Abstract

Even though some research has been carried out on surfactant properties of amaranth protein hydrolysates, their bio-functionality has not been studied yet. In this work amaranth grain Alb 1 and Glob were hydrolyzed (Alb 1H, Glob H) and foams and emulsions at optimal conditions (t, E/S, pH5) were prepared in order to assess techno-functional properties such as foaming (F) and emulsifying (E) (capacity (C) and stability (S)). FC and EC were much better for Glob H than for Alb H. Angiotensin I-converting enzyme-inhibitory activity was higher for Alb 1H (roughly 50 %) than that of Glob H (roughly 30 %). Scavenging of radicals activity (DPPH· or ABTS· + ) of Alb 1H and Glob H, at 2 mg/mL, was similar (approx. 40 %), but lower than Alb 1 (approx. 70 %), which was the best antioxidant. The low reducing power showed that hydrolysates barely donate an electron or hydrogen. Chelating activity on Cu2+ was lower than that exhibited by Fe2+, which was remarkable, approx. 80 % as long as DH% > 10 %, where hydrolysates displayed high solubility (Alb 1H = 85 %, Glob H = 70 %) because of occurrence of 1–10 kDa peptides. Amaranth foams and emulsions prepared with protein hydrolysates have a potential as a nutraceutical food.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amaranth grain was considered as a nutritive food by the Aztec, and Inca civilizations; ever since those ancient times it has been thought of as a very nutritive food. It contains several compounds such as protein, lipid, carbohydrate, vitamin, mineral, dietary fiber, polyphenol, and so on. Several compounds found in amaranth can bring benefits to human health such as decreasing plasma cholesterol levels, stimulating the immune system, exerting an antitumor activity, reducing blood glucose levels and improving conditions of hypertension and anemia. Some compounds may even be chemically modified so that they can exhibit particular techno-functional (physico-chemical) properties as well as bio-functionality (biological activity). By so doing, amaranth may be a source of several nutraceuticals which would exhibit both techno- and bio- functionalities, especially for proteins because various biopeptides occur in their primary structure. Thus amaranth would yield new commodities which might be incorporated to different formulas as food additives and ingredients to prepare functional foods (Rastogi and Shukla 2013).

Among the techno-functional properties observed on amaranth proteins, surfactant properties such as foaming (F) and emulsifiying (E) (capacity (C) and stability (S)) have been studied extensively. Yet knowledge of the techno-functional properties of their hydrolysates is still scarce. Amaranth protein isolates (API) obtained by alkaline extraction resulted in an improvement of solubility, F and E properties at different pH (Cordero-de-los-Santos et al. 2005). Moreover albumin (Alb), globulin (Glob) and glutelin-like were also found to have relatively poor E and F properties when compared to casein and soy protein isolates. (Tömösközi et al. 2008). While amaranth Glob isolates have a higher nutritional value and better physico-chemical properties than soy globulin isolates (Marcone and Kakuda 1999). In turn, Silva-Sánchez et al. (2004) observed that solubility, foaming, water and oil absorption capacities, emulsifying activity and emulsion stability of amaranth albumin showed similar functional properties when compared to egg albumin. Fidantsi and Doxastakis (2001) found that an API, mainly containing Glob, turned out to be a good emulsifier and an effective foaming agent. Differences among results have been partially explained by the mode of preparation of proteins and the methods used to assess the functional properties.

As for amaranth proteins which have been enzymatically hydrolyzed Scilingo et al. (2002) showed that API hydrolyzed with papain improved its solubility, while Condés et al. (2009) observed that by hydrolyzing, API using trypsin, solubility and foaming capacity improved. In turn the API’s EC has been also assessed by using a limited enzymatic hydrolysis (Ventureira et al. 2012). On the other hand, it is well known that hydrolysis of proteins can add value to these starting materials, improving other functional properties such as antioxidant properties, chelation or development of specific biological activities (Dexter and Middelberg 2008). Lately, there have been reports about the assessment of bio-functionality of peptides obtained of amaranth such as: inhibition of angiotensin I-converting enzyme (ACE; Tiengo and Netto 2009; Tovar-Pérez et al. 2009; Vecchi and Añón 2009; Barba de la Rosa et al. 2010; Luna-Suárez et al. 2010; Fritz et al. 2011), antioxidant (Tironi and Añón 2010; Orsini et al. 2011) and inhibition of dipeptidyl peptidase IV (Velarde-Salcedo et al. 2013). Even though there is some work done on surfactant properties of amaranth protein hydrolysates, their bio-functionality still needs to be studied.

Taking into account that peptide composition of protein hydrolysates influences on techno-functional properties and must also affect their bio-functionality, this prompted us to assess the ACE-inhibitory and antioxidant activities of emulsions and foams prepared with albumin 1 (Alb 1) or Glob hydrolysates (Alb 1 H or Glob H), respectively as obtained of amaranth grain (Amaranthus (A.) hypochondriacus L.). These surfactant and bio-functional properties of amaranth protein hydrolysates should be considered in functional foods design.

