Abstract

A high demand exists for gluten free and hypoimmunogenic products from gluten sensitive population. The present study focuses on the development of hypoimmunogenic muffins using a combination of the blend (CB) consisting of modified (protease treated) Whole Wheat Flour (WWF) and Pearl Millet Flour (PMF). The batter density of CB was 0.97, and it varied between 0.91–0.93 and 0.97–0.99 g/cc with the use of emulsifiers and hydrocolloids respectively. The volume of the muffin made using CB was 70 mL, and it increased to 120 mL with the combination of additives (CAD) comprising of Carboxy Methyl Cellulose (CMC) and Polysorbate-60 (PS-60). The muffins made of CB + CAD had the lowest hardness (19.8 N) and gumminess (6.6 N) values and highest springiness value (13.3 mm) indicating that the texture was soft. Sensory characteristics of the muffin made with CB + CAD were good and had an overall quality score of 90.5 out of 100. Rheometer studies showed that the incorporation of additives improved the visco-elastic properties of muffin batters. Microstructure studies showed a change in gluten matrix of muffins followed by treatments. Immunochemical validation of muffins made using CB + CAD showed that the immunogenicity reduced by 70.8 % which may be suitable for patients with gluten sensitivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wheat is one of the major cereals used as a food ingredient around the world. Wheat is the main raw material for bakery products due to the visco-elastic property of gluten proteins, but unfortunately, these gluten proteins are responsible for allergic reactions. Various strategies are carried out to reduce the allergic response of the gluten (Tatham and Shewry 2008). Watanabe et al. (2000) proposed a novel method to produce hypoallergenic wheat flour by enzymatic treatment using cellulase and actinase enzymes. Susanna and Prabhasankar (2011) used different strategies like enzyme treatment, thermal treatment and use of non-gluten blend to produce modified gluten flours. It is not possible to develop a bakery product with 100 % protease treated flour due to poor sensory acceptance of the product.

In India, millets are widely consumed. Approximately 9.12 million hectares are used for pearl millet (Pennisetum glaucum) production and it is the fourth largest cereal produced after wheat, rice and maize (GOI 2013). Pearl millet commonly known as bajra is one of the staple food in economically poor population (Suma and Urooj 2014). Pearl millet has health promoting components and has several health benefits due to its rich nutraceutical properties (Nambiar et al. 2011).

Snack foods like noodles and vermicelli are prepared from pearl millet in India. Biscuits were made from blanched and malted pearl millet and blended with an equal proportion of soybean flour (Singh et al. 2006). Additives like gums, hydrocolloids and emulsifiers are added to gluten free products to improve the quality. Emulsifiers reduce interfacial tension between oil and water hence causes the disruption of emulsion droplets (Turabi et al. 2008) and impart the necessary aeration and gas bubble stability in cake (Sahi and Alava 2003). Hydrocolloids improve the texture and water holding capacity in gluten free baked products (Das et al. 2013). Jyotsna et al. (2011) in their study reported that in muffins made with 60 % finger millet flour, emulsifier PS-60 improved the quality characteristics of muffins. Gan et al. (2001) reported that in composite flour bread based on the ratio of 50:50 of wheat flour and rice flour, hydroxypropylmethylcellulose (HPMC) and CMC acts as good gluten replacers compared to guar gum.

The objective of the present study was to develop the hypoimmunogenic muffins for people with gluten sensitivity by blending modified WWF and PMF, also to evaluate the rheology, microstructure, quality characteristics and immunochemical validation of the muffins as influenced by CB and additives.

Materials and methods

Raw materials

Whole Wheat Flour (WWF) from Triticum aestivum, commercial PMF, sugar powder, salt (food grade sodium chloride) and eggs were purchased from the local market of Mysore. Shortening (Margarine, Hindustan Lever Ltd, Mumbai, India), baking powder (Kwality, Bangalore, India), calcium propionate, glacial acetic acid (S. D. Fine Chemicals Ltd, Mumbai, India) and pineapple essence (Bush Boake Allen Ltd, Chennai, India) were used for the study.

