Abstract

This study presents the results of analyses of ceramics from one of the rare excavated kiln sites that produced amphorae and common wares in Ptolemaic Egypt (332–30 BC), at Kom Dahab in the Western Nile Delta. Ceramics from the kiln trench, unfired ceramics and specific classes of transport, table and kitchen vessels were analysed by polarised microscopy and scanning electron microscope used with energy dispersive spectrometry (SEM–EDX). This made it possible to trace the different steps of the chaîne opératoire and revealed that potters made differentiated use of raw materials. A specific clay, perhaps offering economic advantages, soon dominated the amphora production. A variety of recipes was used for white and red slips applied to both utilitarian and tablewares. Shapes were strongly Greek-influenced, but after some time ceramic technology readmitted earlier Pharaonic traditions, presumably driven by consumer demand and economic considerations. The analysis of slipped bowls from Old Kingdom levels suggests the long-term exploitation of the local clay sources of distinctive chemical composition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Kom Dahab lies at the western edge of the Nile Delta (N 30° 51′ 35″ E 30° 29′ 51″),Footnote 1 10 km south-west of Naukratis (N 30° 53′ 50″ E 30° 35′ 33″), an international harbour founded in the late seventh-century BC (Fig. 1). It was long perceived as a small satellite or industrial site that appeared only in the third century BC next to the major early site of Kom Firin (N 30° 51′ 52″ E 30° 29′ 17″), founded in the thirteenth-century BC (Spencer 2008, 17). Results of a survey and excavations conducted at Kom Dahab by Nancy WilkieFootnote 2 were only partially published (Coulson and Leonard 1981, 73–77; Coulson et al. 1982, 83–84; Coulson and Wilkie 1986, 65–74; Coulson et al. 1986), but a comprehensive reassessment of the evidence in the framework of the British Museum’s Western Nile Delta project (Masson-Berghoff and Thomas forthcoming) now transforms our perception of the site (Masson-Berghoff forthcoming a, forthcoming b), revealing, among other things, a substantial Old Kingdom (c. 2686–2181 BC) phase.

Map indicating the sites and regions mentioned in the text. The site of Kom Dahab, to the southeast of Kom Firin (Google satellite view of the area in May 2020, with the limits of the settlements as known in the 1980s indicated; photograph by N. Wilkie © W.D.E. Coulson Archives, University of Thessaly, Dept of History Archaeology and Social Anthropology)

During the Ptolemaic period (332–30 BC), Kom Dahab was a centre of ceramic production (Fig. 2). The 1980 survey found the site littered with fragments of transport amphorae and other shapes, including kiln wasters. Subsequent small excavations exposed two kilns (one never published). The workshop operated from the mid-3rd to the early first century BC.Footnote 3 As one of only a handful of excavated Ptolemaic pottery kilns, the Kom Dahab complex is highly significant. Both fired and unfired pottery was found here in situ. The assemblage promises rare insights into a pottery chaîne opératoire during a highly dynamic period when newly introduced Greek ways of pottery making intersected with long-established Pharaonic traditions. It establishes a secure technological and chemical reference point for ceramics made in the western Nile Delta in the Old Kingdom and Ptolemaic Period, and an opportunity to examine how natural setting and human agency shaped variation in Delta ceramic fabrics.

Clay resources at Kom Dahab were created over the millennia by the Nile and its dynamic system of delta branches (on the geology of the Delta: Said 1981, sheet IV; Chen et al. 1992; Pennington et al. 2017). During the Old Kingdom, the southwestern fringes of the Delta close to the Western Desert were largely semi-arid, though presumably with a (periodically) active river channel; in the early first millennium BC, they became part of the Nile Delta floodplain, resulting in a gradual build-up of alluvium around the site (Toonen and Pennington forthcoming). In earlier periods, clay resources at Kom Dahab may thus have been more limited, but by the Ptolemaic period, numerous small channels, their levees and back swamps, would have offered a broad range of alluvial sediment (between fine sand and clay) for pottery manufacture. Additional sand (for tempering) could be sourced from the aeolian ridge on which the site had been founded. No marl outcrops are present in the area.Footnote 4

Background and history of research

Pottery kilns and associated finds offer vital insights into the way artisans’ choices were influenced by material conditions and cultural, economic, and technological factors. Yet their discovery remains fortuitous. The kilns of Kom Dahab were the first Ptolemaic amphora workshops ever subjected to detailed archaeological scrutiny, and while others have become known since, they have often only been investigated in surface surveys (Dixneuf 2011, 183; Kenawi and Mondin 2019, 87). The Mareotic region was one of the most important amphora production centres in the Hellenistic world (Blue and Khalil 2011), but only kilns of Roman date have been excavated so far.Footnote 5 The Eastern Marmarica was another major centre (Rieger and Möller 2011; Möller and Rieger 2019), yet only the Ptolemaic kilns at Tell el-Haraby (Majcherek and El-Shennawi 1992) and Bir Abu Sakran at Marsa Matruh (Rieger and Möller 2011, Table 1 no. 14; Möller and Rieger 2019, 71), where both amphorae and common ware vessels were produced, have been uncovered. The recently excavated amphora kiln at Philadelphia in the Fayum can be added to this short list (Marchand et al. 2018). No Ptolemaic kilns have yet been investigated in the large pottery workshops of Medamud in the Theban region, although numerous wasters attest to the production of a wide range of vessels, including amphorae (Barahona-Mendieta 2016, 35–36, Figs. 19–20). A few more Ptolemaic kiln sites have been explored in depth, but they do not include amphora production (see however Tell Atrib: Południkiewicz 1992; 1995; Scholl 1995; Scholl et al. 1995); one example is the large Ptolemaic and Roman industrial quarter at Tell el-Fara’in/Buto, which produced table and kitchen wares as well as jars, bottles, and jugs (Ballet et al. 2019).

Kom Dahab thus represents a rare opportunity to examine Ptolemaic Nile Delta ceramics of known provenance and to characterise a kiln production. A rich array of ceramics was found within or beside the two exposed kilns, besides which more probably existed. Transport amphorae dominate but large numbers of cooking ware, tableware, and household utility vessels were uncovered as well. Wasters and vessels with firing defects confirm local manufacture of amphorae and a wide range of other shapes. They represent the typical shape repertoire of utilitarian and tablewares of Egypt in the Ptolemaic period, a time when the influx of new populations, rule by a Macedonian dynasty, growing interaction with the Mediterranean world and expanding commerce transformed Egypt’s society, economy, and material culture. For Ptolemaic pottery, too, strong affinities with Greek wares, but also elements of earlier Pharaonic traditions, have been noted (e.g., Marchand 2002; Defernez and Marchand 2006; 2016; Masson 2011; 2016). Such observations have mostly been based on shape or appearance.

Even though scientific analysis is a vital tool for understanding processes of cultural and economic change through the lens of material culture, only very little analytical work has been published on Ptolemaic wares and none on pottery from Kom Dahab.Footnote 6 One relevant study concerned the Late Period (664–332 BC) to Ptolemaic pottery, primarily tableware, found and likely produced at nearby Naukratis, which was subjected to chemical and petrographic analysis to investigate provenance and differentiate Greek and Egyptian technological traditions (Spataro et al. 2019). Chemical analyses were recently conducted on local Ptolemaic and Roman productions at Buto, but little detail has so far been published (Ballet et al. 2019, 190).Footnote 7 Perfume bottles produced in a fourth-century BC workshop in Tell el-Timai in the Eastern Delta (Hudson et al. 2018) and late fourth- to early third-century BC amphorae copying, in a rather coarse marl clay, Levantine models discovered at various Egyptian sites (Alexandria, Abu Rawash, Wadi Natrun, and Tebtynis) were analysed by X-ray fluorescence (XRF) (Defernez and Marchand 2016, 149–150, pl. 4). As only some of these analysed ceramics are from kiln sites,Footnote 8 attributions to production places often remain hypothetical, however. Characterising the technical and chemical features of the Kom Dahab production should thus provide a rare reference point for ceramics produced in the western Nile Delta and shed further light on the problematic question of subtle differences between compositionally largely uniform Nile Delta silt fabrics (see Ownby and Brand 2019; Spataro et al. 2019; Bourriau et al. 2006). This is of relevance not least for understanding patterns of trade. As a small- to medium-sized centre (cf. comparative studies in Rieger and Möller 2011), Kom Dahab produced for the local but perhaps also regional market, yet so far it remains impossible to establish whether typologically similar vessels discovered at nearby sites were produced at Kom Dahab or in other workshop sites, such as at Naukratis and Kom Barud (see Masson-Berghoff forthcoming b).

