Abstract

Anisotropy is a very typical observation in the intrinsic bedding structure of coal. To study the influence of anisotropy of coal structure and stress state on the evolution of permeability, a newly developed multifunctional true triaxial geophysical apparatus was used to carry out mechanical and seepage experiments on bedded coal. The permeability and deformation of three orthogonal directions in cubic coal samples were collected under true triaxial stress. It has detected the significant permeability anisotropy, and the anisotropy is firmly determined by the bedding direction and stress state of coal. Based on the true triaxial mechanical and seepage test results, the coal with bedding was simplified to be represented by a cubic model, and the dynamic anisotropic (D-A) permeability model was derived by considering the influence of bedding and stress state. The rationality of the permeability model was verified by the experimental data. Comparing the permeability model with Wang and Zang (W–Z) model, Cui and Bustin (C–B) model and Shi and Durucan (S–D) model, it is found that the theoretical calculated values of the D-A permeability model are in better agreement with the experimental measured values, reflecting the superiority of the D-A permeability model. Based on incorporating the model of D-A permeability under the concept of multiphysics field coupling, the numerical simulation experiments of coal seam gas extraction with different initial permeability anisotropic ratios were carried out by using COMSOL multiphysics simulator. The influence of initial permeability anisotropy ratio on gas pressure distribution in coal seam during gas extraction was explored, which provides theoretical guidance for the optimization of borehole layout for gas extraction in coal mine.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coalbed methane (CBM) is an important unconventional clean energy. CBM extraction can not only reduce greenhouse gas emissions, but also reduce the occurrence of mine disasters related to gas (Liu et al. 2017a; Yan et al. 2015; Karacan et al. 2011; Wang et al. 2019a, b). Coal permeability is the key factor for rational arrangement of boreholes for gas drainage and CBM reservoir productivity (An et al. 2015; Wang et al. 2019a, b; Duan et al. 2019). Coal is an organic-rich sedimentary rock and its structural anisotropy leads to its permeability anisotropy, especially in the direction of bedding (Wang et al. 2011; Pan and Connell 2011; Zhao et al. 2018). Permeability anisotropy is critical in CBM reservoir characterization and well-pattern optimization. At the same time, under the influence of geological structure, faults, folds and man-made excavation, the stress of coal and rock mass is usually three-dimensional unequal stress (σ1 > σ2 > σ3) (Song et al. 2019; Li et al. 2016a). Therefore, the study of coal structure and in situ stress anisotropy can provide better interpretation in reflecting the anisotropic characteristics of coal seam permeability, which can serve better guidance for the rational layout of underground gas extraction boreholes.

At present, there are many mature studies based on isotropic permeability models, such as P-M permeability model (Palmer and Mansoori 1998; Pan and Connell 2007), S–D permeability model (Shi and Durucan 2004), C–B permeability model (Cui and Bustin 2005; Cui et al. 2007). Although these typical permeability models take the concepts of effective stress and adsorption into account, these models do not take into account the anisotropy of bedding structure, which naturally fail to reflect the directionality of coal permeability. With the deepening of coal permeability research,it still remains unclear about the influence of coal permeability anisotropy and seepage characteristics under true triaxial stress conditions.

Many scholars have studied the anisotropy of coal and rock permeability in combination with physical experiments. For example, Koenig and Stubbs (1986) have pointed out that the permeability of parallel bedding plane in coal seam is 17 times higher than that of vertical bedding plane according to in situ logging data of coal seam in Black Warrior Basin near Birmingham, USA. The true triaxial stress coal permeability (TTSCP) was used to measure permeability in different directions, and the permeability anisotropy was defined by Massarotto et al. (2002, 2003) and Wang et al. (2010). Wang et al. (2018) analyzed the anisotropic permeability of coal and determined the anisotropic ratio of coal containing gas. Liu et al. (2018, 2019a, b) tested coal permeability in the direction of face cleats, butt cleats and bedding plane by using a newly developed multifunctional true triaxial geophysical (TTG) apparatus. It is found that coal permeability anisotropy is mainly affected by its own structure and unequal external pressure under true triaxial stress. Li et al. (2016b) conducted seepage experiments on bedded shale and deduced the permeability model of shale under true triaxial stress. Ma et al. (2016) and Tan et al. (2017) found that the permeability of shale also shows certain anisotropy in two directions of parallel bedding. Gu and Chalaturnyk (2010) considered that coal body is a naturally segmented rock mass. The effective strain and aperture change in different directions are different, which leads to the difference of permeability in different directions. Tan et al. (2018) measured the anisotropic permeability of cubic coal samples in three directions under different pressure and confining pressure. The simulation results based on stress-dependent permeability model also revealed that the stress anisotropy inserts significant influence in the development of fracture permeability in geothermal field (Gan and Elsworth 2016a, b; Ijeje and Gan 2019).

However, some other scholars have deduced anisotropic permeability model and simulated it based on physical experiment results. For example, Wang et al. (2014, 2016) established the anisotropic permeability model of coal and studied the influence of coal anisotropic characteristics on gas pressure distribution by numerical simulation. The anisotropic permeability of coal under uniaxial strain, constant volume and constant confining stress conditions was studied by Yang et al. (2016) and Liu et al. (2010). Chen et al. (2012) studied the evolution of permeability anisotropy during the CBM exploitation process first, then improved the permeability model based on coal stress–strain under anisotropic conditions, and finally quantitatively studied the influence of permeability anisotropy ratio on lateral well pattern. However, most of the above studies only consider the anisotropy of coal permeability in the initial state and do not consider the dynamic effect of stress on the anisotropy of coal deformation characteristics. In fact, the anisotropy of coal permeability varies dynamically with the change of stress–strain Liu et al. (2019b, 2010), which influenced by the anisotropy of coal initial structure and stress–strain anisotropy. Considering the influence of coal structural anisotropy and geo-environmental stress anisotropy on permeability comprehensively, it is of great theoretical and practical significance to understand the gas–solid (coal) coupling mechanism in depth.

In this paper, a newly developed multifunctional TTG apparatus was used to conduct seepage experiments on cubic coal samples under different flow directions and stress states. The gas flow and coal deformation data under various flow directions, stress states were measured in the experiment. The influence of bedding direction, flow direction and principal stress direction on coal permeability was analyzed. Based on the experimental data, a dynamic anisotropic (D-A) permeability model considering bedding effect was deduced and validated by the experimental data. The D-A permeability model was compared with the W–Z (anisotropy), C–B and S–D permeability models. Finally, the D-A permeability model, stress balance and gas migration control equations were introduced into COMSOL multiphysics simulator to simulate the gas extraction in anisotropic permeability and stress conditions of coal seam. The influence of initial permeability anisotropy ratio (PAR) on gas pressure distribution and gas production was discussed.