Materials and methods

Amaranth grain flour

A. hypochondriacus grain was harvested at Tulyehualco, Mexico City, Mexico. The whole grain was milled using a Udy mill (Udy Corporation Fort Collins, Co, USA) until a flour was obtained; then it was extracted 3 times with acetone (5 ml/g) with continuous stirring at room temperature for 16 h; filtered and the residue washed with diethyl ether (400 ml). After drying at room temperature, the defatted flour was sieved through a 60-mesh screen and stored at 5 °C until further analysis. The defatted flour proximate analysis was carried out according to AOAC (2000) standard procedures. The content of components was (g/100 g of defatted flour): water (11.1 ± 0.08), ashes (3.15 ± 0.12), crude protein (%N X 5.87 = 15.43 ± 0.18), ether extract (0.18 ± 0.01), crude fiber (4.91 ± 0.06) and carbohydrates calculated by difference (65.23 ± 0.08). All experiments throughout this study were performed in triplicate.

Extraction and enzymatic hydrolysis of albumin 1 and globulin

Alb 1 and Glob were extracted from amaranth grain. Briefly, defatted flour (50 g) was mixed with 300 ml 0.04 Na2SO4 containing 20 mM β-mercaptoethanol and stirred for 30 min, centrifuged for 20 min at 13,000 g; the supernatant was mixed with 50 %, 70 % and 100 % (sat.) (NH4)2SO4. Alb 1 was separated from Glob when supernatant was dialysed for 24 h against distilled water. These crude proteins were lyophilized and stored at 5 °C until alcalase hydrolysis. The Glob/Alb 1 ratio was 0.22.

Alcalase hydrolysis of proteins was carried out following the method reported by Tovar-Pérez et al. (2009) with some modifications: 600 μl protein solution (5 mg/ml) in 0.5 M phosphate buffer (pH 7.4) was incubated for 5 min at 50 °C; then an alcalase solution in 0.5 M phosphate buffer was added to each test tube to reach 0.4, 0.8 and 1.2 UA/g protein or any other final concentration. The reaction, at the appropriate time, was stopped by adding 100 μl phenylmethylsufonyl fluoride in ethanol (2 mg/ml). Then several Alb 1H or Glob H were obtained at different t and E/S conditions.

Emulsion and foam preparation

In a previous work, Alb 1H and Glob H were obtained using the following conditions: E/S = 0.8 UA/g protein and t = 1–48 h in order to assess their ACE-inhibitory activity (ACE-IA). Afterwards different E/S ratio (0.4, 0.8, 1.2 UA/g protein) and time (1–18 h) were assayed to study the influence on the degree of hydrolysis (DH). All of these hydrolysates were used to observe surfactant properties (F and E) as well as their C and S under different pH (3–9), similarly to the study performed by Marcone and Kakuda (1999). It was found that pH influences significantly on techno-functional properties (surfactant properties) of protein hydrolysates. By so doing, foams and emulsions as obtained of hydrolysates were carried out, at the optimum conditions, using the response surface methodology. The reaction time and E/S ratio were selected as independent variables and the foaming and emulsion (capacity and stability) were chosen as response variables. This design permitted different levels to be tested: 1, 9.5 and 18 h and 1, 8 and 15 h for the reaction time for Alb 1 and Glob, respectively; 0.4, 0.8 and 1.2 UA/g protein for the E/S ratio. These assays were performed following the methods reported by Marcone and Kakuda (1999), and Silva-Sánchez et al. (2004) but at pH 5. Table 1 shows the complete design matrix of the experiment carried out along with the results obtained.

The quadratic polynomial model proposed for each response variable, Y, took the form:

Where: β0 is the vertical intercept; ß1 and β2 are linear coefficients; ß1,1 and β2,2 are quadratic coefficients; β1,2 is the interaction coefficient; and ε denotes the experimental error. The parameters were estimated by multiple linear regression using Stargraphics Plus v. 5.1 (Statistical Graphics, Manugistics, MD, USA). The statistical significance of respective model equation was checked using F-test analysis of variance (unpublished results). The fitness of the models was also expressed by the adjusted coefficient of determination (R2 adj.) which was close to 1. The coefficient indicated that models explained 90.4 %, 95.4 %, 92.9 %, and 96.6 % of the variation in the hydrolysis conditions on the foaming and emulsifying capacity of Alb 1H and Glob H, respectively. Table 2 shows the predicting optimal hydrolysis conditions in which the best foams and emulsions of Alb 1H and Glob H were prepared and they were characterized by means of FC, FS. EC, ES, DH, molecular weight (Mr) distribution, ACE-inhibitory activity and antioxidant activity (AOxA).

Degree of hydrolysis

The DH was conducted according to the method reported by Condés et al. (2009). Free amino groups, released by alcalase hydrolysis, were assessed by their reaction with 2,4,6-trinitrobenzenesulfonic acid (TNBS). L-leucine was used as a standard. The DH was calculated using the equation reported by the same authors.

Determination of molecular weight distribution

Foams and emulsions obtained at the optimal conditions with Alb H and Glob H were analyzed by gel filtration chromatography using a molecular exclusion column. A Sephadex G-50 column (Pharmacia, Uppsala, Sweden) and a Pharmacia LKB FPLC System (Uppsala, Sweden) were used. 200 μl of hydrolyzed proteins (15 mg/ml) dissolved in 32.5 mM K2HPO4-2.6 mM KH2PO4, pH 7.5, which contained 0.4 M NaCl and 20 mM 2-mercaptoethanol, were injected and eluted with the same buffer at 0.2 ml/min. Absorbance at 214 nm was monitored and 0.5 ml fractions were collected. An ultra-low range molecular weight marker (Sigma-Aldrich, St. Louis, Mo., USA), containing triose phosphate isomerase 26.6 kDa; mioglobin 17 kDa; α-lactoalbumin 14.2 kDa; aprotinine 6.5 kDa; insulin 3.5 kDa; bradykinin 1.06 kDa, was ussed. The eluted fractions were classified arbitrarily according to the following ranges of relative Mr: ≥ 10 kDa; 5–9.5 kDa; 1–4.5 kDa; 0.2–1 kDa and 0.075–0.2 kDa.

