Abstract

The objective of this study is to evaluate the physicochemical, chromatographic, and thermogravimetric parameters and the oxidative stability of the high-oleic peanut oil (IAC-505) obtained by hydraulic pressing extraction. The analyses were performed according to the International and Official Methods of Analysis (AOAC, AOCS). The high-oleic peanut oil (IAC-505) was obtained by hydraulic pressing and stored at 4 °C. The acidity value (1.20 mg KOH g−1) and peroxide value (3.75 mEq kg−1) obtained were within the maximum values established by the National Health Surveillance Agency (ANVISA) for cold-pressed oil. The fatty acid profile showed high levels of oleic fatty acid (81.88%). The thermogravimetric behavior and differential analysis indicated good stability upon gradual temperature increase around 200 °C. The oxidative stability index or oxidation induction period of the oil was 15.74 h. The differential scanning calorimetry showed crystallization temperature of − 5 °C and − 33 °C and melting temperature of − 16 °C and − 6 °C. Based on the results obtained, the nutritional and functional quality, mass loss pattern, and oxidative stability of the high-oleic peanut oil (IAC-505) were determined, demonstrating its potential applications in various industrial segments and in food technology research.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Advances in research focusing on new techniques to exploit the potential of raw materials with functional characteristics that provide health benefits have led to an increased number of studies on oilseeds; among them are nuts, walnuts, and almonds because their chromatographic profiles show that they are rich in essential fatty acids, known to boost the immune system.

Some oilseeds, such as peanut kernels, stand out. Peanut is one of the most important crops for extraction of edible oil, because of the species’ high drought tolerance, especially in semiarid tropical areas, and because peanut oil possesses a mild flavor and is believed to be stable at high cooking temperatures and can provide resistance to rancidity [1, 2]. Peanut oil is rich in unsaturated fatty acid, as oleic and linoleic acids (about 80% of the fatty acid composition), vitamin E, folate, protein, and manganese [3]. Oleic acid is less oxidized than linoleic acid; therefore, the ratio of oleic to linoleic acid (O/L) which is usually ~ 4 can reach as high as 30 or 40 in high-O/L cultivars, which are possible to breed by conventional breeding methods and by genetic modification [1]. It is possible to obtain, for high-oleic peanuts, very similar flavor attributes to conventional cultivars [4].

Many studies have been carried out focusing on increasing the quality of breed peanut. Therefore, new varieties have been developed. In studies carried out by the Agronomic Institute of Campinas (IAC), they denominated “high-oleic peanut”. This characteristic has two positive aspects. The first is related to public health since it boosts good cholesterol levels, and the second is related to the greater stability of this raw material, resulting in a guaranteed high-quality product and an increase in its shelf life [5,6,7,8,9,10,11].

However, there is a need for further evaluation of the potential and possible changes in the composition of these oilseeds, as well as their applications in various industries, using technologies that allow the isolation of their main macronutrients. Therefore, due to their high content of lipids and proteins and other important compounds, e.g., antioxidants, tocopherol, polyphenols, fat-soluble vitamins, amino acids, and nucleic acids among others, some foods such as peanuts have been considered as functional foods [12,13,14,15].

The studies on high-oleic peanut oil have been carried out focusing on its quality and fatty acid composition [2, 8, 9, 11]. However, there is also a need to evaluate its nutritional and/or functional characteristics and thermal and oxidative stability among other gravimetric measures and specific characteristics of this oil obtained by hydraulic pressing. Accordingly, based on the high-oleic peanut oil (IAC 505) characteristics, the present study aims to evaluate the quality, nutritional and functional composition, and thermal and oxidative stability of high-oleic peanut oil extracted by cold-hydraulic pressing, focusing on the feasibility of application of this oil in nutraceuticals and functional foods [8].

The predominant fatty acids present in peanut oil are unsaturated fatty acids, and this oil is rich in compounds with antioxidant properties such as proanthocyanidins, phenolic acids, and the isoflavones genistein and daidzein among other bioactive compounds [8, 9, 11, 15].

