Abstract

Forty-three pottery samples from the New Kingdom site at Amara West in Nubia (Sudan) were analysed by optical microscopy and scanning electron microscopy-energy dispersive X-ray spectrometry to identify pottery potentially produced at the site. Twenty-two samples from modern local alluvial soils, modern locally made pottery and archaeological material (mudbricks, daub, oven liners and kiln fragments), likely to have been made from locally sourced clays, were also studied. The analytically and microscopically defined pottery fabrics were cross-correlated with macroscopic fabrics defined on-site during fieldwork to demonstrate not only the potential and limitations of both approaches but also how the complementary datasets can provide new insights. The mineralogical and chemical analyses, of 65 samples, suggest that locally manufactured pottery included both Egyptian-style tableware and Nubian-style cooking pots. At the same time, the community at the site imported ceramics from a variety of different regions, including Egypt itself.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

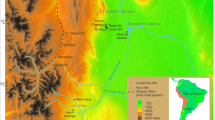

Amara West, located downstream of Sai Island and near the modern town of Abri (Fig. 1), was the administrative centre of Upper Nubia (Kush) during the Ramesside Period (ca. 1300–1070 cal BC). Excavations by the Egypt Exploration Society (EES) in 1938–1939 and 1947–1950 revealed a decorated temple, storage facilities and houses, set within a walled town (Spencer 1997, 2002). Burials associated with the town are located in two cemeteries, to the north and northeast of the settlement. A British Museum project, instigated in 2008, is seeking to elucidate the lived experience of the ancient inhabitants and the permeability between Egyptian and Nubian cultures, set within a bioarchaeological and environmental framework (Ryan et al. 2012; Spencer et al. 2012; Spencer 2014a, b, in press).

(Left) Map of Egypt and northern Sudan showing the location of the site, related settlements, and the modern potter at Abri Sab. (Right) Key plan of Amara West, showing location of town on island and two cemeteries on desert escarpment, with magnetometry data from Archaeological Prospection Services (University of Southampton)/British School at Rome

In terms of geological context, Amara West is located on the north (left) bank of the Nile, but originally upon an alluvial island in the river, in the Cretaceous Nubian sandstone formation, which includes sandstone, siltstones and mudstone conglomerates. A formation of an undifferentiated schist group (marble, quartzite and mica schist) and some outcrops of younger granites are located southeast of the site, while to the northeast lies a Silurian outcrop of coarse sandstone with microfossils (Geological Map of the Sudan 1981). In addition, sediments found at Amara West can be derived from formations much more upstream.

The pottery from the EES excavations has only been partly published, identifying Nubian wares, painted and decorated sherds, and 17 vessel forms, with little consideration given to fabrics (Spencer 2002, pp. 13–39). The later introduction of the Vienna system (Nordström and Bourriau 1993) emphasised the significance of pottery fabrics, such as typical ‘Nile clays’ or ‘marl clays’.

The current fieldwork has produced a large amount of ceramics from well-documented contexts covering the period between the late New Kingdom and the early Napatan Period (ca. 1300–800 cal BC; see Spencer 2009, 2014b; Binder 2011; Binder et al. 2011; Millet forthcoming). The majority of the samples considered in this study come not only from houses of various size within the walled town but also from a large villa (E12.10) set in an extramural suburb outside the town walls and cemetery.

Four broad groups of ceramics can be identified within the excavated assemblages (Fig. 2):

Examples of pottery: C2000 and C4151 (from the town) and C8008 (cemetery D) are of Nile Silt in an Egyptian style; samples C8009 and C9016 from the cemeteries are in Marl clays. C2208 is an import; C2030 is an example of a Nubian cooking pot (drawing scale 1:8; drawings by M. Millet and photographs by N. Spencer)

-

1.

Egyptian-style vessels, in Nile clay, dominate the ceramic assemblages and include plates, jars, bowls, basins, pot stands and lids. These shapes were mainly wheel-thrown (except for bread trays and bread moulds) and intended for cooking, storage and food consumption.

-

2.

Egyptian imports, in marl clay and distinctive Nile silt fabrics (Vienna system Nile D, and/ or mixed clay see below and in Table 1), represent a very small percentage of the assemblage (ca. 0.1 to 1 %). Almost exclusively wheel-thrown, this category includes amphorae and small containers used for the transport of ointments and perfumes.

Table 1 Amara West. Ceramics and other clay objects used as reference material (mudbrick, plaster, oven liners, modern ceramics and sand samples) discussed in the article -

3.

Imports from other regions (e.g. Levant and Greece, as well as Egyptian copies), which are rare and mostly wheel-thrown. They include Canaanite amphorae and Mycenaean stirrup jars, used for storing and transporting wine, oil and perfume.

-

4.

Nubian-style vessels, which represent between 1 and 3 % of the ceramic assemblages, occasionally up to 10 %, were almost exclusively used for cooking. These are all handmade in Nile silt fabrics.

The pottery samples discussed here were collected during the 2009 and 2010 field seasons, when the fabrics were first classified macroscopically by field ceramicist Millet (Table 1). In turn, these were linked, where possible, to the Vienna system (Nordström and Bourriau 1993). This system, developed and widely used in Egypt, is relevant here due to the geographic and cultural setting of Amara West, and the predominance of Egyptian-style vessels similar to those found at contemporary sites in Egypt. The Vienna system distinguishes two main groups: fabrics in Nile silts, and in marl clays rich in calciferous shales and mudstones found between Esna and Cairo, and also deposits in the western and eastern deserts, and the oases. Indeed, the range of fabrics identified at Amara West correlates well with that found at New Kingdom sites in Egypt (for example, Aston 1989, 1996, 1999, 2008; Bourriau et al. 2000a). Groups 3 and 4 above are not covered by the Vienna system, however (Fig. 3).

A number of previous studies have used chemical and mineralogical analyses on Egyptian pottery, Nubian pottery, Canaanite amphorae found in Egypt and modern pottery in Egypt. The aims of these studies were to identify imports and local production and discriminate between Nile silts and marl clays (e.g. Bourriau 2001; Bourriau et al. 2000a; at Kahun: Desmond et al. 1986; at Lahun: Fitton et al. 1998; at Amarna: Mommsen et al. 1992; at Memphis and Amarna: Smith et al. 2004; Bourriau et al. 2001; at Mendes and Karnak: Mallory-Greenough et al. 1998; in Nubia: Carrano et al. 2008, 2009; at modern Egyptian sites: Redmount and Morgenstein 1996. A comparison between neutron activation analysis [NAA] results and the Vienna system are discussed by Bourriau et al. (2006).