2 Orthotropic Permeability Experiments of Cubic Coal Samples

2.1 Coal Samples and Experimental Equipment

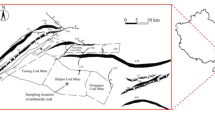

The coal samples used in this experiment were taken from a coal mine of Sichuan Coal Group, and the burial depth of the coal sample is 600 m. The coal measure strata in this mine belong to low permeability coal seam. The gas content in the B3 coal seam is about 18.67 m3/t, and the B3 coal seam has the tendency of outburst and spontaneous combustion. Table 1 summarizes the properties of the coal specimens (Zhang et al. 2016; Cao et al. 2000). The coal samples were processed into cubes with 100 mm ± 0.5 mm sides and were then polished to obtain three pairs of mutually parallel faces. Then, the cubic coal specimens were put into oven and dried at a temperature of 80 °C until the coal quality no longer changed. Finally, the cubic samples were subjected to computed tomography (CT) scanning to identify bedding structure. The cubic coal samples and the three-dimensional reconstruction of CT are shown in Fig. 1. In this experiment, coal with bedding was selected for true triaxial seepage experiments.

A newly multifunctional TTG apparatus developed by Chongqing University was used in the experiment (Li et al. 2016a; Liu et al. 2018), as depicted in Fig. 2. The device can be used to test true triaxial coal mechanics, seepage and hydraulic fracturing under different stress paths. The specimen deformations were monitored and recorded by high precision linear variable displacement transducer (LVDT) and acquisition card. The gas flow was measured by mass flow meter during the experiment.

2.2 Experimental Scheme

To study the anisotropy of coal structure and the anisotropy of ground stress, the permeability of cubic coal samples in three directions under true triaxial stress was tested. There are two variables in the design of the experimental scheme: one is the relationship between the direction of gas flow and bedding, the other is the relationship between three principal stresses and bedding. Nine different experimental conditions were orthogonal designed according to two variables, as shown in Fig. 3. There are three kinds of gas flow directions, that is, flow direction 1 is parallel to bedding 1, flow direction 2 is parallel to bedding 2, and flow direction 3 is perpendicular to bedding. There are also three scenarios between the three principal stresses and the direction of bedding (only considering the vertical relationship with bedding), which includes stress Condition 1: minimum principal stress (σ3) is perpendicular to bedding, stress Condition 2: intermediate principal stress (σ2) is perpendicular to bedding, and stress Condition 3: maximum principal stress (σ1) is perpendicular to bedding. The stress path of each experimental scheme was constant maximum principal stress 50 MPa, minimum principal stress 10 MPa and gas pressure 1 MPa. The intermediate principal stress was loaded from 10 to 50 MPa step by step. The loading increment between each intermediate principal stress test point was 8 MPa. Loaded to the test point, after the flow kept stable, recorded the flow data at this time, and then executed the next loading. For detailed installation process of true triaxial seepage experiment, refer to Li et al. (2016a) and Liu et al. (2019a).

Due to the great difference between different coal samples, this experiment considers several mechanical seepage experiments on the same cubic coal sample, which can more clearly compare the seepage and deformation anisotropy in different directions of the same coal sample (Liu et al. 2019a). However, to minimize the influence of each experiment on the subsequent experiments, the maximum loading stress should ensure that the deformation of coal samples is within the elastic range (Liu et al. 2019b), and the hydrostatic pressure (10 MPa) preloading stage should be carried out in each experiment to ensure that each experiment was nearly the same as the initial state. (Note: Before the experiment, the stress–strain curves of maximum principal stress parallel bedding and vertical bedding were measured, and the elastic deformation stage of coal under this experimental condition can be determined in Fig. 4.)

2.3 Experimental Results

According to the Darcy’s law, the permeability of coal was calculated by (Perera et al. 2012; Jiang et al. 2017; Liu et al. 2018):

where k is the permeability (m2), Q is the gas flow rate (m3/s), μ is the gas kinematic viscosity (Pa s), H is the length of coal specimens (m), p1 is the gas pressure at the upper stream (Pa) and p2 is the gas pressure at the downstream (Pa), S is the cross-sectional area of coal specimens (m2).

Figure 5 clearly demonstrates that the variation of coal permeability with intermediate principal stress under different experimental schemes. The coal permeability decreases with the increasing of σ2 when keeping σ1 and σ3 constant (Liu et al. 2019a), and the permeability of gas flow to parallel bedding plane decreases significantly more than that of gas flow to vertical bedding. The permeability in different flow directions has obvious anisotropic characteristics. The permeability in parallel bedding direction is obviously higher than that in vertical bedding direction. The permeability in two parallel bedding directions is also anisotropic, but the overall difference is not significant in this experiment. When the flow direction is parallel to the bedding plane (under the same σ2), the permeability is the largest when σ3 is vertical to bedding plane, the permeability is the second when σ2 is vertical to bedding plane, the permeability is the smallest when σ1 is vertical to bedding plan. However, when the flow direction is perpendicular to the bedding plane, the change of permeability with the principal stress orientation is small. In summary, there is obvious anisotropy in coal permeability, and anisotropy is closely related to bedding direction and stress state.

Definition of permeability anisotropy ratio (PAR) as permeability ratio in different flow directions (Massarotto et al. 2002, 2003), that is, PARij= ki/kj. When PARij= 1, the permeability is isotropic. So the closer the PARij value is to 1, the weaker the anisotropy is. As shown in Fig. 5, the permeability of the two parallel bedding directions is kx, ky, and the permeability of the vertical bedding direction is kz. When σ2 = 10 MPa, the permeability was regarded as the initial permeability, and initial permeability anisotropy ratio is displayed in Table 2. The variation range of the initial permeability anisotropy ratio between the two parallel bedding directions (PARxy0) is 1.125 ~ 1.262, PARxy0 ≈ 1, which indicates that the initial permeability in the two parallel directions are similar. The initial permeability anisotropy ratio between parallel bedding and vertical bedding (PARyz0 or PARxz0) ranges from 1.308 to 2.655, which indicates that the initial permeability in parallel bedding direction is different from that in vertical bedding direction. The initial permeability in parallel bedding direction is about 2–3 times of that in vertical bedding direction. These observations indicated that coal permeability anisotropy is strongly affected by the orientation of bedding.

