Abstract

Quality protein maize (QPM) is nutritionally improved maize which has twice the amount of lysine and tryptophan than normal maize. The present study evaluated the effect of different proteins namely egg white proteins (EWP), casein, whey protein isolate, soy protein isolate (SPI) on characteristics of gluten free QPM based muffins. QPM muffins without any added protein served as control and muffins prepared using wheat and EWP served as reference. Effect of addition of different proteins on pasting properties revealed that the thermal stability of QPM flour increased as indicated by decrease in breakdown viscosity. The effect of added proteins on QPM muffin-making properties was evaluated for rheology of batter and physicochemical, texture, color and sensory characteristics of muffins. Dynamic rheology showed that storage modulus (G′) and loss modulus (G″) of batter with SPI was the highest while batter with EWP showed lowest value. QPM–EWP muffins were softer, chewy and springier and had more specific volume than control muffins and were comparable to reference muffins. Inclusion of all proteins increased L* values (lightness) and decreased a* (redness/greenness) and b* (yellow/blueness) values of QPM based muffins. Sensory analysis revealed that gluten free QPM muffin prepared from EWP were acceptable with a sensory score of 7.97 which was comparable to reference muffins (8.03).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bakery products like bread, cake, muffin, pastries are widely consumed by the people all over the world. Among these, muffins are sweet leavened high calorie breakfast or afternoon snack generally made of wheat flour along with other basic ingredients like sugar, egg, vegetable oil, milk etc. (Sanz et al. 2009). Wheat protein, gluten, poses superior visco-elastic characteristics that permit retention of carbon dioxide produced during dough fermentation and baking which gives spongy structure to baked foods (Gallagher et al. 2004). However, there is an increasing demand for wheat free, particularly gluten-free (containing less than 20 ppm of gluten), bakery products as about 1% of the world population is suffering from celiac disease (gluten intolerance) and the only treatment for this disease is a strict gluten-free diet (Singh et al. 2016). For gluten-free foods, wheat is generally replaced with corn, rice, soya, millets, potato or other starches (Shevkani et al. 2015).

Production of quality gluten-free bakery products is a key challenge to food scientists and technologists. Gluten-free foods available are of inferior in quality with lower shelf life as compared to gluten containing products. These foods are usually based on various types of starch and flour from plants such as maize, rice, soybean and buckwheat (Ziobro et al. 2013). However, gluten free nature of the flour results in poor quality final baked product. There has been a continuous effort from food industries and researchers to design gluten-free bakery recipes to improve the structure, mouth feel, acceptability, shelf-life and nutritional quality of the final product (Gularte et al. 2012). Several ingredients such as starches, gums and hydrocolloids, dairy products, different protein concentrates and combination of thereof, have been studied as a gluten substitute to achieve desired visco-elastic protein network of the dough and to improve the quality, acceptability and the textural characteristics of the finished product (Sarabhai and Prabhasankar 2015). Gluten-free recipes are usually rich in carbohydrates, for this reason many studies focused on the enrichment of these recipes with protein to compensate dietary requirements. It has been reported that protein, besides enhancing nutritional density of gluten-free baked product, also play fundamental role in improving the final quality (Ronda et al. 2011; Geera et al. 2011). Geera et al. (2011) reported that the replacement of egg proteins with commercial egg replacer influenced different characteristics of wheat muffins. Protein isolates from white cowpea was reported to enhance product characteristics of rice based muffins (Shevkani et al. 2015).

Maize is a gluten free cereal and is suitable for preparation of bakery foods for celiac patients. However, available literature revealed that there are limited studies on gluten-free maize based bakery products; particularly, quality protein maize (QPM) based products is scarce. QPM is nutritionally improved maize with about 70% higher levels of essential amino acids—lysine and tryptophan—than normal maize (Giwa and Abiodun 2010). Keeping above points in view the present study evaluated the effect of different proteins namely egg white proteins (EWP), casein, whey protein isolate (WPI), soy protein isolate (SPI) on characteristics of gluten free QPM based muffins.

Materials and methods

Raw materials

Quality protein maize (QPM), variety HQPM-5, was procured from the department of plant breeding, ICAR-Indian Institute of Maize Research, Ludhiana. The grain was cleaned and stored in polythene bags until used. When required it is ground into flour using a lab scale grinder and sieved through BSS 40 sieve (0.401 mm). Sieved flour was then packaged in air tight container for further use. The proximate composition of the QPM flour was determined by AOAC (2000). Moisture (w.b.), protein, crude fat, total carbohydrates and ash content were found to be 7.2, 9.33, 4.5, 77.64 and 1.33%, respectively. Protein content in different proteins/protein isolates was calculated and found to be in the range of 80–81%. Wheat flour, sugar powder, eggs, shortening/margarine and salt used in the study were procured from local market. Soya protein isolates (SPI) and whey protein isolate (WPI) were procured from A.M. Labs, New Delhi where as egg white protein (EWP) was prepared by using laboratory scale lyophilizer with conditions of temperature (− 40 °C) and pressure (0.07 mbar).