Therefore, techniques and analysis that can reveal the potential and new applications of this oil in industrial segments should be used to broaden the knowledge of this raw material. These analyses require gravimetric, differential, and thermal-based technologies among others, which can predict the material behavior under progressive temperature rise and determine its oxidative stability under accelerated decomposition [11, 14, 15].

Therefore, the objective of this study was to evaluate the physicochemical, chromatographic, and thermogravimetric parameters and the oxidative stability of the high-oleic peanut oil (IAC-505) obtained by hydraulic pressing extraction.

Materials and methods

Materials

The high-oleic peanut samples were donated by the Agronomic Institute of Campinas (IAC) (2013 crop). They were stored under refrigeration (9 °C) and then subjected to drying in an air circulation oven (FABBE, model 170) followed by hydraulic pressing extraction (FMB SIWA, USA) (with capacity of 15 tons of pressure maintained on an average sample of 500 g for a period of 5 min on batch samples) in order to determine their lipid content. The oil obtained was stored in amber glass bottles and refrigerated (4 °C) until analysis.

Physicochemical characterization of peanut

The following physicochemical analyses were performed on peanut—water activity: using an AquaLab thermo hygrometer Series 3TE (DECAGON), at a temperature of 25 °C; humidity: determined by oven-drying at 105 °C until constant mass, according to the AOAC official method 920 151 (2000) [16]; crude protein: determined according to the micro-Kjeldahl as described by the AOAC official method 950.48 (2000) [17]; fixed mineral residue: was quantified after burning at 550 °C, according to the AOAC official method 930.05 (2000) [18]; total carbohydrates: determined by difference according to the RDC Resolution No. 360, December 23, 2003 [19]; and energy value: according to the Resolution RDC No. 360 of December 23, 2003 [19].

Physicochemical characterization of peanut oil

The following analyses were performed: acidity value: determined according to the AOCS Cd 3d-63 method (1998) [20]; saponification value: determined according to the AOCS Cd 3-25 method (1998) [21]; peroxide value: determined according to the AOCS Cd 8-53 method (1998) [22].

Fatty acid profile

Fatty acid profile of high-oleic peanut oil (IAC-505) was determined according to the AOCS Ce 2-66 method (1998) [23]. The analyses were performed on a Shimadzu GC 2012 plus gas chromatograph equipped with a SP-2560 (biscianopropil polisiloxana) fused silica capillary column (100 × 0.25 mm i.d.) (J&W Scientific, Folsom, CA) and a flame ionization detector (splitless mode). The operating conditions were as follows: The injector and detector temperatures were 250 °C and 260 °C, respectively; the column temperature was held at 140 °C for 5 min, increased to 4 °C min−1 to final temperature of 240 °C and held at this temperature for 30 min; total flow of helium (carrier gas) was 1 mL min−1; split injection: 1:200 ratio.

Fatty acid methyl esters (FAME) were obtained according to Hartman and Lago [24]. Peanut oil (50–125 mg) was dissolved in 2 mL of KOH/methanol 0.5 M in an esterification tube with glass pearls for 10 min at 100 °C in a heating block. The sample was cooled to room temperature, 2.5 mL of BF3 14% was added, and the tube was shaken and heated for 2 min at 100 °C. The sample was cooled to room temperature, 2.0 mL of heptane was added, and the tube was shaken and heated for 1 min at 100 °C. After removing from the heating, 5 mL of saturated NaCl solution was added, looking for phase separation. The tube was sealed and vigorously stirred for 15 s. Approximately, 1 mL of the mixture was transferred to a dram vial (2 mL) and some sodium sulfate anhydrous was added. On this way, the heptane extract was dried over sodium sulfate and injected into the GC for FAME analysis.

