Abstract

The stabilization of problematic soils such as marine clays is very important for many geotechnical engineering applications. To fulfill the needs of an ever-increasing population, the infrastructure development activity on marine clay deposits can be done economically using various stabilization methods. Stabilization of soft soil is necessary before any construction of pavement structures, roadways, building foundations, canals, water lines, or sewer lines so as to avoid failure due to settlement. Soil stabilization is any process which improves the soil with respect to shear strength, bearing capacity, etc. This paper explains the stabilization procedure carried out using waste products and presents an investigation of stabilization using waste materials, like (i) ground-granulated blast furnace slag (GGBS) which is a by-product of steel industry, (ii) fly ash, and (iii) a mixture of sewage sludge and lime. In the first series, 10%, 20%, 30%, and 40% of the soil mass is replaced with GGBS and fly ash separately. And in the second series, 15%, 20%, 25%, and 30% of soil mass is replaced with sewage sludge and lime, keeping the percentage of sewage sludge as a constant. In order to understand the effects of additives on marine clay, laboratory tests were conducted on untreated and treated soil specimens. It was observed that with age of curing the UCS values increased greatly and a similar trend was observed for CBR values too.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

For many years mankind was wondering at the instability of earth materials, especially marine clay. Several investigations were made on the marine clay to improve its properties. The properties of saturated marine clay differ significantly from moist soil and dry soil. Marine clay is micro-crystalline in nature, and clay minerals like kaolinite, chlorite, and illite and non-clay minerals like quartz and feldspar are present in the soil. Construction on such ground may result in undesirable settlements due to the soft nature of the soil. Researchers from various fields have focused on solving environmental problems due to the production of wastes. Gidley and Sack [6] suggested methods of utilization of wastes, such as fly ash, iron slag, waste rock, mine tailings, and sludge in construction. In this paper three different additives are used to study the properties of treated marine clay. The additives used are GGBS, fly ash, sewage sludge, and lime. The reason for using the combination of sewage sludge and lime is lime reduces the decomposition nature of sewage sludge, when it is mixed with marine clay. GGBS consists of a substantial proportion of a glassy phase with a substantial content of Ca, Si, Al, and Mg-based compounds. Sewage sludge is one of the major unused waste materials, and if it is used directly to combine with the marine clay then the organic content in sewage sludge may disturb the clay structure. To reduce the organic content, lime is mixed with sludge in a proportionate manner.

Yi et al. [22] investigated the stabilization efficacy of alkali-activated ground-granulated blast furnace slag (GGBS) on marine soft clay. The results indicated that Na2CO3-GGBS mix had no stabilization efficacy for this marine soft clay. Moreover, NaOH-GGBS-stabilized clay yielded the highest UCS values at 7, 28, and 90 days; however, the UCS values decreased from 90 to 180 days because of microcracking. The performance of GGBS-fly ash-modified soft soils was also evaluated [4, 17, 18, 21] using compaction and California bearing ratio (CBR) tests.

Based on the results, it appears that soft soil can be effectively stabilized with the addition of fly ash–GGBS mixtures. It is observed that the plasticity index decreased and unconfined compressive strength (UCS) increased upon addition of slag to the soil. With the age of curing the UCS values increased indicating the chemical reaction between free lime and soil.

Buva and Wayal [2], Ouyang et al. [14], Mousa et al. [13], Monzó et al. [12], Lin et al. [10], Li and Lin [9] studied the properties of the incinerator fly ash derived from MSW incineration process, which indicated that fly ash is a potential source of jet-grouting admixture for soil improvement. The use of fly ash as an admixture in the stabilization of a soft marine clay resulted in stabilized samples with an improved strength, more than 75 times that of the untreated clay, and reduced both the plasticity and compression indices by about 69% and 23%, respectively. It is also noticed that the liquid limit of the marine clay has decreased by 23.88% on addition of 25% fly ash and it has further decreased by 26.30% when 9% lime is added, and the plastic limit of the marine clay improved by 6.93% on addition of 25% fly ash and it further improved by 20.46% when 9% lime is added. It is also found that the MDD of the marine clay has improved by 14.83% on addition of 25% fly ash and it has improved by 7.74% when 9% lime is added.