Batter and muffin preparation

The basic muffin formulation used in the study is described in (Table 1). QPM based muffin formulation without any added protein served as control and formulation prepared using wheat flour with egg white protein served as reference. To study the influence of different non-gluten proteins [soya protein isolate (SPI), whey protein isolate (WPI), egg white protein (EWP), casein (C)] on the batter and muffin characteristics, and calculated amounts of different proteins were added to get a protein content of 13% (w/w) on flour basis. The level of protein (13%) was used as per previous studies of Matos et al. 2014 based on the percentage of protein provided by both milk and egg in a muffin formulation (Sanz et al., 2009).On the basis of protein content (80%) in source protein, final values were calculated.

For preparation of batter, 68 mL of water was taken with sugar and mixed for 30 s at high speed in a mixer. To this solution, citric acid, salt, xanthan gum was added and mixed for 1 min at medium speed followed by addition of flour and sodium bicarbonate and again mixed for 30 s. Shortening and protein powder (depending on type of protein) were added at the last and mixed for 2 min at medium speed. After this, the contents were mixed at high speed until smooth batter was obtained. Muffins were prepared following the method described by Sanz et al. (2009) with slight modifications. Paper muffin cups (50 mm diameter) were placed in a silicone mold. About 30 g of batter was filled into muffin cups using a scoop and baked in a preheated conventional oven at 190 °C for 15–20 min. The muffins were then cooled to room temperature for 1 h in order to avoid moisture condensation on their bottom and sealed in PET jars for further analysis.

Flour and batter characteristics

Water absorption capacity and pasting properties of flour blends

Water absorption capacity (WAC) of flour blends was determined as per method described by Inglett et al. (2009). Sample (2 g) was suspended in 25 g deionized water, allowed to settle for 2 h then centrifuged at 1590 g for 15 min. Weight of the residue was noted after decanting the supernatant. The amount of water absorbed per gram of sample was taken as WAC, expressed as g/g. Viscosity profiles of different flour blends were determined using Rapid Visco Analyzer (RVA-4SA, Newport Scientific, Australia) at 15% solids. The flour suspension (3.5 g flour in 25 mL distilled water) was equilibrated at 50 °C for a minute, heated to 95 °C at a rate of 12 °C/min, held at 95 °C for 2.5 min, cooled at 12 °C/min, and held at this temperature for 2 min. The programme was conducted at 960 rpm for 10 s and thereafter at 160 rpm for the rest of the test (Goswami et al. 2015). The parameters recorded were pasting temperature (PT), pasting time, peak viscosity (PV), breakdown viscosity (BV), final viscosity (FV) and set back viscosity (SBV).

Specific gravity and visco-elasticity of batters

The specific gravity (SG) of the batter was determined gravimetrically as the ratio of weight of known volume of batter to the weight of an equal volume of water at 28 ± 2 °C (Goswami et al. 2015). Dynamic visco-elastic tests of batter was carried out at 25 °C using rheometer (MCR 301, Anton Paar, Germany) fitted with 50 mm parallel plate geometry. Sample was placed between the plates (with 1 mm gap) and 5 min stabilization time was given before starting the test. In order to determine the linear visco-elastic region (LVR), strain sweeps (0.01–100%) were carried out at constant frequency (1.0 Hz). Then the frequency sweep (0.01–10 Hz) tests were performed in the LVR at constant strain to determine the storage (G′, solid component), loss moduli (G″, liquid component) and their ratio, loss tangent (tan δ) (Singh et al. 2016).

Muffin characteristics

Colour

Crust and crumb color parameters (L*, a*, b*) of the muffins was measured using Hunter Lab mini Scan XE Plus colorimeter (Model 45/0-L, HAL, USA) where L* value indicates lightness from black (L = 0) to white (L = 100), a* indicates hue on a green (− a*) to red (+a*) axis, and b* indicated hue on a blue (− b*) to yellow (+b*) axis. In order to measure the colour of crumb, the crust was carefully removed with knife. From measured L*, a* and b* values, hue angle (ho), chroma (C) and the total colour difference between the control and samples (∆E*) were calculated as described by Goswami et al. (2015).

