Abstract

Understanding the efficacy of viable emerging technologies in preserving overall quality attributes and antioxidant characteristics of fruit juices is of great interest. This study aimed to evaluate the effect of high pressure (HP), ultrasound (US), and pulsed electric fields (PEF) processes on natural microbiota inactivation, as well as changes in physicochemical attributes and phytochemical content of strawberry juice (SJ). HP at 300 MPa (1 min), US at 55 °C (3 min) and 517.1 mW/mL acoustic energy density, and PEF at 35 kV/cm (27 μs) using monopolar square pulses with 2 μs pulse width were applied, and then compared with a conventional thermal pasteurization treatment (72 °C, 15 s). The nonthermal processes were equivalent in terms of Escherichia coli (E. coli) inactivation since the selected processing conditions led to almost identical inactivation level (at least 5-log) of inoculated E. coli. The current study analyzes why these equivalent processes had different effect on SJ quality. All treatments significantly reduced the initial natural microbiota (i.e., total mesophilic aerobic bacteria and yeast-molds) below 2 log CFU/mL. No significant changes were observed on the total soluble solid content (7.83–8.00 °Brix), titratable acidity (0.79–0.84 g/100 mL), and pH (3.45–3.50; except in sonication) between SJ processed samples and the untreated ones (p > 0.05). HPP and PEF significantly promoted higher retention of total phenolic content (TPC) and radical scavenging activity (RSA) than thermal pasteurization, and significantly enhanced total anthocyanin content (TAC) compared with unprocessed SJ. HPP and PEF increased the TPC (4–5%), RSA (18–19%), and TAC (15–17%) in comparison with unprocessed SJ. Multivariate data analysis tools, i.e., principal component analysis (PCA) and hierarchical cluster analysis (HCA), were successfully applied for discrimination and classification of SJ samples based on the similarities or differences among physicochemical and phytochemical characteristics. PCA and HCA indicated that HPP- and PEF-treated samples had similar enhanced properties in terms of phytochemical content and were superior to sonicated, thermally pasteurized, and unprocessed samples. The multivariate data analysis methods were very useful to compare and classify SJ quality characteristics as a function of the processing technology. This study demonstrated that the application of the equivalent processing approach may reveal new opportunities to produce equivalent or even enhanced quality fruit juices.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Consumption of fruits and fruit juices has been associated with the risk reduction of several degenerative diseases. Strawberry is a good source of nutrients and phytochemicals such as flavonoids, anthocyanins, and phenolic acids [1]. Regardless of genetic and environmental factors, pelargonidin-3-glucoside, cyanidin 3-glucoside, and pelargonidin 3-rutinoside are the major anthocyanins in strawberries [2]. Strawberry phenolics benefit human health since they are able to (i) block and detoxify free radicals, (ii) regulate gene expression by its involvement in metabolism and antioxidant defense mechanisms, and (iii) avoid DNA damage [1]. From a commercial point of view, strawberries are consumed either fresh or in a processed form including juices, jams, or jellies [3].

Strawberry juice (SJ) is one of the berry juices that is gaining interest because of the availability and cost of the fruit, and its positive effect on health, promoting benefits due to its composition. However, this composition makes SJ susceptible to microbial growth such as total aerobic bacteria, yeasts, and molds [4, 5]. Even though berry juices have a relatively low pH, between 3 and 4.5, pathogenic outbreaks of Escherichia coli O157:H7 and Salmonella spp. are considered a serious problem in terms of microbial safety [6]. Thermal processing has been widely applied for the preservation of fruit juices either as low-temperature long-time (63 °C for no less than 30 min) or high-temperature short-time (72 °C with holding times of 15 s and above) treatments [7, 8]. However, the applied temperatures to reduce the initial microbial population cause the reduction of nutritional and organoleptic quality as well as the bioactive content of fruit juices. Therefore, nonthermal food processing technologies have gained special attention to avoid the undesired impact of thermal processing on the fruit juice quality [9].

SJ has been previously processed by alternative technologies such as pulsed electric fields (PEF) [10, 11], ozone processing [12], ultrasound (US) ([4, 13,14,15]; J. [16]), chemical preservatives [17], and high pressure processing (HPP) [5]. The variances arising from the use of raw material with different initial quality and maturity levels as well as varying processing and storage conditions make the case difficult to compare the product quality as affected by different processes [18]. Several scientific publications related to the effect of HPP, PEF, and ultrasound on fruit juice quality characteristics express how the processed juices are superior to their counterparts treated by thermal or nonthermal processes [19,20,21]. This explanation is usually attributed to the different action mechanism of the nonthermal processes or the reduced thermal effect. However, it should be considered that irrelevant comparisons may appear unless the applied nonthermal processing conditions are selected on an equivalent basis [22]. The equivalence refers to the equivalent microbial safety as described in the studies of Vervoort et al. [22] and Vervoort et al. [23]. The equivalent degree of microbial inactivation constitutes a basis for the comparison of chemical and biochemical quality parameters of the final product [23]. Once the nonthermal processes achieve an equivalent degree of microbial inactivation, then a more relevant comparison could be conducted for the evaluation of quality characteristics of juice products. Therefore, the equivalent processing approach was proposed considering equivalent products in terms of inactivated microorganisms [18].

Multivariate data analysis tools have been used in food science and technology to compare the effect of food processing technologies on food quality by simultaneously evaluating the similarities or differences among several characteristics of multiple samples [24,25,26,27]. Principal component analysis (PCA) and hierarchical cluster analysis (HCA) are two representatives of the unsupervised multivariate data analysis techniques that visualize the data in sub-classes and agglomerative algorithms [28]. PCA leads researchers to interpret in what aspect a sample differentiates from another one [29]. HCA, on the other hand, is a clustering method that displays the relationships among the samples by depicting hierarchical clusters [30]. PCA and HCA can be well applied for the differentiation of fruit juices based on various attributes [10, 24, 26].

In a previous study, equivalent inactivation levels of an inoculated target microorganism, E. coli 11775, were used to identify HPP, US, and PEF treatment conditions that led to at least 5-log reduction [31]. The current research focused on the pasteurization of SJ by HPP, US, and PEF under the previously identified equivalent processing conditions. Thus, the objective of this study was to evaluate the influence of equivalent HPP, US, and PEF technologies on natural microbiota, physicochemical properties, and phytochemical content of SJ immediately after equivalent processing in comparison with a conventional thermal treatment. Multivariate data analyses (i.e., PCA and HCA) were utilized to define the similarities and variations among the studied SJ samples.

