Abstract

This study presents the improvements achieved as a result of the lime stabilization application conducted by the joint effort of the Turkish Association of Lime Industrialists and the General Directorate of Rural Services on the 200 m long section of the Ankara Province Yukarı Yurtçu Village road where green and brown clays are dominant. The study also numerically demonstrates the impacts of these improvements on the road section based on the results of various laboratory and field tests. The lime stabilization in field conditions was performed with 5% lime for both clays and was applied as a 30 cm thick single layer. In the soaked California bearing-ratio (CBR) tests conducted in the laboratory, increases that reach up from 16 and 21 times compared to initial soaked CBR values were observed in green and brown clays, respectively, at the end of 28 days. The high increases observed in soaked CBR values would reduce the upper layer thickness of the roads. The similar improvements are also achieved in unconfined compression and plate loading tests. The comparisons performed with the plate loading tests clearly demonstrated the behavior of the surface to lime and its cure impact.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lime stabilization is one of the most commonly applied soil improvement techniques in the world. As a result of lime stabilization, clay particles stick to each other and form larger particles (Broderick and Daniel 1990). The following changes are observed in the soil in short term: optimum water content values increase, proctor densities decrease, plasticity indices reduce, proctor curve levels out and CBR values increase. Based on the studies conducted by Thomson (1969), lime has been found to reduce the plasticity indices of the clayey soils and has further been determined to transform the soil into a structure that could be worked on more easily. In their studies, Newbauer and Thompson (1972) have found changes in the water content–density relationships as a result of the reactions between the lime and the soil. They have also found that the optimum water contents of the lime-stabilized soils were higher when compared to that of the natural soils. Moreover, the maximum dry unit weight values were lower and the compaction curves became more horizontal. Hence, lime stabilization technique is widely used in the subgrade, subbase and base layers of road construction. There are several advantages of lime stabilization in road construction. In addition to its use in clayey soil, it could also be used to transform soils with inconvenient large-sized materials due to their high clay content into more convenient forms. In such soils, clay with its low strength and geotechnical properties could react with lime and transform the soil’s micro structure into a more particulate form, thus would reduce the swelling potential and increase the strength of the material making it more suitable. The use of lime stabilization for road constructions reduces the thickness of the upper layers due to high CBR values and makes the overall construction more economical.

Lime stabilization dramatically reduces environmental impact through construction and ongoing use of the access road pavement (e.g., minimal excavation and compaction required, minimal effect on visual amenity during construction). The minimal cut and fill volumes during construction works decrease the damages over the rock quarries.

As a result of lime stabilization, liquid limit values and proctor densities decrease while unconfined compressive strength, plastic limit, optimum water content and CBR values increase in the short term. The proctor curve becomes flatter in this period. In the long term, the CBR values, unconfined compressive strength, shear strength and tensile strength further increase, stability against swelling and shrinkage intensifies and the resistance to freezing rises.

In addition to the changes observed in the geotechnical properties of the soil with lime stabilization, radical increases are experienced particularly in the unconfined compressive strength values. In studies conducted by Kavak (1996), pure bentonite and kaolinite clays were lime-stabilized and unconfined compressive strengths were analyzed. His studies revealed that the unconfined compressive strengths of the clays were shown to increase 6 times for bentonite and 12 times for kaolinite in 1-month time. The long term cured samples have shown to experience further strength increases.

The lime stabilization not only creates high increases in the strength of the soil but also results in a change in the behavior of the soil. The unconfined compressive strength test results of the brown clay used in this study under no-lime, 5% lime 7 days cured and 5% lime 1-year cured conditions are presented in Fig. 1. The unconfined compressive strength of the lime stabilized brown clay has increased from a value of 340 kPa under natural conditions to 1,300 kPa in 1 week and to 1,600 kPa after 1 year. The unit deformations at the failure instant have reduced from 3 to 1%. As the unconfined compressive strength is increased, modulus of elasticity has had a definite increase. This behavior was also clearly observed in lime stabilization studies conducted previously with pure clays such as bentonite and kaolinite reported in the literature (Baykal 1987; Kavak 1996; Kavak and Baykal 2001).