Height, specific volume and weight loss

Muffin height, specific volume and weight loss upon baking was determined according to Matos et al. (2014). Height of the muffins was measured using a digital vernier caliper (least count 0.01 mm) from the bottom of the paper cup to the highest point of the muffin after cooling for 1-h at room temperature. Rapeseed displacement method was used to determine the volume of the muffins and specific volume was calculated as volume to weight ratio. The difference in weight of muffins before and after baking and cooling was taken as weight loss, expressed in percentage. Four replicates of muffin samples from each batch were used for analysis and mean values were reported.

Texture

Textural profile analysis of the crumb was performed using texture analyzer (TA-XT2i; Stable Micro System Ltd, UK) fitted with 5 kg load cell. The muffins were cut horizontally at the height of the paper cup and the lower half was considered for texture analysis. Samples were subjected to double compression (50%) using 75 mm flat probe at a test speed of 1 mm/s with 5 s wait time between two cycles. The peak force required during the first compression cycle was noted and expressed as hardness (N). The other parameters obtained from force–deformation curve include resilience, cohesiveness, springiness, and chewiness (Martinez Cervera et al. 2012). From each formulation, four muffin samples were used for analysis.

Proximate analysis of muffins

AOAC (2000) method No. 925.09, 969.24, 950.48, 923.03 were used for determination of moisture, crude fat, protein (Nx6.25) and total ash content of muffin samples, respectively. Total carbohydrates were calculated by subtracting sum of above components from 100. The muffins were crumbled, mixed uniformly and known quantity of the mixed material was used for analysis. All the analysis was performed in triplicate.

Microbiological properties and Free Fatty acid content

Muffins were stored at ambient (25 ± 2 °C) and refrigerated (4 ± 1 °C) conditions for 20 days and analyzed for their microbial quality and free fatty acid content at 5 days interval. Total plate count, yeast, and mould count as well as Shigella and Salmonella were enumerated as described by Harringan and McCance (1976) while free fatty acid content was estimated as described by Goswami et al. 2015. Muffins were packaged in low-density polyethylene (LDPE) pouches (40 µ) which were further placed in aluminum laminate (25 µ). For sample preparation, 10 g muffin was mixed in 90 mL sterile distilled water and homogenised in stomacher (Seward Stomacher® 400 Circulator) for 1 min at 230 rpm. Samples were diluted decimally and 0.1 mL aliquots were spread plated on media plate used, viz., Plate count agar (PCA), Potato Dextrose Agar (PDA) and Xylose-Lysine Deoxycholate Agar (XLD) for the enumeration of total plate count, yeast and mold, Shigella and Salmonella, respectively. The Potato Dextrose Agar (PDA) plates were incubated at 27 ± 2 °C for a period of 3 days while Plate count agar (PCA) and Xylose-Lysine Deoxycholate Agar (XLD Agar) plates were incubated at 35 ± 2 °C for a period of 24–48 h. The colonies were counted and presented as colony forming units per gram (cfu/g) of sample. All counts were done in duplication using the colony counter.

Sensory evaluation

The muffins were evaluated for the sensory characteristics. The sensory panel comprised of 15 semi trained judges aged between 25 and 50 years. Coded muffin samples in duplicate set of each were scored by the sensory panel for different sensory attributes like appearance, texture, flavor, taste and overall acceptability on nine point Hedonic scale (BIS 1971). Water was provided for judges for rinsing their mouth in between the evaluation of samples.

Statistical analysis

Statistical analysis was done using SPSS software, Version 16.0 (Pascal International Software Solution, Boston, MA, USA). One-way ANOVA was used for analyzing the physical, nutritional and sensory properties of the different muffin samples. The difference in the means was further subjected to Tukey’s HSD test.

Results and discussion

Flour and batter characteristics

Water absorption capacity (WAC)

Hydrophilic groups of proteins and carbohydrates enable flours or flour blends to absorb water which can be quantified in terms of WAC. It is important in bulking and consistency of products as well as in baking applications as it represents the amount of water available for gelatinization (Edema et al. 2005). WAC of different flour blends varied from 0.813 to 1.419 g/g (Table 2). WAC of QPM was observed to be 1.184 g/g which is much lower than the reported value (1.742 g/g, Edema et al. 2005) which could be due to varietal variation. Reference sample, wheat blended with EWP, exhibited lowest WAC where as highest value was observed in QPM–SPI blend. The observed variation in WAC of different flour blends may be due to differences in the degree of interaction of protein with water and conformational characteristics (Mcwatters et al. 2003). WAC of protein isolates varies significantly among source and cultivars (Shevkani et al. 2015). Reduction in WAC with addition of EWP and WPI reflects that the added protein contains more non-polar/hydrophobic amino acids that can interact with hydrocarbons. Whereas WAC increased with incorporation of casein and SPI suggesting presence of more polar molecules with primary sites for water interaction in the flour blend. Shevkani and Singh (2014) also reported increase in WAC on addition of protein isolates from kidney bean, field pea and amaranth in maize starch.

