Abstract

The interdisciplinary study of Egyptian- and Greek-style pottery found in the Nile Delta aims to test and expand the potential of different scientific methods to identify regional variation and cultural traditions in ceramic fabrics from a relatively uniform geological setting. Neutron activation analysis (NAA), polarised light microscopy and SEM-EDX analyses were used to examine raw materials and technological tradition in 32 objects, including 15 previously partly analysed pieces, chosen to test the hypotheses of (a) chemical and (b) technological variation between regionally and/or culturally distinct pottery traditions. Several hundred published NAA data from other studies of Egyptian ceramics were re-assessed within this work. Our NAA results confirmed that all 28 objects analysed originated in Egypt, but could not distinguish production centres. Polarised light microscopy clarified the chaîne opératoire and highlighted Greek and Egyptian technological traditions and regional variations in the production of macroscopically similar ware (e.g. Black Ware). SEM-EDX was essential in distinguishing different recipes used for slips, suggesting patterns of technological transfer and adaptation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ceramic objects are a sensitive category for analysing change and interaction among pluri-ethnic communities. Scientific methods can be vital to such research. The present article employs an interdisciplinary scientific approach to a set of ceramic objects from first-millennium BC Egypt as a case study of the contribution that neutron activation analysis (NAA), polarised light microscopy (PLM) and scanning electron microscopy used with energy-dispersive X-ray spectrometry (SEM-EDX) can make to investigating cultural and technological change and exchange. It aims to test the limits and explore and expand the potential of the three methods in the context of an environment, the Nile Delta, that is characterised by great natural (geological) uniformity and consistency, but also by highly dynamic processes of historical and cultural change.

From the seventh century BC, interaction with the Mediterranean world and the influx of foreigners from Greece, Persia, Cyprus and the Levant fundamentally transformed the world of ancient Egypt (Vittmann 2003). The Nile Delta, Egypt’s Mediterranean interface, became a key arena for interaction, especially with immigrant Greeks from the Eastern Aegean (‘East Greeks’). Material culture reflects these processes. In particular, recent research has begun to reveal the pottery workshops of first millennium BC Egypt as dynamic environments, in which external influences and internal change affected form, decoration, technology and usage (Defernez 2002, 2011; Marchand 2011; Defernez and Marchand 2016). However, such conclusions have been based mainly on archaeological and stylistic observations, while archaeometric and technological work in Egypt has been largely confined to earlier periods of the Old and New Kingdom in sites in the Nile Valley, and to the later Roman period (cf. Ownby 2011, 2016; Peacock and Williams 1986). Little attention has been paid to the Late Period (664–332 BC) Nile Delta and its diverse material culture.

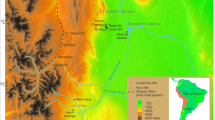

The present article aims to expand the scholarly horizon by applying a multi-pronged archaeometric approach to a place that was a hub of cross-cultural interaction: Naukratis. Founded in the late seventh century BC as an international port for Egypt, Naukratis, in the western Nile Delta (Fig. 1), was home to both Greeks and Egyptians, and provided fertile ground for the development of shared practices (Villing 2015; Villing et al. 2013–2019). As a pilot study for examining the pottery traditions of the Late Period to Ptolemaic (323–30 BC) Nile Delta, we address questions of provenance, technology and change, including questions of technological transfer, through the lens of three different, complementary scientific methods, applied to a carefully chosen small sample of 31 objects from Naukratis and other Nile Delta sites and one sample from Miletos.

We first set out our research questions and their background, as well as our sampling and methods. This is followed by three sections summarising the results of NAA, petrographic analysis and SEM-EDX. Their implications with regard to understanding provenance, tracing technological change and exchange and developing future avenues of research are examined in the following discussion and in the concluding remarks. We will argue that despite considerable geological homogeneity, local and cultural variability and chronological change can be detected especially in technological choices and manufacturing processes, with the chemical study of slip emerging as a particularly promising avenue for future research.

Research history and questions

Scholarship has long noted the existence of locally made Greek-style pottery and other ceramic wares in Egypt, explained as products of emigrant Greek potters or as local imitations of imports. Examples of the sixth century BC and later were observed at Naukratis (Edgar 1905), but also at sites such as Tell Dafana (Cook 1954, 38) and Tell Kedwa (Oren 1984, 18–19, 27) in the Eastern Nile Delta (Fig. 1). These have traditionally been identified as made from local ‘Nile silt’, based on the macroscopic identification of a dark brown gritty fabric distinct from the fine wares found on the Greek mainland. In 1983, Dupont (1983, 36 n. 38; Dupont and Thomas 2006, 80) scientifically confirmed the phenomenon. His chemical analyses of two Archaic Greek-style pottery fragments from Naukratis detected an alluvial Nile clay, characterised by high levels of titanium and low potassium (Table 2, Dupont group G). In 2004, Mommsen used NAA to identify 14 pieces of pottery as made of Nile silt (Mommsen et al. 2006; cf. Mommsen et al. 2012). The chemical group thus discerned (QanN, see Table 2 and discussion below) comprised Archaic Greek-style pottery vessels, Egyptian style pottery, Ptolemaic pottery and Hellenistic kiln supports from Naukratis, including one of the pieces earlier analysed by Dupont (sample no. 4 in the present article), but also a Greek-style vessel (no. 23) found at Tell Dafana.

Given the Greek style of many of the analysed pieces and Naukratis’ unique status as the earliest and most prominent Greek settlement in Egypt, Schlotzhauer and Villing (2006) initially hypothesised that group QanN represented workshops located at Naukratis, in which Greek and Egyptian craftsmen collaborated in producing wares for local and regional consumption. However, questions remained regarding the scientific validity of this precise localisation. While some scholars had discerned localised chemical patterns in Nile Delta wares (Bellido Bernedo 1989; Al-Dayel 1995; Redmount and Morgenstein 1996; Mallory-Greenough, Greenough and Owen 1998; Bourriau 1998; Bourriau et al. 2006; cf. Bourriau et al. 2000a, 133–135), including Nile silt wares, distinctions were clearest between marl and alluvial silt clays and between different marl (calcareous) and kaolinitic fabrics (e.g. Redmount and Morgenstein 1996; Bourriau and Nicholson 1992), clays that had resulted from a series of geological processes over the past 500 million years and that only partly showed a differentiated geographical distribution.Footnote 1 Within alluvial fabric, in contrast, several studies had noted that it was difficult or impossible to chemically distinguish between different Nile Delta sites, both in modern raw clay (Tobia and Sayre 1974) and in ancient ceramics (Hancock et al. 1986a; cf. also Bourriau et al. 2000a, 135; Ownby 2011, 755–758). Variations, if observable, seemed linked less to regions and more to (widely distributed) Nile sediments of different geological ages, as suggested by Allen et al. (1989), Hancock et al. (1986b) and Michelaki and Hancock (2013), who reported elemental concentration depth profiles for different sites in the Delta, with varying limestone and silica additions or dilutions in these sediments.

Variation was clearer in petrographic studies. For example, Bourriau et al. (2000b, 10) found that macroscopically similar fabrics among eighteenth dynasty pottery contained more abundant quartz, limestone and mica at Amarna and more plant remains at Memphis, which they interpreted as different potters’ recipes. Such recipes may influence chemical composition, but only to a limited extent. XRF of ten samples of two distinct Old Kingdom pottery fabrics from Giza by Ownby (2009 ; cf. Ownby 2011, 752–755) revealed consistent differences in two elements (aluminium and iron), interpreted as reflecting varying amounts of added quartz sand temper.

This work raises the question of whether QanN is a site-specific group, as originally suspected, or in fact encompasses a broader region. It also highlights the importance of addressing the agency of the potter, such as the role of raw materials versus potters’ preparation, and the potential impact of different cultural traditions. The hypotheses to be tested are that (a) chemical and (b) technological variation can be distinguished in the pottery traditions of the Egyptian Nile Delta, and that this variation was determined (a) naturally and (b) culturally.

We therefore aim to investigate two issues, one more methodological, the other more archaeological:

-

The difficulty of determining the precise provenance of ceramics made within the Nile Delta, by reason of the geochemical and mineralogical homogeneity of this region, and the role of human versus natural agency.

-

Understanding the nature and transformation of Greek and Egyptian pottery traditions in the Late Period Nile Delta, including the role of Egyptian-Greek interaction, adaptation by immigrant craftsmen and cross-fertilisation between different crafts.

The two questions are intimately related, since unless the problem of provenance is resolved, it is more difficult to understand patterns of production, trade and exchange.

Regarding the first question, previous scholarship (discussed below) has noted the rather uniform character of Nile alluvium, thus hampering efforts to chemically distinguish different local productions. Some studies, however, have observed chemical or petrographic differences between ceramics from different Nile Delta sites. This study aims to test the reliability of provenance attributions within the Delta, and to disentangle natural factors (geographic variation in sediment sources) from human factors (i.e. geographical differences in pottery technology). New NAA results from a set of samples from different sites are compared with the compositional patterns reported by previous researchers, applying a common statistical approach to the relevant data sets so as to better understand the limited variation in chemical signatures of Egyptian ceramics.

