Abstract

Plant biology is an important area for the future of space exploration, but biological spaceflight experiments have been always constrained by the hardware capabilities. The European Modular Cultivation System (EMCS) unit was an incubator for small organisms, such as Arabidopsis thaliana, built by the European Space Agency (ESA) and was decommissioned in 2018. Here, we describe the FixBox system as add-on hardware to provide fixation capabilities to the plant growth cassettes, which, initially, were not designed to be used for that purpose. Tests were performed to ensure the successful use of this device in the EMCS facility. We also evaluate the required adaptations to the hardware, e.g., to guarantee that the reduced fluid motion in microgravity does not cause any bubbles that could impair the quality of fixation. Arabidopsis thaliana seedlings grown during spaceflight were fixed in the FixBox either in glutaraldehyde or formaldehyde. Electron microscopical images and confocal microscopy immunofluorescent localizations showed an excellent preservation of both cell ultrastructure and antigen conformation. Thus, it is possible to modify existing hardware to comply with the scientific requirements to augment the existing capabilities on board the ISS. In addition, it is also possible to reuse culture chambers from predesigned experimental containers into new modular subunits as FixBox. Similarly, we can design new hardware compatible with a novel cultivation chamber on board, such as is available in BIOLAB, to be used later with FixBox. Lessons learned for future space plant biology researchers include how to manage the number of hardware requirements and constraints on how to preserve the biological samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biological spaceflight experiments have been always constrained by the hardware capabilities. When the International Space Station (ISS) became available, most experiments were standalone in closed culture chambers (CC) with little environmental control, and no on-orbit 1 g controls or fixation capabilities. The “Root” experiment, the first European experiment on plant biology performed in the ISS, conducted by our Spanish laboratory in 2003, is an example of these limited controls (Matía et al. 2005; Matía et al. 2010). Plant biology experiments on the ISS have greatly benefited from the implementation of the European Modular Cultivation System (EMCS) on the ISS in 2006. The EMCS was an incubator lab facility for small organisms, both plant and animal, although, in practice, the great majority of experiments were performed on plants, preferentially using the model species Arabidopsis thaliana. It was built by the European Space Agency (ESA). This incubator was controlled by telemetry from the Norwegian User Support and Operations Centre (N-USOC, Trondheim, Norway), and it was able to hydrate the seeds and control atmospheric conditions (humidity and O2, CO2, ethylene levels). The EMCS was equipped with a high-resolution video camera system that allowed to monitor the experiment development in real time. In addition, this device had two rotors (600 mm diameter) that can be independently set at different speed/g-level (from 0,001 g to 2 g) or stopped to be used as static, micro-gravity racks. Each rotor could accommodate up to 4 standard EMCS Experiment Containers (ECs). Temperature of the EMCS incubator can be set between +18 °C and + 40 °C (Brinckmann 2005; Brinckmann 1999; Brinckmann and Schiller 2002). Regrettably, the entire EMCS facility was decommissioned from the ISS in 2018. In recent years, efforts of international space agencies, particularly of NASA, are focusing on providing plant habitats more similar to small green-houses to be used in agriculture, de-emphasizing the scientific value of inflight 1 g controls and reducing the amount of samples to be exposed simultaneously to experimental and control conditions (Monje et al. 2019; Massa et al. 2016; Khodadad et al. 2020).

The standard features of the EMCS experimental containers (EC) must be adapted to the specifications of each experiment to be performed in the facility. This adaptation is provided by the Experiment Unique Equipment (EUE), specific hardware accommodated within the EC which, including a CC inside which the specimens are grown. Several EUEs were designed to be used in the EMCS facility (Kittang et al. 2014). In some cases, the purpose was to optimize CC size (MULTIGEN), whereas in other cases the CC was optimized for the plant species and type of seedling used, e.g. lentil, Lens culinaris (GRAVI). The Tropi hardware was focused on optimizing the number of samples to be exposed to a combination of light and gravity stimuli. This EUE was developed by NASA’s Ames Research Center, and it consists of five seedling growth cassettes per EC, with each of the two centrifuges having four ECs. The principal features of the Tropi were a lighting system (white, red and blue LEDs), a water delivery system, and a substrate for plant growth (filter paper presoaked with nutrient solution; Correll et al. 2005; Kiss et al. 2007).

A wide variety of analyses can be performed from plant samples grown in space, and the type of analysis intended to be done greatly influences the features of the hardware to be used. In vivo morphological and morphometrical studies on plant development, as well as on the response to tropistic stimuli require video- or time-lapse photo-recording, with the ability of simultaneous or immediate downloading of images to scientists. However, most of analyses are performed postflight, on samples downloaded from space. Therefore, it is necessary to accurately preserve and store samples in space, immediately after the completion of the experiment in order to optimize the amount and the quality of relevant novel data that can be obtained from these valuable samples. Deep freezing is a fundamental preservation method, which is mandatory for any molecular biological analyses of samples. For this purpose, the “Minus Eighty-Degree Laboratory Freezer for ISS” (MELFI), an ultra-freezer designed and built in Europe (Chegancas et al. 2013), which functions in connection with GLACIER (“General Laboratory Active Cryogenic ISS Experiment Refrigerator”) designed and developed by University of Alabama at Birmingham (UAB) for NASA. GLACIER was originally designed for use on board the Space Shuttle but is now used for transporting samples to/from orbit via the SpaceX Dragon or Cygnus spacecraft (Kiss et al. 2014).

Apart from freezing, another important method for sample preservation is chemical fixation. It consists of the stabilization of biological tissues from degradation, by preventing autolysis by means of a chemical reaction of certain components of the samples (in most cases, proteins) with reagents that produce stable bonds. Fixation is needed for high-quality microscopical observation of samples. The most commonly used fixatives are aldehydes (formaldehyde, glutaraldehyde) and also alcohols (Hayat 1981). In connection with molecular biology techniques, a chemical fixative specifically stabilizing nucleic acids, called RNA-later (Ambion), has been developed and widely used, also in space experiments (Kruse et al. 2017). Storage of chemically fixed samples, if not immediately followed by dehydration and embedding, requires cooling and, in the case of RNA-later fixed samples, even ultralow freezing (Correll et al. 2013).

Several devices and strategies for sample chemical fixation in flight have been developed. In some cases, they are independent instruments. In other cases, the features of the fixation hardware and procedure are closely linked to the hardware used for growing samples and performing the space experiment. The independent devices include the Kennedy Space Center Fixation Tube (KFT), developed by NASA (Ferl et al. 2011). The Japanese Agency, JAXA, developed and implemented in ISS a triple-sealed bag called the Chemical Fixation Bag (CFB) (Space Life Sciences Flight Experiments Information Package (FEIP) 2014). While independent devices have the advantage of versatility and higher autonomy, their disadvantage is that they usually require a significant time for crew operation, since it is necessary to open the CC, collect the samples and transfer them to the fixation unit. In contrast, fixation hardware linked to culture facilities is usually easier and quicker to use, which, in addition, results in higher efficiency. This type of hardware and EUEs were already used in early experiments, prior to the assembly and operation of the ISS, which were performed in Biorack, an ESA multiuser laboratory installed in the space shuttle. During the space shuttle mission STS-84, experiments on gravitropism, using starch-deficient Arabidopsis mutants, grew seedlings in type-I Biorack containers and fixed samples in glutaraldehyde using type-II containers. Transfer between containers was done within a glovebox (Kiss et al. 1998). During the Gravi-2 experiment in ISS, the EMCS incubator included a fixation reservoir from which the fixative was directly injected into the growth chamber. However, this EUE was exclusively usable for lentil seeds, and not adaptable to, e.g. Arabidopsis seedlings (Driss-Ecole et al. 2008). In the “Polca” experiment, performed in the Kubik ISS facility, Arabidopsis seedlings were fixed for electron microscopical observation, also using a specific device coupled with the growth chamber (Bizet et al. 2018).