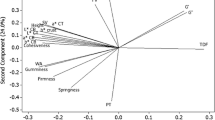

Pasting properties

The results of pasting properties of QPM flour and blends are shown in Supplementary Fig. 1. QPM and QPM based blends exhibited lower values of measured parameters as compared to reference flour (wheat and EWP). Pasting properties reflects the capacity of starch to absorb water and swell during heating.

Pasting properties provide useful information regarding changes in flour paste viscosity with change in temperature which varies depending on the characteristics of starch and protein. PT gives an indication of minimum temperature required for cooking and the temperature at which viscosity starts to increase. It has been reported that baking performance and collapse of the structure varies with pasting temperatures as well as water absorption by the ingredients. PT of different samples varied from 71.06 to 88.64 °C. PT of control (QPM) was 85.29 °C and addition of protein observed to have significant positive influence (p < 0.05) (Table 2).

This might be due to the effect of non starch molecules on the integrity of starch granules that delay the initiation of gelatinization (Trehan et al. 2018). Similar results were reported by others; addition of cow pea protein isolates in rice based formulation (Shevkani et al. 2015) and soya protein in corn starch. PV, the point of maximum starch swelling, of flour blends ranged from 589 to 2481 cP. Addition of proteins, except SPI, significantly (p < 0.05) decreased PV which could be due to dilution effect of the proteins on the starch concentration. Added and increased non starch components compete with starch for water absorption consequently hindering starch swelling (Goswami et al. 2015). It has been reported that egg white proteins consist of approximately 40 different proteins viz. ovalbumin (54%), conalbumin (12%). Ovomucoid (11%) and lysozyme (3.5%) with diferential denaturation pattern. Further, it has been reported that when heat denatured proteins undergo gelation process at different temperatures, proteins exhibit different rheological characteristics. The inverse relation of PV and protein content was also reported by Tan and Corke (2002).

BV, an index of ability of gel to withstand shear damage at high temperature was 112.4 and 541 cP for control and reference, respectively. Higher the BV, lower will be the ability of the flour to withstand high temperature and shear stress during cooking (Adebowale et al. 2005). Inclusion of protein significantly reduced BV of QPM (Table 2) which reflects that added protein provided some protection against the breakdown in viscosity. This showed that the protein offered the starch granules a greater resistant to disintegration at high temperature and agree with the results of previous work on rice (Shevkani et al. 2015) and corn fractions (Shevkani et al. 2014). This might be due to the influence of denatured protein on continuous matrix between the dispersed and continuous phases.

FV is used to define the quality of a particular starch as it indicates the ability of the flour to form a viscous paste upon cooling. The FV of all the flour blends were higher than their respective PV which reflects that viscosity increases upon cooling which could be attributed to the alignment of the amylose chains (Flores-Farias et al. 2000). SV has been correlated with the texture of various end products. The SV of flour indicates its tendency to retrograde on cooling. Starch retrogradation is the process, during which amylose and amylopectin molecules re-associate in an ordered structure in gelatinized starches (Sandhu and Singh 2007). Set back viscosity ranged from 1336 to 3595 cP and for control and reference sample it was 3595 cP and 2467 cP, respectively. SV values decreased with addition of protein in blends. Protein acts as inactive filler thereby affecting the association of hydrogen bonds between starch molecules consequently reducing the SV (Sarabhai and Prabhasankar 2015). The low setback viscosity value indicated the lower retrogradation of the flour paste during cooling (Trehan et al. 2018) and lower the staling rate of the products made from the flour (Adeyemi and Idowu 1990).

Specific gravity of batter

Changes in the SG of batter affect the volume of the cake and its crumb attributes. SG of QPM based batter was 1.068 and ANOVA results depicts that SG was significantly affected (p < 0.05) by protein type (Supplementary Table 1). Mixing of batter incorporated air resulting in small bubbles to form a porous texture while these bubbles expand during fermentation and baking. SG of batter depicts bubble formation and retention capacity of batter, lower the value of SG, and better is the bubble formation and retention and higher final volume after baking. Reference batter samples showed lowest SG value which may be due to presence of gluten proteins. The highest SG value was observed in the QPM based batter prepared with SPI where as batter prepared with EWP exhibited lower SG which reflects that more air was incorporated and retained during mixing. Casein and soya protein increased the SG while converse effect was observed with egg white and whey protein. This differential effect could be attributed to different emulsifying activity or foam stability of different proteins. Similar kind of influence of various proteins was observed by Matos et al. (2014) in rice based muffins.

