Abstract

Stabilization of cohesive soils has been practiced for some time by mixing additives, such as cement, lime, and fly ash, into the soil to increase its mechanical strength. However, there is a lack of investigation on the use of natural pozzolana (NP) alone or combined with lime for soil stabilization applications. This work is a part of a research project focused on the evaluation of the effects of adding natural pozzolana as an additive to improve the lime treatment results of local clayey soils. The main purpose of this paper is to present the results of using lime, natural pozzolana, and their combination on shear strength, shear parameters, and failure mode variations of the local clayey soil, classified as fat clay (CH). CH, selected from Tlemcen city in Algeria, is known for its high plasticity and importance in cohesion and compressibility. To achieve this goal, several physicomechanical tests (pH, compaction, undrained unconsolidated triaxial compression test) and microstructural analysis, scanning electron microscope (SEM) have been carried out for the different studied combinations. Natural pozzolana and lime were added to the studied soils at ranges of 0–20% and 0–6%, respectively. The treated samples were cured for 1, 7, and 28 days. The results indicated that the studied properties of clay soil can be considerably improved when treated with lime. The combination of lime and natural pozzolana appears to produce higher shear strength parameters, than when lime or natural pozzolana is used alone. Adding natural pozzolana to clay soil treated with lime produces an additional chemical reaction, especially in the long term, resulting in better flocculation and additional formation of cementing materials. Therefore, the deviatoric stress of the treated soil, with 6% lime and 20% NP, increased up to 200% within 28 days of curing. The treated soil became more brittle, with a significant increase in shear strength, cohesion, and a higher friction angle.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Clay minerals are very fine particles with very high electrochemical activity. This activity is produced by the interaction between the electrically charged particles [1]. The presence of low content of clay minerals in natural soils considerably modifies their engineering properties. The fat clay soils have a large specific surface and a high ion exchange capacity, which produce high plasticity, high volume change capacities, such as swelling and shrinkage, high compressibility and low bearing capacity [1, 2]. Due to these poor properties, fat clays are difficult to work with when damp, which causes a problem for civil engineers. There are several techniques to improve these soils, such as mechanical, hydromechanical, thermal, and chemical methods [3,4,5].

The high cost of reinforcing or replacing fine clayey soils with resistant material, that meets the project requirements, led researchers to find alternative methods that are less expensive. Chemical soil stabilization techniques are one such method, based on soil mixing with different additives. In this context, vast research and experimental studies have been conducted on additives’ effect on geotechnical properties of stabilized clayey soils, such as lime, cement, fly ash, natural pozzolana, and slag [6,7,8,9,10,11,12].

Lime is one of the most used hydraulic binders for cohesive soils stabilization. It offers considerable improvement in the geotechnical properties of clayey soils by changing their consistency and structure, decreasing their plasticity and swelling properties and increasing their shear strength [13, 14]. There were positive results in lime stabilization of clayey soils and the appearance of composite materials by mixing at least two different components to produce a new material. This material had new properties, such as lightness, hardness and resistance that did not exist in the primary components. Several studies have been published on mixing lime with various mineral additives: lime with cement [15], lime with fly ash [16], lime with slag [17], lime with pozzolana [12] and lime with lignosulphonate [18].

The natural pozzolana (NP) is a basaltic, volcanic material widely available in north-western Algeria, specifically in the Beni-Saf region. These materials, designed as light siliceous granules (silico-aluminous granules), do not themselves have binding properties, but they chemically react with the calcium hydroxide to produce compounds with binding properties [19].

Limited research has been conducted to study the effect of adding NP on lime-stabilized clayey soils. Hossain et al. [20] used natural volcanic ash (VA) in soil stabilization. Harichane et al. [21] studied the influence of lime–NP combination on two different clay soils (CH and CL). Zoubir et al. [22] found that the addition of NP to the lime-stabilized clay soils effectively improved their geotechnical properties, which increased the availability of land resources for civil engineering projects. Positive results have been observed by Al-Swaidani et al. [23] when adding NP to lime-stabilized clayey soils. Several tests of Atterberg limits, compaction, unconfined compressive strength and durability were conducted. However, only a few pieces of research were attended to study the effect of NP and its combination with lime in the shear strength and variation in parameters of clay soils [11].

In the current paper, the main attention was given to the improvement of lime-treated clayey soil characteristics, which is familiar with its high plasticity and compressibility, with natural pozzolana. The effects of utilizing lime, natural pozzolana and both in combination to the soil on shear strength parameters and failure mode were highlighted through the laboratory tests. The tests can be evaluated into the two categories such as physicomechanical tests (pH, compaction, undrained unconsolidated triaxial compression test) and microstructural analysis (Scanning electron microscope).

2 Shear Strength

The shear strength is a very important property in soil mechanics. It represents the magnitude of strength that soil can withstand before shearing. Soil shear parameters are necessary for the study and the realization of civil engineering projects, using the different analysis approaches (effective and total stress-based approach) to address problems encountered in the field.

Confining pressure is one of the essential field conditions, which has the main influence on the soil’s shear strength in modifying the behavior of soils used as in deep foundations and high earth dams. The only existing test to simulate this pressure is the triaxial test. Triaxial pressure tests take various names with the creation of different conditions within themselves. As a result, different shear strength parameters are obtained. Among them is the soil stabilization for short-term conditions, such as dams, foundations and slopes. The shear parameters used are determined from the consolidated undrained (CU) or undrained unconsolidated (UU) triaxial tests. Conversely, at long-term stability, more reliable shear parameter results are given at consolidated drained (CD) conditions.