ACE-inhibitory activity

ACE-IA was analyzed according to the method adapted by Tovar-Pérez et al. (2009). The method is based on the hydrolysis of hippuryl-L-histidyl-L-leucine by ACE to hippurate, which reacts with cyanuric chloride to yield a chromogen quantified by absorbance at 382 nm. The IC50 value was evaluated in order to compare the ACE-IA of foam or emulsion containing amaranth hydrolysates. Captopril was used as control. This value was defined as the hydrolyzate concentration (μg protein/mL) necessary to inhibit 50 % ACE activity.

Antioxidant activity

Scavenging effect on ABTS radical cation

ABTS· + was generated according to Re et al. (1999) with some modifications. The stock solution included 7.4 mM ABTS solution and 2.6 mM potassium persulfate solution. The working solution was then prepared by mixing the two stock solutions in equal quantities and allowing them to react for 12 h at room temperature in the dark. The solution was then diluted by mixing 1 mL ABTS· + solution with 60 mL methanol to obtain an absorbance of 0.7 ± 0.02 units at 734 nm. Fresh ABTS· + solution was prepared for each assay. The absorbance reading was taken at exactly 1 min after initial mixing and up to 6 min in a dark condition. BHA (361 μg/mL) and GSH (0.8 mg/mL) were used as standards. The percentage inhibition of absorbance at 734 nm was calculated as follows:

Where:

- AbsABTS·+ :

-

is the initial absorbance of diluted ABTS· +

- Abssample :

-

is the absorbance of the sample after 6 min of reaction.

DPPH radical scavenging activity

The antioxidant activity of the foams and emulsions prepared with amaranth Alb 1H and Gob H was measured in terms of hydrogen donating or radical scavenging ability according to the procedure described by Bersurder et al. (1998). Briefly: hydrolysates (2 mg/mL) dissolved in 50 μL of distilled water were mixed with 500 μL of 99.5 % ethanol and 125 μL of a DPPH solution (0.2 % in 99.5 % ethanol). The mixtures were incubated for 60 min in the dark at room temperature, and the reduction of DPPH radicals was measured at 517 nm. BHA and GSH were used as standards. Lower absorbance of the reaction mixture indicated higher free radical scavenging activity. DPPH radical scavenging activity was calculated as:

Where:

- Absblank :

-

is the absorbance of the reaction mixture containing distilled water instead of sample.

- Abssample :

-

is the absorbance of the reaction mixture containing the hydrolysate sample.

Reducing power

The reducing power was determined by assessing the ability of the protein hydrolysate to reduce FeCl3 solutions. The Fe2+ reacts with K3[Fe(CN)6] to form KFe2+[Fe3+(CN)6], whose absorbance can be measured at 700 nm (Xie et al. 2008a, b). L-Glutathione reduced (GSH; 0–6.0 mg/mL) was used as control. Increasing absorbance of the reaction mixture indicates the increasing reducing power.

Metal ions chelating activity

Cu2+-chelating activity

The Cu2+-chelating ability was measured as described by Shimada et al. (1992) with some modifications: Briefly, 500 μL of sample were mixed with 2 mL of 10 mM hexamine buffer, containing 10 mM KCl and 3 mM CuSO4, 0.2 mL of 1 mM tetramethyl murexide (TMM), was added to the solution. The mixture was shaken and left for 3 min at room temperature, and the absorbance of the resulting TMM-Cu2+ solution, which formed with free Cu2+, was then measured at 485 nm. TMM showed an absorption maximum at 530 nm. The copper chelating ability was determined by the ratio of 485 nm to 530 nm. Samples having absorbance ratios lower than 3.55 exhibit chelating activity. The lower the values, the better the copper chelating ability. GSH was used as standard.

Fe2+ chelating activity

Fe2+ chelating activity was determined by measuring the formation of the Fe2+-ferrozine complex. The chelating of Fe2+ by the sample was estimated taking 1 mL of sample, then adding 0.1 ml of a solution of 2 mM ferrous chloride and 3.7 mL of deionized water. After 3 min, the reaction was inhibited by adding 5 mM ferrozine (0.2 mL). The mixture was shaken vigorously and left standing at room temperature for 10 min. GSH was used as standard. Absorbance of the resulting solution was measured at 562 nm (Xie et al. 2008a, b). The chelating activity was expressed as:

Statistical analysis

All experimental results were analyzed by one-way analysis of variance (ANOVA). When differences were significant (p < 0.05), mean values were evaluated by Tukey’s multiple comparison test; Stargraphics Plus v. 5.1 (Statistical Graphics, Manugistics, MD, USA) was used for this purpose.

