Abstract

The samples collected from Banxi coal mine in Chongqing, Southwest China, have been used to study on damage of coal based on permeability change rate (PCR) and load-unload response ratio (LURR) under cyclic loading by using thermal-hydrological-mechanical (THM) coupling experimental equipment. Research results show that (1) the LURR is applied to describe the samples response to cyclic loads based on loading/unloading elastic modulus. The LURR is larger at the initial cyclic, with the cyclic loading and unloading, it decreases sharply first, and then slowly decreases to 1 value, and then slowly rises away from 1 value. The increase of LURR after stabilization can be used as the precursory information to judge the failure and instability of coal and rock. (2) A new damage characterization method based on PCR can well characterize the three stages of coal-rock damage under cyclic loading, that is, first accelerates damage and then remains smooth, at last also accelerates damage. The evolution of damage variable based on PCR is similar to the general trend of damage variable based on LURR. As gas monitoring is a routine monitoring indicator for coal mines, so it is a practical, innovative, and economical method to characterize the damage variables based on PCR.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In deep mining engineering, coal and rock often are subjected to cyclic or dynamic loads, which result from the mining activities, blasting vibration, periodic roof weighting, earthquake, underground excavation, and other engineering activities (Song et al. 2012, 2016; Liu et al. 2014; Liu and Qin 2019; Peng et al. 2020; Yang et al. 2019). Cycle loading is one of the important factors that affect the mechanical properties and long-term stability of rock mass, and also has an important influence on strength and gas emission of coal in the mine (Zhong et al. 2019; Duan et al. 2020a). Meanwhile, the intrinsic micro-structure of coal and rock mass, the mechanical properties, and the failure process under repeated mining stress differ enormously from those under static loads (Bagde and Petroš 2005a, b; Heap et al. 2009; Ferrero et al. 2010). Tiered cyclic loading is a special form of cyclic loading, that is, stress amplitude increasing from cycle to cycle (Jiang et al. 2017). In engineering, some stress conditions can be simplified as tiered cyclic loading. Therefore, it is necessary to further analyze the seepage, deformation, and damage properties of coal under the cyclic mining stress, especially the influence of tiered cyclic stress on gas-containing coal seams. This will help for recognizing and comprehending the damage and failure mechanisms of gas-containing coal, which has important theoretical and practical significance for coal and rock disaster warning and prevention (Wang et al. 2013a, b).

During the past few decades, many kinds of research have been carried out on the mechanical properties of coal and rock under equal amplitude cyclic stress. For an example, Ray et al. (1999) reported that the percentage decrease in uniaxial compressive strength increased with the applied stress level and the number of cycles. The failure strength, fatigue stress, and Young’s modulus were found to increase with strain rate. Al-Shayea (2004) concluded that the dynamic elastic modulus and Poisson’s ratio increased with the confining pressure, and under cyclic loading, their values during unloading were slightly higher than those during loading. Bagde and Petroš (2005a, b, 2009) found that the dynamic strength was influenced by the waveform and loading rate in uniaxial cyclic compression tests. Xiao et al. (2010) proposed a damage variable to describe the actual evolution process of granite fatigue damage by analyzing the test results of the uniaxial cyclic dynamic tests. Wang et al. (2017) experimentally investigated the permeability and porosity of porous sandstones under the cyclic loading-unloading conditions. It is inferred from the test results that the evolution of sandstone porosity and permeability is related to the relative movement of particles and the closure of micro-cracks. All the above researches are carried out under constant amplitude cyclic stress; however, in actual engineering stress field, cyclic loading and unloading are not all constant amplitude in nature; therefore, the tiered cyclic loading should be comprehensively investigated.

The mechanical and seepage properties of different rocks under multi-level loading or tiered cyclic loading have been the subject of intense interest in recent years. For example, Yang et al. (2015) carried out triaxial compression experiments on deep-buried marble specimens to investigate their short-term and creep mechanical behavior under tiered cyclic loading. Zhang et al. (2018) conducted acoustic emission experiment to coal samples under the tiered loading, and analyzed damage evolution based on the single-link cluster method. Meng et al. (2016, 2018) explored characteristics of energy accumulation, dissipation, AE in sandstone under tiered cyclic loading with the six different loading rates. The associated seepage characteristics of coal mine gas are not considered in the above tests. The coupling of coal, gas, and cyclic stress may lead to a complex failure process. Therefore, it is necessary to study the influence of cyclic mining stress on the mining process of gas-bearing coal seam.