Functional quality of lipid fractions

The lipid fraction functionality is based on the fatty acid composition and was evaluated using the nutritional quality indexes: atherogenicity index (AI), thrombogenicity index (TI), determined according to Ulbricht and Southgate [25], and hypocholesterolemic/hypercholesterolemic ratio (HH), according to Santos-Silva et al. [26], and the following equations:

Melting characteristics

The differential scanning calorimetry (DSC) analyses were performed on a PerkinElmer calorimeter (Norwalk, CT, USA—Model DSC4000) to determine DSC crystallization and melting curves of the high-oleic peanut oil. The samples of approximately 14–38 mg mass were hermetically sealed in an aluminum pan, and a hermetically sealed empty aluminum pan served as the reference. The analyses were performed according to the AOCS recommended DSC procedure Cj 1-94 (1995) [27]. The samples were initially rapidly heated (40 °C min−1) from room temperature to 80 °C and held at this temperature for 10 min to destroy crystal memory; cooled to − 40 °C at 10 °C min−1, to define the crystallization profile, and held for 30 min; heated to 80 °C at 10 °C min−1 to define the melting profile. Normal standardization of the instrument was performed with n-decane (m.p., − 30 °C) and indium (m.p., 156.6 °C) as reference standards. Liquid nitrogen (− 196 °C) was used as coolant, and helium was used as carrier gas. These DSC curves were subsequently analyzed to determine peaks, onset, and total enthalpies.

Thermal stability analysis

Thermogravimetric (TG/DTG) and differential (DTA) analyses were performed on a Shimadzu-DTG-60 H thermo balance, adapted method according to Santos et al. [14], with the following parameters: air and nitrogen flow: 60 mL min−1, heating ramp: 10 °C min−1, temperature range from 20 to 450 °C, alumina crucible and 5 mg ± 0.5 mass.

Analyses of oxidative stability

Analyses were performed using the Rancimat method (Metrohm 743) (Herisau, Switzerland) under the following parameters: temperature of 120 °C, air flow of 20 m Lh−1, and an oil sample of 5 g, according to the AOCS Cd 12b-92 method (2004) [28]. Induction time (IT) was measured by conductivity. Soybean oil was used as the reference.

Results and discussion

Physicochemical characterization of high-oleic peanuts

Raw high-oleic peanuts showed a high total energy value (TEV), with a mean value of 599.68 expressed in kilocalories (kcal) per 100 g, i.e., 29.98% of the daily calorie needs based on a 2000 kcal calorie diet (Table 1).

Water activity analysis (aw) is of great importance because the presence of water can favor the growth of microorganisms. Bacteria usually require aw of at least 0.90 to grow, yeasts at least 0.85, and fungi at least 0.70. Therefore, the mean values of aw of raw high-oleic peanuts (0.72 ± 0.03) indicate the need to use conservation techniques to maintain good chemical and microbiological stability.

The results of the fixed mineral residue content (2.29 ± 0.29) can indicate that raw high-oleic peanuts are rich in micronutrients. Humidity value was around 5.65%. In a study comparing raw peanuts with other oilseeds, such as Brazil nuts [14], mean humidity value of 4.98% for Brazil nut was found.

The peanut protein content was calculated by multiplying the total nitrogen by 6.25 (%N × 6.25). The mean value obtained was 38.91 g 100 g−1. If compared to protein content found in other studies on oilseeds such as Brazil nut [14] found protein content of 18.22 g 100 g−1, high-oleic peanut protein content is higher; confirming that peanuts are also a good protein source.

Typically, peanuts are rich in oil, containing from 47 to 50% of nondrying oil [29]. The high mean lipid content obtained (46.84%) indicates that lipids are the nutritional compound that contributes the most to the high energy value of this oilseed. The mean value of carbohydrates obtained was 5.62 g 100 g−1, which can be considered as a result of variations in other components since carbohydrates are determined by difference.

Physicochemical analyses of high-oleic peanuts oil

The results of the physicochemical analyses represent parameters related to the conservation and quality of the oil. According to the quality standards established law, acidity and peroxide values are the most important quality control parameters of oils (Table 2).