Results and discussion

Characterization of foams and emulsions at optimal conditions of hydrolysis

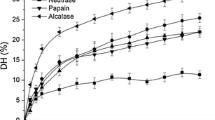

It has been observed that the surfactant properties of proteins can be improved by partial hydrolysis. Nonetheless, hydrolysis products are a complex mixture of peptides, which makes it difficult to establish the optimal conditions for the desired DH to produce foams and emulsions. As far as amaranth is concerned, the conditions to obtain foams and emulsions with hydrolisates of API have already been reported. However, the optimal conditions still have to be carried out. Because of this, the optimal conditions of Alb 1 and Glob hydrolysis needed to prepare the best foams and emulsions at pH 5 are reported in this work. Table 1 shows the hydrolysis conditions for both proteins with alcalase. DH, as expected, depends significatively (p < 0.05) on t and E/S.ratio. Consequently, as t and the E/S ratio increased, the DH was higher. When Alb 1 was hydrolized, the DH% = 62.3 ± 0.5 was reached at 18 h and was more susceptible to hydrolysis than Glob, whose DH of 26.7 ± 0.2 %, was attained after 15 h. In our laboratory we have observed that hydrolysis of amaranth proteins using alcalase takes a long time to achieve an extensive hydrolysis (DH% > 20). A similar feature has also been observed in the research by Ventureira et al. (2012) and Orsini et al. (2011). In this work, by using alcalase, the highest Alb 1 and Glob hydrolysis (DH% = 67 % and 38 %, respectively) was obtained at 24 h. This may be ascribed to the fact that amaranth grain proteins contain an inhibitor I, which belongs to a family of serine proteinase, this inactivates proteins and is referred to as trypsin/subtilisin inhibitor (ATSI; Hejgaard et al. 1994). On the other hand, it has been reported that globulin-P is associated with protein-bodies that do not allow easy access to hydrolytic enzymes. Condés et al. (2009) found that a polypeptide of 45 kDa from 7S globulin was more resistant to the trypsin action and Vecchi and Añón (2009) reported a great resistance to alcalase hydrolysis of hydrophobic B polypeptides of 11S globulin. Therefore, we thought that due to the fact that Glob is more resistant to alcalase hydrolysis, ATSI may occur in a higher concentration in this fraction. The previous characteristic is convenient for a better hydrolysis control with alcalase and trypsin of amaranth proteins since it has been noted that partial hydrolysates with a low degree of hydrolysis (1–10 %) have better surfactant properties relative to the native proteins, mainly foaming and emulsifying properties (Dexter and Middelberg 2008). Tables 1 and 2, show different t and E/S ratio combinations resulted in the setting of the optimal conditions to obtain foams and emulsions of Alb 1 and Glob hydrolysates at pH 5.0, by means of the response surface method (unpublished results). Alb 1 and Glob hydrolysis enhanced the techno-functional properties in comparison to the intact proteins. This was more evident with Glob. Several authors have generally claimed that when DH is lower than 10 %, the FC is improved as it has been observed in protein hydrolysates of soybean, wheat, sun flower and hemp (Yin et al. 2008). Our results, however, coincide with the hydrolysates obtained from quinoa, barley, rice and corn, which showed a DH between 20 and 50 % (Celus et al. 2007). Although DH is relevant, a foam can be formed even if hydrolysis is extensive because it is known that proteins stabilize foam at their pI as long as they do not precipitate. We agree with authors such as Marcone and Kakuda (1999) and Silva-Sánchez et al. (2004) on that pH exerts a great influence on the surfactant properties of amaranth proteins, so this study was carried out at a pH5.0. Yet Condés et al. (2009) realized that API hydrolysis with trypsin (DH between 2 and 7 %) increased solubility notably at pH 8.5, while changes in foaming properties, at the same pH, were less dramatic. Ventureira et al. (2012) assessed the effect of API hydrolysis (DH% = 1.7 and 9.5) on the emulsifying capacity (pH 2.0, 6.3 and 8.0). API contained protein species capable of forming and stabilizing emulsions, mainly at pH 2.0 and, to a lesser extent, at pH 8.0. Alb 1H and Glob H surface hydrophobicity with DH% > 10 was notably higher (p < 0.05; unpublished results) than those of their respective intact proteins at pH 5.0 and 6.0.

The resulting peptide composition of Alb 1 and Glob hydrolisates obtained with alcalase hydrolysis is very complex. Table 3 shows the Mr profile of peptide species found in hydrolisates that were obtained under the optimal hydrolysis conditions in order to produce foams and emulsions. Several research groups have reported that peptides smaller than 2 kDa have poor foam and emulsion-stabilizing properties, whereas others cite size limits as high as 7 kD. Roughly, 50 % of Alb 1 and Glob was not hydrolyzed, thus it seems that peptide fractions of 1–10 kDa determine the surfactant properties of foams and emulsions obtained from Alb 1H and Glob H. Improved surfactant properties in peptides relative to the intact protein may, in part, be a consequence of higher solubility and lower molecular weight. Due to different methods to extract protein from amaranth grain, several hydrolysis conditions as well as the use of several distinct analytical methods to assess the physico-chemical properties of foams and emulsions, it is not easy to compare objectively our findings on techno-functional properties of Alb 1H and Glob H with those obtained by other researchers. Biosurfactants such as those described here have potential as alternatives to synthetic surfactants obtained from petrochemical sources.