As a result of their study, Clare and Crunchley (1957) have determined a total of four factors that creates a stress increase in soils after lime addition. These factors could be stated as follows: (1) the formation of calcium hydroxide crystals that behave like cement as a result of the reactions between the lime and the clayey soils; (2) the exchange of calcium ions found in lime with other ions found in clay’s surface and the resulting amplified attractive forces between clay particles that results in larger clay units; (3) the calcium carbonate formation as a result of the reactions with the atmospheric carbon dioxide; and (4) the formation of calcium silicate and calcium aluminate, which behave like cement minerals as a result of the reactions between the clayey soils and lime.

Lime stabilization has a detrimental effect on soil behavior if adequate amounts of sulfate are present in soil. Sulfate induced heave of soils stabilized with calcium based stabilizers occurs due to the presence of primary and secondary sources of sulfates in soils (Rao and Shivananda 2005). Excessive sulfate in the soil will lead to ettringite formation. Ettringite will lead to excessive heaving or swelling due to its needle like shape. Wild et al. (1999) and Veith (2000) stated that slag at predetermined percentages will decrease this effect. Wild also stated that if the sulfate content is less than 1%, sulfate will not have an effect on swelling.

The objective of this study is to analyze the impacts of lime stabilization on road construction. In addition to the 28-day laboratory experiments, subsequent field studies were also conducted to achieve this objective. Although one might think that 28-day period is a fairly short period of time for laboratory analysis, it is extremely important as the construction works in the field could not wait that long. The field CBR and plate loading tests that were conducted on the field within the 28-day period have provided an opportunity to perform a lot of comparative analysis and to obtain numerous new data.

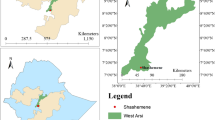

For these purposes, a lime stabilization application was performed on the road to Ankara Yukarı Yurtçu Village that was given to the Association of Lime Industrialists by the General Directorate of Rural Services. In order to achieve this objective, the surface soil on which the road will be constructed would need to be in situ improved. The application was done in two stages. The first stage included the laboratory analysis of the materials that will be lime stabilized and the second stage consisted of the construction works and the field experiments. During the field applications, the surface soil was improved in situ as it consists mostly of clay material. The quality control studies were done during construction and after construction with field experiments.

Materials and methods

A lime stabilization application was performed on the road to Ankara Yukarı Yurtçu Village that was given by the General Directorate of Rural Services. The selected road was first visually inspected and was found that it consisted of brown and green colored clay types. Although the application was initially planned as two stage operations including the laboratory analysis in the first stage and the field application in the second stage, the analysis of the results from these stages has necessitated another group of laboratory analysis.

Within the scope of the laboratory studies, sieve analysis, hydrometer method, liquid-plastic limit analysis, proctor experiments and CBR tests were performed to determine the geotechnical properties of the material. In the next stage, the lime amount to be used in the stabilization process was determined. The Eades and Grim (1963) pH method and Atterberg limits are used for preliminary design lime percent. Experiments for optimum lime determination were conducted on the samples by mixing different amounts of lime to the materials. Based on these experiments, the optimum amount of lime to be used in the field application was determined to be 5% of the dry weight for both materials.

The modified proctor experiments were conducted to find out the optimum water content and the maximum dry unit weight value of the lime stabilized materials. The experiments were performed after waiting for 1 h to let the first reactions to take place upon mixing the determined amount of lime and water to the pure samples.

For the soaked CBR tests, the samples were mixed at the optimum water content and optimum lime ratio and waited for 1-h before they were compacted in the molds. Then, the samples were cured at room temperature for 1, 7 and 28 days and kept waiting in water for 4 days. The swelling amounts in the lime stabilized soil samples were found to be below 1%. The samples were intentionally cured at room temperature such that the field conditions could be better represented. After decreases in the CBR values were observed, the experiments were repeated under controlled temperature and humidity in order to understand the causes for these decreases.