These indexes indicate conservation state of the oil based on the impact of the major environmental oxidants, such as heat, light, and oxygen, elements that can accelerate the decomposition of glycerides, develop rancidity, and lead to the formation of free fatty acids in the matrices.

The mean acidity value obtained by hydraulic pressing was 1.20 mg KOH g−1, indicating the presence of free fatty acids (FFA) expressed as oleic acid. In a study about irradiation effect, the peanut oil presented 1.78 mg KOH g−1 [30]. According to Al-Bachir [30], the results obtained can indicate that the acid value of the oil corresponds to low levels of free fatty acids present in the oil, which also suggested low levels of hydrolytic and lipolytic activities in the oil. But also, this result can be explained by the interaction between the extracting agent and the amount of water in the sample, resulting in an increase in the acidity of the oil extracted [30].

This index is one the most important quality control parameters of oils. The value obtained is within the standards set by the National Health Surveillance Agency (ANVISA), which has established the standards for unrefined cold-pressed oils as maximum values of 4.0 mg KOH g−1 oil [31].

Another quality parameter evaluated was the peroxide value, which is the most common parameter used to determine the quality of oils and fats. The mean peroxide value obtained was 3.75 mEq kg−1. It indicates changes in raw material conservation, time and type of storage, storage period until analysis, and the characteristics of the lipid extraction method used. The value obtained on this work was lower than that obtained by Al-Bachir [30] for peroxide value of lipid produced from un-irradiated peanuts seed (4.07 mEq kg−1) and from irradiates peanuts seed (4.71 mEq kg−1), and meets the standards set by ANVISA, which has established the standards for unrefined cold-pressed oils as maximum values of 15 mEq kg−1 oil [31].

The mean saponification value obtained was 185.30 mg KOH g−1; this parameter indicates the presence of high-molecular-mass fatty acids, so the decrease in this value can indicate the degradation of original long-chain fatty acids to smaller molecules as a result of oxidation and cleavage of bonds during the extraction and preservation process. When compared to normal oleic peanut oil, the saponification value of peanut oil obtained on this work for high-oleic peanut oil is lower than the oil produced from un-irradiated peanuts seed (191.21 mg KOH g−1), like that found for oil produced from irradiates peanuts seed (184.77 mg KOH g−1) [30], and lower than typical characteristics of peanut oil (188–195 mg KOH g−1) [29].

Fatty acid profile

The triglyceride content of peanut oil, which contributes to this oil oxidative stability, is generally in the range of 96% with palmitic, oleic, and linoleic as the main fatty acids [29]. Dong et al. [32] found in their research with high-oleic peanut varieties values from 76.31 ± 0.87 to 80.08 ± 0.76% to oleic fatty acid, from 1.47 ± 0.08 to 3.56 ± 0.11% to linoleic fatty acid, and from 0.42 ± 0.02 to 0.69 ± 0.03% to linolenic fatty acid. On the other hand, Dong et al. [32] also found for normal oleic peanut oils varieties values from 39.48 ± 0.59 to 46.79 ± 0.44% to oleic fatty acid, from 30.19 ± 0.55 to 37.60 ± 0.48 to linoleic fatty acid, and from 0.24 ± 0.02 to 0.53 ± 0.03% to linolenic fatty acid.

It is seen in Table 3 that the percentage of fatty acids in peanut oil varies from 0.39% of linolenic acid to 81.88% of oleic acid, which shows the importance of this raw material. Although it is not considered an essential fatty acid, oleic acid is extremely important in food items as a bioactive compound. Besides, oleic acid, the most common fatty acid in nature, is a key triacylglycerol’s component of at membrane lipids, as well as it may provide up to 20% of total daily calories [33].

Palmitic acid was the predominant saturated fatty acids, followed by stearic, eicosanoic, docosanoic, and lignoceric; the total content of saturated fatty acids was 13.20%, which is lower than 20% cited by O’Brien [29].