Emulsifiers-PS-60 was obtained from S.D. Fine Chemicals Ltd Mumbai, India, Glycerol monostearate (GMS) and Sodium stearoyl-2-lactylate, (SSL) were from PD Brothers, Bangalore, India.

Hydrocolloids-CMC, Guar gum (GG) and Gum Arabic (GA) were obtained from Hi-Media Laboratories Pvt. Ltd. Mumbai, India.

The food grade fungal protease (endoprotease) of source Aspergillus oryzae (Activity 75000PC/g) was procured from Advanced Enzymes, Thane, India. Gliadin and anti-gliadin-Peroxidase conjugate antibody were procured from Sigma-Aldrich, St. Louis, USA. Molecular Marker for SDS-PAGE and 3, 3′, 5, 5′-Tetramethylbenzidine (TMB) were procured from GeNie, Mumbai, India. All other chemicals used were of analytical grade.

Chemical characteristics of raw materials

Raw materials WWF, PMF and CB were analysed for moisture, total ash, crude fat and protein using AOAC (2012) methods. The dietary fibre was measured according to the method of Asp et al. (1983).

Optimization of enzyme concentration in muffin

The optimization of protease enzyme concentration in muffin was carried out at three different levels. The levels tried were 0.125, 0.25 and 0.5 g/100 g flour. Preliminary lab trials indicated that 0.5 g protease enzyme level showed a maximum reduction in immunogenicity of WWF. Hence, further studies were carried out using this.

Modification of WWF

The modification of WWF was carried out according to Bombara et al. (1997) with slight modification. The flour was subjected to modification by enzymatic treatment by using protease at the level 0.5 g/100 g flour. The modification was carried out with 14 % slurry of WWF (w/v) at 37 °C for 24 h with continuous shaking in the water bath. The pH of the slurry was maintained at 6.8 using 1 N sodium carbonate and 1 N lactic acid. The enzyme was inactivated by bringing the pH to acidic using 1 N lactic acid and the initial pH of flour (pH 5.6) was restored by using 1 N sodium carbonate and the slurry was dried at 50 °C for overnight.

Preparation of CB

CB was prepared using the modified WWF and PMF in the ratio of 50:50 (w/w).

Preparation of muffins

Preparation of muffins was carried out according to the method of Jyotsna et al. (2011). WWF (control)-100 g/modified WWF-100 g/CB-100 g, baking powder-1.7 g, calcium propionate-0.5 g, hydrocolloids CMC/GG/GA-0.5 g and salt-0.25 g were sieved together. Shortening-84 g, sugar powder-84 g and emulsifiers GMS/SSL/PS-60-0.5 g were mixed for 4 min at 173 rpm in a Hobart mixer N-50 mixer (Ontario, Canada). A whipper was used for mixing eggs-84 g and essence-0.4 mL for 30 s at 58 rpm and 5 min at 173 rpm in Hobart N-50 mixer (Ontario, Canada). The whipped egg mixture was added to the shortening in 4 parts while mixing for 2 min at 58 rpm. Then flour, acetic acid-0.2 mL and water (WWF-30 mL, PMF-35 mL and CB-28 mL per 100 g flour) were added and mixed for 2 min at 58 rpm. The batter temperature was 27 °C. 55 g of the batter was added to cups in the cake pan and baked at 180 °C for 32 min in baking oven (APV Serial No.965 Queensland, Australia).

Studies on muffin batter

Density of muffin batter

The density of the muffin batter was obtained by dividing the weight of standard measure of the batter by the weight of an equal volume of water (Ashwini et al. 2009).

Rheometer studies of muffin batter

The rheometer studies of muffin batters were carried out using controlled stress rheometer (MCR 301, Anton Paar Physica, Austria) according to the method of Jyotsna et al. (2004). All the experiments were carried out at 30 °C after aging the batter for 17 min. The parallel plate attachment was used with the gap between the plates set at 1.0 mm. About 2 to 3 g batter was put on the bottom plate. Dynamic single-point test with oscillation was carried out at a frequency of 10 rad/s, stress of 30 Pascal and 5 points/decade.

