Abstract

Dredging is an essential process in the development, expansion and maintenance of ports, jetties and various water bodies. The process of removing sediments to create or maintain certain water depths inevitably produces large amounts of dredge materials. These displaced materials are generally soils of fine-grained nature, i.e., clay and silt size particles with limited usability due to low strengths and high compressibility. Besides, exposure of the sediments to contamination via the waterways has made disposal of the material a much more regulated and often costly practise, with uncertain risks of future detrimental effects to the dump site’s surrounding environment. It is therefore favourable to explore the reusability of the dredged soils to minimise the need dumping. The present study examines the reuse potential of a dredged marine clay sample treated with induced solidification using binders like cement and coal ash. A series of geo-parametric measurements were performed on the material, including the physical and chemical properties as well as the relevant mechanical responses, i.e., strength and compressibility. The dredged sample was prepared in dry powder form and remoulded with an optimum water content to produce the base soil for solidification. This was necessary to ensure consistency of the water content in the soil for the various batches of specimens prepared for the different tests. It was found that the fundamental characteristics of the material could be effectively improved with the addition of small dosages of binders, as demonstrated by the filling of voids and aggregates formation in the solidified soil. The mechanical properties were also found to improve with prolonged rest period, where over 100 % strength increment and 60 % compressibility reduction were observed after 28 days. Binder-wise, the coal ash was less potent when used on its own and appeared to require activation by the cement for solidification to take place. Indeed, the blend of (3 % cement + 7 % fly ash) and (5 % cement + 5 % fly ash) produced the most significant strength and compressibility improvement, respectively. In short, corresponding results from the various tests conducted provided a better understanding of the solidification mechanism in the dredged marine clay sample for potential implementation on site.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dredging operations essentially remove sediments from the bottom of lakes, rivers, harbours and other water bodies. Riddell (2003) summarised dredging as a continuous process of loosening or dislodging the materials from the bed of a water body, and transporting them to a different site for placement of disposal. Historically dredging as an engineering practise can be traced to the Roman times (Mountford 2000). Today maintenance dredging is widely carried out for the purpose of maintaining or deepening water depths to ensure safe and efficient navigation of vessels. Dredged marine soils (DMS) is the sediment and debris that were removed during the dredging process (Maher and Douglass 2013). In conventional practise, dredged materials which are considered a geowaste, are either discharged into a confined disposal facility inland or disposed of in designated dump sites located in open waters. Nonetheless inland disposal facilities are costly to construct and require long term prevention measures as well as monitoring against leaching and contamination. As for offshore disposal, the marine environment and ecosystem is often subjected to not only short term disruption but long term lingering negative physical, chemical and biological impacts. In this respect, newly established scientific knowledge and construction technology more inclusive of nature conservation have led to dredged materials being increasingly recognised as a valuable source of usable geomaterial. Indeed this shift in mindset and practise advocates reuse of the dredged materials in place of the traditional “dredged-and-disposed” approach. Some examples of application include the creation and restoration of natural habitats, landscaping, construction of road embankments as well as rehabilitation of eroded shorelines and land creation via reclamation (Pebbles and Thorp 2001).

Legacy of a maritime stronghold has made Malaysia, which consists of a peninsular (Peninsular Malaysia) and island (Borneo), a nation whose economy is still very much driven by marine activities. Maintaining the bustling maritime facilities means regular and large volume dredging, resulting in the inevitable large quantities of dredged soils for disposal. These soft, fine-grained dredged soils are generally of poor geotechnical properties, hence commonly classified as “useless materials” destined for disposal (Goldbeck 2008). Normally, DMS are dumped back into the ocean with at least 50 m depth from mean sea level due to their bad odour and risks to human health (Bray and Cohen 2010). For instance, over 3.5 million m3 of dredged materials were recently dislodged from the Lumut waters for the rehabilitation of Lumut Port in Perak, Malaysia to create and maintain navigation channels for recreational, economic and defence purposes. The dredged material, which was constituted mainly by fine-grained clay soil, was disposed at a predetermined offshore disposal site of adequate distance from the local fishing area. Such disposal methods are, however, known to create disturbance to the aquatic ecosystem since the 70′s (Snyder 1976). For instance, Bogers and Gardner (2004) attributed retardation of the healthy growth of seagrass plants, coral reefs and other marine organisms to the significant light attenuation effect by suspended sediments caused by dredging and dumping activities. Cruz-Motta and Collins (2004) studied the sensitivity of soft bottom macrobenthic assemblages towards disturbances associated with the dumping of dredged materials and concluded that the quick response of the seabed-dwelling organisms could negatively affect the overall marine ecosystem.

Clearly poor handling and disposal management of the dredged materials raise various environmental concerns, calling for the formulation of more viable and sustainable solutions to avoid long term adverse effects. An option forward is to reuse the geomaterial within the vicinity of removal, such as subjecting the soil to pre-treatment with suitable solidifying agents of cementitious materials (Makusa 2012). The treatment is necessary to improve the soil’s mechanical properties to meet the acceptable levels expected of good geomaterials for civil engineering applications. For instance, a treated soil which could withstand traffic loading under all weather conditions without deformation is considered as stable (Flaherty 2002), while other structural applications may consist of roadway sub-base, embankments, or as protective mediums and landfills (Maher and Douglass 2013). The present study was conducted to determine the physico-chemical properties of a dredged marine clay sample pre- and post-solidification, and to identify the geo-mechanical characteristics when the material is subjected to loading. Various tests were performed to examine the improved properties of the soil, particularly strength and compressibility, as these are key parameters governing the reusability of the material. Relationships between the relevant parameters established can be used as reference for design and quality control purposes in future field implementations. Note too that the additives used, i.e., cement–fly ash blend, contributes towards a greener solidification agent or binder, where fly ash is a by-product of coal burning otherwise disposed as a waste.

