Abstract

The blends were prepared of virgin coconut oil with refined soyabean oil (VCO-RSOY) and refined safflower oil (VCO-RSAFF). Blending with VCO improved the fatty acid composition which increased the shelf stability of 20:80 VCO-RSOY and VCO-RSAFF up to 12 months in different packaging systems such as low density polyethylene, linear low density polyethylene, metalized polyester pouches, polyethylene teteraphthalate, high density polyethylene (HDPE), Amber HDPE bottle. The specific spectral regions of FTIR proved to be very useful for the determination of adulteration as well as for the study of oxidation process. Band shifts observed at 3008, 1652, 1397, 1097, 912 and 845 cm−1 have been used to differentiate RSAFF from VCO. VCO spectrums did not have these chemical shifts. Further the spectrum of RSOY showed same band shifts as RSAFF except 1652, 1397, 869.6 and 845 cm−1. Differential Scanning Calorimetry provided useful information regarding the nature of thermodynamic changes related to physical state of vegetable oil. The physical state changes included melting and crystallization events which require the intake and release of energy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Commonly coconut processed products minimally processed tender nut, coconut chips and coconut beverage are available in the market and are getting encouraging response from the consumers. Coconut oil is made from copra (dried kernel or meat of coconut) while virgin coconut oil is extracted from fresh coconut (not copra) meat by mechanical or natural means under controlled temperature and it is having more nutritionally beneficial effects than copra oil (Marina et al. 2009). Virgin coconut oil, is coined as emerging functional food oil both in the local and foreign market due to increase in public awareness on functional food. It has many health benefits such as preventing the oxidation of low density lipoprotein, increasing the antioxidant enzymes, helping in foot crack healing, scar removal and reducing the cholesterol and triglyceride levels.

Medium chain fatty acids (MCFA) do not participate in biosynthesis and transport of cholesterol. It is absorbed directly through the portal vein into the liver and does not require carnitine transport for their entry into the cells and subsequent metabolism for energy release in comparison to long chain fatty acid. MCFA is easy to digest, absorb and oxidize in comparison to long chain fatty acid. Short and MCFA are easily solubilized in the aqueous phase of the intestinal contents, absorbed readily and is carried to the liver where it release energy. MCFA affect the physiology of a body by less deposition in adipose tissue (less obesity), decrease protein catabolism in hypercatabolic states, raise thyroid function and not forming esters with cholesterol while animal fats (having long chain fatty acids) do not mix easily with biologic fluids, need lipase for digestion, bypass the liver and deposit cholesterol in tissues before going to liver for oxidation (energy release) (Ghosh et al. 2009a, b).

Blending of oil is highly beneficial for nutrition as well as for cooking, and maintaining good health. In the present study the objective has been designed to establish the identification and characterization of VCO samples by analyzing the physico-chemical properties and storage stability of refined soybean and safflower oil blends with VCO.

Materials and methods

Extraction of VCO

VCO can be extracted directly from the fresh coconut meat or from coconut milk. It involves two major steps: production of coconut milk and extraction of oil. Extraction of oil can be done by two ways: cold and hot extraction process.

Quality characteristics and storage stability of VCO blends prepared with non-conventional oil

The edible oil blends prepared were as follows: VCO with soybean oil (1:4, 2:3, 3:2, 4:1) and VCO with safflower oil (1:4, 2:3, 3:2, 4:1). Raw VCO, soybean oil and safflower oil were packaged separately. The storage stability of the oil blends were examined by filling them in a series of different packaging materials such as low density polyethylene (LDPE), linear low density polyethylene (LLDPE), metalized polyester (MP) pouches, polyethylene teteraphthalate (PET), high density polyethylene (HDPE), Amber HDPE bottle and stored at room temperature (15–35 °C). The sensory acceptability of the oil blends in the preparation of some typical fried items of a snacks were judged in terms of odour, taste, texture and appearance by organoleptic evaluation using a trained panel of judges. The iodine value, saponification value, specific gravity, refractive index, moisture content and fatty acid composition were determined by AOCS (1990). All the analyses were done in triplicates and average values were calculated. TBA was measured by the method of Tarledgis et al. (1960). Refractive index was estimated by Abbes refractomer according to AOAC (1990) method. Fatty acid composition of oils were determined by standard AOCS (1990) methods using gas liquid chromatography (Model HR 1000, Chemito, Chennai, India) with 10% diethylene glycol succinate (DEGS) column.