Permeability anisotropy appears dynamically evolved with the change of stress or strain. Table 3 shows the dynamic change of coal PAR with the increasing of σ2 under stress Condition 1. As displayed in Table 3, with the increasing of σ2, the PAR between two parallel bedding directions (PARxy) fluctuates between 1.26 and 1.34, and the variation is small. However, the PAR between parallel bedding and vertical bedding (PARyz or PARxz) shows a significant decreasing trend. This shows that the increase of σ2 will weaken the permeability anisotropy between parallel bedding and vertical bedding, and the stress also has some influence on the permeability anisotropy. PARxy is always smaller than PARyz and PARxz in Tables 2 and 3, indicating that bedding direction plays a dominant role in the permeability anisotropy of bedded coal. The plausible interpretation of permeability versus stress in the condition of bedded coal is the large extend of compaction will be created following the direction of minimum principal stress loading, consequently suppress the development of anisotropy by reducing the variation of permeability among different directions. Furthermore, the bedding direction generates influence in the anisotropy by creating directional fabrics along particular direction, especially when certain pattern of joints/veins occurred in rock mass (Faulkner et al. 2006).

3 Theoretical Derivation and Verification of D-A Permeability Model for Coal

Based on the permeability and PAR of cubic coal samples in three orthogonal directions obtained from the true triaxial seepage experiment, it is found that the bedding structure and stress have important influence on the anisotropy of coal permeability (Menezes et al. 2019). However, most of the current studies on coal permeability anisotropy only consider the initial permeability anisotropy and do not consider dynamic permeability anisotropy caused by the change of stress (Zhao et al. 2018). In this research, therefore, based on seepage theory and experimental results, a dynamic anisotropic (D-A) permeability model considering coal structure and the change of stress was deduced. The D-A permeability model was validated by experimental data and which was compared with W–Z (anisotropy), C–B and S–D permeability model.

3.1 Derivation of D-A Permeability Model

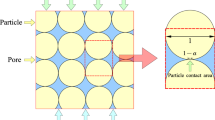

As a dual-porous media, coal body includes two parts: fracture system and matrix pore system cut by fracture (Liu et al. 2010). There are two permeability and two porosity at any point (micro-element volume) in dual media. The coal with bedding and cleats structure was simplified as a cubic model, as shown in Fig. 6.

Assuming that coal matrix unit is transversely isotropic, the homogeneous coal matrix was divided by orthogonal bedding and joint plane. As shown in Fig. 6, the idealized bedding, face and butt cleats width are bz, bx and by, respectively. According to the Poiseuille’s equation, the flow rate along this single cleat can be expressed as (Reiss, 1980):

where q is the flow rate of single cleat (m3/s); b, s and l are the geometry of the cleat which are illustrated in Fig. 7. Δp is the differential pressure (Pa).

Sketch of gas flow through a cleat (Chen et al. 2012)

Assuming that the total flow of fluid through n cleats equals the simple cumulative flow of single cleat, the total flow rate in n cleats flowing through a section A in porous media can also be expressed by Darcy’s law:

where Q is the total flow through cross section A (m3/s); k is the permeability of rock mass (m2).

The cleat permeability can be obtained from the above formula:

where ξ = ∑s/A represents the total cleat length per unit cross section (m−1).

The change of fracture width is determined by the deformation of coal matrix, pore and fracture. The variation of fracture width in coal is mainly caused by external stress and internal pressure of gas adsorption. The variation of fracture width in i direction caused by external stress loading can be expressed as (Liu et al. 2010; Yang et al. 2016)

where Δbstressi is the variation of fracture width caused by external stress (m); u and us is the deformation of coal and coal matrix, respectively (m); L is edge length of cubic coal matrix unit (m); bi is fracture width in i direction (m), and L ≫ bi; Δεi and Δεmi is the strain increment of coal and coal matrix, respectively (%).

When the coal is subjected to true triaxial stress, the stress in all directions will cause the change of crack width. According to the general Hooke’s law, it can be obtained:

where σi, σj and σk represent three principal stresses (MPa); νij and νmij are Poisson’s ratio of coal and coal matrix, respectively; Ei and Emi are Young’s modulus of coal and coal matrix, respectively (MPa). Subscripts i, j and k represent three orthogonal directions.

A modulus reduction ratio γ defined by (Liu et al. 2010; Yang et al. 2016), and γi= Ei/Emi, combining Eqs. (5) and (6) can be obtained:

The coal matrix can swell when it adsorbs methane. The strain can be described using an equation in Langmuir’s form (Harpalani 1990; Guo et al. 2014)

where εs is adsorption volumetric strain (%); εm and pL are isothermal adsorption deformation constants; εm is the maximum adsorption strain when the gas pressure is infinite (%); pL is the pressure when the adsorption strain is half of the maximum adsorption strain (MPa); pm is gas pressure in coal matrix (MPa).

The change of coal fracture width caused by adsorption can be expressed as follows

where Δbadsorptioni is the variation of fracture width caused by adsorption (m); Δεs is adsorption volume strain increment (%).

The total variation of fracture width in coal body is obtained (Liu et al. 2010)

where bi0 is initial fracture width in i direction (m).

Because of faults, joints and cracks other structural surfaces anisotropy, the average initial fracture width in all directions is also different, assuming that the average initial fracture width in three orthogonal directions has the following relationship

where bx0, by0 and bz0 are the initial fracture width in the direction of face cleats, butt cleats and bedding, respectively (m). λxz and λyz are the anisotropic ratio of coal structure in the initial state in the direction of xz and yz, respectively. The relationship between λ and PAR in the initial state is shown in “Appendix A.”

According to Fig. 8, the fracture porosity of coal can be obtained

Since bi≪ L, the higher-order infinitesimal terms of bi can be removed in Eq. (13), then substituting Eqs. (11) and (12) into the simplified Eq. (13)

where φf and φf0 are dynamic fracture porosity and initial fracture porosity, respectively (%).According to Fig. 6, the permeability in x direction is mainly obtained by superimposing the seepage flux of by and bz (which orthogonal to x direction) (Wu et al. 2010, 2011; Gu and Chalaturnyk 2010). By combining Eq. (4), the permeability in x direction can be obtained

The variation of fracture length with stress is much less than that of fracture width. Therefore, it can be assumed that the ξ value remains basically unchanged with the change of stress, that is, ξi ≈ ξi0. Normalized permeability in x direction can be obtained from Eq. (16)

Combined with Eqs. (11)–(12), Eqs. (14)–(15) and Eq. (17), The dynamic anisotropic (D-A) permeability model of coal can be deduced as follows:

and

where Ψ is a constant related to the initial porosity and the anisotropy ratio of coal initial structure.