Research aims and objectives

In this study, we aim to exploit the potential of Kom Dahab to shed light on Ptolemaic pottery production and questions of wider relevance, using scientific analysis, archaeological and textual data. Focusing on a single production centre can allow us to define a workshop’s chaîne opératoire during a particular period in history and to assess technological variation, the agency of potters, and their cultural and environmental milieux. Analysis of Old Kingdom bowls found at the site will make it possible to include questions of long-term change or continuity in the use of raw material and fabric preparations.

The key objectives of this paper are as follows:

-

To describe the ceramic chaîne opératoire (clay selection, addition or removal of inclusions, surface finishing, firing) and the raw materials used by the potters at Kom Dahab;

-

To investigate whether different ceramic recipes, surface treatments, and firing regimes were used to make different ceramic classes, and therefore to examine how considerations of functionality affected the ceramic production and its organisation at Kom Dahab;

-

To interrogate evidence for diverse cultural traditions as well as the role of economic and environmental factors in the pottery production of Ptolemaic Kom Dahab;

-

To determine whether similar or different raw materials and fabric recipes were used in the Old Kingdom and in the Ptolemaic period; and

-

To assess the degree of variability in raw materials, pottery technology, and cultural traditions in regional Nile Delta workshops, and in particular to compare Kom Dahab data with contemporaneous ceramic production elsewhere in Lower Egypt.

Material and methods

Sample selection

Samples were selected from the Kom Dahab finds in the Museum of Bryn Mawr College (Pennsylvania).Footnote 9 During a preliminary study of this collection in 2017, Aurélia Masson-Berghoff counted 667 ceramics and small finds from Kom Dahab and selected 19 sherds for analysis. They are a representative selection of the key shapes and functional categories (storage, cooking, serving) recovered from Kom Dahab, though weighted towards amphorae, with consideration also given to surface treatments and archaeological context. Transport amphorae are represented with different shapes (short rim, more or less squared AE1-2.5 or AE2-1.1; long-collared rim AE2-2.1 or AE2-2.2),Footnote 10 textures (medium to coarse), surface treatments (white-slipped, self-slipped, and unslipped), and dates (from 250 to 50 BC), thus spanning the beginning, middle, and end of production (Fig. 3 and Table 1). Both fired (4) and unfired (3) amphora sherds were selected. Other shapes comprise slipped and unslipped cooking vessels, serving bowls and plates, and a storage vessels (hydria?) (Fig. 4 and Table 1). While only the unfired fragments are unquestionably local, there is little doubt that all the Ptolemaic vessels analysed were made at Kom Dahab: one analysed fragment, probably from a hydria (KOD17), is a waster, wasters of the other shapes analysed were found at the site, and table and cooking wares had been placed alongside amphorae in the last load of one kiln (Masson-Berghoff forthcoming b, Fig. 74). For comparative purposes, two Meidum bowls each in Nile and marl clay and a bowl with a direct rim were selected from the Old Kingdom material (Fig. 5 and Table 1) (discussed in detail in Spataro and Masson-Berghoff forthcoming).

Polarised microscopy and scanning electron microscopy

All 19 selected samples were sent for uncovered polished thin sectioning, and the thin sections were analysed by optical polarised microscopy and scanning electron microscopy with energy dispersive analysis (SEM–EDX) at the Department of Scientific Research at the British Museum (London, UK).

A Leica DMRX polarising microscope was used to identify matrix (clay) types and non-plastic inclusions, in order to characterise the petro-fabrics and to investigate different aspects of the chaîne opératoire, such as clay selection, processing, addition or removal of inclusions, surface finishing, and firing (e.g., Spataro et al. 2019).

The polished thin sections were also analysed with a Hitachi S-3700 N Variable Pressure SEM equipped with an Oxford Instruments AZtec energy dispersive X-ray analyser (SEM–EDX), in order to characterise the chemical composition of the clays. SEM images were used to estimate the firing temperatures and to investigate the surface treatments (Ionescu et al. 2015). The SEM was used at a pressure of 40 Pa with a 20 kV accelerating voltage; the samples were analysed uncoated at a 10-mm working distance. The results were converted into oxide percentages, which were normalised (oxygen by stoichiometry; see below for details on bulk analyses). Principal component analysis (PCA) (Hammer et al. 2001) was also used to interpret the SEM–EDX results (Spataro et al. 2019).

In addition to the body fabrics, particular attention was paid also to analysing slips. Slips are not always easy to detect macroscopically, as self-slipped (well-burnished, also called ‘mechanical slip’ pottery; see Spataro 2016, 168) can be interpreted as slipped ware. Polarised microscopy helps detect most differences, but in some cases, it is difficult to tell apart a very well-polished layer and a slipped surface. In this case, SEM–EDX analyses and the chemical comparison of the body paste and surface layer of the ceramic can inform us about the slip composition.

Results

Polarised microscopy

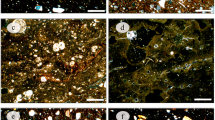

Eight fabrics were defined by optical microscopy, six non-calcareous (NC1-6) and two calcareous (CF1 and 2) (SI Appendix 1; Fig. 6). Fabric groups were defined based on matrix type and its fine minerals, and the variations of other minerals (e.g., serpentine, biotite, etc.; in some cases, part of the deliberately added temper), and their sizes (e.g., fabric NC1 contained the finer and better-sorted minerals). As the main minerals recur in almost all fabrics, differences between fabrics are sometimes subtle.

Kom Dahab: photomicrographs of ceramic thin section of sample a KOD5 (Old Kingdom bowl; fabric NC1) with voids left by the burning off of the plant matter and a red slip; b KOD15 (Ptolemaic cooking pot; fabric NC2a); c KOD17 (Ptolemaic hydria (?); fabric NC3b) probably sand-tempered; d KOD3 (Ptolemaic short rim amphora; fabric NC4) probably sand-tempered; e KOD11 (Ptolemaic unfired long-collared rim amphora; fabric NC5) probably not tempered; f KOD8 (Old Kingdom Meidum bowl; fabric CF2) with a fossiliferous fabric (a microfossil is visible on the left of the photomicrograph). All photomicrographs were taken in cross-polarised light, the field of view is 1.75 mm (photographs by M. Spataro © Trustees of the British Museum)

Fabrics NC1–6 are non-calcareous with relatively abundant inclusions, mainly fine quartz, and in some cases, scattered coarser rounded grains, plagioclase, amphibole, and pyroxene, with variations in the content of fine serpentine, biotite with thick lamellae, and igneous inclusions (Fig. 6). Most of these fabrics were sand- or plant-tempered.Footnote 11 Fabrics CF1 and 2 are calcareous and fossiliferous and they were not tempered (see Table 1).

Fabric NC1 (three Old Kingdom bowls, including two Meidum bowls) is very fine, low-fired, and contains abundant, well-sorted, and fine quartz sand, with occasional plagioclase, serpentine, micas, pyroxene, igneous inclusions, (post-depositional?) carbonates, and abundant iron oxides. There is some plant matter and voids left by the burning out of organics, which might have been added as temper (Fig. 6a). Some areas in the same sample are richer in organics than others. Recurrent clay pellets in one of the bowls (KOD5) suggest that the clay was not thoroughly processed prior to shaping. Fabric NC1 subgroup a, another bowl, contains more abundant biotite micas and carbonates.

Fabric NC2 (a cooking pot) was more highly-fired and it contains coarser and more poorly-sorted sand than fabric NC1. It also contains feldspar, micas, serpentine, occasional pyroxene, and amphibole. Fabrics 2 subgroups a and b contain less serpentine than fabric NC2. Fabric NC2 subgroup a (a cooking pot) contains more abundant biotite than fabric 2 (Fig. 6b). Subgroup b (a fish-plate) contains finer organic inclusions than fabrics NC2 and 2 subgroup a. Fabric NC2 might have been sand-tempered, but not its subgroups a and b.

Fabric NC3 (a cooking pot) contains fine and abundant sand, which might have been deliberately added as temper. Its sand is coarser than that in fabric NC1, but better-sorted than that in fabric NC2. Subgroup a (a cooking pot) contains a calcareous fragment and more voids from burnt-off plant matter, subgroup b (a hydria?/waster; Fig. 6c) also contains a few calcareous fragments, and more biotite micas than fabrics NC3 and 3 subgroup a. They might all have been sand-tempered.