Physical characteristics of muffins

Volume measurement

Rapeseed displacement method (Pierce and Walker 1987) was used for volume measurement of muffins.

Colour measurement

The colour of muffin crumb was measured using colour measuring system (Hunter Lab Colour measuring Lab scan XE System, USA). L value measures lightness from black to white (0 to 100), ‘+a’ value measures redness and ‘+b’ value measures yellowness.

Texture profile analysis (TPA) of muffins

TPA of muffin crumbs was measured using a texture analyser LR-5 K Lloyd Instruments Ltd (Hampshire, England) as per the method adopted by Jyotsna et al. (2011). The following conditions were used: square shaped cake pieces measuring 25 × 25 mm, Load cell-5 kg, circular probe with 80 mm diameter, cross head speed- 100 mm/min and compression-50 % of product height. Hardness (N), Gumminess (N) and Springiness (mm) of muffin crumbs were measured according to the method of Bourne (1978). The data was analysed by using Nexygen 4.0 Software.

Sensory evaluation of muffins

The sensory evaluation of muffins was carried out using the method of Jyotsna et al. (2011) with slight modification. The evaluation was carried out with a panel of 12 members which includes both trained and semi-trained panellists. The evaluation was performed by assigning scores for the following parameters from 1 to 20 point scale. The attributes are given below:

-

Crust shape: 1 = flat/uneven, 20 = normal/typical

-

Crumb grain: 1 = coarse/very dense/close, 20 = fine/normal

-

Thickness of cell wall: 1 = thick cell wall, 20 = thin cell wall/ normal

-

Texture: 1 = hard, 20 = soft/ tender and moist

-

Mouthfeel: 1 = branny/harsh/dry, 20 = no residue in mouth.

The overall quality score (100) is the combined score of all the above parameters.

Composition of muffins

The moisture, total ash, fat and protein content of the muffin samples were analysed according to the AOAC (2012) methods. The dietary fibre was measured according to the method of Asp et al. (1983).

Scanning Electron Microscopic (SEM) Studies

The SEM studies were carried out according to the method of Sowmya et al. (2009). The crumb of muffin samples (5 mm × 5 mm) were defatted with hexane for 48 h with changing of hexane for every 2 h, followed by freeze-drying using Scanvac cool safe freeze dryer (Germany). Leo scanning electron microscope model 435 VP (Leo Electronic Systems Cambridge, U.K.) was used in the studies. The cross section of each muffin was transferred to the microscope and observed at 15 kV and 9.75 × 10−5 torr vacuum.

Immunochemical validation

The reduction in immunogenicity of the muffin samples were analysed by ELISA according to the method of Susanna and Prabhasankar (2014) with modification. Gliadin was extracted according to the method of Van den Broeck et al. (2009) with slight modification. 100 mg of sample was taken and continuously mixed for 30 min with 1 mL of 50 % isopropyl alcohol (50%IPA) followed by centrifugation for 10 min at 1000 g. The supernatant was collected, and the pellet was again treated as mentioned above two times. Finally, all the supernatants were pooled. 100 μl of sample extracts were coated in microplate and incubated at 4 °C for overnight. Then Blocking was carried out using 1 % gelatin in phosphate buffered saline (PBS pH7.4) for 1 h at room temperature followed by washing thrice with PBS and PBST (PBS containing 0.05 % Tween 20). Then anti-rabbit antigliadin (wheat) peroxidase conjugate antibody with dilution of 1:1000 was added and incubated for 2 h followed by washing thrice with PBS and PBST. For color development, substrate TMB 1X was used. The optical density (OD) was measured at 450-nm using an ELISA reader.