From our laboratory, we conducted an early experiment in ISS in 2003, the “Root” experiment, which was part of the “Cervantes” Soyuz Mission. It included the germination of Arabidopsis thaliana seeds, the growth of seedlings for 4 days and their eventual fixation in formaldehyde. Seeds were loaded in Biorack type I/E biocontainers, each provided with an internal MAMBA (Motorized Ampule Breaker Assembly) unit, developed by Dutch Space B.V. (Leiden, The Netherlands), from the “Berlingot-Ampoule” concept, (GSBMS-CNES, Toulouse, France) (Tixador et al. 1981).

In this context, the NASA-ESA “Seedling Growth” (SG) experiment was designed for the ISS, consisting of three successive parts, each one comprising A. thaliana seed germination and seedling growth in EMCS. The Tropi EUE was to be used, providing hydration, illumination with different wavelengths, video- recording, as well as interfacing with other environmental controls provided by EMCS (Kiss et al. 2007). In the design of the experiment, we considered the need of preserving a part of samples by chemical fixation in the third (and last) part of the experimental program (SG3) for microscopical evaluation after return to ground in 2017. When determining the fixation hardware to be used, we noted that neither the Tropi cassettes nor the EMCS facility could provide any fixation capability. Thus, we considered different alternatives to comply with this requirement: (1) to use for this purpose one of the autonomous fixation devices available in the ISS, or (2) to change the EUE used for growing seedlings. The first option was time-consuming with unacceptable limits, in terms of the time that samples were exposed to uncontrolled parameters and due to the extensive crew time required for operations. The second option was not possible, since the experimental requirements of SG3 could not be met by any other facility. Therefore, the decision was to adapt Tropi cassettes to be capable of being filled with fixative solution and to design and build a new device for fixative storage, sample fixation and storage of cassettes containing fixed samples until download to Earth. The combined solution of adapting a pre-existing hardware and implementing an add-on device to complement its capabilities is relatively new and required the agreement of the different involved parties, including scientists as well as ESA/NASA managers and engineers.

This new device is termed the “Fixation Box for Seedling Growth Experiment” (FixBox) system, that we describe in detail in this paper. It is an add-on hardware to provide fixation capabilities to the CC of the Tropi EC that were not designed to be used for that purpose. The research goals of SG were to study the effects of light and gravity on the early development of plants on the ISS. The particular focus of SG3 was to study cell ultrastructure and in situ localization of relevant cellular markers with the confocal microscope, therefore, good quality fixation was required. We describe here the tests that were carried out to guarantee the successful use of FixBox in the EMCS facility. We discuss testing of the required modifications to guarantee that the reduced fluid motion in microgravity does not impede successful fixation of the samples. As a result of the use of FixBox in the spaceflight experiment, images obtained from fixed samples show and excellent ultrastructural and antigenic preservation. While the EMCS is now decommissioned, we can envision using the FixBox directly or in a modified form in other plant space biology experiments.

Material and Methods

Plant Material Culture in Tropi Spaceflight Hardware

Preparation of plant specimens (Arabidopsis thaliana Columbia seeds, including wildtype, Nuc-1 and Nuc-2 mutants, and a DII-VENUS reporter line, Brunoud et al. 2012) has been described in previous publications (Kiss et al. 2014; Kiss et al. 2009; Vandenbrink and Kiss 2019). Briefly, seeds were surface sterilized in 70% (v/v) ethanol for 5 min followed by two rinses in 95% (v/v) ethanol for 1 min each and allowed to air dry in a sterile laminar flow hood. Subsequently, seeds were affixed with 1% (w/v) gum guar to a black gridded nitrocellulose membrane. The growth medium consisting of one-half strength Murashige and Skoog salts buffered with 1 mM MES (pH 5.5), was embedded onto Whatman filter paper by air drying in sterile laminar flow hood. Ten mL of growth medium were used for one piece of filter paper. Finally, the black membrane with the seeds was affixed to the top of filter paper using 1% (w/v) gum guar and placed into the Tropi cassette.

Seed germination and seedling growth was activated by hydration, either manually (laboratory test) or using the injection system implemented in EUE (spaceflight) and the growth period was 6 days at 23 °C with a photoperiod of white light 16 h/darkness 8 h. Figure 1 includes the different fixation ground tests (namely the Science Verification Test (SVT), Storage Tests and Operations and Validation Test (OVT)) and SG3 spaceflight activities. The SG3 project was launched on SpaceX CRS-11 to the ISS, and it was performed during Increment 52. The samples also were returned on the SpaceX CRS-11 mission (summer 2017).

Flow diagram of the tests and operations performed for validating the features and performance of FixBox for its use in the spaceflight experiment in ISS. SVT: Science Verification Test. OVT: Operations Validation Test. SG3: Seedling Growth experiment, Third Part. CIB: Centro de Investigaciones Biológicas, Madrid, Spain. SM: Scientific Model. NASA-ARC: NASA Ames Research Center, California, USA. SENER: SENER Aeroespacial SA, Barcelona, Spain. N-USOC: Norwegian User Support and Operations Center, Trondheim, Norway. NASA-KSC: NASA Kennedy Space Center, Florida, USA. ISS: International Space Station

Conventional Sample Fixation, Embedding and Microscopic Observation

Seedlings were fixed in 4.5% (v/v) glutaraldehyde (Sigma G5882) +1.5% (v/v) formaldehyde (EM grade, prepared from paraformaldehyde EMS catalogue #15710) in PBS, and then washed in buffer (3 times, 10 min) and post-fixed with 1% (v/v) osmium tetroxide aqueous solution (Ted Pella #18459) for 1 h at room temperature (Stockert and Colman 1974). Next, the osmium solution was rinsed with two washes in double distilled water, 10 min each, and the samples were dehydrated in a graded ethanol series (Merck #1.00983). Finally, the root tips were excised from seedlings, infiltrated and embedded in an epoxy resin (EMBED812 EMS #14900, Araldite GY 502 EMS #10900, DDSA EMS #13710 and DMP30 EMS #3013600), through a graded series of resin: ethanol mixtures (1:2, 1:1, 2:1), for 1 h each, at room temperature, and polymerized in pure resin at 60 °C for 2 days. From resin blocks, 2 μm-thick longitudinal sections (semi-thin sections) were cut using an LKB Pyramitome-11,800 microtome and observed unstained with phase contrast under a Leica DM25000 microscope. Images were recorded with a Leica DFC320 CCD camera. For ultrastructural studies, ultrathin sections (500 nm thick) were cut with a Reichert Ultracut E ultramicrotome using a diamond knife, mounted on 0.5% (w/v) Formvar-coated (EMS #15820) nickel grids (EMS G100-Ni), and stained with 5% (w/v) uranyl acetate and 0.3% (w/v) lead citrate. Finally, the samples were observed in a JEOL 1230 transmission electron microscope, operating at 100 kV.

