Abstract

The main aim of the present study was to optimize the hydrolysis conditions of whey protein isolate digested by a protease preparation from Aspergilus oryzae through response surface method (RSM) in order to achieve the maximum angiotensin I-converting enzyme (ACE)-inhibitory activity and antioxidant properties. The effects of hydrolysis conditions including time (2, 13, 24, 35, and 46 h), temperature (40, 45, 50, 55, and 60 °C) and pH (6, 6.5, 7, 7.5, and 8) were investigated on the bioactivity of whey protein hydrolysates. Each process parameter emerged to have a dual effect on bioactivity; that is, increase in all variables promoted bioactive peptide generation through facilitating enzyme access to the primary protein sequence by partial unfolding of the compact globular assemblies of whey proteins. However, prolonged digestion at high temperatures and alkaline pH were concomitant with decreased bioactivity which are attributed to hydrolysate aggregation and splitting of bioactive peptides into biologically inactive counterparts, respectively. Nonetheless, some discrepancies were observed between the trend of ACE-inhibitory activity and that of antioxidant activity changes which was explained in light of their general characteristics. RSM efficiently identified the critical levels of each variable to obtain maximum bioactivity. It was shown that hydrolysate prepared at 56.54 °C and pH 6.04 resulting from digestion for 3.89 h exerted 74% ACE-inhibitory activity, 666.31 μM trolox equivalent/mg antioxidant activity, and 14.03% hydrolysis degree.

摘要:

本文采用响应面法对米曲霉蛋白酶水解乳清分离蛋白的条件进行优化,以取得最大的血管紧张素转化酶(ACE)抑制活性和抗氧化特性。研究了水解时间(2, 13, 24, 35 和46 h)、温度(40, 45, 50. 55 和 60 °C) 和 pH (6, 6.5, 7, 7.5 和8)对乳清蛋白水解物生物活性的影响。每个工艺参数对生物活性会产生双重影响,也就是增加所有变量,通过将致密的球状乳清蛋白部分折叠解开使酶进入一级蛋白序列,从而促进生物活性肽的产生。然而,在高温和碱性pH条件下,延长水解时间会降低水解物的生物活性,主要原因是随着水解时间的延长,水解物聚集以及生物活性肽裂解成没有生物活性的物质。虽然如此,血管紧张素转化酶(ACE)抑制性和抗氧化活性会出现不一致,这由于两者的特性不同。响应面法(RSM)能够有效地确定并获得最大生物活性的每个变量的水平。实验结果表明:在56.54 °C,pH 6.04 水解时间为3.89 h得到的水解物具有74%的血管紧张素转化酶(ACE)抑制活性,等效抗氧化活性为666.31 μM,水解度为14.03%。

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Hydrolysis of proteins to generate biologically active peptides is an area of growing interest. The peptides can be purified and concentrated for designing novel physiologically functional foods (Ven et al. 2002). Milk and soya proteins are among the most commonly employed proteins for hydrolysis (Periago et al. 1998). Whey proteins, which constitute approximately 20% of bovine milk proteins (Kim et al. 2007), are nutritionally superior to most of the other proteins (Sinha et al. 2007) and posses encrypted bioactive peptides within their sequences (Pihlanto-Leppälä 2001). Hydrolysis of the parent protein releases these peptides (Korhonen 2009); among which antihypertensive peptides which show angiotensin I-converting enzyme (ACE)-inhibitory activity are of utmost importance in therapeutic approaches for high blood pressure (Hernández-Ledesma et al. 2011). Since side effects have recently been discovered from the use of conventional antihypertensive drugs (Rho et al. 2009), nonpharmacological alternatives are increasingly sought by health-conscious consumers (Fluegel et al. 2010). Whey proteins, as the safe, abundant, and inexpensive substrates (Smithers 2008) have drawn much attention of researchers for the preparation of ACE-inhibitory activity and antioxidant peptides through microbial fermentation or enzymatic cleavage (Madureira et al. 2010). Optimization of hydrolysis conditions to maximize the ACE-inhibitory and antioxidant activities of protein hydrolysates is a critical and difficult task. Recently, the attitude towards employing response surface method (RSM) for optimizing the hydrolysis conditions of whey proteins to generate bioactive peptides by various proteolytic enzymes has increasingly been promoted. Guo et al. (2009) used RSM to optimize the enzymatic hydrolysis conditions of whey proteins to inhibit ACE as much as possible. Protease type has also been recognized as a determinant factor in the potency of generated bioactive peptides (Samaranayaka and Li-Chen 2011). Flavourzyme is a commercial protease preparation from Aspergillus oryzae which contains both endoprotease and exopeptidase activities (Madadlou et al. 2010). It has been successfully used to generate ACE-inhibitory peptides from casein (Madadlou et al. 2011). Mizuno et al. (2004) showed that flavourzyme was the most potent enzyme among nine different enzyme preparations used to generate the ACE-inhibitory peptides from casein. As well, Peña-Ramos and Xiong (2001) speculated that upon hydrolysis of whey protein isolate (WPI) by seven different proteolytic enzymes, flavourzyme acted as the most efficient preparation in the release of the antioxidant peptides. There is no report in the literature on the preparation of ACE-inhibitory peptides from whey proteins via hydrolysis by flavourzyme. Also, the optimization of whey protein hydrolysis conditions for preparing an antioxidative hydrolysate with A. oryzae protease has not yet been examined. The objective of the present study was therefore to optimize the hydrolysis condition of WPI solution with flavourzyme through an RSM approach in order to achieve the maximum ACE-inhibitory and antioxidant activities. To the best of our knowledge, this study attempted to investigate the hydrolysis process from a different perspective.