Dynamic rheology of batter

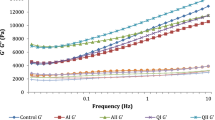

The viscoelastic properties of the QPM batter with different protein sources were studied by dynamic oscillatory test. Small amplitude measurements give information about their linear viscoelastic region (LVR). The LVR of samples were found to be limited to a strain of 0.05% showing weak gel behavior of all samples. The batter should be optimally viscous to trap gas bubbles during mixing and retain during baking.

Mechanical spectra of all batter samples showed that values for storage or elastic modulus (G′, non-dissipative part) were higher than loss or viscous modulus (G″, dissipative part) at all the tested frequencies (Fig. 1) suggesting predominant elastic and typical gel like behavior. Similar results have been reported earlier for rice batters (Matos et al. 2014; Shevkani et al. 2015). Inclusion of proteins affected the batter viscoelastic behaviour and the extent of the effect was protein source dependent. Addition of protein in QPM reduced dynamic moduli, except SPI where converse effect was observed (Supplementary Table 1). G′ and G″ values (191 and 134 Pa, respectively) were the lowest for batters made from QPM to WPI, while the highest values (3118 and 1249 Pa, respectively) were observed for batters containing SPI. Increase in dynamic moduli could be attributed to high WAC of QPM–SPI blend with reduced amount of free water available (Ronda et al. 2011). Crockett et al. (2011) reported that supplementation of SPI in dough resulted in increase in the dynamic moduli. Similar results for plant proteins have been reported by Ronda et al. (2011) and Matos et al. (2014). The ratio of energy lost to the energy stored (G″/G′) expressed as loss tangent (tan δ) could be used to describe the viscoelasticity of batter. Solid material gives tan δ value of 0, whereas an ideal liquid shows infinity. Less than 1.0 value of tan δ corresponds to gel like behavior (Baixauli et al. 2008). Lowest tan δ value (0.311) was obtained for QPM based batter. The tan δ value (Fig. 2) increased with addition of protein, increase was observed to be non significant (p < 0.05) with the addition of plant based protein isolate (SPI). QPM and QPM–SPI based batter, with lowest tan δ, showed more structured and solid like behavior while QPM–EWP batter showed tan δ value comparable to wheat based batter and leading to structures with less solid like character. Similar results have also been observed by Matos et al. (2014) for rice based batter with EWP and casein.

Muffin characteristics

Color

The results of browning index of crust and crumb color values of muffin samples are presented in Table 3. SPI based QPM muffins showed lowest values of BI (115.13) while for control muffins the value was 138.16. Lightening effect in crust BI could be attributed to effect of its influence on the water distribution which may affect browning reactions (Lazaridou et al. 2007). QPM muffins developed using WPI, casein and EWP showed BI values almost comparable to that of reference muffins (148.30). Color in baked products depends on number of factors viz. natural color due to the individual components and color developed during processing. Muffin crust color is developed due to exposure of surface to high temperature during baking and Maillard reactions and caramelization. The L* values for crumb of different protein incorporated muffins showed significant (p < 0.05) higher values than the QPM based (65.47) and reference (65.89) muffins. Increase in Lightness by EWP, SPI, C and SPI addition showed that protein added muffins were lighter in color than control and reference sample. The redness (a*) was highest for control and its value decreased significantly (p < 0.05) with addition of EWP and SPI, on the other hand effect of WPI and casein were non significant (p > 0.05). The yellowness (b*) was also highest for control sample and the value decreased on addition of EWP, casein and SPI. However, WPI added muffins did not differ significantly (p > 0.05) as compared to control sample. Redness (a*) and yellowness (b*) values of reference muffins was lowest.

The hue angle values significantly decreased, except WPI, with addition of protein as compared to control. However, chroma values did not differ significantly with any protein except EWP, addition of which significantly (p < 0.05) increased the chroma (80.06) as compared to control (79.01). The hue angle and chroma values of reference muffin samples were significantly lower than those with protein. As described by Francis and Clydesdale (1975) if the ∆E* value is less than 1, then color difference is not obvious for human eye, if it is between 1 and 3 minor color difference exists that could be appreciated by the human eye depending on the hue, and if ∆E* greater than 3 then color difference is obvious for human eye. In the present study, ∆E* values for all protein added muffins ranged from 3.54 to 5.75 while for reference muffin it was 15.4, implying that their color in comparison to the control was obvious for the human eye.