3.2 The D-A Permeability Model Based on Bedding Effect

The initial PAR of the two parallel bedding directions is close to 1 as listed in Table 2, which shows that the difference of initial permeability between the two parallel bedding directions is small. However, the difference of initial permeability between the parallel and vertical bedding directions is large. For coal with obvious bedding structure, bedding structure plays a key role in the anisotropy of permeability. (Compared with the permeability anisotropy caused by bedding, the permeability anisotropy caused by face and butt cleats is smaller, which will be neglected in this experiment.) Therefore, it can be assumed that the structural anisotropy ratio of coal caused by bedding structure is λ. By substituting λxz= λyz= λ into Eq. (18), the D-A permeability model based on bedding effect can be obtained as follows:

3.3 Verification of D-A Permeability Model Based on Bedding Effect

- (1)

Validation of experimental data

According to Eq. (20), the permeability anisotropy was caused by the anisotropy of coal structure and external stress. The anisotropy of coal structure can be characterized by λ. According to the true triaxial test of coal, the stress–strain values can be obtained, and the strain increment Δεi and Young’s modulus E in all directions can be calculated. There are some differences in Young’s modulus in all directions but not large (Liu et al. 2019a), to simplify the calculation, let Ex= Ey= Ez, and then γx= γy= γz. Initial porosity of coal is measured by mercury intrusion method. PARxz0 ≈ 2 was obtained from the previous true triaxial seepage experiment and λ ≈ 0.6935 was obtained from “Appendix A-4.” The results of calculation and measurement of each parameter are shown in Table 4. By introducing strain data and model parameters into D-A permeability model based on bedding effect, theoretical permeability values under different stress conditions and flow directions can be calculated, and they are compared with the measured permeability values in Fig. 9. It can be seen from Fig. 9 that both flow direction and stress condition affect the anisotropy of permeability. The permeability relationship among different stress states under the same σ2 and flow direction: kx(σ3 ⊥ bedding) > kx(σ2 ⊥ bedding) > kx(σ1 ⊥ bedding); however, the permeability relationship in different flow directions under the same σ2 and stress conditions is kx > ky > kz. Comparing the D-A permeability model calculated value with the experiment measured value, it is found that the model calculated and experiment measured permeability values are in good agreement under different stress conditions and flow directions, which indicates that the D-A permeability model based on bedding effect derived in this paper is reasonable.

- (2)

Comparing with classical permeability model

To study the advantages and disadvantages of the D-A permeability model deduced in this paper and the existing permeability model, the measured permeability data of FSC-2 scheme were compared with the calculated values of D-A permeability model, W–Z anisotropic permeability model (Wang et al. 2014; Zang and Wang 2016), C–B (Cui and Bustin 2005; Cui et al. 2007) and S–D (Shi and Durucan 2004) isotropic permeability model, as shown in Fig. 10. For isotropic permeability model, when σ2 < 34 MPa, the C–B model calculated value agrees well with the experimental data, while S–D model does not. With the increasing of σ2, the consistency between C–B model calculated value and experimental data decreases gradually, while that of S–D model increases step by step. For anisotropic permeability model, when σ2 < 42 MPa, the W–Z anisotropic permeability model calculated values are basically in agreement with the experimental data. When σ2 > 42 MPa, it will deviate greatly from the experimental values. However, the D-A permeability model has a high degree of coincidence at all stages of σ2, which indicates that the D-A permeability model derived in this paper can better reflect the variation law of permeability under true triaxial stress. (Note: W–Z, C–B and S–D permeability model formulas see “Appendix B”)

4 Application of D-A Permeability Model in Numerical Simulation of Gas Extraction

To study the application of D-A permeability model in the field of gas extraction, the influence of different initial PAR on gas pressure distribution and gas drainage quantity was discussed. Combining D-A permeability model and Fluid–Solid (or Gas–Coal) coupling control equation, numerical simulation of gas extraction with different initial PAR was carried out in this paper, which will provide theoretical guidance for rational arrangement of underground gas extraction boreholes.

4.1 Basic Assumptions

-

1.

Coal is considered to be a dual continuous isotropic elastic medium even though the coal consists of the coal matrix and fracture, and its deformation obeys Hooke’s law.

-

2.

The free gas in coal is single-phase and saturated, gas flow in fracture obeys Darcy’s law, and gas diffusion in matrix pore obeys Fick’s law, as shown in Fig. 11.

-

3.

Gas migration and gas adsorption and desorption are carried out in isothermal process. Adsorption and desorption obey the Langmuir isotherm and are reversible.

-

4.

Permeability anisotropy is only in the orthogonal principal direction. The gas slippage (Klinkenberg effect) is not considered.

4.2 Fluid–solid Coupling Control Equation Based on Permeability Anisotropy

- (1)

Stress equilibrium equation

Since coal is a dual poroelastic medium, in consideration of the influence of pores and fractures, gas adsorption and expansion on mechanical characteristics of coal, the Navier-type equation for coal seam deformation can be expressed as (Zhao et al. 2018; Liu et al. 2017b; Wu et al.2011):

and G = E/2(1 + ν), a = 1 − K/Km, β = 1 − K/Kf. Where G represents shear modulus of coal (GPa); E represents the Yong’s modulus of coal (GPa); v is the Poisson ratio of coal; a and β are Biot coefficients of coal matrix and fracture, respectively; ui and uj are the displacement components (m); fi is the body force component (MPa).

- (2)

Gas desorption and diffusion in coal matrix

Gas seepage in coal matrix is very small and relative fracture seepage can be neglected. Therefore, gas migration in coal matrix only considers diffusion and diffusion obeys Fick’s law. Diffusion coefficient varies with the change of matrix pressure (Li et al. 2016c; Liu et al. 2017a), so the dynamic diffusion equation can be expressed as:

where Qd is the gas exchange rate per volume of matrix blocks (kg/(m3 s)); Di and Di0 is the dynamic diffusion coefficients and initial diffusion coefficients in i direction, respectively (m2/s); ς is the shape factor of matrix block (m−2); C is diffusion gradient (kg/m3); M is molar mass of CH4 (kg/mol); R is gas constant (J/(mol K)); T is Kelvin temperature (K); pm and pf are gas pressure in matrix and in fracture, respectively (MPa).

According to the principle of mass conservation, the governing equation of gas diffusion and migration in matrix can be obtained (Liu et al. 2017a, b; Zhao et al. 2018):

where mm, msor and mfree are total gas content, adsorption gas content and free gas content in coal matrix (kg/m3); ρga is gas density under standard atmospheric pressure (kg/m3); ρc is coal density (kg/m3); Vl is the Langmuir volume constant (m3/kg); pL is the Langmuir pressure constant (MPa); φm is porosity of coal matrix.