2 Materials and methods

2.1 Materials

WPI and flavourzyme were kind gifts of Arla Foods (Aarhus, Denmark) and Novozymes (Kanto/Chiba, Japan), respectively. ACE from rabbit lung, hippuryl-histidyl-leucine (HHL), hippuric acid, ethyl acetate, boric acid, and sodium azide were procured from Sigma-Aldrich (Pool, UK). Myoglobin from horse heart, 6-hydroxy-2,5,7,8 tetramethylchromane-2-carboxylic acid (trolox), 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) (ABTS), phosphate citrate buffer, stop solution, and hydrogen peroxide were supplied by Sigma-Aldrich (St. Louis, MO).

2.2 Whey protein hydrolysis

Sixteen grams of WPI were dissolved in 100 mL distilled water and sodium azide (100 mg.L−1) was added to prevent microbial growth. The solution was stored at 4 °C overnight to allow complete hydration. The flavourzyme was incubated in solution at a constant ratio of 1.5 mg.ml−1 and enzymatic hydrolysis was conducted according to the hydrolysis conditions defined by the experimental design (see Section 2.6). 1N HCl and 5N NaOH were used to adjust protein solution pH to desired values and to maintain it constant throughout the reaction. Hydrolysis was terminated by heating the hydrolysate at 80 °C for 20 min, after which the solution was centrifuged at 20,000×g for 5 min; supernatants were collected and stored at −80 °C till analysis

2.3 ACE-inhibitory activity

The ACE-inhibitory activities of the supernatants were measured according to the method of Cushman and Cheung (1971) modified by Hernandez-Ledesma et al. (2002). The method is based on the liberation of hippuric acid from HHL catalyzed by ACE. First, supernatants were diluted in deionised water to an equal nitrogen concentration (60 mg.mL−1) based on the most dilute sample. Then, 225 μL of a 100-mM.L−1 borate solution (pH 8.3) containing 5 M.L−1 HHL and 300 mM.L−1 NaCl was incubated with 25 μL supernatant at 37 °C for 5 min, after which 50 μL ACE solution (60 mU.mL−1) was added and incubation was continued for 30 min. The reaction was stopped by adding 50 μL 1N HCl. The ACE produced hippuric acid was extracted with 900 μL ethyl acetate and after removal of ethyl acetate by evaporation at 95 °C for 15 min, hippuric acid was redissolved in distilled water and measured spectophotometrically at 228 nm. A control was prepared by substituting supernatant with distilled water. The activity of samples was calculated according to the following equation:

Total protein content of supernatants was determined by Kjeldahl method.

