Abstract

Conventional pasteurization treatments often lead to substantial decrease in fruits juice quality. Due to these issues, the objective of this research was to compare the combined effect of a novel thermal (microwave) and non-thermal (ultrasonic) treatments with conventional thermal pasteurization on some qualitative characteristics of sour cherry juice (vitamins, phenolics, anthocyanins, etc.). For this purpose, an automatic control system comprising of ultrasonic generator, ultrasonic transducer, horn, pump, circulator, microwave oven, container, pipe interface, temperature sensor, float, data acquisition card, microwave power control circuit, and reactor was designed and developed. Moreover, in order to optimize the effect of ultrasonic waves on the existing micro-organisms in the sour cherry juice, some preliminary experiments were carried out to optimize the ultrasonic probe and reactor design. The results of evaluations showed that using the combined automatic system, the qualitative properties of sour cherry (vitamin C content 14 %, total phenolics content 1 %, total anthocyanins content 6 %) can be better maintained compared with the conventional thermal method. Based on the results obtained in this study, the following processing conditions: microwave power of 541.7 W, temperature of 41 °C, ultrasonic power of 799.57 W and ultrasonic exposure time of 6 min were recommended for optimum processing of sour cherry juice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A large number of epidemiological studies have associated with consumption of fruits and vegetables with decreased risks of diseases such as cancer and coronary heart. These diseases usually occur due to the presence of health promoting phytochemicals such as carotenoids, flavonoids, phenolic compounds and vitamins (Hansen et al. 2003; Rawson et al. 2011; Sánchez-Moreno et al. 2003). Fruit juice is one of the ways of utilizing fruits and vegetables benefits. One of the important sections in juice processing is pasteurization prior to packaging. The common method used for juices pasteurization is thermal method. However, applying high temperatures would lead to dysfunctional effects on nutrition and food value. Such effects may include vitamin loss, nutritional flavor loss, non-enzyme browning, and protein reshaping (Kuldiloke 2002).

In order to decrease the adverse effects of the thermal pasteurization method, other methods capable of inactivation of microorganisms can be applied. In doing so, non-thermal methods including pasteurization using high hydrostatic pressure processing (HPP), electrical fields, and ultrasound waves are of interest (Álvarez-López et al. 2003; Mertens 1992).

One of the non-thermal methods of pasteurization which has been reported in the literature is use of ultrasonic waves. The ultrasound-based pasteurization is carried out by inducing cavitation in which gas bubbles are formed and the resulted imploding shock waves result in microbial inactivation by disruption of cell membrane and production of free radicals (Piyasena et al. 2003; Valero et al. 2007).

The main challenge concerned with non-thermal technologies in food processing is inactivation of pathogenic microorganisms and food spoilage agents, which can be achieved by various methods. According to the literature, the non-thermal method not only eliminates the microorganisms entirely, but also decreases (or, in some cases, completely removes) the heat required for microorganisms destruction (Samani and Lorigooini 2015).

The nature of thermal contribution is usually manipulated. As an example, the microwave method has been used to heat food products. These methods may have different effects on pasteurized product as compared with common method because of heating manner of product (Yildiz et al. 2009). Many studies have reported on faster eradication of Saccharomyces cerevisiae, Lactobacillus plantarum and Escherichia coli in vinegar and apple juice in microwave applications as compared with the conventional pasteurization practices (Cañumir et al. 2002; Tajchakavit et al. 1998). Igual et al. (2010) reported that using microwaves, the levels of ascorbic acid, total phenol content and antioxidant activities improved comparing with the conventional pasteurization method (Igual et al. 2010).

There are several researches conducted on the use of above-mentioned methods for removal of microorganisms. However, exploring the literature showed that no report is existed about the simultaneously application of ultrasonic and microwave for removing the microorganisms in the form of an automated-control pasteurization system. Hence, the objective of this study was to develop a control system based on microwave and ultrasonic technologies for automatic pasteurization of sour cherry juice.

System description

The main parts of the developed system include: tank (reservoir), microwave oven, pipe interface, thermal sensors, ultrasonic generator, ultrasound transducer, horn, circulator, ultrasonic reactor, microwave reactor, DAC card, level meter, and a provided board for making changes in microwave power and stirrer.

The first part which should be taken into account in design of the control system was hybrid ultrasonic-microwave establishment. This part must be arranged properly to provide two hypotheses:

-

A)

First, the ultrasonic wave destructs the bacterial wall and demolishes the microorganisms in the next step.

-

B)

The microwave wave increases the sample temperature and consequently destroys the microorganisms existed in the sample according to effect of temperature on cavitation intensity.