Materials and Methods

Preparation of Strawberry Juice

Strawberries (Fragaria × ananassa) were purchased from a local grocery store (Pullman, USA) at their commercial maturity. Fruits stored at − 30 °C were defrosted overnight at ambient temperature in the dark. The fruits were homogenized using a blender (Model K, Regal Ware, Inc., USA); then, the homogenate was centrifuged (Beckman J2 HS centrifuge, GMI, MIC Group, Inc., Minnesota, USA) at 6000 rpm and 4 °C for 5 min using a Fiberlite F14 6 × 250 rotor (Piramoon Technologies, Inc., USA). The suspended particles were subsequently removed by filtering the juice through a double-layer cheese cloth [31].

Processing Conditions

The Food and Drug Administration (FDA) recommends 5-log reduction of the most pertinent microorganism for microbial safety of food products [8]. In accordance with the FDA’s pasteurization criteria, the SJ processing conditions were previously identified in an earlier study [31] where the target microorganism (i.e., acid adapted E. coli 11775) rendered at least 5-log reduction, and then adopted here as the equivalent pasteurization conditions for SJ.

High Pressure Processing

A high hydrostatic pressure unit (Engineering Pressure Systems, Inc., Andover, USA) with a cylindrical chamber vessel having a volume of approximately 2 L (0.1-m internal diameter, 0.25-m internal height) was used for HPP treatments. Fresh SJ (100 mL) was packed into Nylon-/PE-type plastic pouches (3 MIL, UltraSource, Kansas City, MO, USA). The pouches were then carefully sealed by a hand-operated sealer, placed into the cylindrical chamber vessel containing the pressure transmitting liquid (5% mobil hydrosol 78 in water), and pressurized at 300 MPa for 1 min in duplicate. Come-up time required to reach the desired pressure was 0.5 s while the depressurizing time was recorded as less than 0.5 s. The temperature of the pressurizing liquid inside the chamber was 18.3 ± 1.0 °C and then it reached to a maximum temperature of 26.1 ± 1.1 °C during the holding period; after decompression, the temperature went back to the original one (temperature rise was 2.6 °C per 100 MPa increase).

Ultrasound

An ultrasonic device (Hielscher USA Inc., Ringwood, NJ) equipped with a probe of 22-mm diameter, double-walled vessel, and a water bath (Thermostat Physica Viscotherm VT 10, Germany) was used. Four hundred milliliters of freshly squeezed SJ at 23.5 °C was placed into the vessel and agitated with a magnetic stirrer; the probe was immersed into the juice up to 2 cm. Once the sonicator was turned on, the temperature of SJ increased to 55.1 ± 0.0 °C after a come-up time of 4 min. US at 55 °C (i.e., thermosonication) was applied at 517.1 mW/mL acoustic energy density, 24 kHz frequency, and 120 μm amplitude in continuous pulse mode for 3 min. The SJ temperature was controlled by circulating water at 25 °C. The maximum temperature during sonication was 56.5 ± 0.3 °C. The processed juice was cooled down to ambient temperature by placing it into ice water.

Pulsed Electric Fields

The PEF process was performed by using a pilot plant scale Powermod™ PEF system (Diversified Technologies Inc., Bedford, MA, USA) equipped with two pairs of co-field electrodes having a diameter of 0.50 cm and a gap distance of 0.65 cm. A freshly prepared SJ (6 L) having an electrical conductivity of 4.1 ± 0.0 mS/cm and an initial temperature of 22.7 °C was circulated through the PEF treatment chamber using a peristaltic pump at a flow rate of 350 mL/min. SJ was subjected to PEF at 35 kV/cm electric field intensity (EFI), 27 μs treatment time, and 155 Hz frequency using monopolar square pulses with 2 μs pulse width. EFI, frequency, and pulse width were adjusted by using the control panel of the modulator cabinet. The maximum temperature reached during PEF processing at the outlet of the treatment chamber was 46 °C. Later on, the juice was pumped through a cooling coil reaching a temperature of 4 °C and transferred to a previously sterilized bottle. All further analyses were carried out at ambient temperature.

Thermal Pasteurization

Conventional thermal pasteurization (T) at 72 °C for 15 s was performed as a reference treatment in a double-walled sample unit connected to a water bath (Viscotherm VT 10). The sample unit containing 400 mL of SJ and a magnetic stir bar was placed on a magnetic stirrer adjusted to 250 rpm. The juice was heated from 23.3 to 72 °C by circulating hot water at 74 °C between the walls of sample unit. Once SJ reached the desired temperature, thermal pasteurization was conducted for 15 s. The treated juice was then transferred into a previously sterilized bottle and immediately cooled down to ambient temperature by placing it into ice water.

Overall Quality Properties and Phytochemical Characteristics

Microbial Quality

The microbial quality of SJ samples was evaluated in terms of total mesophilic aerobic count (TMAC) and yeast-mold (YM) count. The samples were plated on plate count agar (PCA) and potato dextrose agar (PDA) acidified with 10% of tartaric acid, for TMAC and YM count, respectively. The plates were then incubated at 37 °C for 48 h and 25 °C for 5 days for TMAC and YM count, respectively. The number of viable cells was counted, and the results were expressed as log CFU/mL.

Physicochemical Properties

Regarding the physicochemical properties of SJ, pH, total soluble solids (TSS), and titratable acidity were measured. pH measurement was performed by using 10 mL of SJ and a bench top pH meter (Mettler Toledo™ FE20 FiveEasy) at 22 °C. A digital handheld refractometer (PAL-α, Atago CO., LTD.) was used to determine the TSS (°Brix) of the samples. Titratable acidity was determined using 0.1 N NaOH according to the method of AOAC [32] and expressed as g citric acid per 100 mL.

Phytochemical Characteristics

SJ samples were centrifuged at 5000 rpm for 5 min at 4 °C and the supernatant was used for the phytochemical assays. The total phenolic content (TPC) was determined according to the Folin-Ciocalteu method [33, 34]. Results were expressed as mg gallic acid equivalents (GAE)/100 mL.

A pH differential method was used for the determination of total anthocyanin content (TAC) of SJ [35] using two different buffers, i.e., 0.025-M potassium chloride at pH 1.0 and 0.4 M sodium acetate at pH 4.5. In this case, 1 mL of SJ was transferred to glass tubes and added with 9 mL of each buffer. The absorbance values of the mixtures at pH 1 and 4.5 were then measured at 510 and 700 nm. TAC was expressed as mg pelargonidin-3-glucoside/L.