Quicklime and hydrated lime were used [1, 7, 11], to activate ground-granulated blast furnace slag (GGBS) for stabilization of marine soft clay. The UCS results demonstrated that hydrated lime-activated GGBS achieved slightly higher 90-day UCS in stabilized clay than quicklime-activated GGBS. Chandran et al. [3] investigated the efficacy of lime solution with different concentrations when added to the soft soil samples for stabilization and cured with water for 7, 14, 21, 28, and 35 days. From the test results, it was found that the unconfined compressive strength increased up to a curing period of 28 days and thereafter there is no appreciable effect. Stabilization of marine clay with cement, lime, and fly ash and bagasse ash has been studied [5, 15, 19] for strength improvement and plasticity behavior. Specimens were prepared by mixing with varying proportions of lime, cement, and fly ash with clayey soil separately. The unconfined compression test (UCS) and Atterberg’s limits of the soil with different percentages of additives were determined separately after curing specimens for 7 days. The 7-day peak strength of soil-lime specimens was found at 7.5% lime content, although addition of 6% and 12% of lime was suitable.

The 7-day strength of specimens mix with fly ash was found significantly more than that of specimen without fly ash. For Wando marine clay improved [20] with fly ash, and the plasticity index reduced by about 18–26% with an increase of fly ash content. As the amount of fly ash increased, the composite soil resisted the compressive loading better and consequently showed lesser compressibility. Phanikumar and Nagaraju [16], Jamaludin et al. [8] conducted a laboratory investigation study to understand the effect of fly ash on the consolidation characteristics of compacted clay. The A-7-5 clay was stabilized with fly ash at different contents such as 0%, 5%, 10%, 15%, and 20%. The A-7-5 clay is stabilized with fly ash which causes a decrease in the maximum dry density (MDD) and an increase in the optimum moisture content (OMC) because fly ash requires more water during pozzolanic action. And it was observed that the A-7-5 clay became rough or granular and increased the rate of consolidation. It was found that the compression index (Cc) values decreased up to 10% of fly ash content.

2 Materials

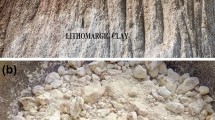

2.1 Marine Clay

The marine clay used in this study is collected from Visakhapatnam Port. The index and engineering properties of marine clay are determined as per IS codes of practice. Samples are taken separately in a box to determine the initial moisture contents. The samples were tested for physical properties and the results are: specific gravity = 2.68, sand size(%) = 31, fines(%) = 69, field moisture content(%) = 72, liquid limit(%) = 68, plastic limit(%) = 21, plasticity index(%) = 47, maximum dry density(g/cc) = 1.50, optimum moisture content(%) = 26.4, Indian standard soil classification = CH, unconfined compressive strength (kN/m2) = 41.11, California bearing ratio(%) (unsoaked and soaked) = 2.02 and 1.12, respectively.

2.2 Fly Ash

Fly ash was obtained from NTPC, Visakhapatnam. The chemical properties of the ash are for the most part influenced by the chemical content of the coal burned. Fly ash is generally gray in color and in powder form. The fly ash used in this study consists of silicon dioxide (SiO2) = 43.6%, aluminum oxide (Al2O3) = 16.90%, ferric oxide (Fe2O3) = 5.80%, calcium oxide (CaO) = 24.30%, magnesium oxide (MgO) = 4.80%, titanium oxide(TiO2), potassium oxide (K2O) = 1.30%, and sulfur trioxide (SO3) = 3.30%.

2.3 Lime

Lime mainly consisting of calcium oxide (CaO) = 74.23%, loss of ignition (LOI) = 24.35%, phosphorous oxide (P2O5) = 0.08%, magnesium oxide (MgO) = 0.74%, calcium sulfate (Ca2SO4) = 0.12%, ferric oxide (Fe2O3) = 0.17%, aluminum oxide (Al2O3) = 0.11%, and silica (SiO2) = 0.20% was used in this study.

2.4 Ground-Granulated Blast Furnace Slag

It is a by-product of iron and steel industry. This slag contains calcium, magnesium, manganese, and aluminum silicates in various combinations. When powder form of GGBS is used in cement manufacturing industries, the grinding operations are costlier. For this reason, slag is stacked near iron industries, thus leading to massive consumption of area. Hence the investigation was undertaken to check the potential usage of granulated blast furnace slag to improve the geotechnical properties of marine clay. The GGBS used in this study has calcium oxide (CaO) = (30–50%), silica (SiO2) = (28–38%), aluminum oxide (Al2O3) = (8–24%), and magnesium oxide = (1–18%) by weight.