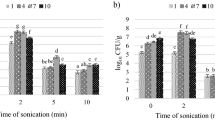

To achieve the goals mentioned above, some initial experiments were carried out. In these experiments, the sour cherry juice samples were studied in four treatments, namely ultrasonic wave, microwave, and ultrasonic-microwave and microwave-ultrasonic. Sour cherry juice was chosen for system evaluation. Sour cherry is listed for many properties such as its value in therapy, for example nephritis, liver disorders, gastric diseases, fever and heart disease (Duke 2010). The produced microwave temperature was 50 °C and the treatment time was 3 minutes for all of the studied treatments. The maximum decline in ultrasonic-microwave mixture was seen according to the number of bacteria (Fig. 1).

The microwave device and further, the ultrasonic wave were evaluated according to the placement order of main parts in the system. Figure 2 shows the schematic diagram of the developed device.

The highest part placed in the system is juice initial storage tank (reservoir). When the system starts working, the electric valve (1) is opened and the juice is entered into the microwave reactor. The applied microwave wave device was microwave oven (SAMSUNG, 800w, 2450 Mhz) with capacity of 2 liters. The microwave oven was selected for performing pre-thermal treatment in this system because increase in juice temperature would lead to increase in the influence of ultrasonic wave in the next step of pasteurization (Soria and Villamiel 2010). Two openings were constructed for pipe interfaces’ crossing in microwave shield. The aluminum sheet was used to isolate the modified shield and the probable leak was checked by safety leak detector device. The developed ultrasonic part was composed of impedance adaptive section, power amplifier and control unit of intensified frequency (Swiss, 1000 W, AMMM).

It has been stated that the contributive elements to ultrasonic performance are sample volume, container dimensions (Z and T), horn diameter (d 0) and horn penetrate depth (d) (Vichare et al. 2001). Therefore, the experiments were conducted for optimizing the reactor (having sample container).

Since the juice temperature increases when applying ultrasonic wave, the circulator device was used to stabilize the temperature. In doing so, a double glazing ultrasonic reactor was utilized. Once the ultrasonic exposure time reached to the set point, the electric valve would be opened and the treated juice was extracted. The main step in development of the pasteurization system was to appropriate design of a control circuit. The control circuit must be designed so that the desired conditions would be incorporated considering the set of assumed variables (temperature, power, time and etc.). The thermal sensor controlled the input and output electric valves of microwave tank (reservoir) through sending pulse. The output electric valve of the ultrasonic reactor and the sample persistence duration were controlled by including a timer in the control system program. Figure 3 shows the different parts of the developed system.

The electric circuit of microwave power controls

To achieve the desired goals and that one of the assumed variables in this study is microwave power, a portion of designing and producing the device is given for microwave oven to the one with interchangeable power capacity. Analysis of several performable methods indicated that the phase control method is more accurate, cost-effective and simple to be implemented, as compared with other methods of power control in pasteurization process. A circuit was provided to be substituted for the original control board of the utilized microwave oven. The power control circuit consisted of a potentiometer, a capacitor, a micro-controller and a small electric motor. When user sets a power in the system, a data acquisition card sends the user’s command to the microwave control circuit as a command signal. Based on the received signal, the microcontroller determines an appropriate angle of rotation for the electric motor and its circuit resistance is changed by the rotation with potentiometer. This procedure changed the input voltage signal to microwave by changing the stored loads in the circuit capacitor. The microwave power was changeable by removing the voltage signal. Figure 4 shows the designed circuit. The power and voltage in the designed electric circuit was calculated using the following formulas (Finney 1980).

The output power of microwave oven can be calculated according to the voltage and power values in each interval (Finney 1980):

In these equations, Z is impedance (Ω), ω is angular frequency (rad/s), P is microwave output power (W), L in inductive load (H), R is electrical resistance (Ω), V max is the maximum voltage (V), χ angle cutoff (rad), e is logarithm on Neper number, α is delay angle (rad), ϕ impedance angle phase (rad), Δ is in the range of 0–0.01389 (rad) for small phase and 0.02778–0.06944 (rad) for large phase. Having determined the power and temperature of product, the circuit changed its input voltage based on its control program, then the output was enhanced by transformer which was given later to Magentron to generate microwave wave.

Designing the reactor within the microwave

Since sour cherry juice is similar to water in terms of dielectric specifications, one would argue that the minimum penetrate depth of microwaves in sour cherry juice is 41 mm at 25 °C . In order to heat the sample juice uniformly, it was necessary to consider a 2.8 cm reactor diameter inside the microwave. Since the selected diameter was larger than the penetration depth of wave, the stirring method was used to uniform the sample temperature. In doing so, the blade as well as the shaft were turned and connected to small DC motor. The stirrer shaft and blade were covered by Teflon because the low rate of electron exchange and high value of dielectric coefficient in Teflon types of covers.