Fabric NC4 (a short rim amphora) and its subgroup a (an amphora) were highly-fired, and most probably sand-tempered (Fig. 6d). The paste contains abundant poorly-sorted size distribution of quartz sand, and subgroup a contains scattered microfossils and more abundant fine quartz.

Fabric NC5 (an unfired amphora) contains some well-sorted quartz, with occasional feldspar, some fine micas, occasional rounded stretched metamorphic polycrystalline quartz, calcareous fragments, and abundant opaques. It was not tempered (Fig. 6e). Some fine elongated voids, probably due to the drying process, are visible in the fabric. Its subgroup (a short rim amphora) contains fewer plagioclase inclusions, and it was probably plant-tempered.

Fabric NC6 (an unfired short rim amphora) contains poorly-sorted sand rich in quartz, with micas, plagioclase, pyroxene, sphene, serpentine, occasional bone fragments and naturally occurring plant matter, and amphibole. It was probably sand-tempered. Its subgroup a (a long-collared rim amphora) contains few sand inclusions and micas, occasional clay pellets, and it was heavily plant-tempered. Fabric NC6 subgroup b (another unfired short rim amphora) does not contain any plant matter and it was probably sand-tempered.

Fabrics CF1 and 2 (two Meidum bowls) are both calcareous, with fine and well-sorted quartz sand, but CF2 is rich in microfossils and biotite and it contains more recurrent fine serpentine (Fig. 6f). They were not tempered.

Scanning electron microscopy with energy dispersive spectrometry

All 19 Kom Dahab samples were analysed by scanning electron microscopy with energy dispersive spectrometry (SEM–EDX) (SI Table 2), to measure the chemical composition of the body pastes and slips, examine their microstructures, and estimate the firing temperatures. The SEM–EDX study consisted of bulk (regional) analyses from four different areas of each sherd, so as to be representative of the fabric. Each covered approximately an area of c. 1.4 × 1.0 mm at a magnification of × 100, to avoid large minerals or rock fragments. The results represent the average composition of the clay matrix and smaller plastic and aplastic inclusions (see Spataro 2011, 257).

Chemical composition

There seems to be a pattern in the use of clays for the production of specific shapes. Figure 7 shows that PC1 separates the Ptolemaic amphorae from all other samples. A scatter plot of FeO vs MgO (Fig. 8) confirms that most amphorae are chemically different from all the other vessels. Apart from the unfired KOD1 (one of two analysed samples of third-century BC unfired white-slipped short rim amphorae), the amphorae have higher magnesia and iron oxide contents. At the same time, Figs. 7 and 8 suggest that raw materials with a similar chemical signature were used to make the Nile silt Old Kingdom bowls and the Ptolemaic household and tableware.

Principal component analysis output (components 1 and 2), based on SEM–EDX compositional data from the Kom Dahab samples, except the two calcareous samples (KOD7 and 8). PCA was carried out using Past v. 3.18 (Hammer et al. 2001). Each point represents the average of four bulk analyses of an individual vessel

Slip analyses

Most of the analysed vessels had a slipped surface. The slips of eleven samples were analysed by SEM–EDX, including red slips, dark slips, and a white slip. Small slip fragments were present on the thin sections, so the EDX analyses were carried out at high magnification (between × 320 and × 1.2 K). Three to four bulk analyses were carried out for each slip. It was possible to analyse the interior and exterior red slip for one sample (KOD5, fabric NC1): these gave very consistent results, showing the homogeneity of the coating (SI Table 3).

Red slips were analysed from eight samples, three bowls from the Old Kingdom (KOD4, 5, 8, respectively fabrics NC1 subgroup a, NC1 and CF2), and the others from the Ptolemaic period (KOD13, 14, 15, 16 and 18, respectively fabrics NC2, NC3 subgroup a, NC2 subgroup a, NC3 and NC2 subgroup b). The slip of one sample (KOD16, a cooking pot) was probably contaminated in the burial environment, as its soda content is too high (SI Table 3). Dark slips of two Old Kingdom Meidum bowls (one with a non-calcareous fabric [sample KOD6, Fabric NC1] and one with a calcareous fabric [KOD7, Fabric CF1]) were analysed.

The SEM images show that both red and dark slip microstructures are very fine (see Fig. 9) and EDX results show that all of them were obtained by levigating non-calcareous clays, to which iron oxides (including ilmenite) were added. This is shown by relatively high alumina (18.3–28.1%) and iron oxide (6.5–9.2%), with variable magnesia (1.4–3.4%) and potash (2.2–7.3%) contents (SI Table 3).Footnote 12 Both red and dark slips were applied very thinly (c. 0.05–0.03 mm), as visible in the low and high magnification images of the Old Kingdom red and dark-slipped bowls (Fig. 9a–f).

Kom Dahab: SEM-BSE images of Old Kingdom red- and dark-slipped bowls, a red slip of sample KOD5; b red slip of sample KOD5 at high magnification showing a very thin coated layer; c red slip of sample KOD4 showing a very thin coating layer; d dark slip of sample KOD6; e dark slip of sample KOD7 at high magnification; and f red slip of sample KOD8 at high magnification (photographs by M. Spataro © Trustees of the British Museum)

The red slips used for the Old Kingdom non-calcareous bowls (KOD4 and 5; Figs. 9 c, a, and b) were made with similar clays: there are some differences in the soda and potash contents, but both have similar high iron oxide levels (c. 9%). The red slip on the calcareous Old Kingdom bowl (KOD8; Fig. 9f) has a different composition to the body fabric, with much less calcium. This might imply that the slip coating was obtained by levigating a different clay from that used for the body fabric.

There seem to be no consistent differences in chemical composition between the red slips on the Old Kingdom bowls and the red slips used for the Ptolemaic pots (Fig. 10a and c), but within each period, the composition of slips is quite variable.

Two dark slips from Old Kingdom bowls were analysed, one from a non-calcareous and probably plant-tempered bowl (KOD6, fabric NC1; Fig. 9d) and one from a bowl with calcareous and fossiliferous fabric (KOD7, fabric CF2; Fig. 9e). The slips were made using different clays, as the slip of KOD6 is richer in potash and iron oxide and poorer in calcium oxide than the slip on KOD7. Both slips contained more alumina and potash than the respective fabrics, and less calcium and iron oxides. The clays used for these slips were probably not from the same sources as the clays used for the pots.

Only some traces of a white slip were visible on sample KOD3 (fabric NC4), a Ptolemaic short rim amphora. It was perhaps made using a dolomitic clay, rich in magnesia, calcium oxide, and potash (SI Table 3, Fig. 10b). The clay used for the white slip was from a different source from that used for the body fabric, richer in soda, magnesia, potash, and calcium and poorer in alumina, silica, and iron oxide.

Firing temperatures

Two Old Kingdom bowls—both of alluvial clays and including a Meidum bowl—were fired below 800 °C and three Meidum bowls—two of marl (KOD7 and 8, fabrics CF1 and 2) and one of alluvial clay (KOD6, fabric NC1)—were fired at higher temperatures, as clay filaments had started to vitrify (Table 1). Of these, the fabrics of the marl bowls (samples KOD7 and 8) are vitrified, although calcareous clays start vitrifying at lower temperatures than non-calcareous clays (e.g., Tite and Maniatis 1975; Table 1 and Fig. 11). The Ptolemaic ceramics were almost exclusively fired below vitrification point (< 850 °C), with some pots showing the first stages of vitrification of the fabrics (Table 1; Fig. 11).

Kom Dahab, firing temperatures: SEM-BSE images of (top left) a red-slipped calcareous Old Kingdom Meidum bowl (sample KOD8), showing a slightly vitrified paste; b an unfired Ptolemaic amphora (KOD11); c an echinus bowl (KOD19) with a well-fired but not vitrified fabric; d a cooking pot (KOD14) with a vitrified fabric (photographs by M. Spataro © Trustees of the British Museum)

Discussion: the potters of Kom Dahab

The ceramic chaîne opératoire

Sourcing raw materials

Analysis indicates that different sources of local raw materials were exploited by the potters at Kom Dahab.