2.4 Antioxidant activity

The antioxidant capacity of WPI hydrolysates was evaluated according to ABTS+ radical scavenging assay. The method is based on formation of ferryl myoglobin radical from metmyoglobin and hydrogen peroxide, which oxidizes the ABTS to produce a radical cation, ABTS·+, a soluble chromogen that is green in color and can be determined spectrophotometrically at 405 nm. Antioxidants suppress the production of the radical cation in a concentration-dependent manner and the color intensity decreases proportionally (Re et al. 1999). The absorbance of solutions was measured by a plate reader spectrophotometer (ELX 80, Universal Microplate Reader, Vermont) at 405 nm. Trolox, a water-soluble analogue of tocopherol, served as a standard or control antioxidant whose standard curve was obtained from absorbance of its different concentrations. Regression analysis revealed a linear model with a slope of 1.69, an intercept of 0.842, and a correlation coefficient of 0.987 which is as follows:

where X is absorbance of each hydrolysate and Y is the antioxidant activity equivalent to millimolar trolox per milligram protein.

2.5 Degree of hydrolysis

The degree of hydrolysis (DH) is defined as the percent ratio of the number of peptide bonds cleaved during the hydrolysis to the total number of peptide bonds in the substrate (Alder-Nissen 1986) and can be calculated from the equations below:

where B is the amount of NaOH added to a substrate to keep the pH constant during the hydrolysis; NB is the normality of NaOH; α is the average degree of dissociation of the α-NH2 groups liberating during hydrolysis; MP is the mass of protein (in grams); h tot is the total number of the peptide bonds in WPI which is assumed to be 8.6 meq.g; and pK is the average dissociation value for the α-amino groups releasing during hydrolysis which is dependent on temperature, peptide chain length, and nature of the terminal amino acid (Guo et al. 2009).

2.6 Experimental design and statistical analysis

The optimum conditions for hydrolyzing WPI by flavourzyme to obtain the most ACE-inhibitory and antioxidant activities was determined based on a statistical design by RSM. The independent variables were temperature, time, and pH value of WPI solutions. Responses sought were ACE-inhibitory activity, antioxidant activity, and DH. A full central composite design (CCD) with three factors at five levels, as coded in Table 1, and α = 0.5 was performed to generate 20 runs. The design consisted of 8 cube points, 6 center points in cubes, 6 axial points, and 0 center points in axial. Cube points are used to estimate the linear and interaction effects while center points provide the possibility of checking for curvature in response and axial points are used to estimate the quadratic terms (Madadlou et al. 2009a, b). Runs generated by CCD design are given in Table 2. A second-order polynomial equation was fitted to the obtained experimental data for responses:

where Y is the response (ACE-inhibitory activity, antioxidant activity, or DH), β 0 , β i , β ii , and β ij are regression coefficients for intercept, linear, quadratic, and interaction coefficients, respectively, and X i and X j are the independent variables. Response surface analysis, mapping of plots, and response optimization were done using Minitab version 15.1.1.0 (Minitab Inc, State College, PA).

3 Results and discussion

Results of ACE-inhibitory activity, antioxidant activity, and DH of treatments are reported in Table 2. Various hydrolysis conditions resulted in different degrees of bioactivity most likely due to the inherent potency of the generated peptides since the nitrogen content of supernatants was equalized prior the analysis. However, it is worthy to note that the nitrogen in the supernatants did not originate solely from the peptide molecules but also from the relatively intact protein chains; therefore the diversity in the bioactivity of WPI hydrolysates may also be slightly related to their peptide concentration.