There are several factors that have significant impact on the shear strength and shear parameters of untreated and treated soils. The shear strength of an untreated cohesive soil is generally influenced by variation in water content, soil texture, gradation, dry density, thixotropy of the soil and the normal effective stress [24]. The molding water content of compacted cohesive soils has a notable effect on their microstructure modification [25], magnitude of initial pore water pressure and soil dry density [26]. Each of these factors has a significant effect on the material shear strength. The increase in the dry density causes an increase in the shear strength for given water content [25, 27]. Langfelder and Nivargikar [24] reported that the shear strength of natural soils can be increased over time at constant water content. This process of resistance change is generally referred to as thixotropy in soil mechanics. The factors that affect the shear strength of treated cohesive soils with different additives are soil structure, sample preparation, compaction condition, confining pressure, type of additive, content of additive and curing condition. Thompson [28] described several properties of soil that influence compressive strength, such as organic carbon content, clay mineralogy and clay content. The soil–lime reaction is generally retarded when the soil contains a large percentage of organic carbon. The variation in the type of predominant clay particles in soil composition has an important effect on lime stabilization results when the montmorillonitic clay soils have better lime reactivity than kaolinite and illitic clays. The molding water content is an influential factor that affects the geotechnical properties, such as compressibility, strength and stiffness of the treated soil. Sabat et al. [29] observed that the unconfined compressive strength (UCS) of a clayey soil stabilized, with its optimal amount of rice straw ash (20% RSA) reached its maximum value when soil is compacted at the optimal condition (OMC and MDD). The variation of confinement pressure has a notable effect on the strength gain. Harichane et al. [12] found that the shear strength of stabilized soils increases with increasing confining pressure. The variation of additive content in soil stabilization has a significant effect on strength gain [30]. In another study, the shear strength of both stabilized clayey soils (CL and CH) increases with increasing lime and NP content [11]. The curing time, as well as the curing conditions (temperature and relative humidity), influence the strength gain of the stabilized soils. As known in the soil stabilization literature, the strength of treated soils increased with increasing curing time due to long-term chemical reactions. However, the rate of increase in the strength of stabilized soils was higher in the short term of hardening, compared to the later periods [6, 31].

3 Failure Modes

Landslides are the downward and outward movements of materials forming slopes, in which shear failure occurs along one or more surfaces [33]. The causes of landslides are often complex and result from a combination of geological, topographic and climatic factors. However, they are always the result of a slope failure when the maximum shear strength of soil (critical stress) is less than the shear stress acting on the slope (safety factor < 1).

A soil element that is involved in a landslide commonly passes through a pre-failure, a shear failure, and a post-failure stage [34]. In the pre-failure stage, the effective shear stress in the slope is less than the shear strength of soil, which leads to a stability case. With increasing stress, the soil passes from linear elastic to nonlinear plastic stress–strain behavior, until the shear stress eventually reaches the shear strength (Fig. 1). When the effective stress is equal to the critical stress, cracks begin to appear, indicating the start of post-failure phase. In ductile soils, the post-failure strength is somewhat equal to the shear strength. However, brittle soils lead to a decrease in stress after failure until a level of constant stress is reached at large strains called remolded or residual strength (Fig. 1).

The state of the sample at the end of the compaction triaxial tests can be classified into seven distinct deformation modes covering the full range of brittle to ductile failure behaviors [35]. Figure 2 schematically represents these different modes. The confining pressure has a significant impact on the variation in soil failure modes. It transforms the brittle behavior by changing the nature of the existing microcracks and other flaws in the soil matrix [36]. Gitau et al. [37] found that the failure behaviors are primarily based on the confinement conditions variation when the low confinement pressures produce brittle failure. However, ductile failure result at high confinement pressures and there is a value of confining pressure, in which the behavior of the soil changes from brittle failure to plastic flow (the transitional state from brittle to ductile). The same results were obtained by Choo and Sun [38], where they found that the failure behavior of geological materials based on the confining pressure and the strain rate.

4 Materials and Methods

4.1 Materials

4.1.1 Soil

In this study, an expansive soil was taken from a depth between 7 and 17 m, coming from a project of resumption of landslide at Mansourah—Tlemcen in Algeria. Figure 3 shows the soil degradation caused by the landslide in the studied area. After several identification tests in the laboratory, the studied soil was classified as fat clay with high plasticity, as determined by the unified soil classification system (USCS) [39]. The geotechnical properties of the clay soil are described in Table 1.

4.1.2 Lime

The lime used in this study is a hydrated lime (Ca(OH)2) produced by the SARL-BSM company, located in the city of Saïda (South-west of the Algerian national territory). Table 2 presents some physical properties and the chemical composition of the hydrated lime used.

4.1.3 Natural Pozzolana

Generally, the pozzolanic materials, whatever natural or artificial, are siliceous or siliceous and aluminous materials that can react with calcium hydroxide (pozzolanic reaction) as described in ASTM C125 [19]. The natural pozzolana used in these experiments is a rock of volcanic origin that was collected from Bou-Hamidi deposit (Béni-Saf) at Ain-Temouchent, as shown in Fig. 4. Table 3 shows the physical and chemical properties of the natural pozzolana.

4.2 Methods

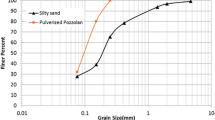

A set of laboratory tests, consisting of initial consumption of lime (ICL), compaction, unconsolidated undrained triaxial test and scanning electron microscopy (SEM) were conducted on the studied soil before and after treatment. Figure 5 shows the scheme of experimental steps. Particle size distribution of clayey soil and natural pozzolana can be seen in Fig. 6. Table 4 shows the studied combination.

4.2.1 Initial Consumption of Lime (ICL)

To determine the initial consumption of lime (ICL) for the studied soil, two different test methods suggested by Hilt and Davidson [40] and Eades and Grim [41] were used. In the first method, Hilt and Davidson [40] recommended using the following empirical expression to calculate the lime fixation point (Lm):

In the second method, the pH tests were carried out according to the standard ASTM D 6276 [42] to determine lime content promoting the increase in pH to a minimum value higher or equal to 12.4. This value is necessary to activate immediate lime-soil reactions and long-term pozzolanic reactions. The increase in pH value causes the dissolution of the clay minerals of soil (Al and Si) and contributes to achieving better flocculation (cation exchange). The pH values measured for soil specimens stabilized with lime, natural pozzolana and their combination are illustrated in Fig. 7. Based on test results, the lime fixation content is between 3 and 4%. Therefore, the following combination was chosen to study (L0P0, L0P10, L0P20, L4P0, L4P10, L4P20, L6P0, L6P10, L6P20).