The free-radical scavenging activity (RSA) of SJ was determined by the stable radical 1,1-diphenyl-2-picrylhydrazyl (DPPH) [11]. The SJ supernatant was diluted 20 times by using MeOH-H2O (3:2) solution. A 3.9 mL of methanolic DPPH solution (0.025 g/L) was added to 0.01 mL of diluted supernatant. Then, the mixture was thoroughly shaken and kept in the dark for 30 min. Absorption of the samples was measured at 515 nm by spectrophotometer (HP 8452A, Agilent Technologies, Palo Alto, USA). A control tube was prepared by using 0.01 mL of MeOH-H2O (3:2) solution instead of juice samples. The antioxidant activities of the samples were then calculated as % inhibition:

where A is the absorbance of the methanolic DPPH solution without sample and Asample is the absorbance of the sample after 30 min of incubation with methanolic DPPH solution.

Data Analysis

All tests related to the microbial quality and physicochemical properties were performed in duplicate, while the phytochemical properties were conducted in triplicate. Results were expressed as mean ± standard deviation. The Excel worksheet (Microsoft Office 2010, USA) and Minitab 16 data analysis software (Minitab Inc., State College, PA, USA) were used for data analysis. The means of measured properties of SJ samples were compared by analysis of variance (ANOVA) considering Tukey’s comparison test at 95% of confidence interval. Multivariate data analysis including principal component analysis (PCA) and hierarchical cluster analysis (HCA) was utilized to visualize the data structure and to classify the SJ samples subjected to different treatments with respect to their physicochemical and phytochemical properties. In this context, a data matrix was constructed using the physicochemical and phytochemical properties of SJ as columns and pasteurization technologies as rows and introduced into Minitab 16. Computation of PCA was conducted considering correlation type of matrix and 5 components. The score values, coefficients, and eigenvalues were saved as storage data. Score and loading plots were drawn as PCA output. PC scores of interest were then used as new input data for HCA. The cluster analysis was implemented considering Ward’s linkage as amalgamation method and Euclidean distance as similarity measurement. Thereby, the similarities/dissimilarities among untreated and treated SJ samples were classified in terms of their physicochemical and phytochemical characteristics and plotted on a tree-shaped map (i.e., dendrogram).

Results and Discussion

Microbial Quality

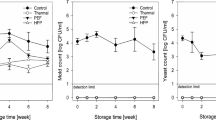

The initial counts of total mesophilic aerobic bacteria (TMAC) and yeasts and molds (YM) in untreated SJ were 3.1 ± 0.1 log CFU/mL and 3.4 ± 0.0 log CFU/mL, respectively. Populations of yeasts are more likely to be predominant in SJ. This could be attributed to the low pH values and high content of sugars of the juice [36]. The natural microbiota of SJ was significantly reduced below 2 log CFU/mL by HPP, ultrasonication, PEF, and thermal pasteurization (Fig. 1). No significant differences were observed for TMAC and YM counts among all treated samples (p > 0.05). HPP reduced TMAC and YM counts to 1.6 ± 0.1 and 1.7 ± 0.0 log CFU/mL, respectively. As reported by Cao et al. [5], more severe conditions such as processing at 600 MPa up to 6 min could result in complete inactivation of TMAC and YM counts when the initial microbial load was less than 4 log CFU/mL in strawberry juices. In another study, HPP at 500 and 600 MPa for 1 min at 20 °C reduced total plate count in carrot juice by approximately 4 log CFU/mL [37].

Ultrasound reduces the microbial load due to acoustic cavitation that can damage biological species by creating local temperature and pressure differences inside the product [38]. However, sonication at 20 °C may not be sufficient to achieve a significant inactivation for the total mesophilic aerobics and yeast-molds [4] which could be attributed to the resistance of microorganisms or presence of bacteria or fungi spores [39]. In general, fungi might show higher resistance compared with bacteria due to the cell wall composition [40]. Thus, sonication at mild temperatures can be considered to increase the lethal effect of the treatment. For instance, natural microbiota of apple juice was reported to be completely inactivated by ultrasound at 60 °C (5 min, 25 kHz, 70% of power) [41]. In the case of this study, ultrasound at 55 °C successfully reduced TMAC and YM counts to 1.7 ± 0.2 log CFU/mL and 1.7 ± 0.1 log CFU/mL, respectively.

PEF reduced TMAC and YM counts to 1.9 ± 0.1 and 1.8 ± 0.2 log CFU/mL, respectively. These findings were in accordance with the results of the study of Elez-Martinez et al. [36], where high-intensity PEF (35 kV/cm for 1000 μs with 4-μs bipolar pulses at 200 Hz) was applied to orange juice having initial total aerobics and yeast-mold count of 3.5 and 2.9 log CFU/mL, respectively. The authors reduced the initial microbial counts below 1 log CFU/mL after PEF processing. Walkling-Ribeiro et al. [42] applied PEF (34 kV/cm, 60 μs) in combination with mild heat (55 °C, 60 s) and reduced natural flora of a fruit smoothie to 1.9 log CFU/mL and 1.1 log CFU/mL in terms of total aerobic and yeast-mold counts, respectively [42].

Thermal pasteurization at 72 °C at 15 s reduced the TMAC and YM counts below 2 log CFU/mL. This finding was in line with previously published studies. Bull et al. [43] reduced the total aerobic bacteria from 7.8 to 4.3 log CFU/mL and YM from 4.8 to 3.0 log CFU/mL in orange juice after applying a thermal treatment at 65 °C for 60 s. Elez-Martinez et al. [36] demonstrated that the initial TMAC and YM counts were reduced below 1 log CFU/mL by applying conventional thermal pasteurization at 90 °C for 1 min. Thermal pasteurization at 72 °C at 71 s was reported to reduce the natural microbiota of lemon-melon juice blend below detection limits [26].

It is relevant to mention that the natural microbiota may show greater resistance than the inoculated targeted microorganism. The identified equivalent processing conditions resulted in at least 5-log reduction of inoculated E. coli in accordance with the FDA’s 5-log inactivation criteria [31], whereas the same conditions resulted in lower inactivation levels in natural microbiota as presented in the current study.

Physicochemical Properties

TSS, pH, and titratable acidity of SJ samples are reported in Table 1. TSS of control sample was 7.9 ± 0.1 °Brix, and no significant difference was observed among all samples. Some studies also reported TSS of SJ as 7.0 ± 0.01 [44] and 7.2 ± 0.2 °Brix [45], where no significant differences were observed after PEF processing of SJ.

pH and acidity are important parameters in food processing to obtain products with consistent and well-defined properties to meet regulatory requirements. Moreover, such parameters affect consumer acceptability towards palatability of the product [46, 47]. In this study, untreated SJ had a pH of 3.5 ± 0.0 while the pH of treated samples varied between 3.45 and 3.48 (Table 1). Even though the numerical values were very close to each other, ultrasound resulted in statistically significant changes in pH compared with control (p < 0.05). This finding contradicted a previous study conducted by Abid et al. [38], where no significant changes were observed in pH values of apple juice after sonication at 20 °C, 25 kHz up to 90 min.