Estimation of Fourier transform infrared spectroscopy (FTIR)

The oil samples were analyzed by Fourier Transform Infrared Spectroscopy (FTIR). The IR spectra were recorded using Thermo Nicolet FTIR spectrometer (Model 5700, Madison, WI) fitted with single bounce Attenuated Total Reflectance (ATR) accessory with ZnSe crystal. Efforts were made to provide same pressure to all samples using the pressure device attached to the accessory. Sixty-four scans were averaged to reduce the noise. All spectra were recorded at 64 resolution and analysis of the spectra was carried out using the software provided along with the instrument (Rohmana and Che Man 2010).

Estimation of differential scanning calorimetry (DSC)

The thermal properties of food samples were determined by using DSC-821 (Mettler Toledo, Switzerland) equipped with a thermal analysis data station. About 8–10 mg of oil sample was placed in hermetically sealed aluminum pans. An empty aluminum pan was used as a reference. For each oil sample, DSC runs (in duplicate) were performed from −60 to 25 °C at a scan rate of 10 °C/min. Based on the measured amount of energy (heat) absorbed by a sample during a run, the DSC manufacturer’s software (TA Universal Analysis and TA Advantage Specialty Library) were used to analyze the heat flow data and determine the onset of melting (To), end set melting (Te), peak melting temperature (Tp) and enthalpy (ΔH) of the oil samples (Yasunga et al. 1968).

Sensory evaluation oil blends

For sensory acceptance tests, bengal gram dhal was fried in fresh and stored VCO-refined safflower oil and VCO-refined soybean oil samples served to a panel of 25 semi trained panelists for grading for aroma, taste and overall acceptability on a 9-point hedonic scale having 9 for excellent in all respects and 1 for complete unacceptability. The experiments were run in duplicate and analyses were done in triplicate (Larmond 1997).

Results and discussion

Changes in free fatty acid (FFA), peroxide value (PV) and saponification values (SV) of VCO blends

FFA content of VCO, refined soybean oil (RSOY), refined safflower oil (RSAFF) and their blends are shown in Table 1. VCO has higher FFA content (0.12% oleic acid) than RSAFF (0.05% oleic acid) and RSOY (0.05% oleic acid). This was due to extraction process of VCO without refining which may lead to more FFA content while RSAFF and RSOY had low FFA due to refining process. As expected an increase of FFA was observed in the blends as the VCO proportions were increased in it. Higher the FFA means higher diglycerides (DGs) and monoglycerides (MGs) content which affect the rate of crystallization and caused cloudiness in oil at low temperature storage conditions (Siew and Ng 1996, 1999). Results in Table 1 clearly showed that there was less change in peroxide value (PV) in RSAFF, VCO, RSOY and their blends. In the present investigation PV were in the acceptable range i.e. less than 10 meqO2/kg.

Saponification value (SV) is a measure of the average molecular weight of oils and fats. VCO had the maximum saponification value (254.82 mg KOH/100 g oil) while soybean (198.38 mg KOH/100 g of oil) and safflower oil (196.84 mg KOH/100 g oil) had minimum. Both the blend of RSOY and RSAFF had higher SV as compared to RSOY, VCO and RSAFF.

Fatty acid profile and thermal properties of VCO blends

The aim for the blending of oil is to modify or improve the functionality of oil without changing the chemical composition of oil. It is the best way to produce edible oils with their natural flavor, characteristics as well as nutritional value. The blends of VCO, RSOY, RSAFF prepared were analyzed for fatty acid profile which provided indication for saturated fatty acid, polyunsaturated fatty acid and mono unsaturated fatty acid (Table 1). The prominent fatty acids in RSOY, RSAFF and VCO were oleic acid (23.12%) and linoleic acid (53.70%), oleic (12.81%) and linoleic (77.63%), lauric (50.21%) and myristic (16.51%) respectively. Blending of edible vegetable oil means an admixture of any two edible vegetable oils where the proportion by weight of any edible vegetable oils used in admixture should be not less than 20% (Rohmana and Che Man 2010). Blending of VCO caused decrease in monounsaturated fatty acid (MUFA) (oleic) as well as polyunsaturated fatty acid (PUFA) (linoleic and linolenic acid) in both VCO-RSOY and VCO-RSAFF blends at different percentage. Blending of RSAFF with VCO in proportions of 20:80, 40:60, 60:40 and 80:20 resulted in the reduction of linoleic acid content from 77.63 to 17.88, 33.12, 47.35 and 62.41%, respectively.