In this paper, the relationship between loading/unloading elastic modulus, permeability, and damage of coal under tiered cyclic loading was analyzed in depth. The PCR and LURR were newly defined to describe this process. Two new damage characterization methods based on PCR and LURR were proposed under tiered cyclic loading.

Test arrangements

Coal samples

The coal samples were collected from coal seam K1 of Banxi coal mine in Chongqing, Southwest China, as shown in Fig. 1a. The K1 coal seam is middle ash, high sulfur, and high heat lean coal. The coal measures strata of this mine belong to low-permeability coal seams (permeability is often less than 0.1 × 10−15 m2). The gas pressure in K1 coal seam is 0.3~1.2 MPa and gas content is 26~29 m3/t. The burial depth of the specimens is 450 m (Jiang et al. 2017). The coal and gas outburst has occurred, and coal and gas outburst hazards seriously threaten mine production safety in this mine. Thus, it is necessary to research permeability, mechanical, and damage of gas-containing coal samples under tiered cyclic loading. The results can help us understand coal and gas outburst mechanisms. Table 1 summarizes the basic physical and mechanical properties of the coal specimens. According to the requirements of the ISRM (2007), the standard samples with 50 mm in diameter and 100 mm in height were prepared (see Fig. 1b). It can be seen from the SEM of coal that specimens have a large number of natural fractures and pores (see Fig. 1c, d).

Test facility

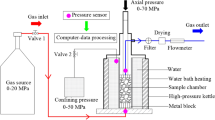

The “thermal-hydrological-mechanical (THM) coupling experimental equipment” was used to carry out the cyclic loading-unloading test. The basic parameters of this experiment system can be referred to in the reports of Jiang et al. (2017) and Duan et al. (2020a), and the experiment instrument is presented in Fig. 2. The apparatus was capable of simulating gas permeation under different load stress paths, gas pressures, and temperatures. The axial and radial deformation was monitored and recorded by high precision linear variable displacement transducer (LVDT) and radial extensometer (see Fig. 2c). Gas permeation rate was measured by mass flow meter, as shown in Fig. 2d.

Test methods and conditions

The specimens were loaded into the triaxial chamber according to the way of seepage experiment (Duan et al. 2020a). After the coal samples were loaded, the axial and radial stresses were applied step-by-step to the initial hydrostatic pressure of 3 MPa at the speed of 0.05 MPa/s, then, the pressure of methane gas (methane concentration of 99.99%) was kept at 1.5 MPa at the upper end of the coal sample. After the gas adsorption reached equilibrium, the gas outlet valve was opened and the steady gas flow observed before the loading-unloading experiment was started. The axial load and unload specific path (that is 10kN → 20kN → 10kN → 25kN → 10kN → 30kN → ··· → peak stress → stop experiment) is presented in Fig. 3.

Test results and analysis

From the two aspects of deformation, permeability law of coal and rock under tiered cyclic loading was analyzed in detail. The evolution laws of damage variables based on LURR and PCR were compared and analyzed. A new damage variable equation was defined based on PCR.

Characteristics of damage based on LURR under cyclic loading

Loading/unloading elastic modulus

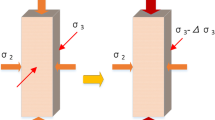

Elastic modulus is an important index of deformation characteristics of the rock. The loading elastic modulus and unloading elastic modulus of each cycle is different under tiered cyclic loading. The change of loading/unloading elastic modulus reflects the damage degree of cyclic stress to coal and rock (Zhang et al. 2010, 2013). Therefore, studying the variation law of loading/unloading elastic modulus can better reveal the damage rule of coal and rock in grading cycle. The formula for calculating the elastic modulus of rock under triaxial compression was as follows:

where E is elastic modulus. Δσ1 and Δε1 are the increments of σ1 and response ε1, respectively. Δσ3 and Δε3 are the increments of σ3 and response ε3, respectively. σ1 and σ3 are axial and radial stresses. ε1 and ε3 are axial and radial strain. In this experiment, confining pressure was kept constant, that is, Δσ3 = 0. Therefore, Eq. (1) can be simplified as Eq. (2):

The stress-strain curve may fluctuate in the process of servo-controlled loading, and calculation results of elastic modulus will change obviously if the calculation interval changes slightly. Therefore, it is more appropriate to use the linear fitting of the axial stress-axial strain straight line segment data as the elastic modulus.