Research questions

Given the variety of shapes and macro-fabrics in the ceramic assemblage, and the large number of Egyptian-style vessels, the aims of this project were:

-

To seek to identify local and non-local production, and where possible suggest provenances, for pottery found at the site, using chemical and mineralogical analyses upon samples representing the four broad groups cited above.

-

To identify whether distinct clay sources for Nile silt fabrics were used for locally produced Egyptian- or Nubian-style vessels, and if there was any correlation between form and fabric.

-

To correlate the fabric classification undertaken during fieldwork (macroscopically) and that in laboratory analyses (microscopically), thus characterising the mineralogical components of ‘Nile silt’ fabrics (whether Egyptian-style or Nubian-style vessels) and ‘marl’ fabrics, and in turn refining the field classification.

This study of the Amara West pottery presents an extensive dataset on ceramic production at a late second millennium BC Egyptian town in Nubia, on the periphery of the pharaonic world. The material offers the potential to elucidate how the phenomena of cultural entanglement (see Smith 2003; Van Pelt 2013) might have affected ceramic production and trade, but also on divergences in pottery production techniques as compared to contemporary sites in Egypt proper. To date, only one small pottery kiln, attributed to the earliest architectural phase, has been discovered in the town. Identification of local clays is thus particularly important in terms of understanding the relative levels of external (from Egypt) or internal supply of ceramic vessels, the latter including not only production methods and forms consistent with the contemporary repertoire in Egypt but also distinctive indigenous (Nubian) traditions of preparing clay and producing different vessel shapes. This study therefore considers for the first time a wide range of reference material, such as modern, locally produced pottery and local soils, as well as archaeological daub, oven liners, mudbricks and kiln samples, to distinguish locally produced and imported pottery. Two complementary methods, optical microscopy of thin sections and compositional analysis for major and minor oxides, were applied to the sherds and reference material.

Methods and sampling

Pottery

Forty-three samples of pottery fabrics from different phases of the settlement were analysed in thin section (Tables 1 and 2). The samples were selected on the basis of differences noted in the initial, macroscopic, study of the fabrics on site (AW1–AW25 and AW61–AW65), with six additional samples to improve representation of Nile clay fabrics (AW26–AW31). In order to complete and refine the macro-classification, three further pottery samples, which had not been attributed to any macro-fabric, were also added (AW57–AW58 and AW60). The analysed samples come from occupation deposits (matrix of silt, organics and other debris), clay floors, rubble layers and also layers of windblown sand that accumulated between occupation phases.

Archaeological clay and modern clay samples

Twenty-two samples of archaeological and modern clay-rich materials considered to be of local origin were also studied, as reference material to help in the identification of potentially locally manufactured archaeological pottery within the sample set (Tables 1 and 2).

Two mudbricks, from the villa (sample AW35) and a storage magazine in the walled town (AW38), mud plaster from the walled town (AW37), two fragments of ceramic oven liner (samples AW66 and AW67; Table 1) and nine fragments from the pottery kiln (AW200, 203, 205, 206, 207, 208, 209a, 209b, 210) were analysed. All are broadly contemporary with the pottery samples, that is, ca. 1300–1070 cal BC. These were complemented by modern reference material: unfired prepared ceramic paste and a fired pottery fabric of the same paste (samples AW36 and 50), supplied by a traditional potter in Abrisab (Figs. 1 and 4), two local sediments from the river banks at Abri and the island of Ernetta, 1 km upstream of Amara West (AW51, 52), and four alluvial soil samples collected northwest of the villa and north of the temple forecourt (AW68, 69, 202, 204) (Table 1; Fig. 1).

Modern pottery production: Workshop of Abrisab. The two potters are Fahmi (c) and his brother in law, Mohamed Ahmed (b). Fahmi’s father, Ismaïl, came during the 1910s or 1920s and was from the west bank of Edfu (Egypt). The local source of the clay used is in Abri Ichlag (a), north of Abrisab. The main production is zir (e, f), pottery used to store water. In the kiln, near the workshop, they can fire around 50 zir vessels at the same time (photographs by M. Millet)

Methods

Macro-analysis

For the macro-fabric classification, the fabrics were examined using a ×20 lens and the following criteria were recorded: texture, grain, section break and the colour of surface/section with a Munsell Soil Chart. In addition, each different inclusion (frequency, shape/sphericity, colour, size, nature) was described as well as any vesicles (frequency, shape, orientation, size, prints). Details on the shaping process and surface treatment were also noted. On the basis of the fieldwork macro-classification, 30 fabrics were distinguished: 14 were interpreted as Nile silt fabrics (nine used for Egyptian-style vessels, one apparently imported from Egypt (Nile D), and four for Nubian-style vessels), seven as Marl clays, six as imports from other regions (Egypt and beyond) and three remain unidentified.Footnote 1

Micro-analysis

The methods used, optical microscopic analysis (Leica DMRX) and variable pressure scanning electron microscopy-energy dispersive X-ray spectrometry (SEM-EDX) of polished thin sections, have been previously described by one of the authors (Spataro 2011, pp. 256–257; Spataro 2014). Four bulk SEM-EDX analyses were carried out on different areas of each sample at ×100 magnification (each giving sample areas of ca.1.5 × 1.1 mm), using a Hitachi variable pressure SEM S-3700N in combination with an Oxford Instruments INCA EDX analyser. The SEM was used at a pressure of 30 Pa with a 20-kV accelerating voltage; the samples were analysed uncoated at a 10-mm working distance. Ten elements (Na, Mg, Al, Si, P, K, Ca, Ti, Mn and Fe) were analysed, and Na, Mg, Al, Si and K were calibrated using a mixture of glass and mineral standards, the others using default calibrations generated by the Oxford Instruments EDX INCA Analyser software. The results were converted into oxide percentages, which were normalised (oxygen by stoichiometry) to take into account the fact that oxygen and carbon are not measured (see also Spataro 2002, Chapter 2). The results of the bulk analyses were averaged, and the low standard deviations show that they are representative of the potsherd composition.