In Toto Immunofluorescence

Samples were fixed in 5% (v/v) formaldehyde in PBS, and then washed three times for 5 min in PBS buffer and incubated 1 h at 37 °C in cell-wall-digestion solution (2% (w/v) cellulase (Sigma #C1794), 1% (w/v) pectinase (Sigma #17289), 0.05% (w/v) macerozyme (Sigma #P2401), 0.4% mannitol (Sigma #M4125),10% (v/v) glycerol (Merck #1.04094),0.2% (v/v) Triton-X100 (Sigma #T9284) in PBS). After incubation, seedlings were washed with 10% (v/v) glycerol; 0.2% (v/v) Triton-X100 in PBS buffer (3 times, 5 min) and excised root tips were placed onto L-polylysine- coated multi-well slides (EMS #63422–06, Sigma #P8920). Root apical parts were then dehydrated with 100% methanol at least 30 min at −20 °C. Immunofluorescence labeling was performed by washing well-slides twice for 5 min with 1% (v/v) NP40 (Sigma #D6750); 0.5% (w/v) DOC (Sigma #I3021) in PBS, pretreating with blocking buffer [0.05% (v/v) Tween 20 (Sigma #P1379);2% (w/v) BSA (Sigma #A7030) in PBS] for 30 min at room temperature, and incubating overnight at 37 °C in a humidified atmosphere with a rabbit antibody raised against AtNUC1 protein (kindly supplied by Dr. Julio Sáez-Vásquez, University of Perpignan-CNRS, Perpignan, France) diluted at 1:1000 in blocking buffer (Pontvianne et al. 2007). Then, slides were washed 3 times for 5 min in 1% (v/v) NP40; 0.5% (w/v) DOC in PBS, and incubated with a secondary antibody, goat anti-rabbit IgG-Alexa 488, diluted at 1:100 in blocking solution for 3 h at 37 °C. Samples were then washed with 1% (v/v) NP40;0.5% (w/v) DOC in PBS (twice, 5 min) and nuclear DNA was stained with 1 mg/mL DAPI solution (Thermo #62248) as described by the manufacturer. Finally, slides were washed with PBS and distilled water (twice, 5 min each) and mounted with DABCO as antifading agent (Sigma #290734). A Leica TCS SP5 confocal laser microscope was used to examine the immunostained samples and record images.

Results

Designing a Fixation Module for the Seedling Growth Experiment: The FixBox Concept and Operation

As previously indicated, the third phase of Seedling Growth experiment (SG3) had the additional requirement of chemically fixing the samples in orbit with aldehydes. The purpose of this chemical fixation is to allow postflight analyses of cell ultrastructure and in situ localization of relevant markers of cellular functions.

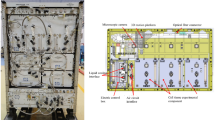

In order to meet this requirement, the Fixation Box, FixBox, compatible with Tropi EUE, was developed and built by the Spanish company SENER Aeroespacial SA, for ESA (Fig. 2). Among its most significant features, the FixBox had to be external and crew-operated: astronauts had to manually remove the cassettes from EC and transfer them into the FixBox to activate the fixation process. Additionally, all the safety regulations of NASA and ESA regarding the use of hazardous and volatile aldehyde fixatives had to be followed. At the same time, the architecture of the Tropi cassettes had to be modified to allow their filling with fixative solution and their further stable storage.

FixBox design. a The three main components of the FixBox are shown disassembled (Carrousel, Base and the Cover (including the Spacer is used only in launch configuration to keep together the FixBox Base and the Cover without risk of puncturing the preload fixative bags). b Diagram of a section of the two cylindrical threaded halves when closed: FixBox cover and FixBox base (without the Spacer or the Carrousel inserted that occupy the same location indicated by arrows). The FixBox cover contains the Fixative bag with corresponding fixative solution volume (50 ml), that is protected with a lid (Fixative Bag lid) with two seals to provide the required three LoCs. This lid has also the septa that will be punctured by the cannula. The set of Fixative Bag plus the septa and the two seals constitutes the three LoC during launch. The Ratchet System on the FixBox Cover blocks the possibility of unscrewing the cover and base. The FixBox Base holds the Cannula and the protective cap to prevent astronaut of puncturing himself. The Cannula includes the fluid path to a common volume that is connected automatically to the five cassettes injection ports to drive the fixative conveniently. In orbit, the FixBox spacer must be replaced with the CC loaded Carrousel (designed to permit the installation of five cassettes in one specific longitudinal direction). It is a metallic part to be fixed to the cover by a clicking mechanism once the five cassettes are installed. The injection ports are used to fix the cassettes and to conduct the fixative flow inside the injection circuit. Silicone non-return valves are included in the injection port to block the cassette draining once filled, for the ground transportation where different orientations and loads can take place. On the right, a view of the launch configuration closed Fixbox is provided including size, compatible with several ISS fridges/freezers when closed after been used in orbit (height is reduced to 74 mm, see Fig. 3c)

The chemical fixatives used were glutaraldehyde and formaldehyde, which for human spaceflight are ranked Toxicity Hazard Level (THL) 2, thus requiring three Levels of Containment (LoCs). In addition, the requirements of the design included its compatibility with RNAlater fixation. Also, the preserved samples (inside FixBoxes) had to be cold stowed on-board the ISS after completion of the experiment, as well as returned to ground at low temperature in cold stowage. Nominal stowage temperatures are +4 °C for aldehyde-fixed samples and − 80 °C for RNAlater. Therefore, the FixBox had to be compatible with the ISS and return flight cold stowage facilities: the MELFI (Minus Eighty-degree Laboratory Freezer for ISS), the GLACIER (General Laboratory Active Cryogenic ISS Experiment Refrigerator) Cooler-Freezer, BIOLAB Thermal Controlled Unit (TCU) and/or other passive means for sample return.

The FixBox consists of two cylindrical threaded halves: the FixBox Base and FixBox Cover. Some of its components have to be installed prior to the launch, such as the fixative bag and the FixBox spacer, whereas others are launched separately, as the carrousel (Fig. 2a). The purpose of these procedures is to minimize the exposure of the seals and septa, which are essential components, since they provide the three LoCs required for use of aldehyde fixatives in space (Fig. 2b). The fixative bag is an aluminum bag, formed, in turn by three thermo-sealed layers: Polyethylene Terephthalate (PET) + Aluminum + Polyethylene. It is used to store the fixative solution before fixation process inside FixBox. The FixBox Spacer is a mechanical part used in launch configuration to keep FixBox Base and FixBox Cover together but not screwed to one another. It keeps the two parts in their position to avoid damage during launch, and it needs be removed to separate the two sides of the FixBox to initiate the close-out process. The carrousel is the holder for the cassettes. It may hold five cassettes, that is, the entire set of cassettes that are mounted on a single EC. It assures the injection of fixative solution into each cassette that is done through the existing temperature sensor port of each cassette (that it is no longer needed during fixation), which is connected to the injection port of the carrousel. There is an injection port for each cassette and a second port to be connected to a blind cap to prevent leakage. The carrousel is a metallic part to be fixed to the cover by a clicking mechanism once the five cassettes are installed on it. Furthermore, the base has a puncturing cannula (tube) that punctures the fixative bag, installed in Fixative Bag Lid, only when the appropriate LoCs are established.