4.2.2 Compaction Tests

The method mentioned in the standard Proctor compaction test ASTM D 698-00 [43] was applied to determine the compaction parameters of the studied samples, such as maximum dry density (MDD) and optimum moisture content (OMC). Studied combinations were carefully mixed at a slow speed with an automatic mixer. After mixing, the mixtures settled for 2 h before compaction, this period is equal to the setting time of the hydrated lime (the time that lime needs to react or hydrate completely with water).

4.2.3 Unconsolidated Undrained Triaxial Tests

To assess the shear strength of the soil under short-term conditions, UU triaxial tests were carried out according to ASTM D2850-03 [44], (with no saturation or consolidation phase). These tests were conducted to determine the shear strength and stress–strain relationships of standard cylindrical specimens, which have a diameter of 38 mm and a height of 76 mm. The treated and untreated samples are prepared according to the results of Proctor compaction tests (at their corresponding MDD and OMC). The cylindrical specimens were prepared by compacting a statically known amount of specimen material. After being filled, the mold was quickly moved onto the pressing machine to be statically compacted with a displacement speed of 1 mm/min. Static compaction was carried out alternately from both ends of a steel mold (Fig. 8) to ensure uniform compaction of samples. When the specimens were compacted to the designated dimension, the load remained stable for two minutes before unloading. Then, the specimens were removed from the mold and the mass’ height and diameter of each specimen were measured and documented. To avoid any loss of moisture, specimens were enveloped in plastic films after demolding and allowed to harden for 1, 7 and 28 days. After hardening, specimens are carried out under three confining fluid pressure 50, 100 and 200 kPa in a triaxial chamber. The deviatoric stress of the studied samples was taken up to a maximum axial deformation equal to 20% of the sample height.

4.2.4 Scanning Electron Microscopy Test (SEM)

The modifications in soil texture and the fabric changes of the clay particles caused by the lime, NP and their combination treatment were examined by scanning electron microscopy (SEM). The SEM is a test process used to generate surface images of samples on a microscopic level with a beam of high energy electrons in an optical column. The elementary composition of the studied combinations was also determined by the X-ray fluorescence analysis (XRF).

5 Results and Discussion

5.1 Compaction Test

The compaction tests were conducted to determine the effect of lime, natural pozzolana and their combination on compaction parameters of the treated soil such as MDD and OMC. Figure 9 represents the variation of the compaction characteristics of the treated and untreated soil.

5.1.1 Effect of Natural Pozzolana on Clayey Soil

In Fig. 10, the variation of MDD and OMC values obtained from the compaction curves in samples with different combinations is given. According to Fig. 10, the OMC is almost consistent with the increase in the NP content. Also, the MDD increases slightly from 0.15 to 0.25 kN/m3 of the samples containing 10% and 20% of NP, respectively. The results of the compaction parameters can be explained by the large specific gravity of NP, compared to the studied clayey soil and the change of particle size distribution of samples.

5.1.2 Effect of Natural Pozzolana on Clayey Soil Treated with Lime

It became obvious that the addition of lime to the studied soil decreases the MDD and increases the OMC (Fig. 10). The reduction in MDD values can be explained by the lower density of lime compared to the studied clayey soil and by the aggregation of soil particles [6, 14]. The increase in the OMC is supposed to be due to the increase in water retention capacity and the additional water requirements for the pozzolanic reaction [14, 23, 45].

Adding NP to the lime-stabilized clayey soil causes an increase in MDD, compared to samples containing the same lime content without NP additive. The addition of NP by 10% and 20% increased the MDD of samples treated with 6% lime from 0.29 to 0.37 kN/m3, accordingly. Whereas the MDD increase of lime–NP-stabilized clayey soil remains significantly lower, compared to that of untreated soil. Similar behavior was also observed by Harichane et al. [11].

When the OMC values are investigated, it is seen that the OMC increased from 20.25% to 23.27% and 22.73% to 24.05%, with adding 20% NP to 4% and 6% lime-stabilized soil, respectively. This increase can be explained by the increase in the water retention capacity to obtain the necessary amount for the pozzolanic reaction between lime and NP, in addition to its reaction with the clayey soil.

5.1.3 Variation of the Degree of Saturation

Table 5 represents the soil degree of saturation in the optimum point of the compaction curve for each soil studied combination. The addition of lime to the studied soil reduced their degree of saturation, despite the increase in the optimum water content. This decrease in the degree of saturation can be explained by the increase in the void index produced by the aggregation of the soil particles after treatment with lime. The soil becomes more flocculated with a more open fabric structure and by the decrease in the density of the mixture, due to the low specific gravity of lime compared to the clay soil.

According to the results represented in Table 5, the addition of natural pozzolana increases the degree of saturation of the clay soil before and after their treatment with lime. This variation is due to the increase in the optimum moisture content and the reduction in the void ratio of the soil treated with the combination of lime and pozzolana, compared to that treated with lime alone. When adding natural pozzolana to lime-treated soil, it produced a denser soil structure and needed more water for the additional pozzolanic reaction between lime and pozzolana.

5.2 Unconsolidated Undrained Triaxial Tests

The effect of lime, NP and their combination on the UU triaxial tests results of the treated clayey soils under different confining pressures, at various curing days are depicted in Figs. 11, 12, 13, 14, 15 and 16. These figures allow us to partially study the soil behavior before and after treatment with different additives.