Petrographic analysis showed that all the Ptolemaic vessels analysed were made from non-calcareous Nile silt clays, confirming macroscopic observations of the exclusive use of such clays for the local wares of this period. Along with sand temper, Nile silt would have been readily available locally. Textual evidence from Ptolemaic and Roman Egypt, such as lease contracts between estate owners and itinerant craftsmen, confirms that pottery workshops were often located in the vicinity of sustainable clay sources (Fülle 1997, 121–122). For example, a second-century AD contract (P.Tebt. 2.342.26–29) specifies that the potters are allowed to extract the earth, the porous clay, and the sand from an unused field located to the south of their amphora workshop, with the cost of the extraction of the clay and its transport to the workshop at the charge of the potters (Gallimore 2010, 167; Burkhalter 2013, 256, note 43). The collection of clay could be handled by potters’ assistants or independent clay miners (Grace and Empereur 1981, 421; Nicholson and Patterson 1985, 222–225; Gallimore 2010, 166–167).

Compositional analysis suggests at least two distinct local clay sources at Kom Dahab. Ptolemaic kitchen/household wares appear chemically very similar to the Old Kingdom slipped bowls (Fig. 7), indicating long-term continuity in the exploitation of local clays sources of a distinctive composition. The clay used for making amphorae was compositionally somewhat different, surprising in view of the limited degree of chemical variability that is often observed among Nile Delta silts (Bourriau et al. 2006). In a previous study, it proved difficult to detect mineralogical and chemical variations in the ceramic fabrics, even using, as well as polarised microscopy, multiple chemical techniques, such as neutron activation analysis and SEM–EDX (Spataro et al. 2019).

Imports were identified only among the Old Kingdom pottery. Two of the analysed Meidum bowls were made of untempered marls with microfossils (KOD 7 and 8). As suitable marl outcrops are lacking in the region, they could have been imported, e.g. from the Memphite region.

Selecting clay

Analysis suggests that Kom Dahab potters chose chemically different clays for some ceramic classes, even if the fabrics show strong mineralogical similarities and were often tempered with the same tempering agents. There is no clear pattern discernible among Ptolemaic utilitarian wares: two cooking pots (KOD14 and 16) were made with a similar raw material to that used to make a hydria(?) and an echinus bowl (samples KOD17 and 19); and a so-called fish-plate (KOD18) was made with a similar fabric to that of two cooking pots (KOD13 and 15).

A different, magnesium- and iron-rich clay, however, was used only to make amphorae (Figs. 7 and 8). This could have been a deliberate choice, as these elements promote vitrification at relatively low firing temperatures (see Spataro 2009), which could provide an economic advantage by saving fuel in wood-poor Egypt.Footnote 13 Alternatively, the clay might have been selected for the whiter colour produced by its calcium oxide content (Spataro 2009, 70), creating a product more attractive to consumers on account of its greater similarity to light-coloured Greek amphorae and thus aimed at another type of economic advantage. Yet another possibility might be that amphorae were made in a different season, and the annual flooding cycle restricted access to a clay source for part of the year. Indeed, the production of amphorae is often seen as a seasonal activity in pottery workshops (Cockle 1981, 93). Wine amphorae needed to be ready for the harvest between mid-July and the end of September, coinciding with the inundation season.Footnote 14 Several months of manufacture were necessary, from the collection of clay to the firing of the containers, through the preparation of clay, the shaping and drying of the amphorae.Footnote 15

In terms of production organisation, two different scenarios are possible, either one and the same potter choosing specific raw materials for different types of pottery, or different workshops or workshop traditions using different raw materials and recipes for their specialised wares, yet sharing the use of the same kilns.

The use of particular clays for particular shapes is a well-attested phenomenon. At Ashmunein in Middle Egypt, for example, Late Roman amphorae VII in Nile silt were produced alongside plain and fine wares made out of Nile and marl clays (Ballet et al. 1991, 137–38). Fine, light-coloured marl, it seems, was a preferred choice for certain Egyptian wares, which would explain its occasional trade, attested in the fourth century BC.Footnote 16 Clays of different qualities were also sometimes specifically mandated in lease contracts. A third-century AD contract (P.Oxy. 50.3595–3597) stipulates that the estate owner had to supply the potters with three sorts of earth (χοῦς), for the production of 15,300 amphorae per year: friable (χαυνόγιος), sandy (ἀμμόγειος), and black (μελάνγειος) clays (Gallimore 2010, 165; Burkhalter 2013, 255), perhaps references to Nile silt, desert marl, and mineral temper (sand, quartz) (Cockle 1981, 92–93).

Processing clay

The clays used to make pots at Kom Dahab were sometimes poorly processed, as fine organic matter, bone fragments, soil, and clay pellets are present in the fabrics. In fact, two of the three unfired amphora samples (KOD1 and 2, fabrics NC6 and 6 subgroup b) contain occasional organics, which reinforces the idea that clays were not always thoroughly processed. In many cases, fabrics also appear tempered, though naturally occurring inclusions cannot always be clearly distinguished from deliberately added temper. The kitchen, household, and tablewares, made using similar clay sources, display a variety of temper types. Three of the four cooking pots with vertical or horizontal handles (KOD13-16) were made by adding sieved sand to the clay. The conspicuous presence of fine sand in Ptolemaic cooking ware fabrics has also been noted macroscopically at other sites (e.g., David et al. 2016, 11–12) and may be linked to sand temper improving the functional properties of cooking wares such as thermal shock resistance (Kilikoglou et al. 1998). For other table and household shapes, the picture is more varied. The ‘fish-plate’, a food-serving dish, was not tempered. The echinus bowl and the hydria(?) were probably sand-tempered.

Among the transport amphorae, two main fabric groups could be distinguished. Each comprises both fired and non-fired sherds and finds from within and outside the kiln. The groups do not, however, reflect a typological distinction (both comprise long and short rim amphorae) but rather a diachronic development: thus, the earlier (mostly slipped) amphorae of the third-century BC were mostly sand-tempered, in some cases with possibly sieved sand, while the later (mostly non-slipped) amphorae were either not tempered (sample KOD11) or plant-tempered (samples KOD9 and 10). This development coincides with what can macroscopically be observed about Kom Dahab’s amphora production, which seems to go through stages of experimentation, perfection, and cost-effectiveness (Masson-Berghoff forthcoming b, esp. Figure 190; Spataro and Masson-Berghoff forthcoming). The fact that the only amphora (KOD1) not to feature the magnesium- and iron-rich amphora clay is from the earliest Ptolemaic context fits in well with a scenario of early ‘experimentation’. The introduction of plant temper is of particular interest, as plant temper had a long tradition in Egyptian (but not Greek) pottery technology, notably for coarser wares (Ownby and Brand 2019; Nordström and Bourriau 1993; cf. Spataro et al. 2019). Also, the analysed Old Kingdom Nile silt bowls from Kom Dahab may have been plant-tempered, even if otherwise their fabric is well-processed and richer in finer sand than that of the Ptolemaic kitchen and tablewares. Appearing only in the second-century BC, the use of plant temper for the Kom Dahab amphorae, however, seems not so much a Pharaonic ‘survival’ but rather a deliberate and perhaps primarily economically motivated strategy, aimed e.g. at enhancing production speed or creating lighter vessels (and thus adding to the advantages of a fuel-efficient clay).

Finishing surfaces

Thin slips were applied to many, but not all, vessels in both the Old Kingdom and Ptolemaic periods. The pots were sometimes smoothed before being slipped. Chemically, the slips on an Old Kingdom red-slipped bowl (KOD5) and a Ptolemaic red-slipped fish-plate (KOD18) are very similar, again suggesting that the same raw material sources were being exploited locally over a long period of time. Overall, though, the composition of Ptolemaic red slips is quite varied, and compositional data from slip samples are more variable than compositional data from ceramic pastes, particularly in magnesia, potash, and iron oxide contents (SI Table 3), revealing less standardisation in surface treatment than in pot-making. Nonetheless, potting and slipping were closely connected: red and dark slips were most likely obtained by levigating non-calcareous clays, mixed with iron oxides. The only analysed white slip, on a third-century BC short rim amphora (KOD3), had high potash, magnesia, and calcium oxide contents, maybe suggesting a dolomitic origin for the source clay, and thus the use of different clays for slip and body fabric (as also observed for two Old Kingdom bowls, KOD6 and KOD7).