Measuring the sample temperature in the microwave

In order to measure the sample temperature inside the microwave, a thermoelectric sensor (Model PT100, Taiwan) having a thermal range of −200 to +600 °C, covered by platinum with measuring accuracy of 0.01 °C was used. The reason for choosing PT100 to measure juice temperature was the slight effect of microwave wave on the output of this sensor. However, the chosen sensor was first covered with aluminum thin sheets to prevent the negative impacts. The sensor was then covered by nail polish.

Measuring sample volume in the microwave

There are a number of limitations concerned with measuring the incorporated sample volume inside microwave devices among which fusion and sparking of sensors were the most important ones. Prior to be entered into the microwave, the sample was experimented in another container. The gauging procedure was carried out by a simple floating device which was installed on an adjustable column. The floating device was arranged as series with respect to input electric valve of microwave. When the sample reached the desired level, the control signal opened the electric valve, and the sample was poured into the microwave chamber (Fig. 5).

Horn design

One of the most common types of horns used for ultrasonic machining technologies is step type horn (Naď, 2010). For obtaining the governing equations on deformation along the step type horn in steady state condition (Fig. 6), Eq. (7) was used. In solution of the mentioned differential equation, the answers are divided into two subsets and each of the answers is obtained considering the boundary conditions (Hosseinzadeh et al. 2013):

From Eq. (7), it can be concluded that:

The boundary conditions for Eq. (8) are written as follows:

Using Eq. (8), the constants of Eq. (7) is obtained as follows:

One of the most important parts in probe design is preventing from stress concentration in locations in which area changes. To avoid this problem, the displacement in this section must be equal to zero (Nanu et al. 2011). For obtaining the probe length, the displacement equation and the l 1 parameter are used:

From Eq. (10) and (11), the variation of stress along the probe can be obtained:

In order to determine the maximum axial stress in step type probe, Eqs. (12) and (13) are derived and set equal to zero. Therefore, the maximum stress will be equal to:

Based on the mentioned calculations, the horn length was selected as the half of wavelength. Since the wavelength depends on sound propagation in horn and that propagation rate relies on horn cover, the horn length was determined after choosing horn cover. Determining the place of surface change is of great importance in stair horns. The length of stair horn sections is determined as one-fourth of wavelength in those methods in which the length is obtained from horn vibrational mode rules and finite element methods. According to the above descriptions, the obtained dimensions were analyzed by computer for designing horn with aluminum cover. According to the vibrational frequency of applied convertor, the device working frequency was obtained in the range of 19 to 21 kHz. Having vibrational frequency and sound propagation rate in aluminum (Eq. (10)), the cylinder horn length was obtained as 126.6 mm. There were several limitations on obtaining the diameter of both heads of cylinder. One of the limitations was the diameter end of amplifier. As mentioned above, to prevent from wave return, the horn diameter should be equal or higher than the convertor diameter. Another factor to be taken into account was the yield stress of horn. Based on the noted limitations, since the transducer diameter was 33.68 mm, the input diameter of horn should be equal to or higher than the end diameter of amplifier booster. The reason for choosing the aluminum horn was its cheapness and easiness to be turned and machined. It is worthy to be noted that the highest amount of tension was run in cross-section interchanging part. Also, aluminum does not endure high amounts of yield stress which impedes its application in amplifying wave in horn. In this design, the thinnest diameter was chosen as 35 mm for input diameter of horn. Considering yield stress limitations, the horn end diameter modal analysis was determined as 25 mm whose amplifying coefficient was 1.96.

In order to design other horns and considering the mentioned limitations as well as amplifying coefficient constant status, two other horns were chosen with 30 and 35 mm end diameter whose input diameters were as 45 and 49 mm, respectively. Figure 7 shows sample of these produced horns.

In order to optimize the horn diameter, three horns were produced in this study and their performance was evaluated. All of the horns were scanned via ultrasonic system AMMM (1000 W) to validate their design prior to experiment conducting so that the resonant frequency of horns were determined in laboratory. In doing so, the ultrasonic generator was connected to the computer via a card interface. Then, the scanning command was made by horn in the relevant software (software relate to AMMM generator). Figure 8 shows the results obtained from resonant frequency determination in the laboratory. Table 1 shows the results of designed horns scanning with 25, 30 and 35 mm diameters. There is little difference between the theoretical methods results and those of laboratory analyses because of a number of simplifications in theoretical design.

Booster design

An amplifier booster was adjusted between the transducer and the horn for amplifying the ultrasonic waves, considering the yield stress in horn design, utilization of booster in ultrasonic system was inevitable. The equations having to do with horn design were followed in order to design the booster. The conical shape is the most resistant one in describing the whole amplifying forms based on the equations and resources available. Aluminum is composed of 2800 kg/m3 density, 74 Gpa elastic coefficient and 5140 m/s sound speed. The booster dimensions are calculated according to Table 2 (Fig. 9).