5.2.1 Stress–strain Relationships

Figure 11 shows the addition effect of natural pozzolana, lime and their combination on the stress–strain relationships of the treated soil. Two types of curves were obtained from the tests. The first type of curve, which has an asymptotic peakless appearance, represents the curves of the clayey soil alone and the soil with different contents of NP. The second type represents the curves of soil treated with lime and lime–NP combination containing peaks expressed the maximum deviatoric stress followed by a stress reduction (residual deviatoric stress) until the sample failure.

The black curves, representing the results of natural soil and that with NP, are hyperbolic. In the first phase, the stress increases rapidly, then slowed down gradually and approached an asymptotic value, representing the maximum deviatoric stress. After adding NP to the soil, the curves are almost identical to the clayey soil curve. However, there is a slight increase in the maximum stress (shear strength), due to the increase in the MDD of samples.

When soil is treated with lime or lime–NP combination, peaks in the stress–strain curves are observed. The stress–strain curves of treated soil with lime and lime–NP combination are linear, almost up to 85% of peak stress. This linearity increases with the increase of lime content and curing period, where they become more pointed (Fig. 11).

For a better analysis of the change in peak shape, the factor Δq, representing the difference between the maximal deviatoric stress (qmax) and the residual deviatoric stress (qr), divided by the residual deviatoric stress, has been calculated to study their relationship with the failure behavior (Fig. 1). The increase in lime and lime–NP content increases Δq, representing the peak shape (Fig. 12), which transforms the behavior of soil from ductile to brittle. Consequently, the axial strain at failure decreases (axial strain corresponding to the peak). For example, the addition of 20% NP to the soil treated with 4% and 6% lime at 1 day of hardening, under a confining pressure of 50 kPa, leads to increase Δq from 9.4% and 28.8% to 17.1% and 1142%. A considerable increase in Δq, followed by a reduction in axial strain at failure, was observed with increasing curing time. After 28 days of hardening, Δq of soil stabilized by 4% and 6% of lime increased 14 and 7 times, respectively, compared to 1 day of hardening (Fig. 11). This change in behavior due to the flocculation of soil particles and the production of pozzolanic compounds, formed by the reaction between lime and silico-aluminous particles present in soil and NP (cementation of particles). The same behavior was observed by Sivapullaiah et al. [46], when they studied the strength variation of the natural black montmorillonitic cotton soil treated with lime. Also, by Harichane et al. [11], when they studied the effects of adding NP to the lime-treated clay soil on the stress–strain relationships of soils, under two confining pressures (25 and 50 kPa).

Figures 11 and 12 clearly show the effect of confining pressure on the shape of the stress–strain curve. The increase of the confining pressure decreases Δq and increases the axial strain at failure. At 1 day of hardening and with increasing confining pressure from 50 to 200 kPa, the peaks were almost disappearing (transition from brittle to ductile behavior). At 28 days of hardening, Δq decreased, but still remains with important values. The same behavior has been observed by several researchers [35, 47].

5.2.2 Failure Modes

Tables 6 and 7 represent typical photographs of the soil failure modes before and after stabilization, under two different confining pressures, low confinement condition (50 kPa) and high confinement condition (200 kPa). During the deformation of natural soil and soil–NP combination samples, ductile behavior was observed. The studied samples retained their cylindrical shape, and the deformation of the sample was basically uniform, until a percentage of axial deformation varied between 9 and 16%, to obtain their maximum deviatoric stress. During this interval, the samples take on a plastic failure mode. When the strain increased more than 16%, small shear lines at the middle level of the samples appeared (Table 6). With a confining pressure of 50 kPa, samples adopt a ductile faulting behavior. When increasing confining pressure from 50 to 200 kPa, the samples show a more ductile behavior than for the low confinement condition (ductile flow) and no cracks were observed. Several researchers found the same behavior when studying the failure modes of clayey soils [48, 49]. Table 6 clearly shows that the addition of NP to the clayey soil causes more cracks, compared to the soil alone. It can justify the appearance of the new inclined angle cracks in soil–NP combination by the decrease in the plasticity of the samples, as a function of NP addition and increase in the maximum dry density. This causes a decrease in the void ratio, which limits the possibility of specimens’ compaction. Increasing the confining pressure transforms the failure mode from ductile faulting to ductile flow (no cracking), by changing the nature of the existing microcracks in the soil matrix. The high confining pressure of 200 kPa closes the microcracks in the sample’s structure of clayey soil and soil–NP combination.

According to Table 7, the failure modes of the soil samples stabilized by lime and lime–NP combination, mainly depend on the curing time and the confining pressure. For 1 day of hardening, under a confining pressure of 50 kPa, the samples showed a brittle-fault behavior when they were sheared with an inclined plane of failure that higher than π/4. This behavior is the result of short-term reactions of lime-stabilized soil when the chemical reaction causes the flocculation of particles, that increases the friction angle and decreases the soil plasticity. When the confining pressure increased to 200 kPa, the samples deformed in a ductile manner, with small cracks, indicating that the high confining pressure (200 kPa) cannot close all the microcracks in the structure of the sample.

After short-term reactions of lime–soil and lime–NP–soil, based on cation exchange and flocculation of particles, long-term reactions are realized. Cementitious compounds are formed at the base of reactions between calcium, alumina and silica in NP soil. These reactions caused the formation of calcium silica hydrates, calcium aluminate hydrate and calcium aluminasilicate hydrate, that transform the soil from a ductile state, with plastic deformation behavior, to a brittle state with a brittle failure mode. Vitale et al. [6] noted that new mineralogical phases are formed with the increase in hardening time, the new cementitious compounds produced, and the microstructural reorganization of the treated soil affects the macroscopic behavior of samples.

The samples stabilized by lime and lime–NP combination deform as brittle-faulting mode, even with increasing the confining pressure to 200 kPa. This result can be explained by the pozzolanic reaction products and the cementing of soil particles that cause a hard and resistant behavior. In fact, a high concentration of microcracks is produced during sample failure, requiring a high confining pressure to close all microcracks in the samples and transform the soil behavior from brittle to ductile. According to Hatibu and Hettiaratchi [35], a soil with a high concentration of microcracks would be very brittle and would require an application of high confining pressure to completely close the microcracks and suppress brittle behavior.