Height, weight loss and specific volume

Influence of protein source on height, weight loss and specific volume of QPM based muffins is presented in Table 4. QPM based muffins prepared using different types of proteins showed changes in height and weight loss (Table 4). Addition of protein, except casein, had a significant positive (p < 0.05) influence on muffin height. Maximum effect on height was observed in QPM–EWP muffins (34.10 mm) and statistical analysis showed no difference (p < 0.05) with that of reference sample (35.03 mm). The increase in height of muffins with addition of protein may be due to decreased specific gravity value and or more air bubble retention capacity of the batter as reported by Khalil (1998). There was a significant (p < 0.05) weight loss during baking. Maximum weight loss (19.21%) was observed in control sample whereas least effect was noticed in QPM–SPI based muffins. Minimum weight loss with added proteins in QPM reflects that the muffins prepared from these proteins were capable of holding more water. Among all protein sources, SPI showed the higher water holding capacity which allowed less moisture to evaporate during the baking process and hence there was less loss in weight. Reduction in weight loss has been reported for rice based muffins with addition of casein (Matos et al. 2014).

Specific volume (SV) is an important property of cupcake samples. SV of muffin samples ranged from 2.4 to 2.9 mL/g (Table 4). Our results are similar to those reported for specific volume values of 2.4–3.0 mL/g for starch and protein isolate based muffins as reported by Shevkani and Singh (2014), respectively. The incorporation of animal proteins increased the specific volume of muffins, highest value was obtained for EWP incorporated QPM muffins (2.85) and this value was comparable to reference muffins (2.98). Higher specific volume value could be due to incorporation and retention of more air within the protein network produced by EWP during mixing and baking.

Texture

The effect of addition of different proteins on the textural profile of QPM based muffins is presented in Table 4. Quality of the muffins is greatly influenced by their appearance due to its texture. A good muffin should be soft in texture. The results revealed that all the muffin samples differed significantly (p < 0.05) in crumb hardness. In comparison to control (68.15 N), addition of EWP (49.03 N) and WPI (35.98 N) decreased the hardness while casein (99.05 N) and SPI (91.85 N) increased the hardness values. If value of chewiness is more it shows difficulty in chewing of the product. Addition of casein and soy increased the chewiness value while EWP and WPI decreased chewiness, thus showing that samples prepared from EWP and WPI were easy to chew. Data revealed that hardness and chewiness showed similar trend for all samples. Results of other workers on rice based cakes showed that the incorporation of legume flour (chickpea, pea, lentil and bean) significantly (p < 0.05) increased the hardness and chewiness in rice based cakes, except with the addition of lentil (Gularte et al. 2012). Reformulation in bakery products has been reported to affect texture. Gluten development is considered important determinant of hardness. Absence of gluten and differences in protein functionalities could be the reason for differences in hardness value of different muffin samples.

Springiness is associated with fresh, aerated, and elastic high quality product (Goswami et al. 2015). Casein and SPI did not affect the springiness values significantly. With addition of WPI springiness value reduced. However, addition of EWP significantly increased this parameter from 0.73 (control) to 0.78 while for the reference sample it was 0.87. The increase in springiness has been reported to be associated to number of air bubbles and presence of aerated matrix in the final product. Cohesiveness is related with the energy required for the second compression and it gives information about sensory crumbliness and energy required to chew the food. Addition of protein decreased this parameter significantly as compared to control showing that lower compression energy was required. The minimum value of cohesiveness was found for QPM–WPI muffins (0.32) and this effect was visually observed as it easily crumbled during handling. Resilience values were also found to be significantly (p < 0.05) decreased by addition of proteins.

It can be observed from the results (Table 4) that hardness, chewiness, springiness of QPM based muffins prepared with EWP is comparable with that of reference sample prepared with wheat-EWP. Matos et al. (2014) reported that addition of animal proteins in rice muffins made them springier, cohesive and chewy as compared to muffins prepared from vegetal proteins.