Titratable acidity of untreated SJ was 0.8 ± 0.0 g/100 mL while the acidity of treated samples varied from 0.79 to 0.84 g/100 mL. US-, HPP-, and PEF-treated samples showed no significant differences in the acidity compared with fresh SJ (control). Titratable acidity of thermally pasteurized and sonicated samples were statistically different from each other. Likewise, acidity of SJ used for sonication trials was reported to be 0.73 g/100 mL [14]. Other studies also showed that product acidity and pH were not affected in several fruit juices treated by HPP, US, and PEF [46, 48, 49]. Thus, the results of our study are in accordance with the previously published studies indicating that nonthermal technologies did not cause significant changes in SJ total soluble solids, pH, and acidity.

Phytochemical Characteristics

Total Phenolic Content

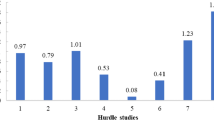

The impact of HPP, ultrasound, PEF, and thermal pasteurization on total phenolics, total anthocyanins, and antioxidant activity is shown in Table 2. Untreated SJ had TPC of 137.8 ± 0.9 mg/100 mL while TPCs of treated samples varied from 132 to 145 mg/100 mL. These values are in the range of those previously reported by Varela-Santos et al. [49]. PEF and HPP treatments resulted in a slight but nonsignificant (p > 0.05) increase in TPC compared with untreated SJ. Thus, PEF- and HPP-treated samples contained the highest amount of phenolics at a concentration of 145 ± 1.5 mg/100 mL and 143.5 ± 2.80 mg/100 mL, respectively. Patras et al. [50] also reported a slight but nonsignificant increase in TPC of strawberry and blackberry purees after HPP treatment at 400 and 500 MPa. Corrales et al. [51] indicated an increase in TPC of grape by-products in the following order: HPP, ultrasonication, and PEF. In the current study, pasteurization by HPP and PEF retained significantly higher amount of TPC in SJ compared with thermal treatment (p < 0.05) (Table 2). The findings indicated that HPP and PEF resulted in 4.16 and 5.20% increase, whereas thermal processing and ultrasound caused 4.06 and 0.16% decrease in TPC of SJ, respectively, in comparison with that of untreated sample. The slight increase in TPC of HPP-treated products could be related to the increased extractability of some of the antioxidant components due to high pressure [52]. In the case of PEF, improving the phenolic content of the juice could be attributed to the increase in the extraction efficiency of intracellular metabolites due to the applied electrical field [53]. Although the initial TPC was slightly reduced by thermal pasteurization (132.2 ± 1.7 mg/100 mL) and ultrasound (137.6 ± 1.9 mg/100 mL), no significant difference was observed among heat-treated, ultrasonicated, and untreated juice samples (p > 0.05). A similar trend was also observed for thermosonicated watermelon juice at varying temperature (25–45 °C), amplitude (24.1–60 μm), and a constant frequency (20 kHz) for 2–10 min, concluding that TPC significantly decreased as the amplitude and processing time increased [54]. Besides, thermal pasteurization at more severe conditions (90 °C for 30 min) caused a considerable amount of loss in TPC of apple juice [46].

Total Anthocyanin Content

TAC of SJ samples varied from 153 to 179 mg/L. The results were higher than those reported for TAC of cloudy strawberry juices (67.8 to 133.5 mg/L) obtained from different kinds of cultivars since varietal and agronomic factors highly affect the anthocyanin content in juices [55]. The stability of anthocyanins in food product depends on many factors such as pH, processing temperature, molecular structure, light, oxygen, enzymes, the presence of other accompanying substances, storage time, and temperature [15, 55]. In this study, HPP and PEF treatments significantly enhanced TAC by 15.24 and 16.90%, respectively, compared with untreated samples (Table 2). This finding was in good agreement with the studies conducted by Odriozola-Serrano et al. [11] and Barba et al. [56]. Likewise, PEF at 35 kV/cm achieved a remarkable increase in anthocyanin content of SJ [11] and blueberry juice [56]. Some other studies also assessed the efficacy of PEF for improving the anthocyanin extraction from the grape pomace and juice [57, 58]. Similar to TPC, the increase in TAC after HPP and PEF can be attributed to the extraction efficiency of these technologies [51, 53]. Thus, HPP enables extraction of anthocyanins and makes them more accessible [59]. PEF, on the other hand, provides enhancement of anthocyanins due to cell membrane permeabilization and subsequent release of intracellular compounds [60].

Anthocyanin content during sonication can be highly affected by the amplitude level, time, and temperature [61]. Ultrasound at 55 °C and 120 μm amplitude increased the SJ initial TAC (153.3 mg/L) by 8.9% after 3 min. However, the increment was not statistically significant (p > 0.05) (Table 2). Similarly, Herceg et al. [62] also indicated negligible effects of sonication on TAC of strawberry and blackberry juice. Tiwari et al. [14] sonicated SJ at varying amplitude levels (40–100%) and time (2–10 min) at a constant frequency of 20 kHz. The authors indicated a slight enhancement (< 1.0%) of anthocyanins in SJ at low amplitude and treatment time while higher amplitude levels and treatment time (> 5 min) caused degradation of anthocyanins (3.2%). Enhancement of TAC by sonication was attributed to the extraction of bound anthocyanins from suspended particles [14], while degradation of anthocyanins was related to the extreme physical conditions occuring within the bubbles during cavitational collapse [63] or oxidation reactions by free radicals formed during sonication [64]. Bhat and Goh [4] also observed an increase in the TAC of SJ after both 15 and 30 min of sonication at 25 kHz and 20 °C. On the opposite, initial concentrations of major anthocyanins in strawberry juice were degraded by 0.7–4.4% after sonication treatments up to 6 min. Nevertheless, the degradation caused by sonication was not as intense as thermal pasteurization (5.3–5.8%) except sonication at 55 °C/9 min (5.8–7.1%) [61].