5.2.3 Maximum Deviatoric Stress Evaluation

The effect of lime, natural pozzolana and their combinations on the maximum deviatoric stress variations of the stabilized soil is shown in Fig. 13. Regarding the use of NP as an additive alone, a marginal increase in maximal deviatoric stress was observed for samples treated with 10% and 20% NP. This increase is caused by the soil texture modification and the increase in their maximum dry density. This type of volcanic material needs a chemical activator to be able to react and develop pozzolanic reactions [12].

The use of lime, as a stabilizer, produced an important increase in maximal deviatoric stress, with increasing both lime content added and curing period. Similar observations were reported by Cai et al. [50] and Sivapullaiah et al. [51]. The pozzolanic reactions between lime, SiO2 and Al2O3 available in clay soils, cause the formation of cementing agents, which develop a significant strength gain.

A considerable increase in the shear strength of clayey soils, stabilized with lime, combined with different NP contents, was obtained in parallel with increasing confining pressure and curing time. Indeed, the addition of NP to lime-treated soil provides a better result for maximal deviatoric stress of treated soil, compared to the use of lime or NP alone. As shown in Fig. 13 with a confining pressure of 200 kPa after 28 days of hardening, the maximal deviatoric stress of a sample treated with 6% lime, combining with 10% and 20% NP, increased by 23.8% and 27.4%, compared to the soil treated with 6% lime only. The significant increase in the maximum deviatoric stress for soils, treated with the combination of lime and NP, compared to that treated with lime only, is probably due to the increase in maximum dry density of the samples. When the NP is added, there is an increase in the Si and Al content in samples, which increases the pozzolanic reaction and lime content, as a function of curing time.

5.2.4 Effect of Curing Time

Figure 14 depicts the results of the effect of curing time on the maximal deviatoric stress under different confining pressures for unstabilized and stabilized soils with lime, natural pozzolana and their combination.

The following observations were noted:

-

The maximum deviatoric stress for clayey soil and treated soil with NP, stayed constant with the curing time because there is no chemical reaction between the clay soil and the NP [11].

-

The addition of lime to clayey soil produced a considerable increase in the maximum deviatoric stress, with an increasing curing period. For the same specimen treated with 6% of lime under 200 kPa confining pressure, the maximum deviatoric stress increased from 701 kPa at 1 day to 1920 kPa at 28 days.

-

The combination of lime and NP gave a higher result for the maximum deviatoric stress of soil that increased with increasing curing time. Under a confining pressure of 200 kPa for 7 and 28 days of hardening, the maximum deviatoric stress of soil treated with 6% lime and 20% NP increased by 64% and 200% respectively, compared to that of treated soil after 1 day of hardening.

5.2.5 Variation of Shear Strength Parameter

Figure 15 shows the qualitative aspect of the variation of Mohr circles for different cure times of 1, 7 and 28 days. However, Fig. 16 shows the results of the shear parameters extracted from the Mohr circle.

The cohesion of soil was almost constant when the NP added. The cohesion of natural soil and soil with 10% of NP is equal to 105 kPa. This value increased slightly with the addition of 20% NP to obtain a cohesion of 114 kPa. Adding a NP content with a percentage of less than 20% has practically no effect on the variation in cohesion. If the NP content is higher than or equal to 20%, the cohesion increased slightly. This increase can be explained by the increase in the maximum dry density and by the modification of soil structure. An increase in the friction angle was observed with the increase in NP content. The addition of 10% and 20% of NP increased the friction angle from 14 to 15.7° and 16.12°, respectively. This increase can be explained by the modification of the soil structure (larger particle) due to the large difference between particle size distribution of soil and NP (Fig. 7). On the other hand, the internal friction angle of the NP is higher than that of the soil. No increase in shear parameters was observed during the increase in curing time for soil combined with NP. This is due to the inactive type of NP used, so it cannot react chemically without a cementitious addition. Harichane et al. [12] observed the same behavior when the effect of the same type of NP on two different types of soil stabilized with lime was studied.

Figure 16 clearly shows that there are three factors that have considerable influence on the shear parameters variation of stabilized clayey soil with lime and lime–NP combination. These factors are lime content, NP content combined with lime and curing time. Increasing lime content caused a considerable increase for shear parameters. For soil stabilized with 6% lime at 1 day of hardening, the cohesion and the friction angle increased from 105 kPa and 14° to 145 kPa and 23°, respectively. These results increased greatly with the increase in curing time. After 28 days of hardening, cohesion and friction angle increased to 350 kPa and 35.53°. The increase in the percentage of NP, combined with lime, increased the samples cohesion. The addition of 10% and 20% of NP increased the cohesion of the soil stabilized by 6% lime, after 25 days of hardening from 350 to 450 kPa and 500 kPa. Conversely, the variation of the friction angle of stabilized soil by lime, combined with various NP contents, had values varying between 31.5 and 36°, where the maximum value was for the soil stabilized with 6% lime and 10% NP.

To explain the variation of the shear parameters and the chemical reaction responsible for this variation, Sivapullaiah et al. [46] suggested that flocculation of particles increases the friction angle value, whereas cementation of particles increases the value of cohesion. Furthermore, higher cohesion values after 28 days of curing by the pozzolanic reaction produced with time [51]. The relation between increasing cohesion and lime content, generated by the formation of flocs, the soil particles become strongly bonded (aggregation/flocculation). Therefore, the treated soil behaves as a coarse-grained soil [12].