Solidification of weak soils

Solidification with cement

Cement solidification is widely used to improve the performance of poor quality soils, where the enhanced engineering properties are mainly attributed to the cement hardening effect. The two main mechanisms involved in the solidifying process are hydration in the short term and pozzolanic reactions in the long term. The improvement of cement-admixed samples is primarily governed by C3S and C2S, i.e., the production of hydroxide ions (OH− driving the formation of CSH gel which binds the soil particles. Cement hydration produces calcium hydroxide (Ca(OH)2), a very active compound which reacts with cement’s own lime content to be absorbed into the soil particles leading to ion exchange, the ultimate result of which is observed as the soil becoming drier with aggregation of the soil particles (Huat et al. 2011). In general, prolonged time lapse between mixing the soil-binder and subjecting the mixture to external loads, i.e., curing period, would allow greater strength gain to take place. While large dosages of cement addition have been reported to solidify clay soils, the addition of small amounts of cement can effectively modify the properties of a soil. For instance, the common range of cement content for clay treatment recommended by Lee and Ali (2004) is 3–16 % by dry weight of soil, though this is a conservative estimation, taking into account the high variability of soil properties which dominates the solidification outcomes. Besides, there has been continuous innovation in the cement treatment of soft soils, such as induced carbonation of reactive magnesia for accelerated solidification (Mo and Panesar 2012; Cai et al. 2015), early-age preloading for strength enhancement (Nishimura and Abe 2015) as well as fibre addition for improved load resistance (Xiao et al. 2015).

Solidification with fly ash

Fly ash used for soil improvement has the advantage of being greener and more sustainable to a certain extent, as it is but an industrial waste from the coal power plants. This is also attributed to the reduction of cement used when incorporating fly ash in the binder. As a solidifying agent, there are two primary mechanisms by which fly ash could alter the soil to form a stronger and more stable matrix, i.e., (1) increase in particle size by cementation leading to higher internal friction resistance, resulting in overall greater shear strength with reduced plasticity and shrink/swell potential; (2) absorption and chemical binding of moisture to enable more efficacious compaction, hence better strength and load-bearing capacity (Rifal et al. 2009). Ahmed (2014) also reported on the effectiveness of a predominantly fly ash–cement blend in lowering the soil’s plasticity and susceptibility to water infiltration, both desirable features for the subgrade of pavements. Other recent solidification attempts with fly ash include mixing the material with reactive binders like lime (Sharma et al. 2012) and limestone dust (Brooks et al. 2011), as well as reinforcement elements like polypropylene fibres (Senol 2012) with soft soils. Note, however, that the quality of fly ashes is highly dependent on the source material and formation processes.

Effect of curing time on solidification

More significant strength development is generally observed in solidified soils kept for longer curing periods due to the time-dependent pozzolanic reaction. As reported by Kamaruzzaman et al. (1998), cement-treated Singaporean marine clay showed significant improvement of physical properties, unconfined compressive strength and compressibility characteristics with longer curing period. In addition, Rekik and Boutouil (2009) found that the pre-consolidation pressure (or yield stress for solidified soils) of a 10 % cement-treated dredged marine soil sample at its natural water content of 160 % underwent 1.75 times improvement between 7 and 28 days, though an extended 1 month curing resulted in limited further improvement.

Materials

Dredged marine soil

Using a trailing suction hopper dredger, the sediments were removed from the Lumut waters at depths of 8–12 m below the average seawater level. Grab samples were retrieved from the dredger and kept in double-layer plastic sampling bags (Fig. 1a), before being transported back to the laboratory. As the soil was not used for biological assessment, it was kept at average room temperature of 30 °C in its as received form in covered containers. To ensure uniformity of the soil sample in preparing test specimens, the soil was first thoroughly mixed in a kitchen mixer, then left overnight to allow redistribution of the pore water. The soil’s water content was measured to compute the soil’s dry mass and binder dosages. Physical and chemical properties of the dredged marine soil are presented in Tables 1 and 2. Note that to avoid variation in the mixing water content while preparing the base soil for making the mechanical test specimens, the dredged soil sample was first oven-dried and ground to particulate form for mixing. The suitable water content was determined by trial compaction tests at various mixing water content, w mix (Fig. 1b), where the water content of twice the soil’s optimum water content for compaction (i.e., 2 × 24 % = 48 %) was found to produce most workable mixtures.

Cement

Ordinary Portland cement, one of the most widely used binder, is produced by pulverising clinker consisting essentially of hydraulic calcium silicates. Due to the widespread availability of its raw materials, such as limestone and shales, cement remains a relatively low cost solidifying agent for treating soils. In the present study, the cement dosage was proportioned based on soil’s dry mass, i.e., mass of solids. Rather against conventional assumptions, Little and Nair (2009) pointed out that many soils can be effectively treated and improved with considerably low cement dosages. Similar successful solidification of soft clay soils with small amounts of cement were reported by Chan (2012) and Mokhtar and Chan (2012). As such, for the present study, a maximum of 10 % binder content was adopted in the solidification of the dredged soil to avoid wastage and over-treatment.

Fly ash

The fly ash (Class F) used was retrieved from a coal power plant in the local area. Fly ash consists mainly of silt-sized glassy spheres which are calcium oxide, silica and alumina (Rifal et al. 2009). Collected by electrostatic precipitators installed in the coal combustion system to avoid air pollution, the ash particles are generally spherical and non-uniform in size. Class C fly ash is self-cementing when in contact with water, producing cementitious compounds similar to those observed in the hydration of cement, unlike Class F ashes with very limited binding efficacy in the absence of an activator (Halstead). Nonetheless, the properties of fly ash are greatly dependent on the parent material and combustion conditions, i.e., coal formation processes. Typically, Class C fly ash is produced from the burning of sub-bituminous coal and lignite, while its Class F counterpart is the product of anthracite or bituminous coal burning (ASCE 1993). This results in a material which is highly non-homogeneous and inconsistent in terms of physico-chemical characteristics.

Solidified test specimens

As mentioned earlier, the dredged marine clay was remoulded and left standing overnight prior to admixing with cement and/or fly ash. Kept at the soil’s natural water content, binders were added to the remoulded soil and mixed for 10 min. Mixing at the soil’s natural water content was found to be suitable to form a uniform mixture, which plays an important role in the specimen-forming process (Chan 2014). The soil-binder mixture was then transferred to respective moulds to form the test specimens, i.e., 38 mm diameter and 76 mm height split mould for the unconfined compression test specimens, or 75 mm diameter and 20 mm height rings for the oedometer specimens. The mixture was placed in layers and lightly compacted in preparing the specimens. Each layer underwent a two-step compaction process which simulated kneading and pressing simultaneously: tamping with a steel cylindrical rod, followed by tamping with a bent fork-like miniature compaction tool. Note that the seemingly easier single-layer static compaction method was not adopted to avoid producing non-uniform bottom-heavy specimens.