Results of petrographic analysis

Pottery

Seventeen microscopic fabric groups were identified in thin section, representing clays from a number of different sources (see Table 2 and Fig. 5). The fabrics have been defined on the basis of their clay matrices (see Table 2) as calcareous if made from a calcareous clay, or non-calcareous if of non-calcareous clay (although non-calcareous clays may contain calcareous inclusions).

Groups 1–4 are non-calcareous and probably from locally sourced clays. Group 1 is rather homogeneous, with some variations in firing temperature and quartz content. It has a slightly micaceous fabric, abundant, fine and well-sorted quartz, some muscovite, plagioclase, feldspar, rare amphibole, biotite, volcanic inclusions, microcline, chert, organics, felsic sub-rounded rock fragments, clay fragments and soil pellets (Fig. 6, top left). Subgroup 1a contains some coarser inclusions, whereas subgroup 1b was probably tempered with organic matter and contains some coarse biotite mica. Group 2 is similar to group 1, but it contains coarser quartz grains, more abundant pyroxene and thicker lamellae of muscovite. Group 3 is more micaceous than groups 1 and 2, probably collected from a deposit richer in red clay fragments and biotite (Fig. 6 top right). Group 4 is mainly non-calcareous but with coarser and poorly sorted quartz inclusions than groups 1–3, coarse calcareous fragments and some organics (Fig. 6, bottom left).

Locally made and imported ceramics. Microphotographs of thin sections showing: sample AW10 (top left) with a non-calcareous fabric, rich in well-sorted quartz; sample AW12 (top right) with non-calcareous fabric with abundant quartz and muscovite and biotite micas, fine clay fragments and occasional voids left by organic matter; sample AW14 (bottom left) with a non-calcareous fabric with abundant quartz, sub-rounded calcareous fragments and some voids left by organics; sample AW15 with a calcareous fabric, rich in well-sorted quartz and iron oxides (cross polarised light, 5.4 mm field of view; photographs by M. Spataro)

Fabric groups 5–17 are non-local (Table 2). In contrast to groups 1–4, group 5, which is the finest of the Amara West fabrics analysed, is calcareous and poor in mica (Fig. 6, bottom right); its subgroup 5a is slightly more iron-rich. Group 6 might come from a source similar to that of group 5, but it is more micaceous, with coarser inclusions, more porous, slightly less calcareous and with rare and fine volcanic grains. Group 7 is very calcareous and fossiliferous, with some coarse calcareous fragments, very few quartz grains and occasional volcanic inclusions (Fig. 7, top left). Group 8 and its subgroups are slightly calcareous, with varying contents and sizes of quartz grains, and abundant calcareous fragments. Group 8 has poorly sorted sand and is rich in quartz (some grains are very coarse and rounded), coarse sub-rounded to sub-angular calcareous fragments, some plagioclase, soil pellets, mudstone, occasional pyroxene and muscovite (see Table 2 for details).

Non-locally made ceramics. Microphotographs of thin sections showing sample AW18 (top left) with a calcareous and fossiliferous fabric, with scattered coarse quartz grains, abundant calcareous fragments and some igneous inclusions; sample AW24 (top right) with a non-calcareous and fossiliferous fabric, with some mudstone and biotite; sample AW60 (bottom left) with calcareous and fossiliferous fabric, with polycrystalline limestone and shell fragments; sample AW64 (bottom right) with a non-calcareous fabric, rich in basalt, calcareous fragments and iron oxides (cross polarised light, 5.4 mm field of view; photographs by M. Spataro)

Groups 9–12 are made from non-calcareous clays. Group 9 is fossiliferous, rich in coarse micas, mudstone, feldspar, chert and foraminifera (Globorotalia; Fig. 7, top right), possibly Miocenic (Y. Goren 2014, personal communication). Group 10 contains abundant and coarse clay pellets, rich in fine quartz and iron oxides. Group 11 has abundant and fine calcareous pellets, biotite and very occasional and fine microfossils. Group 12 contains some well-sorted quartz, abundant coarse and rounded clay pellets, some coarse calcareous pellets, basalt fragments and iron oxides. Group 13 is calcareous and fossiliferous, rich in shell and limestone fragments, very fine Globigerinidae microfossils and abundant fossiliferous and polycrystalline limestone (Fig. 7, bottom left). Group 14 contains microfossils and limestone fragments, but also serpentine. Group 15 is slightly calcareous and rich in limestone fragments with abundant opaques, whereas group 16 is calcareous with fine microfossils and some dolomite. Like group 12, group 17 is made from a non-calcareous clay, but it is richer in basalt, slightly fossiliferous, with abundant calcareous fragments, weathered basalt and volcanic glass with phenocrysts, radiolarian chert and pyroxene (Fig. 7, bottom right).

In summary, groups 1–4 are from non-calcareous sources, with abundant quartz sand and occasional igneous inclusions; most of the quartz sand in the fabric groups discussed here is sub-angular and may not have travelled very far from the parent rock, but there are also some coarse round-shaped quartz grains which were subject to aeolian or fluvial transport.

The remaining groups, probably non-local, are calcareous, or non-calcareous with abundant calcareous pellets, and they are mineralogically distinctive. For example, groups 7, 11, 13, 14 and 16 come from fossiliferous sources, but they are different from each other. Among the fossiliferous fabrics, while group 7 has coarse sand inclusions as well as calcareous fragments and occasional igneous inclusions, group 16 is finer than the others and contains some dolomite, and group 11 is non-calcareous and micaceous with more abundant inclusions than the other fossiliferous fabrics, including micas. On the other hand, groups 13 and 14 are calcareous with occasional very fine sand inclusions, some coarse microfossils and shell fragments, and group 14 also contains some serpentine. Group 15 is non-fossiliferous but rich in calcareous fragments. Fabric groups 12 and 17 are both non-calcareous and rich in calcareous fragments, with basalt, iron oxides and clay pellets. On the other hand, group 10 is rich in coarse clay pellets but no inclusions diagnostic of provenance.

