Abstract

Chemical stabilization is one of the most successful among the techniques devised for reducing the volumetric changes of expansive soils. Lime and cement, fly ash and pond ash, calcium chloride and calcium silicate are some of the additives used for stabilizing expansive soils. This paper presents the influence of ground granulated blast furnace slag (GGBS) on swell-compressibility characteristics of a remoulded expansive clay passing 4.75 mm sieve. FSI, rate and amount of heave, swell potential (S%), swelling pressure (ps), coefficient of compressibility (av), compression index (Cc) and linear shrinkage (LS) of GGBS–clay blends were studied varying the GGBS content such as 0, 4, 8 and 12% by dry weight of the soil. It was observed that swellability and compressibility of the expansive clay decreased with increasing GGBS content. At 12% GGBS, the amount of heave was the lowest. The paper compares the effect of 12% GGBS on clay lumps passing 4.75 mm sieve and clay powder passing 425 µm sieve. While swell potential (S%) was found to be more for clay powder than for clay lumps at 12% GGBS, swelling pressure was higher for clay lumps than for clay powder. The paper also presents FSI data on clay–lime blends with varying lime content. As 4% lime resulted in the highest reduction of FSI, two more series of swell-consolidation tests and FSI tests were conducted on GGBS–clay blends to which 4% lime was added. Interesting phenomena were observed which the paper discusses in detail.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The problems associated with expansive soils as regards their swelling and shrinkage corresponding respectively to absorption of water and loss of water have been recorded all over the world. Civil engineering infrastructure founded in expansive soils experience incalculable distress owing to their susceptibility to undergo swelling and shrinkage, resulting in a huge financial loss [1,2,3]. It was estimated that the annual cost of damage done to civil engineering structures founded in expansive soils was at $1000 millions in the USA, £150 millions in the UK, and many billions of pounds worldwide [4].

To counteract these problems posed by expansive soils and mitigate the distress done thereby, various innovative foundation practices were suggested. These include physical and chemical alteration, sand cushion and CNS layer, drilled and belled piers, undereamed piles and granular pile anchors [1, 5,6,7,8,9,10,11].

In physical alteration a non-swelling, chemically inert material such as sand or gravel is mixed with expansive soils to minimize heave. In cushion techniques, either sand cushion or CNS layer replaces the top few layers of expansive soils to minimise volume changes. Drilled piers or straight-shafted piers are anchored in the inactive zone. They counteract swelling through friction. In belled piers there is an enlarged base by virtue of which shearing resistance is mobilized over an enlarged perimeter.

Under-reamed piles are bored cast in situ piles with enlarged bases called bulbs, connected at the top by plinth beams [8]. In this case also, swelling is counteracted by frictional resistance mobilized over a larger perimeter because of the bulbs. In granular pile-anchors, the foundation is anchored at the bottom of the granular pile by means of an anchor provided in the granular pile. Here the concept is that resistance to heave is mobilized because of the shear parameters (c′ and ϕ′) of the interface of expansive clay and the granular material of the pile.

Chemical stabilization is also a successful method of arresting heave of expansive soils. In this technique, chemical reagents are added to expansive clays for ameliorating their properties [1]. Some of these chemical reagents include lime, calcium chloride, cement, fly ash, pond ash et cetera. Lime, which is available in two forms, namely, quick lime and hydrated lime, is an effective pozzolanic material. Flocculation and cementation are two important reactions that take place upon adding lime to expansive clays. While flocculation reduces plasticity and swelling, cementation causes increase in strength through development of cementitious products [1, 12,13,14,15]. Phanikumar et al. [16] developed an innovative technique called fly ash columns (FACs) for expansive clay beds. Calcium chloride is a deliquescent salt which is hygroscopic in nature that absorbs water from the atmosphere and prevents shrinkage cracks [17, 18].