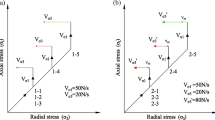

Figure 4a–c show loading elastic modulus (LEM) and unloading elastic modulus (UEM) of coal samples RC-1, RC-2, and RC-3 in each cycle. From the graph, we can see that LEM and UEM of three coal samples show the same trend with the increase of cycle times. The UEM is always greater than LEM in each cycle. The LEM is far less than UEM in the first cycle. With the increase of the cycle times, the LEM firstly increases rapidly and then increases slowly, at last decreases rapidly. But the UEM decreases first and then increases. The LEM and UEM first close to each other and then move away. When LEM is closest to UEM, it means that coal and rock mass is compressed to the closest ideal elastic material. The LEM of coal and rock decreases sharply before failure, and this phenomenon can be used to predict coal and rock failure.

Load-unload response ratio

In order to more directly reflect the relationship between LEM and UEM, load-unload response ratio (LURR) was introduced to characterize it. The LURR is a theory to study the instability precursor and instability prediction of nonlinear systems (Gong et al. 2019; Yin et al. 2006; Zhang et al. 2010, 2013). In this paper, we used LURR theory to define two basic quantities:

- 1.

The response amount X is defined as

where ΔP and ΔR denote the increments of load P and response R, respectively.

- 2.

LURR (denote by Y) is defined as

where X+ and X− refer to the response rate under loading and unloading condition. For the elastic phase, the response rate X+ = X−, thus Y = 1. It shows that the LURR of material is closer to 1, and the stronger elastic property is.

According to the theoretical formula of LURR, the Y value in each cycle can be calculated, as shown in Fig. 5. The Y is larger in the first cycle, but with the cyclic loading and unloading, it decreases sharply and then slowly decreases gradually to 1, and then slowly rises away from the 1, and there is an obvious rapid increasing trend near coal failure (see the enlarge part of Fig. 5). So with the increase of axial cyclic stress, the LURR curves of the three coals can be divided into the decrease stage, the steady stage, and the increase stage, which corresponds to coal compaction stage, elastic stage, and crack unstable growth stage, respectively (the same results had been found by Gong et al. 2019). At the same time, the LURR can reflect the elastoplastic characteristics of the coal and rock from the side. According to the changing trend of the LURR, it was found that the elastic properties of the gas-bearing coal gradually increase and then weaken gradually with the increasing of cyclic stress. Therefore, the increase of LURR after stabilization can be used as the precursory information to judge the failure and instability of coal and rock.

Characterization of damage variables based on LURR

The Y is a parameter that can quantitatively reflect the instability degree of nonlinear systems. Thus, based on the theory that the damage at the fracture limit obeys the Weibull distribution on the meso-scale (Weibull 1951; Wei et al. 2000; Xu et al. 2004; Zhang et al. 2013) established the relationship between the Y variable and the damage variable as:

where DY(i) and DY are single cycle damage variable and cumulative damage variable, respectively. m is Weibull index.

According to Eq. (5), the DY(i) and DY based on LURR can be obtained, as shown in Fig. 6a and b. With the increase of cycle number (or cycle peak stress), the variation law of damage variable in three coal samples is roughly the same trend, DY(i) decreases first and then increases, and change trend is like “U” type, damage is larger in the initial stage and near failure stage, and in the intermediate elastic deformation stage, damage is small and basically below 0.1. However, the change curve of DY is similar to “S” type, showing an obvious 3 zone: The I zone is the initial rapid damage zone (cyclic peak stress is about below 30% of coal peak strength). In the initial cycle stage, a lot of cracks in coal are compressed, and the damage is significant. The II zone is slow damage zone (cyclic peak stress is about between 30 and 60% of coal peak strength). The pore and fracture is compacted, and the coal sample is in the elastic stage. After the cycle, the elastic modulus change is small, and the damage increases slowly. Therefore, in engineering practice, reasonable control of mining cyclic stress is kept at 30~60% of the coal peak strength, which can effectively reduce the damage caused by cyclic stress to coal. The III zone is rapid damage zone near failure (cyclic peak stress is about above 60% of coal peak strength). In this zone, a lot of fractures are produced and elastic modulus deteriorates seriously and decreases.