The shear strength parameters increased with the increase in lime and NP contents, in accordance with the increasing curing time. First, short-term reactions, such as cation exchange and particle flocculation, occur when the soil stabilized with lime or with lime–NP combination. Cation exchange causes the production of new chemical bonds between particles to form larger aggregates. This chemical bond increases the cohesion of the treated soil. Due to flocculation and the fabrication of micro-ports, the friction angle of the stabilized soil has increased. Second, with increasing curing time, pozzolanic reactions occur (C–S–H, C–A–H, C–A–S–H). Particle cementation is one of the results of long-term reactions, which is the cause of the strong increase in cohesion at later stages of curing time. It makes the soil hard and brittle with rough surfaces, which increases the friction angle. To explain the increase in shear parameters with increasing NP content, there are two types of influence. The first one is the effect on the physical properties of soil. Soil becomes denser with a more resistant soil structure. The second one is the effect of NP on the chemical properties of soil stabilized with lime, an additional pozzolanic reaction was produced between lime, Al and Si found in the NP.

5.3 Microstructural Assessment of Stabilized Soil

The mineralogical and microstructural aspect of clayey soil samples, before and after treatment with lime, natural pozzolana and their combination, was studied using a scanning electron microscope (SEM). The objective of these microstructural studies was to determine the structural changes caused by treatment with the various additives used. The XRF results showed a majority of Si and Al with Ca content and traces of Fe, K and Mg in soil at their natural state (Fig. 17). The high percentage of Si and Al is due to the clay mineral components. From Fig. 18b, the addition of NP to the clayey soil modified their texture. The soil becomes denser with a more solid and resistant structure.

Figure 18 shows the effect of 20% NP addition on the microstructural form modification of the clayey soil before and after treatment with 6% lime at 1 day and 28 days of hardening. The SEM micrography of untreated compacted clayey soil (Fig. 18a) clearly shows that the soil has a discontinuous structure and large cracks, due to the drying of water, and the aggregates of clay plates are assembled with a largely mutual contact.

The micrographic photos in Fig. 18c–h represent the modification of the structure of soil stabilized with lime and lime–NP combination. To understand the stages of the soil during chemical stabilization, the reaction between the soil and lime or lime–NP split into two stages, according to the hardening time (short term and long term). When the lime reacted with the clay particles, a porous fabric was created, with an agglomeration effect, forming larger particles and causing an increase in the size of micro-pores. The dissolution of lime in clayey soil, in the presence of water, caused a considerable increase in pH value because of liberating calcium cations Ca2+ and hydroxyls cations (OH)−. These cations are instantly adsorbed and intercalated in clay minerals and replace a part of their constituent cations. The cation exchange leads to a modification of the surface electric charge density of clay particles and consequently changes the texture of the clay soil and improves their consistency. This behavior has been found by several researchers. According to Vitale et al. [6], in the short term, a significant change in the arrangement of clay particles has been detected when the treated soil is more flocculated than the untreated soil. Jha and Sivapullaiah [13] reported that the addition of lime to the studied soil produced several aggregated soil particles with variable size and shape.

Micrographic photos (e) and (f) in Fig. 18 show the microstructure modification of the treated clay soil after 28 days of hardening. The reactions at long-term led to form an alumina and silica hydrate gels (Eqs. 2–4) (cementitious reaction products of lime stabilization) covering the clayey surface. This process is called pozzolanic reaction. The dissolution of lime in the mixture (liberation of Ca2+ and OH−) allows the saturation of the calcium solution, with an elevation of pH. Calcium reacts with alumina and silica in the soil to form calcium silica hydrates (C–S–H), calcium aluminate hydrate (C–A–H) and calcium aluminate silicate hydrates (C–A–S–H) [52].

From Fig. 18g and h, the cementing materials for the stabilized soil with lime, combined with NP are superior to those stabilized with lime only. The Si and Al reacted with Ca for soils treated with lime–NP are higher than those obtained when lime has been added only. This indicates the formation of new additional phases of cementation when adding NP. Al Swaidani et al. [23] concluded that a formation of additional new cementing phases was produced when adding NP. The same behavior was observed by Harichane et al. [12].

6 Conclusion

The main objective of this paper is to study the effect of lime, natural pozzolana and their combination on the compaction parameters, shear strength, shear parameters and the microstructural modification for the different studied combinations. Based on test results, the following conclusions can be drawn:

-

The pH value increases with increasing lime content for lime-stabilized clayey soil, with and without NP addition. This increase in pH is a sign of the start of the chemical reactions between soil–lime or soil–lime–NP.

-

The addition of NP to the clayey soil slightly increases their maximum dry density when the optimal moisture content has remained almost constant. The addition of lime or lime–NP combination to the clay soil decreases their MDD and increases the OMC. The soil stabilized by lime–NP combination is denser compared to the soil stabilized by lime only.

-

The stress–strain curves, of clay soil and the combination of soil with NP, have a hyperbolic form (peakless). Peaks in the stress–strain curves were observed when soil is stabilized with lime or lime–NP combination. The peak shape, represented by Δq, increases with increasing lime or lime–NP content and the curing period, and decreases with increasing confining pressure.

-

Ductile failure mode was observed for natural soil and soil–NP combination samples. This failure mode transforms to a brittle failure when the soil stabilized with lime or lime combined with NP. A significant effect has been observed on the variation in failure modes of stabilized soils, as a function of increasing confinement conditions.

-

A marginal increase in maximal deviatoric stress was observed for soil–NP combination samples. The use of lime, as a stabilizer, produced an important increase in maximal deviatoric stress, with increasing of both lime content added and curing period. The addition of NP to lime-treated soil provide a better result for maximal deviatoric stress of treated soil compared to using lime alone.

-

The shear strength parameter of clayey soil increased slightly when NP is added. No increase in shear parameters was observed during the increase in curing time. A significant increase was observed in cohesion and friction angle of soil stabilized by lime and lime combined with NP. This increase is based on the lime content, the NP content combined with lime and the time of curing.

-

The microstructural reorganization of lime or lime–NP-stabilized clayey soil and the creation of new cementitious products completely changes the behavior of soil. The geotechnical behavior of the treated samples is based on the microstructural reorganization of soil particles at short-term and the formation of cementitious compounds at the long-term reactions.