Ultrasonic reactor design

The analytic and optimizing method used in this research was Response Surface Method (RSM). In this method, one would need the changing range of experiment independent variables. In order to determine the diameter range and reactor height, a number of experiments had to be conducted (Table 3). In this study, the total microbial count was measured using the pour-plate technique. First, to decrease the microbial population and isolate a single colony, the samples were diluted using physiological serum. Then, 1 ml of the diluted samples was poured into a 90 mm plate using a sterile pipette. Subsequently, 20 ml of Plate Count Agar culture which was cooled down to 45 °C was added to the mixture. In order to mix the sample with the culture, plates were gently moved. After the agar was hardened, plates were kept for 24 to 48 hours at 37 °C inside an oven (Valero et al. 2007).

In order to determine the optimum conditions for the developed pasteurization system, two dependent variables (sample size and total microbial count) were considered. The objective was to maximize the product volume and minimize the total microbial count. In optimization, considering the higher importance of total microbial count minimization rather than reactor size, the total microbial count and volume were given weights of 5 and 3, respectively. Table 4 shows the assumed boundary conditions for optimization. The applied software to implement RSM was Design Expert 7. So, the optimal dimensions of horn, reactor diameter and height were obtained as 30, 85 and 41 mm, respectively.

Stabilizing method of ultrasonic temperature during treatments

Since one of the chosen independent variables for conducting the experiments was temperature, it was necessary to stabilize the sample temperature. In order to stabilize sample temperature during treatments, a double-glazed reactor was designed. Water runs in the middle section of reactor. In doing so, a circulator device (Model Sahand, Iran) was used. For stabilizing the assumed temperatures, using trial and error method, the output water temperature from circulator was calibrated as set point.

Experiments relevant to evaluating microwave-ultrasonic system

Chemicals and microbial strains

The applied chemicals including: Proxo di Solphite, Sodium acetate and Potassium Chloride, were purchased from Rankem Company, New Delhi, India. Other chemicals of reactive and solvents were purchased from Merk Company, Darmstadt, Germany. E. coli (PTCC 5052) and S. cervisiae (RITCC 1177) microbial strains were provided from Razi Serum Company and Iran Scientific and Industrial Research Organization, respectively.

Preparation of sour cherry juice samples

For this purpose, a certain amount of sour cherry fruit of Mashhad Champa variety was purchased from local markets. First, the fruits were washed, cleaned and cored. The prepared fruits were then dewatered using an electric juicer. In order to separate pulp suspensions and tissue components, the extracted juice was poured into a centrifuge with the speed of 6000 rpm (4307 g) for 20 minutes. For complete separation of the remaining suspended particles, the transparent portion of the extract was passed through a Whatman filter paper using a vacuum pump (Samani et al. 2013). Afterwards, the samples were poured into a reactor with diameter and height of 80 and 50 mm, respectively. It is necessary to mention that the dimensions of the reactor were optimized during pretests.

Preparation of microbial suspensions

Once the lyophilized standard strain of E. coli and S. cerevisiae vial were opened separately, the strains were cultivated on an agar nutrient culture and an agar malt extract medium. Therefore, to prepare the microbial suspension, a loop of grown microbial strain on agar was inoculated to a 25 ml nutrient liquid culture under sterile conditions. The microbial suspension was kept inside an oven for 18–24 hours at 37 °C. The liquid culture containing the grown cells was centrifuged for 5 minutes at 8000 rpm (7656 g), so that the resulting cellular mass was suspended in sterile sour cherry juice. A total of 3 ml of this suspension was inoculated to 300 ml of sour cherry juice. For adaptation purpose, it was held for 15–30 minutes before the deactivation. It should be noted that the cultures used for primary activation and proliferation included nutrient solid/liquid cultures (Kuldiloke 2002). The microbial level of E.coli (PTCC 5052) and S. cerevisiae (RITCC 1177) was determined from Iran Industrial and Scientific Research Organization.

Experiment description

In order to evaluate the ultrasonic-microwave system, experiment variables and their related statistical levels were fed into the RSM analysis software (Table 5). According to RSM method, the number of tests was 30. The experiment dependent variables included residual number of E. coli (the perilous bacteria leading to individual death) and residual number of S. cervisiae (the affecting index of system on yeast). Also, phenolic compounds, anthocyanin, vitamin C and color indexes were investigated as qualitative properties (Adekunte et al. 2010; Valero et al. 2007). The experiment procedures are described in the following section.