To investigate the effect of hydrolysis conditions on the bioactivity of whey protein hydrolysates, the results of antioxidant activity, ACE-inhibitory activity, and hydrolysis degree were subjected to statistical analysis (Table 3). The influence of individual variables on responses and model coefficients are detailed in Table 3. As seen in the Table, the quadratic models can be used for monitoring the effects of hydrolysis conditions on the bioactivity and the DH of WPI solutions digested by flavourzyme. R 2, coefficient of determination for checking the fitness of model, were close to 1 which indicated that models explained 90.4%, 95.4%, and 96.6% of the variation in the hydrolysis conditions on the ACE-inhibitory activity, antioxidant activity, and DH of WPI hydrolysate, respectively. The statistical analysis of variance (Table 3) also revealed that lack of fit was not significant for all response surface models. This confirmed the adequacy of model terms to describe the experimental data and a more sophisticated model was not required. As revealed by statistical analysis (Table 3), it was expected that whey protein hydrolysate would exert a stronger bioactivity as hydrolysis time was prolonged, while, an increase in temperature would cause a decrease in bioactivity. Moreover, a strong negative correlation between pH and ACE-inhibitory activity indicated that at a higher pH value, less ACE inhibition took place. Results showed (Tables 2 and 3) that the higher degrees of hydrolysis were associated with prolonged digestion while higher digestion temperatures lowered the hydrolysis degree. It possibly implies that whey protein aggregation at high temperatures retarded the enzyme access to primary sequence of proteins resulting in a decrease in the release of α-amino groups, whereas time supplemented the enzyme for proteolytic reaction. Likewise, the hydrolysis degree was markedly promoted as the pH was elevated (Table 2) beyond the isoelectric point of whey proteins (pI = 5.2). This may be due to the disruption of the compact three-dimensional structure of whey proteins at pH values far from pI (Fuente et al. 2002) which allowed the further digestion of polypeptide chains. It is important to note that the observed phenomena could not best be described through individual effects of process parameters and it should therefore be conducted via investigating their interaction effects. On the basis of statistical analysis results (Table 3), time × temperature variation could drastically influence all three responses (p < 0.01) while the interaction of time × pH had only significant effects on antioxidant activity (p < 0.01) and DH (p < 0.05). Also, bioactivity seems to vary noticeably by the interaction of time × temp within a 0.99 confidence interval.

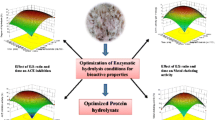

Surface plots were employed to study the interaction effects of process parameters on responses. Model equations are visualized in the form of three-dimensional surface plots which are constructed by plotting the dependent variable on the Z-axis versus any two independent variables while the other variable is set on the middle level. Figure 2 shows the interaction effect of time and temperature on bioactivity of whey protein hydrolysates, the ACE inhibition tended to reach a maximum with increasing time and temperature showing values nearly as high as their central values. However, if this trend continued, protein hydrolysates would dramatically undergo a reduction in inhibitory potency. Nevertheless, antioxidant activity tended to steadily increase with time over the low temperatures; albeit, as the proteolysis time was extended at higher temperatures, the protein hydrolysates experienced a reduction in antioxidative power.

Increase in the hydrolysate bioactivity suggests that the compact globular structure of the whey proteins partially unfolded with the increase in time and temperature. This assisted the enzyme to access the bioactive peptides in the primary sequence of the protein chains (Costa et al. 2007); however, liberated bioactive peptides would be more susceptible to be split into biologically inactive amino acids or peptides if the enzyme reaction was prolonged (Guo et al. 2009). This trend has been observed by many authors; Otte et al. (2007) observed no considerable difference between the ACE-inhibitory activity of milk protein hydrolyzed for either 3 or 24 h and attributed this result to the establishment of a balance between formation and degradation of bioactive peptides by the enzyme. Also, Pihlanto-Leppälä et al. (2000), in an effort to fractionate the whey protein hydrolysates showed that ultrafiltration over 3 kDa membranes would drastically increase the ACE inhibition while a decline in bioactivity was observed when hydrolysates permeated through 1 kDa membranes. Notwithstanding this, since some free amino acids have been found to posses antioxidant activity (Korhonen et al. 1998), it seems that time extension of proteolysis may be favorable to enhance the antioxidant properties of hydrolysates. This has been verified by the results of Ranathunga and Rajapakse (2006) who indicated that hydrolysate fractions ultrafiltered through 1 kDa membranes had higher antioxidant activity compared with 1–3 and 3–5 kDa permeates. These hypotheses can best be supported by the surface plot of the DH (Fig. 1c) showing that prolonged digestion at low temperatures led to a greater DH. If hydrolysis at higher temperature is prolonged, the proteolytic activity of the enzyme might be influenced through structural changes in the enzyme; it is well known that severe heat treatment can denature the protein structure of enzymes (Nelson 2005) resulting in reducing the fit between substrate and the enzyme active site. In addition, it is worth noting that protein aggregation has been found to be accelerated due to intensive heat treatments (Fuente et al. 2002). Accordingly, the bioactive peptides generated may form aggregates with each other (Otte et al. 2007) and denatured proteins leading to the entrapment of peptides within aggregates. The aggregated or encapsulated bioactive peptides could not exert any antioxidant or ACE-inhibitory effects in vitro. This is in line with the findings of Ju and Kilara (1998) who speculated that the proteolysis of whey proteins can induce gelation through the formation of noncovalent bonds between exposed functional groups of hydrolysates. Figure 1c illustrates that the DH increased with the increasing time at high temperatures and subsequently a decline emerged which can be attributed to a reduction in enzyme activity or hydrolysate aggregation at high time-temperature combinations.