Cement is an excellent additive to clays as regards strength. Cement is preferred to lime if increase in strength vis-à-vis reduction in volume change is the criterion [1]. Fly ash and pond ash are industrial by-products which are produced in huge quantities, the disposal of which is a major concern. Both are silt-sized materials, which are chiefly siliceous and pozzolanic in nature. Both these ashes reduce plasticity and swelling [12, 19,20,21]. Ground granulated blast furnace slag (GGBS) is also an industrial by-product resulting from the fusion of limestone flux with coal ash and siliceous and aluminous residue remaining after the reduction and separation of iron from the ore. GGBS basically consists of silicates and alumino-silicates of lime [22, 23]. Research showed that GGBS can also effectively reduce plasticity, and increase strength of clays [22,23,24,25].

This paper not only explores the efficacy of GGBS in reducing free swell index (FSI), swelling and compressibility of highly expansive clays, but also compares the influence of higher GGBS content on the behaviour of expansive clay lumps and clay powders. The paper also studies the effect of 4% lime on swell-consolidation behaviour of GGBS–clay blends. As lime-activated GGBS was found to be an effective stabiliser for clays [26], and lime is an effective pozzolanic agent causing flocculation [27], it was contemplated to study the effect of lime–GGBS combination on swelling properties of expansive clays. 4% lime was chosen in the blend as it resulted in the highest reduction of free swell index (FSI). Further, it was also reported that addition of GGBS to clay–lime mixes resulted in a dramatic reduction in expansion resulting from the relative balance between competing hydration reactions [27].

Experimental Investigation

Test Materials

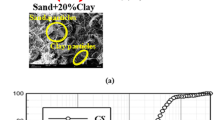

A highly swelling expansive clay collected at a depth of 1 m from the ground level from the town of Bhimavaram, Andhra Pradesh, India, was used in the experimental investigation. It had a free swell index (FSI) of 145%. Based on its LL of 78% and PI of 49%, the soil can be classified CH as per ASTM D2487. GGBS was collected from Venspra Labs Limited, Andhra Pradesh, India. It was a non-plastic, silt-sized material. Lime used in the investigation was Ca(OH)2 powder. Tables 1 and 2 show respectively the index properties and chemical composition of the soil and GGBS. The chemical properties of the expansive soil were obtained through a chemical analysis while those of the GGBS were supplied by Venspra Labs Limited, Andhra Pradesh, India.

Quantities Determined and Variables Studied

Free swell index (FSI), rate and amount of heave, swell potential (S%), swelling pressure (ps), coefficient of compressibility (av), compression index (Cc) and linear shrinkage (LS) of the GGBS–clay blends were determined. GGBS content was varied as 0, 4, 8, and 12% by dry weight of the soil. In swell-consolidation tests, the initial water content (wi) of the specimens was kept constant at 0% and the dry unit weight (γd) was kept constant at 12 kN/m3. Initially, a series of FSI tests was performed on lime–clay blends with varying lime content in order to assess the optimum lime content.

Tests and Procedures

FSI Tests

Free swell index tests were conducted according to ASTM D5890. For the FSI tests, oven-dried expansive soil fraction passing 425 µm sieve was used. 10 grams of oven-dried soil was poured each into a 100 ml cylindrical jar containing kerosene and another 100 ml cylindrical jar containing de-ionized water. The jars were made to stand for 24 h and the volumes of the soil in the jars containing kerosene (VK) and de-ionized water (VW) were noted. FSI, according to [28], is determined as

FSI tests on lime–clay blends and GGBS–clay blends were also performed in a similar fashion, replacing the expansive clay by the required amounts of lime and GGBS, as the case may be, by dry weight.

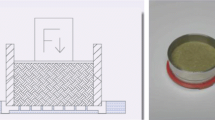

Swell-Consolidation Tests

The oven-dry expansive clay passing 4.75 mm sieve was weighed corresponding to the γd chosen and the volume of the consolidation ring (diameter = 60 mm, height = 20 mm) for conducting one-dimensional swell-consolidation tests. However, in the tests on GGBS–clay blends, the clay was replaced by the required amount of GGBS based on its dosage. The GGBS–clay blends were thoroughly mixed and statically compacted in the consolidometer ring in four layers each of 5 mm thickness so as to ensure a uniform γd. A filter paper and porous stone were placed above and below the sample, and this unit was placed in the consolidometer after positioning the loading pad. This assembly was mounted on the loading frame, and the samples were allowed to undergo free swell by inundation for 72 h under a nominal surcharge of 5 kPa. After the equilibrium heave, the samples were subjected to consolidation under increased vertical stresses.