Thermal processing applies heating at varying temperatures depending on the type of food product and desired shelf life (Patras, Brunton, O’Donnell, & Tiwari, 2010). Even though inter- and intramolecular co-pigmentation with other substances could provide more stability for the anthocyanins towards pH, heat, and light [65], heating has a remarkable influence on anthocyanin stability [66]. Dubrovic et al. [61] applied thermal and ultrasound processes to SJ obtained from seven different cultivars. They observed that thermal pasteurization at 85 °C for 2 min resulted in the lowest levels of anthocyanins in cloudy strawberry juices compared with untreated or sonicated samples. Likewise, heat-treated SJ samples contained the lowest TAC in this study. However, thermal processing at 72 °C for 15 s did not significantly change the TAC of SJ compared with untreated and treated SJ samples (Fig. 2).

Effect of different treatments on the content of total phenolic, total anthocyanin, and radical scavenging activity of strawberry juice (TPC, total phenolic content; TAC, total anthocyanin content; RSA, radical scavenging activity; HPP, high pressure processing; US, ultrasonication; PEF, pulsed electric fields; thermal, thermal treatment)

Radical Scavenging Activity

Antioxidant activities of SJ measured on the basis of DPPH radical are presented in Table 2 as radical scavenging activity (RSA) in percentage. RSA of SJ samples varied from approximately 30 to 40% of DPPH inhibition. This finding is in line with that of previous studies where the antioxidant activity of SJ was reported as 38.5% [11] and 30.42% [4] of DPPH inhibition. The initial antioxidant activity was 33.7 ± 2.7%. Antioxidant activities of HPP (39.98 ± 1.8%)- and PEF (40.3 ± 0.5%)-treated juice samples were found significantly higher than thermally pasteurized SJ (29.9 ± 3.6%) (p < 0.05). Results indicate that HPP and PEF treatments increased RSA by 18.56 and 19.36%, respectively, with respect to untreated SJ. Figure 2 shows the changes in bioactive compounds of SJ immediately after processing. HPP- and PEF-treated SJ showed greater antioxidant activity than thermally pasteurized SJ (p < 0.05), following a similar trend to the TPC results. This similarity can be attributed to the better retention of phenolic compounds by HPP and PEF, thus contributing to RSA of the juice [67, 68]. Likewise, Patras et al. [50] found that HPP and PEF were able to retain significantly higher antioxidant activities in strawberry and blackberry puree compared with thermal pasteurization. The effect of sonication on RSA of SJ samples was also significantly different than those from the thermal pasteurization (p < 0.05). Bhat and Goh [4] reported that sonication (at 25 kHz with a power set at 70%) for 15 and 30 min increased the RSA of SJ to 31.78 and 33.61%, respectively. With respect to heat treatment, the samples showed significantly lower antioxidant activity than sonicated, HPP- and PEF-treated juices (Table 2). The heat treatment was the only process that caused reduction in RSA (11%) compared with control juice. Sánchez-Moreno et al. [20] stated that HPP and PEF did not alter the antioxidant activity of orange juice; however, thermal pasteurization at high temperature (90 °C for 1 min) was reported to cause a significant decrease in antioxidant activity by 6.56%. In the current study, even though heat-treated juice samples showed significantly lower antioxidant activity than sonicated, HPP- and PEF-treated samples, it is noticeable to indicate that thermal pasteurization at 72 °C for 15 s was able to maintain the initial antioxidant activity of untreated SJ with a nonsignificant difference. Thus, reduced pasteurization temperatures can be used in cases where the practitioner needs to preserve bioactive constituents in addition to microbial quality.

Principal Component Analysis

PCA is an unsupervised method that identifies the data pattern, displays the systematic variation in the matrix, and classifies the data based on their similarities and differences [69, 70]. Two-dimensional or three-dimensional projection can be generated for the visual analysis of the samples by locating the significant principal components (PC) on the axes as the factors. Each PC is actually a linear combination of the original responses and obtained in a way that PC1 explains more data variation compared with PC2, and PC2 explains more data variation than the PC3, and so on [24]. In this study, the data were analyzed by PCA to identify the systematic variation and to highlight the relationship between SJ quality attributes and equivalent processing technologies. PCA enabled a simultaneous evaluation of the physicochemical properties and phytochemical characteristics of all SJ samples by reducing the dimension of the data matrix. Figure 3 a shows the distribution of SJ samples in space considering the first two principal components (PC). According to the Kaiser criterion [71], eigenvalues higher than 1 represent a significant factor in PCA evaluation. The first PC had the highest eigenvalues of 2.73 and accounted for 45.5% of the total variation, while the second PC had the eigenvalues of 1.98 and explained 32.9% of the total variation in the current data set. Thus, the total variance explained in PCA procedure was 78.4% (Table 3).

The factor loadings represent the correlation between the tested quality attributes and the components. PC1 was positively correlated to the phytochemical properties, i.e., TPC, TAC, and RSA, that had loadings greater than 0.41 for the PC1. pH and titratable acidity also showed positive correlation; however, TSS was negatively correlated to PC1 with the lowest contribution (− 0.121). With respect to the PC2, the loadings had a different pattern. PC2 showed a positive correlation with the phytochemical properties and pH, while TSS and titratable acidity values were negatively correlated (Table 3). Overall, PC1 was mainly represented by the phytochemical properties while the physicochemical properties made larger contributions to the PC2.

As shown in Fig. 3a, the first PC distinctively separated nonthermal pasteurization technologies from the rest. HPP- and PEF-treated SJ samples are located in the same region, while untreated and thermally pasteurized SJ samples fell close to each other. Locations of the untreated and treated samples were based on the physicochemical and phytochemical properties of the juice. The distribution of SJ quality attributes in space is presented in Fig. 3b. When Fig. 3a and b are evaluated together, it can be seen that the locations of HPP- and PEF-treated SJ samples were far from the control due to their higher levels of total phenolics, total anthocyanins, and antioxidant activity compared with control and the heat-treated ones. Thus, it could be inferred that HPP and PEF treatments were able to enhance the phytochemical characteristics of SJ. Since SJ physicochemical properties before and after treatments were relatively close to each other, the dominating effect for PCA was the phytochemical content which led to a clear separation of the samples. Thus, PCA revealed differentiation of untreated and treated SJ samples based on the phytochemical characteristics and physicochemical properties by explaining 78.5% of total cumulative variance (Table 3). Likewise, PCA has been successfully applied for the estimation of correlations among quality parameters (L*, a*/b*, BI, HMF, viscosity, PME, and PG) of strawberry juice by Aguilo-Aguayo et al. [10]. The authors were able to explain 99.04% of the total variance considering the first two principal components. By means of PCA, Kaya et al. [26] classified lemon-melon juice blends immediately after subjecting them to conventional thermal pasteurization and UV-C light combined with mild heating as well as during subsequent storage up to 30 days. The authors differentiated untreated and treated blends during storage with respect to the physicochemical properties such as pH, acidity, TSS, turbidity, and color parameters by using the first two principal components that explained 51.1% of the total variance.