A new damage variable based on PCR

Curve of permeability and volume strain

The gas flow follows the Darcy’s law; permeability was continuously calculated using (Yin et al. 2015; Lu et al. 2019; Duan et al. 2020b)

where K is permeability of coal sample (m2), μ is the gas kinematic viscosity (Pa·s), l is the sample length (m), and Q is the gas permeation rate (m3/s), measured by mass flow meter. S is the cross-sectional area (m2), p1 is the gas pressure specimen inlet (Pa), and pa is the gas pressure specimen outlet (Pa).

According to the Kozeny-Carman permeability equation, the evolution equation of permeability with temperature and deformation is (Ran and Li 1997):

where K and K0 are dynamic permeability and initial permeability, respectively. φ and φ0 are dynamic porosity and initial porosity, respectively. T and T0 are dynamic temperature and initial temperature, respectively. εv is volume strain (εv = ε1 + 2ε3, ε1 and ε3 are axial and radial strain, which can be calculated by the axial and radial deformation measured by LVDT and radial extensometer). βs is the linear thermal expansion coefficient.

When the gas pressure and temperature are constant and the adsorption is completely balanced, Eq. (7) can be simplified as below:

The permeability of coal varies dynamically under the tiered cyclic loading. Jiang et al. (2017; Duan et al. (2018) have analyzed the relationship between permeability and axial strain under cyclic loading and unloading. But according to Eq. (8), the dynamical changes of permeability mainly depend on the change of volume strain in coal. Therefore, the relationship between permeability and volume strain under tiered cyclic loading is more closely, and should be further studied. The permeability and volume strain change of coal sample was analyzed in detail and is presented in Fig. 7. Coal sample permeability change is closely related to axial stress and volume strain under tiered cyclic loading. With the gradual increase of cyclic stress, volume strain increases rapidly at initial compaction phase, a large number of natural fractures and pores in coal and rock are compressed, and permeability shows a significant spiral reduction. At elastic phase, volume strain increases slowly, and permeability decreases slowly. At the yielding phase, pores and fractures of coal expand and develop, and permeability begins to increase slowly. At the moment of failure, volume strain value decreases sharply, and volume expansion effect in coal is obvious, and permeability increases rapidly. Therefore, permeability variation is in good agreement with volume strain change.

Residual volume strain and permeability change rate

Figure 7 shows the general trend of permeability and volume strain change, but it can be not clearly analyzed and compared the magnitude of permeability and volume strain change at the different cyclic number. In order to quantitatively analyze the influence of each cycle on permeability and volume strain, permeability change rate δ and residual volume strain τ were defined as follows:

where δ(i) is permeability change rate in the ith cycle, Ki + 1 is permeability in the i + 1th cycle, m2. Ki is permeability in the ith cycle, m2. K0 is the initial permeability, m2. τ(i) is residual volume strain in the ith cycle, εvi + 1 is volume strain in the i + 1th cycle, %. εvi is volume strain in the ith cycle, %. The permeability change rate reflects the amplitude of permeability variation in each cycle. The greater the value of permeability change rate, the greater the change of permeability. Residual volume strain τ reflects volume deformation in coal and rock which cannot be recovered after cyclic compression.

According to Eqs. (9) and (10), permeability change rate δ and residual volume strain τ can be calculated as shown in Fig. 8 a and b, respectively. As shown in Fig. 8a and b, the permeability change rate δ and residual volume strain τ in three coal samples show the same trend of change with the increase of cycle number (or cycle peak stress), and they are larger after first cycles. With the increase of cyclic stress, δ and τ decrease gradually, and increases in the near failure stage. This shows that there are a large number of natural cracks and large pores in coal and rock mass, and cracks and large pores are easily closed under low stress, and forming large volume compression. However, cracks and large pores are difficult to recover after stress recovery, which is the main reason for permeability sharp decrease in the initial stage. With the increasing of cyclic stress, cracks and pores are gradually compacted, volume compression gradually decreases, and δ and τ decreases. When the cyclic stress continues to increase, the micro pore fracturing cannot bear its pressure, coal body continues to be compressed and fractured, and δ and τ increase. In order to observe the trend of δ and τ more clearly, the δ and τ of coal sample RC-2 were extracted separately in Fig. 8c. Figure 8c shows that the overall trend of δ is similar to the general trend of τ. The change trend of τ can reflect the change law of permeability from the side. Permeability change can be used as an important indicator for predicting coal and rock failure, so τ can also reflect the evolution process of the coal-rock failure.