Once the carrousel containing cassettes is attached to the cover, the operation of FixBox, and consequently the fixation process, simply consists of screwing the base and the cover. This maneuver causes the bag to be punctured, and the fixative fluid is forced by the threading action to flow through the water inlet ports and fill cassettes. The FixBox has three silicon seals to comply between base and cover and two silicon seals between lid and Fixbox cover (apart of the fixative bag itself and the septa) to permanently guarantee that at least three LoC are maintained during all phases (to comply with all safety requirements of NASA and ESA), from the injection phase until the fixation process is complete and the FixBox is stored.

It is not possible to re-open the box in orbit after puncturing, due to the implementation of a ratchet mechanism, formed by six leaf springs fixed with the ratchet fixation nut. The design is such that the operator is forced to always progress in the direction to screw base and cover and never go back (unscrewing). In fact, there is one on orbit tool, the Closing Tool, that permits the use of both hands of the astronaut for closing, especially for the last turns when the torque is higher. The FixBox is set in a particular position, which also helps to prevent unwanted motions and minimizes the risk of bubbles formation and the leakage of fixative through the cassette venting hole (see later for cassette adaptations). The final step of closing is achieved when the cover is near to contact with the tool and it also includes a positive indication by means of green washers which at the end of the process are aligned to the tool ring (Fig. 3).

FixBox closing tool. a To close FixBox during spaceflight two tools are required: the Closing Tool that allows to fix the device when closing, and thus minimizing the bubble formation and fixative solution leaks, and the FixBox Closure Adapter, that allows the operator to perform the closing operation with only one hand. This adapter has to be placed on the top of the FixBox Cover to be used together with a torque wrench acting as handle. b Detailed view of the Green mark (arrow) when total closure of the FixBox is done. The final closing is reached when the green rings are aligned to Closing Tool ring and become visible at four points. c FixBox on-orbit/return configuration

Once the concept of the device was totally defined and approved by all concerned parties, an extensive process of testing and evaluation began, with the purpose of assuring both the total safety and the maximum efficiency of FixBox at the time of its performance in ISS. This process consisted of several tests and operations which introduced earlier in Fig. 1.

Ensuring an Even Distribution of Fixative in the Cassette Bases: The Science Verification Test (SVT) on Ground

Once the FixBox scientific model (SM) was available and supplied by the designer company, SENER Aeroespacial SA, a test was performed to evaluate whether the device was able to meet some basic requirements. The tested parameters were: the level of cassette filling with the respective fixative solutions, the movement of seedlings inside the cassette after the injection of the fixative solutions, and the quality of the fixation after a storage period of 3 weeks, corresponding approximately to the docking phase of the Space-X Dragon spaceship in ISS. Additionally, for the case that a complete cassette filling by fixative could not be achieved, a possible solution for keeping the fixative solution in contact with the samples was proposed. It consisted of pushing the solution towards the cassette base, where the samples are placed, by implementing magnets in the carrousel in close contact with the cassette bases (Fig. 4a and b) and adding ferrofluid, containing iron nanoparticles, that would be attracted by the magnet (Berger et al. 1999). The advantages of this approach include that the solution is pushed to the cassette base and prevents the seedlings flotation in the fixative solution, reduce the formation of liquid bubbles and ensure a good penetration of fixative into the biological material, thus achieving a good quality fixation on ISS. However, the biocompatibility of ferrofluid had not been previously tested, therefore it was necessary to perform these tests as well as to check whether there would be any interference of this substance with the techniques of analysis to be used, such as structural cell damages or antigen alterations that could block immunolocalization experiments.

Carrousel details and adaptions requirements on the Tropi cassette. a Description of the Carrousel components and placing of the five cassettes. b Representation of a cassette half filled with ferrofluid solution, which should remain close to the base of the cassettes due to the magnets included in the initial design of the FixBox carrousel. Magnet is optional (its location can be occupied by a spacer if not required). c Additional adaptations required to be done in the cassette (wires cut) to fit into the FixBox and to withstand the pressure during injection. Addition of an O-ring between base and cover to make the cassette hermetic, and hole puncturing in orbit, to allow air removal

Four fixative solutions in PBS buffer were used in this test; 4.5% (v/v) glutaraldehyde plus 1.5% (v/v) formaldehyde, 4.5% (v/v) glutaraldehyde plus 1.5% (v/v) formaldehyde plus 30% (v/v) ferrofluid, 5% (v/v) formaldehyde, and 5% (v/v) formaldehyde plus 30% (v/v) ferrofluid. It is important to notice that, within the cassette, the fixative solutions are mixed with the aqueous culture medium, incorporated at the time of hydration. Therefore, the real concentration of aldehydes at which the seedlings are fixed is clearly lower than the nominal concentration of the fixative solutions. This final concentration is difficult to be estimated. The amount of water injected at the time of hydration is 10 mL, which are absorbed by the filter paper and used by the seeds and seedlings for germination and development. Furthermore, there is a transpiration activity from seedlings, which increases the presence of water inside cassettes. The injected volume of fixative solutions is 9 ml (see below). In a rough estimation, we could calculate a reduction of 50% of the nominal fixative concentrations of the injected solutions in the real fixative experimental concentrations, which result in a similar range to those used in conventional fixation procedures in the Earth laboratories (Hayat 1981).

Another issue to be tested in the SVT was the possibility of filling the cassette with fixative solution up to a level comprising most of the cassette volume (90% or more). This possibility had to be considered for the case that the ferrofluid solution would not result efficient enough. As it is well known from physics, it is not possible to fill with a liquid a hermetic box if the air is not removed. Therefore, we explored in the SVT the possibility of perforating the cassette, which allowed the air to be removed as the liquid filled the cassette. The best place for the location of a hole in the cassette architecture was discussed. Once the need of this hole was proven, and its exact location was determined, a dedicated tool was designed and built for an easy and quick performance by the crew (Fig. 4c.3).

The test began with the preparation of four Tropi cassettes and the growth of Arabidopsis thaliana wild type plants in these cassettes, after hydration, for 6 days at 23 °C with a photoperiod light regime (white light 16 h/darkness 8 h). The assembly of the cassettes for the SG3 experiment introduced a modification with respect to the previous experiments (SG1 and SG2), which was the incorporation of a silicone O-ring or gasket between the base and the cassette cover to prevent leakage of the liquid housing the cassette (Fig. 4c.2). Once the seedlings were grown, each cassette was filled individually using the FixBox SM model. Although it allowed the simultaneous injection of five cassettes, we used a model with four positions blinded in the carrousel. The detailed steps of this procedure were as follows (Figs. 4 and 5): 1- cutting the cables that connect the cassette to the EC; 2- manual puncturing a hole with an awl (a tool with which holes can be punctured in a variety of materials) in the upper face of the cover, opposite to the temperature port (this position allows the cassette to be filled between 90% -100% of its capacity); 3- filling of the Fixative bag with 9 mL (around 90% of the cassette volume) of the corresponding fixative solution and insertion in the FixBox cover; 4- connecting the cassette through the temperature and hydration ports in the carrousel and inserting the carrousel into the FixBox cover; 5- complete closing of the FixBox so that the needle of the base punctures the bag with the fixative solution and the mechanism fills the cassette through both ports of the cassette base; 6- opening the FixBox, sticking metal tape in the hole of the cover and putting caps in the ports to avoid the loss of the fixative solution; 7- infiltration and fixation of the seedlings, by keeping the cassette in a horizontal position, for 3 h at room temperature, and 8- storage of the cassettes at 4 °C for 3 weeks in a horizontal position.