As 12% GGBS resulted in the least value of heave, its effect on swell-consolidation behaviour of expansive clay powder passing 425 µm sieve was also investigated. Further, in additional tests on FSI and swell-consolidation data, 4% lime was added to the GGBS–clay blends, and tests were performed following the procedures detailed above. As 4% lime resulted in the least value of FSI, its effect on the swell-compressibility behaviour of GGBS–clay blends was also studied. In the swell-consolidation tests on GGBS–clay blends to which 4% lime was added, the oven-dry expansive clay was replaced by lime and GGBS based on their dosages.

Swell potential (S%) was determined as the ratio of increase in thickness (ΔH) to the initial thickness (H), expressed as S%. And swelling pressure (ps) was determined from the e-log p curves as the pressure corresponding to the initial void ratio.

Discussion of Test Results

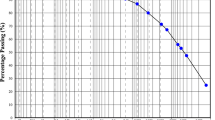

Figure 1 shows the variation of free swell index (FSI) with lime content. FSI decreased significantly with increase in lime content. When lime content increased from 0 to 4%, FSI decreased from 145 to 61.5%, showing a reduction of 57.6%. The reduction of FSI with increase in lime content can be attributed to (i) the replacement of expansive clay particles by non-expansive lime particles, and (ii) flocculation which is an important effect that lime produces upon being added to clays in presence of water. As the swelling expansive clay particles are replaced by non-swelling lime particles, FSI decreases. Moreover, lime is a most effective pozzolanic agent causing quick ‘flocculation’. This also effectively reduces FSI.

Figure 2 shows, by comparison, the variation of FSI with additive content in the case of GGBS–clay blends and of GGBS–clay blends to which 4% lime was added. FSI decreased significantly with increasing GGBS content. When GGBS content increased from 0 to 12%, FSI decreased from 145 to 54% showing a reduction of 62.75%. As mentioned above, the reduction of FSI can be attributed to (i) the replacement of expansive clay particles by non expansive GGBS particles, and (ii) flocculation occurring through pozzolanic reaction. FSI of montmorillonite clays depends upon the particle size. As montmorillonite clay particles are fine particles, their FSI values are high. As the non-plastic, silt-sized GGBS particles replaced the clay particles, the average particle size of the blends increased. Hence, FSI of the blends decreased with increase in GGBS content. Further, flocculation caused by highly siliceous GGBS particles [22, 29, 30] also increased the particle size, which also led to reduction in FSI. Phanikumar and Sharma [13] and Phanikumar [15] also reported a similar observation pertaining to FSI of swelling clays blended with silt-sized fly ash. Further, when 4% lime is added to the GGBS–clay blends, more effective flocculation would occur in the blends, reducing the free swell index (FSI) further. When 4% lime was added to the GGBS–clay blends, FSI decreased from 145 to 43% as GGBS content increased from 0 to 12%, indicating a reduction of 70.3%.

Figure 3 shows the rate of heave profiles of clay–GGBS blends in the form of heave (mm) and log time (minutes) plots. The data pertain to different GGBS contents (0, 4, 8 and 12%). The equilibrium heave was attained by the specimens in 3 days (4320 min). The unblended specimen (0% GGBS) resulted in a heave of 1.41 mm. However, when GGBS was added to the clay in increasing amounts, heave decreased significantly. The measured heave (mm) was 1.41, 1.12, 1.0 and 0.88 mm respectively for GGBS contents of 0, 4, 8 and 12%. When expansive clay particles are replaced by non-expansive GGBS particles, interaction between the clay particles decreases, resulting in reduced amount of heave. Further, flocculation taking place upon adding GGBS to the expansive clay would also effectively reduce heave. Therefore, swell potential (S%) of the blend samples was 7.0, 5.6, 5 and 3.9% respectively for the GGBS contents of 0, 4, 8 and 12%.