Statistical data

The data pertaining to chemical and physical characteristics of muffins were expressed as mean standard deviation. The statistical analysis was done by using Duncan’s multiple range tests with experimental groups appropriate to the completely randomized design with three replicates as described by Steel and Torrie (1960). The significance level was established at P ≤ 0.05.

Results and discussion

Chemical composition of raw materials

Chemical composition of raw materials is given in Table 1. Total ash and fat increased whereas protein content decreased in CB when compared to WWF. Singh et al. (2005) stated that there was an increase in the fat content of the blend when foxtail, barnyard and finger millet flours increased from 10 to 30 % level. Jyotsna et al. (2011) studied the effect of replacement of wheat flour with finger millet flour on the quality characteristics of muffins. They reported that there was an increase in total ash content and decrease in protein content with the increase in finger millet flour level.

Batter rheometer studies

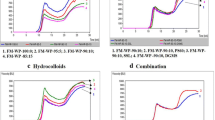

The changes in G’ (storage or elastic modulus), G” (loss or viscous modulus) and tan δ (ratio of moduli) in batter of WWF and modified WWF and CB with additives were studied. G’ indicates the solid-like behaviour, G” indicate the fluid-like behaviour and tan δ indicate the overall visco-elastic response of the material (Das et al. 2013). The G’, G” and tan δ against frequency are given in Fig. 1a(i - iii).

a Rheometer data of muffin batters (a) G’, (b) G” and (c) tan δ. WWF Whole Wheat Flour, PMF Pearl Millet Flour, CB Combination of Blends, PS-60 Polysorbate 60, GMS Glycerol Monostearate, SSL Sodium steroyl-2-lactylate, CMC Carboxy Methyl Cellulose, GG Guar Gum, GA Gum Arabic. b Texture profile analysis of muffins. 1 = WWF, 2 = modified WWF, 3 = PMF, 4 = CB, 5 = CB + PS60, 6 = CB + GMS, 7 = CB + SSL, 8 = CB + CMC, 9 = CB + GG, 10 = CB + GA, 11 = CB + CAD (CMC + PS-60). WWF Whole Wheat Flour, PMF Pearl Millet Flour, CB Combination of Blends, CAD Combination of additives, PS 60 Polysorbate 60, GMS Glycerol Monostearate, SSL Sodium steroyl 2 lactylate, CMC Carboxy Methyl Cellulose, GG Guar Gum, GA Gum Arabica

Both G’ and G” reduced whereas tan δ increased in modified WWF batter compared to WWF batter. It showed that protease treatment changed the visco-elastic property indicating there was a degradation of gluten proteins. The result is in line with Pederson et al. (2005). They explained in their studies the possible lowering of G’ and G” in protease treated wheat flour biscuit dough, and it could be due to the reduction in molecular weight of gluten proteins. In PMF batter G’ was higher compared to G”. Korus et al. (2009) reported that in their study on gluten free dough samples based on corn starch and potato starch, G’ was higher than G” indicating elastic behaviour. The effects of additives were studied individually in CB. Results showed that among emulsifiers, the addition of PS-60 improved the overall visco-elastic properties to the maximum when compared to GMS and SSL. Jyotsna et al. (2004) reported that the addition of PS-60 increased the G’ compared to SSL. Among hydrocolloids CMC brought about the significant improvement in the muffin batter, tan δ value increased when compared to GG and GA. In muffin batter made of CB + CAD G’ and G” increased compared to WWF. Lazaridou et al. (2007) reported that addition of hydrocolloids such as CMC, xanthan and pectin etc. improved visco-elastic properties of gluten free dough based on rice flour and corn starch. This is due to the increased visco-elastic properties of the polysaccharide in an aqueous medium.

Physical characteristics of muffins

Physical characteristics of the muffins are given in Table 2. The batter density decreased in modified WWF when compared to WWF and PMF. CB had a batter density of 0.97 g/cc. The muffin batters treated with emulsifiers + CB had lower batter densities and ranged from 0.91-0.93 g/cc. The lowest batter density (0.89 g/cc) was observed in the case of batter made with CB + CAD indicating that the batter was lighter owing to air incorporation. Turabi et al. (2008) reported that lesser the density more air is incorporated at the time of baking.