Conventional pasteurization

To compare combination and conventional methods, the conventional method was simplified in laboratory to be operationalized. The samples were put into hot water bath with 70 °C for 1 minute and their microbial count was then calculated after cooling (Kuldiloke 2002). A complete randomized design was used in a factorial experiment with three replications using the SAS 16 and MINITAB15 statistical packages. The means values were compared using LSD tests (P < 0.05).

Evaluation system

The raw sour cherry juice was selected for conducting the experiments. In the first step, the raw samples were inoculated with appropriate number of microorganisms (i.e., E. coli and S. cervisiae) after initialization and pasteurization conventional thermal method for surveying the process effect on microorganisms inactivation. In the second part, the effect of process different conditions on raw juice was studied through measuring different items including: total and specific microbial counting before and after treatment (AOAC, 1984), total Phenolic content before and after treatment (Singh et al. 2002), total anthocyanin content (Trappey et al. 2005), juice samples color (L*، a*، b*, total color difference) before and after processing (using Hunter lab device (Maskan 2001)), vitamin C (using titration method with 42,6-Dichloro phenolin dophenol (DCP) color chemicals {James, 1995 #347}, and, energy and power consumption of ultrasonic and microwave devices (using watmeter device).

Results and discussion

RSM analysis

Based on ANOVA results, the interaction effect of reactor diameter and height on microbial count was significant (P < 0.01). With increasing the volume, the effectiveness of ultrasonic waves decreased. This effect was specially obvious at the 85 mm diameter where the total microbial count slope increased with the increase of reactor height. For 65, 75, and 85 mm reactor diameters, increasing the height from 30 to 50 mm caused an increase in the total microbial count by 14.4, 29.6, and 85 %, respectively. Moreover, increasing the height from 50 to 70 mm, for all of the three reactor diameters, increased the total microbial count to 42, 403, and 636 %, respectively. On average, increasing the reactor height from 30 to 70 mm and diameter from 65 to 85 mm increased the total microbial count by 428 and 593 %. In general, it can be said that larger sizes of reactor decrease the effectiveness of ultrasonic waves. Because, in addition to cavitation effect, the sonic movement effect is also developed within the reactor. This helps to agitate the sample which in turn causes multiple exposures of the sample particles to the ultrasonic waves and cavitations. Whereas with the increase of reactor diameter and height, the movement course of a particle to complete one cycle increases, this also decreases the chance of particles exposure to ultrasonic waves during the cycle (Vichare et al. 2001).

The results revealed that the effect of final sour cherry juice temperature on E. coli and sacaromises cerevisae reduction was more significant than that of microwave power and its resulting heat. However, increasing microwave output power had a milder incremental gradient than the microwave induced temperature. At lower temperatures, increasing the microwave power had no effect on reduction of E. coli and sacaromises cerevisae. With increasing the temperature to 50 or 60 °C and raising the microwave power, the E. coli reduction was enhanced. This is possibly due to faster reaching to the higher temperatures and having insufficient chance for microorganisms to adapt with the new conditions (Fig. 10). These findings could also be derived from Table 6, where the product of microwave power by temperature has a negative coefficient. This shows that any increase in the independent variable would result in a larger negative value in the equation; as well as higher E. coli removal. Other researches have similarly indicated the effect of microwaves on removal of microorganisms (Cañumir et al. 2002; Tajchakavit et al. 1998).

According to the results, any increase in the ultrasound power, ultrasonic exposure time and microwave power would lead to a reduction in vitamin C content of the sour cherry juice. The impact of ultrasound power was more effective than the microwave power. This is clearly shown by increased reduction of vitamin C (in gradient form) with increasing the ultrasonic power. The ultrasound-induced loss in vitamin C content was probably the result of ascorbic acid breakdown or interaction with other compounds such as anthocyanin. This, in turn, can lead to loss of pigments and discoloration. Oxidative reactions can be the reason for anthocyanins and ascorbic acid breakdown during the ultrasound treatment. This process can be enhanced by the free radicals created through the ultrasound treatment. Moreover, the cavitation-induced thermolysis could be another reason for the breakdown of these compounds (Tiwari et al. 2008a). It was reported that microwave processing can increase the breakdown of vitamin C content of orange juice, due to its thermal effects (Vikram et al. 2005).

The results indicated that the vitamin C content of sour cherry juice decreased with increasing temperature (Fig. 11). This clearly shows that vitamin C is sensitive to heat, and the process temperature is directly correlated with the breakdown of these compounds. So that, thermal processing adversely affects vitamin C breakdown at high temperatures (Odriozola-Serrano et al. 2009; Torregrosa et al. 2006). In addition, as temperature reached 50 °C, the effectiveness of ultrasonic waves was enhanced owing to the increased internal pressure of the bubbles. However, with further increase in the temperature; the vitamin C content decreases because of a decrease in the cavitation intensity. This, in turn, weakens the impact of ultrasonic waves.