Regarding the second question, the chaîne opératoire (clay processing, slipping, firing, etc.) and ceramic traditions of Greek and Egyptian potters need to be considered, in order to discern potential differences and instances of technological transfer. How does Greek-style pottery made in Egypt differ from traditional Greek pottery, and from Egyptian pottery? Did immigrant potters in Egypt adapt to the local environment and engage with local traditions? To what extent did external factors shape the development of Egyptian pottery in the Late to Ptolemaic periods? Microscopic and chemical analysis is employed to assess ceramic technology, with attention being paid not just to core material but also to slips.

Sampling and methods

A total of 32 objects were examined: 17 new objects, and 15 which had previously been analysed with NAA (Table 1). NAA was carried out on 13 new pieces, and the previous NAA results and chemical data published by other scholars were critically re-evaluated. Petrographic and SEM-EDX analyses were carried out on 16 objects, 12 of them also analysed by NAA.Footnote 2

The analysed objects (Fig. 2) comprise finds from five sites in Egypt: the Greek-Egyptian port town of Naukratis in the western Nile Delta (21); the Egyptian towns of Tell Dafana (6) and Tanis (1) in the eastern Nile Delta; and the capital city of Memphis (1) and its necropolis Saqqara (1 sample) at the apex of the Delta near Cairo; one sample has an unknown findspot but probably comes from Naukratis; another comes from Miletos in western Asia Minor. Samples were chosen to cover a range of typical, well-dated and likely local wares from Naukratis and other, geographically widely separated key sites of the Nile Delta that represent some of the main types of ceramic products to have been manufactured in the region, in different cultural and chronological styles yet mostly using Nile silt, and within a limited chronological range, chiefly the sixth to third centuries BC. This was done with the aim to address the following questions:

-

Provenance: objects likely to have been made in Naukratis were compared to samples thought to have been made in the eastern (Tell Dafana, TanisFootnote 3) and southern (Memphis, Saqqara) Nile Delta, primarily in alluvial but also in marl or mixed marl/silt clays. For Naukratis, local craft production from c. 600 BC is ascertained through finds of moulds and wasters for faience scarabs, terracotta lamps and terracotta figurines and vessels in Greek and Egyptian style (Masson forthcoming; Thomas 2013–2019a, b; Schlotzhauer 2012, 62–65; Spencer 2013–2019; Villing 2013–2019). Our samples comprise objects for which local production is certain (terracotta figurine waster no. 21; scarab mould no. 19; kiln furniture nos. 16, 17) as well as highly likely, based on style (Archaic Greek-style pottery and lamp nos. 1–9, 18). For other material from Naukratis and other sites, local production was considered likely based on findspot, though a Greek-style amphora from Tell Dafana (no. 23), found among Greek pottery in the site’s Egyptian sanctuary (Leclère and Spencer 2014), was suspected to be an import from Naukratis.

-

Technological traditions and change: distinctive, East Greek-style products of sixth century BC Greek pottery workshops operating in Egypt (nos. 1–9, 23) were contrasted with contemporaneous Egyptian ceramic production (nos. 10, 24–26, 29), all made using alluvial clays. They were compared with products of different crafts, terracotta figurines (nos. 20–23) and faience scarab moulds (no. 19) of a culturally mixed character. Examples of later Ptolemaic ‘Black Ware’ (BW) pottery (Gill 2012), which imitate black-glazed Greek tableware but were generally fired in reducing rather than oxidising conditions, were compared between different sites (nos. 13, 14, 30, 31). A range of pottery mortaria (nos. 11, 12, 27, 28) were examined as suspected Egyptian copies of Cypriot and Greek vessels linked with the spread of new culinary customs (Spataro and Villing 2009).

Overview of analysed objects. Photographs of nos. 1, 2, 6–8, 10–17, 19–31 © Trustees of the British Museum; nos. 2, 6 © Museum of Fine Arts, Boston; nos. 4, 18 © Museum of Classical Archaeology, Cambridge; no. 32 photograph A. Villing © DAI Miletos excavations. Drawings of nos. 6, 10,–12, 30–31 Kate Morton © Trustees of the British Museum; drawing of no. 32 A. Villing/Birgit Konnenmann © DAI Miletos excavations

In addition, one sixth century BC sample from Miletos (no. 32), an East Greek city heavily involved in trade with Egypt and hometown of some of the early Greek settlers at Naukratis, was included to test our hypothesis that it might be an import from Egypt, as it macroscopically resembled Nile silt wares.

The scientific methods employed in this study address these issues in different ways, by revealing the chemical fingerprint of a fabric and its constituent parts, as well as its technological features. NAA measures the concentration of trace elements in homogenised bulk samples, which will vary with the addition or removal of mineral inclusions, though these technological choices may only have minimal effects on the ratios between trace elements which are rare in mineral inclusions. Scanning electron microscopy with energy dispersive spectrometry (SEM-EDX) can measure elemental concentrations in either the clay matrix or particular inclusions. SEM backscattered electron (BSE) images allow the measurement of inclusions and the study of microstructures and vitrification. Thin section petrography by polarised light microscopy (PLM) looks at the minerals and rock fragments naturally present in or added to ceramic fabrics. A further question is therefore whether a combination of different techniques, as applied in this study, can determine provenance more precisely and reliably than any single technique.

For NAA (for data, see Appendix), a sapphire (corundum) 10-mm drill bit was used to extract about 80 mg of powder from an undecorated area. NAA was carried out at the Rheinische Friedrich-Wilhelms-Universität Bonn (following Mommsen et al. 1991; Mommsen 2011). Samples were irradiated at the research reactor of the Reactor Institute Delft, and, after 4 weeks of measurement in the Bonn laboratory, quantitative weight concentrations were determined using the Bonn pottery standard (Mommsen and Sjöberg 2007). Since this standard has been calibrated with the Berkeley pottery standard, NAA data from the Berkeley laboratory are directly comparable with the Bonn data. To compare the different concentration patterns of measured samples (see Tables 2 and 3), we used a statistical package developed in Bonn that works like a filter (Mommsen et al. 1988; Beier and Mommsen 1994a, b). It is able to extract from a large data bank all samples with similar data patterns, taking into account experimental uncertainties and also the possibility that the clay fraction of the paste might have been diluted by different amounts of e.g. sand (SiO2) or calcite (CaCO3) or enhanced by levigation (Mommsen and Sjöberg 2007). This is done by calculating a best relative fit factor, the so-called dilution or enhancement factor, with respect to the given filter pattern.

For petrographic and SEM-EDX analysis, a thin slice (c. 1 cm2) taken from the object was sent for thin sectioning and the polished uncovered thin sections were examined using a polarising microscope (Leica DMRX) and by SEM-EDX. A Hitachi S-3700N variable pressure (VP) scanning electron microscope was used to study the microstructure and chemical composition of ceramic fabrics and slips. The SEM was used at a pressure of 30 Pa with a 20-kV accelerating voltage. Four SEM-EDX bulk analyses (each covering an area of c. 1.5 × 1.0 mm) were carried out on each sample, using Oxford Instruments’ default calibration. Nine oxides (Na2O, MgO, Al2O3, SiO2, K2O, CaO, TiO2, MnO and FeO) were detected and measured. Using Oxford Instruments EDX AZtec Analyser software, results were converted into oxide percentages, normalised (oxygen by stoichiometry) to take into account the fact that oxygen and carbon are not measured. By combining SEM-EDX results from a dense network of spot measurements covering a larger area of the sample, the AZtec Analyser software is able to compile distributional maps for the various elements. The results, when compared to BSE images of the same area, can be used (for example) to identify opaque mineral inclusions, differentiate between the pottery matrix and fragments of grog temper or check whether a particular element is associated with post-depositional contamination. Elemental maps were created of sample nos. 24 and 30, in order to compare the compositions of the clay used for the fabrics with those of the black and red slips.

Results

NAA

Nile silts: pattern ‘QanN’ and ‘QanM’

With the exception of sample no. 12, a chemical singleton, all the sherds macroscopically attributed to Nile silt fabrics belong to group QanN, with two classified as QanN associated (no. 18 [Nauk 34], because of lower concentrations of mainly the rare earth elements [REE], no. 31 [Milet 41], primarily because of elevated Cs). We examined whether the QanN samples could be further subdivided into groups that might coincide with findspots and suspected production places, but no coherent compositional clustering is evident. In the following, we discuss the implication of this finding, as well as set our own results in relation to the data and observation of other scholars who have analysed Egyptian Nile silt wares.

The concentration pattern of group QanN is shown in Table 2, first data column. Only the values of Ca, Fe and K can be compared with the Dupont pattern G (Table 2, column 2), as his other elements are not measured in Bonn. Ca agrees considering the large spreads (root mean square deviations σ), and also the Fe value is similar. K is lower; Dupont had already mentioned unusually low values for K.