2.5 Sewage Sludge

Sewage sludge is a product of wastewater treatment and it is a diluted suspension of solids. It consisted of silicon (Si) = 36.7%, iron (Fe) = 16.3%, aluminum (Al) = 14.7%, calcium(Ca) = 13.1%, phosphorous(P) = 11.8%, potassium (K) = 3.66%, titanium(Ti) = 1.00%, zinc (Zn) = 0.81%, magnesium(Mg) = 0.77%, sulfur (S) = 0.36%, manganese (Mn) = 0.16%, copper (Cu) = 0.13%, and nitrogen(N) = 0.17%. A constant amount of sewage sludge is added to the soil in combination with varying percentages of lime.

3 Laboratory Experimentation

The effectiveness of GGBS, fly ash, lime, and sewage sludge as stabilizers was studied using several laboratory tests. First, all the tests were conducted on marine clay alone, and later the tests were conducted on the marine clay mixed with 10% GGBS by weight of soil. Later, the percentage of GGBS was increased to 20%, 30%, and 40%. And the same increment was used in the case of fly ash too. In the case of sewage sludge and lime combination, the sludge was kept at a constant of 10% and lime was varied as 5%, 10%, 15%, and 20% by weight of marine clay, respectively. The tests were conducted in the laboratory to investigate the change in the characteristics of marine clay when compared with untreated marine clay. All the tests were conducted as per the procedures laid down in various parts of IS: 2720.

4 Results and Discussions

4.1 Effect of GGBS, Fly Ash, Sewage Sludge, and Lime on Atterberg’s Limits

Liquid limit reduced from 68% to 59%, 57%, 51%, and 39% and the plastic limit increased from 21% to 23.5, 24.5, 26, and 28% when soil is replaced by GGBS in percentages of 10, 20, 30, and 40, respectively. Eventually the plasticity index decreased as shown in Fig. 1, and the same trend was observed for fly ash. The liquid limit decreased from 68% to 59, 53, 45, 40% and the plastic limit increased in the case of fly ash as shown in Fig. 2.

In the case of combination of sewage sludge and lime when mixed with the soil, the liquid limit decreased from 68% to 64%, 60%, 54%, 50% and the plastic limit increased from 21% to 28%, 31%, 34%, and 36% when the replacement percentages of lime are 5%, 10%, 15%, and 20% (keeping the sewage sludge of 10% as constant), respectively. Eventually the plasticity index decreased from 47% to 40%, 37%, 29%, and 26% as represented in Fig. 3.

4.2 Compaction Test

First, with increase in replacement with GGBS, the OMC decreased from 24% to 18%, 16% and 14%, and the MDD increased from 1.50 g/cc to 1.82 g/cc, 1.90 g/cc and 2.04 g/cc with replacements of 10%, 20%, 30%, and 40%, respectively. On further increase in GGBS by 10% the OMC decreased to 12% and the MDD decreased to 1.79 g/cc as shown in Fig. 4. However, Fig. 5 shows the compaction test results for clay–fly ash mixes.

First, with increase in replacement with fly ash the OMC (%) decreased from 24% to 20%, 18% and 16% and the MDD increased from 1.50 g/cc to 1.90 g/cc, 1.95 g/cc and 2.05 g/cc with replacements of 10%, 20%, 30%, and 40%, respectively. On further increase in fly ash by 10% the OMC decreased to 14% and the MDD decreased to 2 g/cc as shown in Fig. 5.

When sewage sludge and lime combination is used as an additive, the OMC increased from 24% to 26%, 28%, 30%, 32% and the corresponding MDD increased from 1.50 g/cc to 1.95 g/cc, 2.12 g/cc, 2.24 g/cc, 2.30 g/cc with the replacements of 5%, 10%, 15%, and 20% of lime (keeping sewage sludge of 10% as constant) (Figs. 6 and 7).

4.3 California Bearing Ratio (CBR) Test

Unsoaked and soaked CBR values were found from the tests. The CBR values of the soil in soaked and unsoaked conditions are 1.12% and 2.02%, respectively. The soaked CBR values increased to 4.04%, 8.15%, and 11.80% with the replacements of 10%, 20%, and 30% of GGBS, and the CBR values decreased in both soaked and unsoaked conditions with a replacement of 40% GGBS. The soaked CBR values increased to 2.45%, 5.31%, and 7.04% with the replacement of 10%, 20%, and 30% of fly ash and the CBR values decreased in both the soaked and unsoaked conditions with the replacement of 40% fly ash. The soaked CBR values increased to 3.09%, 6.40%, and 8.12% with the replacement of 5%, 10%, and 15% of lime (keeping 10% of sludge as constant) and the CBR values decreased in both the soaked and unsoaked conditions of 20% replacement of lime.