The ends of the specimens were carefully trimmed flat to enable good contact with the end and porous plates of the respective tests. The prepared specimens were carefully wrapped in cling film to prevent surface drying and moisture loss. They were then stored on raised platforms in sealed containers to cure for 3, 7 and 28 days before measurements were made. The containers were partially filled with a diluted bleach solution to prevent fungal growth on the specimens. Table 3 gives a summary of the test specimens examined in this study. Note that all specimens were tested in triplicates to ensure reliability of the measurements made.

Measurements and tests

Characterisation tests

The geotechnical tests were conducted in accordance with prescriptions in BS1377 (1990a, b, c). These include the determination of water content, Atterberg limits, particle size distribution, particle density, organic content, pH and compaction characteristics. Other complementary measurements were X-ray fluorescence (XRF) and X-Ray diffractometry (XRD) analysis as well as field emission scanning electron microscopy (FESEM) for identifying the materials’ chemical composition, mineralogy and nanostructures respectively.

Binder dosages

Referring to Table 3, since this soil falls under the soil group of A-7, 10–16 % of cement in dry weight should be added for effective solidification. For economic reasons and past recommendations for small binder dosages, e.g. Little and Nair (2009), Chan (2012) and Mokhtar and Chan (2012), 10 % of the binder, i.e., cement and/or fly ash, was added to the soil in this study. The specimens were left to cure over a period of 3–28 days for examination of the time effect on the changed properties. Table 3 gives a summary of the test specimens examined in this study.

Bender element (BE) test

Referring to the Bender Element Test System Manual by GDS Instruments Ltd. (2005), the bender element (BE) test was conducted to obtain the P-wave velocity (v p) of the solidified specimens. The test involved placing a pair of transducers, i.e. a transmitter and receiver, on opposite ends of the specimen for measurement. For simplicity and time-saving purposes, the automatic stacking method with manual trigger was adopted as recommended by Mokhtar (2011). Single sinusoidal waves of 5 kHz frequency and ±10 V amplitude were introduced to trigger the transmitter of bender element. The sampling rate per channel was 100,000 samples per second with a 10 ms sampling time. Knowing the tip-to-tip distance of the transmitter and receiver bender elements embedded in the specimens (L), v p was simply calculated by dividing the P-wave travel distance with the propagation or arrival time (t), i.e. v p = L/t. P-waves were used in the present study as preliminary exploration showed poor received signals when S-waves were transmitted through the hardened and stiffened material, making the arrival time impossible to ascertain. Moreover, in a solidified soil with relatively low water content, the risk of P-waves propagating through the water and not the soil’s skeleton is minimised. In addition, to ensure good contact between the bender element and the specimen, a slot was premade at both ends of the specimen prior to curing. Plasticine was inserted in the slot for a good fit of the protruding element during tests. In addition, to ensure consistency in the measurements, the same specimen was kept and tested at the specified curing age. The particular specimen was considered identical to those subjected to the compression test as they were all produced from the same batch of mixture, with careful monitoring of the specimens’ mass per volume of the split mould.

Unconfined compression test (UCT)

The unconfined compression test (UCT) was conducted according to procedures prescribed in BS1377: Part 7: 1990c: 7, where the compressive load was applied at a constant strain rate of 1.5 mm per minute. Caution was also taken to ensure both the top and bottom surfaces of the specimen were smooth and square to avoid bedding error upon loading.

Oedometer test

The oedometer test was carried out by following the procedure prescribed in BS1377: Part 5: 1990b: 3. The ring containing the cured specimen was placed between the two porous plates, one at the top of the specimen and another at the bottom to allow 2-way drainage of the specimen. Incremental vertical stress was applied as follows: 12.5, 25, 50, 100 200, 400 and 800 kPa, with each load being maintained for 24 h.

Results and discussions

Physico-chemical properties

Natural moisture content

The average moisture content of the dredged soil was 166.2 %. A soil with natural moisture content higher than its liquid limit is considered very soft and may have very low shear strength, i.e., undrained shear strength of about 2 kPa (Kayabali and Tufenkci 2010). As the dredged sample’s liquid limit is 95.8 %, it falls under this category of soft, weak material, requiring treatment before any beneficial reuse in engineering applications.

Atterberg limits

For determining the liquid limit (LL), the cone penetration is first plotted against moisture content. Corresponding to the cone penetration of 20 mm is the liquid limit, i.e., 95.8 %. The average value of plastic limit (PL) is 34.4 %. The difference between LL and PL gives the plasticity index (PI), which in this case is 61.4 %. PI indicates the magnitude of the range of moisture content over which the soil remains plastic, where the inherent chemistry of the clay minerals binds the soil particles together. Referring to the Unified Soils Classification System’s plasticity chart, the soil is classified as ‘high plasticity clay’, CH.

Particle size analysis

The particle size distribution curve in Fig. 2 shows that the passing percentage of gravel, sand, silt and clay are 3, 14, 8 and 75 % respectively, indicating the dominance of fine-grained materials in the soil. The ASSHTO classification system puts the soil under the category of ‘clayey soil’, or soil group of A-7-5. The group index (GI) of this soil was calculated to be 58, a parameter needed to evaluate the quality of soil as a highway subgrade material using the ASSHTO system (Das 2010). Soils with GI values nearer to 0 are considered as good soils, while those with GI values larger than 20 represent soils which are unsuitable subgrade materials. As with the present dredged soil sample of GI = 58, solidification is necessary for its reuse as a sound subgrade fill material, for instance.

Particle density analysis

The average particle density of the dredged soil sample is 2.60 Mg/m3. Most sand, silt and clay have particle density which range from 2.60 to 2.80 Mg/m3 (Huat et al. 2004). Apparently the dredged soil’s particle density lies in the lower region of this common range, though many clay particles fall close to particle density of 2.65 Mg/m3. The presence of large amounts of heavy minerals, such as magnetite, limonite and hematite could result in higher particle density values too.