Figure 4 shows the rate of heave profiles of unblended expansive clay (0% additive) and clay–GGBS blends (0, 4, 8 and 12%) to which 4% lime was added. The unblended specimen (0% additive) resulted in an equilibrium heave of 1.41 mm as mentioned above. However, when GGBS was added to the clay in increasing amounts in the presence of 4% lime, heave decreased significantly. The measured heave (mm) of GGBS–clay blends to which 4% lime was added was 1.21, 1.35, 0.93 and 0.73 mm respectively for the GGBS contents of 0, 4, 8 and 12%. When expansive clay is replaced by non-expansive GGBS and lime, heave decreases. Moreover, flocculation taking place upon adding GGBS and 4% lime to the expansive clay would also effectively reduce heave [15, 27]. Hence, swell potential (S%) of the above GGBS–clay–4% lime blends was 6.05, 6.75, 4.65 and 3.65% respectively for the GGBS contents of 0, 4, 8 and 12%. The addition of lime modifies the electric double layer, reducing the thickness of the adsorbed water layer and thus reducing the swelling capacity; further, flocculation also occurs [27]. It was also reported that addition of GGBS to clay–lime mixes resulted in a dramatic reduction in expansion resulting from the relative balance between competing hydration reactions [27]. Another curious point which may be highlighted in respect of 4% lime specimens is the attainment of equilibrium heave in a short time duration of 10 min or so, which indicates that lime-induced reactions such as hydration and flocculation are quite fast at higher lime contents. This is also an observation in agreement with recent research [31]. Obuzor et al. [26] also reported that lime-activated GGBS was an effective binder for clays.

Figure 5 shows, by comparison, the variation of swell potential (S%) with additive content in the case of GGBS–clay blends and of GGBS–clay blends to which 4% lime was added. S% decreased continuously with increasing GGBS content. However, when 4% lime was added to the GGBS–clay blends, an increase in S% was found at 4% GGBS compared to 0% GGBS. This could be attributed to the possibility that the heat release caused by 4% lime was more influential in heave spike than 4% GGBS (see Fig. 4). At higher GGBS contents, however, S% decreased.

Swelling pressure (ps) of GGBS–clay blends was determined from e-log p curves as the pressure corresponding to the initial void ratio eo, which was 1.24. Figure 6 shows the e-log p curves of GGBS–clay blends for different GGBS contents. The swelling pressure (ps) was 88, 80, 65 and 60 kPa respectively for the GGBS contents of 0, 4, 8 and 12%. As GGBS content in the blends increased, heave decreased and so, swelling pressure also decreased.

Figure 7 shows the e-log p curves of unblended expansive clay (0% additive) and of clay–GGBS blends (0, 4, 8 and 12%) to which 4% lime was added. The e-log p data show that swelling pressure (ps) could not be determined for GGBS–clay blends when 4% lime was added. At 4% lime, strong cementitious products develop in the blend samples rendering them very hard. Hence, they could not be compressed back to the initial void ratio; so, swelling pressure could not be determined. Figure 8 shows the variation of swelling pressure (ps) with GGBS content. When GGBS content increased from 0 to 12%, ps decreased from 88 to 60 kPa, indicating a reduction of 32%.

Figure 9 shows, by comparison, the variation of coefficient of compressibility (av) of GGBS–clay blends and of GGBS–clay blends to which 4% lime was added. av decreased significantly with increase in GGBS content. This is evident in samples having higher GGBS contents producing strong cementitious bonds. av decreased from 0.0022 to 0.0009 m2/kN when GGBS content increased from 0 to 12%, indicating a reduction of 59%. In the case of 4% lime samples, the reduction in av was even steeper. When 4% lime was added to the GGBS–clay blends, av sharply decreased from 0.0022 to 0.00014 m2/kN (indicating a reduction of 93%) when GGBS content increased from 0 to 8% and thereafter it remained constant. This is evident in GGBS–clay samples having 4% lime also producing strong cementitious bonds.