Reference materials

Archaeological clay samples

Mudbricks (AW35 and 38; Fig. 8, top left) and mud plaster (AW37) were manufactured using what appears to be the same raw material, almost certainly local clay. Indeed, an area outside the town walls in which mudbricks were laid out to dry was exposed by the EES excavators (Spencer 1997, pl. 143[a]). The clay is yellowish-brown, non-calcareous and micaceous, rich in fine and well-sorted quartz, including plagioclase, pyroxene, muscovite, biotite with long lamellae, amphibole, rounded calcareous fragments and very fine igneous inclusions (see Table 2). Samples were taken from the clay lining of cylindrical ovens, perhaps fired in situ, and almost certainly made in the immediate vicinity. As with the mudbricks and wall plaster, the clay from these ovens would have been sourced in the immediate vicinity of the site. Although the two samples (AW66, 67) contain the same range of minerals, such as quartz, muscovite, pyroxene, feldspar, clay pellets, iron oxides and opaques, they are made of materials which come from different areas of the same basin: sample AW67 is notable for being finer than AW66, with better-sorted quartz and more red clay fragments (Fig. 8, top right). The fabrics of the kiln samples (AW200, 203, 205, 206, 207, 208, 209a and b, 210) have non-calcareous paste, rich in rather well-sorted sand, including feldspar, amphibole and clay fragments. They have different levels of vitrification, some reaching bloating, as they were collected from various parts of the kiln (inner and outer wall, from the base, etc.).

Reference material: mudbrick, oven liner, modern pot and alluvial soil. Microphotographs of thin sections showing sample AW38 (top left) with non-calcareous and micaceous fabric, with abundant quartz, opaques and fine micas; sample AW67 (top right) with a non-calcareous fabric rich in mica, fine pyroxene and voids left by the burning out of the organic matter; sample AW50 (bottom left) with a non-calcareous fabric rich in quartz, fine pyroxene and voids left by the organic matter; sample AW69 (bottom right) with a non-calcareous fabric, with quartz, muscovite and pyroxene (cross polarised light, 5.4 mm field of view; photographs by M. Spataro)

Nowadays, the inhabitants of Ernetta, an alluvial island similar in morphology to ancient Amara West, collect clay from different parts of the island depending on its intended use (e.g. for mudbricks or wall and floor plaster).

Modern clay samples

The sediment (AW51, 52), the prepared paste (AW36: unfired clay with organic temper) and the fired fabric (AW50) used and produced by the active potter at Abrisab, 6 km upstream of the archaeological site, on the opposite river bank, were also analysed. Four alluvial soil samples (AW68, 69, 202, 204) were also collected, north of the temple forecourt and northwest of the villa (Fig. 1). All samples are non-calcareous and micaceous.

The prepared potter’s paste AW36 is very micaceous, with abundant and poorly sorted quartz, some long and packed lamellae of micas, ash fragments, some plagioclase, very occasional microcline, rounded polycrystalline calcareous fragments, amphibole, red clay fragments and occasional calcite. The fabric of the fired product (AW50) has the same poorly sorted inclusions as the clay paste; the main difference is in the change of colour and the disappearance of organic matter and calcareous pellets due to the firing process (Fig. 8 bottom left; Table 2). As in the archaeological ceramics, the sand inclusions in the modern clay have bimodal size distribution and include some rounded grains, and from examination of the sediment samples (AW51 and 52, see below), it is clear that the sand was naturally present in the clay and not deliberately added.

The clay used for modern pottery manufacture (Fig. 4) contain similar types of minerals to the one used for the ancient mudbrick architecture, but the sand sorting, size and shapes are different (e.g. pyroxene, plagioclase, amphibole and micas); the inclusions in the ancient mudbricks are finer.

The two sediment samples (AW51, 52) used in pottery manufacture contain similar minerals, but AW51 includes more abundant, coarser and poorly sorted quartz sand. They have a very small amount of non-calcareous matrix, with abundant and poorly sorted quartz, some feldspar, occasional muscovite, pyroxene, some red clay fragments, occasional clay pellets and abundant opaques. Finally, the alluvial soils (AW68, 69, 202, 204) are similar (Fig. 8 bottom right). They contain abundant, fine and well-sorted quartz, some feldspar, pyroxene, abundant opaques, very occasional and rounded calcareous pellets, occasional amphibole and red clay fragments.

Results of SEM-EDX analysis

The SEM-EDX results are presented in Tables 3 and 4. The results were interpreted using principal component analysis (PCA). Normalised PCA (of the correlation matrix, which weights all oxides equally) was performed using the Microsoft Excel add-in XLSTAT (Version 2011.4.02, ©Addinsoft 1995–2011). In scatter plots of PCA output, samples that are chemically similar should cluster together in the same areas of the plots as the elements that are relatively abundant in those samples. It is therefore possible to compare clustering based on chemical composition to the microscopic fabric grouping (based on mineralogy) and to relate these clusters to elemental abundances. For the purpose of this exercise, phosphate was omitted from the compositional data because it has been shown that this compound can be absorbed by buried pottery (Freestone et al. 1985). In fact, phosphorus might be particularly abundant in low-fired and non-calcareous ceramics (Fabbri et al. 1994, pp. 188–189).

When all the samples are considered in the same analysis (Fig. 9), the elemental compositions of the Nile silt fabrics (microscopic fabric groups 1–4) are chemically rather homogeneous, rich in silica, alumina and iron oxides, and poor in calcium oxide (Table 3). The reference material (daub, plaster, mudbrick, oven liners, kiln fragments and alluvial soil from Amara West, along with sediment, prepared clay and a fired pot from Abrisab) seem to have a very similar chemical signature to the Nile silt and Nubian fabrics. Moreover, the ancient reference material, undoubtedly from clay sources local to Amara West, has more variation than the local fabric groups 1–4. None of the remaining microscopic fabric groups (5–17) produced any data points which fall in the ‘local’ cluster (Fig. 9), and it is therefore arguable that these samples represent non-local pottery. None of the non-local sherds according to the chemical analysis were made in Nile silt fabric. Many of the non-local sherds are relatively rich in calcium oxide and some are also rich in magnesium. Sample AW66 (oven liner from Amara West) appears to be an outlier of the ‘local’ cluster, probably due to its very high sodium and potassium content (Table 4), which can be linked to its burial in ash deposits.