Compaction test

The compaction curve of the dredged soil shown indicates the maximum dry density as 1.49 Mg/m3 or 14.62 kN/m3, with corresponding optimum moisture content of 24 %. As air in the voids of the soil mass cannot be expelled totally by manual compaction alone, approximately 7 % air was entrapped in the compacted soil. This can be observed in Fig. 2, where the peak of the curve coincides with a point between the air void lines of 5 and 10 %.

Loss on ignition (LOI)

The loss on ignition parameter for the sample was found to be 6.33 %, suggesting the presence of a small amount of organic matter in the dredged soil. Soil with organic content greater than 20 % is considered as organic soil in geotechnical engineering. In fact, the mechanical characteristics of soil will no longer apply if the organic content exceeds 20 % (Schülli-Maurer et al. 2007). According to ASTM 2007 C150, ordinary Portland cement should have an LOI value of less than 3 %. On the other hand, the LOI value for Class C and Class F fly ash should be less than 6 %, but the LOI value of Class F fly ash can be as high as 12 % (ASTM 2005 C618). The rather wide range provided is attributed to the variation in sources and properties of fly ashes.

Looking at Fig. 3, all the solidified specimens follow a decreasing trend in LOI throughout the curing period up to a month, except for 3C7FA which shows a slight rise towards the end. As the constituents of the solidified specimens are relatively complex, i.e., soil, cement and fly ash and cementitious products from the chemical reactions, the LOI values barely represent the actual amount of organic matter present. In addition, it is very likely that the cementitous products coated and entrapped the organic matter contained in the respective raw materials, resulting in the weight loss measured in the LOI test as time progressed. Longer curing periods allow more hydration and pozzolanic reactions to take place, hence the less organic matter available or ‘exposed’ for combustion in the furnace.

pH

The average pH of the natural dredged soil sample is 8.22, making it a moderately alkaline material. Alkality is often associated with low organic content in the soil (Schülli-Maurer et al. 2007). Figure 4 shows the pH values of the solidified specimens over 1-month curing period. It appears that a combination of 3 % cement and 7 % FA is the minimum before the pH trend starts to decline with time. Generally, the hydration of cement leads to pH increment of the pore water, caused by the dissociation of the hydrated cement (Lee and Faisal 2004). As the soil is naturally alkaline, the addition of fly ash actually caused a reduction in the pH of the mixture, as demonstrated by the dip in specimen 10FA. According to Zhang et al. (2000), the lower the pH is, the higher the degree of reaction in fly ash is in the mixture. This could explain the pH trend observed when fly ash content increased while the cement dosage decreased, where pozzolanic reaction of the fly ash caused the simultaneous occurrence of two mechanisms: (1) decline of the alkality of the pore water solution, and (2) consumption of calcium hydroxide (CH) from the hydration of cement. The exception of 5C5FA and 7C3FA may be due to non-uniform mixing of the materials, leading to formation of sporadic and localised pockets of incomplete fly ash reaction within the specimens.

X-ray fluorescence (XRF) and X-ray diffractometry (XRD) analyses

Silicon (Si) constitutes the largest share of element in the dredged soil, i.e., 63.3–63.5, followed by aluminium (Al) at 17.0–17.2 %. The high percentage of Si is attributed to the presence of quartz in dredged soil, as supported by the XRD analysis. It is not surprising to find abundant of quartz in geomaterials as it is the most common mineral in earth. Indeed, it is a significant mineral for all igneous, sedimentary and metamorphic rocks, which constitute the parent material of most soils. For specimen 10C, as illustrated in Fig. 5a, a marked increase in the CaO content of the solidified specimen was recorded in comparison with the original soil (CaO = 3.33 %).

On the other hand, the addition of FA alone (i.e., specimen 10FA) did not result in much change of the CaO content, as can be seen in Fig. 5b. This is understandable as the Class F fly ash itself contains negligible amount of CaO. This little amount of free CaO could cause dilution effect and reduce the quantity of cementitious gel formed. As a consequence, strength degradation could take place in the solidified soil. Overall, judging from Fig. 5c–e, other elements in the mixture remained largely unchanged, regardless of the variations in the binder ratio and curing period. This is suggestive of the limited solidification impact of small dosages of binder in these soft dredged soils, and that prolonged curing could not overcome the unsatisfactory solidification outcome from using small quantities of binder. Figure 6 shows the relationship between CaO content and fly ash dosage in the solidified specimens. Note the almost linear declining trend of the plot, irrespective of the curing period. This highlights the nominal effect of Class F fly ash in the solidification of the dredged soil. Cement treatment typically leads to flocculation of the fractions in soils, consequently increasing the particle size and modifying the plasticity of the original soil (Rekik and Boutouil 2009). This grain size changing was attributed to colloidal reactions observed as decreased plasticity accompanied by improved workability of the solidified soil (Bose 2012).

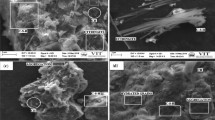

Field emission scanning electron microscopy (FESEM)

The FESEM images of the specimens captured with magnification factor 5000 are shown in Fig. 7. Figure 7a shows the original dredged soil as a poorly graded material with large pores. An unidentified object was found in the dredged soil (boxed in dashed lines), probably debris of foreign origin in the sample. Considering that the soil was collected from a near-shore seabed, exposure to influx of solid wastes from river discharge is not unlikely. In Fig. 7a, b, cementation was evident where the pores were significantly filled. Note that the particles size grew too as cementation bound the particles into larger aggregates, thus encroaching on the boundaries of the voids and eventually filling them. Cement treatment typically results in the flocculation of fractions in soils, which increases the relative particle size and consequently changing the soil’s plasticity (Rekik and Boutouil 2009). In addition, Lin et al. (2013) attributed the reduction of plasticity in fly ash admixed soils to the combined effects of flocculation and iron oxide coating, manifested in subdued water retention capacity of the solidified soils. This further demonstrates the efficacy of adding fly ash in cement treatment of the soil.