- (3)

Gas seepage in coal fracture

The gas in the fracture originates from gas desorption and diffusion in the matrix. The gas seepage in the fracture satisfies Darcy’s law. There is also free gas in the fracture space. Therefore, the governing equations of gas seepage in the fracture were listed as follows (Yan et al. 2014; Liu et al. 2015, 2017a)

where mf is gas content in coal fracture (kg/m3); ρf is gas density in coal fracture (kg/m3); vf is vector of gas convective velocity in coal fracture (m/s); φf is porosity of coal fracture; kx, ky and kz are permeability in three orthogonal directions.

Equations (20)–(21) and (23)–(25) constitute the dual-porosity medium fluid–solid (or gas–coal) coupling model based on permeability anisotropy for coal containing gas. The model simultaneously considers dynamic permeability anisotropy, dynamic diffusion, effective stress, matrix shrinkage and bedding effects. All of these governing equations were implemented and solved using COMSOL multiphysics finite element code, which provides a complete and integrated modeling environment for creating, analyzing and visualizing multiphysics models. Three modules of COMSOL Multiphysics were used in these numerical simulations: the stress and strain of coal was implemented through “Solid Mechanics module”; the Darcy flow of gas in coal fracture was calculated using “Darcy’s Law module” and the gas diffusion in coal matrix was implemented through the “coefficient type PDE (partial differential equation) module.” The gas diffusion into fractures was defined as a “Mass Source,” and its value was calculated using Eq. (24) in the “Darcy’s Law module” (Liu et al. 2015).

4.3 Geometrical Model and Boundary Conditions

The simulated physical parameters were based on the coal seam in Sichuan Coal Group and the reference literature (Liu et al. 2015, 2017a; Wu et al. 2010; Zhao et al. 2018), as listed in Table 5. The geometrical physical model is shown in Fig. 12a. The model is single-hole dry extraction, drilling along parallel bedding direction, depth 50 m, aperture 0.5 m (To reduce the calculation time of numerical simulation, the simulated borehole was magnified by 10 times of the field borehole). Because this research focuses on the anisotropy of permeability caused by the bedding structure in the process of extraction, the real bedding structure was not established in the extraction model, and the bedding effect was only reflected in the anisotropy of permeability. The boundary conditions of the model were set: The top boundary of the model was set to be a pressure boundary to bear overlying stress of 20 MPa; the bottom boundary of the model was set be a fixed constraint boundary; the roller support boundaries were applied to the front, rear, left and right surfaces to constrain the normal displacement, and the six exterior end faces of the model were all zero flux surfaces, so the no-flow boundary condition was applied to the six exterior end faces of the model for the seepage and diffusion field. In addition, a constant pressure of 0.1 MPa was applied to the boundaries of gas drainage boreholes. An initial pressure of 3.3 MPa was applied to the fracture and matrix of coal. The time step of numerical simulation was 1 day, and the simulated extraction time was 500 days. To monitor the variation of parameters in different time and space during the simulated extraction process, a monitoring point P1, two orthogonal line segment AB, BC along the z and y directions and cross section ABC perpendicular to the borehole were added, whose specific location is shown in Fig. 12b. At the same time, the “Domain Probe” was defined to integrate the gas amount in the whole area, in order to monitor the performance of gas extraction. The gas content of coal seam at each time point can be obtained by Domain Probe, and then, the gas extraction amount can be obtained according to the change amount of coal seam gas.

Due to the coal seam anisotropy in flow and mechanical properties, there is a great difference between gas seepage in parallel bedding direction and that in vertical bedding direction in the process of gas drainage by borehole pressure relief. To explore the influence of permeability anisotropy on the gas extraction range, shape and reasonable drilling hole layout, and to evaluate the influence of permeability anisotropy on single well dry CBM production, four numerical simulations of coal bed gas extraction with different initial PAR were carried out in this paper. Initial directional permeability values of the four simulation cases are exhibited in Table 6. Previous physical experiments show that there is little difference in permeability between two horizontal directions of bedded coal. For simplicity of calculation, assuming that the permeability in two horizontal directions is the same, the permeability in vertical direction is generally less than that in horizontal direction. (Note: For the effective comparison between different permeability anisotropy ratios, the equivalent initial permeability of the four cases in the simulation experiment is the same, that is, the equivalent initial permeability is ke= (kx0ky0kz0)1/3 = 4.16 × 10−17 m2.)

4.4 Simulation Results Analysis and Discussion

- (1)

Effect of initial PAR on gas pressure distribution

Figure 13 shows the distribution map of gas pressure, section ABC pressure contour and gas flow streamline of coal seams with different initial permeability anisotropy ratio after 50-d gas drainage. It can be seen from Fig. 13 that with the increasing of initial PAR, the larger the ratio between long and short axes of the ellipse pressure isoline centered on the borehole, the flatter the gas pressure iso-surface. When PARxz0 = 1, the gas pressure iso-surface presents a “nearly circular funnel” shape centered on boreholes. When PARxz0 > 1, the gas pressure iso-surface presents an “elliptic funnel” shape centered on boreholes (Lin et al. 2019). With the increasing of time, the pressure iso-surface expands toward the periphery of borehole, and the expansion velocity along parallel bedding direction is faster than that in vertical bedding direction. Gas streamlines show three-dimensional radial flow centered on boreholes, and streamlines in parallel bedding direction are greater density than those in vertical bedding direction. Therefore, drilling spacing along bedding direction is larger than that along vertical bedding direction for coal seam with bedding.

To more intuitively and accurately reflect the spatio-temporal evolution of gas pressure during extraction process, the change curves of gas pressure for different initial PAR with extraction time and the length of distance from borehole are given in Figs. 14 and 15, respectively. As shown in Fig. 14, with the increasing of extraction time, gas pressure decreases sharply at first, and then linearly, eventually tends to be flat (Xu et al. 2018). The larger the initial PAR, the larger the gas pressure under the same extraction time and location, indicating that the larger the initial PAR, the slower the gas pressure decreases at the same time and space.