Science Verification Test (SVT). a Scientific model (SM) of the FixBox. b It is composed of a base and a cover. c Carrousel where the five cassettes of each EC are placed, connected through the temperature and hydration ports. d Bag that contains 9 mL of the corresponding fixative solution. e Seedlings fixed in a microfuge tube with and without ferrofluid (control experiment). f Cassettes filled using the FixBox. g and h Open cassettes showing that the seedlings remained attached to the nitrocellulose membrane, both in the presence or absence of ferrofluid, after storage for 3 weeks at 4 °C

In parallel, seedlings were immersed in the same fixative solutions, but in an Eppendorf tube (standard laboratory conditions), to be used as a control of the fixation quality. These samples were also fixed for 3 h at room temperature and stored at 4 °C for 3 weeks. The four cassettes were filled correctly, approximately, at 90% of their capacity. In all cases, seedlings were immersed in the corresponding fixative solution, and even after the storage period, they remained attached to the nitrocellulose membrane (Fig. 5).

After 3 weeks of storage (to simulate the storage time in the spaceflight experiment), the cassettes were opened and the standard protocol for structural microscopic analysis was continued for the samples fixed in glutaraldehyde, whereas the standard protocol for in toto immunofluorescence was carried out for the samples fixed in formaldehyde (see section Material and Methods).

Images taken from semi-thin sections of the resin-embedded samples after fixation and dehydration, observed unstained, under phase contrast microscopy, showed an equivalent quality fixation, whether they had been fixed in cassette or an Eppendorf tube, in the absence of ferrofluid (Fig. 6). These samples presented a compact cytoplasm without vacuoles, or of very small size, and well-defined large round nuclei. In contrast, samples fixed in the ferrofluid presence showed a less homogeneous fixation. A strong contraction and large vacuoles were observed in the cytoplasm of the cells, resulting in a worse preservation of the subcellular components. Therefore, this fixation was considered inadequate compared to the standard ones. (Fig. 6).

Comparison of fixation quality in samples fixed during Science Verification Test (SVT). Phase contrast microscope images of glutaraldehyde-fixed samples (left part) showing the root structural conservation (left) and meristematic area (right). Confocal laser microscope images of formaldehyde-fixed samples (right part) showing the immunofluorescent detection of the nucleolar protein nucleolin1 (AtNUC1) (green signal) and DNA staining with DAPI (blue). Both the entire root tip and a magnification of meristematic cells are shown in each case. The figure shows samples fixed in Eppendorf tube (control) and within cassettes, using the SM FixBox in the presence and in the absence of ferrofluid

Immunofluorescence experiments were performed after incubation with an anti-nucleolin antibody for in situ detection of the nucleolar protein AtNUC1. Images taken in the confocal laser microscope from samples without ferrofluid, fixed either with the FixBox, or with the standard control procedure, showed a similar quality fixation. In these seedlings, an antigen good preservation and a good antibody penetration were obtained, as shown by the intense green fluorescent signal of nucleoli. Nuclei appeared well stained, with blue DAPI signal, with a rounded shape. However, in the samples fixed in the ferrofluid presence, there was poor preservation of the antigenicity due to a worse quality of fixation. Areas without signal appeared in the root meristem. In some cases, a halo pattern of the green signal around the nucleolus was detected, indicating a low quality fixation of the nucleolus and/or failures in the penetration of antibodies (Fig. 6).

Thus, this test verified that the incorporation of ferrofluid in the fixative solution was not a good approach. First of all, it would difficult to process samples due to the opacity of the solution. Furthermore, and more importantly, this procedure would decrease the fixation quality, possibly by reducing the permeability of the fixatives and antibodies into the biological material, which ultimately produces structural damage and a worse preservation of antigenicity. These results, together with the success achieved in the strategy used (without ferrofluid) to fill the cassette up to more than 90% of its capacity, obviated the need for the addition of ferrofluid to the fixative solutions in the space experiment. Furthermore, the absence of leakage and the retention of seedlings attached to the nitrocellulose membrane throughout the entire duration of the test made unnecessary the traction effect of the ferrofluid towards the magnet. The final architecture of FixBox eliminated the magnets, although the capability of incorporating them was kept, to leave it open to future uses of the device.

Determining the Fixation Quality after Storage Time Expected in Orbit (Storage Ground Test)

In spaceflight experiments, we need to be prepared to recover the samples several days or weeks after the space experiment, but we also had to deliver all the materials in advance to the launch, sometimes several weeks. Thus, we performed ground tests to establish the best handling conditions and storage temperature of the fixative solutions until launch, during this and until its use (fixation of the samples after the growth period in the EMCS) to achieve the best possible fixation quality in the space environment.

This test consisted of preparing the two fixative solutions (4.5% glutaraldehyde +1.5% formaldehyde in PBS and 5% formaldehyde in PBS) and storing them in 2 mL microfuge tubes without any air (filled to overflow), for 3 weeks at room temperature (RT) and at 4 °C. After this storage period at different temperatures, 6-day old Arabidopsis thaliana (Col-0) seedlings were fixed for 3 h at room temperature and processed to assess the quality of the fixation (see Material and Methods). In addition, a control was carried out, which consisted of fixing similar seedlings with fresh fixative solutions (prepared just before use).

The samples fixed in freshly prepared glutaraldehyde solution had a good quality fixation according to our evaluation criteria, that is, the cells presented a little vacuolated cytoplasm and well-preserved nuclei with a round shape (Fig. 7). The samples fixed in the solution (prepared 3 weeks before and stored at 4 °C) also showed good fixation quality, but with a higher number of vacuoles and larger size. Finally, in the seedlings fixed with a solution stored for 3 weeks at room temperature, some cytoplasm contraction was observed, with deformation of nuclei and subcellular components, indicating a poorer fixation.

Seedlings fixed during the Storage Test of fixative solutions. The figure is composed of images of samples fixed in glutaraldehyde (GA), to evaluate the structural conservation parameters (left part), and of samples fixed in formaldehyde (FA) showing the immunofluorescent detection of the nucleolar protein nucleolin1 (AtNUC1) (green signal) and DNA staining with DAPI (blue) to evaluate the conservation of antigenicity (right part). The results obtained after different storage conditions of the corresponding fixative solutions are shown: 4 °C (center) and room temperature (RT, bottom). Also, the fixation in fresh solution of the control samples, (upper part), is shown. Both the entire root tip and a magnification of meristematic cells are shown in each case

The anti-nucleolin1 immunofluorescent localization with samples fixed with a fresh solution showed excellent preservation of the antigenicity, as well as a very good penetration of the antibody, with rounded nuclei and fully defined bright nucleoli. This antigenicity conservation decreased in seedlings fixed with solution stored at 4 °C (a small deformation of nuclei and nucleoli was detected), and there was even less antigenicity in the samples fixed in solution preserved 3 weeks at room temperature, in which immunostaining was irregular and nuclei and nucleoli showed alterations in their shape (Fig. 7).