Figure 10 shows by comparison, the variation of compression index (Cc) of GGBS–clay blends and of GGBS–clay blends to which 4% lime was added. Cc decreased from 0.585 to 0.239 when GGBS content increased from 0 to 12%, reflecting a reduction of 59%. When 4% lime was added to the GGBS–clay blends, Cc evinced a sharp fall from 0.585 to 0.0372 (indicating a reduction of 93%) when GGBS increased from 0 to 8% and thereafter it remained constant.

Figure 11 shows, by comparison, the variation of rebound (mm) of GGBS–clay blends and of GGBS–clay blends to which 4% lime was added. When GGBS content increased from 0 to 12%, rebound decreased from 0.7 to 0.19 mm, indicating a reduction of 73%. As compressibility decreased with increased GGBS content, rebound also decreased. When 4% lime was added to the clay sample alone (0% GGBS), rebound showed a significant reduction from 0.70 to 0.16 mm indicating a reduction of 77%. And when 4% lime was added to GGBS–clay blends, rebound decreased from 0.16 to 0.06 mm (indicating a reduction of 62.5%) as GGBS increased from 0 to 12%.

Figure 12 shows, by comparison, the variation of linear shrinkage (%) of GGBS–clay blends and of GGBS–clay blends to which 4% lime was added. When GGBS content increased from 0 to 12%, linear shrinkage (LS) decreased from 11 to 2%, indicating a reduction of 82%. When 4% lime was added to the clay sample alone (0% GGBS), LS showed a striking fall from 11 to 5% indicating a reduction of 55%. And when 4% lime was added to GGBS–clay blends, LS decreased from 5 to 1% (indicating a reduction of 80%) as GGBS increased from 0 to 12%. As swelling decreased with increasing GGBS content, shrinkage also decreased accordingly.

Table 3 shows the entire test data.

As 12% GGBS yielded the lowest amount of heave in the case of oven-dry clay lumps passing 4.75 mm sieve, its effect was studied on oven-dry powder too, of the same clay passing 425 µm sieve, for the sake of comparison. A one-dimensional swell-consolidation test was conducted on the blend of GGBS–clay powder having a GGBS content of 12%. Heave, swell potential (S%), swelling pressure (ps), compressibility (av), compression index (Cc), rebound and linear shrinkage (LS) were determined as in the case of lumps. Figure 3 shows the rate of heave plot of 12% GGBS–clay powder also vis-à-vis that of clay lumps. There was a discrepancy found between the values of heave et cetera of lumps and those of powder. While the initial density, the initial water content and the initial surcharge pressure on the samples remained the same in both the cases, the factor causing this notable difference could be the texture of the soil. While one sample was of lumps, the other was a thorough powder.

Table 3 shows that heave and swell potential values at 12% GGBS were more for the clay powder than for the lumps. Heave at 12% GGBS was respectively 0.88 and 0.79 mm for the powder and the lumps. The lower value of the heave in the case of lumps can be attributed to the difficulty in water reaching all the unsaturated pockets within the clay lumps in the process of developing equilibrium heave; and the higher value of heave in the case of clay powder can be attributed to the relative ease water would have in saturating the uniform, dry clay powder. Thus the clay powder resulted in higher amounts of heave and swell potential than the clay lumps.

Swelling pressure (ps) at 12% GGBS was determined as 60 and 52 kPa respectively for clay lumps and clay powders. Figure 6 shows the e-log p curve of 12% GGBS–clay powder also vis-à-vis the e-log p curves of clay lumps. Effective penetration of GGBS into the lumps would be difficult, but whatever amount of GGBS that penetrated would develop flocculation and cementation and the remaining amount of GGBS would form a matrix enveloping the lumps. The combined effect of lumps, flocculation and the GGBS matrix was to offer more resistance to the applied pressure. Hence, ps was higher in the case of lumps. However, in the case of clay powder, GGBS would cause flocculation, and the saturated sample would undergo more compression under the applied loads than would the lumps, so that the resulting swelling pressure (ps) in the case of clay powder was lower. Hence, as the compressibility of powders would be higher than that of lumps, av and Cc were higher for clay powder than for clay lumps (see Table 3). For the same reason, rebound was also higher for clay powder than for lumps.