The pattern QanN can be identified as of Egyptian origin on archaeological grounds and because it is not very different from another Egyptian pattern, QanM (Table 2, column 4), previously identified among pottery from Qantir in the eastern Nile Delta (Mountjoy and Mommsen 2001, 125–6; Mommsen et al. 2006, 71, 75, Table 2). The location of the workshops using pastes QanN and QanM are not known. QanM is here represented by a figurine from Naukratis (no. 22), not analysed by PLM or SEM-EDX. This figurine had been suspected to be an import to Naukratis on stylistic grounds, and our results support this assessment. The normalised difference (distance/average spread) in composition between QanM and QanN is depicted in Fig. 3a, after adjusting QanM with the best relative fit factor of 1.06 with respect to QanN. All elements agree statistically (distance/ave. spread < about 2) except Cr (lower) and La and Th (higher in QanM). These differences can also be seen in Table 2.

a Graphical comparison of chemical compositions of group QanN and group QanM. Plotted are the differences of the concentration values normalised by the average standard deviations (spreads, see Table 1). The values of QanM have been multiplied first by the best relative fit factor 1.06 with respect to group QanN. The concentrations of Cr, La and Th are statistically significantly different (bar larger about ± 2.0), and all the other element concentrations agree statistically. b Graphical comparison of chemical compositions of group QanN and group EgB similar to the Berkeley Nile mud group (see text, Cr and Yb values corrected). Plotted are the differences of the concentration values normalised by the average standard deviations (spreads, see Table 2). The best relative fit factor between the two groups is here 1.0. The concentrations of Fe, La and Sc are statistically significantly different (bar larger about ± 2.0), and all the other element concentrations agree statistically. c Graphical comparison of chemical compositions of group Bonn QanN and Berkeley group YAHU-21. Plotted are the differences of the concentration values normalised by the average standard deviations (spreads, see Table 3). The values of YAHU-21 have been multiplied first by the best relative fit factor 1.17 with respect to group QanN. The concentrations agree nicely except for a small difference in the Sm and Ta values (bar larger about ± 2.0). d Graphical comparison of chemical compositions of group QanN and group Marl. Plotted are the differences of the concentration values normalised by the average standard deviations (spreads, see Table 3). The values of Marl have been multiplied first by the best relative fit factor 1.22 with respect to group QanN. The concentrations for many elements significantly differ (bar larger about ± 2.0)

Both groups QanN and QanM resemble the chemical profile of 32 samples of ‘Nile mud’ pottery analysed by the Berkeley laboratory (Perlman and Asaro 1969, group of 32, Table 6, 18 elements, see also Michel et al. 1976, Table 2, last column including Ca.), repeated here in Table 2, column 5. These samples stem from three early cemeteries within a small area of Upper Egypt: Naga ed-Deir, Ballas, and El Ahaiwah. The Berkeley individual sample data are available for download from tDar (Boulanger 2014a). The data bank of 377 samples has been evaluated using the Bonn filter procedure, and, among the different groups formed, a large group of 49 samples with a pattern named EgB shown in Table 2, last column, has been separated. It turned out to be identical to the pattern of 32 samples published in 1969 (mentioned above, but not specifying the individual sample labels), showing now more elemental values and generally lower spreads due to the best relative fit correction, which is probably also the reason for the increased group size. In Fig. 3b, the normalised difference in composition between QanN and EgB is shown deviating only in Fe, La and Sc,Footnote 4 supporting the assignment of the members of group QanN to vessels made of Nile silt clays.

Table 3 gives a pattern, also measured in Berkeley, of Bronze Age Tell el Yahudiyeh Ware imported to Cyprus and assumed to have been produced in the Nile Delta (Artzy and Asaro 1979). The YAHU group of 21 samples has been formed using again the Berkeley data collection at tDar (Boulanger 2014b). From the best relative fit correction, not two, as published, but only one YAHU group is formed. This ware is statistically similar in composition to the vessels of group QanN (except for slightly lower Sm and higher Ta values) as demonstrated in Fig. 3c, if adjusted by a best relative fit factor of 1.17 with respect to QanN.

The close similarity of these Bonn and Berkeley patterns QanN, QanM, EgB and YAHU promotes the assumption that they all point to workshops using Nile silt deposited along the river and in the Delta. Variations in recipe that involve e.g. the addition of sand (cf. Ownby 2009) and may be linked to workshop tradition or functional considerations are largely stripped from these data through the application of dilution/best fit factors. They thus also underline the close chemical similarity of Egyptian alluvial fabrics. This further underpins the conclusion that QanN, which now includes pottery in all likelihood produced at Tell Dafana, Memphis and Saqqara, cannot identify the production of Naukratis alone, but rather represents Nile silt wares across the Nile Delta and possibly beyond.

This is further supported by the work of Hancock et al. (1986a, 112, Table 3) on 99 Nile silt sherds found at sites mostly along the Nile valley. Table 2, column 3, shows values of the 11 elements obtained in their NAA, recalculated using the seven groups of Nile alluvium given in their publication that turned out to be statistically similar once dilution effects were considered.Footnote 5 Again, not very many values can be compared to ours, but the importance of this pattern is the distribution of its members, showing similar compositions for Nile alluvium from as far south as Gebel Adda to Memphis in the north, and also from as early as 3000 BC up to modern times. Inductively coupled plasma-mass spectrometry (ICP-MS) by Mallory-Greenough et al. (1998) of 20 samples of ancient marl (4) and silt (16) pottery from Mendes in the eastern Nile Delta and Karnak in the Nile Valley reached the same disappointing conclusion, though three possible groups for the silt pottery based on Pb, Li, Yb and Hf data were discerned and attributed to ‘changes in headwater sources for the Nile during prehistoric times’, echoing Allen et al. (1989).

The conclusions reached by other scholars seemed more positive. Redmount and Morgenstein (1996) analysed 22 modern and two ancient Nile silt pottery samples from widely scattered sites in the Delta, the Memphis region, Upper Egypt, the Fayum and Sinai. Based on their NAA, ICP and X-ray fluorescence (XRF) results, they concluded that chemical fingerprints could be distinguished primarily in trace and rare earth elements. They presented many scatter plots for their small number of samples, yet without showing experimental uncertainties and without discussing the suitability of single elements for provenancing. Some of these scattergrams suggest that dilution effects should have been considered (Fe vs Ti, Fe vs Sc, Sc vs Co and the REE Sm vs Eu). No pattern assigned to a specific site is shown. Larger datasets were analysed by Bellido, who conducted NAA on 356 samples of ancient pottery of different periods from sites across Egypt (Bellido Bernedo 1989; Bourriau et al. 2006; the raw data are available at the University of Manchester archaeometry database: archaeometry.missouri.edu/databasets). In some instances, compositional groupings, including of alluvial samples, appeared largely (though not entirely) to coincide with the samples’ findspots, suggesting possible local chemical fingerprints. Similar observations were made in Omar Al-Dayel’s (Al-Dayel 1995; Bourriau 1998) NAA of 64 Middle Kingdom cups in a similar fabric from different sites in Egypt and Nubia.

So as to better understand the relationship of previous work to our analysis and to broaden our sample base, we decided to re-evaluate Bellido’s data, using the Bonn statistical procedure. This resulted in many different groups, of which we compare here only those of Nile silt samples with low Ca content. Most of them are very similar in composition, if adjusted by a best relative fit; in many cases, only one or two elements differ between these groups. Unfortunately, although the Manchester data are said to have been calibrated to the Berkeley pottery standard, and should be, therefore, directly comparable to our data, none of the groups are statistically similar to one of the Bonn Egyptian groups QanM, QanN or Marl, even after tentative adjustment to the Bonn values by calibration factors obtained before for Manchester data (Mommsen forthcoming). We can thus only assess them on their own merits. In Table 3, column 4, the concentration pattern NILES of 150 samples assigned to silt groups is reprinted from Table 2 in Bourriau et al. 2006, and compared to the largest newly formed group, named ESIL, of 46 samples (Table 3, column 5).Footnote 6 The distribution of the findspots of its members, mainly Dahshur and Memphis, point to a production site in the region south of modern Cairo. The group ESIL has low Ca and high Mn concentrations, as expected for silt clays of the Delta, and agrees for nearly all elements with the summed group NILES, but has generally more uniform values.Footnote 7 The numerous other smaller newly formed groups formed deviate from the general silt pattern often only in one element, as do the many samples that have not been assigned to a group. It is difficult to explain the difference of a single element in Nile silt with otherwise unchanged elemental abundances. One possibility might be different irradiation conditions between batches of samples. Such batch differences might even potentially be responsible for the attribution of samples from one site to one group as published, if samples from one site were measured in the same or consecutive runs. Given the marginal variation of the different concentration patterns of the samples assigned to Nile silt wares, and the uncertainty over the reasons for variation, interpretations needs to remain subject to caution.