In Fig. 7c, observe that the soil’s microstructure was changed significantly with prolonged curing time, where the 28-day specimen shows remarkably less voids and larger lumps of particles. Nonetheless the manifested changes in the geotechnical properties and textural composition due to cementation are affected by other factors too, such as the particle size, mineralogy, water content and chemical properties of the binder. The binder type effect can be observed in Fig. 7d, e, which depict the 28-day old specimens of 10C and 10FA respectively. 10 % of cement apparently induced greater binding effect in the soil, producing larger aggregates and smaller pores (Fig. 7d), while 10 % of fly ash brought forth a lesser effect. This can be accounted for by the higher percentage of CaO in cement compared to fly ash (see Fig. 7d, e), where CaO is the main compound for the cementitious reaction.

Geo-mechanical properties

Unconfined compressive strength (q u)

As expected, solidification with cement alone produced the most significant strength gain. It is, however, not the aim of the present study to ascertain highest qu attainable with solidification, rather the focus is on identifying the efficacy of cement-FA blend for a more economical and ‘greener’ treatment of the poorly dredged soils. Hence plots for the cement-treated only specimen with qu ranging between 300 and 700 kPa over the 28-day curing period were not included in Figs. 8 and 9. The stress–strain curves derived from the unconfined compression tests are compiled in Fig. 8 according to the curing period, i.e., 3, 7 and 28 days. In general, it can be observed that longer periods resulted in greater strength gain in all specimens. By comparing the highest strength attained over the 28-day curing period, a satisfactory 100 % strength improvement (from about 70–140 kPa) was registered. However, it is also apparent that fly ash added to the soil on its own was ineffective as a strength enhancer, with negligible change in the strength measured over the 4-week period. This could be attributed to the excessive amount of impurities in the fly ash which hinders cement hydration and solidification.

On the other hand, fly ash clearly needed the presence of cement to enable the solidification mechanism to be initiated. Nonetheless higher dosages of cement in the cement–fly ash mixture were not found to produce more significant strength gain, where the highest strength values were achieved by the 3C7FA specimens. Indeed, with prolonged curing, specimens with 30 % fly ash as binder substitution showed almost no changes in strength, hovering at approximately 70–80 kPa. The 5C5FA specimens, on the other hand, demonstrated a steady climb in strength from about 50 to 100 kPa in 28 days. These findings indicate that while fly ash can only produce meaningful solidification with cement present, it does not require an excessive amount of cement for greater strength gain. This is perhaps counter-intuitive as it is commonly perceived that cement, as a ubiquitous soil-binder, would have an overwhelming effect on the overall solidification results when partnered with fly ash.

Figure 9 shows the q u—curing period plots for the solidified specimens. Albeit the absence of dramatic strength improvement, the strength recorded of the solidified specimens were within the acceptable range for reuse as construction geomaterials, such as stipulated in the minimum requirements by Japan’s Ministry of Land, Infrastructure and Transport (2005). Excluding specimen 10FA which showed negligible strength improvement with time, the overall strength of the specimens appears to grow in parallel with higher fly ash content. Considering the presence of fine particles and unburned carbon in the fly ash has been reported to negatively affect the strength when large dosages of fly ash are added to the soil (Wang et al. 2011), the present results seem to suggest otherwise. Zentar et al. (2012) attributed the strength improvement to the formation of gelatinous cementing compounds, which effectively bridge the voids in the soil spaces leading to bonding of the soil particles.

Figure 7b, c further reveal the expedient effect of solidification, where FESEM (field emission scanning electron microscopy) images of specimen 5C5FA were captured periodically. At 5000× magnification, large voids visible at the early-age (3-day) were observed to be occupied by the cementing compounds derived from cement–fly ash by the time the specimen reached 28 days old. There are marked with thick-line boxes in the 3-day micrograph of Fig. 7b, where the apparent changes can be clearly seen in Fig. 7c a little over 3 weeks later. In addition, note the transformation of the soil’s microstructure with prolonged curing time, where the 28-day specimen showed larger adjoined lumps of solids. Notwithstanding the uncertainty of the extent to which fly ash contributed to the gelatinous filler formation, they almost certainly helped to strengthen and stiffen the originally weak soil structure by formation of solid mass. Referring to works by Vara Prasad and Sharma (2014), Vizcarra et al. (2014) and Lopes et al. (2012), the California Bearing Ratio as well as resilient modulus, both indicators of load-bearing capacity and hence strength, were significantly raised in compacted soft soils admixed with cement–fly ash.

P-wave velocity (vp)

The determination of P-wave arrival time from the waves captured with the BE measurement system were performed with the following techniques: peak-to-peak (p–p), trough-to-trough (t–t) and cross-correlation (cr), as illustrated in Fig. 10. By performing all three methods, the arrival time could be cross-checked to minimise errors. The resulting P-wave velocities calculated using the arrival time from the three techniques are denoted as v p–p, v t–t and v p(cr) respectively. However, upon cross-checking, the P wave arrival time derived from all three techniques were found to be very similar. Accordingly, for convenience, v p derived from t p–p was used for subsequent analysis and discussions.

Referring to the v p-curing period plots in Fig. 11, the general evolution pattern corroborated with that of the strength’s (q u) evolvement with time (Fig. 9). Note that it is for the same reason as the strength test results that the 10C data were excluded from the plot. Specimen 10FA was found to have lowest velocities, followed by 5C5FA, 7C3FA and 3C7FA with consistently rising v p though. Observe that specimen 5C5FA initially had a lower vp compared to 10FA, but this was eventually exceeded at around 18 days. Considering that the plot of specimen 7C3FA lies above that of 5C5FA, it shows apparent incongruence of the relationship between strength increase and fly ash content in the solidified specimens. Nevertheless it was the specimen with the least cement content, i.e., 3C7FA, which attained the highest v p. In comparison, the strength and stiffness of the solidified specimens do match up to a certain extent, despite v p being an indicator of stiffness at small strain levels (i.e., strain not exceeding 0.001 %).