Conclusions

The following conclusions can be drawn from the foregoing experimental study:

-

1.

Free swell index (FSI) decreased significantly with increasing GGBS content, reflecting a reduction of 63% when GGBS content increased from 0 to 12%. When 4% lime was added to GGBS–clay blends, FSI further decreased indicating a reduction of 70.3% as GGBS content increased from 0 to 12%.

-

2.

Upon addition of GGBS to the expansive clay, both the amount of heave and rate of heave decreased. When GGBS content increased from 0 to 12%, heave decreased from 1.41 to 0.88 mm, showing a reduction of 38%. The amount of heave and rate of heave decreased further when 4% lime was added to GGBS–clay blends. As GGBS content increased from 0 to 12%, heave decreased from 1.21 to 0.73 mm when 4% lime was added to GGBS–clay blends.

-

3.

Swelling pressure (ps) also decreased with increasing GGBS content in the blends. Swelling pressure decreased from 88 to 60 kPa when GGBS content increased from 0 to 12%, indicating a reduction of 32%. However, swelling pressure (ps) could not be determined when 4% lime was added to GGBS–clay blends as 4% lime caused development of strong cementitious bonds.

-

4.

Coefficient of compressibility (av) and compression index (Cc) of the GGBS–clay blends (both determined for the pressure range of 80–160 kPa) decreased significantly with increasing GGBS content. av and Cc decreased by 59% when GGBS content increased from 0 to 12%. And when 4% lime was added to GGBS–clay blends, av and Cc decreased by 93% as GGBS content increased from 0 to 12%.

-

5.

Rebound and linear shrinkage of the GGBS–clay blends respectively decreased by 73 and 82% when GGBS content increased from 0 to 12%. And when 4% lime was added to GGBS–clay blends, rebound and linear shrinkage respectively decreased by 62.5 and 80% as GGBS increased from 0 to 12%.

-

6.

A one-dimensional swell-consolidation test performed on the blend of GGBS–clay powder having a GGBS content of 12% indicated that heave and swell potential were higher for clay powder than for clay lumps, all the placement conditions for both being the same. This is attributable to the difficulty in water reaching the unsaturated pockets within the clay lumps. However, swelling pressure (ps) was found to be slightly more in the case of clay lumps than in the case of clay powder. This is attributable to the lumps resisting the applied compressive loads more effectively than the clay powder. Hence, av and Cc were also found to be higher for clay powder than for clay lumps.

References

Chen FH (1988) Foundations on expansive soils. Elsevier, Amsterdam

Nelson DJ, Miller JD (1992) Expansive soils: problems and practice in foundation and pavement engineering. Wiley, New York

Lu N, Lykos W (2004) Unsaturated soil mechanics. Wiley, New York

Gourley CS, Newill D, Schreiner HD (1993) Expansive soils: TRL’s research strategy. In: Proceedings of the 1st international symposium on engineering characteristics of arid soils, London

Satyanarayana B (1966) Swelling pressure and related mechanical properties of black cotton soils. Ph.D Thesis, I.I.Sc., Bangalore

Ranganatham BV, Sathyanarayana B (1965) A rational method of predicting swelling potential for compacted expansive clays. In: Proceedings of the 6th international conferrence on soils mechanics and foundation engineering, Canada, vol 1, pp 92–96

Katti RK (1978) Search for solutions to problems in black cotton soils. First I.G.S annual lecture, Indian Geotech. Society at I.I.T., Delhi

Sharma D, Jain MP, Prakash C (1978) Handbook on underreamed and bored compaction pile foundations. Central Building Research Institute, Roorkee

Phanikumar BR (1997) A study of swelling characteristics of and granular pile-anchor (GPAF) foundation system in expansive soils. PhD thesis. JN Technological University, Hyderabad, India