Final Validations: Operations and Validations Test, OVT

This test was carried out considering all the results and conclusions obtained from the prior tests, for the determination of the sequence of actions that would be followed in the SG3 space experiment. This test began at NASA Ames Research Center (ARC) in California with the assembly of cassettes and their loading in the corresponding ECs, approximately 1 month before their hydration. Specifically, four ECs were used for this test, of which only three were used to fix the samples with the FixBox, while the other was treated as if the samples were frozen at −80 °C, trying to reproduce all the activities that were expected to be done in orbit. The ECs destined to be fixed in the FixBox were marked with labels and colors to facilitate the crew following the protocol to follow for each EC. The preparation of the FixBoxes, specifically the fixative bag filling with the corresponding fixative solutions and sufficient volume for 5 cassettes (50 ml / bag), began at the premises of SENER Aeroespacial SA (in Spain) approximately 2 weeks before the hydration of the cassettes, using a specifically designed ground-tool (Bag Filling Tool) for these operations. The fixative was included in the bag in a protective atmosphere (to avoid aldehydes oxidation) and avoiding bubble formation (tested by visual inspection) (Fig. 8a). Once the ECs and the FixBoxes with their respective labels were prepared, they were sent to the N-USOC (Norwegian User Support and Operations Centre). The ECs were transported at room temperature and the FixBoxes at 4 °C.

Operations Verification Test (OVT) of the Seedling Growth-3 (SG3) Experiment. Sequence of activities performed during the OVT, including: a the Fixative bag filling with 50 mL of the corresponding fixative solution; b the EC preparation with their corresponding labels, followed by the activation of seed germination and seedling growth; c the cutting of the cables that connect the cassettes with the EC, d the puncturing of the hole in the upper part of the cover, using the puncturing tool; E) the FixBox closing process; f FixBoxes completely closed, g FixBox transport to Madrid at 4 °C, and h verification of the complete filling of the cassettes up to 90% -100% of their capacity with the corresponding fixative solution

In the N-USOC (Trondheim, Norway), the ECs were installed in the EMCS, the cassette hydration took place and the seedling growth began. After the growth period (6 days), we proceeded to fix the cassettes following the steps below (Fig. 8): 1- Take out the EC from inside the EMCS and opening it by removing its top cover, 2- Cut the cables that connect each cassette with the EC, 3- Extract the cassettes from EC one by one and making the hole in the cassette cover using a puncturing tool, 4- Assembling the five cassettes on the FixBox carrousel and installing the carrousel on the FixBox cover, 5- Complete closing of the FixBox (Closing Tool) and 6- Samples fixation for 3 h at room temperature and storage for 3 weeks at 4 °C.

One of the two FixBox filled with 5% (w/v) formaldehyde in PBS was opened after 3 h of fixation at room temperature, to verify that the filling of the cassettes had been correct (90% -100% of its capacity) and without leakage. In addition, we tested the opening of the cassettes filled with liquid and seedling recovery. The other two FixBoxes were transported at 4 °C to our laboratory in Madrid where they were opened, the correct cassette filling was also checked, and the samples were processed to assess the fixation quality (Fig. 8).

The cellular structure preservation in the glutaraldehyde-fixed samples was good in that we observed some irregularities, such as the presence of vacuoles. The result of the anti-nucleolin 1 immunofluorescence was also very satisfactory, due to the good preservation of antigenicity and primary antibody penetration. Nuclei and nucleoli appeared brightly stained and with rounded shape (Fig. 9). The DII-VENUS seedlings, which harbor a yellow fluorescent protein reporter construction, could be observed directly in the confocal laser microscope, showing that the fluorescence signal was adequate in location and intensity (Fig. 9).

Quality of seedling fixation using FixBox on the ground, after the SG3-OVT. Seedlings fixed in the FixBox in the course of the SG3-OVT. This test, carried out at the N-USOC in Norway a few months ahead of launch, using the EMCS Engineering Model (EMCS-EM) was a full replica of all the operations included in the SG3 spaceflight experiment. The EMCS-EM settings corresponded to the same environmental parameters as will be set in flight. Images at the top show the results of glutaraldehyde (GA) fixation on structural features of the root tip and the root meristem, observed on semi-thin sections examined with phase contrast microscopy. Images at the bottom are from samples fixed in formaldehyde (FA) showing the immunofluorescent localization of the nucleolar protein nucleolin and DNA stained with DAPI (left) and the detection of auxin in the root tip in the reporter gene line DII-VENUS. The results were considered satisfactory and, after this final assessment, the FixBox was qualified for use in the SG3 space experiment in ISS

Fixation Results of the Spaceflight Experiment (Seedling Growth, SG3)

For the ISS experiment, seeds mounted on cassettes, and cassettes mounted on ECs, together with FixBoxes (one per EC) containing fixative solutions were uploaded in SpaceX CRS-11, a Commercial Resupply Service mission to the ISS. The same spaceship returned the fixed samples, contained within FixBoxes, 1 month later. Indeed, SG3 experiment was performed on ISS during the docking phase of this mission to minimize the storing time of fixatives in space (see Supplementary material video of the FixBox onboard utilization). As an example of the good quality of fixation obtained during spaceflight, we provide some examples of samples from SG3 mission. Transmission electron microscopical observation showed a very good quality preservation of cell ultrastructure (Fig. 10). Glutaraldehyde fixation in flight allowed osmium tetroxide postfixation postflight, which produced an excellent contrast of cell membranes and membranous organelles, such as plastids and mitochondria. The number of vacuoles remained moderate, according to the identity of root meristematic and columella tissues observed. Inside the nucleus, the structure and substructure of the nucleolus and nucleolar components could be well discriminated (Fig. 10). In the same way, the seedlings fixed with formaldehyde maintained an antigenicity equivalent to that obtained in the OVT with nuclei and nucleoli well preserved in size and round shape after the anti-nucleolin1 immunofluorescence and a totally clear-cut fluorescence signal in the reporter line DII –VENUS (Fig. 10).

Quality of seedling fixation using FixBox after the spaceflight experiment SG3 in ISS. a-e Transmission electron microscopical images of samples fixed in glutaraldehyde (GA). a-b: Meristematic cells. c-d: Columella cells. In all cases, a good fixation quality was obtained, allowing a detailed discrimination of ultrastructural cellular details. N: nucleus; Nu: nucleolus; ne: nuclear envelope; m: mitochondria; p: plastid; V: vacuole; arrows: statoliths. e-h: Confocal microscopical images of samples fixed in formaldehyde, showing the immunofluorescent detection of the nucleolar protein nucleolin-1 (AtNUC-1) in the root tip (e-g), and the localization of auxin in the reporter gene line DII-VENUS. Nucleoli appear in bright green in meristematic cells, against the blue staining of nucleoli by DAPI. The pattern of auxin distribution is clearly appreciated by YFP visualization in the transformed line

Discussion and Conclusions

The development of new hardware for spaceflight experiments has been very limited due to financial constraints in Europe. In particular, plant biology researchers have had to face the decommissioning of EMCS in 2018. At the same time, other international space agencies have taken the opportunity to develop new tools for plant biology research in orbit (Khodadad et al. 2020; Massa et al. 2016; Monje et al. 2019). In this scenario, it is important to apply the three “R” rule to spaceflight hardware; reduce new developments but reuse existing hardware and recycle previous concepts to be used in new experiments. Our results show that it is possible to modify existing hardware to comply with scientific requirements that may evolve faster than the existing capabilities on board Space Stations. The design, development and testing of FixBox has been paradigmatic in this exercise, which already is, and probably will be in the future more and more essential for the most efficient use of the limited resources of spaceflight experimentation.