On the basis of our findings, longer ultrasonic exposure times decreased the vitamin C content, more likely because of the increased duration of oxidative reactions and occurrence of thermolysis. Other researchers have shown that the breakdown level of ascorbic acid in watermelon juice increased significantly with the ultrasonic amplitude, exposure time and temperature (Rawson et al. 2011).

Regarding the amount of phenolic content remained after the process, analysis of variance showed that the effects of first-degree coefficients of microwave power, quadratic coefficients of temperature, interaction effect of microwave power * temperature, and also the interaction effect of microwave power * time of ultrasonic wave treatment were not significant in the model fitting. As shown in Fig. 12, with increasing the ultrasonic power, the phenolic compounds of sour cherry juice decreases compared with the untreated sample. Considering the variation trend of phenolic compounds with respect to ultrasonic power and microwave power, it can be concluded that the effect of ultrasonic waves was higher than that of microwave. This is due to the fact that the variations versus ultrasonic power were higher than that of microwave power. Ashokkumar et al. 2008 demonstrated that the hydroxyl radicals are generated in the sound hole and the amount of radicals is remarkably depends on the ultrasonic frequency and also chemical compositions of food materials such as phenolic compounds. Such compounds can be sonochemically hydroxylated, which is a process based on ultrasonic frequency. Therefore, the increasing trend of phenolic compounds in some ultrasonic time and intensities may be possibly due to addition of hydroxyl radicals to the aromatic ring of phenolic compounds (Ashokkumar et al. 2008; Bhat et al. 2011).

The amount of phenolic compounds in the sour cherry juice decreased with increasing the temperature. Considering the variations versus temperature and ultrasonic power (Fig. 12) and also regarding the curve inclination with respect to the mentioned parameters, it can be deduced that temperature has a more prominent effect on the amount of phenolic compounds as compared with the ultrasonic power. From Fig. 12, it can be also seen that the effect of sample temperature on the phenolic content was higher than that of ultrasonic exposure time. Since thermal pasteurization is a standard and conventional method in the food industry, the effect of thermal processing on functional components and anti-oxidation properties of different foods have been published in scientific literature. It has been proven that temperature and time of processing are both effective factors on the amount of phenolic compounds (Wagener 1981). Apart from reduction of anti-oxidant compounds, which is occurred during juice extraction and filtration, thermal pasteurization has similar effects on these compounds. It has been reported that processing of pomegranate juice at 100 °C for 20 min caused a 7.1 % reduction in the amount of phenolic compounds (Alper et al. 2005).

Analysis of variance in the case of anthocyanin content remained after the process showed that the first-degree coefficients of microwave power, quadratic coefficients of ultrasonic power and ultrasonic wave exposing time, interaction effect of temperature * time, and also the interaction effect of microwave power * temperature were not significant in the fitted model.

With increasing temperature, the amount of anthocyanin in the sour cherry juice decreased. Regarding the notion that the first coefficient of microwave power is not significant in the fitted model and considering the variation trend of anthocyanin versus power and temperature, it can be concluded that temperature is a more effective factor than ultrasonic power. This implies the thermal effect of microwave on the sample. The adjusted power in the device to reach the desired temperature was not effective and it just overshadowed time and energy consumption.

Increasing the ultrasound exposing time caused an increase in the time required for anthocyanin decomposition in sour cherry juice. Consequently, the amount of anthocyanin in the sample decreased with increasing the time. It has been indicated that utilization of ultrasonic waves in blackberry pasteurization with an intensity of 100 % for 10 min caused to more than 94 % preservation of anthocyanin compounds (Tiwari et al. 2009). The amount of anthocyanin remained in the sample decreased with increasing the ultrasonic power (Fig. 13). It can be observed from Table 6 that ultrasonic power and interaction effect of microwave and ultrasonic have negative coefficients. Accordingly, anthocyanin decomposition increases with increasing ultrasonic power. Increasing the ultrasonic wave exposing time also caused an increase in decomposing time of anthocyanin (Fig. 13). Similar trend have been reported for blackberry juice (Wong et al. 2010) and strawberry juice (Tiwari et al. 2008b).