The discrepancies mentioned earlier can plausibly be attributed to the adverse effect of poorly waveforms captured in the BE tests. Masking of the actual arrival time is indeed commonly encountered in less than satisfactory waveforms received, particularly when visual picking method is adopted for the arrival time determination. Unsatisfactory waveforms can be caused by several factors, such as loose contact between the bender element and specimen, poor BE-specimen interface at uneven end surfaces of the specimen, and signal interference by external electromagnetic elements (Chan 2012). On the other note, prolonged curing was not observed to result in significant increase in v p as observed in the q u plots. This is especially true for specimen 3C7FA. On the other hand, body wave velocities have been known to increase with curing of solidified soil specimens due to the stiffening matrix of the material, accompanied by an increase in the shear strength of treated soil (e.g. Ahnberg and Holmen 2011; Barrett et al. 2011; Porbaha et al. 2005). The increased wave velocity is sometimes not as distinct as the dramatic rise observed in the strength though. For instance, taking into account the largely unchanged velocities in the pre-yield zone of an instrumented oedometer test of solidified clay (Hird and Chan 2008), it would seem that the small strain stiffness does not undergo as significant change as strength with solidification.

Correlation between P-wave velocity (v p) and unconfined compressive strength (q u)

Figure 12 shows the relationship between v p and q u, where a a linear correlation was derived for the data set, i.e., v p = 0.92q u. The rather dispersed nature of the data points needs to be addressed to make the chart more viable. Hence an upper and lower limit boundaries were included in the same figure, which were drawn parallel to the original regression line, i.e., v p = 0.92q u. The boundaries help give an estimate of the corresponding q u with only the v p measurement taken. On closer inspection, the strength and stiffness as represented by v p recorded are relatively low regardless of the solidification introduced. This suggests inherent experimental limitations, particularly on the specimen’s preparation and formation procedure. Take the unconfined compression test for instance, which essentially makes an indirect measurement of the compressive strength by crushing the specimen. The measured gradual displacement with loading can easily be marred by imperfections of the specimen, such as uneven ends and isolated weak zones within the specimen undetectable visually prior to tests. The possible errors notwithstanding, the relationship between v p and q u, serves as a promising tool for quick estimation of the improved strength of solidified dredged marine soil without repeated tests on multiple specimens. For example, referring to Fig. 12, P-wave velocity = 100 m/s corresponds with an estimated strength of 25 kPa ≤ q u ≤ 185 kPa, and taking the average at approximately 105 kPa. Taking in account the irregularity and non-uniformity often encountered in field implementation of soil mixing, the seemingly large margins may yet prove the estimated strength range to be acceptable for design mix purposes.

Correlation between strength and stiffness

The Young’s modulus (E) was also derived from the stress–strain curves (Fig. 8) to ascertain the large strain stiffness changes with solidification. E i was defined from the initial rise of the curve, while E P was taken from origin to the peak of the curve. The relationship between E and q u (28-day) are shown in Fig. 13. Note that E i is almost double that of E P , suggesting a steep initial rise of the stress–strain curve before the peak strength was reached (see Fig. 8). This corresponds with the rather flat part of the curve approaching the peak, highlighting the gradual deformation sustained by the specimens before yielding under compression. It is probable that fly ash somehow contributed to a more ductile yielding mechanism in the specimens.

Compressibility

Figure 14 shows the settlement curves for all specimens, as recorded in the oedometer tests. Referring to the low-lying plot for the original soil (0C0FA), the treated specimens recorded an average of approximately 68 % settlement reduction. This suggests stiffening of the soil mass, either by cementation alone or with the filler effect mentioned earlier. Similarly, Kumar Pal and Ghosh (2014) reported fly ash induced accelerated consolidation with subsequent high endurance of applied stresses against excessive deformation. The compression index was also found to decrease, suggesting hastened consolidation rate in fly ash–admixed soils (Phani Kumar and Sharma 2007). Mir and Sridharan (2013) corroborated these findings with reduced settlement recorded in compressibility tests of cement–fly ash treated soils. The solidification process transformed the soft soil into a structured mass, as demonstrated by the curvature of the treated specimens’ plots. The initial part of the curve with a gentler slope shows the pre-yield state, while the second part with a steeper plot represents the yield state. The intersection of the two parts gives the yield stress (σ y′), a parameter commonly used in the study of solidified soils to indicate the maximum vertical stress bearable by the soil before failure, i.e., excessive compressibility. Also, it is apparent that the extended curing period of 7 days did not contribute significantly to the improved compressibility, where the compression curves for all the pairs of 3d and 7d treated specimens did not differ much. Nonetheless the longer curing time did result in slightly lower compressibility, i.e., the 7d curve lies above that of 3d.

Figure 15 illustrates an example of the possible function of fly ash in a cement–fly ash mixture. Incorporated in the same figure is the data from Hird and Chan (2008) on the cement-treated soft clay (MC: water content = 74 %, G s = 2.66), cured for 7 days, as well as the data from the present study with the same cement content, i.e., 3C7FA. With a much higher mixing water content, 3 % cement produced marginal reduction to MC’s compressibility. On the other hand, a 3C7FA blend reduced settlement of the present dredged soil by almost 70 %, besides giving structure to the initially weak mass. As such, it can be concluded that with low cement dosages, prolonged curing cannot ensure meaningful stiffness gain in solidified soils, and that the mixing water content plays an important role too for effective solidification.

Yield stress (σ y′) and strain (ε f)

From Figs. 14 and 15, it can be seen that in general, σ y′ increased with cement content (i.e., 5C > 3C > 0C), but the most significant increment over time was demostrated by 0C10FA, i.e., ≈53 %. This is indeed contradicting with reports by Kamaruzzaman et al. (1998) that time effect on the yield stress is dependent on the cement content, as the specimens with the least cement dosage (i.e., 0C10FA) showed the highest σ y′ increment. However, considering the absence of a certain pattern in σ y′ evolution with time for the same dosages of solidifying agent and a large quantity of data, further work is required for conclusive understanding of the correlation.

Figure 16 shows ε f (the strain which corresponds with σ y′) for the solidified specimens. Again there appeared to be no specific relationship between cement and fly ash dosages with ε f, though lower cement content seemed to cause greater deformation pre-yield. The curing period did not show any dramatic changes in ε f, except in 5C5FA which registered approximately 65 % reduction. This suggests stiffness gain, where the solidified specimen became more rigid and yield at lower strain. In fact, this low εf is in agreement with the highest σ y′ discussed above. It is hypothesised that fly ash takes longer to stiffen the soil compared to cement, and that the threshold for effective stiffness gain in this case is 5 % cement.