Sensory characteristics of muffins

Sensory scores of QPM based muffins are presented in Table 4. QPM muffins prepared with addition of EWP showed sensory score of 7.97 which was comparable to reference muffins (8.03) and differed significantly (p < 0.05) from control samples (6.43). SPI based muffins and control muffins showed hard crust and crumb with gritty mouth feel. Muffins prepared from casein were also hard indicating more compact crumb. WPI based muffins were very soft and easily crumbled. However, use of EWP in formulation of QPM muffins had improved crust shape, texture and mouth feel in comparison to control muffins. Among all proteins incorporated muffins QPM–EWP muffins showed best taste, texture, and appearance (Supplementary Fig. 2).

Proximate composition of muffins

All the muffin samples were evaluated for their proximate composition and results are reported in (Supplementary Table 2). Data revealed that control muffins had low moisture content (21.44%) and it was highest for SPI based QPM muffins (24.96%) and wheat based muffins (25.95%). As expected, all muffins showed higher protein values as compared to control and this fact could be attributed to the addition of protein. Ash content ranged from 1.35 to 2.10%. SPI based muffins exhibited highest fat content which could be attributed to associated fat in SPI. Supplementation of soy flour to other flours has also given similar increase in fat content due to soy flour (Mishra and Chandra 2012; Man et al. 2014).

Microbiological quality and free fatty acid content of muffins

Muffins contain high moisture and hence are prone to spoilage by microbes. In order to check microbial load, shelf life studies for 20 days were carried out. The microbial count of the muffins samples in terms of total plate count, yeast, and mould count was found to be under the acceptable range of FSSAI (2016) and Shigella and Salmonella count were zero up to 20 days under ambient and refrigerated temperature conditions. Hence, samples were found to be microbiologically safe. The free fatty acid content was within permissible limit (< 1.2%) up to 10 days and 20 days period of storage at ambient temperature and under refrigerated conditions, respectively.

Conclusion

Overall results revealed that the pasting properties of flour blends, rheological properties of the batters and physical, color, texture, and sensory characteristics of muffins were significantly affected by the type of protein added. Addition of EWP significantly improved the batter by decreasing the specific gravity in comparison to control. Textural studies revealed that EWP containing muffins were softer, easier to chew and springier with more specific volume than control muffins. Sensory studies showed that EWP incorporated QPM based muffins were comparable to wheat based muffins. From the study it can be concluded that among the studied proteins, EWP incorporation in gluten free QPM muffins improved specific gravity and viscoelasticity properties of the batter which lead to the development of most accepted muffins with increased height and improved texture and taste.

References

Adebowale AA, Sanni LO, Awonarin SO (2005) Effect of texture modifiers on the physicochemical and sensory properties of dried fufu. Food Sci Technol Int 11:373–382

Adeyemi IA, Idowu MA (1990) Evaluation of pregelatinized maize flour in the development of Maissa, a baked product. Niger Food J 8:63–73

AOAC (2000) Official method of analysis of AOAC International, 17th edn. Method 925.09, 969.24, 950.48 and 923.03. Association of Official Analytical Chemists, Gaithersburg, MD, USA

Baixauli R, Sanz T, Salvador A, Fiszman SM (2008) Muffins with resistant starch: baking performance in relation to the rheological properties of the batter. J Cereal Sci 47:502–509

BIS (1971) Indian Standard IS: 6273 Part I and Part II. Guide for sensory evaluation of foods. Indian Standard Institution (BIS), Manak Bhawan, New Delhi

Crockett R, Ie P, Vodovotz Y (2011) Effects of soy protein isolate and egg white solids on the physicochemical properties of gluten-free bread. Food Chem 129:84–91

Edema MO, Sanni LO, Sanni A (2005) Evaluation of maize-soybean flour blends for sour maize bread production in Nigeria. Afr J Biotech 4(9):911–918

Flores-Farias R, Martinez-Bustos F, Salinas-Moreno Y, Chang YK, Hernandez JS, Rios E (2000) Physicochemical and rheological characteristics of commercial nixtamalised Mexican corn flours for tortillas. J Sci Food Agric 80:657–664

Francis FJ, Clydesdale FM (1975) Food colorimetry: theory and applications. AVI Publishing Company Inc, Westport

FSSAI (2016) Manual of methods of analysis of foods microbiological testing. Food Safety and Standards Authority of India, Ministry of health and Family Welfare, Government of India, New Delhi

Gallagher E, Gormley TR, Arendt EK (2004) Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci Technol 15:143–152

Geera B, Reiling JA, Hutchison MA, Rybak D, Santha B, Ratnayake WS (2011) A comprehensive evaluation of egg and egg replacers on the product quality of Muffins. J Food Qual 34:333–342

Giwa EO, Abiodun V (2010) Quality characteristics of biscuits produced from composite flours of wheat and quality protein maize. Afr J Food Sci Technol 5:116–119