Characterization of damage variables based on PCR

The closure, development, expansion, and connectivity of internal cracks and pore in coal are the fundamental reasons for the change of permeability. Meanwhile, the change of pore structure and cracks in coal under the action of external load is also the root cause of coal damage (Chen et al. 2014). Coal damage will occur after each cycle, the most direct cause of damage is the change of coal pores and cracks, and the change of pores and cracks can be indirectly reflected by permeability changes. Therefore, it is theoretically feasible to describe the damage variation of coal and rock mass by permeability change. In this paper, it is found that PCR can better reflect the evolution process of fracture deterioration in coal and rock. Therefore, the author defines the damage variable equation based on PCR as follows:

where DK(i) and DK are single cycle damage variable and cumulative damage variable, respectively. β is damage correction coefficient. σr is residual strength. σmax is peak strength. In this experiment, cumulative damage variable of all cycles is assumed to be 1, and damage variable of each cycle is characterized by the ratio of the permeability change of each cycle to that of all cycles. DK(i) can reflect damage magnitude of each cycle stage.

According to Eq. (11), single cycle damage variable DK(i) and cumulative damage variable DK based on PCR can be obtained, as shown in Fig. 9a and b. With the increase of cycle number, DK(i) first decreases, then maintains stability and basically below 0.1, and finally increases. The whole change trend is like “U” type. However, with the increase of cycle times, the whole change curve of DK is similar to “S” type, DK shows an obvious 3 zone, that is, accelerated increase first, and then slowly increase, and at last accelerated increase. The I zone is the initial rapid damage zone. In the initial cycle stage, a lot of pores and cracks in coal are compressed, the permeability changes greatly, and the damage is significant. The II zone is slow damage zone. The pore and fracture is compacted, and the coal sample is in the elastic stage. After the cycle, the permeability change is small, and the damage increases slowly. The III zone is rapid damage zone near failure. In this zone, a large number of pore fractures are produced and a large number of seepage channels are formed. The change of permeability increases and the damage and deterioration is aggravated.

Comparing and observing Figs. 6 and 9, it can be seen that the change trend of damage variable based on PCR and LURR is the same. To clearly compare the two damage variable characterizations, the damage variable based on PCR and LURR in coal sample RC-3 is shown in Fig. 10. We found that the change curve of damage variable based on LURR and PCR basically coincided, which indicated that damage variable could be expressed by different macroscopic physical quantities, and the same change rule could be obtained. This also proves the correctness of the new damage variable definition based on PCR. At the same time, for gas-bearing coal mines, routine measurements of gas flow must be performed daily to ensure that the gas does not exceed the standard. Therefore, it is a practical, innovative, and economical method to characterize the damage variables by using permeability changes.

Conclusions

In this paper, the samples collected from Banxi coal mine in Chongqing, Southwest China, have been used to study on damage of coal based on PCR and LURR under cyclic loading by using THM coupling experimental equipment. The relationship between permeability, loading/unloading elastic modulus, and damage of coal under tiered cyclic loading was analyzed in depth. The damage variable based on PCR and LURR was newly defined to describe this process. Research result shows that:

- 1.

The LURR was applied to describe the sample response to cyclic loads based on loading/unloading elastic modulus. The LURR is larger at the initial cyclic, with the cyclic loading and unloading, it decreases sharply first, and then slowly decreases to 1 value, and then slowly rises away from 1 value. The increase of LURR after stabilization can be used as the precursory information to judge the failure and instability of coal and rock.

- 2.

The change of permeability is in good agreement with the change of volume strain. With the increase of cycle times, the values of δ and τ decrease rapidly at first cycle stage and then decrease slowly, finally increase in the coal failure stage. The new damage variable DK based on PCR shows a trend of “S” type, which can well characterize the three stages of coal-rock damage under cyclic loading, that is, first accelerates damage and then remains smooth, at last also accelerates damage. The evolution of damage variable DK based on PCR is similar to the general trend of damage variable DY based on LURR. This also proves the correctness of the new damage variable definition based on PCR. As gas monitoring is a routine monitoring indicator for coal mines, so it is a practical, innovative, and economical method to characterize the damage variables based on PCR.