Hierarchical Cluster Analysis

As a clustering method, HCA explores the organization of samples and their relationships in groups and among groups depicted in a hierarchy [30]. The samples are considered as a cluster which then forms pairs of agglomerated clusters. As an output of HCA, the similarities and differences among the SJ samples treated by HPP, ultrasonication, PEF, and thermal pasteurization were described based on a dendrogram. The plot obtained by considering Ward’s linkage method and Euclidean distance is given in Fig. 4. The cluster analysis verified the results of PCA indicating higher similarity in the quality of HPP- and PEF-treated SJ samples. HPP and PEF technologies were grouped into the same cluster and located far from the untreated juice since these technologies enhanced the SJ phytochemical content immediately after equivalent processing compared with control (Fig. 4). The sonicated samples located closer to the cluster of HPP and PEF treatments on the dendrogram (Fig. 4) show higher similarity to HPP- and PEF-treated juices than thermally pasteurized and untreated SJ. Untreated and thermally treated SJ samples, on the other hand, fell close to each other and located far from the HPP and PEF clusters on the dendrogram indicating less similarity to HPP- and PEF-treated samples in terms of phytochemical characteristics and physicochemical properties. Discrimination of these technologies was achieved due to the effect of HPP and PEF increasing the total phenolics, total anthocyanins, and antioxidant activity compared with either untreated or heat-treated SJ (Table 2, Fig. 4). Kaya et al. [26] also successfully applied HCA for the differentiation of UV-C light–treated, heat-treated, and untreated lemon-melon juice blends during 30 days of refrigerated storage. Thus, HCA was very useful to visualize the clusters of fruit juice samples treated by different technologies based on their physicochemical or phytochemical attributes.

Conclusions

The equivalent processing approach as applied to SJ using HPP, US, and PEF led to a relevant comparison of these technologies in terms of microbial quality, physicochemical properties, and phytochemical characteristics. Natural microbial counts were below 2 log CFU/mL in all processed SJ. Since microbial safety of the final product is the first prerequisite for regulatory acceptance, this result is a promising outcome suggesting that nonthermal pasteurization at the applied conditions was able to reduce the initial microbial population to an acceptable level. The use of multivariate data analysis tools (i.e., principal component analysis and hierarchical cluster analysis) facilitated an effective way for visualization of the data set and interpretation of the results to achieve the understanding of how similar/different products were obtained once the equivalent food processing technologies were applied. PCA and HCA successfully discriminated and classified the pasteurization technologies based on the physicochemical attributes and phytochemical content of the SJ. This study showed that the applied equivalent processes (resulting in an equivalent degree of E. coli inactivation) may lead to different outcomes in terms of SJ physicochemical and phytochemical quality. It is remarkable to indicate that SJ quality attributes were better retained, even enhanced, by HPP and PEF compared with a conventional thermal pasteurization treatment while microbial safety was achieved regardless of the treatment type under the adopted equivalent processing conditions. Finally, multivariate analysis techniques were very useful tools to characterize the strawberry juice samples subjected to equivalent processes in terms of several quality-related parameters. This study also demonstrated that the equivalent processing approach offers excellent opportunities to attain equivalent or even enhanced quality fruit juices in comparison with a given benchmark

References

Giampieri F, Forbes-Hernandez TY, Gasparrini M, Alvarez-Suarez JM, Afrin S, Bompadre S, Quiles JL, Mezzetti B, Battino M (2015) Strawberry as a health promoter: an evidence based review. Food Funct 6(5):1386–1398

da Silva FL, Escribano-Bailon MT, Alonso JJP, Rivas-Gonzalo JC, Santos-Buelga C (2007) Anthocyanin pigments in strawberry. Lwt-Food Science and Technology 40(2):374–382

Giampieri F, Tulipani S, Alvarez-Suarez JM, Quiles JL, Mezzetti B, Battino M (2012) The strawberry: composition, nutritional quality, and impact on human health. Nutrition 28(1):9–19

Bhat R, Goh KM (2017) Sonication treatment convalesce the overall quality of hand-pressed strawberry juice. Food Chem 215:470–476

Cao XM, Liu FX, Wu JH, Liao XJ, Hu XS (2014) Effects of high hydrostatic pressure combined with blanching on microorganisms and quality attributes of cloudy and clear strawberry juices. Int J Food Prop 17(9):1900–1920

Duan J, Zhao Y (2009) Antimicrobial efficiency of essential oil and freeze-thaw treatments against Escherichia coli O157:H7 and Salmonella enterica Ser. Enteritidis in strawberry juice. J Food Sci 74(3):M131–M137

Chen Y, Yu LJ, Rupasinghe HP (2013) Effect of thermal and non-thermal pasteurisation on the microbial inactivation and phenolic degradation in fruit juice: a mini-review. J Sci Food Agric 93(5):981–986

FDA. (2001). Hazard analysis and critical control point (HACCP); procedures for the safe and sanitary processing and importing of juices; final rule, Fed. Regist., vol. 66, pp. 6137–6202, US Food and Drug Administration, Washington, D.C.

Sánchez-Moreno C, De Ancos B, Plaza L, Elez-Martinez P, Cano MP (2009) Nutritional approaches and health-related properties of plant foods processed by high pressure and pulsed electric fields. Crit Rev Food Sci Nutr 49(6):552–576

Aguilo-Aguayo I, Oms-Oliu G, Soliva-Fortuny R, Martin-Belloso O (2009) Changes in quality attributes throughout storage of strawberry juice processed by high-intensity pulsed electric fields or heat treatments. Lwt-Food Science and Technology 42(4):813–818

Odriozola-Serrano I, Soliva-Fortuny R, Martin-Belloso O (2009) Impact of high-intensity pulsed electric fields variables on vitamin C, anthocyanins and antioxidant capacity of strawberry juice. Lwt-Food Science and Technology 42(1):93–100

Tiwari BK, O'Donnell CP, Patras A, Brunton N, Cullen PJ (2009a) Effect of ozone processing on anthocyanins and ascorbic acid degradation of strawberry juice. Food Chem 113(4):1119–1126

Dundar B, Agcam E, Akyildiz A (2019) Optimization of thermosonication conditions for cloudy strawberry nectar with using of critical quality parameters. Food Chem 276:494–502

Tiwari BK, O'Donnell CP, Patras A, Cullen PJ (2008) Anthocyanin and ascorbic acid degradation in sonicated strawberry juice. J Agric Food Chem 56(21):10071–10077