ACE-inhibitory activity

Our study did not mean to find the optimal conditions to obtain any biological activity in foams and emulsions of Alb 1 and Glob hydrolysates. What is more, on few occasions foams and emulsions prepared with protein hydrolysates were expected to contain any peptides with bio-functional properties. That is why ACE-inhibitory activity was chosen as high blood pressure is one of the major independent risk factors for myocardial infarction, congestive heart failure, arteriosclerosis, stroke, and end stage renal disease. ACE plays a critical physiological role in regulation of blood pressure by converting angiotensin-I to angiotensin-II, a potent vasoconstrictor. Therefore, the inhibition of ACE activity is a major target in the prevention of hypertension (Tovar-Pérez et al. 2009). Thus, ACE-IA of several hydrolysates of Alb 1 and Glob was assessed as shown on Table 1. Various hydrolysis conditions resulted in different degrees of bioactivity, most likely due to the inherent potency of the generated peptides. However, it is worth noting that nitrogen content in the foams and emulsions did not originate solely from the peptide molecules, but also from intact protein chains (Table 3). Therefore the diversity in the biofunctionality may also be related to their peptide concentrations. Alb 1 and Glob had no ACE-IA, but all of the hydrolysates from Alb 1 and Glob did have this inhibition of the enzyme. Hydrolysates of Alb 1 that developed the greatest inhibitory activity afforded approximately 50 % (DH% = 21–56), whereas those of Glob showed 77.3 ± 0.1 % (DH% = 16.9 ± 0.4). Even though DH was extensive (DH > 10 %), it should be noted that a higher hydrolysis may not always result in a higher ACE-IA. Foams and emulsions prepared with Alb 1H, at the optimal hydrolysis conditions, keep an estimated 50 %, whereas for Glob H, ACE-IA diminishes up to 30 %. There was no direct correlation between DH with ACE-IA when the IC50 values, for both proteins, were compared. Table 2 shows that Glob H is more resistant to hydrolysis and requires a higher peptide concentration (p < 0.05) in order to inhibit the ACE-IA (IC50 = 1,391 μg/mL and 1,887 μg/mL for FC and EC, respectively). In turn, Alb 1H with higher DH needs a lower peptide concentration (IC50 = 925 μg/mL and 985 μg/mL for FC and EC, respectively). The IC50 values of Alb 1H and Glob H were seen in the range from 160.2 μg/mL to 3,770 μg/mL in a variety of different proteins or food enzymatic hydrolisates (Shengqi et al. 2012). It has come to our attention that it is not possible to obtain foams and emulsions with the optimal surfactant capacity, along with the highest ACE-IA, as this depends largely on the peptide composition. However, there are studies in which the optimal hydrolysis conditions have been assessed so as to obtain the highest ACE-IA or antioxidant activity, using response surface method. These hydrolysates, naturally, should not be expected to exhibit any optimal foam or emulsion capacity (Goudarzi et al. 2012). On Table 3, it can be seen that there is a greater peptide concentration (Mr = 0.2 to 1.0 kDa) for Alb 1H (DH% = 34.6 and 42.1 for FC and EC, respectively), thus resulting in a higher ACE-IA, than that which was observed for Glob H at the same Mr range (6 % and 20 % for FC and EC, respectively). It has been reported that peptides with ACE-IA usually display a Mr < 1.5 kDa as they are able to bind to the enzyme active site. There are peptides between 2.2 and 5.5 kDa that inhibit the enzyme by other modes such as acompetitive or non-competitive, though. (Lo and Li-Chan 2005). The finding about the ACE-IA potential of amaranth proteins indicates that these may have a health-promoting potential because their peptides obtained with alcalase are resistant to gastrointestinal hydrolysis. It has been found out that globulin 11S contains two potents biopeptides (IKP and LEP) and the occurrence of two inhibitory tetrapeptides, ALEP and VIKP, was validated by an in vitro ACE inhibition assay that showed IC50=6.32 mM and 175 μM, respectively. Intragastric administration of hydrolysates with DH% = 45 lowered blood pressure of male spontaneously hypertensive rats. Thus, amaranth foams and emulsions prepared with protein hydrolysates have also a potential as a nutraceutical food in preventing cardiovascular diseases.