Firstly, we needed to redesign the CC. Due to the fixation requirements to preserve our plant samples, we solved this problem by using the same CC from predesigned experimental containers into a fixation compatible container. A hole was placed in the chamber tap to allow the air removal while the fluid is injected was required in combination with new O-rings to guarantee the seal of the CC under increased pressure during injection. Also, a new modular hardware (i.e. the FixBox) was required to perform the injection of the fixative, including several accessories to be operated safely in orbit and designed to be compatible with the storage facilities on the ISS and new cargo ships. This approach resulted in a positive outcome for our research community to develop hardware components compatible with existing CC on board (for example a BIOLAB compatible Plant Biology container) that eventually could take advantage of the fixation capabilities already provided by FixBox. Unless crew time is available to collect material from a different CC and insert it into a TROPI sized fixation chamber, two proposals for hardware modifications from existing hardware may be possible: (1) to develop a dedicated plant-EC for the new BIOLAB facility considering several small CC that can use the existing FixBox as described here, and (2) to develop dedicated FixBox carrousels that can host larger fixation chambers.

Secondly, we performed several tests to achieve an optimal fixation quality. Our results showed that fixation in samples placed in fixative solution kept at 4 °C for 3 weeks was better than in those put in fixative solution stored during the same period at room temperature. Therefore, the fixative delivery protocol was modified, incorporating the requirements of a storage temperature of 4 °C and preparation of solutions as late as possible with respect to the launch date and as close as possible to the launch site. Finally, fixative solutions were prepared 8 days before launch, at NASA Kennedy Space Center (KSC), Florida, USA.

Thirdly, we efficiently solved the problem of using a hardware that was not originally designed to be filled with fixatives. By puncturing the CC, we ensured the fixatives to fill the CC completely in orbit, so the need of permanent contact of samples with fixative solution through the entire time of storage was achieved. We tested the possibility of incorporating a limited amount of fixative by using a combination of magnets and ferrofluid, but we verified that the incorporation of ferrofluid in the fixative solution was not an optimal approach. Ferrofluid would be difficult for sample processing due to its opacity. Furthermore, it would decrease the fixation quality, possibly by reducing the permeability of the fixatives and antibodies into the biological material, which ultimately would produce structural damage and a poor preservation of antigenicity. These results, together with the success achieved in the strategy used to fill the cassette up to more than 90% of its capacity, obviated the need for the addition of ferrofluid to the fixative solutions in the space experiment. Also, the absence of any leakage and the retention of seedlings attached to the nitrocellulose membrane made unnecessary the traction effect of the ferrofluid towards the magnet. Despite that, the future possibility of including magnets in the FixBox units may be useful for other users.

Finally, we were able to provide updated methodological and timing requirements that have been considered (Table 1) and successfully integrated into a successful mission thanks to our research. We want to highlight also that this work has been possible due to the collaboration of research teams at USA and Europe in combination with two space agencies, ESA and NASA. Working together, we were able to solve the significant challenges faced in achieving on-orbit fixation. Our studies also provide lessons learned for future space plant biology researchers, and in the long term, will produce plant biology research that will aid in optimizing crop plant production for future settlements on the Moon, Mars as well as other planets.

References

Berger, P., Adelman, N.B., Beckman, K.J., Campbell, D.J., Ellis, A.B., Lisensky, G.C.: Preparation and properties of an aqueous ferrofluid. J. Chem. Educ. 76(7), 943 (1999)

Bizet, F., Pereda-Loth, V., Chauvet, H., Gérard, J., Eche, B., Girousse, C., Courtade, M., Perbal, G., Legué, V.: Both gravistimulation onset and removal trigger an increase of cytoplasmic free calcium in statocytes of roots grown in microgravity. Sci. Rep. 8(1), 11442 (2018). https://doi.org/10.1038/s41598-018-29788-7

Brinckmann, E.: Spaceflight opportunities on the ISS for plant research — the ESA perspective. Adv. Space Res. 24(6), 779–788 (1999). https://doi.org/10.1016/S0273-1177(99)00413-5

Brinckmann, E.: ESA hardware for plant research on the international Space Station. Adv. Space Res. 36(7), 1162–1166 (2005)

Brinckmann, E., Schiller, P.: Experiments with small animals in BIOLAB and EMCS on the international Space Station. Adv. Space Res. 30, 809–814 (2002). https://doi.org/10.1016/S0273-1177(02)00401-5

Brunoud, G., Wells, D.M., Oliva, M., Larrieu, A., Mirabet, V., Burrow, A.H., Beeckman, T., Kepinski, S., Traas, J., Bennett, M.J., Vernoux, T.: A novel sensor to map auxin response and distribution at high spatio-temporal resolution. Nature. 482(7383), 103–106 (2012)

Chegancas, J., Stephan, H., Jimenez, J., Campana, S., Hutchison, S.: Seven years of permanent running of MELFI-1 on board the ISS and utilisation of the three MELFI units refrigeration pool. Paper presented at the 64th international Astronautical congress, Beijing; China (2013)

Correll, M.J., Edelmann, R.E., Hangarter, R.P., Mullen, J.L., Kiss, J.Z.: Ground-based studies of tropisms in hardware developed for the European modular cultivation system (EMCS). Adv. Space Res. 36(7), 1203–1210 (2005)

Correll, M.J., Pyle, T.P., Millar, K.D.L., Sun, Y., Yao, J., Edelmann, R.E., Kiss, J.Z.: Transcriptome analyses of Arabidopsis thaliana seedlings grown in space: implications for gravity-responsive genes. Planta, 1–15 (2013). https://doi.org/10.1007/s00425-013-1909-x

Driss-Ecole, D., Legué, V., Carnero-Diaz, E., Perbal, G.: Gravisensitivity and automorphogenesis of lentil seedling roots grown on board the international Space Station. Physiol. Plant. 134(1), 191–201 (2008). https://doi.org/10.1111/j.1399-3054.2008.01121.x

Ferl, R.J., Zupanska, A., Spinale, A., Reed, D., Manning-Roach, S., Guerra, G., Cox, D.R., Paul, A.-L.: The performance of KSC fixation tubes with RNALater for orbital experiments: a case study in ISS operations for molecular biology. Adv. Space Res. 48(1), 199–206 (2011). https://doi.org/10.1016/j.asr.2011.03.002

Hayat, M.A.: Fixation for Electron Microscopy. Academic Press, New York (1981)