Firing and post-firing treatments

The reddish surface colour of the non-calcareous vessels shows that they were fired in oxidising conditions. Fabrics were generally fired below vitrification (Table 1), suggesting that both functionality and economy were of concern. The question arises, though, whether the fact that the Kom Dahab transport amphorae were not highly-fired was fully counteracted by the use of clay that, as suggested earlier, probably had a lower vitrification point. According to preserved contracts, potters were legally obliged to supply only amphorae of good quality, i.e. well fired and without cracks (Gallimore 2010, 173–177; Burkhalter 2013, 253). Yet containers manufactured in Nile silt are especially liable to firing and leakage issues (Nicholson 2010, 6). In addition to the choice of specific Nile clay and/or recipes, surface treatments were another way to mitigate any permeability problems, as inner coatings, such as resins, could make amphorae impermeable. However, no pitch was macroscopically detected on the amphorae found at the site and no pitch-furnace nor any pitch containers have been discovered during excavations.Footnote 17 One possibility is that finished amphorae were transported empty to be pitched and filled elsewhere. This practice is attested in papyri of the mid-third century AD (P.Cair.Zen. 4.59611 and 4.59741: Gallimore 2010, 179), but already Ptolemaic texts stress the necessity for potters to hire teams of experienced craftsmen and indicate a division of labour between potting and resin coating (Burkhalter 2013, 259–261).

Making pottery in the Ptolemaic Nile Delta

The finds from Kom Dahab indicate a well-organised, professional local pottery production centre of substantial scale and breadth. At least two, but probably more, kilns were in operation during the Ptolemaic period, with production focused on transport amphorae but including a wide range of utilitarian and tablewares. Raw materials were sourced locally, but comprised clays of at least two distinct chemical compositions, one of which was already used in the Old Kingdom, while the other may only have become accessible in the first-millennium BC.

To better understand the craft of the potters at Kom Dahab in its wider geographical and cultural context, we compared our results to previous work on pottery of the Late Period and Ptolemaic era, conducted with the same analytical techniques and instruments (Spataro et al. 2019). This earlier study focused on vessels found (and mostly also probably produced) at Naukratis, located not far from Kom Dahab on the Canopic Nile branch (Fig. 1). As an international port where Egyptian and non-Egyptian people and traditions had come into contact several centuries before the Ptolemaic period, the site provides a valuable comparison for Kom Dahab. Besides Greek and Egyptian-style pottery from Naukratis, the study included Late Period Egyptian and Ptolemaic wares from other Lower Egyptian sites.

The fabrics of fourteen Late Period to early Ptolemaic table and household vessels (as well as two terracotta figurines and a scarab mould) from Naukratis, Memphis, Tanis, Tell Dafana, and Saqqara were analysed by SEM–EDX (Spataro et al. 2019, table 5). Except for two ‘marl’ grinding bowls from Tell Dafana,Footnote 18 all were made of Nile clay, and similarly to the analysed Kom Dahab material most were not tempered or sand-tempered, with only few plant-tempered.Footnote 19 The Kom Dahab ceramics appear to be chemically distinct (based on Fe and Mg levels) from these vessels (Fig. 12), though in the amphorae Fe levels are higher and thus closer to vessels from Naukratis. The analyses thus lend further confirmation to evidence from archaeology that the assemblages were made in different places and show that variations in chemical make-up can reflect regional differences. This is remarkable given the often-observed general chemical closeness of Nile clays across the Delta, and considering that the Canopic Nile branch, on which Naukratis lay, also fed the Khenes system responsible for the alluvial deposits of the area around Kom Dahab, which should thus be very similar (Toonen and Pennington forthcoming). However, geologists have also noted that the alluvium at the western fringes of the Delta is notably sandier compared to Nile muds of the central delta plain, because of the continued influx of aeolian material from the nearby desert, and it may be that this influx, as well as the local sands sourced by potters as temper, influenced its chemical composition.Footnote 20 Also, the chemical separation of amphorae and other vessels at Kom Dahab is in part perhaps due to Nile silt being diluted to different degrees by aeolian sand (with negligible Fe). Kom Dahab’s Ptolemaic potters, it seems, drew not just on ‘pure’ Canopic alluvial deposits, but on naturally occurring mixtures when they exploited the region’s diverse clay sources.

Kom Dahab and other sites: principal component analysis output (components 1 and 2), based on SEM–EDX compositional data from the Kom Dahab samples (except the two calcareous samples KOD7 and 8) and the samples analysed from Naukratis, Tell Dafana, Memphis, and Tanis (all made of Nile clay with or without temper). PCA was carried out using Past v. 3.18 (Hammer et al. 2001). Each point represents the average of four bulk analyses of an individual vessel (see Table 2 and Table 5 in Spataro et al. 2019)

At Kom Dahab, none of the Ptolemaic household and tablewares (and none of the amphorae) analysed was made with levigated clays, or with fine clays which were then plant-tempered. This corresponds to observations on analysed third-century BC vessels from Naukratis, Memphis, and Tanis (?) (which like the Kom Dahab pots were modelled on Greek shapes), as well as on the earlier, sixth century BC Greek-style vessels likely made at Naukratis (Spataro et al. 2019, Tables 1 and 4, samples 1, 13, 14, 23, 30, 31). It contrasts clearly, however, with the picture presented by sixth century BC vessels of Pharaonic tradition, such as a red-polished jar and a red-slipped cup from Tell Dafana, that were made with levigated clays from which coarse inclusions had been mechanically removed, a red-slipped cooking pot from the same site made with a very fine plant-tempered clay, and a likely plant-tempered plate from Naukratis (Spataro et al. 2019, Tables 1 and 4, samples 10, 24–26).

The choice of temper types thus seems to reflect different technical and cultural traditions. The lack of plant temper and the use of fine silts is characteristic for the Greek-style chaîne opératoire that was introduced to sixth-century BC Naukratis by Greek immigrant potters and that lived on in Ptolemaic wares, while the contemporaneous Egyptian tradition often included added plant temper (Spataro et al. 2019, 1059–60).Footnote 21 This is apparent also in shapes originally of foreign origin, such as sixth-century BC grinding bowls (mortaria) (Spataro et al. 2019, Tables 1 and 4, samples 27, 28). This widely popular shape had been introduced to the Egyptian repertoire from Cyprus and was often made with plant-tempered marl fabrics, traditional recipes that were presumably chosen, at least in part, so as to replicate the original vessels’ light-coloured appearance.

Spataro et al. (2019, Tables 1 and 6) also analysed red slips and red paint on the seventh- to sixth-century BC Nile silt pottery of both Egyptian and Greek traditions. They were made following a similar recipe to that used at Kom Dahab: the clays were levigated, as their only visible inclusions are very fine quartz grains and iron oxides (Spataro et al. 2019, 1080 and Fig. 5a and b). However, they were much richer in iron oxide than those from Kom Dahab. No white slips were analysed.

A more diverse picture is represented in terms of firing temperatures. Both the Old Kingdom and Ptolemaic ceramics from Kom Dahab were mainly fired below the point of vitrification (< 850 °C). A similar relatively low firing temperature was observed in Late Period Egyptian vessels from Saqqara, Tell Dafana, and Naukratis (< 850 °C), in contrast to the Late Period and early Ptolemaic Greek-style ceramics, all but one of which were fired close to or above vitrification region (> 850–900 °C) (Spataro et al. 2019, 1078–1080).

The analyses of the seventh-/sixth century BC pottery suggest a cultural divide between coexisting Egyptian and foreign (Greek) pottery traditions on Egyptian soil. Due to its status as international harbour town, Naukratis is, however, an exceptional case. More widespread and substantial interaction and evidence for greater convergences are generally observed only from the Ptolemaic period, underpinned by a radically different balance of (political and social) power. In the study by Spataro et al. (2019), this development was represented by some third-century BC bowls and plates from Memphis, Saqqara, and Tanis that are typical examples of Egyptian ‘Black Ware’, imitating Greek black-glazed vessels (e.g. Marchand 2002, 2013). Manufactured in a very silty paste slipped and fired (usually) at high temperatures, Black Ware was one aspect of a widespread fashion for Greek-inspired vessels that were added to the Egyptian repertoire in the late fourth- to early third-century BC. Our analyses suggested that, besides shapes and styles, technology could also betray Greek influence, as in some instances plant ash was used to improve the slips’ dispersion and appearance, reflecting a long concern of Greek potters with improving the fluxing or flocculation of black glazes. Related processes of cultural adaptations have been observed at many Ptolemaic sites (e.g. Blondé et al. 2002; Defernez and Marchand 2006; Masson 2011; Ballet and Południkiewicz 2012), including in the workshops at Buto, where not just Greek and Roman shapes but also kiln technology were adopted, such as in the making of local versions of black glazed and sigillata wares (Ballet et al. 2019, 72–109, 138–143, 185–191).