Process optimization

In order to optimize the process, the goal functions were needed. These functions were obtained using RSM method. For optimization of the process and described goal functions, the boundary conditions were considered according to Table 7. The boundary conditions such as independent varibales (microwave power, sample temperature, ultrasonic power and ultrasonic exposure time) were considered within the determined variable range. The aim of this optimization was maximizing phenolic, anthocyanins and vitamin C compounds contents well as minimzing the total color difference amount (ΔE), consumed energy and most importantly, E. coli and S. cervisiae total number tendency to zero. Based on the results, the suggested optimal point obtainedby the software was: microwave power 541.7 W, sample temperature of 41 °C, ultrasonic power of 799.57 W and ultrasonic treatment time of 6 minutes. The qualitative and microbial properties of the sample obtained by the model included: phenolic compunds content of 1955.77 mg GAE/1, anthocyanin content of 373.303 mg C3GE/, vitamin C content of 132.289 mg/100 ml, total color difference (ΔE) of 1.76, E. coli 19, S. cervisiae 0 and consumed energy of 35,071 J. To validate the obtained results, the suggested values were evaluated experimentally. In this condition, the dependent variables were: phenolic compounds content of 1961 mg GAE/1, anthocyanin content of 369 mg C3GE/, vitamin C content of 130 mg/100 ml, total color difference (ΔE) of 1.69, E. coli 0, S. cervisiae 0 and consumed energy of 3489 J. The results showed that there was a significant difference between the obtained results of experiment and those of the developed model. The results also revealed that the proposed models had an appropriate accuracy.

Comparison of conventional and combined methods

The combined method in its optimal point was compared with the conventional method. Table 8 shows the qualitative and microbial properties of pasteurized sour cherry juice in both combined and conventional methods. As Table 8 shows, the combined method can keep the phenolic compounds, anthocyanin, Vitamin C and color compounds compared to conventional method. The combined method also consumes less energy than the conventional method. In general, it can be concluded that the developed method was in close agreement with research goals in terms of qualitative properties.

Conclusion

In this research, an automatic control system comprising of ultrasonic generator, ultrasonic transducer, horn, pump, circulator, microwave oven, container, pipe interface, temperature sensor, float, data acquisition card, microwave power control circuit, and reactor was designed and developed for pasteurization of sour cherry juice. Based on ANOVA results, the interaction effect of reactor diameter and height on microbial count was significant (P < 0.01). With increasing the volume, the effectiveness of ultrasonic waves decreased. It was found that the effect of final sour cherry juice temperature on E. coli and sacaromises cerevisae reduction was more significant than that of microwave power and its resulting heat. According to the results, any increase in the ultrasound power, ultrasonic exposure time and microwave power would lead to a reduction in vitamin C content of the sour cherry juice. With increasing the ultrasonic power, the phenolic compounds of sour cherry juice decreased as compared to the untreated sample. Anthocyanin decomposition increased with increasing ultrasonic power. Increasing the ultrasonic wave exposing time also caused an increase in decomposing time of anthocyanin. Based on the result obtained in this study, the following processing conditions: microwave power of 541.7 W, temperature of 41 °C, ultrasonic power of 799.57 W and ultrasonic exposure time of 6 min are recommended for the optimal processing of sour cherry juice. The results of evaluations showed that the combined and automatic systems can better keep the qualitative properties of sour cherry as compared with the conventional thermal method.

References

Adekunte A, Tiwari B, Cullen P, Scannell A, O’Donnell C (2010) Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem 122:500–507

Alper N, Bahçeci KS, Acar J (2005) Influence of processing and pasteurization on color values and total phenolic compounds of pomegranate juice. J Food Process Preserv 29:357–368

Álvarez-López J, Jiménez-Munguia M, Palou E, López-Malo A (2003) Ultrasound and antimicrobial agents effects on grapefruit juice. In: 2003 IFT Annual Meeting-Chicago

Ashokkumar M, Sunartio D, Kentish S, Mawson R, Simons L, Vilkhu K, Versteeg CK (2008) Modification of food ingredients by ultrasound to improve functionality: a preliminary study on a model system. Innov Food Sci Emerg Technol 9:155–160

Bhat R, Kamaruddin NSBC, Min-Tze L, Karim A (2011) Sonication improves kasturi lime (< i > Citrus microcarpa</i>) juice quality. Ultrason Sonochem 18:1295–1300

Cañumir JA, Celis JE, de Bruijn J, Vidal LV (2002) Pasteurisation of apple juice by using microwaves. LWT-Food Sci Technol 35:389–392

Duke JA (2010) Handbook of medicinal herbs. CRC press

Finney D (1980) The power thyristor and its applications. McGraw-Hill

Hansen SL, Purup S, Christensen LP (2003) Bioactivity of falcarinol and the influenceof processing and storage on its content in carrots (Daucus carota L). J Sci Food Agric 83:1010–1017

Hosseinzadeh B, Khoshtaghaza MH, Minaei S, Zareiforoush H, Najafi GH (2013) Design of Ultrasonic Probes for use in Food and Chemical Industries

Igual M, García-Martínez E, Camacho M, Martínez-Navarrete N (2010) Effect of thermal treatment and storage on the stability of organic acids and the functional value of grapefruit juice. Food Chem 118:291–299