One final interesting result is the likely identification of a sixth century BC Nile silt ware bowl of Greek shape at Miletos (no. 32 [Milet 41]), an associate member of QanN with elevated levels of Cs, testimony to the close links between Miletos and Late Period Egypt, including the presence of Milesian traders at Naukratis.

Marly clays: pattern ‘Marl’

Marl clays were not a focus of our study, but a small number of vessels macroscopically identified as marl or marl-silt mixes were included in the study, all of them sixth century BC mortaria, suspected to be locally made versions of this foreign shape. One of these, dedicated in a sanctuary at Naukratis and bearing a Greek graffito, was analysed and found to be associated to an NAA group named ‘Marl’ (no. 11 [Nauk 18]). This group also comprised inscribed clay tablets of Ramses II seemingly made from a marl-silt mix and found at Hattusha, and therefore could be assigned an Egyptian provenance.Footnote 8 The concentration values of pattern Marl multiplied with the best relative fit factor (dilution factor) of 1.22 with respect to QanN are shown in Table 3 together with the pattern QanN for comparison. The normalised differences between these patterns are depicted in Fig. 3d, demonstrating that the Egyptian marly clays can be very well separated from the not very differently composed clays used for the vessels of group QanN and QanM. In group Marl, the Ca, La and Th concentrations are much higher, whereas Co and Sc concentrations are lower.

Optical microscopy

Notwithstanding the relatively uniform sedimentology of the Nile Delta, optical microscopy revealed that the ceramic fabrics are petrographically quite diverse (Fig. 4). Differences in the frequency, size and sorting of mineral inclusions, and technological aspects such as temper and clay processing, resulted in nearly all samples being assigned to separate fabric groups, or occasionally sub-groups (Table 4). Petrographic fabric groupings can be relevant to both the determination of provenance and to differences in pottery technology but, in the context of alluvial sediments, are likely to be more revealing regarding technological variation than provenance.

Fabric comparison

We assessed the mineralogy of objects found at, and definitely or most likely made at, Naukratis (nos. 1, 13, 14, 19–21 and probably 10) in comparison to objects found at Tell Dafana (nos. 23–26), Memphis (no. 31), Saqqara (no. 29) and probably Tanis (no. 30).

Texture variations were noticed especially within samples from Naukratis. All fabrics include alluvial silts with mainly sub-angular quartz, pyroxene, plagioclase, micas and scattered very fine igneous rock fragments. There is much mineralogical similarity throughout the samples, but variations in percentages, size and sorting. The Ptolemaic Greek-style BW fabrics (nos. 13, 14, Fig. 4c) were richer in well-sorted silt, which included more abundant and well-sorted inclusions and thicker biotite than in the other samples. The silt inclusions are finer than in the other samples from Naukratis, except for the Archaic Greek-style oinochoe (no. 1, Fig. 4a), which contains fewer and finer silt inclusions and occasional fine stretched metamorphic rock fragments. The female figurine (no. 21, Fig. 4d) includes very occasional stretched metamorphic quartz, and occasional calcareous fragments, which are otherwise only present in the phallic figurine (no. 20).

The Egyptian plate (no. 10, Fig. 4b) is very different from the Greek-style ceramics, as the pottery fabric contains many fewer inclusions than the Hellenistic BW (nos. 13, 14, Fig. 4c) and also slightly fewer than the oinochoe (no. 1, Fig. 4a), in particular feldspar and pyroxene. This is probably in part due to different technological choices (see below). The coarse scattered rounded quartz grains in its fabric are probably part of the original raw material. Inclusions are less well sorted, and the fabric also included some coarse pellets and scattered organics, which burnt out of the clay during firing, a feature characteristic for Egyptian pottery. It was also fired at a lower firing temperature than the Greek-style wares.

The Greek-style amphora (no. 23, Fig. 4e) found at Tell Dafana, but suspected to have been made at Naukratis, contains silt inclusions similar to those in sherds found at Naukratis, e.g. the scarab mould (no. 19), with finer well-sorted grain size distribution of the inclusions, an igneous rock fragment and more abundant muscovite. Comparing the amphora to the contemporaneous Greek-style oinochoe from Naukratis (no. 1, Fig. 4a), both include very fine and similar silt, while the oinochoe has slightly less abundant inclusions and some longer muscovite lamellae. The sixth century BC scarab mould from Naukratis (no. 19) was made with clay less well-processed and with slightly less abundant silt than the Hellenistic BW from Naukratis, and fired at a lower temperature. The silt of the BW includes more abundant pyroxene, plagioclase and biotite. The Tell Dafana amphora might have been made at Naukratis, as it is not dissimilar in fabric to the scarab mould, whereas it could not be grouped with any of the Tell Dafana pots.

The fabrics of the Tell Dafana Egyptian red-polished pottery (nos. 24, 25) contain fewer and finer silt inclusions than the fabrics from Naukratis, and pyroxene and micas occur more occasionally. The red-slipped Egyptian cooking pot found at Tell Dafana (no. 26, Fig. 4g, h) is made of a paste very similar to that of the red silt ware vessels, including stretched metamorphic quartz grains, with more abundant and slightly coarser quartz sand grain inclusions and some biotite mica, which is very occasionally present in the red-polished vessels, as well as plant temper (see the voids from burnt-out organics visible in Fig. 4h). Compared to the Egyptian plate from Naukratis (no. 10, Fig. 4b), the cooking pot is richer in silt.

The Egyptian red-slipped jar (no. 29, Fig. 4f) from the Memphite burial grounds at Saqqara, which includes occasional coarse epidote,Footnote 9 has more poorly sorted quartz inclusions than the samples from Tell Dafana and the BW vessels, of a more sub-angular to sub-rounded shape. These inclusions are similar to, but coarser and more abundant than, those in the Egyptian plate (no. 10, Fig. 4b) from Naukratis.

The Memphis, Tanis and Naukratis Ptolemaic BWs were made with similar fabrics. The Memphis BW (no. 31) has a silty fabric very similar to the BW from Naukratis (nos. 13 and 14, Fig. 4c), rich in sub-angular fine quartz, plagioclase, biotite (thicker in the Memphis fabric) and pyroxene (fewer inclusions in the Memphis fabric), with very occasional microcline and chert, not present in the other BW fabrics.Footnote 10 These samples could either come from the same workshop or use a shared fabric recipe. The Tanis BW (no. 30), however, though it includes the same minerals, contains finer silt inclusions and thinner and slightly less biotite, and is fired at a lower temperature. Production of BW is attested for different sites in Egypt, though it has not yet been confirmed with certainty for any of the sites discussed here (Gill 2012).

The two mortaria from Tell Dafana (nos. 27, 28) were made with plant-tempered calcareous clays.

Ceramic chaînes opératoires

In addressing technology, thin section petrography is more helpful than any other analytical technique, as it allows the identification of clay type and processing, of the addition (temper) or removal of non-plastic inclusions to make the clay less or more plastic prior to modelling, and the determination of surface treatments (e.g. slipping or polishing) and firing temperatures. One of the aims of our technological study was to examine whether different cultural traditions might be discernible in the Greek-style and Egyptian-style vessels.

Clay processing

The second step in pottery production, after clay sourcing, is mechanical processing of the clay, in order to remove unwanted coarse inclusions (sometimes carried out by sieving, e.g. see Spataro 2004). This is usually followed by kneading, when air is expelled, and clay pellets or lumps are homogenised. The clay of both the analysed Greek-style and Egyptian-style vessels was generally well processed. In the scarab mould and the terracotta figurines from Naukratis, however, clay pellets, papules and occasional voids left by plant material point to poorly kneaded clays, suggesting that moulds and figures were subject to different standards to vessels from the same site (compare nos. 19, 20 and 21).Footnote 11

Addition or removal of non-plastic inclusions: temper and levigation

The Hellenistic Naukratis and Memphis BW were made using fabrics very rich in fine and well-sorted sub-angular silt (c. 40%; typical size 0.03 mm), which might have been added to the clay, while the Archaic oinochoe was made with a fabric with fewer and finer silt inclusions (c . 20%; typical size 0.02 mm, see Table 4). The Archaic Greek-style amphora found at Tell Dafana was made of a silt richer in quartz inclusions than the oinochoe (Table 4), but probably naturally present in the clay. As far as can be judged from the small sample selection, then, there seems to be no specific long-term trend followed by the potters who made Greek-style pottery.

One consistent feature in the early Greek-style pottery is the lack of obvious plant remains, setting them apart from the majority of contemporaneous Egyptian wares (Defernez 2011, 116–9, 124–6; Arnold and Bourriau 1993; cf. Thomas 2013, 179): the cooking pot (no. 26) and the mortaria (nos. 27, 28) found at Tell Dafana were plant-tempered, as was the Egyptian plate (no. 10) from Naukratis. Macroscopic observation during recent excavations at Naukratis confirms that plant temper was present in nearly all Egyptian wares. East Greek potters thus did not adopt one of the most pervasive long-term practices of Egyptian pottery making, but continued the Greek tradition of not adding or removing plant matter. Conversely, the organic fabrics of the mortaria from Tell Dafana and—judging from macroscopic observation—Naukratis (no. 11) mirror the calcareous, plant-rich fabrics common for this shape across Egypt (Defernez 2002; Villing 2006), yet differ from the fabrics used for their Cypriot prototypes (as well as East Greek imitations: Spataro and Villing 2009), thus suggesting potters working in an Egyptian tradition. Plant remains, probably naturally present, were also observed in one of the terracotta figurines representing a mixed Greek-Egyptian figure type (no. 20).