The Kom Dahab workshop offers another example of this same phenomenon. Its repertoire of trade amphorae, cooking pots, and tablewares largely derives from a Greek tradition. Also, the application of a white slip to its earliest production of transport amphorae may have been intended to replicate the appearance of Greek amphorae, widely imported, used, and reused across Egypt. However, contrary to what can be observed at Naukratis (and Alexandria and many other sites), there is a conspicuous absence of any Black Ware, or black-slipped, tablewares at Kom Dahab. This could suggest that Kom Dahab catered to the demands of people who did not necessarily follow the fashion for hellenised tablewares. Most Ptolemaic settlements in the region of Kom Dahab, in fact, received few imports and produced few black-slipped wares (Thomas forthcoming b). It is important to note, though, that this is only partly a regional phenomenon. Most tableware from Kom Dahab does not predate the late third-century BC and thus belongs to a period when, from around the middle of the third- and especially in the second-century BC, potters in Egypt more generally began to take their repertoires into new directions. This included some workshops adopting an oxidised, red slip finish for their tablewares, which not only mirrored Italian sigillata wares but also the millennia-old Egyptian preference for red slips (Defernez and Marchand 2016, 141). Our observations of plant-tempered fabrics re-appearing in the second-century BC amphora production at Kom Dahab could be one further aspect of this same phenomenon, reviving old, Pharaonic traditions and technologies, even if driven primarily by economic considerations.

Conclusions

As a case study, analysing the wares made by the potters of Kom Dahab not only offers new insights into the pottery production of Ptolemaic Egypt but also contributes more widely to understanding the mechanisms of pottery production as shaped by environmental, cultural, and economic factors; it also highlights the contributions made by different methodologies.

On a more general level, compositional and technological investigations revealed similarities and differences in clay fabrics at all stages along the chaîne opératoire—from raw material choices to different manufacturing techniques, such as recipes for body pastes and slips, to firing technology and regime. These could be shown to be influenced by functional considerations, organisation of labour, as well as economic concerns such as cost-effectiveness; interestingly, the latter intersects with cultural choices and traditions. There were also clear indications that within a single workshop tradition, pottery technology could evolve over time in response to economic and consumer demands, affecting the choice of raw materials, fabric recipes, and surface treatments.

To Egyptian pottery studies, the analyses contribute, for the first time, distinct chemical characteristics for pottery made at Kom Dahab, as some non-calcareous fabrics of both Old Kingdom and Ptolemaic date showed close similarities to each other, as well as clear differences from wares made at Naukratis and other sites. This not only suggests that certain local clay sources were exploited over a long period of time but also indicates the existence of subtle differences between alluvial Nile Delta wares from different centres. These results are encouraging especially in view of the often strong chemical and mineralogical similarities that pose significant challenges for provenancing Egyptian Nile silt pottery. It may be that the site’s particular geological evolution and its position between desert and delta is partly responsible for this result. This natural setting may also be one of the reasons why Kom Dahab potters were able to use specific clays to make different ceramic classes.

As the compositional analysis showed, table and kitchen wares were made at the site using similar raw materials, but amphorae were produced with a distinct clay, rich in iron oxide and magnesia. Slipped and unslipped amphorae of different types were manufactured with that same clay over a period stretching over up to two centuries. Several hypotheses were put forward as possible factors behind this choice, including the seasonality of amphora production (potentially determining access to certain clay sources), functional and economic reasons (related to a likely lower vitrification threshold of the amphora clays), and/or the existence of workshops specialised in different pottery classes. Petrographic investigation showed that fundamentally the same temper types, such as sieved sand and plant tempers, and in a few cases no temper, were used across all shapes—amphorae, kitchen- and tablewares. It also, however, suggested an evolution in the recipes used for making amphorae, with an experimental stage in which a specific raw material source began to be exploited, and a late phase characterised by a ‘return’ to traditional ‘Egyptian’ methods of plant tempering. Finally, the greatest technological variability and experimentation within each period was noted in the recipes used for creating slips, which in some instances might derive from the same (but levigated) clays as the vessel body, and in others from different sources, and which could feature admixtures such as iron oxide.

The importance of cultural traditions emerged as a constant factor in the pottery production of Ptolemaic Kom Dahab, yet one that was subject to choice more than a matter of ‘ethnic’ identity. We have no reason to assume that Kom Dahab’s potters were Greeks, yet like most Ptolemaic potters much of their shape repertoire (and partly their fabric recipes) was of Greek origin, and they slipped their amphorae to better resemble Greek ones, so as to meet consumer expectation. And when the long Egyptian tradition of plant tempering was revived in later Ptolemaic amphora production, this was presumably done primarily because it afforded an economic advantage. The popularity of Greek-style Black Wares, too, was neither universal nor lasting. The fact that they are entirely absent in the output of Kom Dahab further underlines the regional diversity of Ptolemaic Egypt. Although situated close to international centres with strong Greek links such as Naukratis or Alexandria, the potters of Kom Dahab produced a range and style of wares that catered to a local or regional clientele with slightly different preferences.

Notes

Geographical coordinates given in the article refer to archaeological sites and are taken from Thomas forthcoming a.

Wilkie’s work formed part of the ‘Naukratis Project’ led by William Coulson and Albert Leonard Jr and conducted under the auspices of the American Research Center in Egypt (ARCE).

Contrary to Berlin (2001, 45–46), assuming third-century BC activity only (see also Masson-Berghoff forthcoming b).

In Egypt, marl clays occur primarily at locations along the Nile valley between Esna and Cairo (Memphite region); the closest sources to Kom Dahab were probably the Lake Mareotis banks and the apex of the delta around Memphis.

Wilkie had initiated scientific analysis of some Kom Dahab finds, but this was never completed or published: Coulson et al. 1986, 550 and note 27.

Five groups were discerned based on the chemical composition and the (relatively minor) variance was explained in terms of distinct clay preparations.

A programme of thin section analysis of Ptolemaic amphorae from various kiln sites (Marsa Matruh, Medamud and Philadelphia) is in progress, led by ceramicists Sylvie Marchand and Catherine Defernez, and by geologist Éric Goemaere, Institut Français d’Archéologie Orientale in Cairo. A series of analyses is also currently being undertaken for the amphorae of the Mareotic region by Valérie Pichot and Aude Simony at the Centre d’Études Alexandrines.

The selection of finds that, following the end of fieldwork, was sent to the USA under the terms of a finds division agreement has since 2017 been given a permanent home in the archaeological collection of Bryn Mawr College.

On Egyptian amphora nomenclature see Dixneuf 2011. The profile evolution of the amphorae produced at Kom Dahab over two centuries is described in Masson-Berghoff forthcoming b.

Except Fabrics NC2 subgroups a and b and NC5, which were not tempered.

The alternatives, earthy hematite or warm ochre, are unlikely as earthy hematite is characterised by higher iron oxide and lower silica and alumina, while warm ochre contains high alumina and silica, but also very high iron (see Bikiaris et al. 1999).

The firing of amphorae is recorded between late May and late July in one lease contract: Burkhalter 2013, 255.

In the Eastern Delta ceramic workshop of Tell el-Timai XRF analyses identified perfume bottles made with marl clay from Upper Egypt (Hudson et al. 2018), and in Tell Atrib in the southern Delta amphorae were found containing raw marl clay that was used to manufacture amphorae copying Levantine torpedo models (Defernez and Marchand 2016, 149).

Not included in the plot of Fig. 12.

Naukratis: six sand- or not tempered objects (one Late Period Greek-style vessel, two Ptolemaic Black Ware vessels, one scarab mould and two Egyptian figurines) and one plant-tempered Late Period Egyptian vessel; Tell Dafana: one not tempered (?) Late Period Greek-style vessel, two not tempered (levigated?) Late Period Egyptian vessels, one plant-tempered Egyptian vessels; Saqqara: one not tempered Late Period Egyptian vessel; Memphis and Tanis(?): one sand-tempered (?) Ptolemaic Black Ware vessel each.