4.4 Unconfined Compressive Strength (UCS) Test

The UCS values increased with increase in the percentages of additives for curing durations of 0, 7, 14, and 28 days. For GGBS-mixed soil, the increase in UCS values is shown in Fig. 8. The UCS values decreased for 40% replacement of GGBS after 0, 7, 14, and 28 days of curing. The UCS values decreased at 40% replacement of GGBS after 0, 7, 14, and 28 days of curing.

In the case of fly ash, there is an increase in UCS values up to 30% of soil replaced with fly ash and the UCS values decreased at 40% replacement of fly ash for 0, 7, 14, and 28 days of (curing) testing as shown in Fig. 9.

A similar trend was observed in the case of clay–lime–sewage sludge mixes (keeping 10% sewage sludge as constant), as shown in Fig. 10.

5 Conclusions

On the basis of experimental investigation, the following conclusions are drawn:

-

1.

With the addition of any type of admixture used in this study and by the replacement of clay in 10, 20, 30, and 40 percentages, the liquid limit and the plasticity index values gradually decreased. When clay is treated with GGBS, the liquid limit and plasticity index values decreased appreciably by 42.6% and 76.5%, respectively, when compared with that of the untreated clay.

-

2.

When clay was replaced with various admixtures in 10, 20, 30, and 40 percentages, the plastic limit values increased. Amongst all the additives used, the performance of sewage sludge–lime combination was the best, which resulted in an appreciable increase of 71% in the plastic limit value when compared with that of the untreated clay.

-

3.

When clay was replaced with GGBS in percentages of 10, 20, 30, and 40, it was observed that with decrease in OMC values, the MDD values increased correspondingly. The same trend was observed when fly ash was used in the same percentages as mentioned above. But in the case of clay treated with sewage sludge–lime combination, an increase in MDD values was observed with a corresponding increase in OMC values. Hence, the sewage sludge–lime combination is not a suitable additive to improve marine clay.

-

4.

The highest shear strength value of clay treated with GGBS is 340 kPa for 30% replacement. The value of 350 kPa was obtained for 30% replacement using fly ash. Similarly, the value of 770 kPa was obtained for replacement of 10% sewage sludge + 15% lime.

-

5.

The California bearing ratio (CBR) value of clay treated with GGBS is 11.80% in soaked condition for 30% replacement by GGBS. Similarly, a value of 7.04% was obtained for 30% replacement using fly ash in soaked condition. In addition, a value of 8.12% was obtained for 30% replacement using 10% sewage sludge + 15% lime in soaked condition, whereas for untreated clay the CBR value is 1.12% in soaked condition. The CBR value of 30% GGBS as replacement is more than the CBR value of 30% fly ash as replacement. The cost of bituminous road constructed using fly ash-treated marine clay is more economical than using GGBS. Therefore, it may be concluded that GGBS and fly ash are effective stabilizers. According to the performance aspect, GGBS is better, but fly ash is better from an economic standpoint.

References

Balasubramaniam, A.S., Bergado, D.T., Buensucoso Jr., B.R., Yan, W.C.: Strength and deformation characteristic of lime treated soft clay. J. Geotech. Eng. 20, 49–65 (1989)

Buva, V., Wayal, A.S.: Use of fly ash and lime for stabilization of soft soil. Electron. J. Geotech. Eng. 21.18, 6235–6246 (2016)

Chandran, S., Rajani, G, Padmakumar, P.: Stabilization of clayey soil using lime solution. In: 10th National Conference on Technological Trends (NCTT09), 1, 13–19 (2009)

Dhanalakshmi, P., Chandrakaran, S, Stabilisation of soft clay using ground granulated blast furnace slag and lime. In: Proceedings of 6th Young Geotechnical Engineers Conference, 1, 156–161 (2017)

Gandhi, K.S.: Expansive soil stabilization using bagasse ash. Int. J. Eng. Res. Technol. 1(5), 1–3 (2012)

Gidley, J.S., Sack, W.A.: Environmental aspects of waste utilization in construction. J. Environ. Eng. 110(6), 1117–1133 (1984)