-

The addition of natural pozzolana, alone, to the studied soil, did not lead to a significant variation in their geotechnical properties, since the type of pozzolana used does not themselves have binding properties. Thus, the use of this type of pozzolana on soil stabilization is only viable with other compounds acting in synergy.

-

The combination of two local materials, such as natural pozzolana and lime, can effectively improve the mechanical properties of the fat clay soil and help to increase land availability for construction projects. In this research, the better soil strength behavior was observed for samples treated with a combination of 20% natural pozzolana and 6% lime.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Davis LE (1952) Electrochemical properties of clays. Clays and Clay Miner 1(1):47–53. https://doi.org/10.1346/ccmn.1952.0010106

Cernica JN (1995) Geotechnical engineering: soil mechanics. Wiley, Californie

Dembicki E, Kisielowa N, Nowakowski H, Osiecimski R (1980) Compactage des fonds marins sableux à l’explosif, vol 1. Colloque sur le compactage, Paris, pp 295–299

Kirmani SMH (2004) Consolidation of soil for Foundation using sand drains. IEP-SAC J. pp. 49–55.

Bryson S, El Naggar H (2013) Evaluation of the efficiency of different ground improvement techniques. 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris.

Vitale E, Deneele D, Paris M, Russo G (2017) Multi-scale analysis and time evolution of pozzolanic activity of lime treated clays. Appl Clay Sci 141:36–45. https://doi.org/10.1016/j.clay.2017.02.013

Long G, Li L, Li W, Ma K, Dong W, Bai C, Zhou JL (2019) Enhanced mechanical properties and durability of coal gangue reinforced cement-soil mixture for foundation treatments. J Clean Prod 231:468–482. https://doi.org/10.1016/j.jclepro.2019.05.210

Driss AAE, Harichane K, Ghrici M, Gadouri H (2022) Assessing the effect of moulding water content on the behaviour of lime-stabilised an expansive soil. Geomech Geoeng 17(3):896–908. https://doi.org/10.1080/17486025.2021.1903092

Okagbue CO, Yakubu JA (2000) Limestone ash waste as a substitute for lime in soil improvement for engineering construction. Bull Eng Geol Env 58(2):107–113. https://doi.org/10.1007/s100640050004

Driss AAE, Harichane K, Ghrici M (2021) Effect of natural pozzolana on microstructural behavior and hydraulic conductivity of lime-stabilized clayey soil. Innova Infrastruct Solut 6(4):1–17. https://doi.org/10.1007/s41062-021-00544-7

Harichane K, Ghrici M, Kenai S, Grine K (2011) Use of natural pozzolana and lime for stabilization of cohesive soils. Geotech Geol Eng 29(5):759–769. https://doi.org/10.1007/s10706-011-9415-z

Harichane K, Ghrici M, Kenai S (2018) Stabilization of Algerian clayey soils with natural pozzolana and lime. Period Polytech Civil Eng 62(1):1–10. https://doi.org/10.3311/ppci.9229

Jha AK, Sivapullaiah PV (2015) Mechanism of improvement in the strength and volume change behavior of lime stabilized soil. Eng Geol 198:53–64. https://doi.org/10.1016/j.enggeo.2015.08.020

Garzón E, Cano M, O`Kelly BC, Sánchez-Soto PJ (2016) Effect of lime on stabilization of phyllite clays. Appl Clay Sci 123:329–334. https://doi.org/10.1016/j.clay.2016.01.042

Khemissa M, Mahamedi A (2014) Cement and lime mixture stabilization of an expansive overconsolidated clay. Appl Clay Sci 95:104–110. https://doi.org/10.1016/j.clay.2014.03.017

Sivapullaiah PV, Jha AK (2014) Gypsum induced strength behaviour of fly ash-lime stabilized expansive soil. Geotech Geol Eng 32(5):1261–1273. https://doi.org/10.1007/s10706-014-9799-7

McCarthy MJ, Csetenyi LJ, Sachdeva A, Dhir RK (2014) Engineering and durability properties of fly ash treated lime-stabilised sulphate-bearing soils. Eng Geol. 174:139–148. https://doi.org/10.1016/j.enggeo.2014.03.001

Ijaz N, Dai F, Meng L, Rehman Z, Zhang H (2020) Integrating lignosulphonate and hydrated lime for the amelioration of expansive soil: a sustainable waste solution. J Cleaner Prod 254:119985. https://doi.org/10.1016/j.jclepro.2020.119985

ASTM C125–21 (2021) Standard terminology relating to concrete and concrete aggregates. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/C0125-21

Hossain KM, Lachemi M, Easa S (2006) Characteristics of volcanic ash and natural lime based stabilized clayey soils. Can J Civ Eng 33(11):1455–1458. https://doi.org/10.1139/l06-099

Harichane K, Ghrici M, Kenai S (2012) Effect of the combination of lime and natural pozzolana on the compaction and strength of soft clayey soils: a preliminary study. Environ Earth Sci 66(8):2197–2205. https://doi.org/10.1007/s12665-011-1441-x

Zoubir W, Harichane K, Ghrici M (2013) Effect of lime and natural pozzolana on dredged sludge engineering properties. Electron J Geotech Eng 18(c):589–600

Al-Swaidani A, Hammoud I, Meziab A (2016) Effect of adding natural pozzolana on geotechnical properties of lime-stabilized clayey soil. J Rock Mech Geotech Eng 8(5):714–725. https://doi.org/10.1016/j.jrmge.2016.04.002

Langfelder LJ, Nivargikar VR (1967) Some factors influencing shear strength and compressibility of compacted soils. Highway Res Rec 177:4–21

Seed HB, Mitchell JK, Chan CK (1960) The strength of compacted cohesive soils. Proc. ASCE Research Conf. on Shear Strength of Cohesive Soils, Boulder. Accession Number: 00231422, pp.877-964

Mitchell JK, Hooper DR, Campanella RG (1965) Permeability of compacted clay. J Soil Mech Found. Div., Proc. ASCE 91(4):41–65

Casagrande A, Hirschfeld RC (1962) Second progress report on investigation of stress-deformation and strength characteristics of compacted clays. Soil Mechanics Series No. 65. Harvard University.