In the second stage, the field studies were conducted with the help of the construction machinery of the Ankara Regional Directorate of Rural Services. For the field application, the 200 m section at the entrance to the Yukarı Yurtçu Village was selected and this section was further divided into 25 m long portions. The first 100 m of the selected 200 m long section consisted of brown clay where as the second 100 m consisted of green clay. For comparison purposes, the first 25 m portion of the brown clay section was excavated 30 cm thick and then compacted at optimum water content without lime. Of the remaining 175 m, a 75 m long portion remained in the brown clay zone whereas the other 100 m was left on the green clay zone. The compaction operation was done with a single layer. At the beginning of the operation, the entire road was excavated at a depth of 25–35 cm such that the soil was made loose. The lime stabilization was applied on the 175 m long portion of the road at a compacted thickness of 30 cm. The optimum lime dosage was applied on the 75 and 100 m long portions of the road where brown and green clays were present, respectively, as determined amounts in the laboratory tests. The determined lime amount was programmed, adjusted and applied by a lime sprinkler machine. The sprinkled lime was later mixed with the natural soil by construction machinery, watered by a water sprinkler, compressed and ironed by a vibration road roller. The quality of the compression operation was in situ tested by density experiments.

The improvements achieved by lime stabilization on the experimental road were tested by field plate loading tests and field CBR tests. These tests were conducted separately on natural surfaces, compacted surfaces without lime and lime stabilized surfaces. The experiments were repeated on the field immediately after stabilization, after 1 day and after 28 days, and comparisons were made.

Physical and chemical properties of clays used in the study

When the field that will be lime-stabilized was examined, it was seen that there were two different types of clays in the field. One of these clays was brown and the other one was green in color. The geotechnical properties and chemical analysis of both clays are given in Tables 1 and 2, respectively.

The properties of lime used in stabilization

The standard calcium hydroxide lime produced by three factories, which are members of the association, is used in this study. The standard chemical and physical properties of the lime used are given in Table 3.

Results

Particle size analysis

A sieve analysis was performed for both clays in accordance with the standards depicted in ASTM D 421 and 422. The purpose of this analysis was to determine the gradations of the material and to classify them. When the results of this experiment were analyzed, it was seen that both materials contained 99% clay and silt.

Atterberg limits

The Atterberg limits were conducted on the samples by mixing 2, 3, 4, 5 and 6% lime (by weight) to the green and brown clays. In cases where lime was used, the experiments were performed after clay–lime mixtures were rested for 1 h allowing the first reactions to occur. The mixtures were selected such that the plasticity index was roughly below 10% and/or considering the economy of the lime used in the mixture. The experiments were conducted in accordance with the ASTM D 4318 standard. The results of this analysis are given in Table 4 for both the materials.

Based on the experiments conducted, it was seen that as the amount of lime in the mixture was increased, substantial reductions in PI values were observed. Accordingly, the PI value of the natural brown clay is 34% without lime, which has reduced to 23% when mixed with 2% lime and further reduced down to 1% when mixed with 6% lime as could be seen from Table 4. Similar reductions were also observed for the green clay. While the PI value of the green clay in its natural state was 24%, it reduced to 4% when mixed with 6% lime. According to the Atterberg limit tests, the 5% lime mixture that essentially reduced both clays’ PI value below 10% appears to be suitable.

pH determination

The pH experiments were conducted by using the method of Eades and Grim (1963) in order to determine the amount of lime. The pH tests were performed on the samples by mixing 1, 2, 3, 4, 5 and 6% lime with the natural soils. The results of this analysis are given in Table 5.

The pH tests revealed that the natural pH values of brown and green clays were found to be 7.7 and 7.8, respectively. It was also observed that lime increased the pH value of the medium for both clays. The amount of lime that increased the pH value to 12.4 has been found to be the optimum lime amount as described by Eades and Grim (1963). These results were in parallel with the results obtained from the Atterberg limits.

Determination of optimum lime amount

The optimum lime amount was jointly determined by making use of the lime amount that reduced the plasticity index value below 10% with 1 h Atterberg limit method and the lime amount that increased the pH value to 12.4. When the changes in the plasticity index values, the pH values and the economies of scale were considered, the optimum lime amount was selected to be 5% by weight. This value was used in all field studies.

Compaction tests

The optimum water content of the lime-stabilized clays and the maximum dry unit weights were analyzed by the modified Proctor tests in accordance with ASTM D 1557–1578. The Proctor tests were performed for both clays under their natural states and after mixing with 5% lime. The results are given in Table 6 and are present in Fig. 2.