The gas pressure in monitoring line AB (vertical bedding direction) increases with the increasing of initial PAR, as described in Fig. 15a. However, The gas pressure in monitoring line BC (parallel bedding direction) decreases with the increasing of initial PAR, and when the length of distance borehole is greater than 10 m, a different phenomenon appear that the gas pressure of the initial permeability isotropy is lower than the gas pressure of the initial PAR= 3, as shown in Fig. 15b. From Fig. 15c, it’s easy to find that when the initial permeability is isotropic, gas pressure at the same distance from the borehole on the monitoring line AB and BC is also different (that is pAB ≠ pBC), and the different become larger with the increasing of the length distance from borehole. At the same time, the gas pressure isoline with initial permeability isotropic also shows elliptic shape, as illustrated in Fig. 15c. This is due to the difference of stress between the two directions. The vertical direction was subjected to the overlying stress. The vertical stress compressed the horizontal hole and crack, and the horizontal permeability decreased. Therefore, even if the initial permeability is isotropic, the anisotropy of the external force can also cause the permeability anisotropy. When the initial permeability is anisotropic, the gas pressure at the same length position from the borehole on the monitoring line AB and BC shows: pAB (vertical bedding direction) > pBC (parallel bedding direction). It shows that the decrease of gas pressure along bedding direction with the same length from borehole is larger than that along vertical bedding direction, as presented in Fig. 15d.

- (2)

Effect of initial PAR on gas extraction rate

Figure 16 presents the variation of gas extraction rate with extraction time in different initial PAR. It can be seen from Fig. 16 that the extraction rate decreases with the increase of extraction time in a negative logarithmic function. In the initial stage of gas extraction, the gas production rate is higher. With the increase of extraction time, the gas production rate gradually decreases, and the initial attenuation is larger, and then tends to be gentle. These phenomena are consistent with the situation of field gas extraction. The gas extraction rate decreases with the increasing of the initial PAR, which indicates that the higher the permeability anisotropic ratio, the lower the gas extraction output. This is because the larger the anisotropy ratio of initial permeability, the narrower the elliptical shape of gas extraction range, the smaller the area of gas extraction reach, and the larger the distance of gas flowing to boreholes. Therefore, for the rational arrangement of gas drainage boreholes, it is necessary to take measures according to local conditions, especially for coal seams with obvious anisotropic structure, permeability monitoring in different directions should be carried out in order to reasonably select the spacing and layout shape of boreholes. From the numerical simulation results of gas extraction, it can be found that the coal seam permeability anisotropy has an important influence on the rational layout of gas extraction boreholes. The stronger the anisotropy of permeability is, the stronger the non-uniformity of gas drainage borehole layout is.

- (3)

Effect of PAR on multi-extraction drilling layout shape

Based on the numerical simulation results of single well dry CBM extraction with anisotropic permeability, we can deduce that permeability anisotropy has an important influence on the layout shape of multi-borehole group gas extraction, and the layout shape of multi-borehole directly determines the gas extraction efficiency. Figure 17 indicates the diagram of the effect of PAR on multi-extraction drilling layout shape. It is found that for different permeability anisotropic coal seams, the layout shapes of multiple boreholes groups are different, such as rhombus, rectangle, triangle and so on. The anisotropy characteristics of coal seam permeability in different areas and directions result in the different effective extraction radii in different areas and directions and then lead to the well group arranged in different shapes. For how to optimize the borehole group layout for gas extraction in coal mine, we should first test permeability (i.e., effective extraction radii) in different underground coal seam areas and directions, especially for the anisotropic characteristics of the bedded coal mass, the effective extraction radii in the directions parallel and perpendicular to the bedding planes (i.e., R1 and R2 in Fig. 17) should be measured (Lin et al. 2019). According to the permeability in different directions and areas measured on site, the effective extraction radii of gas can be predicted, and then, different drilling groups shape can be selected according to the effective extraction radii. The principle of optimizing or selecting the drilling group shapes is that make full use of the permeability characteristics of the coal seam itself, reduce the number of wells in the dominant direction of seepage, increase the number of wells in the inferior direction of seepage, make full use of each well, reduce the blind area and overlap area of extraction.

The results of Wicks et al. (1986) also show that the extraction efficiency of coal seam with anisotropic permeability is related to drilling layout shape, and the rectangular drilling model increases gas production compared with the square pattern for an anisotropic CBM reservoir with water saturation. Therefore, according to the characteristics of permeability anisotropy, we can optimize the location and shape of multi-pumping drilling, make full use of the characteristics of permeability anisotropy, improve gas production efficiency and maximize the use of drilling and pumping capacity. In the later study, the influence of multi-borehole layout shape and spacing on gas extraction efficiency in permeability anisotropic coal seam will be further discussed.

5 Conclusions

The seepage experiments of cubic coal samples under different seepage directions and true triaxial stress states were carried out by using TTG apparatus in this paper. Based on the experimental data and seepage theory, a D-A permeability model considering bedding effect was deduced. A multi-field coupling mathematical model of coal seam based on D-A permeability model was established. The influence of initial PAR on the change of gas pressure and gas extraction rate was discussed. The main conclusions are as follows:

- 1.

The permeability in different seepage directions has significant anisotropic characteristics, and anisotropy is closely related to bedding direction and stress state. The permeability in parallel bedding direction is higher than that in vertical bedding direction.

- 2.

Based on the coal structure and cubic model, a D-A permeability model considering the change of coal structure and stress was derived. Compared with the experimental data, it is found that the D-A permeability model is superior to W–Z, C–B and S–D permeability models.

- 3.

For coal seam with bedding, the decrease of gas pressure along bedding direction is larger than that along vertical bedding direction. The bigger the initial PAR, the bigger ratio of long axis to short axis of elliptical pressure isoline. The narrower the ellipse shape represents gas extraction rate reduction.

References

An, H., Wei, X., Wang, G., Massarotto, P., Wang, F., Rudoph, V., Golding, S.D.: Modeling anisotropic permeability of coal and its effects on CO2 sequestration and enhanced coalbed methane recovery. Int. J. Coal Geol. 152, 15–24 (2015)

Cao, Y., Mitchell, G.D., Davis, A., Wang, D.: Deformation metamorphism of bituminous and anthracite coals from China. Int. J. Coal Geol. 43, 227–242 (2000)

Cui, X., Bustin, R.M.: Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. Am. Assoc. Pet. Geol. Bull. 89(9), 1181–1202 (2005)

Cui, X., Bustin, R.M., Chikatamarla, L.: Adsorption-induced coal swelling and stress: implications for methane production and acid gas sequestration into coal seams. J. Geophys. Res. 112, B10202 (2007)

Chen, D., Pan, Z., Liu, J., Connell, L.D.: Characteristic of anisotropic coal permeability and its impact on optimal design of multi-lateral well for coalbed methane production. J. Petrol. Sci. Eng. 88–89, 13–28 (2012)

Duan, M., Jiang, C., Gan, Q., Li, M., Peng, K., Zhang, W.: Experimental investigation on the permeability, acoustic emission and energy dissipation of coal under tiered cyclic unloading. J. Nat. Gas Sci. Eng. (2019). https://doi.org/10.1016/j.jngse.2019.103054