When data from groups 1–4 and the reference material are analysed separately (Fig. 10), the first factor (F1) loadings correspond to silica abundance, which varies between ca. 60 and 70 %. The second factor (F2), accounting for 22.96 % of variation in the data, separates the Abrisab reference materials (AW36 and 50–52) from the Amara West samples (both pottery and reference materials, with the exception of sample AW06, the sole representative of fabric group 2). The variation within the Amara West reference materials is similar to that within the sherds from fabric group 1.

PCA of SEM-EDX compositional data of samples from Amara West and Abrisab (microscopic fabric groups 1–4 and local reference material samples AW36-38, 50-52, 66–69, 200, 202–210). The scatter plot is a distance biplot, showing factors 1 and 2, which together account for 65 % of variation in the data. Each symbol represents the mean of the four bulk analyses performed for each sherd

PCA analysis also clearly reveals the great variation in micro-fabrics, which correlates well with their macro-classification as vessels from disparate provenances with very different geological contexts, including the Egyptian oases, the Levant and perhaps Cyprus.

Discussion

Local products and imports

The variability among the fabrics studied by optical microscope from Amara West stems from the sample selection, made on the basis of the macro-fabrics recognised during fieldwork (e.g. Nile, Nubian, Marl, etc; see Table 1).

Groups 1–3 are non-calcareous and rich in alluvial sand, and group 4 is slightly different with some calcareous fragments. The alluvial quartz sand of groups 1–4 might come from the weathering of sandstone or siltstones, which are reflected in the surrounding geological settings (see above ‘Introduction’). From the macro-fabric point of view, they are considered local or possibly local, and there is a strong mineralogical and chemical similarity at the micro-fabric level between the local reference material (ancient and modern) and these groups (Fig. 6, top left and right, and Fig. 8, top left and right and bottom left and right).

The archaeological and modern reference materials have many similarities:

-

The fabric of one oven liner (AW66) and that of the modern pot (AW50) from Abrisab are very similar to that of group 1, although less well sorted. The main difference between the pots and oven liners is in the abundance of clay fragments in the oven liners; a less carefully sorted paste was needed for these ovens, supported by clay and brick surrounds. Moreover, the ceramics of group 1 have similar quartz size and sorting to the mudbrick samples, with fine clay fragments and pyroxene, but are more levigated (fewer inclusions, such as opaques, and calcareous fragments and more clay);

-

The fabrics of the samples (AW200, 203, 205–210) taken from the kiln have a similar chemical and mineralogical composition to those of the ceramics from groups 1 and 3. In general, the sand inclusions from the kiln fragments are finer and better sorted than within ceramic fabrics;

-

The sand inclusions in the alluvial soils are extremely similar in sorting, size and type to those of the archaeological mud plaster and mudbrick samples, one of the oven liner samples (AW67) and in turn to fabric group 3. The only difference is that the fabric of the oven liner is richer in clay. Furthermore, the sand of group 3 is very similar to that of the mudbrick, although group 3 does not contain calcareous pellets.

In contrast, most of the non-local fabrics are calcareous (e.g. groups 5–7, 13, 14 and 16). Their raw material comes from different geological settings, and they have very distinctive and varied pastes, mineralogically and chemically (Tables 2 and 4; Fig. 7). This suggests that the pots were imported from different sources. In group 8, AW65 is a fabric sample from a ‘Canaanite jar’, by its shape. The analysis showed that AW65 belongs to a ‘marl clay’ group which could imply that the pottery is an Egyptian copy of a Canaanite jar. Group 7 (sample AW18, Table 2) appears to be from the Levant, probably from the Akkar Plain, as it contains foraminifera, occasional chert and hypocrystalline alkali olivine basalt (Mary Ownby 2013, personal communication), but it might also be from Cyprus (Y. Goren 2014, personal communication). Similarities are apparent between micro-fabric group 9, attributed to possible Canaanite ware (sample AW24, Table 1), and the petrographic fabrics published by Smith et al. (2004) and Bourriau et al. (2001). Sample AW24 might be from Cyprus (M. Ownby 2013, personal communication; Y. Goren 2014, personal communication). Group 4 of Smith et al. contains a combination of igneous, metamorphic and sedimentary rocks and planktonic and benthic foraminifera, whose source was thought to be Turkey, northwest Syria or Cyprus (Smith et al. 2004, p. 61). It would be very useful to compare the chemical composition of these sherds. Nevertheless, in order to identify the non-local workshops, the number of ‘imported’ samples studied would need to be augmented (more than one for each macro-fabric) and include reference material from studied and published sites.

Some groups of ‘Nile silt’ and marl Egyptian ceramics were identified using inductively coupled plasma mass spectrometry (ICP-MS) by Mallory-Greenough et al. (1998) on the basis of rare-earth elements, and NAA was used to characterise Nile silt clays from different sites (Tobia and Sayre 1974; Bourriau 1998, pp. 192–193). Furthermore, NAA helped in provenancing ceramics from Kahun (Desmond et al. 1986) and Mycenean sherds from Tell el-Amarna (Mommsen et al. 1992) and Amara West. Trace element data are currently unavailable for Amara West, so we have not attempted to compare our samples to these published results.

Nubian and Egyptian pottery from Amara West

Distinguishing, macroscopically, Nile silt fabrics of local and non-local production remains challenging, though differences in other aspects of the pottery manufacture can provide indications. For example, during this period and as a general statement, Egyptian pottery is wheel-made, whereas Nubian pottery is handmade (Nordström and Bourriau 1993, p. 184; Rose 2012, p. 13 and 16). In addition, Egyptian pottery is fired in kilns, while Nubian pottery may have been produced in bonfires (Bourriau et al. 2000b, p.128; Gratien 2000, p. 114). At Amara West, a few examples of 20th dynasty plates, which are usually wheel-made, have been handmade, probably fired in a reducing atmosphere. These examples illustrate well the mixture of technologies in an Egyptian town in Nubia.

The results of the mineralogical and chemical analyses indicate that the potters used the same clay sources to manufacture Nubian-style and Egyptian-style vessels at Amara West (Table 2 and Fig. 8). The clays were not processed in different ways, suggesting that Nubian and Egyptian-style vessels may have been made in the same workshops, notwithstanding the different techniques used to fire the pottery nor the different forms and decorations preferred.