Antioxidant activity at different degrees of hydrolysis

Scavenging of radicals activity

Owing to the occurrence of polyphenolic compounds and squalene, the antioxidant activity of amaranth has already been evaluated. However, it is well known that proteins also have excellent potential as antioxidant additives in foods because they can inhibit lipid oxidation through multiple pathways including inactivation of reactive oxygen species, scavenging free radicals, chelation of prooxidative transition metals, reduction of hydroperoxides, and alteration of the properties of food systems. DPPH is relatively nitrogen centered free radical that can become a stable diamagnetic molecule. The solution then loses color stoichiometrically depending on the number of electrons taken up. The color changes from purple to yellow after reduction, which can be quantified by decrease in the absorbance at 517 nm (Prathapan et al. 2011; Rani and Padmakumari 2012). The antioxidant activity assessed on foams and emulsions prepared with Alb 1H and Glob H is shown in Table 1 and it was compared with % DPPH scavenging activity of BHA and GSH (91.9 ± 1.7 % and 92.3 ± 0.8 % at 361 μg/mL and 0.8 mg/mL, respectively). A remarkable feature is that all samples at same concentration of 2 mg/mL as obtained of intact Alb 1 exhibit a higher AOxA than its hydrolysates (p < 0.05). When Alb 1 was hidrolyzed, AOxA diminished. In spite of this, the higher the DH, the higher the AOxA. It was only when the highest DH (62.3 %) was displayed that AOxA turned out to be similar to that obtained by native Alb 1. In turn, intact Glob showed a low AOxA (p < 0.05) when compared to their hydrolysates. In the same way as Alb 1, when the protein was hydrolyzed, DH also increased and so did AOxA. At the optimal conditions (Table 2) with Alb 1H (DH% = 34.6 ± 0.5 % and 42.1 ± 0.4 % for FC and EC, respectively), these surfactants were obtained, displaying roughly 70 % of AOxA, at 2 mg/mL, as assessed for Alb 1 and Alb 1H. As for Glob H, foams and emulsions at optimal conditions, AOxA was similar to the one observed for Glob and its Glob H at similar DH. No intact proteins or their hydrolysates in foams or emulsions could reach the high AOxA showed by both of the standards because of the AOxA for foams and emulsions of Alb 1H and Glob H is a consequence of a complex peptide composition (Table 3), which is in turn influenced by the occurrence of different Mr peptide fractions. Antioxidant activity of an API as obtained of A. mantegazzianus has already been studied in Alb, Glob, GlobP and Glutelin fractions as well as their hydrolysates (DH% = 2.4 and 30 %). The intact protein and its hydrolysates afforded AOxA, showing that the higher the hydrolysis with peptide occurrence of <0.5 kDa, the higher the AOxA (Tironi and Añón 2010). When API was hydrolyzed with alcalase it showed a potential capacity to scavenge free radicals after gastrointestinal digestion (Orsini et al. 2011). The production of peptides through hydrolytic reactions seems to be the most promising technique to form proteinaceous antioxidants since peptides have substantially higher antioxidant activity than intact proteins (Elias et al. 2008).

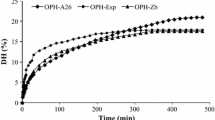

Reducing power and chelating activity

Reducing power assay is usually used to measure the ability of an antioxidant to donate an electron or hydrogen. Presence of reductones causes the reducing properties of the antioxidants, which have been shown to exert antioxidant activity by breaking the free radical chain by donating a hydrogen atom (Prathapan et al. 2011). It has been widely accepted that the higher the absorbance at 700 nm, the greater the reducing power. Many researchers have claimed that there is a direct correlation between AOxA and reducing power (Xie et al. 2008a, b). The reduction power of foams and emulsions, prepared from Alb 1H and Globulin H at optimal conditions, was determined at 700 nm, as shown in Fig. 1. Once the foams or emulsions were prepared at 0.2 % (w/v), this concentration was tested within a range from 1.0 to 6.0 mg/mL to evaluate the reducing power. The reducing power was concentration dependent, but the value increased minimally with higher concentration and reached values between 0.05 and 0.1 of absorbance at 700 nm (at 2 mg/mL). All foams and emulsions showed reducing power lower than the tripeptide GSH that was used as control. Within the concentration range of 1.0–6.0 mg/mL, the reducing power of foams and emulsions was lower than that of GSH (0.6 UA). Our findings were similar to those reported by Carrasco-Castilla et al. (2012) for peptide fractions from phaseolin and bean protein hydrolisates which afforded Abs values between 0.048 and 0.249 at 700 nm. The low reducing power observed in foams and emulsions from Alb H and Glob H revealed that they have a limited capability to donate electrons involved in the antioxidant activity. It is possible that Alb 1H and Glob H tertiary structure may not have an optimal exposure of Tyr, Met, Cys, His, Lys and Trp residues, which would then explain their low reducing power.

As for metal Cu2+ chelating activity, this was only assessed in foams and emulsions of both proteins at optimal conditions (Table 3). The chelating activity on Cu2+ of Alb 1 and Glob (2 mg/mL) was compared with that of GSH that was used as control. Alb 1 and Glob afforded a good chelating activity on Cu2+, which diminished as hydrolysis went on (p < 0.05) with a lower 485 nm/530 nm ratio than that of GSH (1.99 ± 0.15). Only Glob H (t = 2.3 h; E/S = 0.73) kept nearly the same chelating capability on Cu2+ as did intact Glob. It seems that hydrolysis of Alb 1 and Glob restricts its ability to form Cu2+ complexes as higher chelating activity on Cu2+ might be ascribed to the occurrence of peptides >5 kDa that can be mostly found in the prepared emulsion with Glob H (t = 2.3 h; E/S = 0.73). However there is no correlation between Mr of peptides with chelating activity on Cu2+ and this can be observed in bean protein isolates and phaseolin hydrolisates in which peptide fractions > 1 kDa showed Cu2+ chelating activity (40 %–50 %) while peptide fractions < 1 kDa afforded activities ranging from 20 to 80 % (Carrasco-Castilla et al. 2012).