Faulkner, D.R., Mitchell, T.M., Healy, D., Heap, M.J.: Slip on ‘weak’ faults by the rotation of regional stress in the fracture damage zone. Nature 444(7121), 922 (2006)

Gan, Q., Elsworth, D.: Production optimization in fractured geothermal reservoirs by coupled discrete fracture network modeling. Geothermics 62, 131–142 (2016a)

Gan, Q., Elsworth, D.: A continuum model for coupled stress and fluid flow in discrete fracture networks. Geomech. Geophys. Geo-Energy Geo-Resour. 2(1), 43–61 (2016b)

Gu, F., Chalaturnyk, R.: Permeability and porosity models considering anisotropy and discontinuity of coalbeds and application in coupled simulation. J. Petrol. Sci. Eng. 74(3), 113–131 (2010)

Guo, P., Cheng, Y., Jin, K., Li, W., Tu, Q., Liu, H.: Impact of effective stress and matrix deformation on the coal fracture permeability. Transp. Porous Media 103(1), 99–115 (2014)

Harpalani, S., Schraufnagel, A.: Measurement of parameters impacting methane recovery from coal seams. Int. J. Min. Geol. Eng. 8, 369–384 (1990)

Jiang, C., Duan, M., Yin, G., Wang, J., Lu, T., Xu, J., Zhang, D., Huang, G.: Experimental study on seepage properties, AE characteristics and energy dissipation of coal under tiered cyclic loading. Eng. Geol. 221, 114–123 (2017)

Koenig, R.A., Stubbs, P.B.: Interference testing of a coalbed methane reservoir. In: SPE Unconventional Gas Technology Symposium (1986)

Karacan, C.O., Ruiz, F.A., Cote, M., Phipps, S.: Coal mine methane: a review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 86, 121–156 (2011)

Li, M., Yin, G., Xu, J., Song, Z., Jiang, C.: A novel true triaxial apparatus to study the Geomechanical and fluid flow aspects of energy exploitations in geological formations. Rock Mech. Rock Eng. 49(12), 1–13 (2016a)

Li, M., Yin, G., Xu, J., Cao, J., Song, Z.: Permeability evolution of shale under anisotropic true triaxial stress conditions. Int. J. Coal Geol. 165, 142–148 (2016b)

Li, Z., Liu, Y., Xu, Y.P., Song, D.: Gas diffusion mechanism in multi-scale pores of coal particles and new diffusion model of dynamic diffusion coefficient. J. China Coal Soc. 41, 633–643 (2016c). (in Chinere)

Lin, B., Song, H., Zhao, Y., Liu, T., Kong, J., Huang, Z.: Significance of gas flow in anisotropic coal seams to underground gas drainage. J. Petrol. Sci. Eng. 180, 808–819 (2019)

Liu, J., Chen, Z., Elsworth, D., Miao, X., Mao, X.: Linking gas-sorption induced changes in coal permeability to directional strains through a modulus reduction ratio. Int. J. Coal Geol. 83(1), 21–30 (2010)

Liu, Q., Cheng, Y., Wang, H., Zhou, H., Wang, L., Li, W., Liu, H.: Numerical assessment of the effect of equilibration time on coal permeability evolution characteristics. Fuel 140, 81–89 (2015)

Liu, T., Lin, B., Yang, W.: Impact of matrix–fracture interactions on coal permeability: model development and analysis. Fuel 207, 522–532 (2017a)

Liu, T., Lin, B., Yang, W., Liu, T., Kong, J., Huang, Z., Wang, R., Zhao, Y.: Dynamic diffusion-based multifield coupling model for gas drainage. J. Nat. Gas Sci. Eng. 44, 233–249 (2017b)

Liu, T., Lin, B., Yang, W., Cheng, Z., Liu, D.: Coal permeability evolution and gas migration under non-equilibrium state. Transp. Porous Media 118(3), 393–416 (2017c)

Liu, Y., Li, M., Yin, G., Zhang, D., Deng, B.: Permeability evolution of anthracite coal considering true triaxial stress conditions and structural anisotropy. J. Nat. Gas Sci. Eng. 52, 492–506 (2018)

Liu, C., Yin, G., Li, M., Shang, D., Deng, B., Song, Z.: Deformation and permeability evolution of coals considering the effect of beddings. Int. J. Rock Mech. Min. Sci. 117, 49–62 (2019a)

Liu, Y., Yin, G., Li, M., Zhang, D., Deng, B., Liu, C., Lu, J.: Anisotropic mechanical properties and the permeability evolution of cubic coal under true triaxial stress paths. Rock Mech. Rock Eng. 52(8), 2505–2521 (2019b)

Massarotto, P., Rudolph, V., Golding, S.D., Iyer, R.: The effect of directional net stresses on the directional permeability of coal. In: International Coalbed Methane Symposium, Tuscaloosa, Alabama (2003)

Massarotto, P.: 4-D Coal Permeability Under True Triaxial Stresses and Constant Volume Conditions. Division of Chemical Engineering, The University of Queensland, Brisbane (2002)

Menezes, F.F.: Anisotropy of volume change and permeability evolution of hard sandstones under triaxial stress conditions. J. Petrol. Sci. Eng. 174, 921–939 (2019)

Ma, Y., Pan, Z., Zhong, N., Connell, L.D., Down, D.I., Lin, W., Zhang, Y.: Experimental study of anisotropic gas permeability and its relationship with fracture structure of Longmaxi Shales, Sichuan Basin, China. Fuel 180, 106–115 (2016)

Mckee, C.R., Bumb, A.C., Koenig, R.A.: Stress-dependent permeability and porosity of coal and other geologic formations. SPE Form. Eval. 3(1), 81–91 (1988)

Palmer, I., Mansoori, J.: How permeability depends on stress and pore pressure in coalbeds: a new model. SPE Reserv. Eval. Eng. 1, 539–544 (1998)

Pan, Z., Connell, L.D.: Modelling of anisotropic coal swelling and its impact on permeability behaviour for primary and enhanced coalbed methane recovery. Int. J. Coal Geol. 85, 257–267 (2011)

Pan, Z., Connell, L.D.: A theoretical model for gas adsorption-induced coal swelling. Int. J. Coal Geol. 69, 243–252 (2007)

Perera, M.S.A., Ranjith, P.G., Choi, S.K., Airey, D.: Investigation of temperature effect on permeability of naturally fractured black coal for carbon dioxide movement: an experimental and numerical study. Fuel 94, 596–605 (2012)