Khodadad, C.L.M., Hummerick, M.E., Spencer, L.E., Dixit, A.R., Richards, J.T., Romeyn, M.W., Smith, T.M., Wheeler, R.M., Massa, G.D.: Microbiological and Nutritional Analysis of Lettuce Crops Grown on the International Space Station. Front. Plant Sci. 11, 199 (2020). https://doi.org/10.3389/fpls.2020.00199

Kiss, J.Z., Katembe, W.J., Edelmann, R.E.: Gravitropism and development of wild-type and starch-deficient mutants of Arabidopsis during spaceflight. Physiol. Plant. 102, 493–502 (1998). https://doi.org/10.1034/j.1399-3054.1998.1020403.x

Kiss, J.Z., Kumar, P., Bowman, R.N., Steele, M.K., Eodice, M.T., Correll, M.J., Edelmann, R.E.: Biocompatibility studies in preparation for a spaceflight experiment on plant tropisms (TROPI). Adv. Space Res. 39, 1154–1160 (2007)

Kiss, J.Z., Kumar, P., Millar, K.D.L., Edelmann, R.E., Correll, M.J.: Operations of a spaceflight experiment to investigate plant tropisms. Adv. Space Res. 44(8), 879–886 (2009). https://doi.org/10.1016/j.asr.2009.06.007

Kiss, J.Z., Aanes, G., Schiefloe, M., Coelho, L.H.F., Millar, K.D.L., Edelmann, R.E.: Changes in operational procedures to improve spaceflight experiments in plant biology in the European modular cultivation system. Adv. Space Res. 53(5), 818–827 (2014). https://doi.org/10.1016/j.asr.2013.12.024

Kittang, A.-I., Iversen, T.-H., Fossum, K.R., Mazars, C., Carnero-Diaz, E., Boucheron-Dubuisson, E., Le Disquet, I., Legué, V., Herranz, R., Pereda-Loth, V., Medina, F.J.: Exploration of plant growth and development using the European modular cultivation system facility on the international Space Station. Plant Biol. 16(3), 528–538 (2014). https://doi.org/10.1111/plb.12132

Kruse, C.P.S., Basu, P., Luesse, D.R., Wyatt, S.E.: Transcriptome and proteome responses in RNAlater preserved tissue of Arabidopsis thaliana. PLoS One. 12(4), e0175943 (2017). https://doi.org/10.1371/journal.pone.0175943

Massa, G.D., Wheeler, R.M., Morrow, R.C., Levine, H.G.: Growth chambers on the international Space Station for large plants. Paper presented at the VIII International Symposium on Light in Horticulture (2016)

Matía, I., González-Camacho, F., Marco, R., Kiss, J.Z., Gasset, G., Medina, F.J.: Nucleolar structure and proliferation activity of Arabidopsis root cells from seedlings germinated on the international Space Station. Adv. Space Res. 36(7), 1244–1253 (2005). https://doi.org/10.1016/j.asr.2005.01.068

Matía, I., González-Camacho, F., Herranz, R., Kiss, J.Z., Gasset, G., van Loon, J.J.W.A., Marco, R., Medina, F.J.: Plant cell proliferation and growth are altered by microgravity conditions in spaceflight. J. Plant Physiol. 167(3), 184–193 (2010). https://doi.org/10.1016/j.jplph.2009.08.012

Monje, O., Richards, J.T., Hanson, D.T., Turpin, M.M., Moinuddin, S.G.A., Costa, M.A., Davin, L.B., Lewis, N.G., Carver, J.C., Dimapilis, D.: New perspectives for watering substrate-based root modules in microgravity in the advanced plant habitat (APH). Paper presented at the 35th annual meeting of the American Society for Gravitational and Space Research, Denver, CO; United States (2019)

Pontvianne, F., Matia, I., Douet, J., Tourmente, S., Medina, F.J., Echeverria, M., Saez-Vasquez, J.: Characterization of AtNUC-L1 reveals a central role of nucleolin in nucleolus organization and silencing of AtNUC-L2 gene in Arabidopsis. Mol. Biol. Cell. 18(2), 369–379 (2007). https://doi.org/10.1091/mbc.E06-08-0751

Space Life Sciences Flight Experiments Information Package (FEIP): (Page. 74, Table 4) http://iss.jaxa.jp/kiboexp/participation/application/documents/life_med_2014/feip2014.pdf. (2014)

Stockert, J.C., Colman, O.D.: Observations on nucleolar staining with osmium tetroxide. Experientia. 30(7), 751–752 (1974). https://doi.org/10.1007/BF01924164

Tixador, R., Richoilley, G., Raffin, J., Bost, R., Kojarinov, V., Lepskye, A.: The Cytos biological experiments carried out on the Soviet orbital station Salyut 6. Aviat. Space Environ. Med. 52, 485–487 (1981)

Vandenbrink, J.P., Kiss, J.Z.: Preparation of a spaceflight experiment to study tropisms in Arabidopsis seedlings on the international Space Station. In: Yamamoto, K.T. (ed.) Phototropism: Methods and Protocols, pp. 207–214. Springer, New York (2019)

Acknowledgements

We would like to thank the skillful technical assistance of Mrs. Mercedes Carnota (CIB-CSIC), the generous supply of anti-nucleolin antibodies by Dr. Julio Sáez-Vásquez (University of Perpignan-CNRS, Perpignan, France), the fine support of NASA’s Ames Research Center in the use of Tropi hardware, the European Space Agency, and the Norwegian User Support and Operations Center (N-USOC) for their continuous support throughout the entire “Seedling Growth” space project including the supplementary material video recording. Finally, we would like to thank the astronauts on board the ISS for their fine work.

Funding

This work was supported by the Agencia Estatal de Investigación of the Spanish Ministry of Science an Innovation, Grants #ESP2015–64323-R and #RTI2018–099309-B-I00 (co-funded by EU-ERDF), awarded to FJM, and by pre-doctoral fellowships to (AM), (MV) and (AV) from the Spanish National Program for Young Researchers Training (MINECO, Ref. BES-2013-063933, BES-2016-077976). This research was supported also by grants (NNX12A0656 and 80NSSC17K0546) from NASA to JZK. The Seedling Growth Project spaceflights and activities to the ISS were funded by ILSRA2009–0932/1177 of ESA-ELIPS Program. The FixBox has been built under a contract to SENER Aeroespacial SA by ESA (4000105697/12/NL/FC) to support the SG project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations

Not applicable.

Additional information

This article belongs to the Topical Collection: The Effect of Gravity on Physical and Biological Phenomena

Guest Editor: Valentina Shevtsova

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

Multimedia file. Video recording of the orbital operations performed by the Astronaut Jack “2Fish” Fisher during the orbital Seedling Growth 3 operations (June 2017, extracting the CC from the EMCS EU and assembling the FixBoxes for fixation) captured during spaceflight monitoring activities at N-USOC (Trondheim, Norway)). (MP4 54808 kb)

Rights and permissions

About this article

Cite this article

Manzano, A., Creus, E., Tomás, A. et al. The FixBox: Hardware to Provide on-Orbit Fixation Capabilities to the EMCS on the ISS. Microgravity Sci. Technol. 32, 1105–1120 (2020). https://doi.org/10.1007/s12217-020-09837-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12217-020-09837-5