Goswami D, Gupta RK, Mridula D, Sharma M, Tyagi SK (2015) Barnyard millet based muffins: physical, textural and sensory properties. LWT Food Sci Technol 64:374–380

Gularte MA, De la Hera E, Gómez M, Rosell CM (2012) Effect of different fibers on batter and gluten-free layer cake properties. LWT Food Sci Technol 48:209–214

Harrigan WF, Mccance MF (1976) Laboratory methods in food and dairy microbiology, Revised edn. Academic Press Inc. Ltd., London

Inglett GE, Xu J, Stevenson DG, Chen D (2009) Rheological and pasting properties of buckwheat (Fagopyrum esculentum Moench) flours with and without jet-cooking. Cereal Chem 86(1):1–6

Khalil AH (1998) The influence of carbohydrate-based fat replacers and with and without emulsifiers on the quality characteristics of low fat cake. Plant Foods Hum Nutr 52:299–313

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J Food Eng 79:1033–1047

Man S, Adriana P, Sevastiţa M, Anamaria P (2014) Studies on the formulation and quality characteristics of gluten free muffins. J Agro Aliment Process Technol 20:122–127

Martinez Cervera S, Sanz T, Salvador A, Fiszman SM (2012) Rheological, textural and sensorial properties of low-sucrose muffins reformulated with sucrolase/polydextrose. LWT Food Sci Technol 4:213–220

Matos ME, Sanz T, Rosell CM (2014) Establishing the function of protein on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll 35:150–158

McWatters KH, Ouedraogo JB, Resurreccion AVA, HungY Phillips RD (2003) Physical and sensory characteristics of sugar cookies containing mixtures of wheat, fonio (Digitaria exilis) and cowpea (Vigna unguiculata) flours. Int J Food Sci Technol 38:403–410

Mishra N, Chandra R (2012) Development of functional biscuit from soy flour and rice bran. Int J Agric Food Sci 2:14–20

Ronda F, Oliete B, Gómez M, Caballero PA, Pando V (2011) Rheological study of layer cake batters made with soybean protein isolate and different starch sources. J Food Eng 102:272–277

Sandhu KS, Singh N (2007) Some properties of corn starches II: physicochemical, gelatinization, retrogradation, pasting and textural properties. Food Chem 101:1499–1507

Sanz T, Salvador A, Baixauli R, Fiszman SM (2009) Evaluation of four types of resistant starch in muffins. II. Effects in texture, colour and consumer response. Eur Food Res Technol 229:197–204

Sarabhai S, Prabhasankar P (2015) Influence of whey protein concentrate and potato starch on rheological properties and baking performance of Indian water chestnut flour based gluten free cookie dough. LWT Food Sci Technol 63:1301–1308

Shevkani K, Singh N (2014) Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int J Food Sci Technol 49:2237–2244

Shevkani K, Kaur A, Singh G, Singh B, Singh N (2014) Composition, rheological and extrusion behaviour of fractions produced by three successive reduction dry milling of corn. Food Bioprocess Technol 7:1414–1423

Shevkani K, Amritpal K, Shresth K, Narpinder S (2015) Cowpea protein isolates: functional properties and application in gluten-free rice muffins. LWT Food Sci Technol 63:927–933

Singh JP, Kaur A, Singh N (2016) Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol 53:1269–1278

Tan Y, Corke H (2002) Factor analysis of physicochemical properties of 63 rice varieties. J Sci Food Agric 82:745–752

Trehan S, Singh N, Kaur A (2018) Characteristics of white, yellow, purple, corn accessions: phenolic profile, textural, rheological properties and muffin making potential. J Food Sci Technol 55:2334–2343

Ziobro R, Witczak T, Juszczak L, Korus J (2013) Supplementation of gluten-free bread with non-gluten proteins. Effect on dough rheological properties and bread characteristic. Food Hydrocoll 32:213–220

Acknowledgements

The authors acknowledge the ICAR-IIMR, Ludhiana for providing QPM grains, help provided for texture analysis by Dr M.S. Alam, College of Agricultural Engineering, PAU, Ludhiana, facilities and financial support extended by the Director, ICAR-CIPHET, Ludhiana, Punjab (India) and Indian Council of Agricultural Research (ICAR), New Delhi (India).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bala, M., Arun Kumar, T.V., Tushir, S. et al. Quality protein maize based muffins: influence of non-gluten proteins on batter and muffin characteristics. J Food Sci Technol 56, 713–723 (2019). https://doi.org/10.1007/s13197-018-3529-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3529-8