Table 3 shows chelating activity on Fe2+ as measured by the reduction rate of color, which is quantitatively formed by ferrozine with ferrous ions. Foams and emulsions prepared with Alb 1H and Glob H possessed a remarkable chelating activity on Fe2+, which was better than the chelating activity on Cu2+. Extensive hydrolysis (DH% = 16 to 42) of foams and emulsions may favor this activity and it seems that a limited hydrolysis, such as the emulsion prepared from Glob H (DH% = 4.7 ± 0.2 %), displays less Fe2+ chelating activity, as do intact Alb 1 and Glob. On the contrary, a tripeptide such as GSH barely displays this chelating activity (p < 0.05). Ferrous ions can catalize Haber-Weiss reaction and induce superoxide anion to produce more hazardous hydroxyl radicals. Hydroxyl radicals react rapidly with the adjacent biomolecules and induce severe damage. Ferrous ion is one Xie et al. (2008a, b)). This means that a foam or emulsion can neutralize ROS, which would extend shelf life of food products. Cheng et al. (2010) have reported use of potato protein hydrolysates for two objectives: to stabilize (techno-functional property) and to inhibit lipid oxidation (bio-functional property) of oil droplets in soybean oil-in-water emulsions. In some cases peptides have in vitro activity similar to or greater than chemical AOx’s (BHT, BHA). However, there is no standardized methodology to assess in vitro AOx activity and the diversity of methodologies in use hinders direct comparison of data (Bahareh and Amin 2010).

Conclusions

The surfactant properties of amaranth Alb 1 and Glob are improved not only by partial hydrolysis, but also show angiotensin I-converting enzyme-inhibitory and antioxidant activities and could probably have other biological activities which should be assessed. Hence, amaranth foams and emulsions prepared with protein hydrolysates have a potential as a nutraceutical food in prevention of some chronic-degenerative diseases. Furthermore, antioxidant peptides can also be useful in avoiding the generation of reactive oxygen substances, whose occurrence may spoil food, especially because of their chelating activity on metal ion and, by so doing, extend shelf-life of food stuffs.

References

AOAC (2000) Official methods of analysis. Association of Official Analytical Chemists

Bahareh HS, Amin I (2010) Antioxidative peptides from proteins: a review. Peptides 31:1949–1956

Barba de la Rosa AP, Barba-Montoya A, Martínez-Cuevas P, Hernández-Ledesma B, León-Galván MF, De León-Rodríguez A, González C (2010) Tryptic amaranth glutelin digests induce endothelial nitric oxide production through inhibition of ACE: antihypertensive role of amaranth peptides. Nitric Oxide 23:106–111

Bersurder P, Hole M, Smith C (1998) Antioxidants from a heated histidine-glucose model system. I. investigation of the antioxidant role of histidine and isolation of antioxidants by high performance liquid chromatography. JAOCS 75:181–187

Carrasco-Castilla J, Hernández-Alvarez AJ, Jiménez-Martínez C, Jacinto-Hernández C, Alaiz M, Girón-Calle J, Vioque J, Dávila-Ortiz G (2012) Antioxidant and metal chelating activities of peptide fractions from phaseolin and bean protein hydrolysates. Food Chem 135:1789–1795

Celus I, Brijs K, Delcour JA (2007) Enzymatic hydrolysis of Brewer’s spent grain proteins and techno functional properties of resulting hydrolysates. J Agric Food Chem 55:8703–8710

Cheng Y, Xiong YLL, Chen J (2010) Antioxidant and emulsifying properties of potato protein hydrolysate in soybean oil-in-water emulsions. Food Chem 120:101–108. doi:10.1016/j.foodchem.2009.09.077

Condés MC, Scilingo AA, Añón MC (2009) Characterization of amaranth proteins modified by tripsin proteolysis: structural and functional changes. Food Sci Technol 42:963–970

Cordero de los Santos MY, Osuna-Castro JA, Borodanenko A, Paredes-Lòpez O (2005) Physicochemical and functional characterisation of amaranth (Amaranthus hypochondriacus) protein isolates obtained by isoelectric precipitation and micellisation. Food Sci Technol Int 11:269–280. doi:10.1177/1082013205056491

Dexter AF, Middelberg PJ (2008) Peptides as functional surfactants. Ind Eng Chem Res 47:6391–6398

Elias JR, Kellerby SS, Decker EA (2008) Antioxidant activity of proteins and peptides. Crit Rev Food Sci 48:430–441

Fidantsi A, Doxastakis G (2001) Emulsifying and foaming properties of amaranth seed protein isolates. Colloid Surf B 21:119–124. doi:10.1016/S0927-7765(01)00165-5

Fritz M, Vecchi B, Rinaldi G, Añón MC (2011) Amaranth seed protein hydrolysates have in vivo and in vitro antihypertensive activity. Food Chem 126:878–884. doi:10.1016/j.foodchem.2010.11.065

Goudarzi M, Madadlou A, Mousavi ME, Emam-Djomeh Z (2012) Optimized preparation of ACE-inhibitory and antioxidative whey protein hydrolysate using response surface method. Dairy Sci Technol 92:641–653. doi:10.1007/s13594-012-0081-6

Hejgaard J, Dam J, Petersen LC, Bjorn SE (1994) Primary structure and specificity of the major serine proteinase inhibitor of amaranth (Amaranthus caudatus L) seeds. Biochim Biophys Acta 1204:68–74

Lo WMY, Li-Chan ECY (2005) Angiotensin I converting enzyme inhibitory peptides from in vitro pepsin-pancreatin digestion of soy protein. J Agric Food Chem 53:3369–3376