The effect of temperature and pH on responses is illustrated in the surface plots (Fig. 2) where proteolysis time was kept constant at 24 h. As seen in this figure, the highest ACE-inhibitory activity lay at the boundary pH values while it went through a minimum at central pH values over the temperature range studied. It could be proposed that at pH values, far from the isoelectric point of whey proteins (pI = 5.2), thermal denaturation was synergistically favored (Fitzsimon et al. 2007). In fact, excess concentrations of OH − caused their penetration into protein structures resulting in the creation of repulsive electrostatic forces among the anionic groups. This in turn disrupted the secondary and tertiary structure of proteins to some extent (Giroux and Britten 2004; Madadlou et al. 2009a, b) exposing the hindered parent sequence of bioactive peptides available for proteolytic reaction of enzyme. Consequently, the relevant maximum ACE-inhibitory activity was reached in shorter times at higher pH values (Fig. 2a). Breakdown in the hydrolysate bioactivity due to the degradation of bioactive peptides to smaller inactive counterparts (Madadlou et al. 2011) occurred earlier with an increase in pH. Moreover, since central pH values appear to be the optimum condition for peptidase activity of the enzyme (Mizuno et al. 2004), a major breakdown of the ACE-inhibitory peptides must have occurred.

It is observed in Fig. 2 that the antioxidant activity increased with the increasing pH of WPI solution at 40 °C. Higher pH values, as stated before, likely promoted the protein dissociation due to the repulsive forces exerted by anionic groups. This improved the generation of antioxidant peptides or amino acids; however, a reduction in the antioxidant activity was observed in the boundary alkali pH values. The latter is legitimized either by the prooxidative effect of certain antioxidant amino acids at high concentrations (Peña-Ramos and Xiong 2001) or modification of the antioxidative potency through the isomerization or destruction of pH-sensitive amino acids under alkali conditions (Korhonen et al. 1998). Counter to ACE-inhibitory activity, protein digests tended to be least potent in confronting oxidant agents by increasing the temperature at all pH values tested (Fig. 2b). It is hypothesized that the condition is more desired for the production of ACE-inhibitory peptides rather than for that of antioxidant counterparts. Therefore, changes in the protein structure induced by enzyme action or hydrolysis condition would presumably cause a decline in the generated or intrinsic antioxidative properties of the intact whey protein. Nevertheless, a further increase in the temperature promoted antioxidant capacity (Fig. 2) possibly due to the release of bioactive peptides or amino acids whose production were more apparent at central pH values likely to be the optimum pH of enzyme reaction (Mizuno et al. 2004).

As expected from the above hypotheses, prolonged proteolysis at pH values far from the isoelectric point of whey proteins promoted the antioxidant activity (Fig. 3). However, boundary alkali conditions induced a reduction in bioactivity and were related to the destruction of antioxidant amino acids or the degradation of bioactive peptides. As shown in Fig. 3, DH was progressively promoted with increasing reaction time at all pH values tested which favored antioxidant activity at central pH values. This does not contradict the fact that intensive thermal treatment may limit the enzyme freedom and consequently reduce the DH through the formation of hydrolysate aggregates or structural changes in the active site of the enzyme, because at times >24 h at 50 °C (Fig. 3b), it is not possibly as strong as temperatures of >50 °C at 24–46 h (Fig. 1c) to induce profound changes in the enzyme or substrate.

Based on these findings, the optimization of hydrolysis conditions was performed to maximize the ACE-inhibitory and antioxidant activities of whey protein hydrolysate alone and in combination. RSM optimization yielded the optimal hydrolysis conditions as listed in Table 4.