Vessel forms and fabric choice

The majority of ceramic vessels (plates, bowls, jars, etc.) used at Amara West are of Nile silt, predominantly made using Egyptian shapes and production techniques. The PCA analyses suggest that the raw materials used for the Nile silt groups are not only mineralogically similar but that they are also chemically homogeneous and likely to have been produced using local raw materials, given the correlation with reference materials. As well as Egyptian-style vessels, cooking pots—handmade in the Nubian tradition—were also made from clays consistent with a local source. Vessels in marl clay, such as jars, pilgrim flasks and small bowls, can be interpreted as imports from Egypt proper, as no extraction site for this type of clay has yet been identified in Sudan.

While the fabric groupings illustrate the range of ceramic pastes employed at the site, it does not reflect the frequency with which certain fabrics were used. As mentioned above (‘Introduction’), imports from beyond Egypt are very rare. Rather, micro-fabric group 1 dominates the ceramics recovered from the site, the vast majority of vessels in these fabrics being produced in a manner consistent with contemporary sites in Egypt (for example, Aston 1989, 1996, 1999, 2008; Bourriau et al. 2000a). Within this group, the cooking pots in Nubian-style amount to 1 % of the assemblage, and occasionally up to 10 %, in any given deposit (occupation layer, rubble, windblown sand).

Correlating micro- (laboratory) and macro-fabrics (field)

There are some correlations between macro and micro-fabrics. As might be expected, micro-fabric descriptions are more detailed, usually resulting in a larger number of micro-fabric groups. For example, the Nile D samples (AW6 and 7) were attributed to different micro-fabrics (groups 2 and 1) and are also chemically different (Fig. 10 and Table 3), something not possible to differentiate during fieldwork (see Table 1). Thirteen sherds which had been designated as three classes of Nile silts in the macro-classification were divided into three different micro-fabrics (groups 1–3); four samples which had been attributed to the Nubian macro-fabric were divided into three micro-fabrics (groups 1, 3 and 4). Seven samples which had been designated as four types of Marl macro-fabric were split into four micro-fabrics, groups 5–8, but the division among fabric groups was different (see Tables 1 and 2). In other cases, some of the sherds attributed to different macro-fabrics were defined as the same micro-fabric and subgroups (e.g. Nile B1, B2 and D, Nubian attributed to group 1 and subgroups; Marl A3 and A4 were microscopically almost identical and were therefore grouped into one micro-fabric [group 5 and subgroup 5a]). This discrepancy between micro/macro-fabrics has already been observed by Fitton et al. (1998, p. 126), where the visual fabrics Nile B1, B2 and C were microscopically attributed to subgroups of the same micro-fabric. In addition, three new micro-fabrics (possible imports; groups 11–13) were determined, and these have been added as new macro-fabrics in our classification system at Amara West.

Conclusions

Excavations at Amara West, a late second millennium BC colonial administrative centre in occupied Nubia, have shown that the majority of artefacts are made in locally available materials: ceramic, unfired clay, schist and sandstone, and tamarisk or sycamore fig wood. Copper alloy and faience objects are also encountered in excavations, and it is possible small-scale production occurred on site. Objects of granodiorite, carnelian, calcite, jasper and ostrich egg-shell come from further afield, though not necessarily Egypt proper, whereas fine vessels in calcite are undoubtedly brought from Egypt; none of these materials are common amongst the artefact assemblages.

Only one pottery kiln has been discovered at Amara West, clearly not large enough to supply the whole town, and abandoned within a generation of the town’s foundation. Lacking further architectural evidence for pottery production, this minero-chemical study has proven that much of the pottery was indeed made locally, though ‘local’ could include vessels produced at other towns, perhaps including Sai, just upstream. At contemporary Deir el-Medina (Bavay 2004, pp. 23–24; Frood 2003), texts attest to the delivery of pottery to workmen, though without mention of the location of workshops. However, Deir el-Medina was built to house workmen employed on royal tomb construction and near the large city of Thebes. Amara West was more isolated, and it is reasonable to expect production of pottery in the town itself, at least for vessel types needed on a regular basis.

Petrographic microscopy identified strong similarities in size, sorting, type and shape of the minerals in the archaeological and modern material used as reference for local production, with that in the non-calcareous pottery fabrics (groups 1–4). The analyses of the clay prepared for present-day pottery production at Abrisab, as well as providing an insight into the technological choices of contemporary potters, identified similarities with the raw material exploited during the New Kingdom and its immediate aftermath at Amara WestFootnote 2.

Petrographic analysis also identified the different mineralogical composition of ‘non-local’ ceramics, which seem to come from multiple different sources, both in Egypt and further afield. PCA scatter plots of SEM-EDX results did not identify additional fabric groups, but helped to separate the local and non-local products and to explain the chemical composition of the different fabrics. In addition, the EDX results confirm the petrographic interpretation that the Egyptian-style vessels and the Nubian pots were manufactured using the same raw materials.

There are close correlations between the pottery forms, macro-fabrics and the micro-fabrics. The four main groups of pottery shapes could be restricted in term of fabrics to three groups: many of the ‘Nubian fabrics’ are in fact petrographically and chemically identical to the dominant Nile silt fabrics. In the macro-classification, the Nile silt fabrics (including those used for Nubian-style vessels) were divided into 14 groups according to the nature and quantity of inclusions.

The imported fabrics from outside Egypt are all mineralogically distinctive. In general, the macro-fabrics of the Marl clays and the Oases are closely correlated with the identified micro-fabrics. Petrographic analysis allowed three new micro and macro-fabrics (groups 11, 12 and 14, possibly Levantine imports) to be added to the macro-classification.

Detailed microscopic analysis thus allows the macro-classification to be refined, but suggests macro-analysis can over-emphasise distinctions between silt fabrics. There were some discrepancies between the Vienna system macro-fabrics and the fabrics identified through petrographic analyses. The Vienna system, while very useful, should be used with caution, as it can mask local variations (see Bourriau et al. 2006). In pragmatic terms, macro-classification must be deployed during fieldwork, due to the considerable mass of sherds processed each season. The micro-analyses provide important evidence that the fabrics distinguished macroscopically do not necessarily reflect difference in paste preparation.

The micro-classification also suggests a clear correlation and similarity between the fabrics used for the ceramics found in the settlement and in the cemeteries (Tables 1 and 2). These results show that the potters at the New Kingdom site of Amara West used the same raw materials to manufacture the vessels for the living and the dead. On the other hand, the range of forms was more restricted in the cemeteries compared to the diversity of ceramic assemblage in the town.