The nutritional quality of this oil is based on the predominance of unsaturated fatty acids (86.81%); oleic acid is the fatty acid that contributes due to its high content and stability. Foods high in acid oleic can provide benefits related to reduction in cardiovascular diseases due to its effect on the reduction in LDL-cholesterol and triacylglycerol levels in the blood and on tumor growth, among others, but did not affect the beneficial high-density lipoprotein (HDL) cholesterol levels. These findings align with numerous studies that have shown that diets high in mono- and polyunsaturated fatty acids and low in saturated fatty acids can be heart healthy [14, 15, 29].

In addition to the nutritional functions, the importance of the presence of essential fatty acids lies in their potential ability to prevent pathological conditions, which characterizes them as nutrients with functional claims, according to the indexes based on their functional quality, as shown in Table 4.

Camargo et al. [15] and Godoy [5] consider the relationship between oleic and linoleic acid levels (O/L acid ratio) as a quality index that is directly related to the material characteristics such as density, viscosity, and oxidative stability.

According to Camargo et al. [15], this quality index has been widely used in studies on oilseeds, and it is classified according to the O/L acid ratio as follows: normal oleic peanuts: O/L acid ratio between 1.0 and 1.5; medium oleic peanuts: O/L acid ratio between from 1.5 to 9.0, and high-oleic peanuts: O/L acid ratio higher than 9.0.

Peanut oil classifications are of great nutritional and commercial importance since the O/L acid ratio values determine their order of increasing oxidative stability as: normal oleic peanuts < medium oleic peanuts < high-oleic peanuts, under normal temperature conditions.

The highlight of this genotype peanut type high oleic presented in this study, with an average of O/L acid ratio of 32.88, makes it to have lower density, higher viscosity and, especially, greater oxidative stability, which confirms a higher nutritional quality and extension of its shelf life [15]. Dong et al. [32] found in their research with high-oleic peanut varieties values from 21.44 to 53.35 to O/L acid ratio, and for normal oleic peanut, Dong et al. [32] found varieties value from 1.05 to 1.55 to O/L acid ratio.

The levels of AI and TI indexes in foods and diets in general are expected to be low. They indicate a good nutritional composition and functional potential by helping to reduce risks of cardiovascular diseases. On the other hand, the hypocholesterolemic/hypercholesterolemic ratio (H/H) is expected to be high since it is directly related to the cholesterol metabolism; higher the H/H is, more suitable the oil is for human consumption [15, 25, 26].

In general, the presence of essential fatty acids (EFA) in the diet is of great importance since they are associated with cell membrane structure and functional integrity, immune response, and the pro- and anti-inflammatory properties. This high-oleic profile of the peanut genotype shows its nutritional and functional potential and its stability, confirmed in the analysis of oxidative stability by the Rancimat method [15, 16].

Oxidative stability analysis by the Rancimat method

The oxidative stability of the peanut oil showed a peak or induction time around 15.74 ± 0.01 h. This parameter shows the oil ability to resist oxidation under certain conditions of atmosphere and temperature, simulating real work conditions with this material [14]. In O’Brien [29], the oxidative stability results have been recorded as much as 14.5 times better for high-oleic peanut oil than normal oleic peanut, depending upon the method of measurement.

The oil degradation is mainly characterized by a radical mechanism that leads to hydroperoxides that in turn evolve into aldehydes, ketones, lactones, alcohols, and acids; so the overall stability of the oils, and above all their resistance to the oxidation process, depends on their composition and on the conditions on which they are subjected. On this way, besides the considerable content of vitamin E, which delays the ramification process, the high-oleic oil, that has a reduced content of linoleic acid in its composition, presents greater resistance to lipid oxidation and therefore a higher shelf life [34].

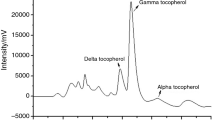

Other characteristics of the material evaluated are the behaviors related to difference in energy released or provided, the peak where it changes the physical state due to the presence of chemical reactions with release or absorption of heat. The curve (Fig. 1) shows the melting and crystallization profiles of the oil. The oil had low-melting components. The sample had high levels of oleic fatty acid (C18:1): with a melting component at − 6 °C (heat flow = 46.57 mW); maybe some unstable crystals at − 16 °C (heat flow = 22.53 mW); crystallization components at − 5 °C (heat flow = 14.31 mW) (saturated fatty acids, that can be high melting point polymorphs) and − 33 °C (heat flow = 14.06 mW) (unsaturated fatty acids, mainly triolein).