The volume of the muffins made with CB was 70 mL whereas with the addition of emulsifiers (90 to 100 mL) and hydrocolloids (85 to 90 mL) to this blend increased the volume of muffins. The highest volume of 120 mL was recorded by the muffins made with CAD (CMC + PS-60) and CB. The lightness (L) value of muffin crumb prepared with CB was 46.5 and use of additives increased the lightness values. Lazaridou et al. (2007) reported that the breads with 1 % CMC improved the volume of bread. Rosell et al. (2001) stated that the hydrocolloids improve dough development and gas retention by increasing the dough viscosity. Bell (1990) reported that polysaccharides such as CMC, HPMC contain hydrophobic groups which increase the interfacial activity within the dough system during proofing and forms gel network on heating during the bread making process. The network further strengthens the boundaries of the expanding cells in the dough leading to increased gas retention during baking thus resulting in better loaf volume.

TPA of muffins

Figure 1b represents the data on texture profile analysis of muffins. The hardness (N) values of muffins made with WWF, modified WWF and CB were 21, 13 and 35.5 N respectively. Use of emulsifiers lowered the hardness (N) values indicating the improvement in texture. A similar trend was also observed when hydrocolloids were used. The springiness (mm) values improved with the use of additives in CB. The gumminess (N) values for CB treated with emulsifiers ranged from 7.2 to 11.6 N and for CB treated with hydrocolloids varied between 8.6 to 11.2 N. The muffins prepared with CB + CAD had lowest hardness (19.78 N) and gumminess (6.6 N) values and highest springiness (13.3 mm) showing that the texture was soft and acceptable. Jyotsna et al. (2011) reported that emulsifier PS-60 improved the volume and texture of muffins with 60 % finger millet by decreasing hardness values.

Sensory evaluation of muffins

Sensory evaluation of the muffins is given in Table 3. The overall quality scores were (out of 100) 80.5, 72, 74.5 and 80 for WWF, modified WWF, PMF and CB respectively. The muffins made with PMF had dense crumb grain, hard texture and gritty mouth feel. The muffins made with CB had improved crust shape, crumb grain and texture. The photograph of muffins is given in Fig. 3. The CB was further treated with emulsifiers and hydrocolloids to bring about improvement in the quality of muffins.

Among the hydrocolloids, CMC brought about significant improvement in the overall quality characteristics of muffins as evident by the highest overall quality score of 86.5 out of 100. The muffins possessed medium crumb grain, soft texture with a moist, clean mouthfeel. Use of hydrocolloids GG and GA in muffins made with CB improved the quality of muffins almost equally as indicated by the overall quality score of 83.5 and 81.5 respectively. Muffins made with emulsifier PS-60 was the best as the overall quality characteristics of muffins improved significantly.

Muffins made with CB + CAD had the highest overall quality score of 90.5 out of 100. The muffins possessed typical crust shape, medium fine crumb grain, soft texture and typical mouthfeel.

Composition of muffins

The data on the chemical composition of muffins is given in Table 4. The moisture content and fat content of muffins was in the range of 17-22 % and 30-33 % respectively. The protein content of the muffins made of CB + CAD decreased when compared to WWF. Desai et al. (2010) stated that the nutritional values of cakes improved in terms of mineral and fiber content when malted finger millet flour and wheat flour were blended in 50:50 ratios.