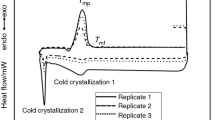

Further, the oleic acid was decreased from 12.81 to 7.89% at 80% of VCO. In addition to this, the linoleic acid was decreased from 53.70 to 43.14, 33.07, 22.42 and 12.26% in VCO-RSOY blends and linolenic acid from 7.56 to 6.33, 4.21, 3.04 and 1.52% in VCO-RSOY blends with respect to blending proportions. Blending of RSOY (PUFA) and RSAFF (PUFA) with VCO (SFA) was done to adjust fatty acids to optimal level so that the ratio of PUFA/MUFA decreased and as a result increase the oxidative stability of the oil blends. The present study revealed that the SFA/PUFA and SFA/MUFA ratio were decreased in both VCO-RSOY and VCO-RSAFF blends. The changes in SFA/PUFA and SFA/MUFA have direct impact on melting and crystallization temperatures (Myat et al. 2009). Differential Scanning Calorimetry (DSC) cooling/melting thermograms have been reported for studying various heat related phenomenon in oil by monitoring the changes in enthalpy (Chiavaro et al. 2007). In the present study the melting and crystallization points were determined as the end set temperature values of the last melting and crystallization peaks. The thermal properties of various oil samples from the DSC melting and crystallization curves can be characterized by onset (To), peak temperature (Tp) and endset (Te) transition temperatures. It has been observed that blending of VCO (rich in SFA) with RSOY and RSAFF (high unsaturated fatty acid) resulted in more stable blends which did not crystallize easily at low temperatures. Similar, results of heating and cooling profile of palm-olive oil blend and palm-peanut oil blend were studied by Myat et al. (2009). They have concluded that melting peaks were shifted from lower to higher temperature as percentage of peanut oil and the palm oil proportion increased in oil blends. Basically, oils are composed of complex mixture of triglycerides and when they are subjected to the crystallization conditions, from the molten state the oils pass through the nucleation, activation, crystal growth and crystal lattice stage like polymers. The crystallization curve of VCO showed two distinct peaks, whereas RSAFF and RSOY showed overlapped peaks (Fig. 1). Results indicated that there was a shift in the crystallization peak of various VCO blends to lower temperature. Decrease in crystallization enthalpy could be due to the depletion of triglycerides or increase of FFA. Depending on the proportion of the soybean and safflower oil, the Tp of cooling curve varies from −21.13 to −4.8 and −20.61 to −7.67 in VCO-RSAFF and VCO-RSOY blends respectively. In another way it might be hypothesized that the level of diglycerides may have a role in TAG crystallization (accelerating or delaying) (Chiavaro et al. 2007) (Table 2). Similar results have been reported by Toro-Vazquez et al. (2000) in Palm Stearin in Blends with Sesame Seed Oil.

The melting characteristics [onset melting temperature (To), peak melting temperature (Tp), endset melting temperature (Te) and enthalpy of melting (ΔH)] were obtained from enthalpy-temperature data (Fig. 1, Table 2). The results indicate that the melting point was significantly influenced by the percentage of VCO, soybean and safflower oil. Results showed that there was shift in melting peaks from lower temperature to higher temperature as the percentage of VCO increased. Similar results have been reported by Naghshineh et al. (2010) in Palm Olein–Olive Oil Blend. In general, a close relation between melting point and fatty acid ratio (C16/C18:2 + C18:3) was observed. Consequently the blend containing highest ratio of C16/C18:2 + C18:3 showed the maximum melting point while the oil blend composed of the lowest ratio of C16/C18:2 + C18:3 showed the lowest melting point in VCO-RSAFF and VCO-RSOY blends (Table 2).

Changes in Fourier transform infrared spectroscopy (FTIR) spectra of VCO and its blends with RSOY and RSAFF