Even with the predominance of locally produced ceramics (and other artefacts), Amara West is clearly embedded within an Egyptian cultural sphere, as attested through architecture, artefact types, the presence of elite literary texts (Spencer 2014a) and of course ceramic forms, seen in both town and cemetery. With Egyptian towns in the area from around 1500 BC (Sai, Sesebi, Soleb, Tombos), two centuries before Amara West existed, this is perhaps unsurprising. Future work may reveal chronological nuances to the preferences for different ceramics at Amara West. Over two centuries, the settlement developed from a planned urban layout with few houses to a densely occupied settlement with more areas of housing, including beyond the town walls (Spencer 2014b). Was there a reliance on pottery imported from Egypt (and beyond) in the period following the foundation of the town around 1300 BC? As the town developed into a more densely inhabited settlement, with a higher profile to Nubian material culture and architecture, was there an increasing reliance on local pottery production? Finally, in the post-colonial era, were there further changes in the preparation and sourcing of ceramic fabrics?

Notes

For more details on the macro-fabric description, see Millet (forthcoming).

One reviewer commented that fully quantitative trace element data were required to separate Nile clays from different sources in Egypt and, therefore, that it is possible that some of the sherds in groups 1–4 are non-local; we are unable to reject this suggestion with the existing data, but we think it is highly unlikely that more than the occasional sherd in groups 1–4 was imported.

References

Aston D (1989) Qantir/Piramesse Nord: Pottery report 1988. Göttingen

Aston D (1996) Egyptian pottery of the Late New Kingdom and Third Intermediate Period (twelfth-seventh centuries BC): tentative footsteps in a forbidding terrain. Studien zur Archäologie und Geschichte Altägypten 13. Heidelberg

Aston D (1999) Elephantine XIX. Pottery from the late New Kingdom to the early Ptolemaic Period. Archäologische Veröffentlichungen 95. Mainz am Rhein

Aston D (2008) Untersuchungen im Totentempel des Merneptah in Theben. IV: The pottery. Beiträge zur aegyptischen Bauforschung und Altertumskunde 17. Mainz am Rheim

Bavay L (2004) Du tesson à l’histoire économique. Perspectives nouvelles sur la céramique du Nouvel Empire à Deir el Médina. Egypte Afr Orient 36:21–30

Binder M (2011) The 10th–9th century BC—new evidence from the Cemetery C of Amara West. Sudan and Nubia 15:39–53

Binder M, Spencer N, Millet M (2011) Cemetery D at Amara West: the Ramesside Period and its aftermath, British Museum Studies in Ancient Egypt and Sudan 16, http://www.britishmuseum.org/research/online_journals/bmsaes/issue_16.aspx

Bourriau J (1998) The role of chemical analysis in the study of Egyptian pottery. In: Eyre CJ (ed) Proceedings of the Seventh International Congress of Egyptologists, Cambridge, 3–9 September 1995. Orientalia Lovaniensa Analecta 82, pp 189–99. Leuven

Bourriau J (2001) The role of chemical analysis in the study of Egyptian pottery. In: Shortland AJ (ed) The social context of technological change. Egypt and the Near East, 1650-1550 BC. Proceedings of a conference held at St Edmund Hall, Oxford 12-14 September 2000. Oxbow Books, Oxford, pp 189–199

Bourriau J, Smith LMV, Nicholson PT (2000a) New Kingdom pottery fabrics. Nile clay and mixed Nile/Marl clay fabrics from Memphis and Amarna. The Egypt Exploration Society, London

Bourriau J, Nicholson P, Rose P (2000b) Pottery. In: Nicholson N, Shaw (eds) Ancient Egyptian Material and Technology, pp 121–147. Cambridge

Bourriau J, Smith L, Serpico M (2001) The provenance of Canaanite Amphorae found at Memphis and Amarna in the New Kingdom. In: Shortland AJ (ed) The social context of technological change. Egypt and the Near East, 1650-1550 BC. Proceedings of a conference held at St Edmund Hall, Oxford 12–14 September 2000, 189–199. Oxbow Books, Oxford

Bourriau J, Bellido A, Bryan N, Robinson V (2006) Egyptian Pottery Fabrics: a Comparison between NAA Groupings and the “Vienna System”. In: Czerny E, Hein I (eds) Timelines. Studies in Honour of Manfred Bietak. OLA 149, pp 261–92. Vienna

Carrano J, Ferguson JR, Girty GH, Smith ST, Carrano CJ (2008) A chemical and mineralogical comparison of Nubian and Egyptian style ceramics and the implications for culture contact: preliminary report, Sudan & Nubia 12:90–98

Carrano JL, Girty GH, Carrano CJ (2009) Re-examining the Egyptian colonial encounter in Nubia through a compositional, mineralogical, and textural comparison of ceramics. J Archaeol Sci 36:785–797

Desmond JA, Newton VJ, Robinson VJ, Williams OR (1986) The origins of Kahun pottery: a study by neutron activation analysis. In: David RA (ed) Science in Egyptology, pp 433–446. Manchester University Press

Fabbri B, Guarini G, Arduino E, Coghe M (1994) Significato del fosforo nei reperti ceramici di scavo. In: Burragato F, Grubessi O, Lazzarini L (eds) 1st European Workshop on archaeological ceramics. Universita’ degli Studi di Roma “La Sapienza”, Rome, pp 183–192

Fitton L, Hughes M, Quirke S (1998) Northerners at Lahun. In: Quirke S (ed) Lahun Studies. SIA Publishing

Freestone IC, Meeks ND, Middleton AP (1985) Retention of phosphate in buried ceramics: an electron microbeam approach. Archaeometry 27(2):161–177

Frood E (2003) The potters: organization, delivery, and product of work. In: Janssen JJ, Frood E, Goecke-Bauer M (eds) Woodcutters, potters and doorkeepers. Service personnel of Deir el Medina workmen, 29–42. Leiden

Geological Map of the Sudan (1981) 1:10.000.000. Prepared by the Geological and mineral Resources Department (G.M.R.D. Kathoum). Impact Graphic, Paris