References

Al-Shayea NA (2004) Effects of testing methods and conditions on the elastic properties of limestone rock. Eng Geol 74:139–156

Bagde MN, Petroš V (2005a) Fatigue properties of intact sandstone samples subjected to dynamic uniaxial cyclical loading. Int J Rock Mech Min Sci 42:237–250

Bagde MN, Petroš V (2005b) Waveform effect on fatigue properties of intact sandstone in uniaxial cyclical loading. Rock Mech Rock Eng 38:169–196

Bagde MN, Petroš V (2009) Fatigue and dynamic energy behaviour of rock subjected to cyclical loading. Int J Rock Mech Min Sci 46:200–209

Chen L, Liu JF, Wang CP, Liu J, Su R, Wang J (2014) Investigation on evolution characteristics of granite under compressive stress condition and its impact on permeability. Chin J Rock Mech Eng 33:287–295 (in Chinese)

Duan MK, Jiang CB, Yu H, Lu TY, Niu BW, Sun DL (2018) Experimental research on loading-unloading behavior about energy and seepage properties of coal at different stress levels. Rock Soil Mech 39:1346–1354 (in Chinese)

Duan MK, Jiang CB, Gan Q, Zhao HB, Yang Y, Li ZK (2020a) Study on permeability anisotropy of bedded coal under true triaxial stress and its application. Transp Porous Media 131:1007–1035. https://doi.org/10.1007/s11242-019-01375-y

Duan MK, Jiang CB, Gan Q, Li MH, Peng K, Zhang WZ (2020b) Experimental investigation on the permeability, acoustic emission and energy dissipation of coal under tiered cyclic unloading. J Nat Gas Sci Eng 73:103054. https://doi.org/10.1016/j.jngse.2019.103054

Ferrero AM, Migliazza M, Tebaldi G (2010) Development of a new experimental apparatus for the study of the mechanical behaviour of a rock discontinuity under monotonic and cyclic loads. Rock Mech Rock Eng 43:685–695

Gong FQ, Wu C, Luo S, Yan JY (2019) Load–unload response ratio characteristics of rock materials and their application in prediction of rockburst proneness. Bull Eng Geol Environ 78:5445–5466

Heap MJ, Vinciguerra S, Meredith PG (2009) The evolution of elastic moduli with increasing crack damage during cyclic stressing of a basalt from Mt. Etna volcano. Tectonophysics 471:153–160

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds) Prepared by the commission on testing methods. ISRM, Ankara

Jiang CB, Duan MK, Yin GZ, Wang JG, Lu TY, Xu J, Zhang DM, Huang G (2017) Experimental study on seepage properties, AE characteristics and energy dissipation of coal under tiered cyclic loading. Eng Geol 221:114–123

Liu HT, Qin T (2019) Study on damage characteristics and acoustic emission Kaiser effect of sandstone under cyclic loading and unloading conditions. Coal Sci Technol 47(6):73–80 (in Chinese)

Liu JF, Xie HP, Hou ZM, Yang CH, Chen L (2014) Damage evolution of rock salt under cyclic loading in uniaxial tests. Acta Geotech 9:153–160

Lu J, Yin GZ, Deng BZ, Zhang WZ, Li MH, Chai XW, Liu C, Liu YB (2019) Permeability characteristics of layered composite coal-rock under true triaxial stress conditions. J Nat Gas Sci Eng 66:60–76

Meng QB, Zhang MW, Han LJ, Pu H, Nie TY (2016) Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression. Rock Mech Rock Eng 49:3873–3886

Meng QB, Zhang MW, Han LJ, Pu H, Chen YL (2018) Acoustic emission characteristics of red sandstone specimens under uniaxial cyclic loading and unloading compression. Rock Mech Rock Eng 51:969–988

Peng K, Zhou JQ, Zou QL, Song X (2020) Effect of loading frequency on the deformation behaviours of sandstones subjected to cyclic loads and its underlying mechanism. Int J Fatigue 130:105349. https://doi.org/10.1016/j.ijfatigue.2019.105349

Ray SK, Sarkar M, Singh TN (1999) Effect of cyclic loading and strain rate on the mechanical behaviour of sandstone. Int J Rock Mech Min Sci 36:543–549