Overall, the recipes of the Greek-style pottery in Egypt correspond well to fabrics used in the potters’ homelands, at sites such as Miletos, where Archaic table amphorae showed a relatively homogenous matrix with 10–30% fine to medium inclusions, free of plant matter, and firing temperatures typically of 700–900 °C (Seifert 2004, 41–5). At the same time, fine, plant-free fabrics were not entirely confined to Greek practice, as shown by the red-polished wares from Saqqara and Tell Dafana.Footnote 12 The latter in particular feature a paste that might have been levigated, as the scattered quartz inclusions are mostly very fine, and their fabric is finer than that of the contemporaneous Greek-style oinochoe and amphora.Footnote 13

Wheel throwing

The overall shape and details of the Greek-style oinochoe and amphora (nos. 1 and 23) reveal the hand of a potter trained in routinely making and finishing shapes of this kind on a fast potter’s wheel, most likely a wheel spun by an assistant, such as was in regular use across Greece (Berg 2013). The more rounded, less sharply defined shapes of many contemporaneous and earlier Egyptian pottery shapes, before the fifth to fourth centuries BC, have sometimes been attributed to the use of a slower wheel, but the use of faster wheel speeds is also attested (e.g. Defernez 2011, 116–9, 124–6, but cf. Klotz 2013; Berg 2013).

Surface treatments: slipping and painting

Slips could be examined in nine thin sections. All were made of very fine levigated clays, with occasional scattered fine inclusions (e.g. quartz and iron oxides). The BW vessels (nos. 13, 14, 30, 31) have a thin (c. 0.02–0.04 mm, see Fig. 5c, d) slip layer which includes very rare quartz inclusions. After polishing, they were fired in a reducing atmosphere. The red-slipped-wares from Tell Dafana (nos. 24, 25) and Saqqara (no. 29) have a thin coating (c. 0.01–0.04 mm, see Fig. 5a, b) of iron-rich clay, with rare inclusions such as quartz. These pots were polished and then fired in an oxidising atmosphere. A thin pink slip was also applied to the amphora found at Tell Dafana (no. 23). Very thin (<c. 0.01 mm) reddish paint was used for decorative patterns on top of a largely worn whitish slip on the oinochoe (no. 1) (Table 6).

Firing conditions

Most Greek-style fabricsFootnote 14 (groups 1, 2 and 5) and the mortaria (groups 8 and 9) were fired at temperatures above 850–900 °C, as they include vitrified clays. The Greek-style amphora (no. 23) has clay filaments which began to vitrify, suggesting a temperature between 800 and 850 °C. The oinochoe (no. 1) has well-sintered clay but was less highly fired than the BW. The BW was all fired in reducing conditions, in contrast to the rest of the ceramics, which were fired in an oxidising atmosphere.

The Egyptian-style plate and female figurine and the scarab mould from Naukratis were fired at below 800–850 °C, as the clays were well-sintered, without vitrification (> 850 °C) (in the case of the scarab mould, however, some of the clay filaments began to vitrify). The phallic figurine (no. 20) was more highly fired, as it is vitrified in most regions. The clays of the Egyptian Tell Dafana and Saqqara ceramics (nos. 24, 25 and 29) were not highly fired (below 850 °C).

SEM-EDX

SEM-EDX analysis was carried out on 16 samples (Tables 5 and 6). Analyses of body pastes help understand similarities and differences between fabrics and fabric groups. A detailed microscopic and chemical study of the slips and paints based on high-magnification SEM images proved especially revealing.

Body paste

The objects found at Naukratis have high silica (59.1–65.3%), iron oxide (7.8–9.6%) and titania contents (1.3–1.8%), relatively high magnesia (2.9–3.4%) and low calcium oxide (2.6–6.4%). The figurines (nos. 20, 21) have slightly higher silica contents, and less titania and iron oxide, than the other Naukratis sherds; sample no. 20 also has lower alumina. The samples from Memphis and Tanis (nos. 31, 30) contain higher alumina and potash, and lower magnesia, iron and calcium oxides than the Naukratis samples. The Saqqara jar (no. 29) is slightly more calcareous and with very slightly lower titania than the Naukratis samples.

Of the finds from Tell Dafana (nos. 23–28), the red-polished ceramics and the cooking pot were found to have very similar chemical compositions, with magnesia (3.2–3.6%), alumina (18.1–18.4%), silica (59.6–60.2%), potash (1.7–1.9%), calcium oxide (3.6–3.8%), titania (1.7–1.9%) and iron oxide (8.9–9.0%). The Greek-style amphora has relatively similar values with slightly higher soda (2.5%) and silica (62.3%), and lower magnesia (2.9%) and calcium oxide (3.3%). The mortaria (nos. 27, 28) have a different chemical composition, very rich in calcium oxide (12.2–18.4%), as typical for marl clays and as also observable in NAA for the marl mortarium from Naukratis (no. 11) and the male figurine (no. 22). In addition, they also have higher magnesia (3.7–4%), and lower alumina (14.1–16.3%), silica, titania (1.2–1.4%) and iron oxide (6.9–7.6%) than the red-slipped samples nos. 24–26.

Black slips

SEM BSE images (Fig. 5) and elemental maps (Fig. 6) confirm that the black surfaces of BW pottery are slips, rather than merely the result of polishing or burnishing, as often assumed. The slips of the Naukratis BW (nos. 13, 14) are chemically very similar. They were prepared with a very fine depurated clay, richer in alumina and potash, and poorer in soda, magnesia and calcium than the body paste, with a similar iron oxide content (Tables 5 and 6).

SEM-EDX elemental X-ray map of slip and fabric of sample no. 30 (Tanis BW). a Mapped area (× 150, covering c. 0.8 × 0.6 mm). b Elemental map for aluminium, which is particularly abundant in the slip. c Elemental map for silicon. d Elemental map for iron, which is almost absent in the slip. e Elemental map for sodium, very abundant in the slip. f Elemental map for potassium, concentrating in slip. Colour reflects the concentration of the chosen elements: from very abundant to absent (from white to black, see legend above)

Though similar in macroscopic appearance, the vitrified Memphis and Tanis BW slips (nos. 30, 31) are chemically very different from each other and also from the Naukratis BW slips, especially the Tanis slip (Table 6). Compared to the respective pottery fabrics, however, both slips are again richer in alumina and potash, and generally poorer in magnesia, calcium and iron oxides. The Tanis slip is a very fine/depurated clay, with some iron oxides and rutile. Its high soda and potash contents are not apparently due to post-depositional contamination, as these elements coincide with aluminium in the elemental map (Fig. 6). The slip could therefore be a mixture of very fine depurated clay, potash and soda ash. The most plausible explanation is intentional addition of alkali plant ash, possibly added to lower the melting point of the slip or aid flocculation. Alkali plant ash is typically high in soda, even higher in potash and low in lime and magnesia (Tite et al. 2006). The Tanis slip meets all these criteria, whereas the Tell Dafana slip (no. 24) with even higher soda has much lower potash and average magnesia contents, and in this case the high soda is interpreted as post-depositional.

Red and pink slips and paints

The red-polished slips of the Egyptian vessels at Tell Dafana (nos. 24, 25) have a different chemical composition from that of the black slip on the imitation-Greek BW. One (no. 24) has a very high soda content, which might be due to post-depositional contamination, as the elemental map shows that soda is diffused into the body paste and not only associated with the thin (c. 0.01 mm) slip. Both are very rich in iron oxide and poorer in calcium oxide than their pastes, but are chemically similar overall to their respective body pastes, and might have been produced by levigating the same clays and adding iron oxide.Footnote 15 They are very thinly applied to the vessel surface and include very few visible inclusions. Also, the red slip of the jar from Saqqara (no. 29) is very thin (c. 0.025 mm); it has some very rare quartz inclusions. It is richer in iron oxide and poorer in potash and calcium oxide than the vessel paste. The iron oxide content (c. 34%) is even higher than in the Tell Dafana slips.

The Greek-style amphora (no. 23) from Tell Dafana has a thin pink coating (c. 0.01 mm) made of very fine levigated clay. Like the Egyptian red-polished slips, it is richer in alumina and potash than the body paste, and slightly richer in iron oxide and soda, but poorer in silica and calcium oxide. However, it differs from the red slips by being richer in alumina, silica, calcium oxide and potassium, and especially poorer in iron oxide. Its appearance is much lighter in colour, and it was probably intended to replicate the traditional white slips of Archaic East Greek pottery. A whiter, barely visible slip can be macroscopically observed on the oinochoe found at Naukratis (no. 1), but was not detectable in the thin section. However, we were able to examine the red paint of the decoration. It, too, was applied in a very thin layer (c. 0.01 mm), consisting of a clay slip rich in iron oxide, alumina, magnesia and potash. Compared to the pottery fabric, it has higher levels of potash, titania and iron oxide, and is poorer in silica and calcium oxide.