As seen in the Table, the desirability of the optimization process is reduced as more responses are included. Therefore, the optimum hydrolysis conditions obtained to generate the maximum ACE-inhibitory activity were subjected to the predicting model of antioxidant activity. This yielded an antioxidant power equivalent to 666.31 μM trolox per mg protein at 14.03% DH. Generally obtaining an optimum peptide size distribution is not a priority in nutraceutical production. Hence, the hydrolysis degree is regarded as a monitoring parameter on inherently or artificially protein originated nutraceutical rather than a character of interest. The performance of models in predicting the optimum conditions was evaluated using one sample t test. The t test was conducted to compare the bioactivity of whey protein hydrolysates prepared under optimized conditions with those predicted by models. Results showed that there is no statistically significant difference between the experimental and estimated values within a 95% confidence interval (Table 4); thereby, the adequacy of the models in predicting the optimum hydrolysis condition was confirmed.

4 Conclusions

Hydrolysis conditions influence the potency and concentration of whey protein-derived bioactive peptides both through changes in the kinetics of the enzyme activity and contributing in the denaturation/aggregation of sensitive whey proteins structures. Our results indicated that intensive heat treatment could reduce the bioactivity expression as a two-edged sword, either by facilitating bioactive peptide cleavage to biologically inactive counterparts through heat-assisted protein unfolding or via hydrolysate flocculation. The latter was argued to be also responsible for the reduction in the intrinsic bioactivity of intact substrate. RSM, as a promising optimization approach, was employed to extract the optimal hydrolysis conditions to achieve a relatively high bioactivity. However, since hydrolysis time tended to remarkably increase as the responses of interest were added, optimum hydrolysis conditions of a 74% ACE-inhibitory activity (time, 3.89 h; temperature, 56.54 °C at pH 6.04) were applied to investigate the antioxidant activity of hydrolysates. Each milligram of hydrolysates prepared using the optimum conditions of ACE-inhibitory activity showed the same antioxidative potency as 663.31 μM trolox and 14.03% DH. Bioactive whey protein hydrolysates as an available, low cost, safe, and healthy nutraceutical have generated much interest for designing novel physiologically functional foods.

References

Alder-Nissen J (1986) Enzymaic hydrolysis of food proteins. Elsevier, New York

Costa EL, Gontijo JAR, Netto FM (2007) Effect of heat and enzymatic treatment on the antihypertensive activity of whey protein hydrolysates. Int Dairy J 17:632–640

Cushman DW, Cheung HS (1971) Spectrophotometric assay and properties of the angiotensin-converting enzyme of rabbit lung. Biochem Pharmacol 20:1637–1648

Fitzsimon SM, Mulvihill DM, Morris ER (2007) Denaturation and aggregation process in thermal gelation. Food Hydrocolloid 21:638–644

Fluegel SM, Shultz TD, Powers JR, Clerk S, Barbosa-Leiker C, Wright BR, Freson TS, Fluegel HL, Minch JD, Schwarzkopf LK, Miller AJ (2010) Whey beverages decrease blood pressure in prehypertensive and hypertensive young men and women. Int Dairy J 20:753–760

Fuente MA, Singh H, Hemar Y (2002) Recent advances in the characterization of heat-induced aggregates and intermediates of whey proteins. Trends Food Sci Tech 13:262–274

Giroux H, Britten M (2004) Heat treatment of whey proteins in the presence of anionic surfactants. Food hydrocolloid 18:685–692

Guo Y, Pan D, Tanokura M (2009) Optimisation of hydrolysis conditions for the production of the angiotensin-І-converting enzyme (ACE) inhibitory peptides from whey protein using response surface methodology. Food Chem 114:328–333

Hernandez-Ledesma B, Recio I, Ramos M, Amigo L (2002) Preparation of ovine and caprine β-lactoglobulin hydrolysates with ACE-inhibitory activity: identification of active peptides from caprine β-lactoglobulin hydrolysed with thermolysin. Int Dairy J 12:805–812

Hernández-Ledesma B, Ramos M, Gómez-Ruiz JA (2011) Bioactive components of ovine and caprine cheese whey. Small Ruminant Res 101:196–204

Ju ZY, Kilara A (1998) Gelation of hydrolysates of a whey protein isolate induced by heat, protease, salts and acid. Int Dairy J 8:303–309

Kim SB, Seo IS, Khan MA, Ki KS, Nam MS, Kim HS (2007) Separation of iron-binding protein from whey through enzymatic hydrolysis. Int Dairy J 17:625–631

Korhonen H (2009) Milk-derived bioactive peptides: from science to application. J Funct Food 1:177–187