Phanikumar BR, Sharma RS, Rao AS, Madhav MR (2004) Granular pile-anchor foundation (GPAF) system for improving the engineering behavior of expansive clay beds. Geotech Test J Am Soc Test Mater 27(3):279–287

Phanikumar BR (2006) Expansive Soils: problems and remedies. In: Invited lecture, conference on corrective engineering practices in troublesome soils (CONCEPTS), Kakinada, pp 77–82

Cokca E (2001) Use of class C fly ash for the stabilization of an expansive soil. J Geotech Geoenviron Eng 127(7):568–573

Phanikumar BR, Sharma RS (2004) Effect of fly ash on engineering properties of expansive soils. ASCE J Geotech Geoenviron Eng 130(7):764–767

Phanikumar BR, Sharma RS (2007) Volume change behavior of fly ash-stabilized clays. J Mater Civ Eng 19:67–74

Phanikumar BR (2009) Effect of lime and fly ash on swell, consolidation and shear strength characteristics of expansive clays—a comparative study. Geomech Geoeng Int J 4(2):175–181

Phanikumar BR, Mani Anand J, Sathiyasheelan S, Reddy PR (2009) Fly ash columns (FAC) as an innovative foundation technique for expansive clay beds. Geomech Geoeng Int J 4(3):183–188

Phanikumar BR, Sastry MVBR (2001) Stabilizing swelling subgrades with calcium chloride. In: Highway research bulletin, vol 65, Journal of Indian Roads Congress, pp 77–82

Ramanamurthy V, Harikrishna P (2006) Stabilisation of expansive clay bed using calcium chloride stabilization. Ground Improv 10(9):39–46

Cokca E (1999) Effect of fly ash on swell pressure of an expansive soil. In: Electronic Journal of Geotechnical Engineering, vol 4

Kumar A, Walia BS, Bajaj A (2007) Influence of fly ash, lime and polyester fibers on compaction and strength properties of expansive soil. J Mater Civ Eng 19(3):242–248

Puppala AJ (2001) Fibre and fly ash stabilization methods to treat soft expansive soils. Geotech Spec Publ 112:136–145

Yadu L, Tripathi RK (2013) Effects of granulated blast furnace slag in the engineering behaviour of stabilized soft soil. Procedia Eng 51:125–131

Higgins DD (2005) Soil stabilization with GGBS. UK Cementitious Slag Makers Association (CMSA), Oxted

Gupta S, Seehra SS (1989) Studies on lime-granulated blast furnace slag as an alternative binder to cement. Highw Res Board Bull 38:81–97

Akinmusuru JO (1991) Potential beneficial uses of steel slag wastes for civil engineering purposes. Resour Conserv Recycl 5:73–80

Obuzor GN, Kinuthia JM, Robinson RB (2012) Soil stabilization with lime-activated GGBS—a mitigation to flooding effects on road structural layers/embankments constructed on floodplains. Eng Geol 151:112–119

Wild S, Kinuthia JM, Robinson RB, Humphreys I (1996) Effects of ground granulated blast furnace slag (GGBS) on the strength and swelling properties of lime-stabilised kaolinite in the presence of sulphates. Clay Miner 31:423–433

Holtz WG, Gibbs HJ (1956) Engineering properties of expansive clays. Trans ASCE 121:641–677

Yi Y, Gu L, Liu S (2015) Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blast furnace slag. Appl Clay Sci 103:71–76

Sharma A, Sivapullaiah PV (2012) Improvement of strength of expansive soil with waste granulated blast furnace slag, GeoCongress 2012, Oakland, California, USA. https://doi.org/10.1061/9780784412121.402

Phanikumar BR, Sreedharan Rishi, Aniruddh C (2015) Swell-compressibility characteristics of lime-blended and cement-blended expansive clays—a comparative study. Geomech Geoeng Int J 10(2):153–162

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Phanikumar, B.R., Nagaraju, T.V. Swell and Compressibility of GGBS–Clay Mixes in Lumps and Powders: Effect of 4% Lime. Indian Geotech J 49, 161–169 (2019). https://doi.org/10.1007/s40098-018-0302-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40098-018-0302-x