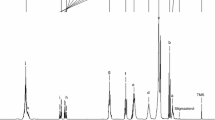

The FTIR spectra of RSOY, VCO, RSAFF and their blends with different proportions are shown in Fig. 2. Visual examination of the spectra revealed that absorption bands at wavenumbers 2954 cm−1 stretching –C–H [CH3], 2921 cm−1 asymmetric stretching –C–H [–CH2], 2853 cm−1 symmetric stretching –C–H [–CH2], 1743 cm−1 stretching –C = O, 1463 cm−1 [Bending –C–H [CH2], 1417 cm−1 Bending =C–H, 1377 cm−1 symmetrical bending –C–H [CH3], 1232 cm−1 stretching –C–O, 1158 cm−1 stretching –C–O, 1116 cm−1 stretching –C–O, 963 cm−1 trans olefin bending –HC=CH–, 870 cm−1 bending =CH2 (wagging) and 721 cm−1 bending –(CH2)n– (rocking) for VCO samples. Vibrational frequencies observed at 3008 cm−1 (C=CH stretching), 1652, 1397, 1097, 912 and 845 cm−1 differentiate the RSAFF from VCO. Further the spectrum of RSOY showed similar bands as RSAFF except 1397, 869.6 and 845 cm−1.

FTIR is a modern tool for qualitative and quantitative analysis of oil blends. Several quantitative studies using FTIR spectroscopy have been reported on blends of VCO with canola oil, olive oil and palm oil in different proportions (Rohmana and Che Man 2010; Yaakob et al. 2012). VCO is having characteristics absorption at 1109 and 1151 cm−1. The corresponding absorption bands for RSAFF and RSOY are at 1099 and 1159 cm−1. It has been observed that for any blend of RSAFF or RSOY involving VCO, there is a shift in the absorption band at 1099 and 1159 cm−1 of RSAFF and RSOY. Hence, any high frequency shift of 1099 cm−1 band and low frequency shift of 1159 cm−1 qualitative indicates the presence of VCO in it. The peak positions of these bands in the blend could promote to a large extent the information on the percentage of VCO in it (Fig. 2).

RSAFF and RSOY are rich in unsaturated fatty acids which is evident from their higher iodine value. Generally, iodine value (IV) is not only the indication of degree of unsaturation in oils and fats but also measure the oil quality (Haryati et al. 1998). Several authors studied the relation between the absorbance’s ratios (A3008/2924, A3008/2853, A3008/1746) and the degree of unsaturation of fats and oils (Toro-Vazquez et al. 2000; Naghshineh et al. 2010). Table 1 shows that IV increased with increase in concentration of RSOY and RSAFF in VCO-RSOY and VCO-RSAFF blends, respectively at different proportions. The trend was comparable with increasing intensity of 3008 cm−1 band. The variation of absorption ratio (A3008/2922 and A3008/2853) also gives a similar trend indicating a positive correlation between IV and the absorption ratios. RSAFF (145.36 g I2/100 g oil) and RSOY (128.35 g I2/100 g oil) have high iodine value due to more unsaturation while VCO is rich in saturated fatty acid (SFA) having less iodine value (7.01 g I2/100 g oil). The presence of linolenic, linoleic and oleic acids from RSAFF and RSOY is the reason for higher IV and increase in intensity of 3008 cm−1 band. Similar results have been reported in various edible oils by Guillen and Cabo (1998).

Sensory evaluation of VCO-refined safflower oil blend and VCO-refined soybean oil blends

The sensory evaluation of VCO-refined safflower oil and VCO-refined soybean oil blends has been carried out by the soaked bengal gram dhal frying. The results indicate that OAA of 80:20, 60:40, 40:60 and 20:80 of both the blends scored 6–8 for all the sensory parameters. But the sensory scores were higher in blends containing 20:80 VCO-refined safflower oil and VCO-refined soybean oil in terms of flavor and aroma. The values obtained from sensory score provide an idea not only for consumer acceptance but also related to the modification of fatty acid composition which play an important role during frying and storage.

Storage study of 20:80(v/v) virgin coconut oil-refined safflower oil (VCO-RSAFF) blend and virgin coconut oil-refined soybean oil (VCO-RSOY) blends

Two oil blends, namely, hot extracted virgin coconut oil (HEVCO)–refined soybean oil (RSOY) and hot extracted virgin coconut oil (HEVCO)–refined safflower oil (RSAFF) were prepared in the proportion of 20:80, 40:60, 60:40 and 80:20 (v/v) respectively, but 20:80(v/v) was stored for a period of one year in different packaging systems. Off-flavor resulting from oxidation of unsaturated fatty acids is the major cause of spoilage in stored oils. In the present investigation, the oxidation was determined by analyzing the changes in peroxide value and the carbonyls, the final products of oxidation. The changes in chemical characteristics of virgin coconut oil, refined soybean oil, refined safflower oil and their blends during storage at room temperature are given in Tables 3 and 4.