Microstructure of raw materials and muffins

Figure 2a–d and 3a–e represents the scanning electron micrographs of raw materials and muffin crumbs respectively. Figure 2a represents the micrograph of WWF in which aggregates of protein matrix can be observed and is in accordance with the study of Rojas et al. (2000). Pyler (1988) explained wheat flour particles as jagged pieces of protein wedged between starch granules. Figure 2b represents the micrograph of modified WWF in which big and small wheat starch granules and aggregates of protein matrix broken into smaller segments can be seen. Findings of Susanna and Prabhasankar (2011) showed the same result. Figure 2c represents the micrograph of PMF in which the chunks of starch granules with protein bodies attached to it can be seen. Dendy (1995) described the microstructure of pearl millet and stated that the starch granules and small bead like protein bodies can be seen. Figure 2d shows the micrograph of CB in which protein aggregates of wheat, bead like protein bodies of PMF and starch granules can be observed. Susanna and Prabhasankar (2011) reported in the microstructure studies that the use of non-wheat flours caused the dilution of gluten matrix, and the matrix appeared discontinuous.

Scanning electron micrographs and Photographs of muffins. a WWF, b modified WWF, c PMF, d CB, e CB + CAD. WWF Whole Wheat Flour, PMF Pearl Millet Flour, CB Combination of Blends, CAD combination of additives (CMC + PS-60), PS-60 Polysorbate-60, CMC Carboxy Methyl Cellulose, PM Protein Matrix, DPM Discontinuous Protein Matrix, GS Gelatinised Starch

Figure 3a represents the micrograph of WWF muffin in which gelatinized starch granules embedded in protein matrix can be observed. Sowmya et al. (2009) reported that the micrograph of control cake crumb showed continuous gluten matrix with gelatinized starch granules. Figure 3b represents the micrograph of muffin crumb made with modified WWF in which slightly discontinuous protein matrix can be seen. Indrani et al. (2003) stated that the gluten matrix appeared degraded in bread dough treated with protease. Figure 3c represents the micrograph of PMF muffin in which gelatinized starch granules have formed film like structure. The result is in accordance with the microstructure of finger millet muffin reported by Jyotsna et al. (2011). Figure 3d represents the micrograph of muffin crumb made with CB, which exhibited a film like structure of matrix formed due to the interaction of modified WWF and PMF. The matrix has pores in it and appears thick. Figure 3e represents the micrograph of muffin crumb of CB + CAD in which gelatinized starch granules and somewhat continuous protein matrix can be seen. Barcenas and Rosell (2005) stated that the microstructure of bread with HPMC enfolds other components, and it gave a smooth structure. Indrani et al. (2011) reported that the microstructure of North Indian parotta dough with multigrain blend and combination of additives (SSL and HPMC) produced more continuous protein matrix compared to the dough without additives.

Immunochemical validation of muffins

Figure 4 represents the immunochemical validation of muffins. The graph shows that the muffin prepared by CB + CAD showed less immunoreactivity against IgG compared to the control. It showed 70.8 % reduction in immunogenicity when compared to WWF muffin. Susanna and Prabhasankar (2011) reported that protease treated flour showed less immunoreactivity against IgG antibodies. Susanna and Prabhasankar (2014) reported that protease treated pasta showed very less immunoreactivity against antigliadin antibodies.

Relationship between rheometer, quality characteristics, microstructure and sensory characteristics of hypoimmunogenic muffins

Hypoimmunogenic muffins were developed by using a blend of optimised protease treated (0.5 g/100 g) whole wheat flour and pearl millet flour, as the use of only protease treated whole wheat flour resulted in an unacceptable taste and product quality. The rheometry studies of the muffin batter showed that there was an increase in the elastic and storage moduli of batters when the blend was treated with emulsifiers and hydrocolloids. A significant improvement in rheological properties of the batter was observed in the case of muffin batter made with modified Whole Wheat Flour, Pearl Millet Flour and combination of Polysorbate-60 and Carboxy Methyl Cellulose. The lowest batter density was recorded in the batter made with the combination of additives in blend showing that the batter was lighter with air incorporation and higher volume. The texture profile analysis of these muffins had the lowest hardness and highest springiness values indicating improvement in texture owing to the addition of the combination of additives. The microstructure of crumb of these muffins also showed a somewhat continuous protein matrix. The developed hypoimmunogenic muffins had better quality characteristics and showed the overall quality score of 90.5 out of 100.