Gratien B (2000) Les pots de caisson nubiens et les bols décorés de la première moitié du IIe millénaire avant J.-C. Cah Céram Égypt 6:113–148

Mallory-Greenough LM, Greenough JD, Owen JV (1998) New data for old pots: trace-element characterization of ancient Egyptian pottery using ICP-MS. J Archaeol Sci 25:85–97

Millet M (forthcoming) Ceramics from Egyptian towns in Nubia: a case study of Amara West (in press)

Mommsen H, Beier T, Diehl U, Podzuweit C (1992) Provenance determination of mycenean sherds found in tell el Amarna by neutron activation analysis. J Archaeol Sci 19:295–302

Nordström HÅ, Bourriau J (1993) The Vienna System. In: Arnold D, Bourriau J (eds) Ceramic technology: clays and fabrics, fascicle 2, an introduction to ancient Egyptian pottery, Chapter 4, pp 168–182. Deutsches Archäologisches Institut Abteilung Kairo Sonderschrift 17, Mainz am Rhein: Philipp von Zabern

Redmount CA, Morgenstein MA (1996) Major and trace element analysis of modern Egyptian pottery. J Archaeol Sci 23:741–762

Rose P (2012) Early 18th Dynasty Nubian Pottery from the site of Sesebi, Sudan. In: Forstner-Müller I, Rose P (eds) Nubian pottery from Egyptian cultural contexts of the middle and early New Kingdom, Proceedings of a Workshop held at the Austrian Archaeological Institute at Cairo, 1–12 December 2010, pp. 13–29. Vienna

Ryan P, Cartwright C, Spencer N (2012) Aspects of ongoing archaeobotanical research in a pharaonic town in ancient Nubia. Br Mus Tech Res Bull 6:97–107

Smith ST (2003) Wretched Kush: ethnic identities and boundaries in Egypt’s Nubian Empire, London and New York

Smith LMV, Bourriau JD, Goren Y, Hughes MJ, Serpico M (2004) The Provenance of Canaanite Amphorae found at Memphis and Amarna in the New Kingdom: results 2000–2002. In: Bourriau J, Phillips J (eds) Invention and innovation. The social context of technological change 2: Egypt, the Aegean and the Near East, 1650-1150BC. Proceedings of a conference held at the McDonald Institute for Archaeological Research, Cambridge, 4–6 September 2002, Chapter 4, pp 54–77. Oxbow Books, Oxford

Spataro M (2002) The first farming communities of the Adriatic: pottery production and circulation in the early and middle neolithic. Società per la Preistoria e Protostoria della Regione Friuli-Venezia Giulia, Quaderno 9. Trieste

Spataro M (2011) A comparison of chemical and petrographic analyses of Neolithic pottery from South-eastern Europe. J Archaeol Sci 38:255–269

Spataro M (2014) Continuity and change in pottery manufacture between the early and middle Neolithic of Romania. Archaeol Anthropol Sci. 6(2):175–197. doi:10.1007/s12520-013-0171-2

Spencer P (1997) Amara West, I: the architectural report. Excavation Memoir 63. London

Spencer P (2002) Amara West, II: the cemetery and the pottery corpus. Excavation Memoir 68. London

Spencer N (2009) Cemeteries and a late Ramesside suburb at Amara West, Sudan & Nubia 13:47–61

Spencer N (2014a) Creating and re-shaping Egypt in Kush: responses at Amara West. J Anc Egyptian Interconnect 6/1:42-61. https://journals.uair.arizona.edu/index.php/jaei/article/view/18030

Spencer N (2014b) Amara West: considerations on urban life in occupied Kush. In: Welsby D, Anderson JR (eds) Proceedings of the 12th International Conference for Nubian Studies. British Museum Publications on Egypt and Sudan 1:457–485. Leuven

Spencer N (in press) Amara West: house and neighbourhood in Egyptian Nubia. In: Müller M (ed) Household studies in complex societies: (micro) archaeological and textual approaches. Oriental Institute Seminars 10. Chicago

Spencer N, Macklin M, Woodward J (2012) Re-assessing the abandonment of Amara West: the impact of a changing Nile? Sudan & Nubia 16:37–47

Tobia SK, Sayre EV (1974) An analytical comparison of various Egyptian soils, clays, shales and some ancient Pottery by Neutron Activation. In: Bishay A (ed) Recent advances in science and technology of materials 3, pp 99–128. New York

Van Pelt WP (2013) Revising Egypto-Nubian relations in New Kingdom Lower Nubia: from Egyptianization to cultural entanglement. Camb Archaeol J 23:523–50

Acknowledgments

This study was undertaken under the auspices of a Leverhulme Trust sponsored project on Health and diet in ancient Nubia; the Amara West Research Project (www.britishmuseum.org/AmaraWest) has also received generous support from the British Academy and Fondation Michela Schiff Giorgini. All fieldwork is undertaken in collaboration with the National Corporation for Antiquities and Museums (Sudan). We are grateful to Abdelrahman Ali (Director General), Hassan Hussein Idris (former Director General), Salah Mohamed Ahmed (Director of Fieldwork) and our site inspector, Shadia Abdu Rabo, for facilitating work and permitting export of samples. The material discussed here was recovered from excavations supervised by Neal Spencer, An Van Camp, Mary Shepperson, Mat Dalton, Charly Vallance, Shadia Abdu Rabo, René Kertesz, Stephanie Aulsebrook, Tom Lyons, Michaela Binder, Nicole Lorenz and Nick Soderberg.

The authors would also like to thank Dr Catherine Higgitt, Dr Andrew Middleton, Mr Nigel Meeks and Dr Roberta Tomber (CSR, The British Museum), Dr Mary Ownby (Desert Archaeology Inc.), Prof. Y. Goren (Tel Aviv University), three anonymous reviewers, and Dr John Meadows (Zentrum für Baltische und Skandinavische Archäologie, Leibniz-Labor für Altersbestimmung und Isotopenforschung, Christian-Albrechts-Universität, Germany) for their useful comments and discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spataro, M., Millet, M. & Spencer, N. The New Kingdom settlement of Amara West (Nubia, Sudan): mineralogical and chemical investigation of the ceramics. Archaeol Anthropol Sci 7, 399–421 (2015). https://doi.org/10.1007/s12520-014-0199-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12520-014-0199-y