According to the Proctor experiment results, the maximum dry unit weight of the brown clay has reduced from 15.51 to 14.60 kN/m3, whereas the optimum water content has increased from 20.5 to 26.0%. On the other hand, the maximum dry unit weight of the green clay has reduced from 15.30 to 14.88 kN/m3, whereas the optimum water content has increased from 20 to 23%. When the proctor graphics are analyzed, it could be seen that lime addition has reduced the maximum dry unit weight and increased the optimum water contents of both clays. Furthermore, the slope of the graphs was reduced and slightly leveled out. The obtained results were as expected and demonstrated parallelism with the literature values.

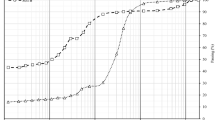

CBR tests in the laboratory before field application

In the CBR experiments performed in the laboratory, the materials were prepared at their optimum water content by adding 5% lime and were compacted. The prepared samples were rested for different cure times before soaked CBR experiments are performed in accordance with ASTM D 1883–1887. Cure conditions included the following: (1) the ambient laboratory temperature varied between 10° and 25°C for a period of 28 days and (2) the ambient humidity has been below 60%. The soil samples in the experiments were cured at room temperatures in order to better observe the conditions in the field. The results obtained from CBR tests are given in Table 7 and are present in Fig. 3.

As seen from Table 7 and Fig. 3, the soaked CBR values of the materials have shown significant increases when they were mixed with lime. After 28 days, the CBR value of the brown clay with 5% lime has increased 21 times when compared to its natural state. This increase was observed to be 16 times in the green clay. These results clearly demonstrated the fact that addition of lime to clays definitely increased the CBR values. Hence, the selected lime amount was found to be suitable for these soils. Obtaining soaked CBR values that were within the range of filling materials demonstrated the success of lime stabilization. Swelling values of less than 1% were observed in lime added soaked CBR tests. As seen from the Fig. 3, the soaked CBR values exhibited a slight decrease in 28-day values. After the field applications, the CBR tests were cured under controlled temperature and humidity and the experiments were repeated in order to understand the cause of this decrease. The cause of this decrease is discussed in details in the studies performed after the field applications.

Field CBR tests

Field CBR experiments were performed on the test road with cure times reaching up to 28 days and the changes in CBR values after stabilization were analyzed. The results of the experiments are given in Table 8 and are present in Fig. 4.

The field experiments were performed on an area where two clays exist on the road surface. The field CBR values of the clays were found to be 18 and 15 for brown and green clays, respectively. The field CBR value slightly increased to 20 in an area where brown clay was present and where compaction was done without lime. When lime compaction was done, the field CBR values of both soil reached 41–42 in 1 day. In the area where green clay was present, the 1-day field CBR value of 41 has decreased to 35 in 28 days. In the brown clay case, however, the increase in the field CBR value continued and has reached 54. Although the lime stabilized green clay has experienced an increase as compared to the natural conditions, the observed decrease in 28-day sample was attributed to the drying of the clay’s surface.

Soaked CBR tests after field application

As a result of the soaked CBR tests performed in the laboratory as well as the field applications, it has been observed that the green clay exhibited significant decreases in 28-day tests both in the laboratory and in the field. In brown clay, however, the decreases were observed in the laboratory tests performed on 28-day cured samples. The reason for the decreases in both the laboratory and the field tests was believed to be attributed to the absence of pozzolonic reactions due to lack of water as a consequence of lime stabilization and/or the fracture of the formed cement minerals as a result of shrinkage effect (Kavak et al. 2005).

In the literature, these reactions were defined as follows: when lime and clay were mixed and compacted, cementation emerged among the surface of clay particles. After reaction between lime and clay, calcium silicate and calcium aluminate gels occurred and this created cementation among particles. These cement minerals were similar to the minerals in Portland cement (Ingles and Metcalf 1972).