The typical characteristics of peanut oil are melting point − 2.0 °C and solidification point: from 0 to 3.0 °C [29]. But, by characterizing normal oleic peanut oil, Long et al. [3] observed that the onset crystallization peak (− 3.94 °C) was relatively steep, indicating initial nucleation over a short period of time, and found three other overlapping peaks with low intensity for what was suggested a low growth of crystal structure. In this same work, Long et al. [3] observed a major endotherm peak (− 17.26 °C) with two shoulder peaks at higher temperature (− 2.17 °C and 7.55 °C) and a small fusion peak at a lower temperature (− 30.04 °C) on the melting curve.

In this way, the no specific melting and crystallization temperatures make thermal characterization of edible oils difficult. However, it is evident that the composition of the oil in fatty acids affects the thermal proprieties and alters the crystallization and melting behavior [35].

Thermal analysis of the peanut oil under air atmosphere

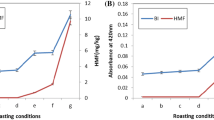

The graphic behavior of the thermogravimetric (TG/DTG) and differential (DTA) curves of the high-oleic peanut oil under air atmosphere is shown in Fig. 2.

The TG and DTG curves of the high-oleic peanut oil under air flow exhibited thermogravimetric behavior. The results showed a tendency to constant decrease with the progressive increase in temperature, with great mass loss around 200 °C, as can be seen from the respective DTG curves. The initial mass loss can be observed between initial and final degradation at 200 °C, which increased around 250 °C and 400 °C, respectively, followed by a noticeable change in the first derivative curve (DTG), an event of mass gain; possibly caused by air-induced oxidative processes due to the presence of oxygen in the atmosphere of analysis.

With regard to the behavior of the differential thermal curve (DTA), it shows three exothermic peaks, characteristic of release of energy; the sharpest peak at 275 °C, the second close to 350 °C, and the third around 400 °C. This behavior indicates stability of this material, and its degradation is detected by predominantly exothermic peaks related to the intensive oxidation of the material caused by the air atmosphere, the amount of oxygen, and the progressive increase in temperature, breaking its unsaturations, causing energy release, among other reactions.

Conclusions

The analyses of this oilseed showed a raw material with high lipid and protein content, suitable for research on isolated compounds aiming at exploiting their potential.

The lipid content of the oil obtained by cold extraction and its chemical characteristics are within the standards established by law. Its chromatographic profile confirmed the high levels of oleic fatty acid and possible applications of this material.

Its melting and cooling temperatures are lower than its crystallization temperature, which allows obtaining oil with a smooth texture that can be used in refrigerated products.

The thermogravimetric behavior showed mass loss around 200 °C, which increased around 250 °C and 400 °C, indicating good stability upon gradual temperature increase.

Differential curves show the presence of successive exothermic peaks, characteristic of oxidative processes with release of energy. However, they are shown only at higher temperatures, between 300 and 400 °C, much higher than the temperature commonly found for this type of raw material. The oxidation induction time determined using the Rancimat method confirmed the oil stability and therefore its suitability for industrial applications.

Given the above, the present study shows that the new peanut variety obtained resulted in a high nutritional and functional quality oil with high differential thermal and oxidative stability demonstrating the potential use of high-oleic peanut (IAC-505) as a raw material in various industries.

References

Shirasawa K, Kuwata C, Watanabe M, Fukami M, Hirakawa H, Isobe S. Target amplicon sequencing for genotyping genome-wide single nucleotide polymorphisms identified by whole-genome resequencing in peanut. Plant Genome. 2016. https://doi.org/10.3835/plantgenome2016.06.0052.