Korhonen H, Pihlanto-Lepällä A, Rantamäki P, Tupasela T (1998) Impact of processing on bioactive proteins and peptides. Trend Food Sci Tech 9:307–319

Madadlou A, Emam-Djomeh Z, Mousavi ME, Ehsani M, Javanmard M, Sheehan D (2009a) Response surface optimization of an artificial neural network for predicting the size of re-assembled casein micelles. Comput Electron Agric 68:216–221

Madadlou A, Mousavi ME, Emam-Djomeh Z, Sheehan D, Ehsani M (2009b) Alkaline pH does not disrupt re-assembled casein micelles. Food Chem 116:929–932

Madadlou A, Iacopino D, Sheehan D, Emam-Djomeh Z, Mousavi ME (2010) Enhanced thermal and ultrasonic stability of a fungal protease encapsulated within biomimetically generated silicate nanospheres. BBA-Gen Sub 1800:459–465

Madadlou A, Sheehan D, Emam-Djomeh Z, Mousavi ME (2011) Ultrasound-assisted generation of ACE-inhibitory peptides from casein hydrolyzed with nanoencapsulated protease. J Sci Food Agric 91:2112–2116

Madureira AR, Tavares T, Gomesa AM, Pintado M, Malcata F (2010) Invited review: physiological properties of bioactive peptides obtained from whey proteins. J Dairy Sci 93:437–455

Mizuno S, Nishimura S, Matsuura K, Gotou T, Yamamoto N (2004) Release of short and proline-rich antihypertensive peptides from casein hydrolysate with an Aspergillus oryzae protease. J Dairy Sci 87:3183–3188

Nelson D (2005) Lehninger principles of biochemistry. Amazon, New York

Otte J, Shalabi S, Zakora M, Pripp A, El-Shabrawi S (2007) Angiotensin-converting enzyme inhibitory activity of milk protein hydrolysates: effect of substrate, enzyme and time of hydrolysis. Int Dairy J 17:488–503

Peña-Ramos EA, Xiong YL (2001) Antioxidative activity of whey protein hydrolysates in a liposomal system. J Dairy Sci 84:2577–2583

Periago MJ, Vidal ML, Ros G, Rincón F, Martínez C, López G, Rodrigo J, Martínez I (1998) Influence of enzymatic treatment on the nutritional and functional properties of pea flour. Food Chem 63:71–78

Pihlanto-Leppälä A (2001) Bioactive peptides derived from bovine whey proteins: opioid and ACE-inhibitory peptides. Trends Food Sci Tech 11:347–356

Pihlanto-Leppälä A, Koskinen P, Pillola K, Tupasela T, Korhonen H (2000) Angiotensin-І-converting enzyme inhibitory properties of whey protein digest: concentration and characterisation of active peptides. J Dairy Res 67:53–64

Ranathunga S, Rajapakse KS (2006) Purification and characterization of antioxidative peptide derived from muscle of conger eel (Conger myriaster). Eur Food Res Technol 222:310–315

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorisation assay. Free Radic Biol Med 26:1231–1237

Rho SJ, Lee JS, Chung YI, Kim YW, Lee HG (2009) Purification and identification of an angiotensin І-converting enzyme inhibitory peptide from fermented soybean extract. Process Biochem 44:490–493

Samaranayaka AGP, Li-Chen ECY (2011) Food-derived peptidic antioxidants: a review of their production, assessment, and potential application. J Funct Food 3:229–254

Sinha R, Radha C, Prakash J, Kaulm P (2007) Whey protein hydrolysate: functional properties, nutritional quality and utilization in beverage formulation. Food Chem 101:1484–1491

Smithers GW (2008) Whey and whey proteins—from gutter-to-gold. Int Dairy J 18:695–704

Ven CVD, Gruppen H, Bont BAD, Vorgan GJA (2002) Optimization of the angiotensin converting enzyme inhabitation by whey protein hydrolysates using response surface methodology. Int Dairy J 12:813–820

Acknowledgment

The authors thank the Iran National Scientific Foundation (INSF) for its financial support.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Goudarzi, M., Madadlou, A., Mousavi, M.E. et al. Optimized preparation of ACE-inhibitory and antioxidative whey protein hydrolysate using response surface method. Dairy Sci. & Technol. 92, 641–653 (2012). https://doi.org/10.1007/s13594-012-0081-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13594-012-0081-6