Discussion

Provenancing ceramics made within the Nile Delta combining multiple scientific techniques

Different techniques were used to address complementary questions. NAA was employed to establish the provenance of samples, based on their chemical signatures and previous research, including a critical examination of earlier scholarship and their data, regrouped using the Bonn statistical method. PLM and SEM-EDX focused more on examining variation in ceramic recipes and technological processes that might help distinguish different workshops or cultural traditions, and trace technological change or transfer.

The contribution of NAA: Chemical analysis as a method of determining the provenance of Nile alluvial fabrics

One key aim of our study was to re-examine NAA group QanN and its geographical precision, thus testing the usefulness of chemical analysis for provenancing alluvial fabrics. Results clearly confirmed QanN as representing Nile silt fabrics originating from Egypt, based on the nature of the analysed objects and comparison with data from our own work and that of other scientists. All but one analysed Nile silt sample belongs to it, including (as an associated sample) one vessel apparently exported to Miletos. QanN is, moreover, clearly different from a pattern termed ‘Marl’, present in a vessel from Naukratis, which may represent marl or mixed marl-silt clays. As marl clays are not found around Naukratis, either the clay or the finished vessels must have been brought to Naukratis (for the possibility of clay transport, see Defernez and Marchand 2016, 149). Whether a specific provenance can be assigned to this still small group remains to be investigated further.

The hypothesis, however, that QanN might specifically represent workshops at Naukratis could not be confirmed, as it includes samples in all likelihood produced at sites across the western, eastern and southern Nile Delta. Our results thus largely support observations of a great uniformity of Nile silts across the Nile Delta and Valley, which hinder precise chemical fingerprinting of specific sites or workshops, though regional variation cannot be entirely ruled out. QanN, for example, is different, if not very, from another Egyptian NAA group, QanM, comprising primarily objects of earlier periods found at Qantir. Certain localised patterns may also exist in the Manchester data. Given the marginal variation in concentrations, however, interpretations need to be treated with caution and other potential factors such as fabric recipes or measurement in batches need to be considered.

NAA confirms the existence of Archaic Greek-style pottery made from alluvial Nile clays from as early as the early sixth century BC. Even if their workshop(s) cannot be located via compositional ‘fingerprinting’, archaeological evidence, including wasters, attests Naukratis as a centre for the manufacture of Greek-style material culture in the Nile Delta. The question of whether workshops could have existed elsewhere nonetheless remains open, as the sixth century BC Greek-style amphora (no. 23) from Tell Dafana could not be unequivocally attributed to a non-local provenance either by NAA or petrographic and SEM-EDX data. However, NAA indicates a rare export of alluvial Nile pottery to Archaic Miletos.

Another surprising result was the fact that, apart from an exceptionally high Ca concentration (13.5%), the chemical composition of the large male terracotta statuette in a micaceous calcareous fabric from Naukratis (no. 22) was found to best match pattern QanM. The well-made figure in Greek style had previously been suspected to be a Cypriot import (cf. Bailey 2008, 152 no. 3590), but our results confirm it was produced in Egypt. The compositional similarity, apart from Ca, of an apparent ‘marl’ clay to Nile silts echoes Riederer’s (1989) observation of Old Kingdom Nile silt pottery with high calcium carbonate content at Dahshur and Saqqara and raises questions about the nature and origins of (some) calcareous fabrics in the Nile Delta that warrant further investigation. Closely related is also the question of the production centres of mortaria within Egypt and their possible regional distribution. Neither of the analysed examples found at Naukratis fell into group QanN, with one, made of Nile silt, remaining a chemical single (no. 12) and the other (no. 11), probably made from a marl-silt mix, sharing its chemical composition with inscribed clay tablets of Ramses II.

The contribution of combined SEM-EDX and PLM: Ceramic recipes, technologies and provenance

Like NAA, PLM and SEM-EDX confirm the limited variability of Nile silt raw materials in the geological region of Nile Delta, both in terms of chemical and mineralogical composition. However, they also highlight similarities and differences in clay fabrics based on different manufacturing techniques, such as recipes for body pastes and slips and other steps in the chaîne opératoire. These may be linked with functional considerations, production in different workshops or cultural traditions, though the present small sample can only hint at such interpretations.

For example, the combined use of PLM and SEM-EDX shows that red-polished wares and the cooking pot from Tell Dafana were made from the same raw materials, but were differently processed (levigated and tempered), reflecting their different functions. Similarly, our results support the hypothesis that at Naukratis different artisans refined and worked similar clays in different ways to produce Greek- and Egyptian-style pottery. For example, the Greek-style oinochoe (no. 1) has a similar paste to the contemporaneous Egyptian plate (no. 10), but better processed with finer sand.

Petrographic results combined with SEM microstructure studies of the ceramic fabric also help in defining ceramic formulas, such as the BW made with a very silty paste, slipped and fired at high temperatures in reducing conditions, to make a high-strength, impermeable vessel for daily use reminiscent in appearance to Greek imports. Based on NAA and EDX results, the chemical composition of the Greek-style BW pottery from Memphis, Tanis and Naukratis is almost identical, but subtle differences are visible in the minerals and technological processes employed in their manufacture. Compared to the Naukratis and Memphis pots, the BW from Tanis contains a slightly different sand (e.g. less biotite) and was fired at a lower temperature. Very occasional microcline and chert were identified in the Memphis BW, but are absent in the other samples. In addition, the Tanis black slip was made with a different recipe from those of the other black slips. These results suggest that the Tanis BW was made in a different workshop or at different time from that of Memphis and Naukratis. The Memphis and Naukratis BW were made using the same recipe and extremely similar raw materials, implying a shared workshop tradition between potters at Naukratis and Memphis, or alternatively, production in a single workshop. The results illustrate the potential of the method for clarifying the range of technological variation between different BW workshops and tracing possible patterns of trade.

PLM was more helpful than SEM-EDX in identifying variations in recipes and traditions, such as addition or removal of non-plastic inclusions and sand types used. These might be linked to a specific workshop or to the making of specific products (e.g. moulds, figurines, vessels). For example, BWs were made with the addition of fine silty sand and high firing temperatures, whereas the red-polished wares from Tell Dafana were probably made with levigated clays and fired at lower temperatures.

SEM imaging together with EDX proved vital to understanding the technology of slips. Black slips were always more levigated than red slips, but there are also variations within the black slips, e.g. that of the Tanis BW is finer than that applied to the Memphis BW. It is essential to measure the chemical composition of slips in order to understand what clays they were made from, as the slip fabrics are too fine for inclusions to be identified by PLM. SEM-EDX was therefore essential, as the slips were too thin to be sampled for NAA. The red slip from Saqqara contained more iron than the red slips from Tell Dafana, suggesting different recipes. Two slips had very high soda contents; in one case, this may be due to post-depositional contamination, but in the second case, Ptolemaic BW from Tanis, it appears to reflect the deliberate addition of plant ash as flux or flocculation agent.

Making pottery in Egypt: technological (ex)change, tradition and innovation

The results of the present study represent a first step towards investigating the technological choices made by Greek and Egyptian artisans, interacting with both their natural and their (multi)cultural environment.

Adaption and interaction

Technologically, the early Greek-style pottery of Egypt analysed here emerges as the work of artisans trained in a Greek chaîne opératoire, rather than as superficially similar copies by Egyptian craftsmen, as have been noted, for example, for Greek and Levantine transport amphora shapes (Villing 2013–2019, 24; Defernez and Marchand 2016). The use of fine silts, their processing, decoration and firing match traditional practices in the potters’ East Greek homelands, and contrast with typically coarser and plant-rich Egyptian recipes, even if fine non-organic alluvial fabrics were not unknown to Egyptian potters per se.

But there was also change and innovation. The pink slip made of finely levigated clay on the early Greek-style amphora from Tell Dafana (no. 23) may be an attempt to replicate traditional East Greek white or cream slips. SEM-EDX has shown it to be not dissimilar to the Egyptian red-polished slips, but poorer in iron and richer in alumina, silica, calcium oxide and potassium. In comparison, slips on sixth century BC Milesian Fikellura pottery have been shown to be highly calcareous, with a ratio of 1:7 K2O and CaO in the slip compared to 1:2.5 in the clay bodyFootnote 16; in contrast, whereas the clay bodies of the Nile Delta ceramics have a similar K2O/CaO ratio (1:2.3 on average), K2O is more abundant than CaO in the slips (1:0.67 on average). The variation in recipe may suggest an immigrant vase painter adapting locally available raw materials and slip recipes when faced with no easy access to naturally occurring calcite or kaolin-rich clays, which are likely to have been the Greek potter’s raw material of choice.Footnote 17 Also later on, in the Ptolemaic period, craftsmen at Naukratis typically coated their terracotta figurines with gypsum, rather than the calcite/kaolinite slips of the Greek coroplastic tradition (Bailey 2008, 5–6; Thomas 2013–2019b, 4–5). That the use of gypsum (CaSO4·2H2O) to produce white slips on alluvial clays had a long tradition in Egypt is suggested by analyses of Old Kingdom vessels at Saqqara, though the use or addition of calcite/ground limestone (CaCO3) and the use of marl clays are also attested (Rzeuska 2006, 537–567; cf. also Noll 1981, 1991, 298–306; Bourriau et al. 2000a, 123, Fig. 5.1).