Conclusions

In an attempt to reuse dredged marine soils as an acceptable geomaterial for civil engineering applications, a parametric study on the physico-chemical and geotechnical characteristics of a Malaysian dredged marine soil sample solidified with cement–fly ash was conducted.

For the physico-chemical properties, the following main findings were made:

-

The dredged soil has a natural water content in excess of its liquid limit (w nat ≈ 1.75 LL), hence necessitating solidification to enhance the originally weak and characteristics for general handling, and more importantly, load-bearing.

-

The Atterberg limits indicate the dredged soil to be of the high plasticity clay type, susceptible to significant deformation under loading.

-

Particle size analysis revealed the dominance of fines, making the dredged soil unsuitable as a subgrade fill material.

-

The organic content of the dredged sample was found to be negligible, though solidification could effectively further reduce the amount via encapsulation within the cementitious gel formed.

-

No marked change in pH was observed as the binder dosage was relatively small. Besides, chemical composition of the soil remained largely unchanged, and CaO emerged the main active compound for solidification to take place.

-

Micro-imaging shows the solidification mechanism filling voids within the soil by cementation as well as enlarging soil aggregates.

As for the geo-mechanical characteristics, the primary observations include:

-

Effective solidification of dredge marine soil cannot be achieved with the addition of fly ash alone.

-

Significant increase in strength and P-wave velocity (stiffness) was not observed despite prolonged curing, most likely due to the small binder dosage admixed with the dredged marine soil.

-

Consistency in the P-wave arrival time identification methods, i.e. peak-to-peak, trough-to-trough and cross-correlation suggests their applicability for cross-check purposes.

-

The q u–v P correlation established can be used as a quick reference for trial mix design, notwithstanding some incongruous between the strength and P-wave velocity evolution with time.

-

Curing period of 1 week is insufficient to produce significant stiffness gain in the dredged soil specimens treated with cement–fly ash.

-

The mixing water content affects the resulting compressibility of the treated soil, where wet samples generally require higher dosages of solidifying agents.

-

The yield stress and failure strain—curing period relationship is unclear and requires more study.

In a nutshell, dredged marine soils can be potentially solidified to make a sound geomaterial for reuse in various construction areas, particularly as backfills. Nonetheless as soils are generally non-homogeneous and vary in terms of physical and chemical as well as mechanical properties, the treatment (e.g., types, mix ratio and dosage of binder used) would have to be tailor-made for a specific soil following a thorough characterization exercise. Besides, the geo-environmental aspect of the solidified material requires further examination to ensure its safe application on site.

References

Ahmed AGA (2014) Fly ash utilisation in soil stabilisation. Proceedings of Int. Conf on Civil. Biological and Environmental Engineering, Istanbul, Turkey, pp 76–78

Ahnberg H, Holmen M (2011) Assessment of stabilised soil strength with geophysical methods. Ground Improv 164(13):109–116

ASCE (1993) Geotechnical special publication GSP 36: fly ash for soil improvement. American Society for Civil Engineers, New York, USA

ASTM (2005) C618-05 Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. Pennsylvania, USA

ASTM (2007) C150-07 Standard specification for Portland cement. American Society for Testing and Materials, Pennsylvania, USA

Barrett AG, Nauleau E, Le Kouby A, Pantet A, Reiffsteck P and Francois M (2011) Free-free resonance testing of in situ deep mixed soils. Geotech Test J 36(2):283–291

Bogers P, Gardner J (2004) Dredging near live coral. In: Proceedings of the 17th. World Dredging Congress (WODCON XVII 2004), Hamburg, Germany

Bose B (2012) Geo engineering properties of expansive soil stabilized with fly ash. Electron J Geotech Eng 17:1339–1353

Bray N, Cohen M (2010) Dredging for development. International Association of Dredging Companies (IADC) and International Association of Ports and Harbours (IAPH), Netherlands

British Standards (1990a) Methods of test for soils for civil engineering purposes. Part 2: classification tests. BS 1377. British Standard Institution, UK

British Standards (1990b) Methods of test for soils for civil engineering purposes. Part 5: compressibility, permeability and durability tests. BS 1377. British Standard Institution, UK

British Standards (1990c) Methods of test for soils for civil engineering purposes. Part 7: Shear strength tests (total stress). BS 1377. British Standard Institution, UK

Brooks R, Udoeyo FF, Takkalapelli KV (2011) Geotechnical properties of problem soils stabilized with fly ash and limestone dust in Philadelphia. J Mater Civ Eng 23(5):711–716

Cai G, Liu S, Cao J, Zheng X (2015) Experimental study on mechanical and acid-alkali properties of reactive magnesia carbonated-stabilised soils. In: Proc. of 15th Asian regional conference on soil mechanics and geotechnical engineering, Fukuoka, Japan

Chan C-M (2012) Variation of shear wave arrival time in unconfined soil specimens measured with bender elements. J Geotech Geol Eng 30(2):419–430

Chan C-M (2014) Influence of mix uniformity on the induced solidification of dredged marine clay. Environ Earth Sci 71(3):1061–1071

Cruz-Motta JJ, Collins J (2004) Impacts of dredged material disposal on a tropical soft-bottom benthic assemblage. Mar Pollut Bull 48(3–4):270–280

Little DN, Nair S (2009) Document 144: recommended practice for stabilisation of subgrade soils and base materials. National cooperative highway research program: contractor’s final task report for NCHRP project 20-07

Das BM (2010) Principles of geotechnical engineering, 7th edn. Cengage Learning, USA

Flaherty CA (2002) The location, design, construction and maintenance of pavements. Edward Arnold Ltd, London

Goldbeck S (2008) State of the estuary report: A greener shade of blue. San Francisco Estuary Report and CALFED State of the Estuary Conference Proceedings, California, 8

Hird CC, Chan C-M (2008) One-dimensional compression tests on stabilized clays incorporating shear wave velocity measurements. Geotech Testing J 31(2):166–174

Huat BK, Gue SS, Faisal HA (2004) Organic and peat soils engineering. Universiti Putra Malaysia Press, Malaysia

Huat BBK, Kazemian S, Prasad A (2011) State of the art review of peat: general perspective. Int J Phys Sci 6(8):1988–1996