Tiwari BK, O'Donnell CP, Patras A, Brunton N, Cullen PJ (2009b) Stability of anthocyanins and ascorbic acid in sonicated strawberry juice during storage. Eur Food Res Technol 228(5):717–724

Wang J, Wang J, Ye J, Vanga SK, Raghavan V (2019) Influence of high-intensity ultrasound on bioactive compounds of strawberry juice: profiles of ascorbic acid, phenolics, antioxidant activity and microstructure. Food Control 96:128–136

Ayub M, Ullah J, Muhammad A, Zeb A (2010) Evaluation of strawberry juice preserved with chemical preservatives at refrigeration temperature. International Journal of Nutrition and Metabolism 2(2):27–32

Timmermans RAH, Mastwijk HC, Knol JJ, Quataert MCJ, Vervoort L, Van der Plancken I et al (2011) Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice. Part I: impact on overall quality attributes. Innovative Food Sci Emerg Technol 12(3):235–243

Plaza L, Sánchez-Moreno C, De Ancos B, Elez-Martínez P, Martín-Belloso O, Cano MP (2011) Carotenoid and flavanone content during refrigerated storage of orange juice processed by high-pressure, pulsed electric fields and low pasteurization. LWT-Food Science and Technology 44(4):834–839

Sánchez-Moreno C, Plaza L, Elez-Martínez P, De Ancos B, Martín-Belloso O, Cano MP (2005) Impact of high pressure and pulsed electric fields on bioactive compounds and antioxidant activity of orange juice in comparison with traditional thermal processing. J Agric Food Chem 53(11):4403–4409

Sulaiman A, Farid M, Silva FV (2017) Quality stability and sensory attributes of apple juice processed by thermosonication, pulsed electric field and thermal processing. Food Sci Technol Int 23(3):265–276

Vervoort L, Van der Plancken I, Grauwet T, Verlinde P, Matser A, Hendrickx M, Van Loey A (2012) Thermal versus high pressure processing of carrots: a comparative pilot-scale study on equivalent basis. Innovative Food Sci Emerg Technol 15:1–13

Vervoort L, Van der Plancken I, Grauwet T, Timmermans RAH, Mastwijk HC, Matser AM et al (2011) Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice Part II: impact on specific chemical and biochemical quality parameters. Innovative Food Sci Emerg Technol 12(4):466–477

Granato D, Santos JS, Escher GB, Ferreira BL, Maggio RM (2018) Use of principal component analysis (PCA) and hierarchical cluster analysis (HCA) for multivariate association between bioactive compounds and functional properties in foods: a critical perspective. Trends Food Sci Technol 72:83–90

Jandric Z, Cannavan A (2017) An investigative study on differentiation of citrus fruit/fruit juices by UPLC-QToF MS and chemometrics. Food Control 72:173–180

Kaya Z, Yildiz S, Unluturk S (2015) Effect of UV-C irradiation and heat treatment on the shelf life stability of a lemon-melon juice blend: multivariate statistical approach. Innovative Food Sci Emerg Technol 29:230–239

Tian Y, Sun LJ, Tanzeela N, Liang D, Gou XJ, Guo YR (2018) Multivariate statistical analysis of the quality of apple juice to integrate and simplify juice industrial production technologies. Cyta-Journal of Food 16(1):190–198

Wang XQ, Zeng QM, Contreras MD, Wang LJ (2017) Profiling and quantification of phenolic compounds in Camellia seed oils: natural tea polyphenols in vegetable oil. Food Res Int 102:184–194

Ocakoglu D, Tokatli F, Ozen B, Korel F (2009) Distribution of simple phenols, phenolic acids and flavonoids in Turkish monovarietal extra virgin olive oils for two harvest years. Food Chem 113(2):401–410

Lee I, Yang J (2009) Common clustering algorithms. In: Brown SD, Tauler R, Walczak B (eds) Comprehensive chemometrics. Elsevier, Oxford, pp 577–618

Yildiz S, Pokhrel PR, Unluturk S, Barbosa-Canovas GV (2019) Identification of equivalent processing conditions for pasteurization of strawberry juice by high pressure, ultrasound, and pulsed electric fields processing. Innovative Food Sci Emerg Technol 57:102195

AOAC (1984) AOAC official analytical methods. AOAC International, Gaithersburg, MD, USA

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 16(3):144–158

Tezcan F, Gultekin-Ozguven M, Diken T, Ozcelik B, Erim FB (2009) Antioxidant activity and total phenolic, organic acid and sugar content in commercial pomegranate juices. Food Chem 115(3):873–877

Meyers KJ, Watkins CB, Pritts MP, Liu RH (2003) Antioxidant and antiproliferative activities of strawberries. J Agric Food Chem 51(23):6887–6892

Elez-Martinez P, Soliva-Fortuny RC, Martin-Belloso O (2006) Comparative study on shelf life of orange juice processed by high intensity pulsed electric fields or heat treatment. Eur Food Res Technol 222(3–4):321–329

Patterson MF, Mckay AM, Connolly M, Linton M (2012) The effect of high hydrostatic pressure on the microbiological quality and safety of carrot juice during refrigerated storage. Food Microbiol 30(1):205–212

Abid M, Jabbar S, Wu T, Hashim MM, Hu B, Lei SC et al (2013) Effect of ultrasound on different quality parameters of apple juice. Ultrason Sonochem 20(5):1182–1187

Chandrapala J, Oliver C, Kentish S, Ashokkumar M (2012) Ultrasonics in food processing. Ultrason Sonochem 19(5):975–983

Chemat F, Zill-e-Huma, Khan MK (2011) Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason Sonochem 18(4):813–835

Abid M, Jabbar S, Hu B, Hashim MM, Wu T, Lei SC et al (2014) Thermosonication as a potential quality enhancement technique of apple juice. Ultrason Sonochem 21(3):984–990

Walkling-Ribeiro M, Noci F, Cronin DA, Lyng JG, Morgan DJ (2010) Shelf life and sensory attributes of a fruit smoothie-type beverage processed with moderate heat and pulsed electric fields. Lwt-Food Science and Technology 43(7):1067–1073

Bull MK, Zerdin K, Howe E, Goicoechea D, Paramanandhan P, Stockman R et al (2004) The effect of high pressure processing on the microbial, physical and chemical properties of Valencia and Navel orange juice. Innovative Food Sci Emerg Technol 5(2):135–149

Mosqueda-Melgar J, Raybaudi-Massilia RM, Martin-Belloso O (2012) Microbiological shelf life and sensory evaluation of fruit juices treated by high-intensity pulsed electric fields and antimicrobials. Food Bioprod Process 90(C2):205–214