The refined oils had initially lower free fatty acids (0.05% oleic) than the virgin coconut oil (0.12% lauric). The initial peroxide value of refined oil varied from 2.95–3.39 meq O2/kg oil as compared to 3.32–3.91 meq O2/kg in VCO-RSOY and VCO-RSAFF blends respectively. After 12 months at room temperature, the PV in VCO-RSOY and VCO-RSAFF blends samples stored in flexible packaging viz. LDPE, LLDPE, MP and rigid containers viz. PET, HDPE and amber HDPE bottles increased to 17.98, 15.34, 12.54, 15.32, 13.92, 10.76 and 17.98, 14.38, 11.99, 13.98, 11.21 and 9.89 meq O2/kg oil, respectively. The free fatty acid contents of all edible oils increased steadily during storage at room temperature (Tables 3, 4). This increase was slightly higher in oil samples stored in LDPE and LLDPE as compared to oils stored in other packaging system. A concomitant increase in anisidine value and in the formation of total carbonyls was also observed from 1.76 to 14.87 units and 3.21 to 12.98 mg/100 g hexanal in VCO-RSOY blends whereas 3.93 to 15.75 units and 4.92 to 14.99 mg/100 g hexanal in VCO-RSAFF blend, respectively. The changes in thiobarbituric acid (TBA) value also followed the similar trend. The increase in TBA value, anisidine value (AV), peroxide value (PV) and total carbonyls (TC) were linearly correlated (r > 0.90) with the storage period.

The correlation coefficient between TBA and storage period ranged between 0.9 and 0.99, and 0.95 and 0.99 in VCO-RSOY and VCO-RSAFF blends, respectively. The changes in PV, TBA, AV and TC were not large enough to cause perceptible change in sensory quality of both the oil blends up to 12 months in all the packaging materials at room temperature. Refractive index of VCO-RSOY and VCO-RSAFF blends ranged from 1.4655 to 1.4660 and 1.4660 to 1.4665 respectively and did not change significantly during the entire storage period in any of the packaging system studied. Iodine value, which normally decreases as a result of oxidation (decreased by 1–1.5 units after 12 months of storage in both the blends) showed the consistency in chemical characteristics reflecting the stability of the oil blends.

Autoxidation of vegetable oils affects their fatty acid composition as polyunsaturated fatty acids (PUFA) are oxidized faster than saturated and monosaturated fatty acid (MUFA) (Yasunga et al. 1968). The fatty acid composition of oils and their blends are shown in Tables 1 and 2. The most prominent fatty acids in VCO, RSOY and RSAFF were lauric (50.21%), linoleic (53.7%) and linoleic (77.63%) respectively. Blending of VCO with RSOY and RSAFF caused lauric acid to decrease and linoleic acid to increase in both the oil blends. Blending of VCO with RSOY and RSAFF in proportion of 20:80 resulted in the reduction of lauric acid content from 50.21 to 10.24 and 9.81% respectively. Linoleic acid content increased from 1.91 to 43.14 and 62.41% respectively, following the above blending ratio. The fatty acid profile of the oil blends did not change significantly during the entire storage period (Tables 3, 4). Initially the aroma, taste and overall acceptability of bengal gram dhal fried in oils and their blends were not different, but tended to decrease when fried in stored samples. The consumer acceptance indicated preference for VCO-refined safflower oil blend than the VCO-refined soybean oil blend.

From the foregoing discussion it is evident that both the oil blends remained in acceptable condition for 12 months without any significant change in flavor when stored and packed in different flexible and rigid packaging systems. Rate of lipid peroxidation was found to be slightly slower in samples stored in amber HDPE and HDPE bottles as compared to LDPE to LLDPE stored ones. Increase in PV, TBA, AV and TC correlated linearly with storage period and can be used as objective parameters for quality determination on storage.

Conclusion

In the present study, the blending of VCO-RSOY and VCO-RSAFF has been encouraged to modify the fatty acid composition of the oil because RSOY and RSAFF are rich in PUFA while VCO is rich in SFA. The sensory evaluation of VCO-RSOY and VCO-RSAFF blends in different proportions (20:80, 40:60, 60:40, 80:20) with bengal gram dhal frying gave an idea that blends with 20:80 VCO-RSOY and VCO-RSAFF found a higher score by panelist than the other blends. The data obtained from storage study of 20:80(v/v) VCO-safflower oil blend and VCO-soybean oil showed 12 months storage stability in different packaging system in terms of PV, FFA, TBA, AV, TC and OAA.