Luna-Suárez S, Medina-Godoy S, Cruz-Hernández A, Paredes-López O (2010) Modification of the amaranth 11S globulin storage protein to produce an inhibitory peptide of the angiotensin I converting enzyme, and its expression in Escherichia coli. J Biotechnol 148:240–247

Marcone MF, Kakuda Y (1999) A comparative study of the functional properties of amaranth and soybean globulin isolates. Food/Nahrung 43:368–373. doi:10.1002/(SICI)1521-3803(19991201)43:6<368::AID-FOOD368>3.0.CO;2-R

Orsini DMC, Tironi VA, Añón MC (2011) Antioxidant activity of amaranth protein or their hydrolysates under simulated gastrointestinal digestión. LWT – Food. Sci Technol 44:1752–1760

Prathapan A, Singh MK, Anusree SS, Kumar DRS, Sundaresan A, Raghu KG (2011) Antiperoxidative, free radical scavenging and metal chelating activities of Boerhaavia diffusa L. J Food Biochem 35:1548–1554

Rani MP, Padmakumari KP (2012) In vitro studies to assess the antidiabetic, antiperoxidative, and radical scavenging potential of Stereospermum colais. Pharm Biol 50:1254–1260

Rastogi A, Shukla S (2013) Amaranth: a new millennium crop of nutraceutical values. Crit Rev Food Sci 53:109–125

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237

Scilingo AA, Molina SE, Martínez EN, Añón MC (2002) Amaranth protein isolates modified by hydrolytic and termal treatments. Relationship between structure and solubility. Food Res Int 35:855–862

Shengqi R, Sun J, Liu Y, Zeng H, Su Y, Yang Y (2012) ACE inhibitory peptides and antioxidant peptides derived from in vitro digestión hydrolysate of hen egg white lysozyme. Food Chem 135:1245–1252

Shimada K, Fujikawa K, Yahara K, Nakamura T (1992) Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. J Agric Food Chem 40:945–948. doi:10.1021/jf00018a005

Silva-Sánchez C, González-Castañeda J, De León-Rodríguez A, Barba de la Rosa AP (2004) Functional and Rheological properties of amaranth albumins extracted from two Mexican varieties. Plant Foods Hum Nutr 59:169–174

Tiengo AM, Netto EM (2009) Characterization and ACE-inhibitory activity of amaranth proteins. J Food Sci 74:H121–H126

Tironi VA, Añón MC (2010) Amaranth proteins as a source of antioxidant peptides: effect of proteolysis. Food Res Int 43:315–322. doi:10.1016/j.foodres.2009.10.001

Tömösközi S, Gyenge L, Pelcéder A, Varga J, Abonyi T, Lásztity R (2008) Functional properties of protein preparations from amaranth seeds in model system. Eur Food Res Technol 226:1343–1348

Tovar-Pérez EG, Guerrero-Legarreta I, Farrés-González A, Soriano-Santos J (2009) Angiotensin I-converting enzyme-inhibitory peptide fractions from albumin 1 and globulin as obtained of amaranth grain. Food Chem 116:437–444. doi:10.1016/j.foodchem.2009.02.062

Vecchi B, Añón MC (2009) ACE inhibitory tetrapeptides from Amaranthus hypochondriacus 11S globulin. Phytochemistry 70:864–870

Velarde-Salcedo AJ, Barrera-Pacheco A, Lara-González S, Montero-Morán GM, Díaz-Gois A, Gonzalez de Mejia E, Barba de la Rosa AP (2013) In vitro inhibition of dipeptidiyl peptidase IV by peptides derived from the hydrolysis of amaranth (Amaranthus hypochondriacus L.) proteins. Food Chem 136:758–764

Ventureira JL, Bolontrade AJ, Speroni F, David-Briand E, Scilingo AA, Ropers MH, Boury F, Añón MC, Anton M (2012) Interfacial and emulsifying properties of amaranth (Amaranthus hypochondriacus) protein isolates under different conditions of pH. LWT – food. Sci Technol 45:1–7

Xie Z, Junrong H, Xu X, Jin Z (2008a) Antioxidant activity of peptides isolated from alfalfa leaf protein hydrolysate. Food Chem 111:370–376. doi:10.1016/j.foodchem.2008.03.078

Xie Z, Hunag J, Xu X, Jin Z (2008b) Antioxidant activity of peptides isolated from alfalfa leaf protein hydrolysate. Food Chem 111:370–376. doi:10.1016/j.foodchem.2008.03.078

Yin S-W, Tang C-H, Cao J-S, Hu E-K, Wen Q-B, Yang X-Q (2008) Effects of limited enzymatic hydrolysis with trypsin on the functional properties of hemp (Cannabis sativa L.) protein isolate. Food Chem 106:1004–1013. doi:10.1016/j.foodchem.2007.07.030

Acknowledgments

This research was supported by Secretaría de Ciencia, Tecnología e Innovación (SECITI) with the project PINV11-13, contract ICYTDF/295/2011. The authors thank Mr. Erick Tovar for his technical support. The authors also thank Prof. Abraham Avendaño-Martínez for translating and reviewing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soriano-Santos, J., Escalona-Buendía, H. Angiotensin I-Converting Enzyme inhibitory and antioxidant activities and surfactant properties of protein hydrolysates as obtained of Amaranthus hypochondriacus L. grain. J Food Sci Technol 52, 2073–2082 (2015). https://doi.org/10.1007/s13197-013-1223-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-1223-4