Bhat R, Reddy KR. Challenges and issues concerning mycotoxins contamination in oil seeds and their edible oils: updates from last decade. Food Chem. 2017. https://doi.org/10.1016/j.foodchem.2016.07.161.

Long Z, Zhao M, Liu N, Liu D, Sun-Waterhouse D, Zhao O. Physicochemical properties of peanut oil-based diacylglycerol and their derived oil-in-water emulsions stabilized by sodium caseinate. Food Chem. 2015. https://doi.org/10.1016/j.foodchem.2015.03.052.

Lykomitros D, Fogliano V, Capuano E. Flavor of roasted peanuts (Arachis hypogaea)—part I: effect of raw material and processing technology on flavor, color and fatty acid composition of peanuts. Food Res Int. 2016. https://doi.org/10.1016/j.foodres.2016.09.024.

Godoy IJ. Nova variedade de amendoim IAC com alto teor de ácido oleico. In: Secretaria de Agricultura e Abastecimento de São Paulo. 2013. http://agricultura.sp.gov.br/noticias/agrishow-nova-variedade-de-amendoim-iac-com-alto-teor-de-acido-oleico/. Accessed 13 Nov 2017.

Godoy I, Santos J, Carvalho C, Michelotto M, Bolonhezi D, Freitas R, Kasai F, Ticelli M, Finoto E, Martins A. IAC OL 3 and IAC OL 4: new Brazilian peanut cultivars with the high-oleic trait. Crop Breed Appl Biotechnol. 2014. https://doi.org/10.1590/1984-70332014v14n3a30.

Pinto LM, Souza AL, Souza AG, Santos IMG, Queiroz N. Comparative evaluation of the effect of antioxidants added into peanut (Arachis Hypogae L.) oil biodiesel by P-DSC and rancimat. J Therm Anal Calorim. 2015. https://doi.org/10.1007/s10973-014-4181-9.

Escobedo R, Luna P, Torres I, Mopreno A, Ramirez M. Physicochemical properties and fatty acid profile of eight peanut varieties grown in Mexico. CyTA J Food. 2015. https://doi.org/10.1080/19476337.2014.971345.

Gulluoglu L, Bakal H, Onat B, Sabagh A, Arioglu H. Characterization of peanut (Arachis hypogaea L.) seed oil and fatty acids composition under different growing season under mediterranean environment. JEBAS. 2016. https://doi.org/10.18006/2016.4(5S).564.571.

Klevorn C, Hendrix K, Sanders T, Dean L. Differences in development of oleic and linoleic acid in high- and normal oleic virginia and runner-type peanuts. Peanut Sci. 2016. https://doi.org/10.3146/0095-3679-43.1.12.

Davis J, Leek J, Sweigart D, Dang P, Butts C, Sorensen R, Chen C, Lamb M. Measurements of oleic acid among individual kernels harvested from test plots of purified runner and spanish high oleic seed. Peanut Sci. 2017. https://doi.org/10.3146/PS16-21.1.

Santos J, Godoy I, Moraes A, Michelotto M, Freitas R, Bolonhezi D, Cavichioli J, Martins A. Productivity, adaptability and stability of high-oleic peanut lines in the State of São Paulo. Bragantia. 2018. https://doi.org/10.1590/1678-4499.2017152.

Gong A, Shi A, Liu H, Yu H, Liu L, Lin W, Wang Q. Relationship of chemical properties of different peanut varieties to peanut butter storage stability. J Integr Agric. 2018. https://doi.org/10.1016/S2095-3119(18)61919-7.

Santos OV, Corrêa NCF, Soares F, Gioielli LA, Costa CEF, Lannes SCS. Chemical evaluation and thermal behavior of Brazil nut obtained by different extraction processes. Food Res Int. 2012. https://doi.org/10.1016/j.foodres.2011.06.038.