The following studies were applied to prevent that effect. The material needed water so that lime could get into reaction with clay. In order to better understand these decreases, two groups of CBR tests were performed in the laboratory. In all these tests, the previously determined lime amount of 5% by weight was used. In the first group of tests, the prepared samples were cured under controlled temperature (22°C) and humidity (95%) for 28-days and soaked CBR experiments were performed. In the second group of tests, the samples were watered as in the case of concrete production. The samples were watered for the first 7 days. The water was applied at a rate of 9 l/m2 every day and it was only applied to the surface of the CBR mould. These samples were rested in room temperature. During this period, the room temperature was in the range of 10°–26°C and the humidity was below 60%. The results of these tests and their comparisons are given in Table 9 and are present in Fig. 5.

When the results of the experiments were evaluated, it was seen that the soaked CBR values did not decrease and continued to increase under controlled temperature and humidity. Once watering was performed, high increases were observed despite the fact that there were no controlled temperature and humidity. As seen from the table and the figure, the soaked CBR values have reached 100 in lime stabilized brown clay and 105 in green clay as a result of the watering effect. Based on these results, surface watering after application was understood to be extremely beneficial for lime stabilization studies performed particularly in summer.

Plate loading tests

The effect of lime stabilization on the road was analyzed by plate loading tests. The experiments were performed with 30 cm diameter circular plate. The tests are completed and either the stress reaches 1,000 kPa or the soil collapses. The failure or collapse of the soil is the point where deformations reaches and passes 2.5 cm in the stress-deformation graph. In all the plate loading experiments conducted, all samples were initially loaded to 1,000 kPa or collapse of the soil and then unloaded in order to make comparisons.

For each stress level, it was kept waiting in each level till deformations stopped. The selected 1,000 kPa loading was much higher than the traffic loadings that would normally be exerted on the lime stabilized road surfaces. As a result of this loading and unloading behavior, plate loading unloading figures, modulus of sub grade reaction values and the permanent deformations that occur on the surface were evaluated and compared. Just as in field CBR values, the experiments were conducted on natural surfaces, on areas where brown clay was compacted without lime and on areas where brown and green clays were lime stabilized. In lime stabilized areas, the plate loading tests were conducted at the end of 1st and 28th day. The moduli of subgrade reaction values are given in Table 10 and are present in Fig. 6.

When the results of the plate loading experiments are examined, the modulus of subgrade reaction values in both clays was observed to increase sharply after lime stabilization. While this increase was eight times in brown clay, it was about four times in green clay.

The permanent deformation values were obtained and also the details of the plate loading tests are shown graphically in Figs. 7 and 8. Based on these figures, it is clearly seen that the permanent deformations decreased significantly for lime stabilized brown and green clay soils. In brown clay, these permanent deformations were originally 24 mm and then reduced to 4 mm in the experiments performed after 28-days. In green clay, these permanent deformations were originally 18 mm and then reduced to 1 mm.

According to the stress-deformations graphs formed as a result of the plate loading tests, it can clearly be seen that lime stabilization was extremely effective in the behavior of both clays. The permanent deformations that occurred on the soils have reduced significantly in lime stabilized cases despite the amount of the loading. Moreover, the plastic behavior of the soil has changed and became more rigid

The permanent deformation values obtained as a result of plate loading tests has reduced from the natural value of 24 to 3 mm after 28 days in lime stabilized brown clay and from the natural value of 25 to 6 mm after 28 days in lime stabilized green clay. It is also seen from Fig. 9 that the pozzolonic reactions continued in the field and the permanent deformations reduced every other day.

This field application of the lime stabilization study was considered to be successful based on the experiments conducted and the observations made. This was further supported by the observations made after the rains that occurred on the area after 3 months. While no noteworthy deformations were observed in the lime stabilized portion of the road under real-time traffic load, the first 25 m long portion that was compacted without lime has totally deformed.

Scanning electron microscopy

The studied green and brown clays were also analyzed under scanning electron microscope. Both the natural and the lime stabilized, compacted and 6 months-cured green and brown clays were analyzed and compared under electron microscope with 200 and 2,500 times magnification. These are presented in Figs. 10, 11, 12, 13, 14, 15, 16, 17.

These examinations were done again after the samples were compacted at the optimum water level and cured for 6-months and the results were compared. These examinations were done for both the brown and the green clay under 200 and 2,500 magnification. Based on these examinations, the silica and aluminum of the clay particles were easily detected and it has been observed that they have dissolved as a result of lime and water impact and have reacted with lime surrounding them. The soil structure has transformed from a particle based form to a more integrated composition.