Continuity and change

The extent to which change and innovation represent responses to local conditions or adaptations of foreign practices is often difficult to assess. Certainly, contact between craftsmen would have been inevitable, given their close proximity at sites such as Naukratis, and exchange is likely to have been reciprocal. Scholars have long attributed change and innovation in Egyptian pottery of the first millennium BC in part to interaction with Persia, Greece and the Levant, especially from the fifth to fourth centuries BC onwards (Defernez 2002, 2011; Marchand 2011; Defernez and Marchand 2016). The introduction of the mortarium and its spread from Cyprus and East Greece across the Archaic Mediterranean (Villing 2006; Spataro and Villing and 2009) are an early example of the phenomenon, beginning in the early sixth century BC. The sixth century BC mortaria from Tell Dafana and Naukratis analysed here use Egyptian organic marl or mixed marl-silt fabrics to replicate the looks and functionality of the fabrics of the Cypriot originals; different from the Greek-style wares of Naukratis, they represent an indigenous adoption of a foreign shape, and perhaps foreign culinary practice.

A new range of Greek-inspired forms was added to the repertoire of Egyptian pottery in the late fourth to early third century BC, including ‘Black Ware’ imitating Greek black-glazed vessels (Marchand 2002, 2013; Gill 2012). Our analyses show a uniform recipe being used in its manufacture at different Nile Delta sites, a very silty paste, slipped and fired at high temperatures, which represents a departure from the finer wares of both earlier Egyptian and Greek tradition in Egypt. It seems that plant ash was used in the slip on the vessel from Tanis (no. 30), presumably to improve its dispersion and appearance. That aiding the fluxing or flocculation of black glazes was a long-standing concern of Greek potters is suggested by recent analyses that have noted increased levels of Zn in the refined clay suspensions used to coat the Greek black-glazed wares that Egyptian BW imitates, which were achieved either by the addition of certain substances (Walton et al. 2015; cf. Maish et al. 2006, 10) or by sourcing special clays naturally rich in Zn (Chaviara and Aloupi-Siotis 2016). Potash appears not to have been used for this purpose, though it could be added to the white kaolinite slips of Classical Attic wares (Noll et al. 1975; Noll 1991, 166). In an Egyptian context, however, the use of potash could also have been inspired by local faience production: the use of mixed alkali plant ash as a flux in glazed composition (faience) production had a long tradition in Egypt, even if during the first millennium BC this was widely replaced by natron (Tite et al. 2006). The technology of the Tanis BW slip could thus represent an instance of technology transmission not just across cultural boundaries but between different crafts.

Conclusions

The paper demonstrates the value of combining multiple analytical techniques when addressing archaeological and historical questions, establishing that using more than one approach is necessary to reduce the risk of misinterpreting the results of a single technique. It confirms the difficulty of detecting regional variation among the chemical uniform alluvial Nile clay and suggests that NAA is more effective in more diverse geological environments. It also highlights the potential of still underexploited scientific techniques, such as the chemical study of slips.

The research shows that it is possible to detect manmade differences between ceramic assemblages which come from relatively uniform natural settings. Technological traditions, such as levigation, temper addition, firing temperatures and slip recipes, can be analysed to identify different workshops and investigate possible technological transfer. Variations in slip composition were particularly helpful to distinguish ceramics made with very similar pastes, also suggesting processes of adaptation and perhaps cross-fertilisation between crafts.

Results confirm the existence of Greek-style pottery workshops in the Nile Delta from the early sixth century BC onwards, concentrated at but not necessarily confined to the site of Naukratis. While immigrant potters maintained Greek technological traditions, such as avoiding the organic inclusions that are typical for contemporaneous Egyptian wares, there are also instances of adaptation and change, notably in slip recipes. The geographically widespread production of ‘Black Wares’ imitating imported Greek black-glaze pottery from the Ptolemaic period onwards reveals a diversity of technological approaches to achieve a superficially similar appearance. Given the complexity of the material included here and of its historical context (e.g. diversity of shapes, social and ethnic complexity, chronological variability, potential for trade/specialisation), it would be necessary to analyse a much larger number of objects by PLM and SEM-EDX to more fully address the archaeological questions raised. However, the case study has contributed by indicating possible pathways for such future research.

Notes

Kaolinite clays deriving from Nubian sandstone were deposited by the Tethys Sea in the Lower Cretaceous, principally at Aswan and in the western desert oases of Kharga, and Dakhla. Marl clays, originating from shale and limestone, are found along the Nile valley between Esna and Cairo and in the western oases, deposited between the Upper Cretaceous and Miocene. Alluvial ‘Nile silt’ or ‘silt’ clay is the youngest product, deposited by the Nile along its valley and delta, including far away from present course river branches, between the Upper Pleistocene and the present. See Bourriau and Nordström 1993, 157–161.

A core of 12 samples for both NAA and petrographic/SEM-EDX analysis was chosen at the start of this phase of the project, guided by archaeological and macroscopic fabric assessment. Only some of the objects previously analysed by NAA were available for thin sectioning, but additional pieces representing specific archaeological groups were selected for petrographic and SEM-EDX so as to expand the scope for technological examination. This selection process explains why there is no complete overlap between the sample groups for each method.

The likely findspot of Tanis is inferred from the date and circumstances of the object’s acquisition by the British Museum, researched by Jeffery Spencer.

In pattern EgB given in Table 2, the Cr (11.4% down: 154.) and Yb (5.7% up: 3.44) values were not yet corrected as in group QanN and as in Fig. 3b. This correction of the Berkeley results was introduced by Strange et al. (1995, 186). The 49 samples of group EgB and their best relative fit factor with respect to EgB are the following: Egy1 (1.18), Egy2 (0.95), Egy5 (0.92), Egy6 (1.00), Egy11 (0.95), Egy17 (1.11), Egy18 (0.97), Egy21 (0.99), Egy23 (1.00), Egy24 (0.94), Egy26 (1.00), Egy30 (1.02), Egy32 (0.97), Egy35 (1.06), Egy36 (0.93), Egy37 (0.97), Egy40 (0.99), Egy41 (1.03), Egy52 (0.94), Egy53 (0.91), Egy54 (0.90), Egy55 (1.00), Egy58 (0.98), Egy59 (0.96), Egy60 (1.04), Egy62 (0.99), Egy63 (0.96), Egy64 (0.99), Egy70 (1.02), Egy80 (0.95), Egy127 (1.02), Egy129 (0.94), Egy131 (0.91), Egy132 (0.99), Egy133 (0.95), Egy134 (0.96), Egy135 (1.01), Egy164 (1.12), Egy165 (0.94), Egy166 (1.05), Egy174 (0.96), Egy178 (1.00), Egy217 (1.20), Egy220 (0.96), Egy324 (0.93), Egy331 (1.15), Egy342 (0.96), Egy365 (1.12), Egy382 (1.02)

The seven groups and their best relative fit factor with respect to the average values are as follows: MEMPHIS-34 (1.01), AMARNA-3 (0.97), DAKHLE-2 (1.00), BENI HASAN-3 (0.98), GEBEL ADDA-13 (0.95), GEBEL-ADDA-1 (0.97), LUXOR-3 (1.08). The Ti value of group MEMPHIS has been corrected; see this same pattern repeated in Table 2 with the correct Ti value. Also, a 10 has been added to the certainly erroneously given single-digit uncertainties for V before calculating the average values of this Nile mud group using all elements given except Ca, Na and Cl. These elements are known to scatter widely probably due to often occurring lime and salt contaminations and, if considered in grouping, will often result in wrongly formed groups.