Camargo AC, Souza Vieira TM, Regitano-d’Arce MA, Alencar SM, Calori-Domingues MA, Spoto MH, Canniatti-Brazaca SG. Gamma irradiation of in-shell and blanched peanuts protects against mycotoxic fungi and retains their nutraceutical components during long-term storage. Int J Mol Sci. 2012. https://doi.org/10.3390/ijms130910935.

AOAC. Official methods of analysis of international of the association of official analytical. Gaithersburg: AOAC-Method 920.151, 2000.

AOAC. Official methods of analysis of international of the association of official analytical. Gaithersburg: AOAC-Method 950.48, 2000.

AOAC. Official methods of analysis of international of the association of official analytical. Gaithersburg: AOAC-Method 930.05, 2000.

ANVISA. Technical regulation on nutritional labeling of packaged foods of the National Health Surveillance Agency. Brasília: ANVISA-Resolution RDC nº 360, 2003.

AOCS. Official methods and recommended practices of the American oil chemists’ society. Champaign: AOCS-Method Cd 3d-63; 1998.

AOCS. Official methods and recommended practices of the American oil chemists’ society. Champaign: AOCS-Method Cd 3-25; 1998.

AOCS. Official methods and recommended practices of the American oil chemists’ society. Champaign: AOCS-Method Cd 8-53, 1998.

AOCS. Official methods and recommended practices of the American oil chemists’ society. Champaign: AOCS-Method Ce 2-66, 1998.

Hartman L, Lago RCA. Rapid preparation of fatty acid methyl esters from lipids. Lab Pract. 1973;22:475–6.

Ulbricht TLV, Southgate DAT. Coronary heart disease: seven dietary factors. Lancet. 1991;338:985–92.

Santos-Silva J, Bessa RJB, Santos-Silva F. Effect of genotype, feeding system and slaughter weight on the quality of light lambs: II. Fatty acid composition of meat. Livest Sci. 2002. https://doi.org/10.1016/S0301-6226(02)00059-3.

AOCS. Official method, DSC melting properties of fats and oils of the American oil chemists’ society. Champaign: AOCS Press; 1995.

AOCS. Official method oil stability index of the american oil chemists’ society. champaign: AOCS Press; 2004.

O’Brien RD. Fats and oils: formulating and processing for applications. 2nd ed. Florida: CRC Press; 2004.

Al-Bachir M. Quality characteristics of oil extracted from gamma irradiated peanut (Arachis hypogea L.). Radiat Phys Chem. 2015. https://doi.org/10.1016/j.radphyschem.2014.06.026.

ANVISA. Technical regulation on nutritional labeling of packaged foods of the National Health Surveillance Agency. Brasília: ANVISA-RDC nº 270, 2005.

Dong XY, Zhong J, Wei F, Lv X, Wu L, Lei Y, Liao BS, Quek SY, Chen H. Triacylglycerol composition profiling and comparison of high-oleic and normal peanut oils. J Am Oil Chem Soc. 2015;92:233–42.

Paz SM, Bermudez B, Cardelo MP, Lopez S, Abia R, Muriana FJG. Olive oil and postprandial hyperlipidemia: implications for atherosclerosis and metabolic syndrome. Food Funct. 2016;7:4734–44.

Derbyshire EJ. A review of the nutritional composition, organoleptic characteristics and biological effects of the high oleic peanut. Int J Food Sci Nutr. 2014. https://doi.org/10.3109/09637486.2014.937799.

Ovaska S, Hiltunen S, Ernstsson M, Schuster E, Altskär A, Backfolk K. Characterization of rapeseed oil/coconut oil mixtures and their penetration into hydroxypropylated-starch-based barrier coatings containing an oleophilic mineral. Prog Org Coat. 2016. https://doi.org/10.1016/j.porgcoat.2016.10.001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

dos Santos, O.V., Agibert, S.A.C., Pavan, R. et al. Physicochemical, chromatographic, oxidative, and thermogravimetric parameters of high-oleic peanut oil (Arachis hypogaea L. IAC-505). J Therm Anal Calorim 138, 1793–1800 (2019). https://doi.org/10.1007/s10973-019-08182-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08182-z