The reactions led to form alumina and silica hydrate gels, which are cementation products of lime stabilization. This process is called pozzolonic reaction. The reason for strength increases of lime stabilized soils in the long term is mainly due to the pozzolonic reactions.

Conclusions

-

1.

The optimum lime contents obtained from Atterberg limits and Eades and Grim pH method was found to be suitable for both clays based on the results of performance tests such as CBR and plate loading tests. As they could be conducted quickly, these two methods could be effectively used together with lime stabilization applications.

-

2.

The results obtained from the experiments were in harmony with the literature values. The results of the plate loading tests, the increase in modulus of subgrade reaction values as a result of lime stabilization and the definitive decrease in the permanent and maximum settlement values revealed that the deformation of the road under traffic loads would be low. The comparisons made in the plate loading tests demonstrated that the plate loading test clearly exhibited the fill’s performance. Hence, it is beneficial to use it seldom in quality control studies.

-

3.

When mixed with lime, the wet CBR values of the materials have exhibited significant increases. At the end of 28 days, the wet CBR value of 5% lime added brown clay has increased 21 times compared to the natural state of the same material. Similarly, the wet CBR value of 5% lime added green clay has increased 16 times compared to the natural state of the same material. The swelling values of both clays were below 1%. Based on these results, there will be reductions in the thickness of road layers with the design methods that depend on CBR values.

-

4.

It has been observed that the 28-day CBR values were lower than the 7-day CBR values in the initially conducted CBR experiments. No decreases were observed in the 28-day CBR values when watering was applied. Hence, it is recommended to water the surface after lime stabilization is completed for a period of 1 week, minimum of 3 days, particularly for field applications in hot climates in order to prevent strength loses. In future applications, it would be beneficial to apply watering in the field.

References

Baykal GI (1987) The effect of micromorphological development on the elastic moduli of fly ash, lime stabilized bentonite. Ph.D. dissertation, Louisiana State University

Broderick GP, Daniel DE (1990) Stabilizing compacted clay against chemical attack. ASCE J Geotech Eng Div 116(10):1549–1567

Clare KE, Crunchley AE (1957) Laboratory experiments in the stabilization of clays with hydrated lime. Geotechnique VIII:97–111

Eades JE, Grim RE (1963) A quick test to determine lime requirements for lime stabilization. Highway Research Board, Record No. 139, pp 61–72

Ingles OG, Metcalf JB (1972) Lime stabilization, soil stabilization, Melbourne, pp 127–167

Kavak A (1996) The behavior of lime stabilized clays under cyclic loading. Ph.D. dissertation, Bogazici University

Kavak A, Baykal GI (2001) The behavior of lime-stabilized clays subjected to repeated loading. Proceedings of the 15th international conference on soil mechanics and geotechnical engineering, Istanbul

Kavak A, Keskin E, Yılmaz C, Mutman U (2005) Lime stabilization and its effects on road cross-section. GEOPROB 2005—international conference on problematic soils, Famagusta, N. Cyprus, 25–27 May 2005

Newbauer CH, Thompson MR (1972) Stability properties of uncured lime-treated fine grained soils. Highway Research Record 381, HRB. National Research Council, Washington DC, pp 20–26

Rao S, Shivananda P (2005) Impact of sulfate contamination on swelling behaviour of lime-stabilized clays. J ASTM Int 2(4):1–10

Thomson MR (1969) Engineering properties of lime-soil mixtures. J Mater ASTM 4(4):968–969

Veith G (2000) Essay competition green, ground and great: soil stabilization with slag. Build Res Inf 28(1):70–72

Wild S, Kinuthia JM, Jones GI, Higgins DD (1999) Suppression of swelling associated with ettringite formation in lime stabilized sulphate bearing clay soils by partial substitution of lime with ground granulated blastfurnace slag. Eng Geol 51:257–277

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kavak, A., Akyarlı, A. A field application for lime stabilization. Environ Geol 51, 987–997 (2007). https://doi.org/10.1007/s00254-006-0368-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00254-006-0368-0