Recent, albeit rare, finds of decorated pottery of Cypriot type made in Nile silt raise the question whether perhaps also Cypriot potters worked at Naukratis (Thomas and Villing forthcoming).

References

el-Ashmawi F (1998) Pottery kiln and wine factory at Burg el-Arab. In: Empereur J-Y (ed) Commerce et artisanat dans l’Alexandrie hellénistique et romaine, Bulletin de correspondance hellénique Supplément 33. École française d’Athènes, Athens 55–64

Ballet P, Mahmoud F, Vichy M, Picon M (1991) Artisanat de la céramique dans l’Égypte romaine tardive et byzantine. Prospections d’ateliers de potiers de Minia à Assouan. Cahiers De La Céramique Égyptienne 2:129–144

Ballet P, Fr B, Lecuyot G, Schmitt A (eds) (2019) Tell el-Fara‘în – Buto VI: Recherches sur les ateliers romains de Bouto, prospections et sondages (2001–2006), Archäologische Veröffentlichungen 110. Harrassowitz, Wiesbaden

Ballet P, Południkiewicz A (2012) La céramique des époques hellénistique et impériale. Campagnes 1988–1993. Production, consommation et réception dans le Fayoum méridional, Tebtynis V. Fouilles de l’Institut français d’archéologie orientale du Caire 68. Institut français d’archéologie orientale, Cairo.

Barahona-Mendieta Z (2016) La producción cerámica en época ptolemaica en Medamud hasta en época comienzos de la dominación romana. Cahiers De La Céramique Égyptienne 10:25–45

Berlin AM (2001) Naukratis/Kom Hadid: a ceramic typology for Hellenistic Lower Egypt. In: Leonard A (ed) Ancient Naukratis: Excavations at a Greek emporium in Egypt, part II: the excavations at Kom Hadid, Annual of American Schools of Oriental Research 55. Scholars Press, Atlanta, GA, pp 26–163

Bikiaris D, Daniilia S, Sotiropoulou S, Katsimbir O, Pavlidou E, Moutsatsou AP, Chryssoulakis Y (1999) Ochre-differentiation through micro-Raman and micro-FTIR spectroscopies: application on wall paintings at Meteora and Mount Athos, Greece. Spectrochimica Acta Part A 56:3–18

Blondé F, Ballet P, Salles J-F (2002) Céramiques hellénistiques et romaines – Productions et diffusion en Méditerranée orientale (Chypre, Égypte et côte syro-palestinienne) Travaux de la Maison de l’Orient 35. Maison de l’Orient Méditerranéen-Jean Pouilloux, Lyon

Blue L, Khalil E (2011) A multidisciplinary approach to Alexandria’s economic past: the Lake Mareotis Research Project, BAR International Series 2285. Archaeopress, Oxford

Bourriau JD, Bellido A, Bryan N, Robinson V (2006) Egyptian pottery fabrics: a comparison between NAA groupings and the “Vienna System.” In: Czerny E et al (eds) Timelines: studies in honour of Manfred Bietak, III, Orientalia Lovaniensia Analecta 149. Peeters, Leuven, pp 261–292

Burkhalter F (2013) Les amphores vinaires dans la documentation papyrologique d’époque ptolémaïque: production, prix et capacité. In: Tsingarida A, Viviers D (eds) Pottery markets in the ancient Greek world (8th - 1st centuries B.C.), Proceedings of the International Symposium held at the Université libre de Bruxelles 19–21 June 2008. CReA-Patrimoine, Brussels, pp 251–271

Chen Z, Warne AG, Stanley JD (1992) Late Quaternary evolution of the northwestern Nile Delta between the Rosetta promontory and Alexandria, Egypt. J Coastal Res 8(3):527–561

Cockle H (1981) Pottery manufacture in Roman Egypt: a new papyrus. J Religion and Society 71:87–97

Coulson WDE, Leonard A Jr (1981) Cities of the Delta I, Naukratis, American Research Center in Egypt Reports 4. Undena Publications, Malibu, CA

Coulson WDE, Leonard A Jr, Wilkie NC (1982) Three seasons of excavations and survey at Naukratis and environs. J Am Res Center in Egypt 19:73–109

Coulson WDE, Wilkie NC (1986) Ptolemaic and Roman kilns in the Western Nile Delta. Bull Am Sch Orient Res 263:61–75

Coulson WDE, Wilkie NC, Rehard JW (1986) Amphoras from Naukatis and environs. In: Empereur J-Y, Garlan Y (eds) Recherches sur les amphores grecques,Bulletin de correspondance hellénique Supplément 13. École française d’Athènes, Athens, Paris, pp 535–550

David R, Reda MN, Barahona-Mendieta Z, Consonni A, Lecuyot G, Licitra N, Marangou-Lerat A, Marchand S, Masson A, Schreiber G, Simoni A (2016) Theban ceramics in Hellenistic context – fabrics classification. Cahiers De La Céramique Égyptienne 10:11–22

Defernez C, Marchand S (2006) Imitations égyptiennes de conteneurs d’origine égéenne et levantine (VIe s.–IIe s. av. J.-C.). In: Mathieu B, Meeks D, Wissa M (eds) L’apport de l’Égypte à l’histoire des techniques. Méthodes, chronologie et comparaisons, Bibliothèque d’étude 142. Institut français d’archéologie orientale, Cairo, pp 63–99

Defernez C, Marchand S (2016) État actuel de la recherche sur l’industrie amphorique égyptienne des IVe–IIIe siècles av. J.-C. In: Bader B, Knoblauch CM, Köhler EC (eds) Vienna 2 – ancient Egyptian ceramics in the 21st century. Orientalia Lovaniensia Analecta 245. Peeters, Leuven, pp 127–154, 558–560

Dixneuf D (2011) Amphores égyptiennes: production, typologie, contenu et diffusion (IIIe siècle avant J.-C.–IXe siècle après J.-C.), Études Alexandrines 22. Centre d’études alexandrines, Alexandria.

Fülle G (1997) The internal organisation of the Arretine terra sigillata industry: problems of evidence and interpretation. J Roman Studies 87:111–155

Gallimore S (2010) Amphora production in the Roman world: a view from the papyri. Bull Am Soc Papyrol 47:155–184

Garzanti E, Andò S, Padoan M, Vezzoli G, El Kammar A (2015) The modern Nile sediment system: processes and products. Quatern Sci Rev 30:1–48

Grace V, Empereur J-Y (1981) Un groupe d’amphores ptolémaïques estampillées. Bulletin De L’Institut Français D’Archéologie Orientale 81:409–426

Hammer Ø, Harper DAT, Ryan PD (2001) PAST: Paleontological statistics software package for education and data analysis. Palaeontologia Electronica 4(1):1–9. http://palaeo-lectronica.org/2001_1/past/issue1_01.htm

Hudson N, Gentelli L, Trampier J (2018) Importing clay for local production in the 4th century B.C. at Tell el-Timai, Egypt. J Field Archaeol 43:1–16

Ionescu C, Hoeck V, Crandell ON, Šarić K (2015) Burnishing versus smoothing in ceramic surface finishing: a SEM study. Archaeometry 57(1):18–26

Kenawi M, Mondin C (2019) Continuity of production: kilns and fuel in Egypt and the Mediterranean. In: Veal R, Leitch V (eds) Fuel and fire in the ancient Roman world. McDonald Institute for Archaeological Research, Cambridge, pp 87–98

Kilikoglou V, Vekinis G, Maniatis Y, Day PM (1998) Mechanical performance of quartz-tempered ceramics: part I, strength and toughness. Archaeometry 40:261–279

Majcherek G, El-Shennawi A (1992) Research on amphora production on the northwestern coast of Egypt. Cahiers De La Céramique Égyptienne 3:129–136

Marchand S (2002) Le maintien de la tradition pharaonique pour les productions des céramiques datées de l'époque Ptolémaïque en Égypte. In: Blondé et al., pp 247–261.