The 46 samples taken from the PhD of Bellido, 1995, forming group ESIL and their best relative fit factors with respect to this group are as follows: EGMA06 (0.93), EGNC09 (1.16), EGNC62A (0.98), EGNBA5 (0.89), EGNBA8 (1.00), EGNB37 (0.96), EGNB43 (1.17), EGNB01 (0.98), EGNBA0 (1.10), EGNBA1 (1.05), EGNBA2 (1.02), EGNB24 (1.00), EGNB25 (0.97), EGNB26 (0.94), EGNB27 (1.03), EGNB29 (1.02), EGNB30 (0.95), EGNB31 (1.00), EGNB32 (0.98), EGNB44 (0.87), EGNB45 (0.92), EGNB46 (1.06), EGNB48 (0.93), EGNB63M (0.98), EGNBA3 (0.88), EGNB39 (0.87), EGN 35 (1.36), 36 (1.15), EGK12M (0.97), EGK51M (0.91), EGK56M (0.90), EGB103 (1.02), EGB104 (1.07), EGB105 (1.07), EGB106 (1.07), EGB107 (0.94), EGB108 (1.09), EGB109 (1.11), EGB110 (1.09), EGB111 (1.01), EGB131 (0.90), EGB132 (0.95), EGB134 (0.94), EGB137 (0.96), EGB138 (0.95), EGMM50 (0.86).

It seems that the Ce values of the data had already been changed for the Bourriau et al. (2006) publication (Berkeley calibration?). In the data archives we used here, the Ce value seems to be the older, higher one.

Fine inclusions of epidote are occasionally present in other samples as well, but not as coarse grains.

No biotite was present in the Memphis fabric published by Bourriau et al. (2000b), colour plate 3b.

Without analysing samples of all soil types available to ancient craftsmen at each production centre, it is difficult to exclude the alternative interpretation, that the figurines were made from a particularly fine homogeneous raw material, without additional processing, but this is considered less likely.

Levigated alluvial fabrics have also been observed in earlier pottery at Memphis: Bourriau et al. (2000b, 31), fabric group G2 (Nile B1).

With the exception of the Tanis sample

Analyses of the red slips on Old Kingdom pottery from Saqqara have noted the likely addition of hematite, soot and organic binder: Rzeuska (2006, 567)

Seifert (2004, 41, 46 Fig. 25); on average, they are 0.005 mm thick.

References

Al-Dayel OAF (1995) Characterisation of ancient Egyptian ceramics. University of Manchester, PhD Dissertation

Allen RO, Hamroush H, Hoffman MA (1989) Archaeological implications of differences in the composition of Nile sediments. In: Allen RO (ed) Archaeological chemistry IV. American Chemical Society, Washington DC, pp 33–56. https://doi.org/10.1021/ba-1988-0220.ch003

Arnold D, Bourriau J (1993) An introduction to ancient Egyptian pottery, SDAIK 17. Philipp von Zabern, Mainz am Rhein

Artzy M, Asaro F (1979) Origin of Tell El-Yahudiyah Ware found in Cyprus. Reports of the Department of Antiquities of Cyprus 1979:135–150

Bailey DM (2008) Catalogue of the terracottas in the British Museum. British Museum Press, London, IV. Ptolemaic and Roman terracottas from Egypt

Beier T, Mommsen H (1994a) Modified Mahalanobis filters for grouping pottery by chemical composition. Archaeometry 36(2):287–306. https://doi.org/10.1111/j.1475-4754.1994.tb00971.x

Beier T, Mommsen H (1994b) A method for classifying multidimensional data with respect to uncertainties of measurement and its application to archaeometry. Naturwissenschaften 91:546–548

Bellido Bernedo AV (1989) Neutron activation analysis of ancient Egyptian pottery. University of Manchester, PhD Dissertation

Berg I (2013) The potter’s wheel in Mycenaean Greece: a re-assessment. In: Graziadio G, Guglielmino R, Lenuzza V, Vitale S (eds) Φιλικη Συναυλια. Studies in Mediterranean archaeology for Mario Benzi. BAR International Series 2460. Archaeopress, Oxford, pp 113–121

Boulanger M (2014a) Egyptian ceramics: compositional and descriptive database, Lawrence Berkeley National Laboratory (core.tdar.org: tDAR id: 372352). https://doi.org/10.6067/XCV8ZC8187

Boulanger M (2014b) Cypriot ceramics: compositional and descriptive database, Lawrence Berkeley National Laboratory (core.tdar.org, tDAR id: 372330). https://doi.org/10.6067/XCV8K35SJ5

Bourriau JD (1998) The role of chemical analysis in the study of Egyptian pottery. In: Eyre CJ (ed) Proceedings of the 7th International Congress of Egyptologists, Cambridge, 3–9 September 1995, Orientalia Lovaniensia Analecta, vol 82. Peeters, Leuven, pp 189–199

Bourriau JD, Nicholson PT (1992) Marl clay pottery fabrics of the New Kingdom from Memphis, Saqqara and Amarna. J Egypt Archaeol 78:29–91. https://doi.org/10.2307/3822066

Bourriau JD, Nordström H-Å (1993) Ceramic technology: clays and fabrics. Arnold, Bourriau 1993:143–190

Bourriau JD, Nicholson PT, Rose P (2000a) Pottery. In: Nicholson PT, Shaw I (eds) Ancient Egyptian materials and technology. Cambridge University Press, Cambridge, pp 121–147

Bourriau, JD, Smith LMV, Nicholson PT (2000b) New Kingdom pottery fabrics: Nile clay and mixed Nile/marl clay fabrics from Memphis and Amarna. Egypt Exploration Society Occasional Publication 14. Egypt Exploration Society, London

Bourriau JD, Bellido A, Bryan N, Robinson V (2006) Egyptian pottery fabrics: a comparison between NAA groupings and the "Vienna System”. In: Czerny E et al. (eds) Timelines: studies in honour of Manfred Bietak, III. Orientalia Lovaniensia Analecta 149. Peeters, Leuven, pp 261–292

Chaviara A, Aloupi-Siotis E (2016) The story of a soil that became a glaze: chemical and microscopic fingerprints on the Attic vases, J Archaeol Sci: Reports 7. June 2016:510–518. https://doi.org/10.1016/j.jasrep.2015.08.016

Cook RM (1954) CVA Great Britain 13, British Museum 8. Trustees of the British Museum, London

Defernez C (2002) Le poids de l'orientalisation et de l'hellénisation au travers des échanges et des productions céramiques dans l'angle nord-est du Delta égyptien. In: Blondé F, Ballet P, Salles JF (eds) Céramiques hellénistiques et romaines, productions et diffusion en Méditerranée orientale (Chypre, Égypte et côte syro-palestinienne). Maison de l'Orient et de la Méditerranée Jean Pouilloux, Lyon, pp 235–245

Defernez C (2011) Les témoignages d’une continuité de la culture matérielle saïte à l’époque perse: l’apport de l’industrie céramique. In: Devauchelle D (ed) La XXVIe dynastie: continuités et ruptures. Promenade saïte avec Jean Yoyotte. Actes du colloque international organisé les 26 et 27 novembre 2004 à l’Université Charles-de-Gaulle – Lille 3. Cybèle, Paris, pp 109–126

Defernez C, Marchand S (2016) État actuel de la recherche sur l’industrie amphorique égyptienne des IVe-IIIe siècles av. J.-C. In: Bader B, Knoblauch CM, Köhler EC (eds) Vienna 2—ancient Egyptian ceramics in the 21st century. Proceedings of the international conference held at the University of Vienna, 14th–18th of May, 2012, Orientalia Lovaniensia Analecta, vol 245. Peeters, Leuven, pp 127–154

Dupont P (1983) Classification et détermination de provenance des céramiques orientales archaïques d’Istros: Rapport préliminaire. Dacia N.S. 27:19–43

Dupont P, Thomas A (2006) Naukratis: les importations grecques orientales archaïques. In: Villing A, Schlotzhauer U (eds) Naukratis: Greek diversity in Egypt. Studies on East Greek pottery and exchange in the Eastern Mediterranean. British Museum Research Publication 162. British Museum Press, London, pp 77–84

Edgar CC (1905) Naukratis 1903, G.—minor antiquities. J Hellenic Studies 25:123–136

Friedrich T (2009) Über die Charakterisierung weißgrundiger Lekythen, ein Beitrag zur Schnittstelle Archäologie – Restaurierung – Materialkunde. Restauro 3:172–180

Gill JCR (2012) Ptolemaic 'Black Ware' from Mut el-Kharab. In: Knoblauch CM, Gill JC (eds) Egyptology in Australia and New Zealand 2009: proceedings of the conference held in Melbourne, September 4th–6th, BAR International Series, vol 2355. Archaeopress, Oxford, pp 15–25

Goren Y, Mommsen H, Klinger J (2011) Non-destructive provenance study of cuneiform tablets using portable X-ray fluorescence (pXRF). J Archaeol Sci 38(3):684–696. https://doi.org/10.1016/j.jas.2010.10.020

Hancock RGV, Millet NB, Mills AJ (1986a) A rapid INAA method to characterize Egyptian ceramics. J. Arch Sci 13(2):107–117. https://doi.org/10.1016/0305-4403(86)90002-6

Hancock RGV, Aufreiter S, Elsokkary I (1986b) Nile alluvium: soil and ceramics. Bulletin of the Egyptological. Seminar 8:61–71

Klotz D (2013) The earliest representation of a potter’s kick-wheel in Egypt. ENiM - Égypte nilotique et méditerranéenne 6:169–176