Thompson MR (1964) Lime reactivity of illinois soils as it relates to compressive strength. Civil Eng. Studies, Univ. of Illinois, Illinois Coop. Highway Res. Prog. Series NP-4.

Sabat AK, Mohanta S, Swain S (2015) Effect of moulding water content on geotechnical properties of rice straw ash stabilized expansive soil. ARPN Journal of Engineering and Applied Sciences 10(22):10427

Maaitah ON (2012) Soil stabilization by chemical agent. Geotech Geol Eng 30(6):1345–1356. https://doi.org/10.1007/s10706-012-9549-7

Sharma NK, Swain SK, Sahoo UC (2012) Stabilization of a clayey soil with fly ash and lime: a micro level investigation. Geotech Geol Eng 30(5):1197–1205. https://doi.org/10.1007/s10706-012-9532-3

Carlsten P, Ekstrom J (1995) Lime and lime/cement columns. Swedish Geotechnical Society Report 4:95E, Linkoping

Hampton MA, Lee HJ, Locat J (1996) Submarine landslides. Rev Geophys 34(1):33–59

Terzaghi K, Peck RB, Mesri G (1996) Soil mechanics in engineering practice, 3rd edn. John Wiley and Sons Inc, New York

Hatibu N, Hettiaratchi DRP (1993) The transition from ductile flow to brittle failure in unsaturated soils. J Agric Eng Res 54(4):319–328. https://doi.org/10.1006/jaer.1993.1024

Joshi RC, Wijeweera H (1990) Post peak axial compressive strength and deformation behavior of fine-grained frozen soils. In Proc. Collection Nordicana 54(Proc. 5th Canadian Permafrost Conf.). pp. 317–325.

Gitau AN, Gumbe LO, Mwea SK (2008) Mechanical behavior of a hard-setting luvisol soil as influenced by soil water and effective confining stress. Agric Eng Int: CIGR J X. Manuscript LW 07 021

Choo J, Sun W (2018) Coupled phase-field and plasticity modeling of geological materials: from brittle fracture to ductile flow. Comput Methods Appl Mech Eng 330:1–32. https://doi.org/10.1016/j.cma.2017.10.009

ASTM D2487–17e1 (2020) Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D2487-17E01

Hilt GH, Davidson DT (1960) Lime fixation in clayey soils. Highway Research Board Bulletin 262, Washington, DC, pp 20–32

Eades JL, Grim RE (1966) A quick test to determine lime requirements for lime stabilization. Highw Res Rec 139:61–72

ASTM D6276–19 (2019) Standard test method for using pH to estimate the soil-lime proportion requirement for soil stabilization. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D6276-19

ASTM D698–12R21 (2021) Standard test methods for laboratory compaction characteristics of soil using standard effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D0698-12R21

ASTM D2850–15 (2016) Standard test method for unconsolidated-undrained triaxial compression test on cohesive soils. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D2850-15

Kinuthia JM, Wild S, Jones GI (1999) Effects of monovalent and divalent metal sulphates on consistency and compaction of lime-stabilised kaolinite. Appl Clay Sci. 14(1–3):27–45. https://doi.org/10.1016/s0169-1317(98)00046-5

Sivapullaiah PV, Sridharan A, Ramesh HN (2000) Strength behaviour of lime-treated soils in the presence of sulphate. Can Geotech J 37(6):1358–1367. https://doi.org/10.1139/t00-052

Walton G, Hedayat A, Kim E, Labrie D (2017) Post-yield strength and dilatancy evolution across the brittle–ductile transition in indiana limestone. Rock Mech Rock Eng 50(7):1691–1710. https://doi.org/10.1007/s00603-017-1195-1

Wong CK, Wan RG, Wong RCK (2017) Tensile and shear failure behaviour of compacted clay—hybrid failure mode. Int J Geotech Eng 14(3):231–241. https://doi.org/10.1080/19386362.2017.1408242

Wang Y, Guo P, Li X, Lin H, Liu Y, Yuan H (2019) Behavior of fiber-reinforced and lime-stabilized clayey soil in triaxial tests. Appl Sci 9(5):900. https://doi.org/10.3390/app9050900

Cai Y, Shi B, Ng CWW, Tang CS (2006) Effect of polypropylene fiber and lime admixture on engineering properties of clayey soil. Eng Geol 87(3–4):230–240. https://doi.org/10.1016/j.enggeo.2006.07.007

Furlan AP, Razakamanantsoa A, Ranaivomanana H, Levacher D, Katsumi T (2018) Shear strength performance of marine sediments stabilized using cement, lime and fly ash. Constr Build Mater 184:454–463. https://doi.org/10.1016/j.conbuildmat.2018.06.231

Kavak A, Akyarlı A (2007) A field application for lime stabilization. Environ Geol 51(6):987–997. https://doi.org/10.1007/s00254-006-0368-0

Acknowledgements

This research was sponsored by the General Directorate for Scientific Research and Technological Development (DGRSDT) of the Algerian Minister of Higher Education and Scientific Research. The authors thank the head of civil engineering department and the laboratory engineers of Belhadj Bouchaib University of Aïn-Temouchent in Algeria and Sakarya University of Adapazarı in Turkey for their contribution to the laboratory tests and the carrying out of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Driss, A.A.E., Harichane, K., Ghrici, M. et al. Effect of Natural Pozzolana on the Unconsolidated Undrained Shear Strength of a Lime-Stabilized Clay Soil. Int J Civ Eng 21, 1007–1026 (2023). https://doi.org/10.1007/s40999-023-00817-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-023-00817-5