Marchand S (2013) Céramiques d’Égypte de la fin VIe siècle av. J.-C. au IIIe siècle av. J.-C.: entre tradition et innovation. In: Fenn N, Römer-Strehl C (eds) Networks in the Hellenistic world according to the pottery in the Eastern Mediterranean and beyond, BAR International Series S2539. Archaeopress, Oxford, pp 239–253

Marchand S, Chang R-L, Nannucci S (2018) Philadelphie 2018. Amphores égyptiennes locales AE 1 en pâte calcaire. Époque ptolémaïque, seconde moitié du IIIe s. av. J.-C. Bulletin De Liaison De La Céramique Égyptienne 28:125–154

Masson A (2011) Persian and Ptolemaic ceramics from Karnak: change and continuity. Cahiers De La Céramique Égyptienne 9:269–310

Masson A (2016) Ptolemaic ceramics of the Theban region between tradition, imitation and innovation: the Priests’ Quarter as a study case. Cahiers De La Céramique Égyptienne 10:149–164

Masson-Berghoff A (forthcoming a) Kom Dahab: a comprehensive survey. In: Masson-Berghoff A, Thomas R forthcoming.

Masson-Berghoff A (forthcoming b) Kom Dahab excavations: the Old Kingdom settlement and the Ptolemaic industrial site. In: Masson-Berghoff and Thomas forthcoming.

Masson-Berghoff A, Thomas R (forthcoming) The Western Nile Delta: ARCE fieldwork in the region of Kom Firin and Naukratis (1977–1983) revisited, British Museum Publications on Egypt and Sudan. Peeters, Leuven.

Möller H, Rieger A-K (2019) Necessity is the mother of invention: the fuel of Graeco-Roman pottery kilns in the semi-arid Eastern Marmarica. In: Veal R, Leitch V (eds) Fuel and Fire in the Ancient Roman World. McDonald Institute for Archaeological Research, Cambridge, pp 71–86

Nicholson PT (2010) Kilns and firing structures. In Wendrich W (ed.) UCLA Encyclopedia of Egyptology. University of California at Los Angeles, Los Angeles. http://digital2.library.ucla.edu/viewItem.do?ark=21198/zz0025sr24

Nicholson P, Patterson H (1985) Pottery making in Upper Egypt: An ethnoarchaeological study. World Archaeol 17:222–239

Nordström H-Å, Bourriau J (1993) Ceramic technology: clays and fabrics. In: Arnold D, Bourriau J (eds) An introduction to ancient Egyptian pottery, fascicle 2, Sonderschrift des Deutschen Archäologischen Instituts Abteilung Kairo 17. P. von Zabern, Mainz, pp 143–190.

Ownby M, Brand M (2019) Advances in Egyptian ceramic petrography. Bulletin De Liaison De La Céramique Égyptienne 29:371–391

Pennington BT, Sturt F, Wilson P, Rowland J, Brown AG (2017) The fluvial evolution of the Holocene Nile Delta. Quatern Sci Rev 170:212–231

Pennington BT, Hamdan MA, Pears BR, Sameh HI (2019) Aridification of the Egyptian Sahara 5000–4000 cal BP revealed from x-ray fluorescence analysis of Nile Delta sediments at Kom al-Ahmer/Kom Wasit. Quatern Int 514:108–118. https://doi.org/10.1016/j.quaint.2019.01.015

Pichot V, Flaux C (2015) Les fours à amphores du Haut-Empire du site d’Akadémia (Maréotide): campagne de fouille et carottages 2014. Bulletin De Liaison De La Céramique Égyptienne 25:259–276

Pichot V, Şenol K (2015) Amphores de Gaza et résine sur le site de production d’amphores du Haut-Empire d’Akadémia (Maréotide). Bulletin De Liaison De La Céramique Égyptienne 25:277–289

Południkiewicz A (1992) Local imitations of Greek pottery found in Tell Atrib. Cahiers De La Céramique Égyptienne 3:95–101

Południkiewicz A (1995) Unfired pottery from ceramic workshops at Tell Atrib. In: Meyza H, Młynarczyk J (eds) Hellenistic and Roman pottery in the Eastern Mediterranean: advances in scientific studies. Research Center for Mediterranean Archaeology. Polish Academy of Sciences, Warsaw, pp 299–329

Rieger A-K (2011) Möller H (2011) Kilns, commodities and consumers – Greco-Roman pottery production in the Eastern Marmarica (northwestern Egypt). Archäologischer Anzeiger 1:141–170

Said R (1981) The geological evolution of the river Nile. Springer Verlag, Berlin

Scholl T (1995) ‘Kilns’ of the Ptolemaic period at Tell Atrib. In: Meyza H, Młynarczyk J (eds) Hellenistic and Roman pottery in the Eastern Mediterranean: advances in scientific studies. Research Center for Mediterranean Archaeology, Polish Academy of Sciences, Warsaw, pp 423–430

Scholl T, Daszkiewicz M, Raabe J (1995) ‘Kilns’ from the Ptolemaic Period in Tell Atrib. Études Et Travaux 17:279–307

Spataro M (2009) The first specialised potters of the Adriatic region: the makers of Neolithic figulina ware. In: Forenbaher S (ed) A connecting sea: maritime interaction in Adriatic prehistory, BAR International Series 2037. Archaeopress, Oxford, pp 59–72

Spataro M (2011) A comparison of chemical and petrographic analyses of Neolithic pottery from south-eastern Europe. J Archaeol Sci 38(2):255–269

Spataro M (2016) Playing with colours: understanding the chaîne opératoire of the earliest red monochrome and white-on-red painted ware of the central Balkans. In: Bacvarov K, Gleser R (eds) Southeast Europe and Anatolia in prehistory: essays in honour of Vassil Nikolov on his 65th anniversary. Universitätsforschungen zur Prähistorischen Archäologie 293, Habelt, Bonn, pp 167–174

Spataro M, Mommsen H, Villing A (2019) Making pottery in the Nile Delta: ceramic provenance and technology at Naukratis, 6th–3rd centuries BC. Archaeol Anthropol Sci 11(3):1059–1087

Spataro M, Masson-Berghoff A (forthcoming) Western Nile Delta craft production: scientific analyses of Old Kingdom and Ptolemaic ceramics from Kom Dahab. In: Masson-Berghoff and Thomas forthcoming.

Spencer N (2008) Kom Firin I: the Ramesside temple and the site survey, British Museum Research Publication 170. British Museum Press, London

Thomas RI (forthcoming a) Western Nile Delta site gazetteer. In: Masson-Berghoff and Thomas forthcoming.

Thomas RI (forthcoming b) Western Nile Delta ceramics: Ptolemaic to early Islamic periods. In: Masson-Berghoff and Thomas forthcoming.

Thomas RI, Villing A (forthcoming) Naukratis – Egypt’s cosmopolitan port city: British Museum excavations 2012–2019. Sidestone Press, Leiden.

Tite MS, Maniatis Y (1975) Scanning electron microscopy of fired calcareous clays. Trans J Br Ceram Soc 74(1):19–22

Toonen W, Pennington B (forthcoming) Palaeo-environmental evolution of the western Nile Delta: a context for settlement patterns. In: Masson-Berghoff and Thomas forthcoming.

Acknowledgements

The authors are grateful to the Bryn Mawr Collections Committee and the Collections Manager for Art and Artifact Collections, Marianne Weldon, for authorising the sampling, and to Professor Astrid Lindenlauf for taking the samples; to Benjamin Pennington and Willem Toonen for generous help and advice on Nile Delta geology; to Nigel Meeks (Department of Scientific Research, The British Museum) for his help in formatting Figs. 6, 9, 10, and 11; and to Kate Morton (Department of Greece and Rome, The British Museum) for her help in making Fig. 1. Aurélia Masson-Berghoff and Alexandra Villing would like to acknowledge the support of the Shelby White and Leon Levy Program for Archaeological Publications, which funded the British Museum research program on the Western Nile Delta. The authors would also like to thank Prof. C. Heron (Department of Scientific Research, The British Museum), Dr J. Meadows (ZBSA, Germany) and the two anonymous reviewers for their useful comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Kom Dahab is one of the rare excavated kilnsites in Ptolemaic Egypt to produce amphorae and common wares.

• Samples of fired and unfired Ptolemaic pottery were analysed.

• Results offer insights into potters’ choices during the production of various shapes (transport amphorae, tableware, cooking pots, and other common ware).

• Both cultural and economic factors are evident in the development of pottery production, influencing choices of raw materials, shapes, and firing technology.

• Finds from earlier, Old Kingdom levels were also analysed, suggesting enduring exploitation of chemically distinct local clay sources.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Spataro, M., Masson-Berghoff, A. & Villing, A. The potters of Kom Dahab: the ceramic chaîne opératoire in the Ptolemaic Nile Delta. Archaeol Anthropol Sci 13, 208 (2021). https://doi.org/10.1007/s12520-021-01457-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-021-01457-3