technol Res J 12:21–33

Kumar V, Kushwaha R, Goyal A, Tanwar B, Kaur J (2018) Process optimization for the preparation of antioxidant rich ginger candy using beetroot pomace extract. Food Chem 245:168–177. https://doi.org/10.1016/j.foodchem.2017.10.089

Lau MH, Tang J, Paulson AT (2000) Texture profile and turbidity of gellan/gelatin mixed gels. Food Res Int 33:665–671. https://doi.org/10.1016/S0963-9969(00)00111-3

Lee KY, Shim J, Lee HG (2004) Mechanical properties of gellan and gelatin composite films. Carbohydr Polym 56:251–254. https://doi.org/10.1016/j.carbpol.2003.04.001

Mendis E, Rajapakse N, Kim SK (2005) Antioxidant properties of a radical-scavenging peptide purified from enzymatically prepared fish skin gelatin hydrolysate. J Agric Food Chem 53:581–587. https://doi.org/10.1021/jf048877v

Moghaddas Kia E, Ghasempour Z, Ghanbari S, Pirmohammadi R, Ehsani A (2018) Development of probiotic yogurt by incorporation of milk protein concentrate (MPC) and microencapsulated Lactobacillus paracasei in gellan–caseinate mixture. Brit Food J 120:1516–1528. https://doi.org/10.1108/BFJ-12-2017-0668

Molaei H, Jahanbin K (2018) Structural features of a new water-soluble polysaccharide from the gum exudates of Amygdalus scoparia Spach (Zedo gum). Carbohyd Polym 182:98–105. https://doi.org/10.1016/j.carbpol.2017.10.099

Morris ER, Nishinari K, Rinaudo M (2012) Gelation of gellan–a review. Food Hydrocoll 28:373–411. https://doi.org/10.1016/j.foodhyd.2012.01.004

Otálora MC, de Jesús Barbosa H, Perilla JE, Osorio C, Nazareno MA (2019) Encapsulated betalains (Opuntia ficusindica) as natural colorants. Case study: gummy candies. LWT-Food Sci Technol 103:222–227. https://doi.org/10.1016/j.lwt.2018.12.074

Periche A, Heredia A, Escriche I, Andrés A, Castelló ML (2014) Optical, mechanical and sensory properties of based-isomaltulose gummy confections. Food Biosci 7:37–44. https://doi.org/10.1016/j.fbio.2014.05.006

Saha D, Bhattacharya S (2010) Characteristics of gellan gum based food gels. J Texture Stud 41:459–471

Savedboworn W, Phuditcharnchnakun S, Khuntaweetap T (2015) Development of antioxidant gummy jelly candy supplemented with Psidium guajava leaf extract. KMUTNB Int J Appl Sci Technol 8:145–151. https://doi.org/10.14416/j.ijast.2015.02.002

Sayyari Z, Farahmandfar R (2017) Stabilization of sunflower oil with pussy willow (Salix aegyptiaca) extract and essential oil. Food Sci Nutr 5:266–272. https://doi.org/10.1002/fsn3.389

Strack D, Vogt T, Schliemann W (2003) Recent advances in betalain research. Phytochem 62:247–269. https://doi.org/10.1016/S0031-9422(02)00564-2

Yee LP, Wah CS (2017) Application of red pitaya powder as a natural food colourant in fruit pastille. J Gizi Klinik Indones 13:111–120. https://doi.org/10.22146/ijcn.17863

Zia KM, Tabasum S, Khan MF, Akram N, Akhter N, Noreen A, Zuber M (2017) Recent trends on gellan gum blends with natural and synthetic polymers: a review. Int J Biol Macromol 109:1068–1087. https://doi.org/10.1016/j.ijbiomac.2017.11.099

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moghaddas Kia, E., Ghaderzadeh, S., Mojaddar Langroodi, A. et al. Red beet extract usage in gelatin/gellan based gummy candy formulation introducing Salix aegyptiaca distillate as a flavouring agent. J Food Sci Technol 57, 3355–3362 (2020). https://doi.org/10.1007/s13197-020-04368-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04368-8