Odriozola-Serrano I, Soliva-Fortuny R, Martin-Belloso O (2008) Phenolic acids, flavonoids, vitamin C and antioxidant capacity of strawberry juices processed by high-intensity pulsed electric fields or heat treatments. Eur Food Res Technol 228(2):239–248. https://doi.org/10.1007/s00217-008-0928-5

Aguillar-Rosas SF, Ballinas-Casarrubias ML, Nevarez-Moorillon GV, Martin-Belloso O, Ortega-Rivas E (2007) Thermal and pulsed electric fields pasteurization of apple juice: effects on physicochemical properties and flavour compounds. J Food Eng 83(1):41–46

Bates, R. P., Morris, J. R., & Crandall, P. G. (2001). General juice manufacture principles Principles and Practices of Small- and Medium-scale Fruit Juice Processing (pp. 37-58): FAO Agricultural Services Bulletin 146

Aadil RM, Zeng XA, Han Z, Sun DW (2013) Effects of ultrasound treatments on quality of grapefruit juice. Food Chem 141(3):3201–3206

Varela-Santos E, Ochoa-Martinez A, Tabilo-Munizaga G, Reyes JE, Perez-Won M, Briones-Labarca V, Morales-Castro J (2012) Effect of high hydrostatic pressure (HHP) processing on physicochemical properties, bioactive compounds and shelf-life of pomegranate juice. Innovative Food Sci Emerg Technol 13:13–22

Patras A, Brunton NP, Da Pieve S, Butler F (2009) Impact of high pressure processing on total antioxidant activity, phenolic, ascorbic acid, anthocyanin content and colour of strawberry and blackberry purees. Innovative Food Sci Emerg Technol 10(3):308–313

Corrales M, Toepfl S, Butz P, Knorr D, Tauscher B (2008) Extraction of anthocyanins from grape by-products assisted by ultrasonics, high hydrostatic pressure or pulsed electric fields: a comparison. Innovative Food Sci Emerg Technol 9(1):85–91

Xi J, Shen DJ, Zhao S, Lu BB, Li Y, Zhang R (2009) Characterization of polyphenols from green tea leaves using a high hydrostatic pressure extraction. Int J Pharm 382(1–2):139–143

Knorr D, Angersbach A, Eshtiaghi MN, Heinz V, Lee DU (2001) Processing concepts based on high intensity electric field pulses. Trends Food Sci Technol 12(3–4):129–135

Rawson A, Tiwari BK, Patras A, Brunton N, Brennan C, Cullen PJ, O'Donnell C (2011) Effect of thermosonication on bioactive compounds in watermelon juice. Food Res Int 44(5):1168–1173

Teleszko M, Nowicka P, Wojdylo A (2016) Effect of cultivar and storage temperature on identification and stability of polyphenols in strawberry cloudy juices. J Food Compos Anal 54:10–19

Barba FJ, Jager H, Meneses N, Esteve MJ, Frigola A, Knorr D (2012) Evaluation of quality changes of blueberry juice during refrigerated storage after high-pressure and pulsed electric fields processing. Innovative Food Sci Emerg Technol 14:18–24

Barba FJ, Brianceau S, Turk M, Boussetta N, Vorobiev E (2015) Effect of alternative physical treatments (ultrasounds, pulsed electric fields, and high-voltage electrical discharges) on selective recovery of bio-compounds from fermented grape pomace. Food Bioprocess Technol 8(5):1139–1148

Leong SY, Burritt DJ, Oey I (2016) Evaluation of the anthocyanin release and health-promoting properties of Pinot Noir grape juices after pulsed electric fields. Food Chem 196:833–841

Cao XM, Zhang Y, Zhang FS, Wang YT, Yi JY, Liao XJ (2011) Effects of high hydrostatic pressure on enzymes, phenolic compounds, anthocyanins, polymeric color and color of strawberry pulps. J Sci Food Agric 91(5):877–885

Soliva-Fortuny R, Balasa A, Knorr D, Martin-Belloso O (2009) Effects of pulsed electric fields on bioactive compounds in foods: a review. Trends Food Sci Technol 20(11–12):544–556

Dubrovic I, Herceg Z, Jambrak AR, Badanjak M, Dragovic-Uzelac V (2011) Effect of high intensity ultrasound and pasteurization on anthocyanin content in strawberry juice. Food Technol Biotechnol 49(2):196–204

Herceg Z, Lelas V, Jambrak AR, Vukušić T, Levaj B (2013) Influence of thermo-sonication on microbiological safety, color and anthocyanins content of strawberry juice. Journal of Hygienic Engineering and Design 4(1):26–37

Suslick KS (1988) Ultrasound: its chemical, physical, and biological effects. VCH Publishers

Portenlanger G, Heusinger H (1992) Chemical-reactions induced by ultrasound and gamma-rays in aqueous-solutions of L-ascorbic-acid. Carbohydr Res 232(2):291–301

Francis FJ (1992) A new group of food colorants. Trends Food Sci Technol 3:27–30

Patras A, Brunton NP, O'Donnell C, Tiwari BK (2010) Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci Technol 21(1):3–11

Gil MI, Tomas-Barberan FA, Hess-Pierce B, Holcroft DM, Kader AA (2000) Antioxidant activity of pomegranate juice and its relationship with phenolic composition and processing. J Agric Food Chem 48(10):4581–4589

Miller NJ, RiceEvans CA (1997) The relative contributions of ascorbic acid and phenolic antioxidants to the total antioxidant activity of orange and apple fruit juices and blackcurrant drink. Food Chem 60(3):331–337

Kramer R (1998) Chemometric techniques for quantitative analysis. Marcel Dekker, New York

Shin EC, Craft BD, Pegg RB, Phillips RD, Eitenmiller RR (2010) Chemometric approach to fatty acid profiles in runner-type peanut cultivars by principal component analysis (PCA). Food Chemistry 119(3):1262–1270

Kaiser HF (1960) The application of electronic computers to factor analysis. Educ Psychol Meas 20(1):141–151

Acknowledgments

Semanur Yildiz expresses her sincere thanks to the staff of the Center for Nonthermal Processing of Food, Biological Systems Engineering Department for the technical assistance and help during her stay as a visiting scholar at Washington State University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yildiz, S., Pokhrel, P.R., Unluturk, S. et al. Changes in Quality Characteristics of Strawberry Juice After Equivalent High Pressure, Ultrasound, and Pulsed Electric Fields Processes. Food Eng Rev 13, 601–612 (2021). https://doi.org/10.1007/s12393-020-09250-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09250-z