Abbreviations

- VCO:

-

Virgin coconut oil

- HEVCO:

-

Hot extracted virgin coconut oil

- CEVCO:

-

Cold virgin coconut oil

- CCO:

-

Commercial coconut oil

- FTIR:

-

Fourier transform infrared spectrum

- SFA:

-

Saturated fatty acid

- MUFA:

-

Mono unsaturated fatty acid

- PUFA:

-

Poly unsaturated fatty acid

- MGs:

-

Monoglycerides

- DGs:

-

Diglycerides

- DSC:

-

Differential scanning calorimetry

References

AOAC (1990) Official methods of analysis, 15th edn. Association of official Analytical Chemists, Washington, DC, USA, Gaithersburg

Chiavaro E, Vittadini E, Rodriguez EMT, Cerrettani L, Bonoli M, Bendini A, Lercker G (2007) Monovarietal extra virgin oliven oils: coorelation between thermal properties and chemical composition. J Agric Food Chem 55:10779–10786

Ghosh DK, Ghosh A, Manojkumar C, Samsudeen K (2009a) A simpler approach to understand coronary heart disease, fat facts and its correlation with consumption of coconut oil. Indian Coconut J 10:15–19

Ghosh RD, Mehra I, Dhande VM, Kakade VJ, Vohra RR (2009b) Antihyperglycemic activity of Madhuca longifolia in alloxan-induced diabetic rats. Int J Pharmacol 6:25–30

Guillen MD, Cabo N (1998) Relationships between the composition of edible oils and the ratio of the absorbance of specific bands of their Fourier transform infrared spectra. J Agric Food Chem 46:1788–1793

Haryati T, Che Man YB, Ghazali HM, Asbi BA, Buana L (1998) Determination of iodine value of palm oil based on triglyceride composition. J Am Oil Chem Soc 75:789–792

Larmond E (1997). Laboratory methods for sensory evaluation of foods Publication No. 1637, Research Branch, Department of Agriculture, Ottawa, Canada, pp 33–37

Marina AM, Che Man YB, Nazimah SAH, Amin I (2009) Chemical properties of virgin coconut oil. J Am Oil Chem Soc 86:301–307

Myat MW, Abdulkarim SM, Ghazali HM (2009) Physicochemical and sensory characteristics of palm olein and peanut oil blends. J Food Agric Environ 7:175–181

Naghshineh M, Ariffin AA, Ghazali HM, Mirhosseini H, Mohammad AS (2010) Effect of saturated/unsaturated fatty acid ratio on physicochemical properties of palm olein-olive oil blend. J Am Oil Chem Soc 87:255–262

Rohmana A, Che Man YB (2010) Fourier transform infrared (FTIR) spectroscopy for analysis of extra virgin olive oil adulterated with palm oil. Food Res Int 43:886–892

Siew WL, Ng WL (1996) Effect of diglycerides on the crystallization of palm oleins. J Sci Food Agric 71:496–500

Siew WL, Ng WL (1999) Influence of diglycerides on crystallization of palm oil. J Sci Food Agric 79:722–726

Tarledgis BG, Watts BM, Younathan MT, Dugan LJ (1960) A distillation method for the qualitative determination of malonaldehyde in rancid food. J Am Oil Chem Soc 37:44–47

Toro-Vazquez JF, Briceño-Montelongo M, Dibildox-Alvarado E, Charó-Alonso M, Reyes-Hernández J (2000) Crystallization kinetics of palm stearin in blends with sesame seed oil. J Am Oil Chem Soc 77:297–310

Yaakob B, Man Che, Abdul R (2012) Analysis of canola oil in virgin coconut oil using FTIR spectroscopy and chemometrics. J Food Pharm Sci 1:5–9

Yasunga T, Bushuk W, Irvin GN (1968) Gelatinization of starch during bread baking. Cereal Chem 45:269–274

Acknowledgements

Authors express their gratitude to the National Agricultural Innovation Project (NAIP) and Director, Central Plantation Crops Research Institute (CPCRI), Kasargod, Kerala for providing the VCO required for the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivastava, Y., Semwal, A.D., Sajeevkumar, V.A. et al. Melting, crystallization and storage stability of virgin coconut oil and its blends by differential scanning calorimetry (DSC) and Fourier transform infrared spectroscopy (FTIR). J Food Sci Technol 54, 45–54 (2017). https://doi.org/10.1007/s13197-016-2427-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2427-1