Ran QQ, Li SL (1997) Study on dynamic models of reservoir parameters in the couple simulation of multiphase flow and reservoir deformation. Pet Explor Dev 24:61–65

Song DZ, Wang EY, Liu J (2012) Relationship between EMR and dissipated energy of coal rock mass during cyclic loading process. Safety Sci 50:751–760. https://doi.org/10.1016/j.ssci.2011.08.039

Song HP, Zhang H, Fu DQ, Zhang Q (2016) Experimental analysis and characterization of damage evolution in rock under cyclic loading. Int J Rock Mech Min Sci 88:157–164

Wang HL, Xu WY, Cai M, Xiang ZP, Kong Q (2017) Gas permeability and porosity evolution of a porous sandstone under repeated loading and unloading conditions. Rock Mech Rock Eng 50:1–13

Wang ZC, Li SC, Qiao LP, Zhao JG (2013b) Fatigue behavior of granite subjected to cyclic loading under triaxial compression condition. Rock Mech Rock Eng 46:1603–1615

Wang SG, Elsworth D, Liu JS (2013a) Permeability evolution during progressive deformation of intact coal and implications for instability in underground coal seams. Int J Rock Mech Min Sci 58:34–45

Wei YJ, Xia MF, Ke FJ, Yin XC, Bai YL (2000) Evolution-induced catastrophe and its predictability. Pure Appl Geophys 157:1945–1957

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 13:293–297

Xu XH, Ma SP, Xia MF, Ke FJ, Bai YL (2004) Damage evaluation and damage localization of rock. Theor Appl Fract Mech 42:131–138

Xiao JQ, Ding DX, Jiang FL, Xu G (2010) Fatigue damage variable and evolution of rock subjected to cyclic loading. Int J Rock Mech Min Sci 47:461–468

Yang XL, Cao J, Cheng XY, Liu YB, Li XL, Sun ZG, Guo JJ (2019) Mechanical response characteristics and permeability evolution of coal samples under cyclic loading. Energy Sci Eng 7:1588–1604

Yin GZ, Jiang CB, Wang JG, Xu J (2015) Geomechanical and flow properties of coal from loading axial stress and unloading confining pressure tests. Int J Rock Mech Min Sci 76:155–161

Yin XC, Zhang LP, Zhang HH, Wang YC, Zhang YX, Peng KY, Wang HT, Song ZP, Yu HZ, Zhuang JC (2006) LURR’s twenty years and its perspective. Pure Appl Geophys 163:2317–2341

Yang SQ, Xu P, Ranjith PG, Chen GF, Jing HW (2015) Evaluation of creep mechanical behavior of deep-buried marble under triaxial cyclic loading. Arab J Geosci 8:6567–6582

Zhong CL, Zhang ZY, Ranjith PG, Lu YY, Choi X (2019) The role of pore water plays in coal under uniaxial cyclic loading. Eng Geol 257:105125. https://doi.org/10.1016/j.enggeo.2019.05.002

Zhang LP, Yu HZ, Yin XC, Liang NG (2010) Application of the load/unload response ratio method in catastrophic failure prediction of structures. Eng Mech 27:228–235

Zhang LP, Yu HZ, Yin XC (2013) Failure potential evaluation in engineering experiments using load/unload response ratio method. Pure Appl Geophys 170:237–245

Zhang ZB, Wang EY, Li N, Li XL, Wang XR, Li ZH (2018) Damage evolution analysis of coal samples under cyclic loading based on single-link cluster method. J Appl Geophys 152:56–64

Acknowledgments

The authors are grateful to Hong-Neng Coal Industrial Company and Banxi coal mine in Chongqing, China, for their help and technical support in obtaining the raw coals.

Funding

This study was financially supported by the National Natural Science Foundation of China (51674048), and Fundamental and Advanced Research Projects of Chongqing (cstc2015jcyjA90009). The first author also acknowledges the financial support provided by the China Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Amjad Kallel

Rights and permissions

About this article

Cite this article

Duan, M., Jiang, C., Xing, H. et al. Study on damage of coal based on permeability and load-unload response ratio under tiered cyclic loading. Arab J Geosci 13, 250 (2020). https://doi.org/10.1007/s12517-020-5249-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-5249-4