Reiss, L.H.: The reservoir engineering aspects of fractured formations. Editions Technip 27 Rue Ginoux 75737. Cedex, Paris, p. 15 (1980)

Shi, J., Durucan, S.: Drawdown induced changes in permeability of coalbeds: a new interpretation of the reservoir response to primary recovery. Transp. Porous Media 56(1), 1–16 (2004)

Song, Z., Yin, G., Ranjith, P.G., Li, M., Huang, J., Liu, C.: Influence of the intermediate principal stress on sandstone failure. Rock Mech. Rock Eng. 52(9), 3033–3046 (2019)

Tan, Y., Pan, Z., Liu, J., Wu, Y., Haque, A., Connell, L.D.: Experimental study of permeability and its anisotropy for shale fracture supported with proppant. J. Nat. Gas Sci. Eng. 44, 250–264 (2017)

Tan, Y., Pan, Z., Liu, J., Zhou, F., Connell, L.D., Sun, W.: Experimental study of impact of anisotropy and heterogeneity on gas flow in coal. Part II: permeability. Fuel 230, 397–409 (2018)

Wang, G., Wei, X., Wang, K., Rudolph, V.: Sorption-induced swelling/shrinkage and permeability of coal under stressed adsorption/desorption conditions. Int. J. Coal Geol. 83, 46–54 (2010)

Wang, K., Zang, J., Wang, G., Zhou, A.: Anisotropic permeability evolution of coal with effective stress variation and gas sorption: model development and analysis. Int. J. Coal Geol. 130, 53–65 (2014)

Wang, D., Lv, R., Wei, J., Zhang, P., Yu, C., Yao, B.: An experimental study of the anisotropic permeability rule of coal containing gas. J. Nat. Gas Sci. Eng. 53, 67–73 (2018)

Wang, D., Lv, R., Wei, J., Yao, B.: An experimental study of seepage properties of gas-saturated coal under different loading conditions. Energy Sci. Eng. 7(3), 799–808 (2019a)

Wang, L., Chen, Z., Wang, C., Elsworth, D., Liu, W.: Reassessment of coal permeability evolution using steady-state flow methods: the role of flow regime transition. Int. J. Coal Geol. 211, 103–210 (2019b)

Wang, S., Elsworth, D., Liu, J.: Permeability evolution in fractured coal: the roles of fracture geometry and water-content. Int. J. Coal Geol. 87, 13–25 (2011)

Wicks, D., Schwerer, F., Militzer, M., Zuber, M.: Effective production strategies for coalbed methane in the Warrior Basin. In: SPE Unconventional Gas Technology Symposium. Society of Petroleum Engineers (1986)

Wu, Y., Liu, J., Chen, Z., Elsworth, D., Miao, X., Mao, X.: Development of anisotropic permeability during coalbed methane production. J. Nat. Gas Sci. Eng. 2(4), 197–210 (2010)

Wu, Y., Liu, J., Elsworth, D., Siriwardane, H., Miao, X.: Evolution of coal permeability: contribution of heterogeneous swelling processes. Int. J. Coal Geol. 88(2–3), 152–162 (2011)

Xu, K., Wang, B., Liu, Q.: Study on gas drainage radius and distance between boreholes based on dynamic fluid–solid coupling model. Coal Sci. Technol. 46(5), 102–108 (2018)

Yan, F., Lin, B., Zhu, C., Shen, C., Zuo, Q., Guo, C., Liu, T.: A novel ECBM extraction technology based on the integration of hydraulic slotting and hydraulic fracturing. J. Nat. Gas Sci. Eng. 22, 571–579 (2015)

Yang, D., Qi, X., Chen, Z., Wang, S., Dai, F.: Numerical investigation on the coupled gas–solid behaviour of coal using an improved anisotropic permeability model. J. Nat. Gas Sci. Eng. 34, 226–235 (2016)

Yan, P., Liu, J., Wei, M.: Why coal permeability changes under free swellings: new insights. Int. J. Coal Geol. 133, 35–46 (2014)

Zang, J., Wang, K.: A numerical model for simulating single-phase gas flow in anisotropic coal. J. Nat. Gas Sci. Eng. 28, 153–172 (2016)

Zhao, Y., Lin, B., Liu, T., Li, Q., Kong, J.: Gas flow field evolution around hydraulic slotted borehole in anisotropic coal. J. Nat. Gas Sci. Eng. 58, 189–200 (2018)

Zhang, Z., Zhang, R., Xie, H., Gao, M., Xie, J.: Mining-induced coal permeability change under different mining layouts. Rock Mech. Rock Eng. 49(9), 3753–3768 (2016)

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (51674048) and Fundamental and Advanced Research Projects of Chongqing (cstc2015jcyjA90009). The first author also acknowledges the financial support provided by the China Scholarship Council (CSC). We thank Bozhi Deng, Chao Liu, Zhenlong Song and Siyu Yin for their support of the experiment of our study. We are also grateful to Tang Yu and Cai Wei for their help of analyzing the data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: The relationship between the initial PAR and the anisotropy ratio of coals structure

According to the definition of coal fracture permeability, the permeability in all directions can be obtained as follows (Yang et al. 2016):

It is assumed that the curvature of coal and rock in the initial state is equal in all directions, i.e., ξx0 = ξy0 = ξz0. The relationship between initial PAR and fracture width anisotropy λ can be obtained

For coals with obvious bedding, it can be assumed that the anisotropy of fracture width in two horizontal directions is equal in the initial state. The anisotropy of fracture width in horizontal and vertical directions is λyz= λxz= λ. Therefore, the relationship between the initial permeability anisotropy and the initial fracture width anisotropy can be obtained

Therefore, the anisotropy of initial fracture width of coal with bedding effect

Appendix B: W–Z (anisotropy), C–B and S–D permeability model formulas

The W–Z anisotropic permeability model under constant gas pressure can be obtained with zero increment of gas pressure (Wang et al. 2014; Zang and Wang 2016)

Cui and Bustin (Cui and Bustin 2005; Cui et al. 2007) found that the relationship between permeability change and average stress increment was exponential. The C–B permeability model was obtained as follows

And the mean stress is the average of three principal stresses.

Shi and Durucan (2004) applies the fracture compressibility calculation method (Mckee et al. 1988) to the permeability model and obtains the modified S–D permeability model

Rights and permissions

About this article

Cite this article

Duan, M., Jiang, C., Gan, Q. et al. Study on Permeability Anisotropy of Bedded Coal Under True Triaxial Stress and Its Application. Transp Porous Med 131, 1007–1035 (2020). https://doi.org/10.1007/s11242-019-01375-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-019-01375-y