Conclusions

Protease treated wheat flour with partially hydrolysed gluten was used for the development of hypoimmunogenic muffins. These muffins were developed by blending modified (protease treated) Whole Wheat Flour with Pearl Millet Flour (CB) in the ratio of 50:50 and using combination of additives. Among different hydrocolloids and emulsifiers, CMC and PS-60 improved the overall quality of muffins and hence they were used in combination to improve the product quality. Sensory characteristics of the developed muffin were good and had an overall quality score of 90.5 out of 100. The texture profile analysis of CB + CAD showed that these muffins had lowest hardness and gumminess values and highest springiness values. Microstructure of muffins clearly indicated the difference in gluten matrix upon modification by enzymatic hydrolysis. The use of the combination of additives improved the continuity of gluten matrix. Immunochemical validation showed that the developed muffin was hypoimmunogenic as the reduction in the immunogenicity was found to be 70.8 % and hence can be used by subjects with gluten sensitivity.

References

AOAC (2012) Official methods of analysis, 19th edn. Association of Official Analytical Chemists, Washington

Ashwini A, Jyotsna R, Indrani D (2009) Effect of hydrocolloids and emulsifiers on the rheological, microstrucural and quality characteristics of eggless cake. Food Hydrocoll 23:700–707

Asp MG, Johanson CG, Holmertt, Silifestron M (1983) Rapid enzymatic assay of insoluble and soluble dietary fiber. J Agric Food Chem 31:476–482

Barcenas ME, Rosell CM (2005) Effect of HPMC on the microstructure quality and aging of wheat bread. Food Hydrocoll 19:1037–1043

Bell DA (1990) Methylcellulose as a structure enhancer in bread baking. Cereal Foods World 35:1001–1006

Bombara N, Anon MC, Pilosof AMR (1997) Functional properties of protease modified wheat flour. Lebensm Wiss Technol 30:441–447

Bourne MC (1978) Texture profile analysis. Food Technol 32:62–66

Das L, Raychaudhuri U, Chakraborty R (2013) Role of hydrocolloids in improving the physical and textural characteristics of fennel bread. Int Food Res J 20:2253–2259

Dendy DAV (1995) Sorghum and millets: chemistry and technology. AACC, St. Paul, pp 76–80

Desai AD, Kulkarni SS, Sahoo AK, Ranveer RS, Dandge PB (2010) Effect of supplementation of malted ragi flour on the nutritional and sensorial quality characteristics of cake. Adv J Food Sci Technol 2(1):67–71

Gan J, Rafael LGB, Cato L, Small DM (2001) Evaluation of potential of different rice flours in bakery formulations. In: Wooton M, Batey IL, Wrigley CW (eds) Cereals 2001. Proceedings of the 51st Australian Cereal Chemistry Conference, 9–13 Sept. 2001, Coogee, New South Wales, Australia. Royal Australian Chemical Institute, Werribee, pp 309–312

GOI (2013) Pocket book on agriculture statistics 2013. Directorate of Economics and Statistics Department of Agriculture and Cooperation Ministry of Agriculture Government of India, New Delhi

Indrani D, Prabhasankar P, Rajiv J, Rao GV (2003) Scanning electron microscopy, rheological characteristics and bread baking performance of wheat flour dough as affected by enzymes. J Food Sci 68:2804–2809

Indrani D, Swetha P, Soumya C, Rajiv J, Rao GV (2011) Effect of multigrain on rheological, microstructural and quality characteristics of north Indian parotta- An Indian flat bread. LWT Food Sci Technol 44:719–724

Jyotsna R, Prabhasankar P, Indrani D, Rao GV (2004) Improvement of rheological and baking properties of cake batters with emulsifier gels. J Food Sci 69:16–19

Jyotsna R, Soumya C, Indrani D, Rao GV (2011) Effect of replacement of wheat flour with finger millet flour (Eleusine corcana) on the batter microscopy, rheology and quality characteristics of muffins. J Texture Stud 42:478–489