Ibrahaim, M.A., Al-Kiki Khawla, A. K., Al-Juari, S., Khattab, A.A.: Strength, durability and hydraulic properties of clayey soil stabilized with lime and industrial waste lime. Al-Rafidain Eng. J. 16(1), 102–116 (2008)

Jamaludin, N., Mohd.Yunus, N. Z., Jusoh, S. N., Pakir, F., Ayub, A., Zainuddin, N. E., Hezmi, M. A.: Nordiana Mashros, potential and future: utilization of waste material on strength characteristics of marine clay. In: IOP Conference Series: Materials Science and Engineering, pp. 1–8 (2019)

Chen, Li, Lin, Deng-Fong: Stabilization treatment of soft subgrade soil by sewage sludge ash and cement. J. Hazard. Mater. 162(1), 321–327 (2018)

Lin, D.F., Lin, K.L., Luo, H.L.: A comparison between sludge ash and fly ash on the improvement in soft soil. J. Air Waste Manage. Assoc. 57(1), 59–64 (2007)

Gharib, Mehdi, Saba, Hamidraza: Experimental investigation of impact of adding lime on Atterberg’s limit in golestan province soils. Int. Res J. Appl. Basic Sci 3(4), 796–800 (2012)

Monzó, J., Payá, J., Borrachero, M.V., Peris-Mora, E.: Mechanical behavior of mortars containing sewage sludge ash (SSA) and Portland cements with different tricalcium aluminate content. Cement Concrete Res. 29(1), 87–94 (1999)

Attom, M., Mortula, M.Md, Munjed, A.: Shear strength stabilization using burned sludge ash, International Journal of Advances in Mechanical and Civil. Int. J. Adv. Mech. Civil Eng. 4(3), 42–45 (2017)

Ouyang, C.F., Xu, Z.L., Lan, W.Z:. Study of the treatment and reuse of municipal sewage treatment plant sludge. Proceedings on 8th Annual Meeting Sanitary Engineering, 1, 221–232 (1998)

Pandian, N.S., Krishna, K.C.: California bearing ratio behavior of cement-stabilized fly ash-soil mixes. J. Test. Eval. 30(6), 1–5 (2002)

Phanikumar, B.R., Nagaraju, T.V.: Swell and compressibility of GGBS–clay mixes in lumps and powders. Indian Geotech. J. 49, 161–169 (2019)

Preetham, H.K., Nayak, S., Surya, E.V.: Experimental investigation on the stabilization of soft clay using granulated blast furnace slag. In: IOP Conference Series on Materials Science and Engineering, 1, 1–6 (2019)

Ramesh, B., Hima Bindu, P.: An experimental study on stabilization of clayey soil by using granulated blast furnace slag. Int. J. Trend Sci. Res. Dev. ISSN: 2456-6470, 3(5) (2019)

Sen, P., Mukesh, M. D.: Evaluation of strength characteristics of clayey soil by adding soil stabilizing additives. Int. J. Earth Sci. Eng. 4,1060–1061 (2011

Suneel, M., Jeonggeun Kwon, J.-C., WookJeon, C.: Long-term consolidation and strength behavior of marine clay improved with fly ash. J. Marine Geores. Geotechnol 28, 105–114 (2010)

Tarun, K.R., LaxmikantYadu, S.K.C.: Strength characteristics of fly ash stabilized soil embankment and stability analysis using numerical modelling. In: Proceedings on Indian Geotechnical Conference, GeoNEst, 1, 14–16 (2017)

Yaolin, Y., Gu, L., Liu, S., Puppala, A.J.: Carbide slag–activated ground granulated blast furnace slag for soft clay stabilization. Can. Geotech. J. 52, 656–663 (2015)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Srujana, A.V.S.A., Hemanadh, M., Ravi Kumar, K., Preethi, S., Manchikanti, S. (2022). A Study on the Performance of Marine Clay Stabilized with Waste Materials. In: Satyanarayana Reddy, C.N.V., Saride, S., Krishna, A.M. (eds) Ground Improvement and Reinforced Soil Structures. Lecture Notes in Civil Engineering, vol 152. Springer, Singapore. https://doi.org/10.1007/978-981-16-1831-4_42

Download citation

DOI: https://doi.org/10.1007/978-981-16-1831-4_42

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1830-7

Online ISBN: 978-981-16-1831-4

eBook Packages: EngineeringEngineering (R0)