Kuldiloke J (2002) Effect of ultrasound, temperature and pressure treatments on enzyme activity and quality indicators of fruit and vegetable juices. Universitätsbibliothek

Maskan M (2001) Kinetics of colour change of kiwifruits during hot air and microwave drying. J Food Eng 48:169–175

Mertens B (1992) Developments of nonthermal processes for food preservation. Food Technol 5:124–133

Nanu AS, Marinescu NI, Ghiculescu D (2011) Study on ultrasonic stepped horn geometry design and FEM simulation. Nonconventional Technologies Review, vol. 4

Odriozola-Serrano I, Soliva-Fortuny R, Hernández-Jover T, Martín-Belloso O (2009) Carotenoid and phenolic profile of tomato juices processed by high intensity pulsed electric fields compared with conventional thermal treatments. Food Chem 112:258–266

Piyasena P, Mohareb E, McKellar R (2003) Inactivation of microbes using ultrasound: a review. Int J Food Microbiol 87:207–216

Rawson A, Tiwari B, Patras A, Brunton N, Brennan C, Cullen P, O’Donnell C (2011) Effect of thermosonication on bioactive compounds in watermelon juice. Food Res Int 44:1168–1173

Samani BH, Lorigooini Z (2015) Effects of ultrasonic on microorganisms and enzymes. Int Sci Investig J 4:106–113

Samani BH, Khoshtghaza MH, Minaee S, Abbasi S (2013) Effect of ultrasonic waves on pasteurization of sour cherry juice. Int J Biosci (IJB) 3:193–200

Sánchez-Moreno C, Plaza L, de Ancos B, Cano MP (2003) Quantitative bioactive compounds assessment and their relative contribution to the antioxidant capacity of commercial orange juices. J Sci Food Agric 83:430–439

Singh R, Chidambara Murthy K, Jayaprakasha G (2002) Studies on the antioxidant activity of pomegranate (Punica granatum) peel and seed extracts using in vitro models. J Agric Food Chem 50:81–86

Soria AC, Villamiel M (2010) Effect of ultrasound on the technological properties and bioactivity of food: a review. Trends Food Sci Technol 21:323–331

Tajchakavit S, Ramaswamy H, Fustier P (1998) Enhanced destruction of spoilage microorganisms in apple juice during continuous flow microwave heating. Food Res Int 31:713–722

Tiwari B, Muthukumarappan K, O’Donnell C, Cullen P (2008a) Effects of sonication on the kinetics of orange juice quality parameters. J Agric Food Chem 56:2423–2428

Tiwari B, OʼDonnell C, Patras A, Cullen P (2008b) Anthocyanin and ascorbic acid degradation in sonicated strawberry juice. J Agric Food Chem 56:10071–10077

Tiwari B, O’Donnell C, Cullen P (2009) Effect of sonication on retention of anthocyanins in blackberry juice. J Food Eng 93:166–171

Torregrosa F, Esteve M, Frígola A, Cortés C (2006) Ascorbic acid stability during refrigerated storage of orange–carrot juice treated by high pulsed electric field and comparison with pasteurized juice. J Food Eng 73:339–345

Trappey A II, Bawadi HA, Bansode RR, Losso JN (2005) Anthocyanin profile of mayhaw (< i > Cretaegus opaca</i>). Food Chem 91:665–671

Valero M, Recrosio N, Saura D, Muñoz N, Martí N, Lizama V (2007) Effects of ultrasonic treatments in orange juice processing. J Food Eng 80:509–516

Vichare NP, Gogate PR, Dindore VY, Pandit AB (2001) Mixing time analysis of a sonochemical reactor. Ultrason Sonochem 8:23–33

Vikram V, Ramesh M, Prapulla S (2005) Thermal degradation kinetics of nutrients in orange juice heated by electromagnetic and conventional methods. J Food Eng 69:31–40

Wagener G (1981) The effect of different thermovinification systems on red wine quality. Am J Enol Vitic 32:179–184

Wong E, Vaillant F, Pérez A (2010) Osmosonication of blackberry juice: impact on selected pathogens, spoilage microorganisms, and main quality parameters. J Food Sci 75:M468–M474

Yildiz H, Bozkurt H, Icier F (2009) Ohmic and conventional heating of pomegranate juice: effects on rheology, color, and total phenolics. Food Sci Technol Int 15:503–512

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseinzadeh Samani, B., Khoshtaghaza, M.H., Minaei, S. et al. Design, development and evaluation of an automatic fruit-juice pasteurization system using microwave – ultrasonic waves. J Food Sci Technol 53, 88–103 (2016). https://doi.org/10.1007/s13197-015-2026-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2026-6