Korus J, Witczak M, Ziobro R, Juszczak L (2009) The impact of resistant starch on characteristics of gluten free dough and bread. Food Hydrocoll 23:988–995

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten–free formulation. J Food Eng 79:1033–1047

Nambiar VS, Dhaduk JJ, Sareen N, Shanu T, Desai R (2011) Potential functional implications of pearl millet (Pennisetum glaucum) in health and disease. J Appl Pharm Sci 01(10):62–67

Pederson L, Kaack K, Bergsoe MN, Adler-Nissen J (2005) Effects of chemical and enzymatic modification on dough rheology and biscuit characteristics. J Food Sci 70:152–158

Pierce MM, Walker CE (1987) Addition of sucrose fatty acid ester emulsifiers to sponge cakes. Cereal Chem 64:546–552

Pyler EJ (1988) Baking science and technology. Sosland, Merriam, 185–194, 607–610

Rojas JA, Rosell CM, Benedito de Barber C, Pere-Munnera I, Lluch MA (2000) The baking process of wheat rolls followed by cryo scanning electron microscopy. Eur Food Res Technol 212:57–63

Rosell CM, Rojas JA, Benedito de Barber C (2001) Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll 15:75–81

Sahi SS, Alava JM (2003) Functionality of emulsifiers in sponge cake production. J Sci Food Agric 83:1419–1429

Singh P, Singh G, Srivasta S, Agarwal P (2005) Physico-chemical characteristics of wheat flour and millet flour blends. J Food Sci Technol 42:340–343

Singh G, Sehgal S, Kawatra A, Preeti (2006) Mineral profile, antinutrients and in vitro digestibility of biscuit prepared from blanched and malted pearl millet flour. Nutr Food Sci 36:231–239

Sowmya M, Jeyarani T, Jyotsna R, Indrani D (2009) Effect of replacement of fat with sesame oil and additives on rheological, microstructural, quality characteristics and fatty acid profile of cake. Food Hydrocoll 23:1827–1836

Steel RGD, Torrie JH (1960) Principles and procedures of statistics. McGraw Hill, New York, pp 99–131

Suma PF, Urooj A (2014) Influence of germination on bioaccessible iron and calcium in pearl millet (Pennisetum typhoideum). J Food Sci Technol 51:976–981

Susanna S, Prabhasankar P (2011) A comparative study of different bio-processing methods for reduction in wheat flour allergens. Eur Food Res Technol 233:999–1006

Susanna S, Prabhasankar P (2014) Effect of different enzymes on immunogenicity of pasta. Food Agric Immunol. doi:10.1080/09540105.2014.893999

Tatham AS, Shewry PR (2008) Allergens and wheat related cereals: review. Clin Exp Allergy 38:1712–1726

Turabi E, Sumnu G, Sahin S (2008) Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocoll 22:305–312

Van den Broeck HC, America AHP, Smulders MJM, Bosch D, Hamer RJ, Gilissen LJWJ, Van der Meer IM (2009) A modified extraction protocol enables detection and quantification of celiac disease-related gluten proteins from wheat. J Chromatogr B 877:975–982

Watanabe M, Watanabe J, Sonoyama K, Tanabe S (2000) Novel method for producing hypoallergenic wheat flour by enzymatic fragmentation of the constituent allergens and its applications to food processing. Biosci Biotechnol Biochem 64:2663–2667

Acknowledgments

The authors are grateful to Department of Biotechnology, New Delhi, India for providing financial support (grant no.BT/PR7033/FNS/20/684/2012) and also CSIR-CFTRI for providing facilities to carry out research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ashwini, Umashankar, K., Rajiv, J. et al. Development of hypoimmunogenic muffins: batter rheology, quality characteristics, microstructure and immunochemical validation. J Food Sci Technol 53, 531–540 (2016). https://doi.org/10.1007/s13197-015-2028-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2028-4