Kamaruzzaman AHM, Chew SH, Lee FH (1998) Behaviour of soft Singapore marine clay treated with cement. ASCE Geotechnical Special Publication GSP113, pp 472–485

Kayabali K, Tufenkci O (2010) Shear strength of remoulded soils at consistency limits. Can Geotech J 47(3):259–266

Kumar Pal S, Ghosh A (2014) Volume change behaviour of fly ash—montmorillonite clay mixtures. J Geomech 14(1):59–68

Lee ST, Ali FH (2004) Behaviour of clayey soils with cement additive. G&P Geotechnics S/B, http://www.gnpgeo.com.my. Accessed 01 Sept 2014

Lee ST, Faisal A (2004) Behaviour of clayey soil with cement additives. In: Malaysian geotechnical conference, 16–18 March 2004, Selangor, Malaysia

Lin B, Cerato AB, Madden AS, Elwood Madden ME (2013) Effect of fly ash on the behaviour of expansive soils: microscopic analysis. Environ Eng Geosci 19(1):85–94

Lopes LSE, Szeliga L, Casagrande MDT, Motta LMG (2012) Applicability of coal ashes to be used for stabilized pavements base. GeoCongress 55(21):2562–7759

GDS Instruments Ltd (2005) The GDS bender elements system handbook for vertical and horizontal element. Bender Element Hardware Handbook, Hampshire, UK

Maher A, Douglass WS, Jafari F, Pecchioli J (2013) The processing and beneficial use of fine-grained dredged material: a manual for engineers. RUTGERS Centre for Advanced Infrastructure and Transportation, Washington, NJ

Makusa GP (2012) Soil stabilization methods and materials in engineering practice. Luleå University of Technology, Luleå

Ministry of Land, Infrastructure and Transport, Japan (2005) Current state of construction by-products (in Japanese)

Mir BA, Sridharan A (2013) Physical and compaction behaviour of clay soil - fly ash mixtures. Geotech Geol Eng 31:1059–1072

Mo L, Panesar DK (2012) Effects of accelerated carbonation on the microstructure of Portland cement pastes containing reactive MgO. Cement Concrete Res 42(6):769–777

Mokhtar M (2011) A laboratory investigation of shear wave velocity in soft soils stabilised with cement-RH (rice husks). Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia: Master’s thesis

Mokhtar M, Chan C-M (2012) Settlement control of soft ground with cement-ricehusk stabilisation. Civ Eng Dimens 14(2):69–76

Mountford K (2000) History of dredging reveals deeper need to understand Bay’s bottom line. Bay J 10(5):8–10

Nishimura S, Abe K (2015) Effects of early-age consolidation on strength development in cement-treated clay. In: Proc. of 15th Asian regional conference on soil mechanics and geotechnical engineering, Fukuoka, Japan

Pebbles V, Thorp S (2001) Waste to resource: beneficial use of great lakes dredged material. Great Lakes Commission, USA

Phani Kumar BR, Sharma RS (2007) Volume change behavior of fly ash-stabilized. J Mater Civ Eng 19(1):67–74

Porbaha A, Ghaheri F and Puppala AJ (2005) Soil cement properties from borehole geophysics correlated with laboratory tests. In: Proceedings of the international conference on deep mixing best practice and recent advances, Stockholm, Sweden, vol 1, pp 605–611

Rekik B, Boutouil M (2009) Geotechnical properties of dredged marine sediments treated at high water/cement ratio. Geo Mar Lett 29:171–179

Riddell JF (2003) Dredging for development. International Association of Dredging Companies (IADC), Japan

Rifal A, Yasufuku N, Tsuji K (2009) Characterization and effective utilization of coal ash as soil stabilization on road application. Geotechnical Society of Singapore, Singapore, pp 469–474

Schülli-Maurer I, Sauer D, Stahr K, Sperstad R, Sørensen R (2007) Soil formation in marine sediments and beach deposits of southern. Norway: investigations of soil chronosequences in the Oslofjord region. R Rev Mex Cienc Geol 24(2):237–246

Senol A (2012) Effect of fly ash and polypropylene fibers content on the soft soils. Bull Eng Geol Environ 71:379–387

Sharma NK, Swain SK, Sahoo UC (2012) Stabilization of a clayey coil with fly ash and lime: a micro level investigation. Geotech Geol Eng 30:1197–1205

Snyder GR (1976) Effect of dredging on aquatic organisms with special application to areas adjacent to the Northeastern Pacific Ocean. Mar Fish Rev 38(11):34–38

Vara Prasad CR, Sharma RK (2014) Influence of sand and fly ash on clayey soil stabilization. IOSR J Mech Civ Eng 4/8:36–40

Vizcarra GOC, Casagrande MDT, da Motta LMG (2014) Applicability of municipal solid waste incineration ash on base layers of pavements. J Mater Civ Eng 26:1–7

Wang DX, Abriak NE, Zentar R (2011) Durability analysis of fly ash/cement-solidified dredged materials. Coastal and Maritime Mediterranean Conference, pp 245–250

Xiao HW, Lee FH, Goh SH (2015) Fiber distribution effect on behavior of fiber-reinforced cement-treated clay. In: Proc. of 15th Asian regional conference on soil mechanics and geotechnical engineering, Fukuoka, Japan

Zentar R, Wang DX, Abriak NE, Benzerzour M, Chen WZ (2012) Utilization of siliceous-aluminous fly ash and cement for solidification of marine sediments. Constr Build Mater 35:856–863

Zhang YM, Sun W, Yan HD (2000) Hydration of high-volume fly ash cement pastes. Cement Concr Compos 22:445–452

Acknowledgments

The laboratory work described in the paper is attributed to the diligence and commitment of S.-Y. Jong, L-S Hoo and K-H Pun, who have since left the University as high flyers in the civil engineering industry. Invaluable technical advice by Prof. F. Ahmad is also duly acknowledged. The project was funded by the RACE research grant, Ministry of Education Malaysia, with technical support by UTHM’s RECESS and Geotechnical Lab personnel.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chan, CM. Geo-parametric study of dredged marine clay with solidification for potential reuse as good engineering soil. Environ Earth Sci 75, 941 (2016). https://doi.org/10.1007/s12665-016-5639-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-016-5639-9